Patents

Literature

660results about "Lubrication/cooling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

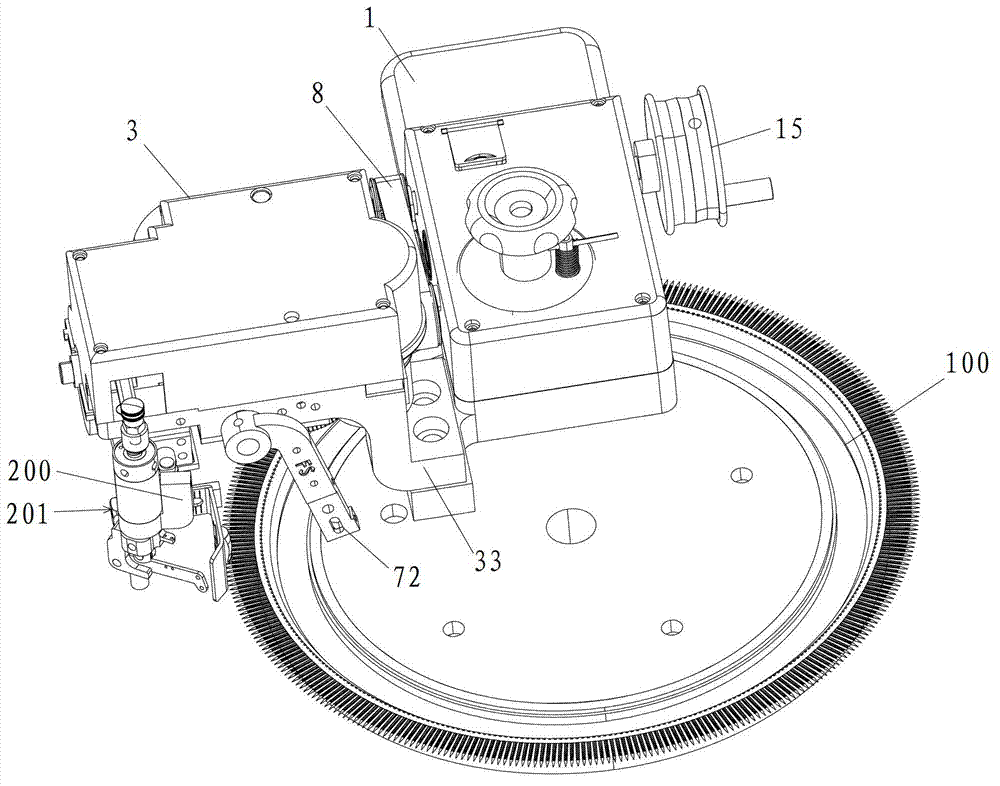

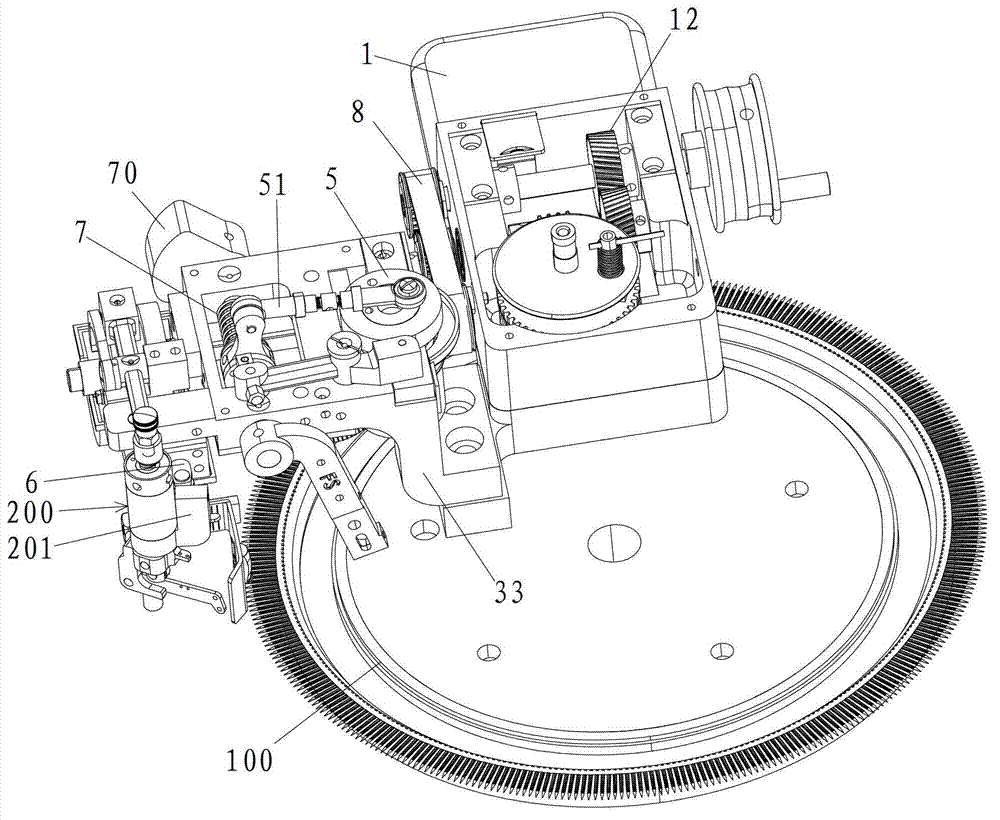

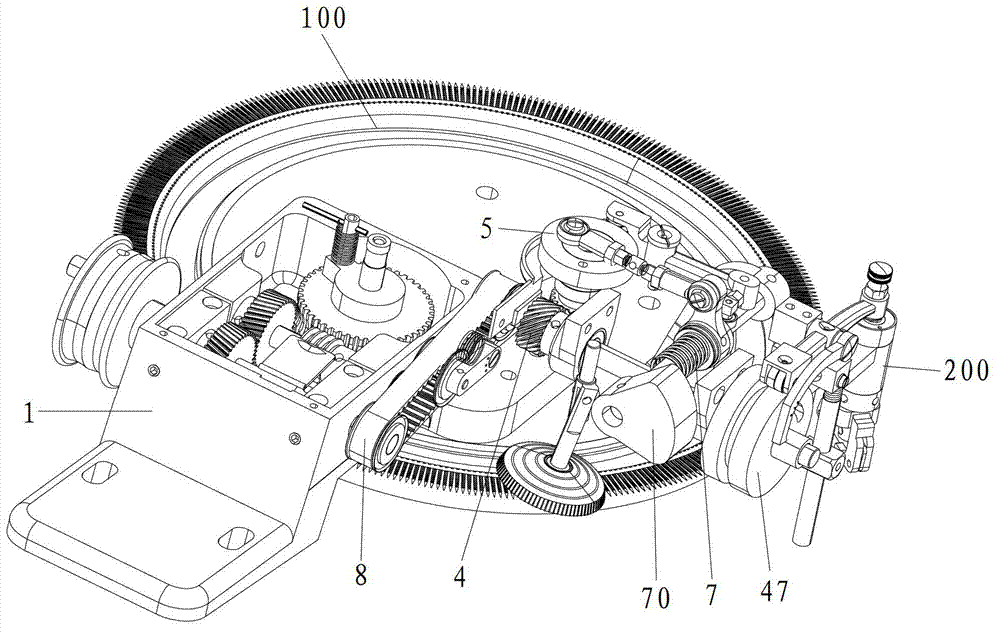

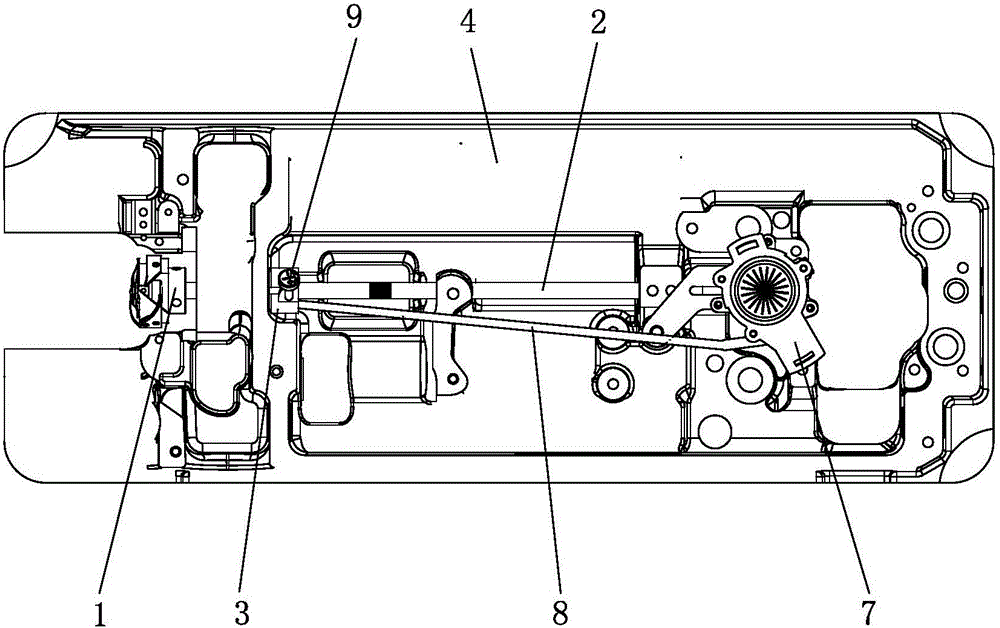

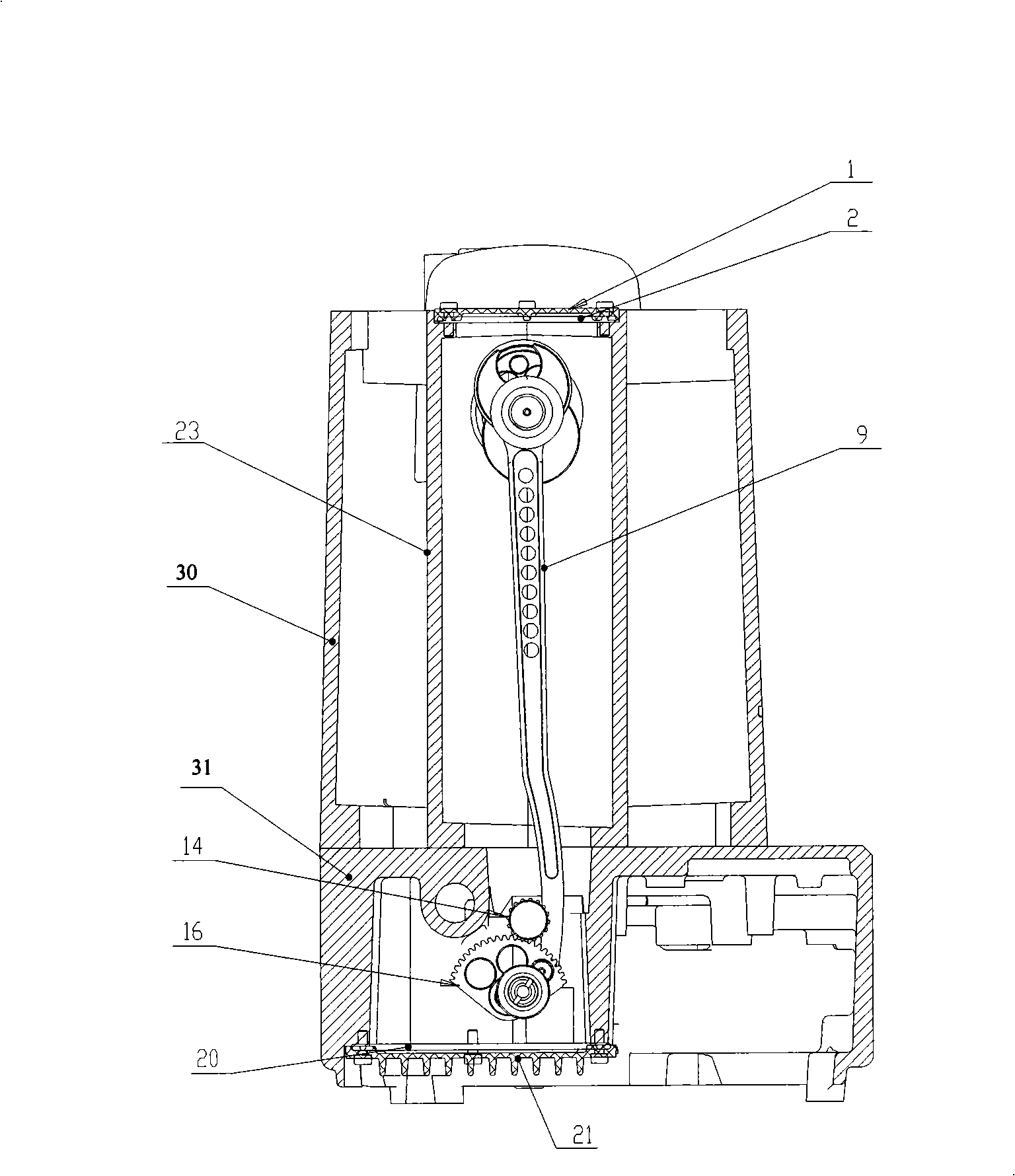

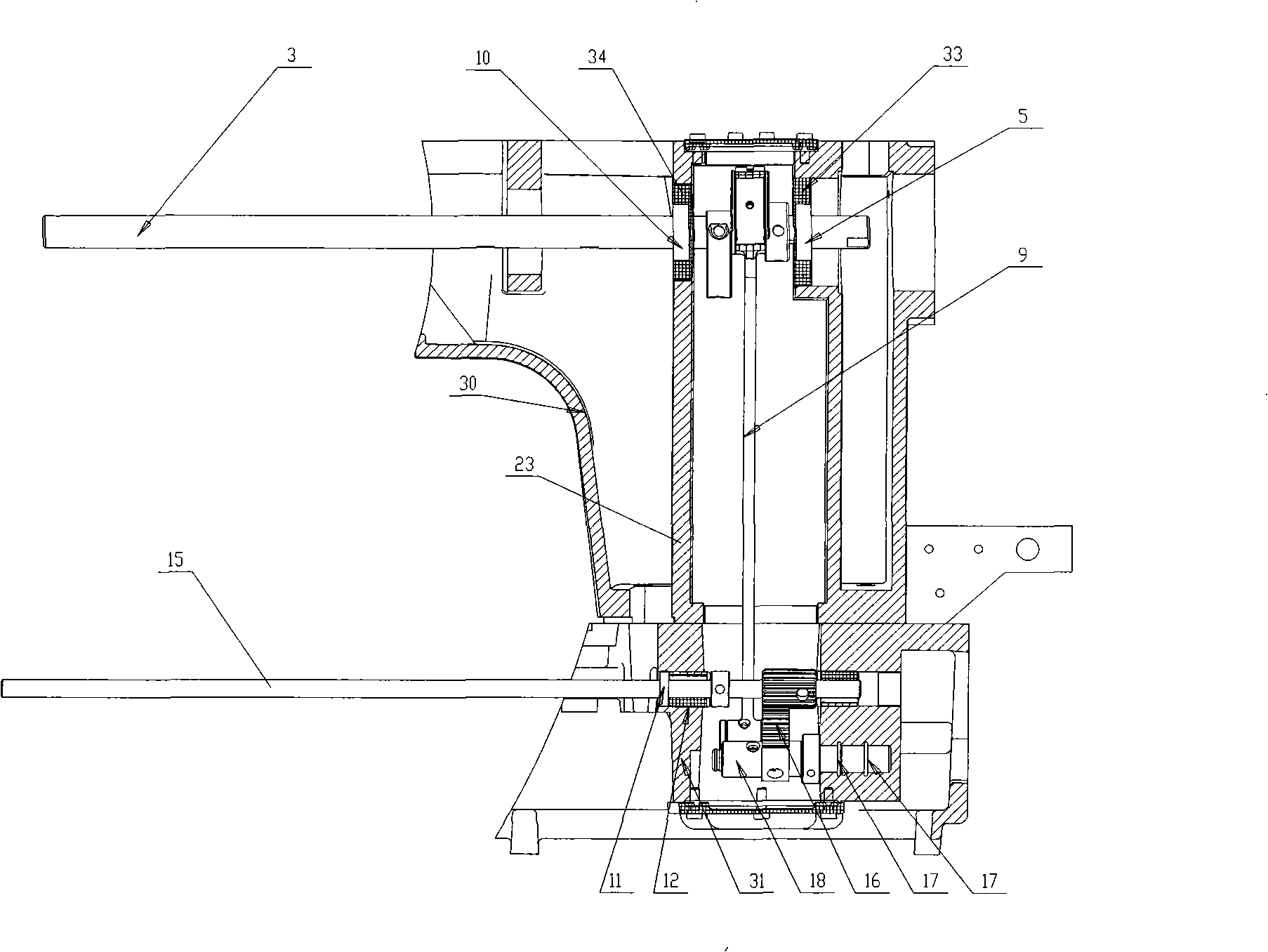

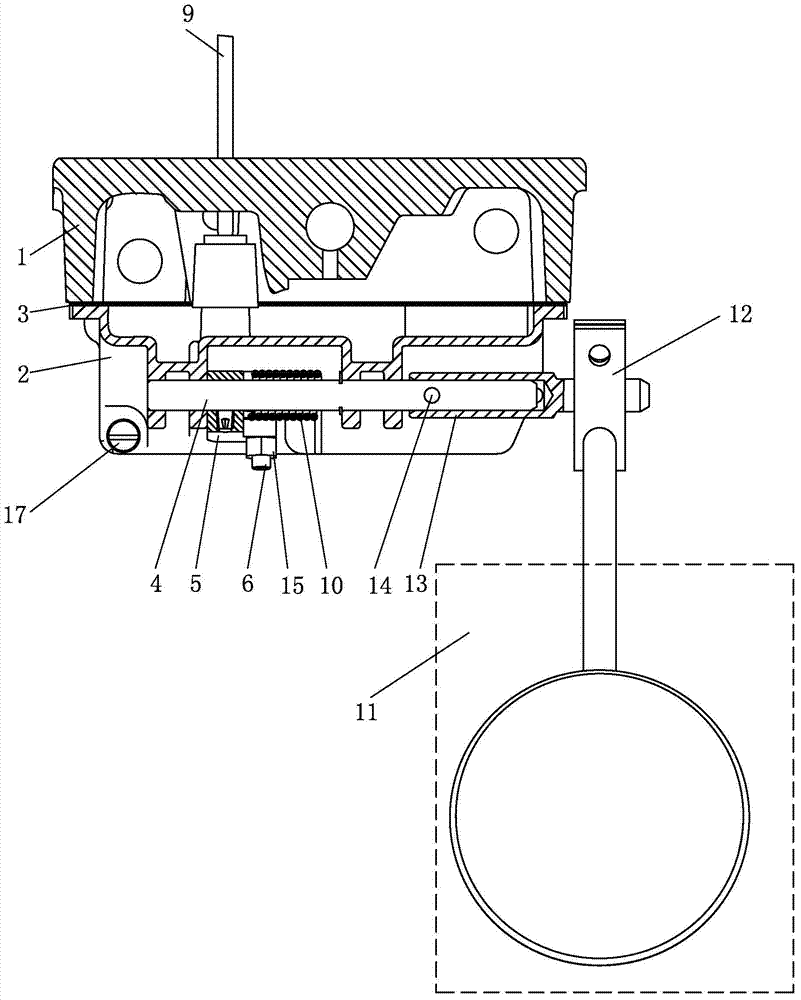

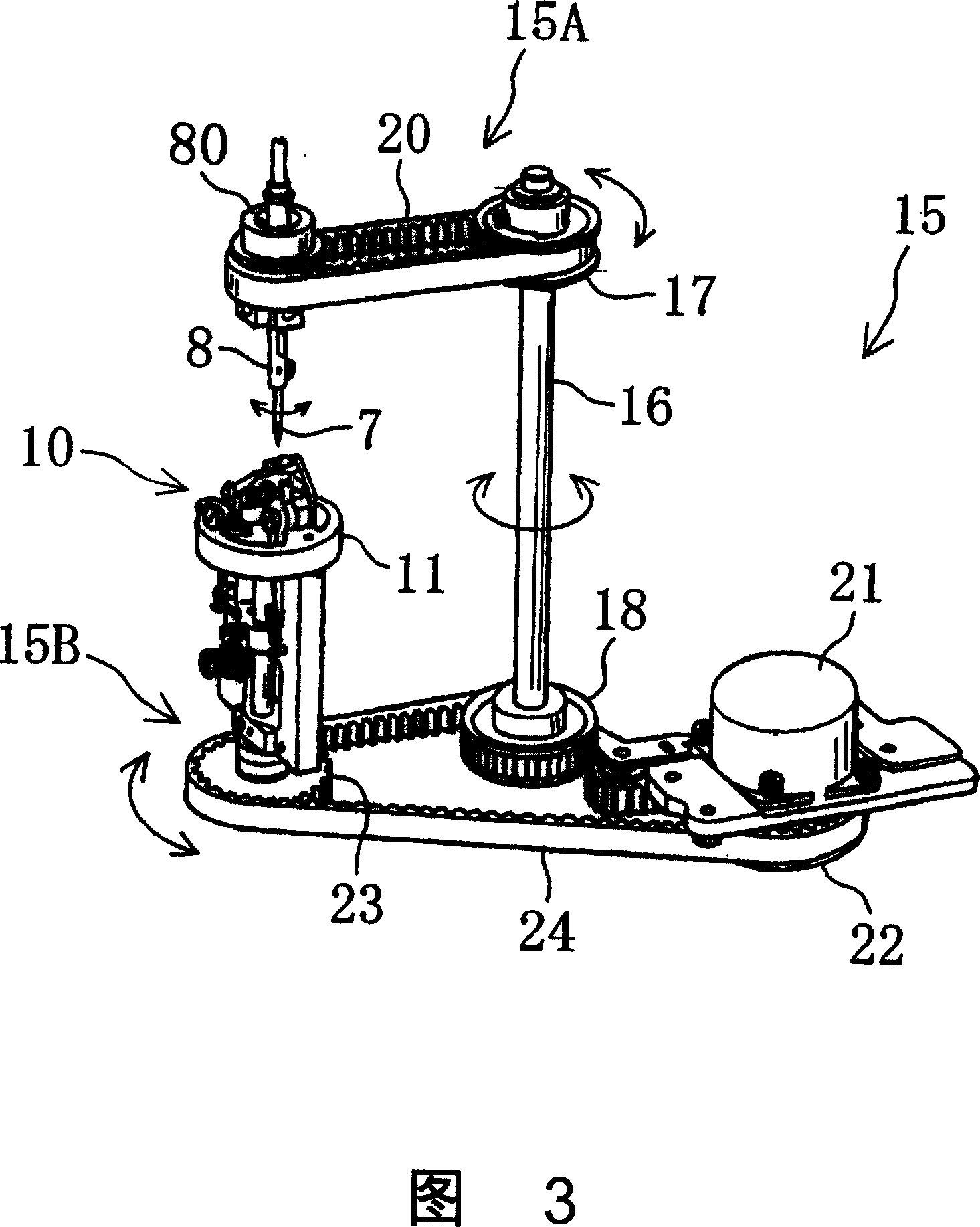

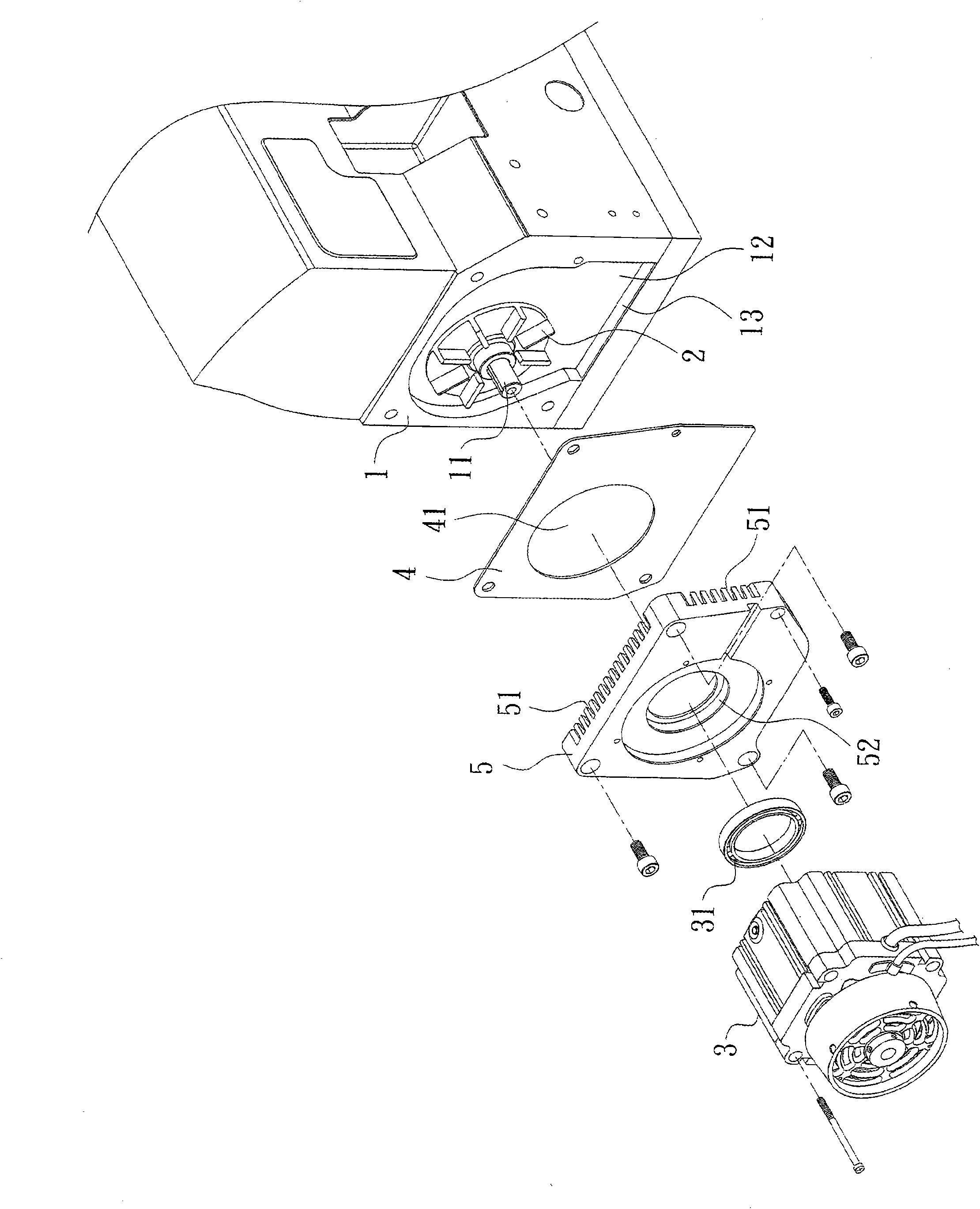

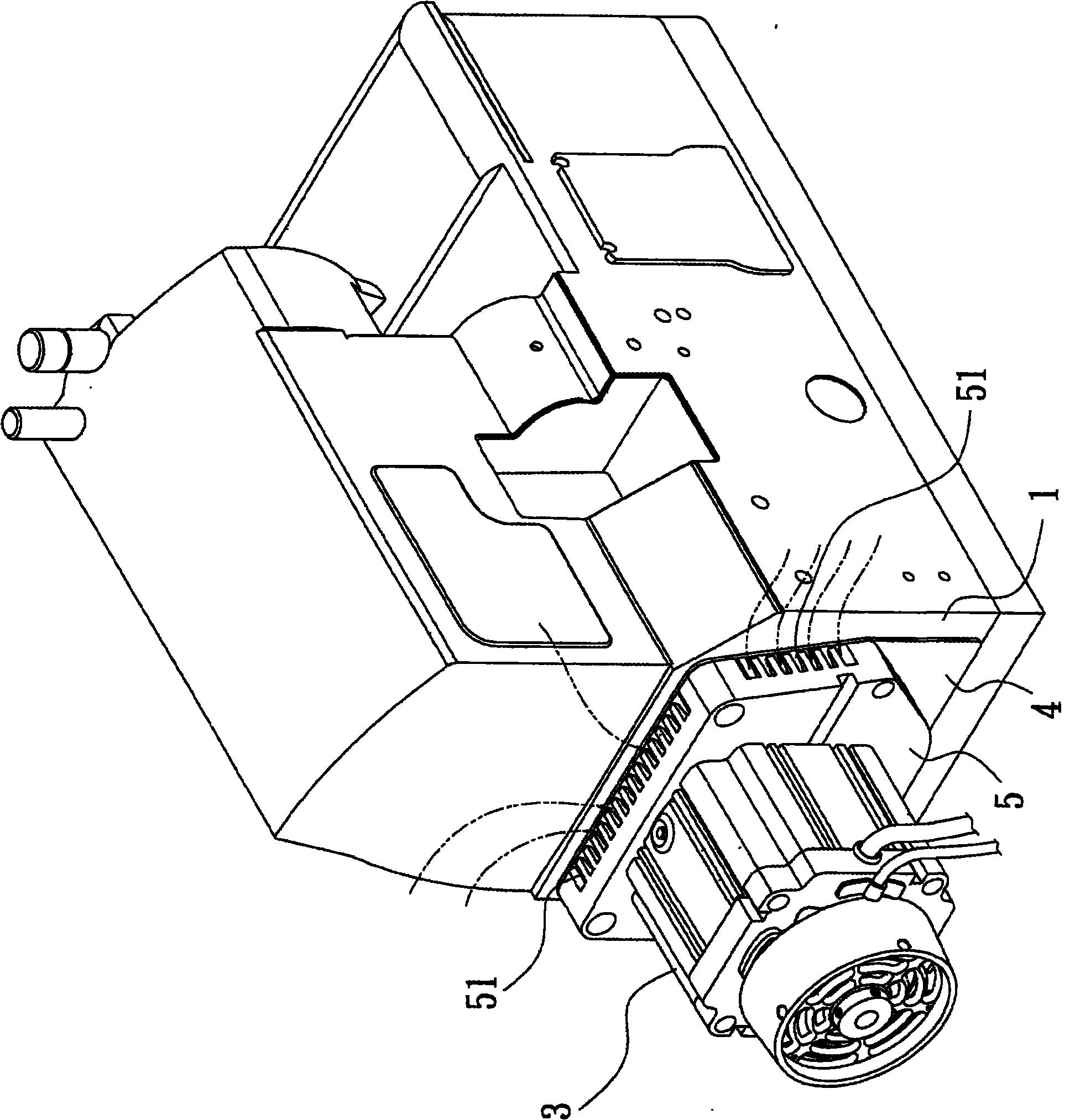

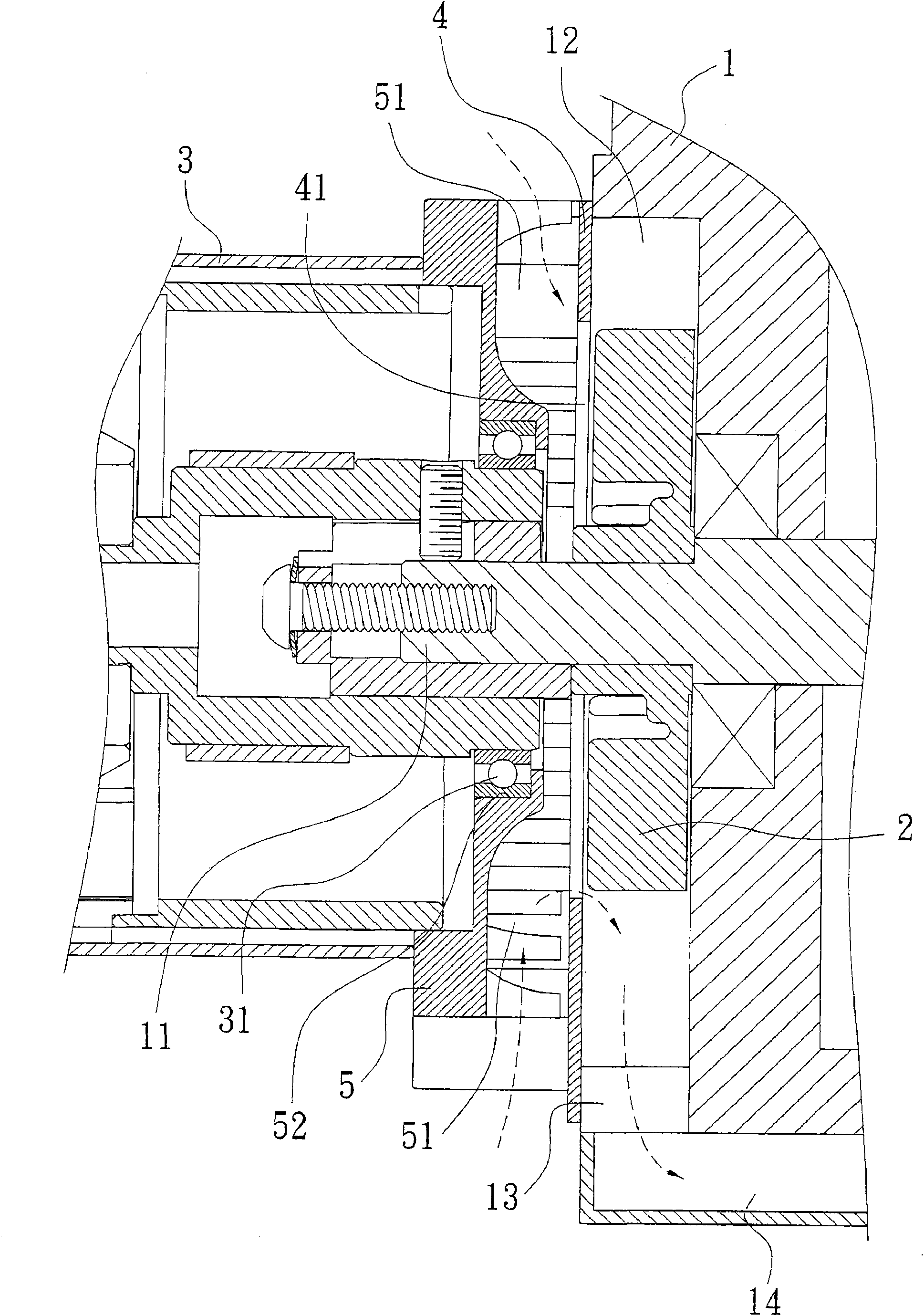

High-efficiency dial linking machine

ActiveCN102953234AStable structureGuaranteed uptimeLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

The invention discloses a high-efficiency dial linking machine. The high-efficiency dial linking machine comprises a headstock, a speed-regulating unit, a case and a dial; the headstock comprises a box, a box cover, a gear assembly and an adjusting handle, wherein the box cover is mounted on the top of the box, the gear assembly is mounted in the box, the adjusting handle is linked with the gear assembly, and the gear assembly comprises a first gear assembly and a second gear assembly which are respectively provided with a first helical gear and a second helical gear and are engaged with each other; the speed-regulating unit is linked with the gear assembly through a transmission by being matched with a motor; the case comprises a mounting bracket, an upper shield and a lower shield, and the upper shield and the lower shield are jointly formed into an automatic oil filling device; a helical tooth drive unit, a cam drive mechanism linked with the helical tooth drive unit, a striping unit, a push rod drive mechanism and a dividing unit linked with the cam drive mechanism are mounted in the case, wherein the helical tooth drive unit is linked with the gear assembly through a synchronous drive mechanism; and a debuggable counterweight is mounted on the dividing unit. The high-efficiency dial linking machine has the advantages of stable and smooth operation, good sewing quality, long service life and the like.

Owner:东莞市缝神机械设备有限公司

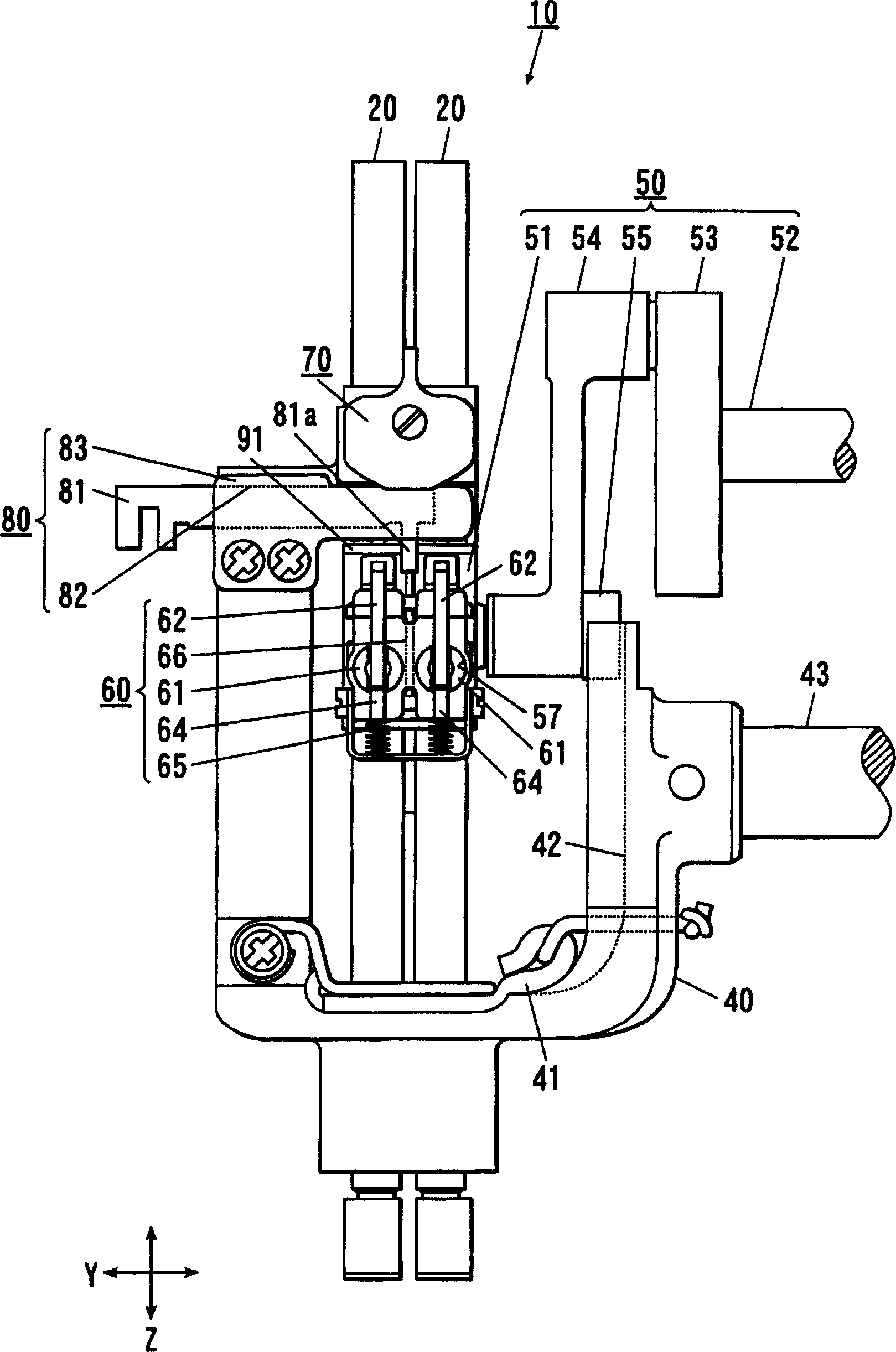

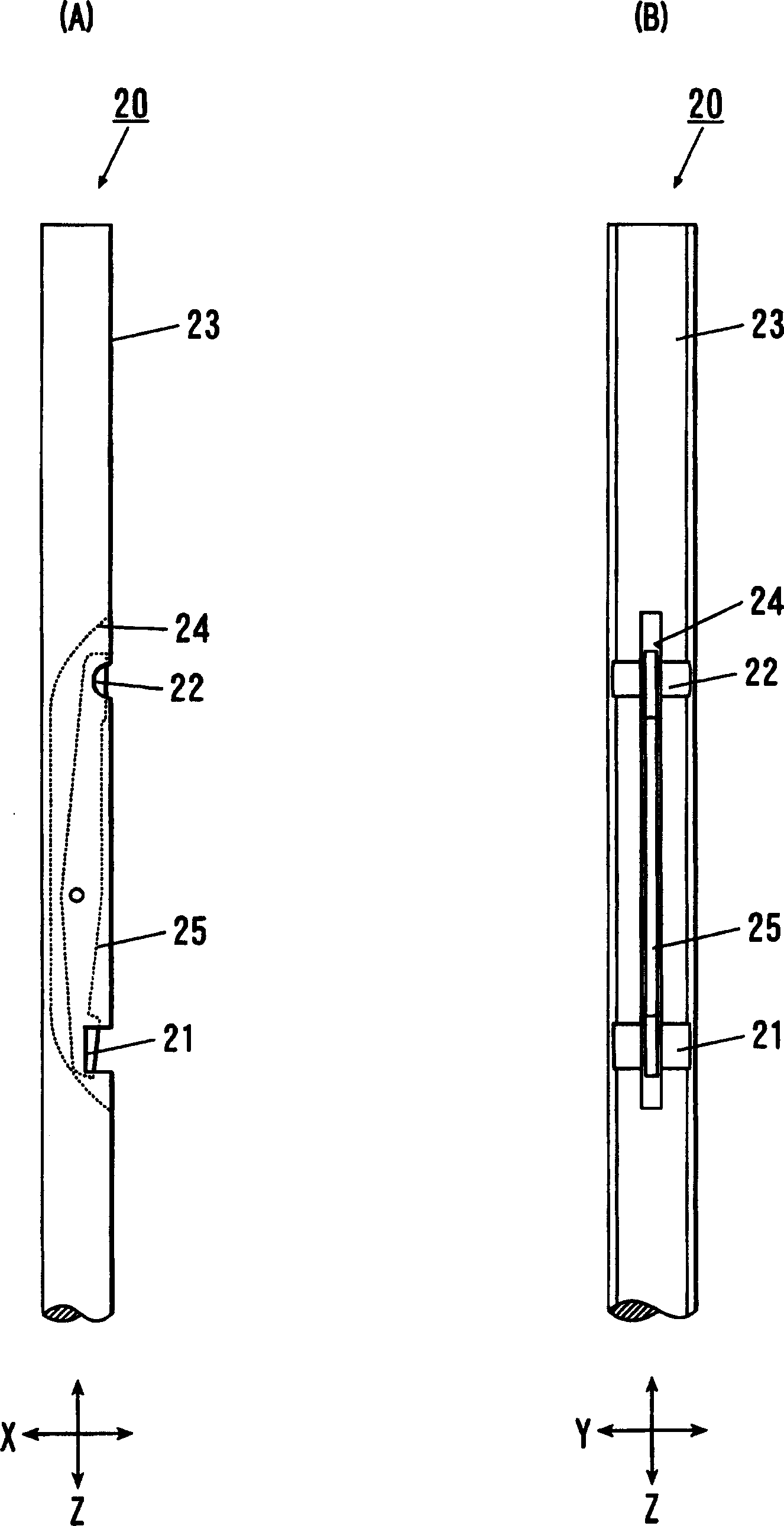

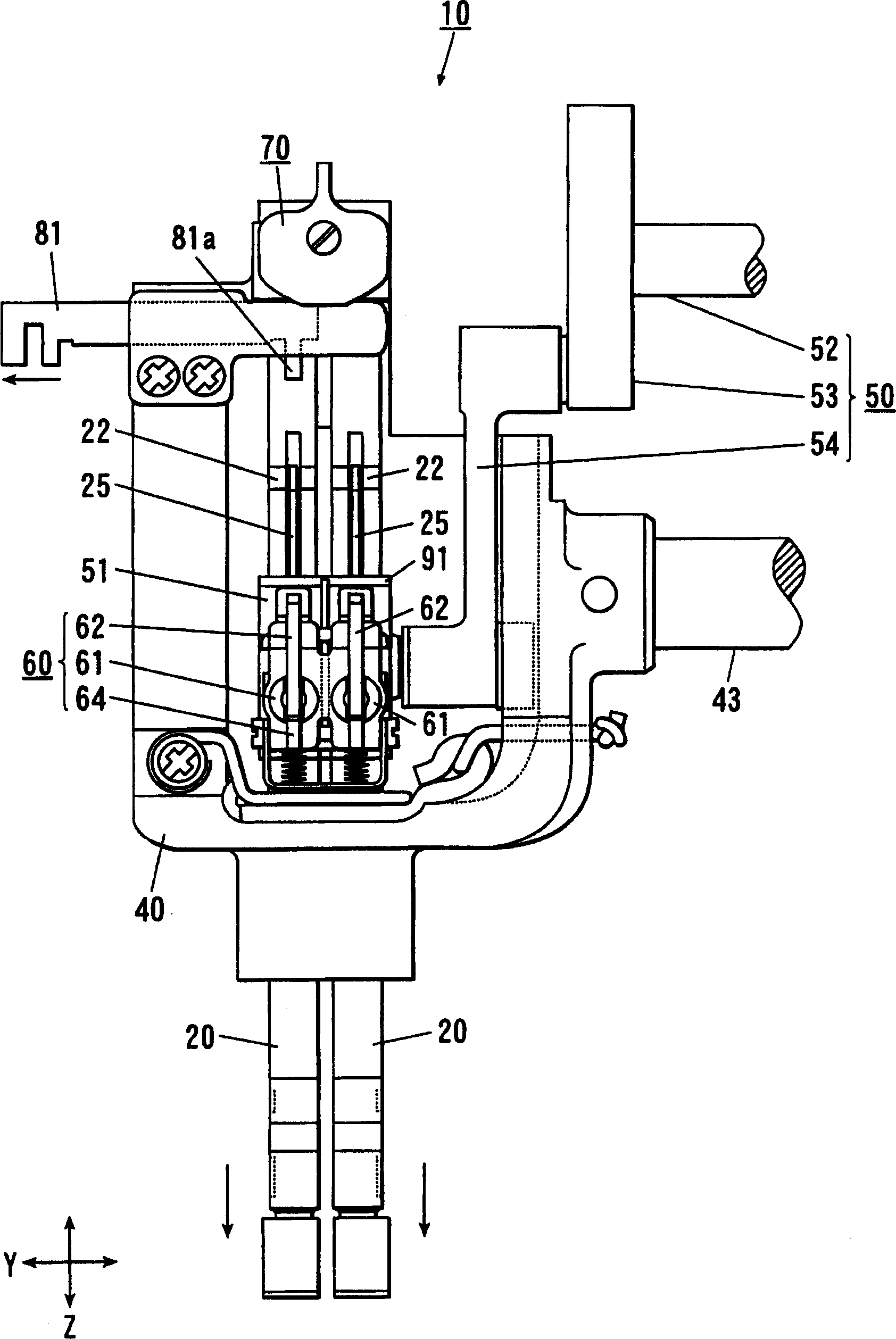

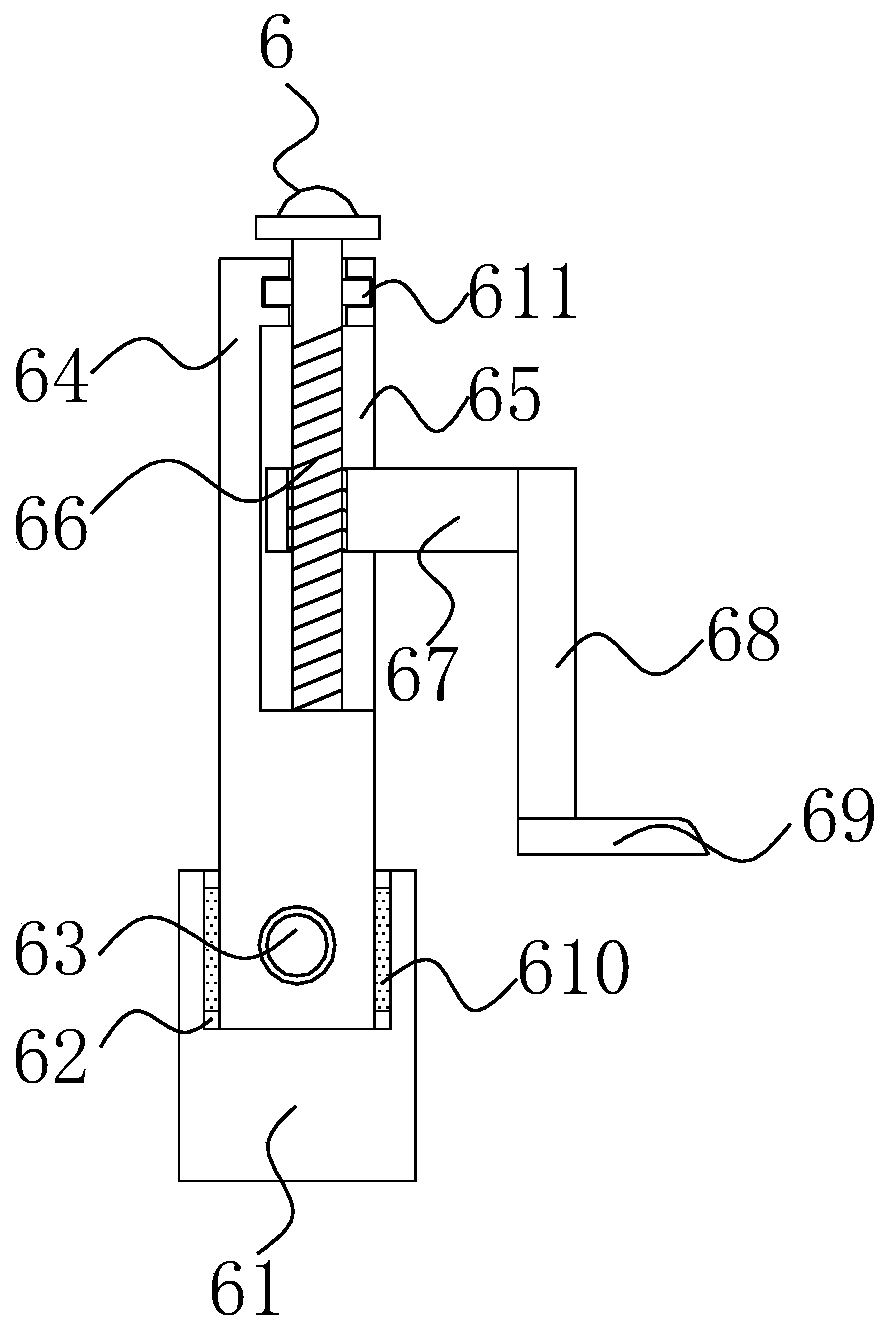

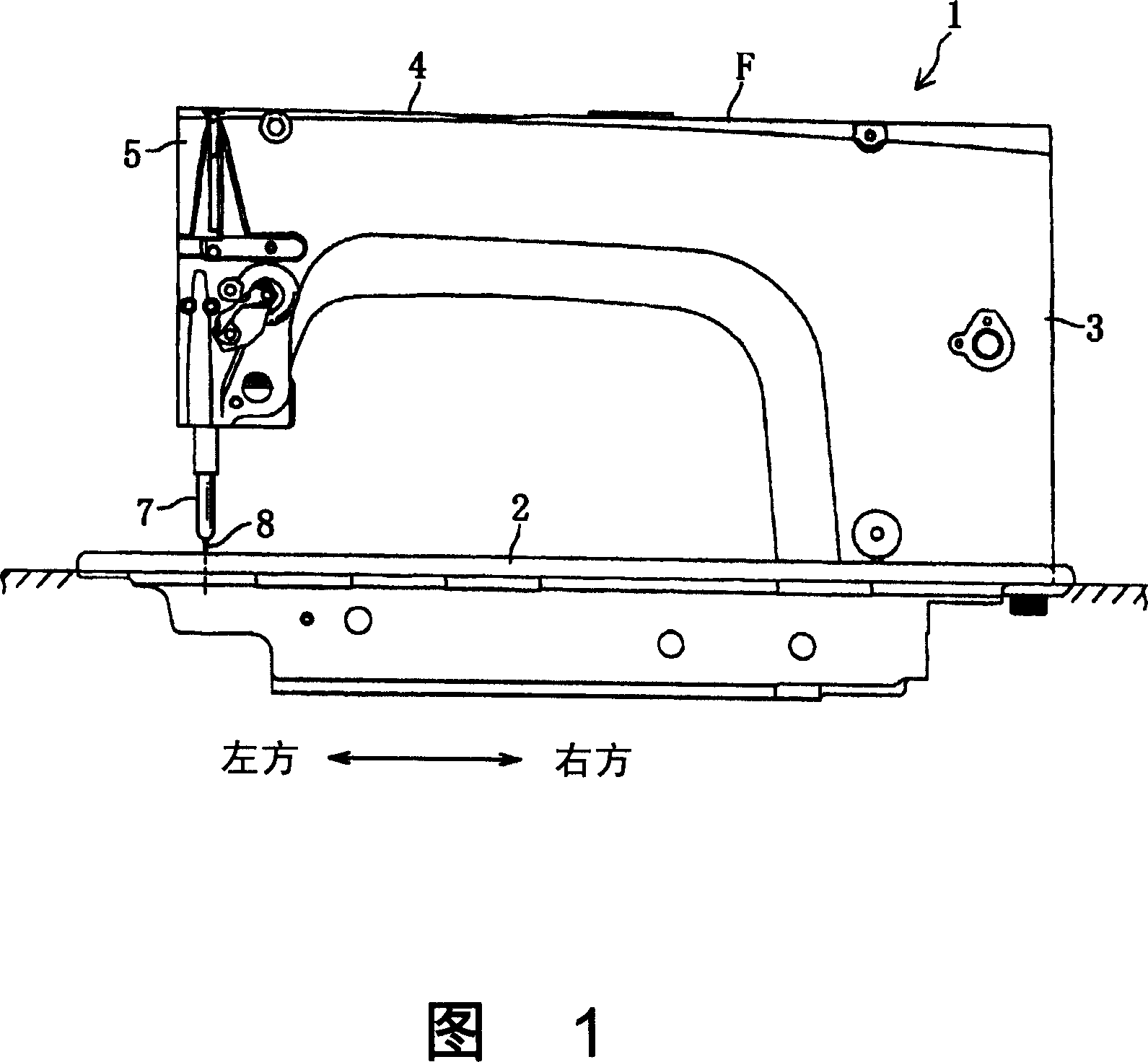

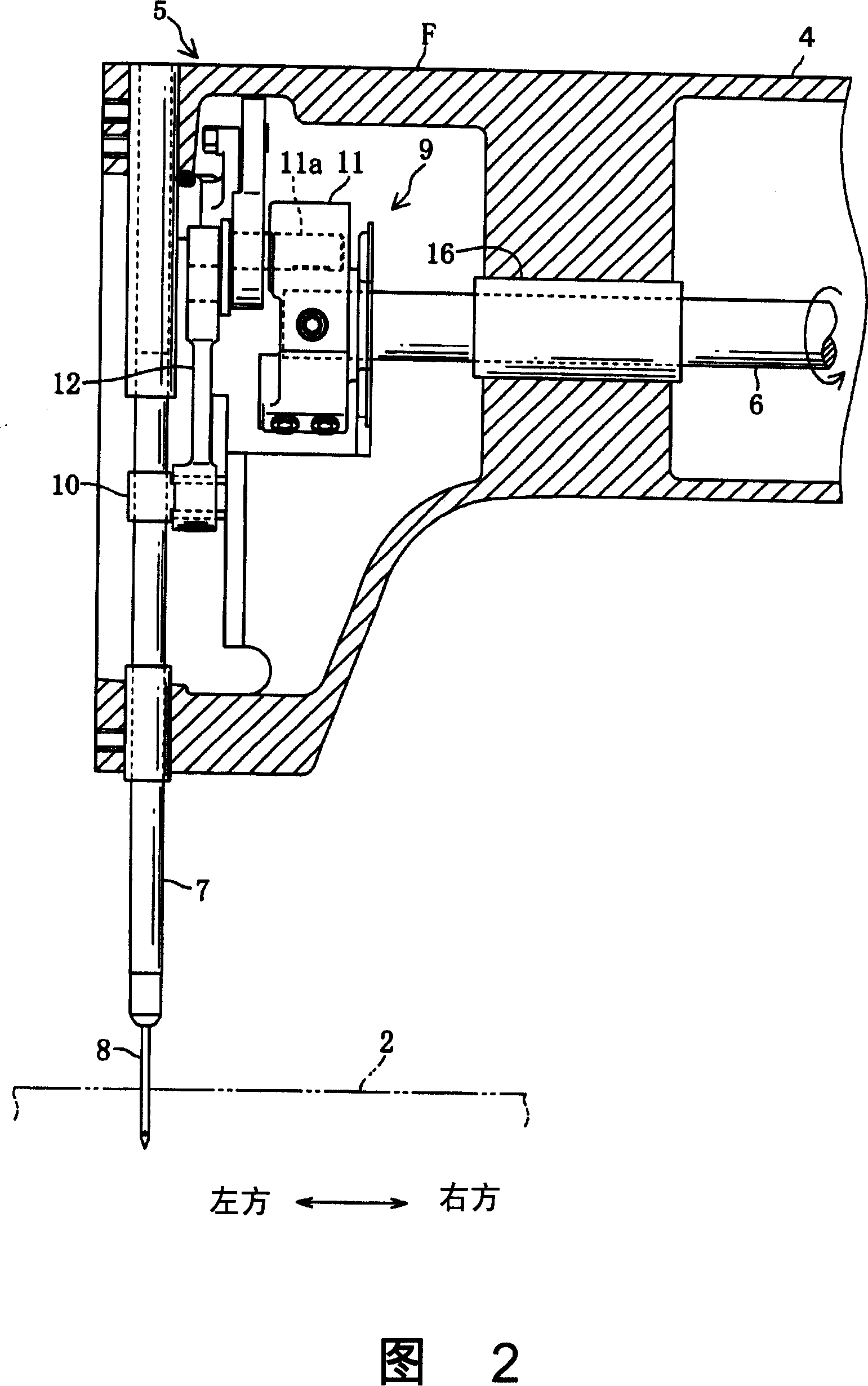

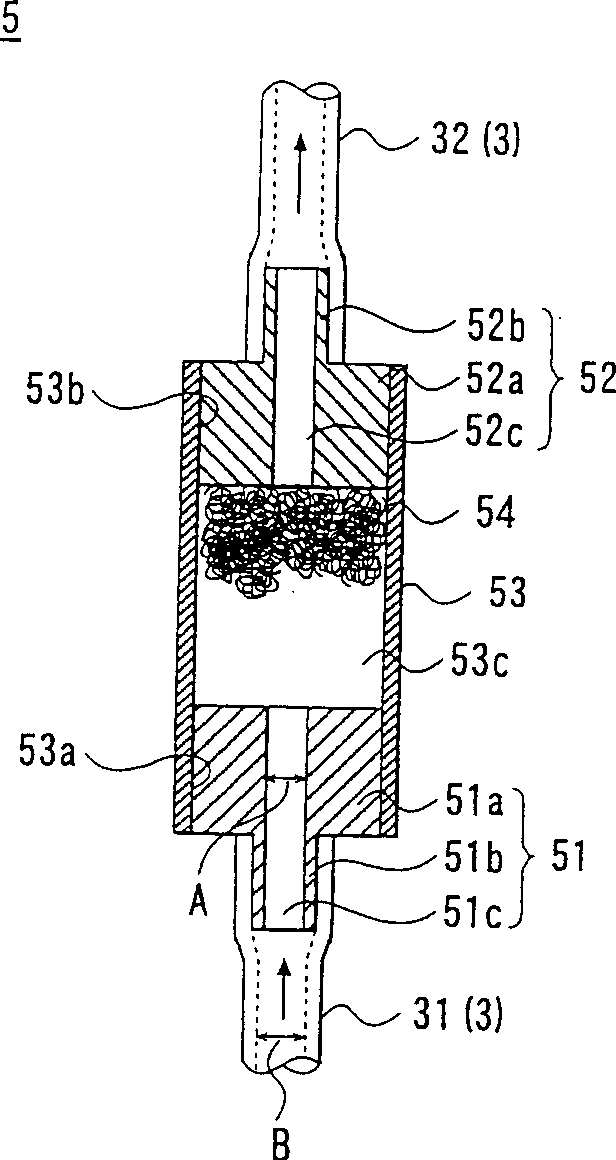

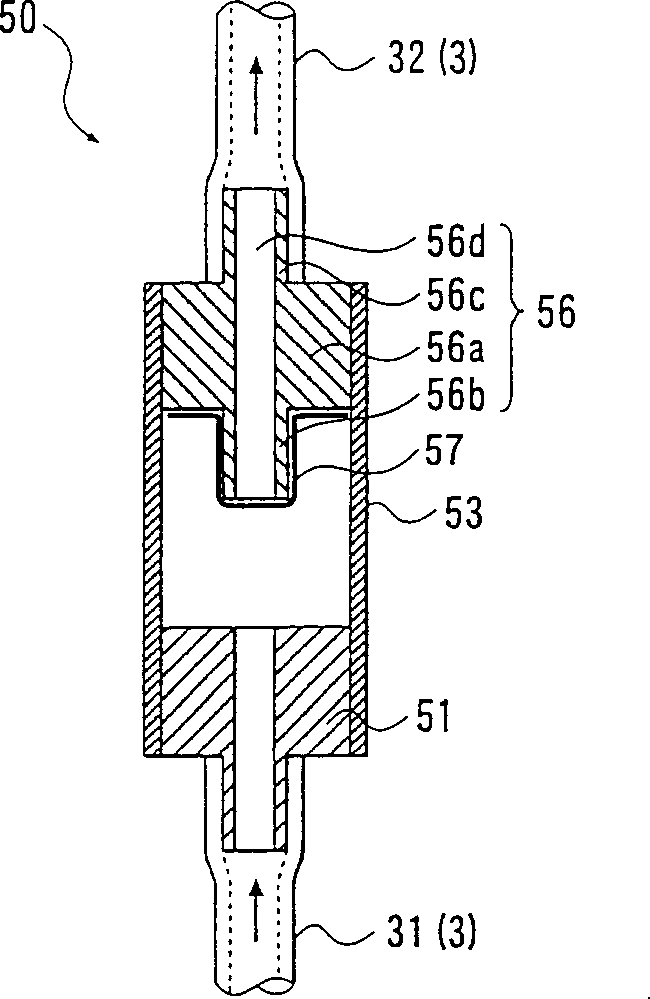

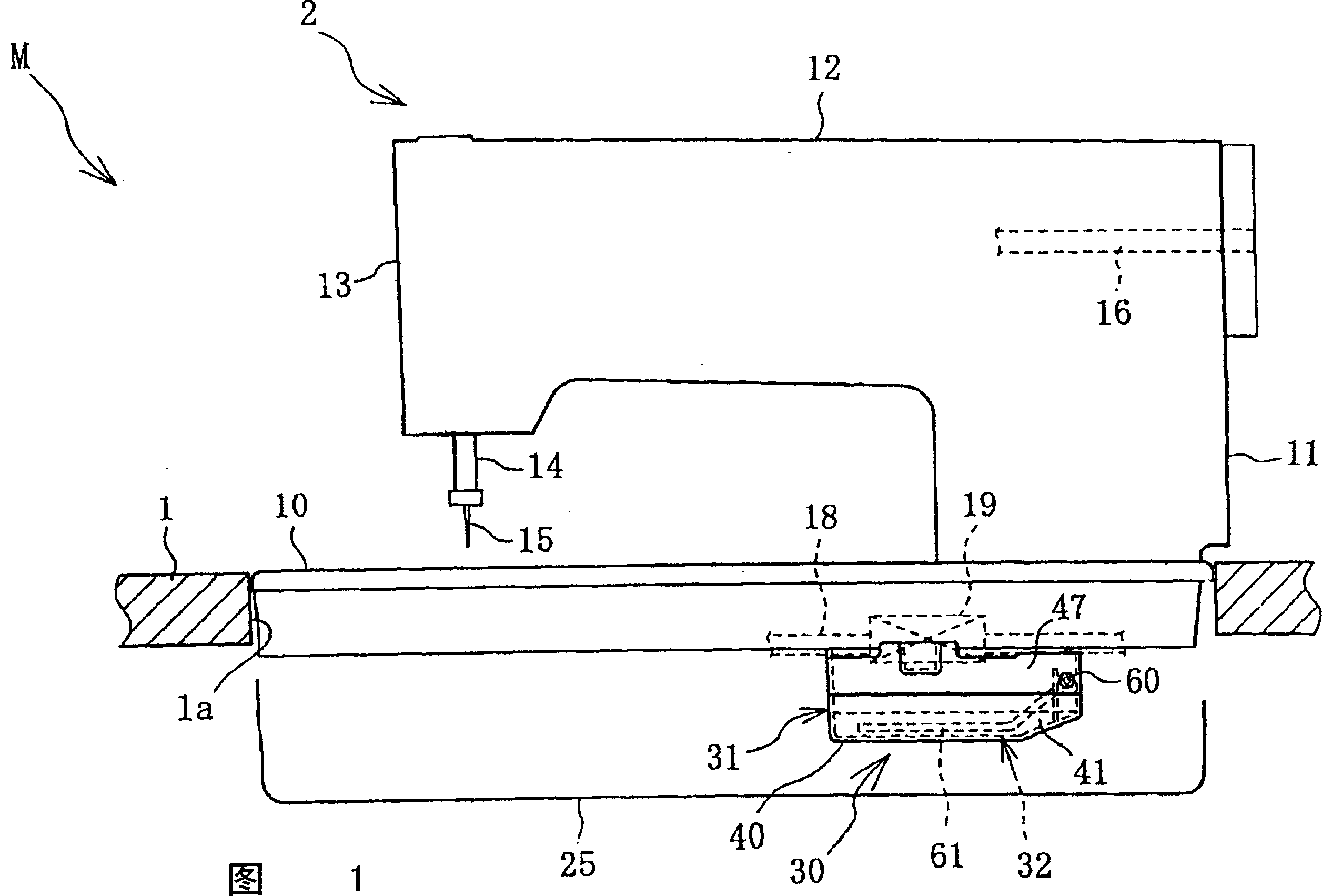

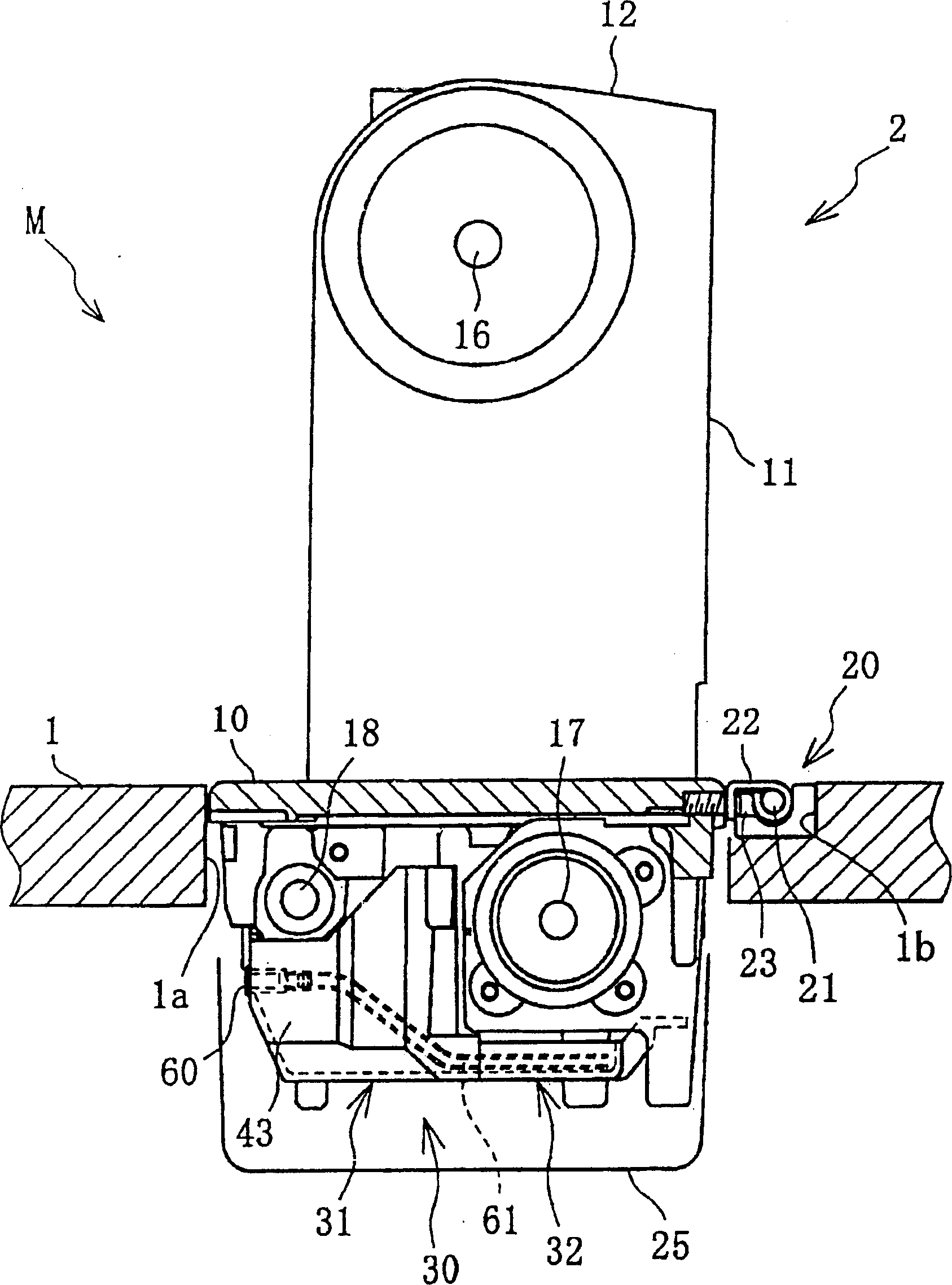

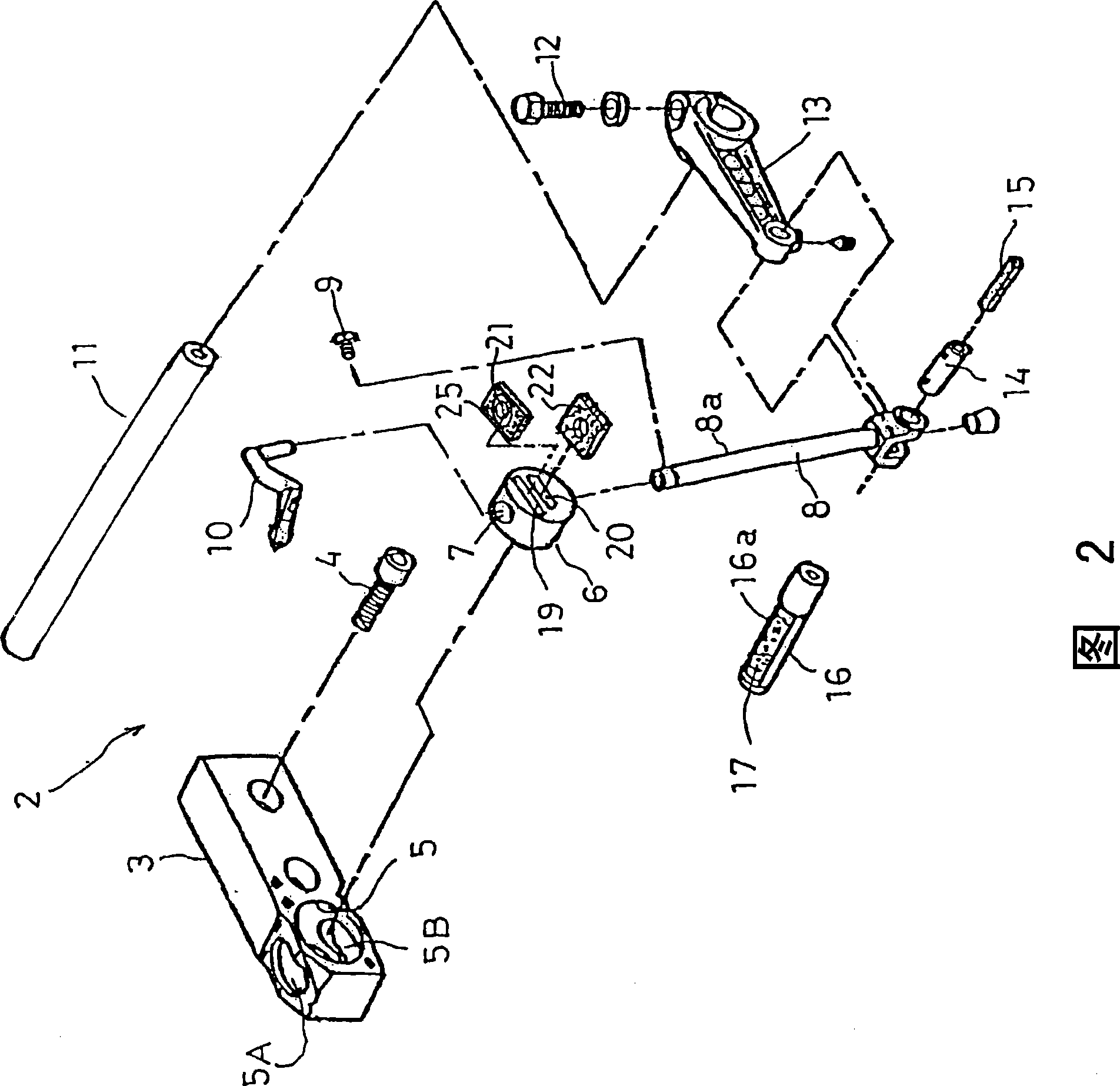

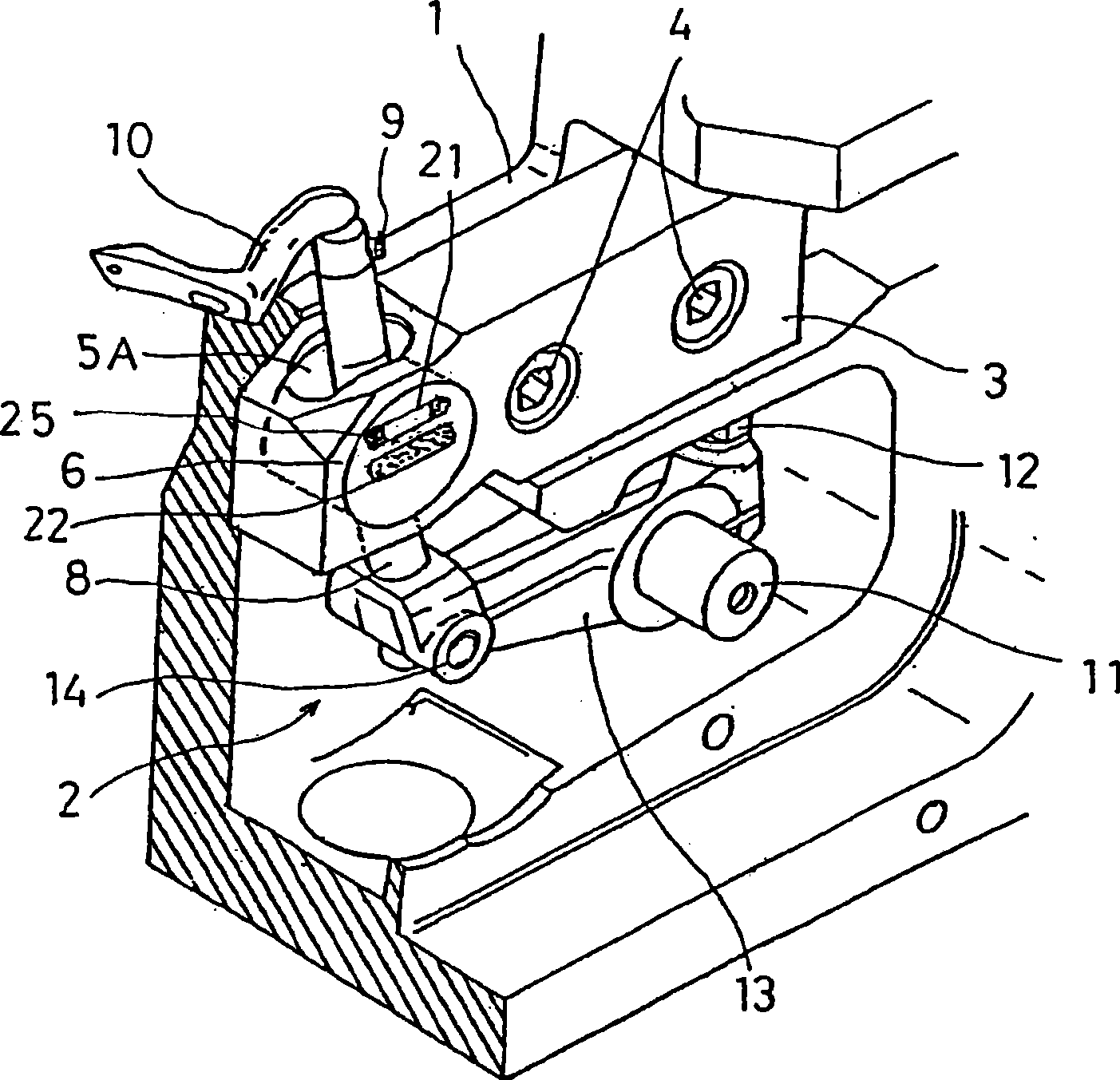

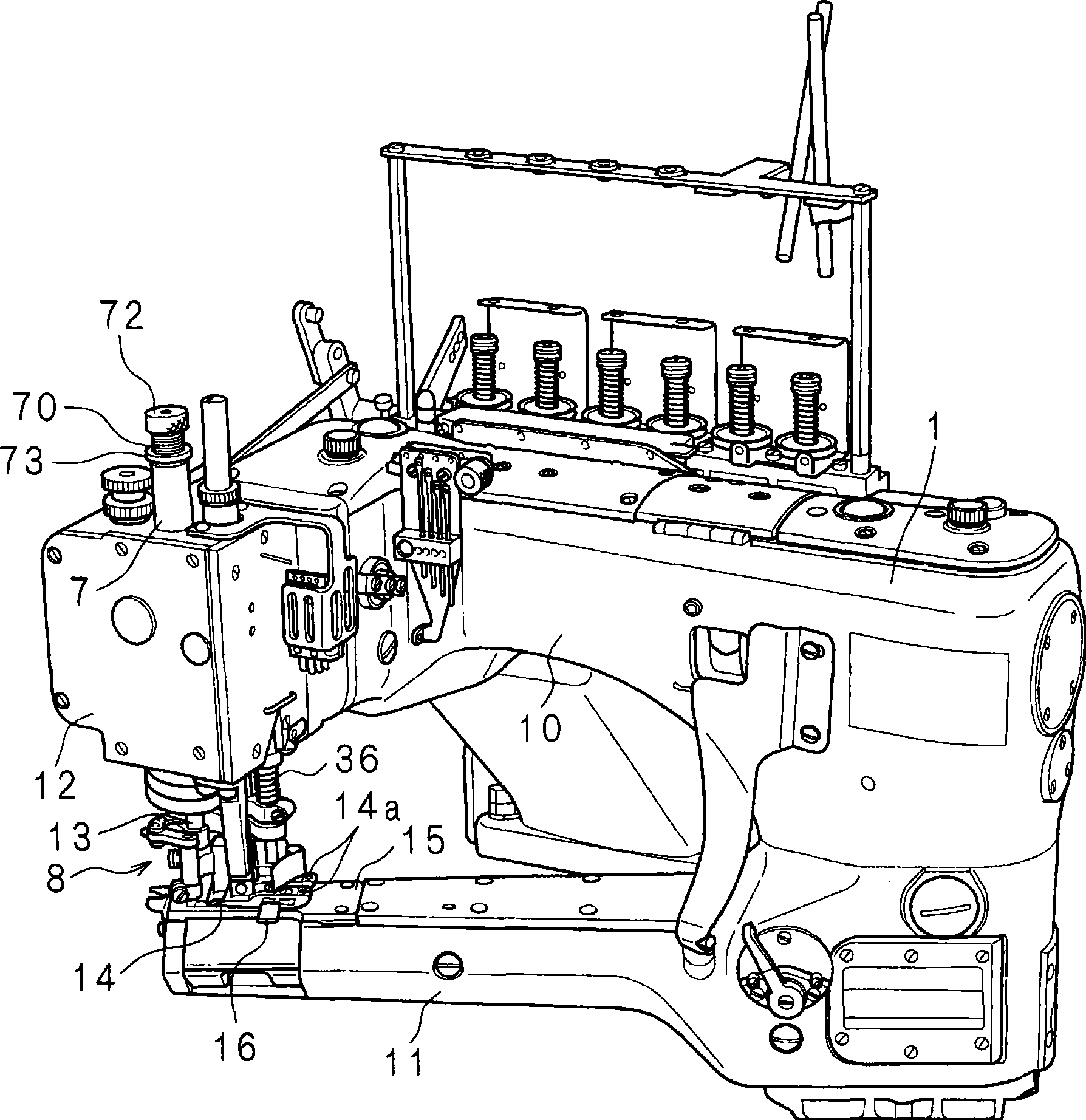

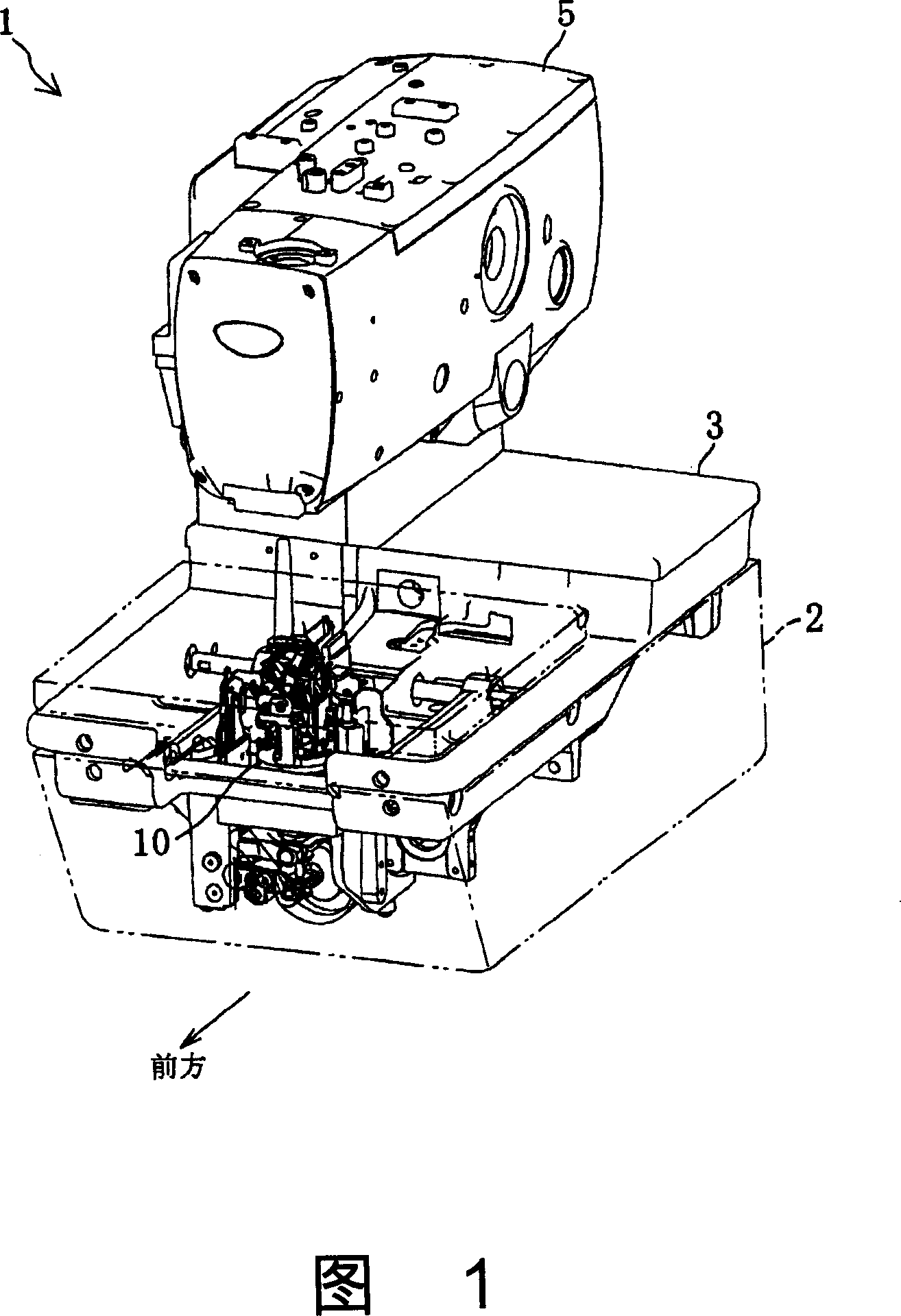

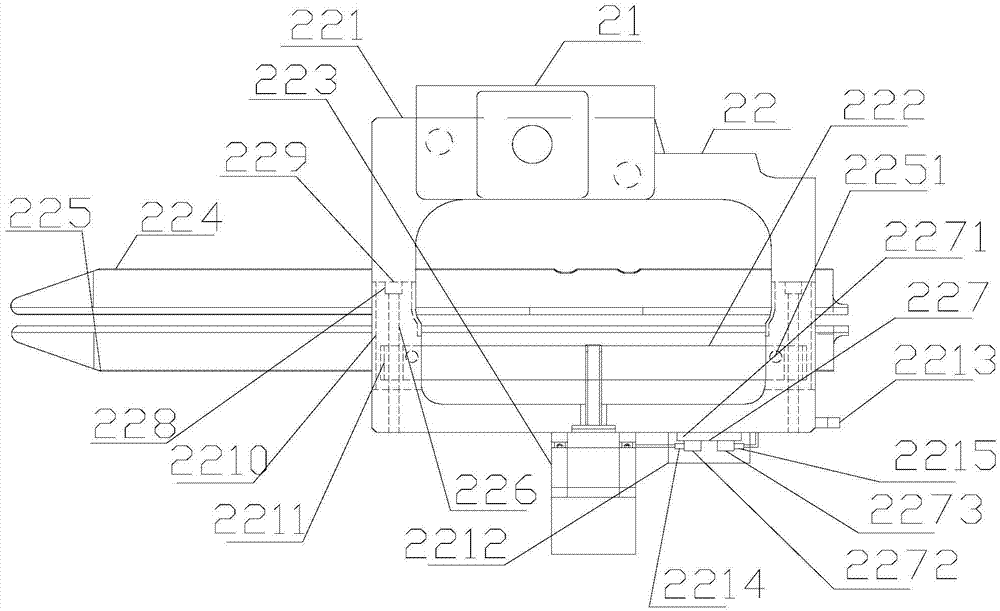

Needle stem mechanism of double-needle sewing machine

InactiveCN1776066AEven sewingSmooth up and down movementLubrication/cooling devicesNeedle barsBiomedical engineeringClutch

A needle bar mechanism for a double-needle sewing machine, comprising: a needle bar support body (40) supporting a pair of needle bars (20) capable of moving up and down; A needle bar up and down movement mechanism (50) for each needle bar to move up and down; a clutch mechanism (60) equipped with a plurality of input parts (62, 66) that accept the holding and release input of each needle bar; a switching part (81), the switching Parts (81) are selectively docked on each input part that carries out the lifting action and carry out the switching of holding or releasing the needle bar; and also have a grease supply mechanism (91), and the grease supply mechanism (91) is set On the needle bar abutment, at the same time, it is used to supply grease to the sliding parts of the needle bar abutment and each needle bar. The needle bar mechanism of this double needle sewing machine increases the durability of the unit.

Owner:JUKI CORP

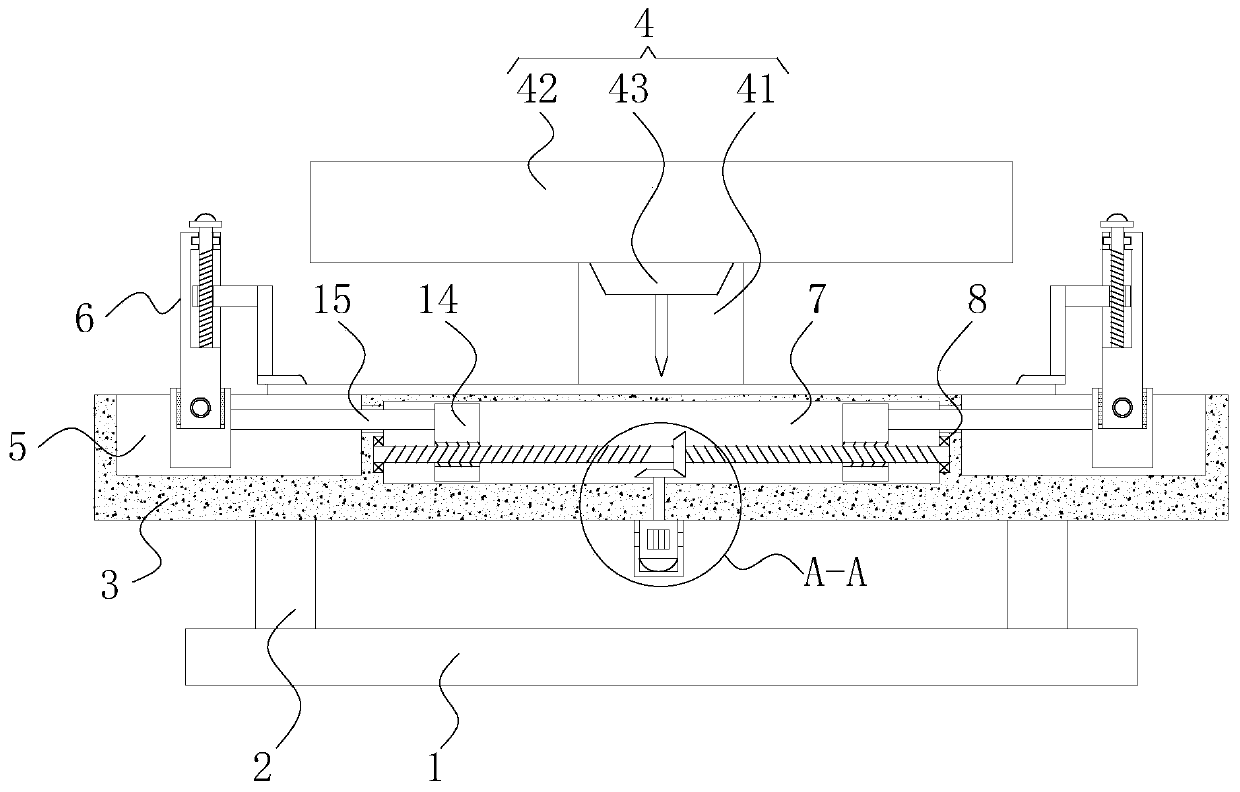

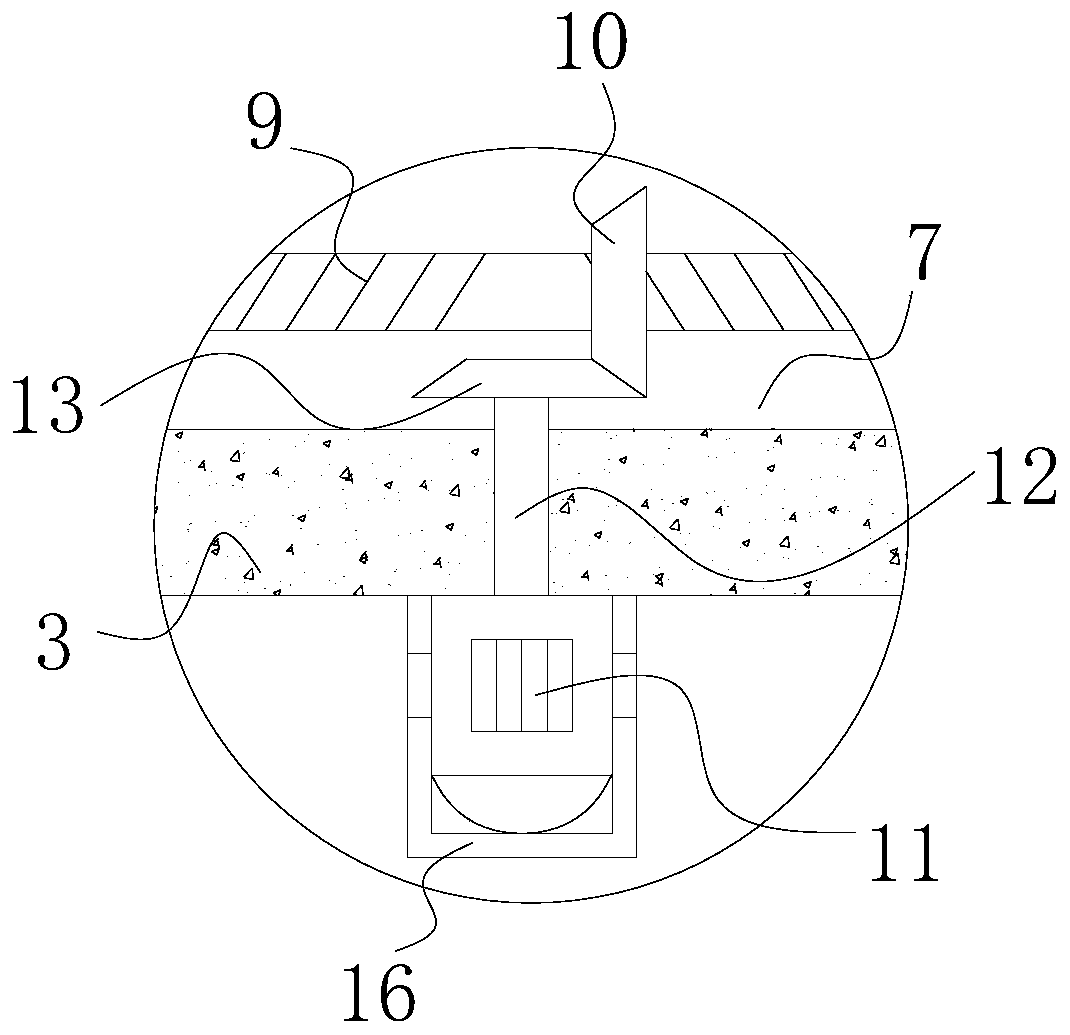

Sewing machine capable of compressing fabric

InactiveCN110468510AReasonable structural designEasy to useLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

The invention discloses a sewing machine capable of compressing a fabric, comprising a base, supporting pillars, a workbench and a sewing mechanism; the base is fixedly connected with the workbench through the two supporting pillars, the sewing mechanism is arranged at the top of the workbench, left and right sides of the top of the workbench are provided with sliding slots, each sliding slot is internally provided with a fabric compressing mechanism, a driving cavity is arranged inside the workbench and is located between the two sliding slots, left and right sides of the inner wall of the driving cavity are movably connected with a bidirectional screw rod through two bearings, the surface of the bidirectional screw rod is fixedly connected with a first bevel gear, and the bottom of the workbench is fixedly mounted with a drive motor.The sewing machine capable of compressing the fabric has the advantages that the structure design is reasonable, the use is very convenient, convenient adjustment can be realized according to the size of the fabric, the purpose of compressing and fixing is realized, the use limitation is reduced, the working efficiency is increased, and the use requirement can be fully met.

Owner:王绍梅

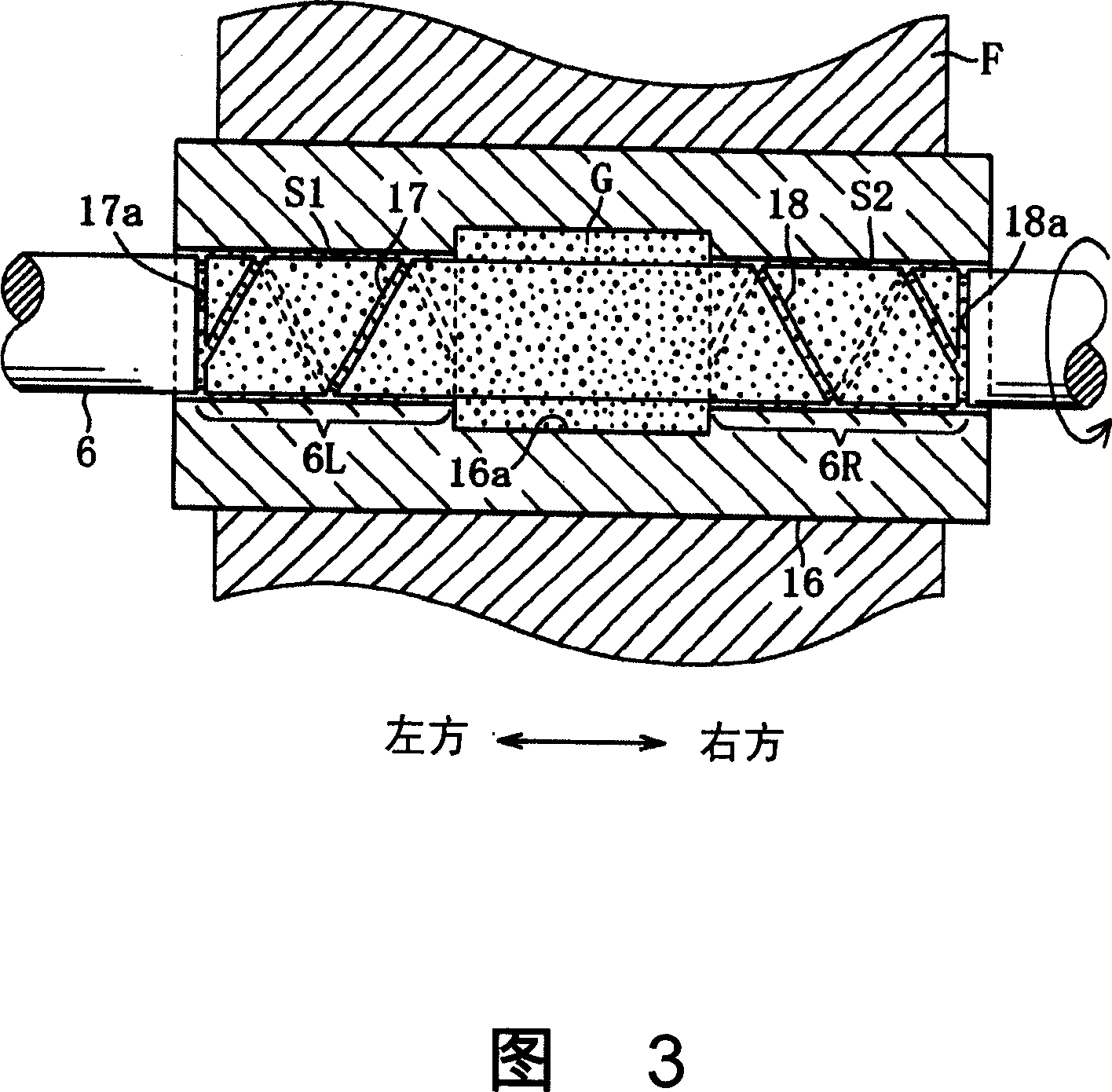

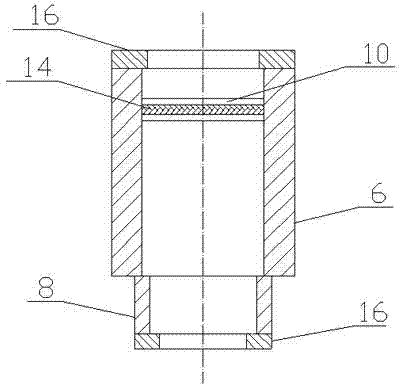

Bearing arrangement of sewing machine

InactiveCN1990936AStop the leakReduce consumptionLubrication/cooling devicesEngine lubricationEngineeringLubrication

The present invention provides a bearing structure of a sewing machine. In the bearing structure in which a rotating shaft or a rotating member is rotatably supported by a bearing member or a supporting shaft fixed on a machine frame, the contact portion or The contact portion between the support shaft and the rotating member is formed with an annular grease receiving portion that holds grease for lubrication. On both sides of the grease receiving portion, there are formed a second grease holder that advances toward the grease receiving portion following the rotation of the rotating shaft or the rotating member. 1. The second helical groove, whereby the grease diffused between the rotating shaft and the bearing member or between the supporting shaft and the rotating member is returned to the grease housing under the action of the first and second helical grooves, preventing Grease leaks from both sides of the bearing member or rotating member, thereby preventing a decrease in lubricating performance due to insufficient grease, maintaining smooth rotation for a long period of time, and improving durability.

Owner:BROTHER KOGYO KK

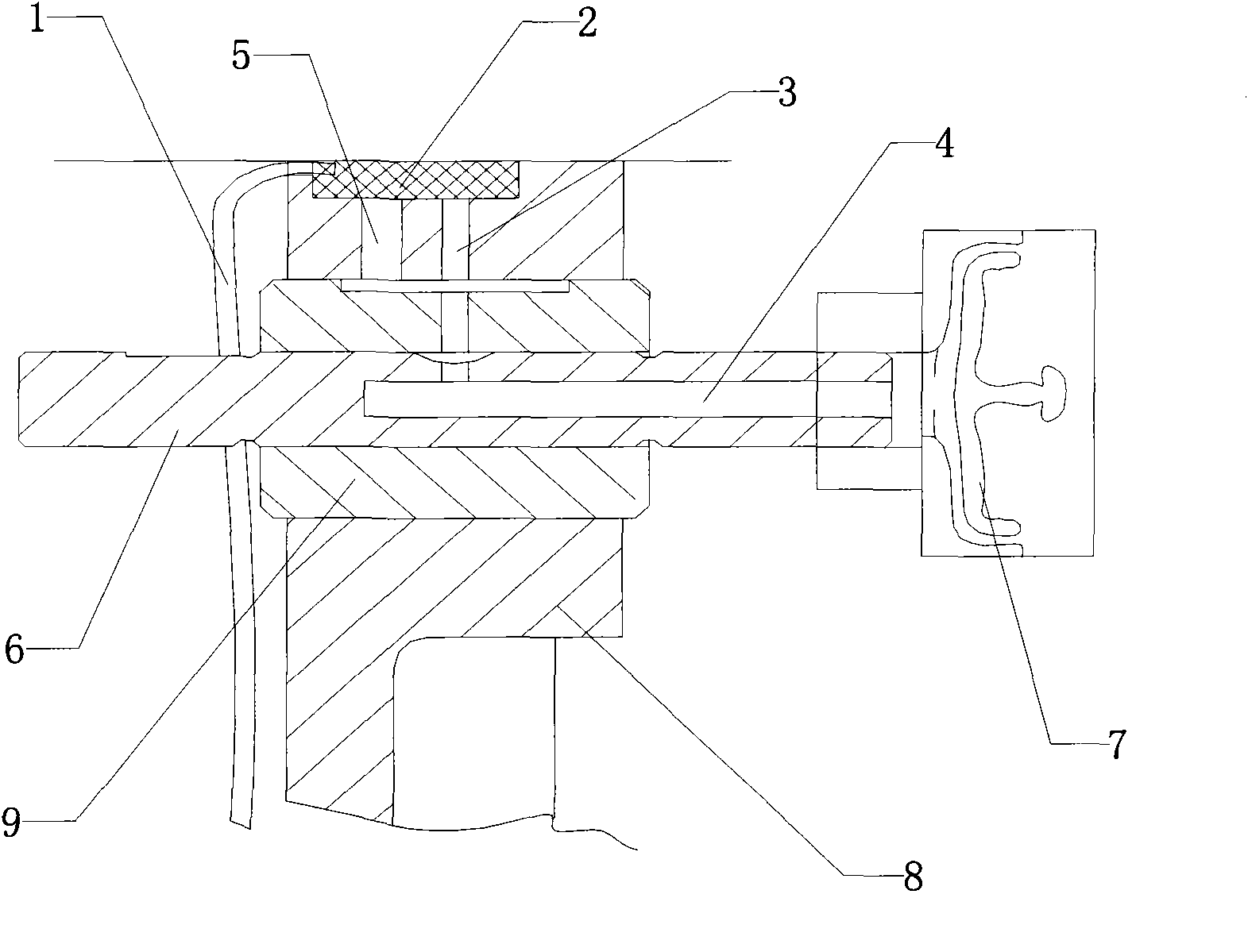

Oil supplying mechanism for rotating shuttle of sewing machine and sewing machine

InactiveCN105908402APrevent leakageLeak notLubrication/cooling devicesPetroleum engineeringSewing machine

The invention belongs to the technical field of sewing equipment, and particularly relates to an oil supplying mechanism for a rotating shuttle of a sewing machine. The oil supplying mechanism is characterized in that the rotating shuttle is arranged at one end of a lower shaft; a front sleeve is arranged on the lower shaft, and sealing oil seals are arranged at two ends of the front sleeve of the lower shaft; an oil feeding hole and an oil returning hole are formed in the front sleeve of the lower shaft; the oil feeding hole is communicated with the oil returning hole; an oil supplying tube which is connected with an oil pump is connected to the oil feeding hole; the sealing oil seals are used for preventing lubricating oil from leaking outside from two ends of the front sleeve of the lower shaft; the oil feeding hole or the oil returning hole is communicated with a thread hole of an oil volume adjusting screw; the oil volume can be adjusted according to the position where the oil volume adjusting screw is screwed into the thread hole. According to the oil supplying mechanism, the sealing oil seals are embedded into the left end and the right end of the front sleeve of the lower shaft, so that the lubricating oil can be prevented from being leaked from the left side and the right side of the front sleeve of the lower shaft; in addition, one end of the oil feeding hole is sealed through the corresponding sealing oil seal; the oil returning hole is radially formed and can be used for directly returning oil into an oil receiver through an oil returning tube. Therefore, the lubricating oil can be prevented from leaking, and as a result, the purpose of clean sewing can be achieved.

Owner:JACK SEWING MASCH CO LTD

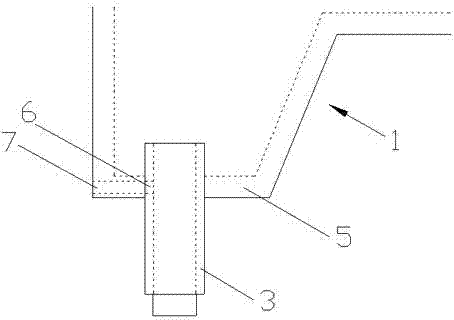

Fully sealing transmission mechanism of caracol hook race sewing machine

ActiveCN101314900AReduce frictionConrod size reductionLubrication/cooling devicesSewing-machine control devicesGear wheelEngineering

The invention discloses a fully-sealed transmission mechanism of a semi-rotating shuttle sewing machine. The fully-sealed transmission mechanism comprises an upper housing case, a lower housing case, a lower main shaft, a swinging gear shaft, an upper main shaft, a link rod and a sealing box body arranged in the upper housing case, wherein the lower main shaft is arranged in the lower housing case, and is provided with a lower main shaft gear; the swinging gear shaft is arranged on the lower side of the lower main shaft, and is provided with a swinging gear meshed with the lower main shaft gear; and the upper main shaft horizontally passes through the sealing box body in the upper housing case, and is provided with a cam; the cam on the upper main shaft and the pin shaft of the swinging gear are respectively sleeved with the two ends of the link rod; the upper main shaft and the cam are of an integral structure, and the outer diameter of one side of the cam is smaller than the semidiameter of the upper main shaft. The fully-sealed transmission mechanism connects the cam with the upper main shaft into a whole under the condition that the eccentric distance remains unchanged, thereby reducing the volume. Besides, the perfect-sealed transmission mechanism runs in the machine oil in the sealing box body, thereby solving the difficult problems that the prior product has large noise, the machine oil pollutes the sewing, the abrasion is fast, the rotating speed is low, and the maintenance is inconvenience, and greatly improving the service life and the working efficiency.

Owner:四川中缝重工股份有限公司

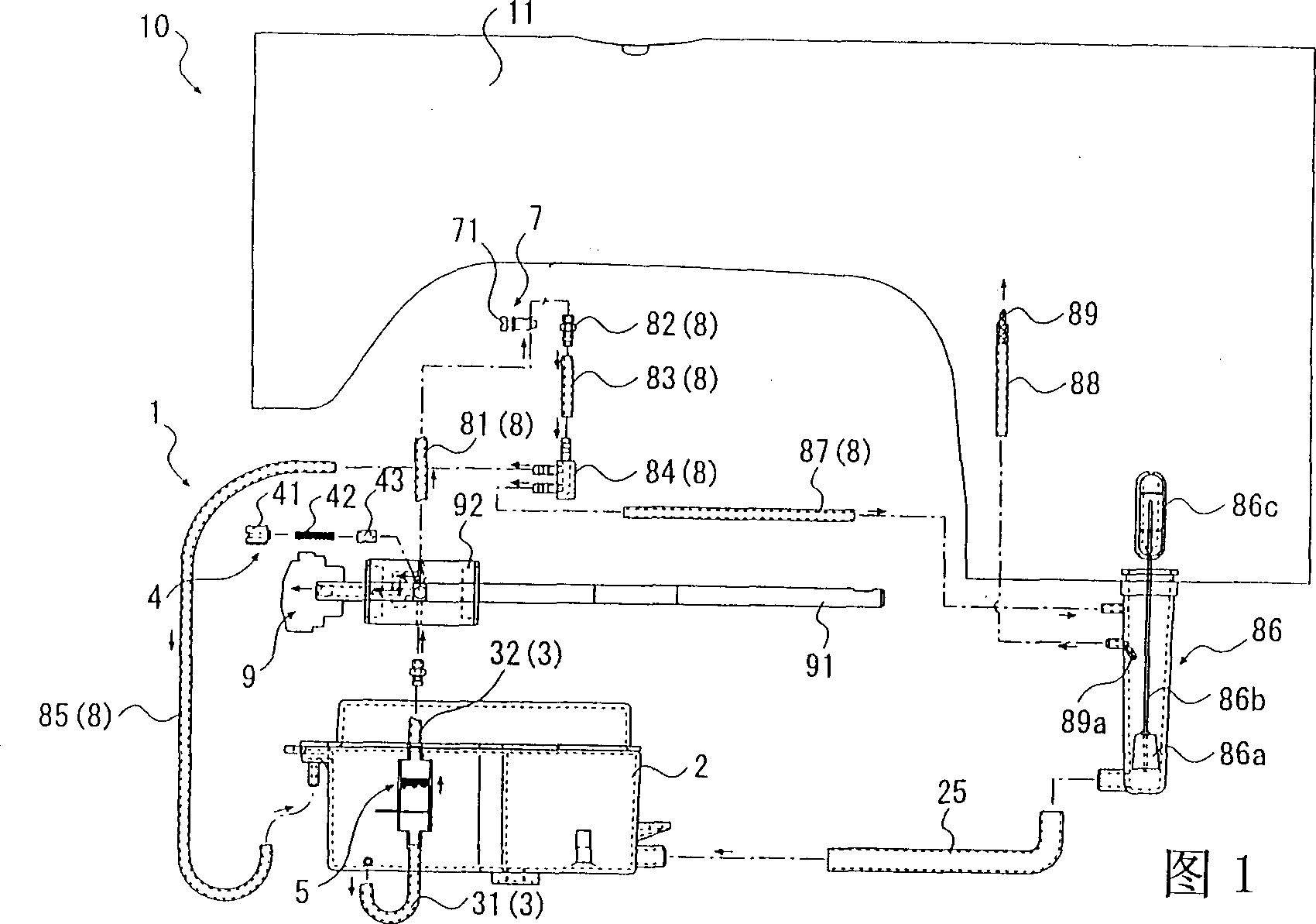

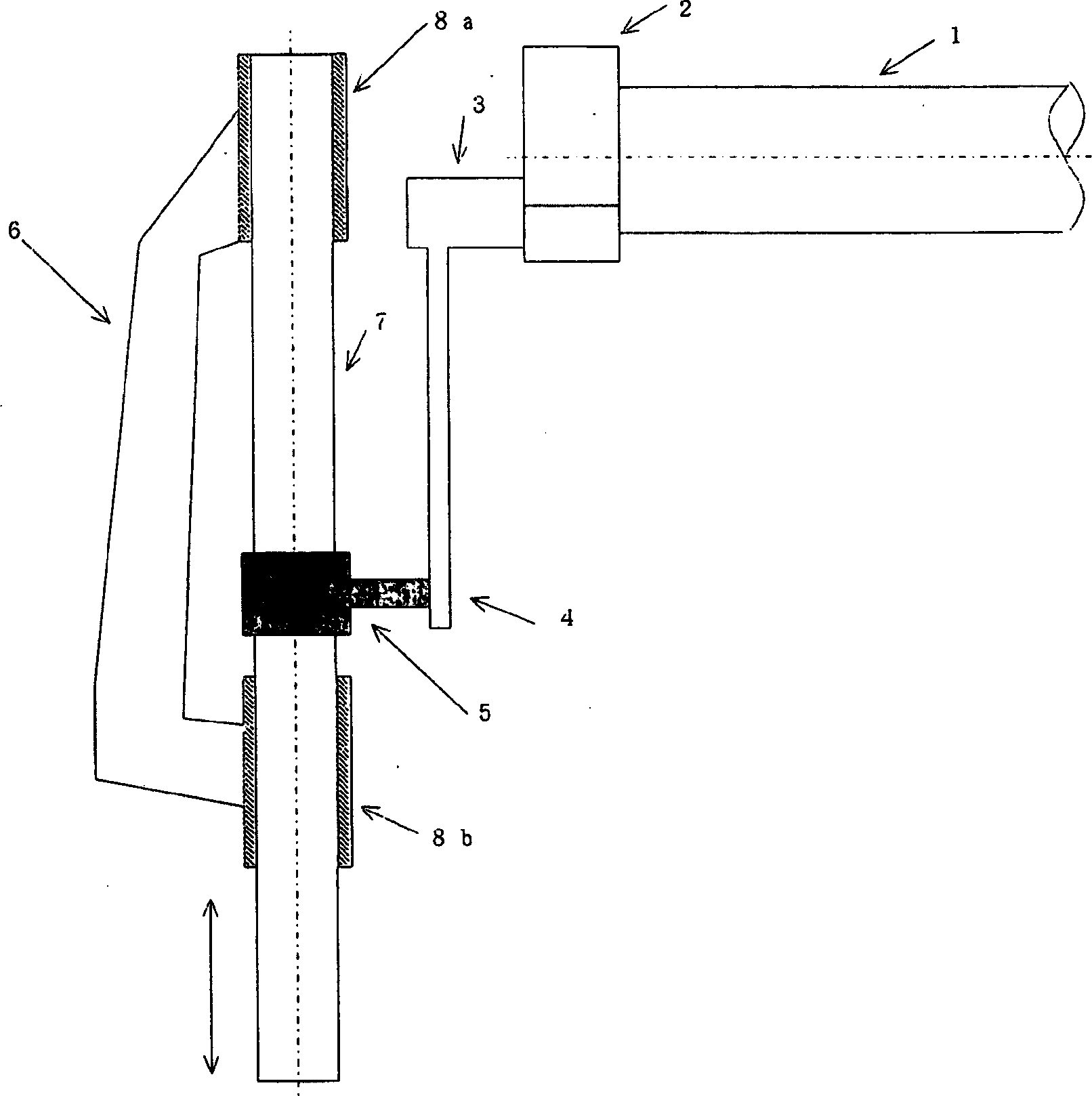

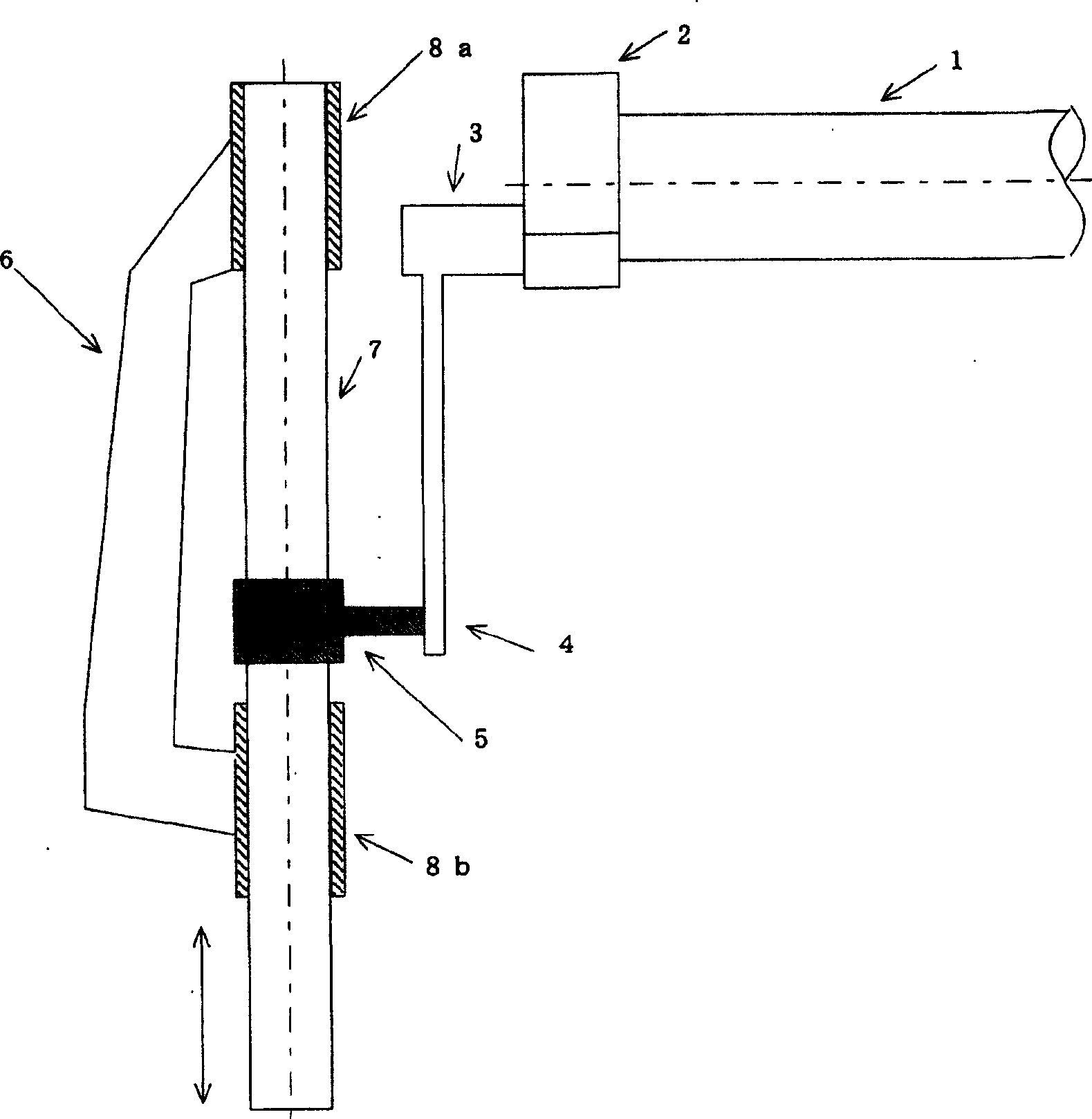

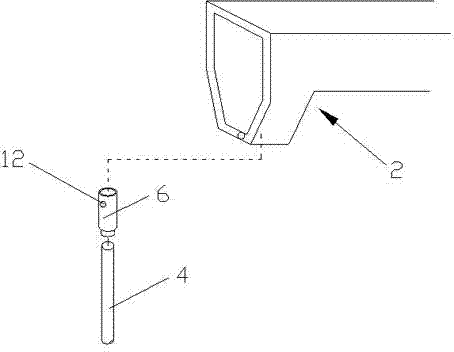

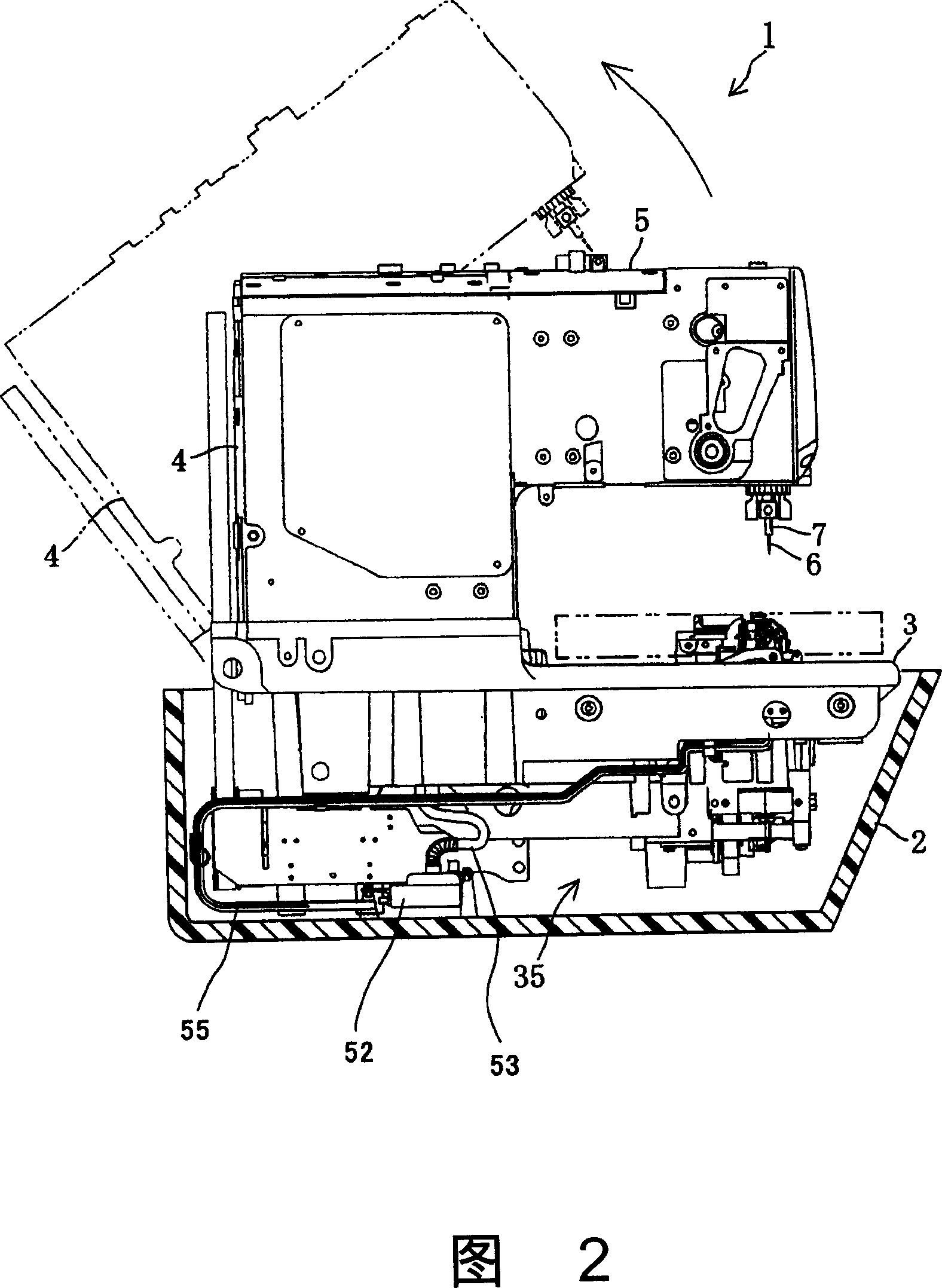

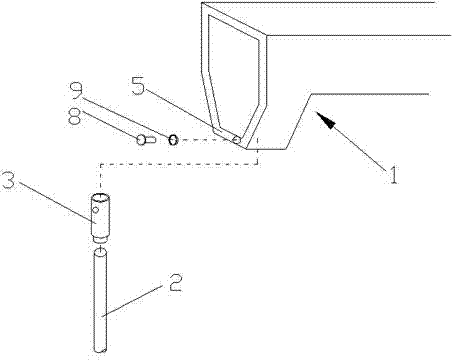

Lubricating device for sewing machine

InactiveCN1368573ADrive stabilityOil quantity adjusted correctlyLubrication/cooling devicesEngine lubricationOil canForeign matter

An oil supply device for a sewing machine capable of adjusting the amount of oil supplied to an oil supply point (rotary hook) regardless of the operating speed of the sewing machine and at the same time uniformly adjusting the amount of oil supplied to the oil supply point. Driven by the oil tank 2 located at the base of the sewing machine, driven by the driving force transmitted by the driving device of the sewing machine, the plunger-type oil pump 4 that can extract lubricating oil from the oil tank 2 and supply it to the rotary hook 9 communicates with the oil tank 2 and the plunger-type oil pump respectively. 4 and the hook part 9 and guide the lubricating oil pumped by the plunger type oil pump 4 to the oil supply pipe 3 of the hook part 9, and return part of the lubricating oil supplied to the hook part 9 from the oil supply pipe 3 to the oil tank 2 oil return pipeline 8 composition. On the oil return line 8, there is an oil quantity regulating member 7 that adjusts the oil quantity supplied to the rotary hook 9 by adjusting the oil quantity flowing through the oil return line 8. On the oil supply pipe 3, it is detachably installed for A filter 5 that removes foreign matter in the fuel supply pipe 3.

Owner:JUKI CORP

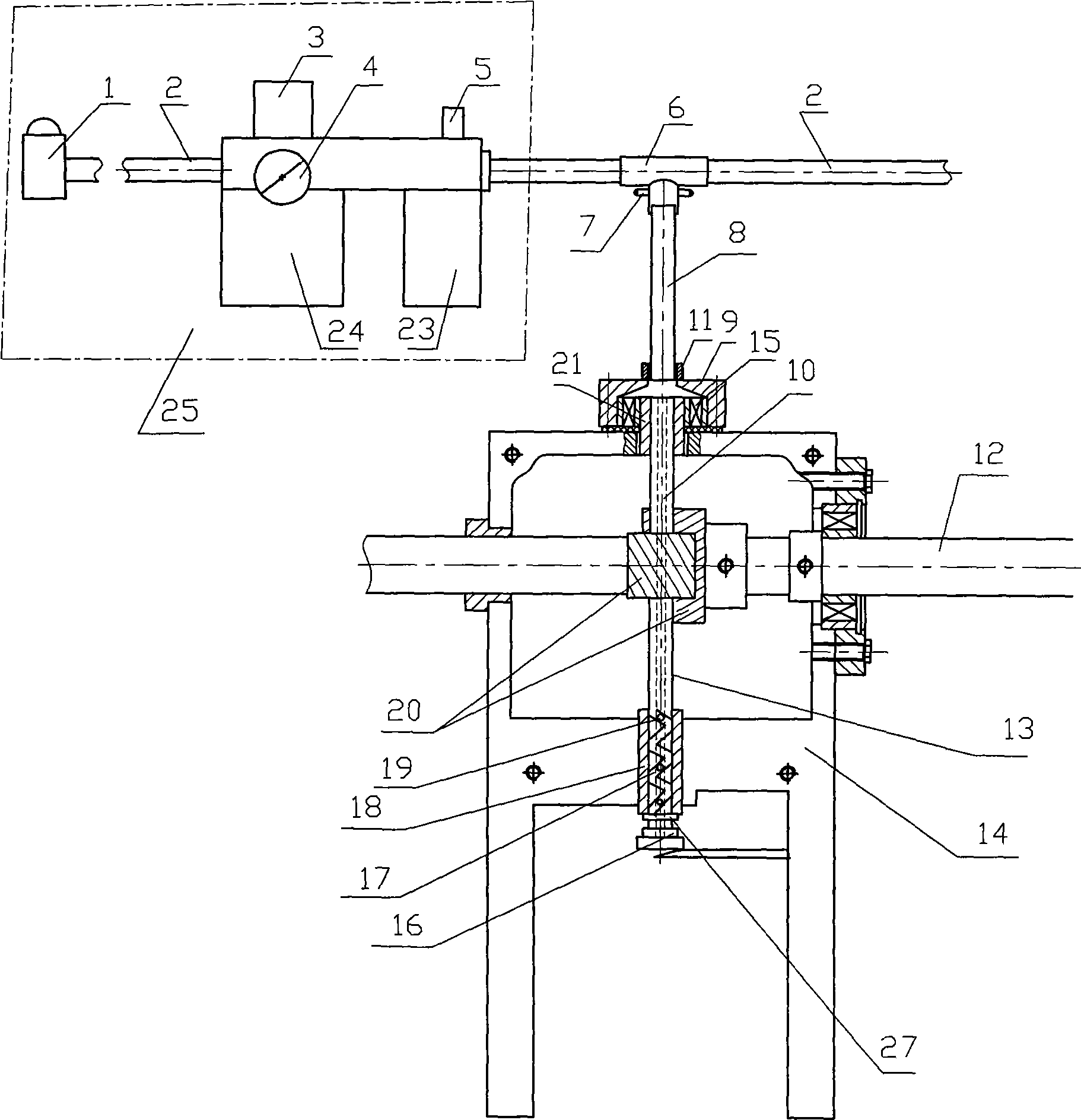

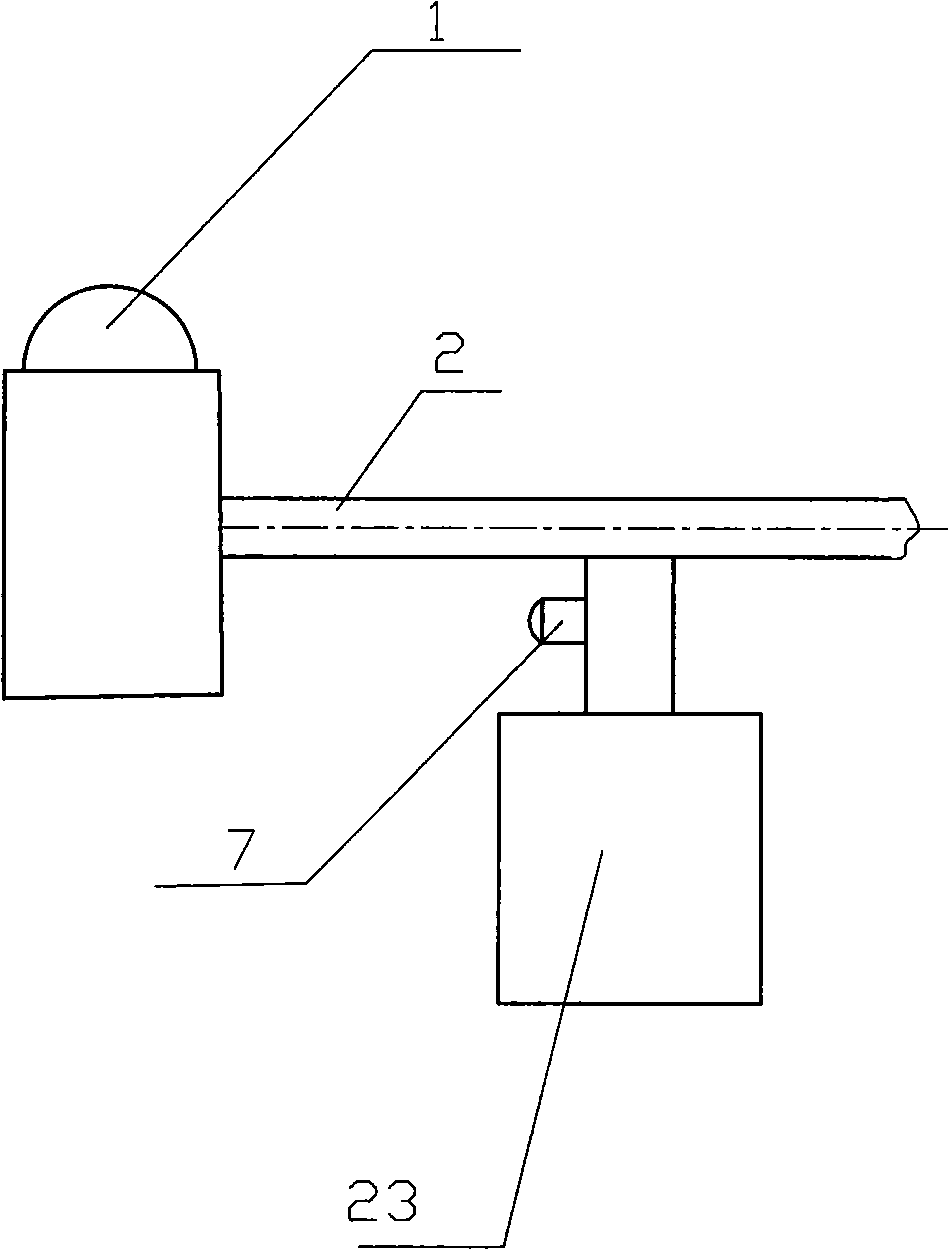

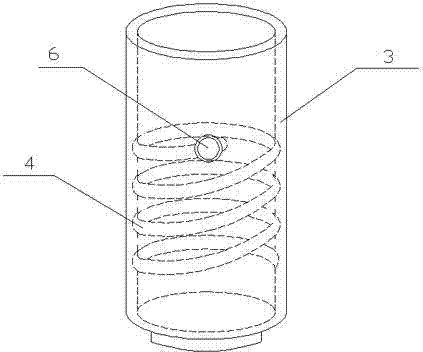

Lubrication system for rotating shuttle components of embroidery machines

ActiveCN101545184AExtend your lifeIncrease rotation speedLubrication/cooling devicesAuxillary devicesEngineeringGuide tube

The invention relates to a lubrication system for rotating shuttle components of embroidery machines, in particular to a rotating-shuttle-component lubrication system consisting of a rotating shuttle, a rotating-shuttle shaft and a rotating-shuttle shaft sleeve, wherein the inside of the rotating-shuttle shaft is provided with a through hole coaxial with the rotating-shuttle shaft; one end of the through hole is a lubricating oil inlet communicated with a rotating-shuttle oil supply device through a duct, and the other end of the through hole is a lubricating oil outlet communicated with an inner cavity of the rotating shuttle; and the surface of the rotating-shuttle shaft is provided with an oil spray hole communicated with the through hole. The lubrication system not only can continue oiling the rotating shuttle, the rotating-shuttle shaft and the rotating-shuttle shaft sleeve, but also can cool and clean the components.

Owner:杭州大云自动化科技有限公司

Sewing machine

InactiveCN107858790AReduce frequent exerciseNot easy to aging and damageLubrication/cooling devicesPressersElectromagnetSewing machine

The invention relates to the technical field of sewing equipment, in particular to a sewing machine. The upper end of a top rod is hinged to a lifting presser foot rear lever, the middle of the lifting presser foot rear lever is hinged to a machine shell, the back end of the lifting pressing pedal back lever is connected with an electromagnet, and the front end of the lifting pressing pedal back lever is connected with a lifting pressing pedal front lever through a pull rod; the lifting pressing pedal front lever is connected with a press rod, a boss is arranged in an oil sealing disc, and a through hole which runs through the oil sealing disc is formed in the boss; an oil sealing cap is arranged on the boss, the sealing cap comprises a cap body and a rod part, the lower end of the rod part extends out of the oil sealing disc through the through hole in the boss, and a spring and a limit part are arranged at the lower end of the rod part; one end of the spring abuts against the limit part, the other end of the spring abuts against the bottom plane of the oil sealing disc, and the cap body is connected with a sealing part which is used for preventing the through hole in the boss from leaking oil; the lower end of the top rod penetrates through a baseplate and is located above the oil sealing cap, and the oil sealing cap is driven by a jacking device to move up and down to drivethe top rod to up and down move. According to the sewing machine, frequent movement of the oil sealing cap is reduced, so that the oil sealing cap is not easily aged and damaged, and the risk of oil leakage is reduced.

Owner:JACK SEWING MASCH CO LTD

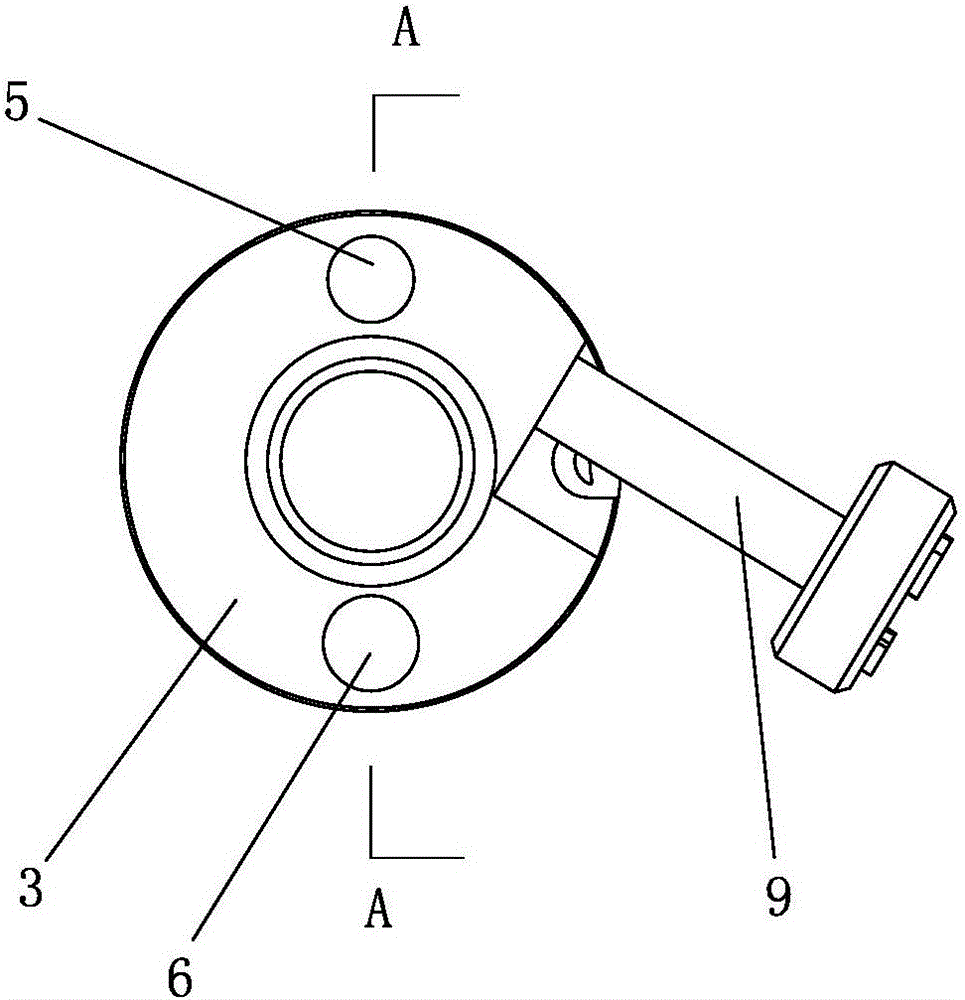

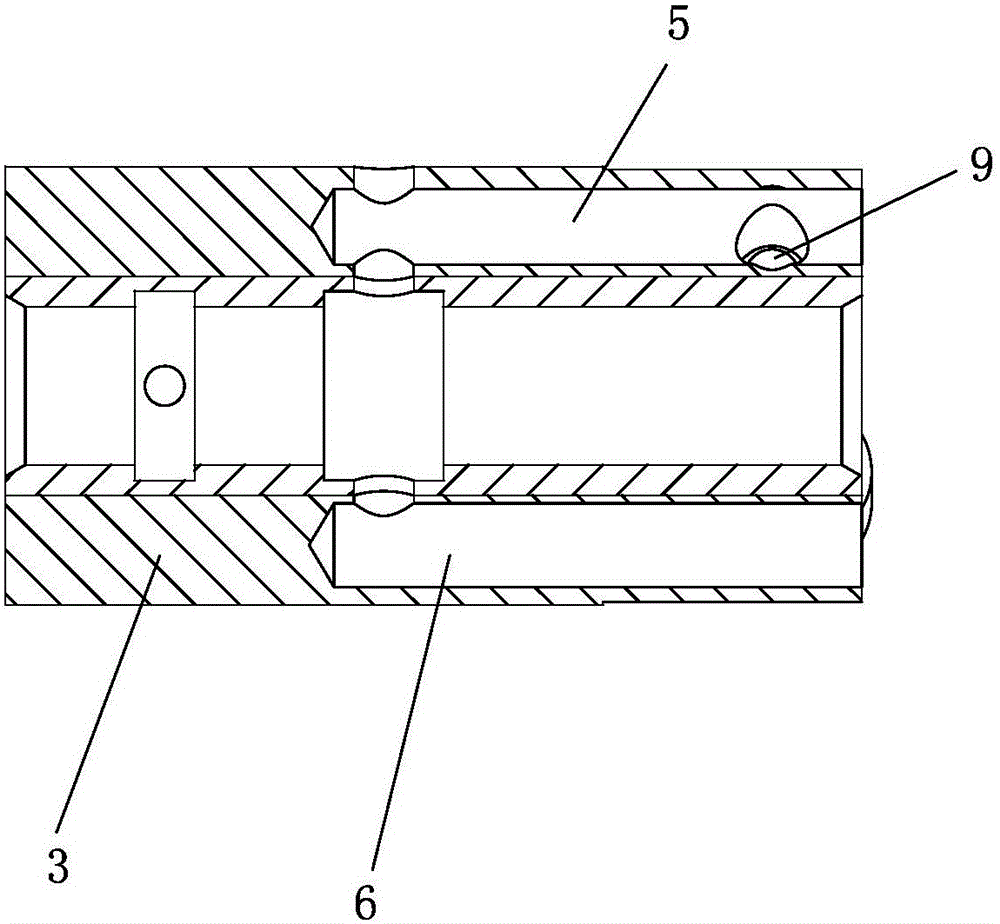

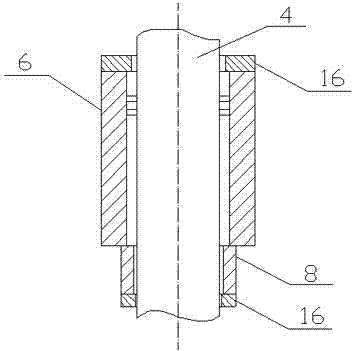

Rotary shuttle oil-supplying device

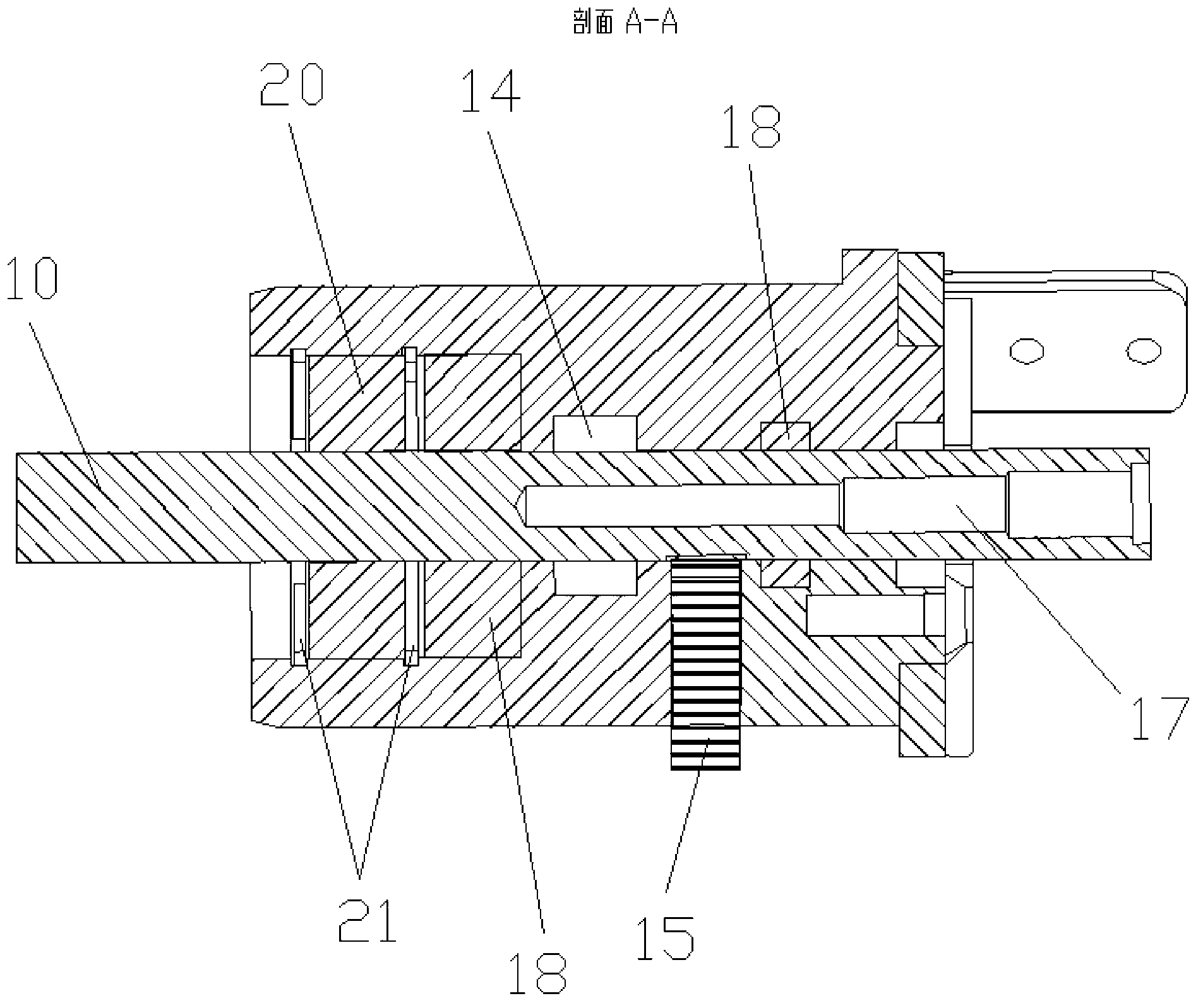

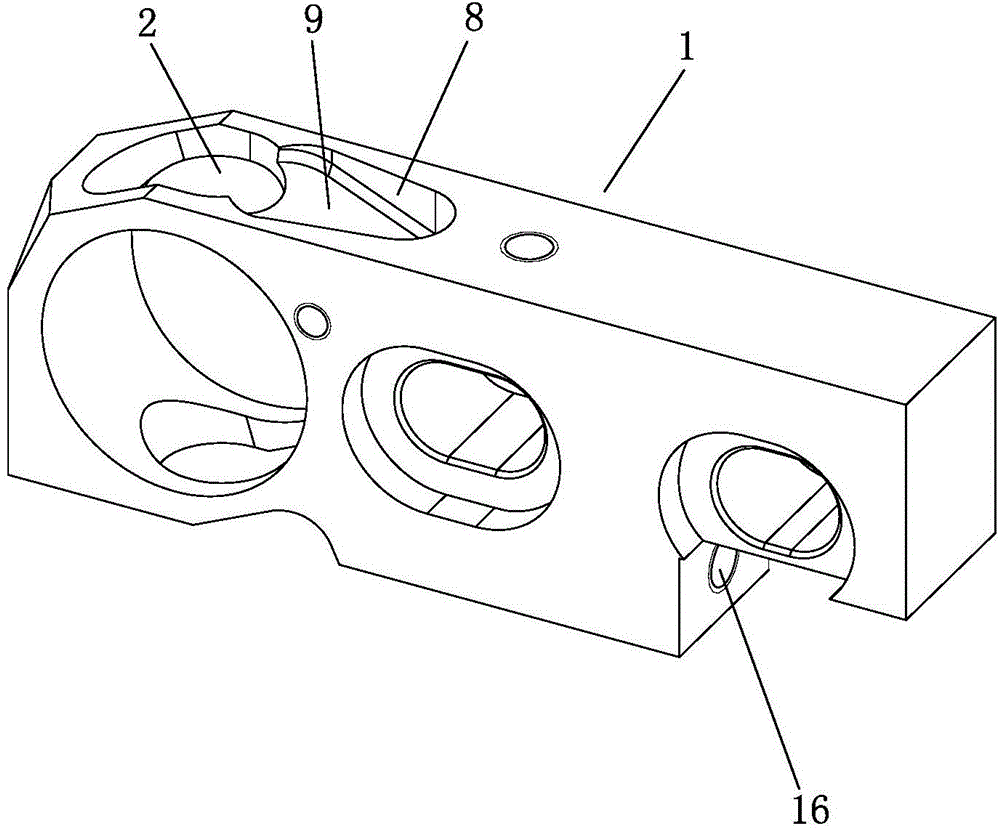

ActiveCN103074744APrevent axial movementChange the oil supply sizeLubrication/cooling devicesInterference fitManufacturing cost reduction

The invention belongs to the technical field of sewing machines and particularly relates to a rotary shuttle oil-supplying device for realizing automatic oil supply by high-speed rotation of a rotary shuttle shaft. The rotary shuttle oil-supplying device comprises a shaft sleeve and the rotary shuttle shaft, wherein the rotary shuttle shaft penetrates through the shaft sleeve and can rotate at high speed; the rotary shuttle shaft rotates at high speed to enable an oil pumping mechanism on the shaft sleeve to pump oil and supply oil to the rotary shuttle by the shaft sleeve and an oil conveying mechanism on the rotary shuttle shaft; a bearing is arranged at the tail part of the rotary shuttle shaft; the two sides of the bearing are provided with clamping springs which are used for fixing the bearing to prevent the rotary shuttle shaft from jumping axially; the outer diameter of the bearing is in interference fit with the inner diameter of the shaft sleeve, and the inner diameter of the bearing is in interference fit with the outer diameter of the rotary shuttle shaft so as to prevent the radial jumping of the rotary shuttle shaft. The rotary shuttle oil-supplying device has the advantages that a plunger spring arranged in a through hole is matched with a groove to form a simple oil pump under high-speed rotation of the rotary shuttle shaft and finish piston type oil pumping; and the structure is simple and compact, the space is saved and the manufacturing cost is greatly reduced.

Owner:JACK SEWING MASCH CO LTD

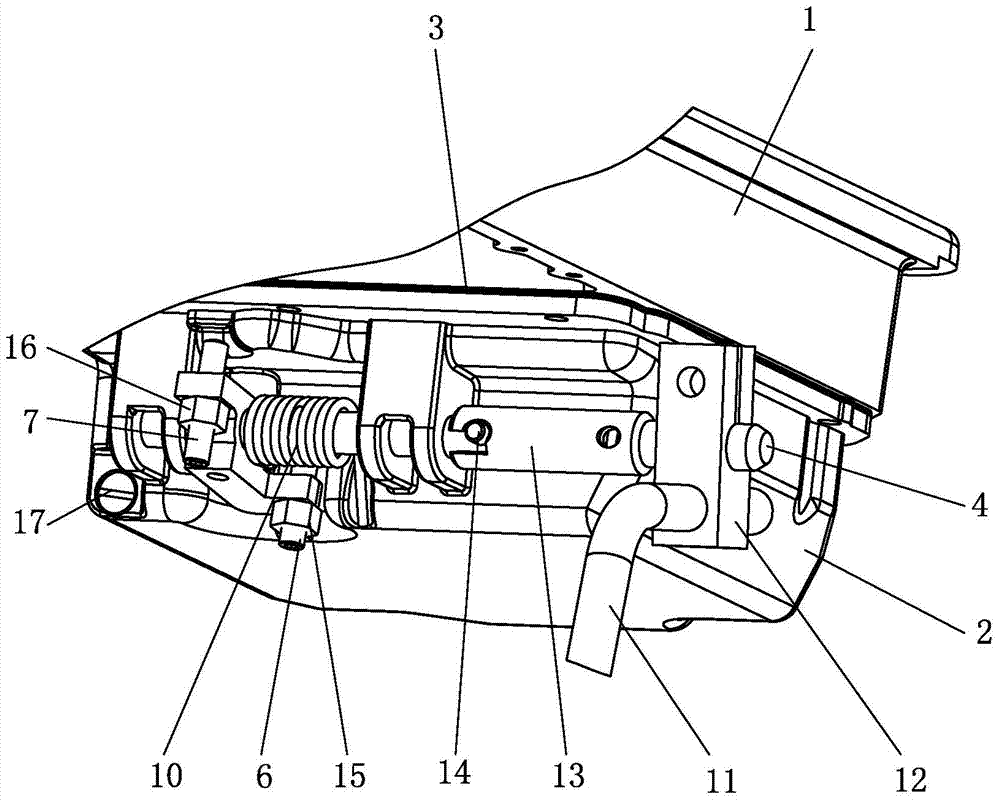

Novel barrel type sewing machine

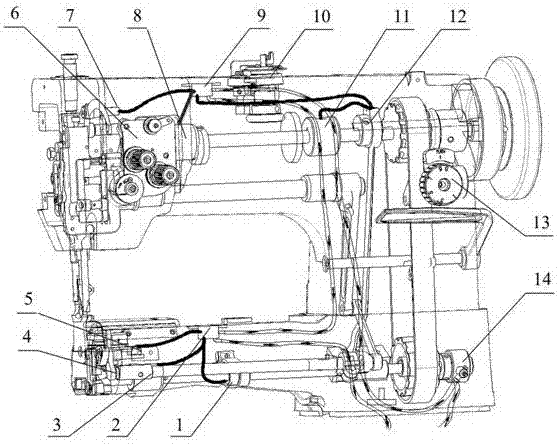

ActiveCN107043999ASolve the problem of instability and affecting the quality of sewingStable stitchLubrication/cooling devicesWork-feeding meansLocking mechanismEconomic benefits

The invention relates to the technical field of sewing devices, in particular to a novel barrel type sewing machine. The novel barrel type sewing machine includes a sewing machine body, an oil tan, and a fabric feeding mechanism, a stitch length locking mechanism, a pre-winding device, a dual-clamping machine, and an automatic lubrication system which are arranged on the sewing machine body; the fabric feeding mechanism includes a lower shaft, a tooth lifting cam, a tooth lifting fork, a tooth lifting shaft, a fabric feeding tooth guide rack, a fabric feeding tooth guide rack slide block, a fabric feeding tooth support, a fabric feeding tooth support shaft, a fabric feeding support slide block, and a fabric feeding tooth support positioning plate; the stitch length locking mechanism includes a stitch length button, a locking pin and a locking pin spring; and the pre-winding device includes a base, a winding shuttle core, a shuttle core shaft, a cutter, a shuttle core seat, a winding positioning wheel, a friction wheel, a winding positioning hook, and a limiting adjustment wrench which are fixed on the sewing machine body. The mechanical structure of the conventional sewing machine is changed, the automatic lubrication system is added, the performance of the sewing machine is fully improved, and the novel barrel type sewing machine has good application prospect and economic benefits.

Owner:TYPICAL SEWING MACHINE WANPING MACHINERY

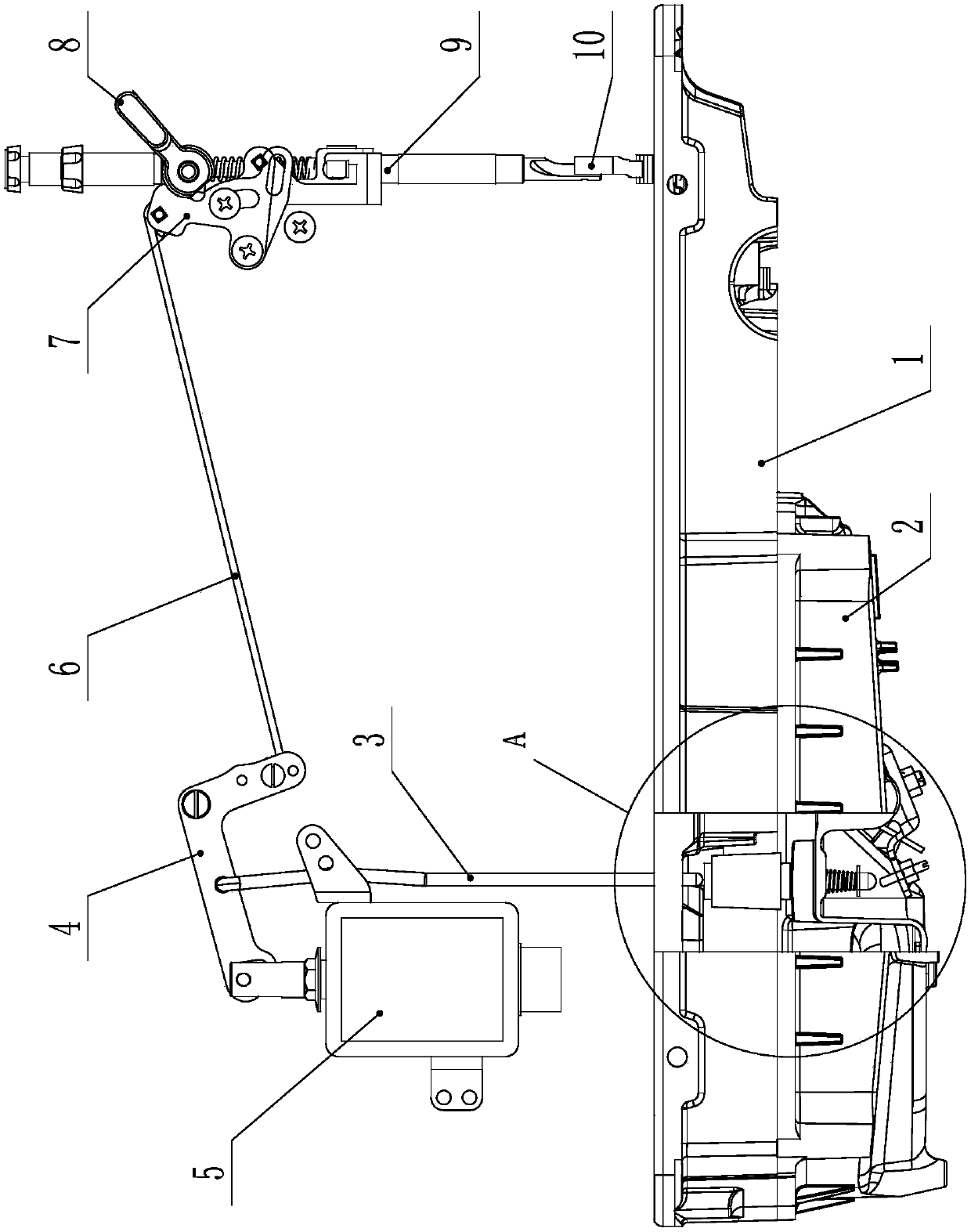

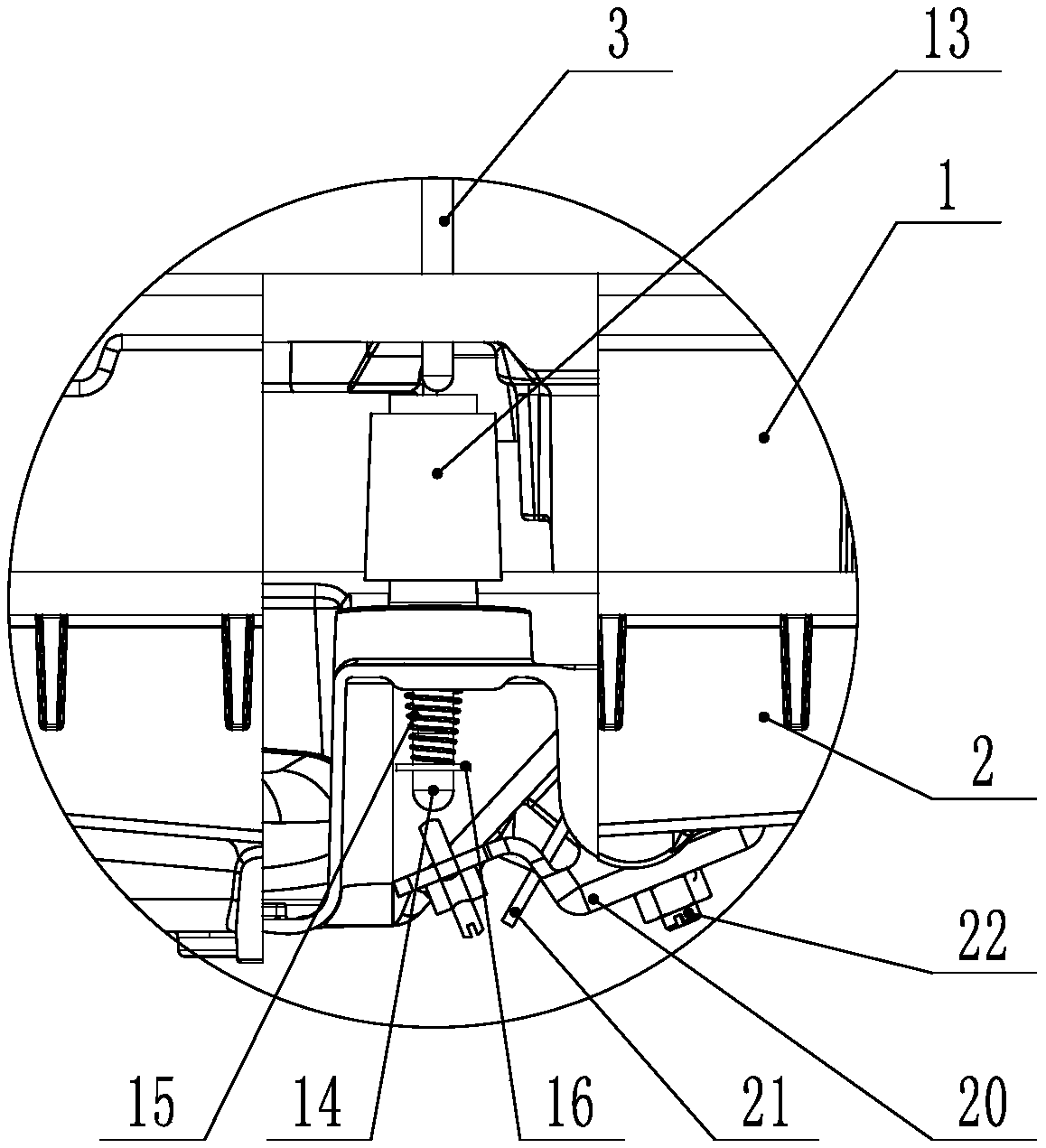

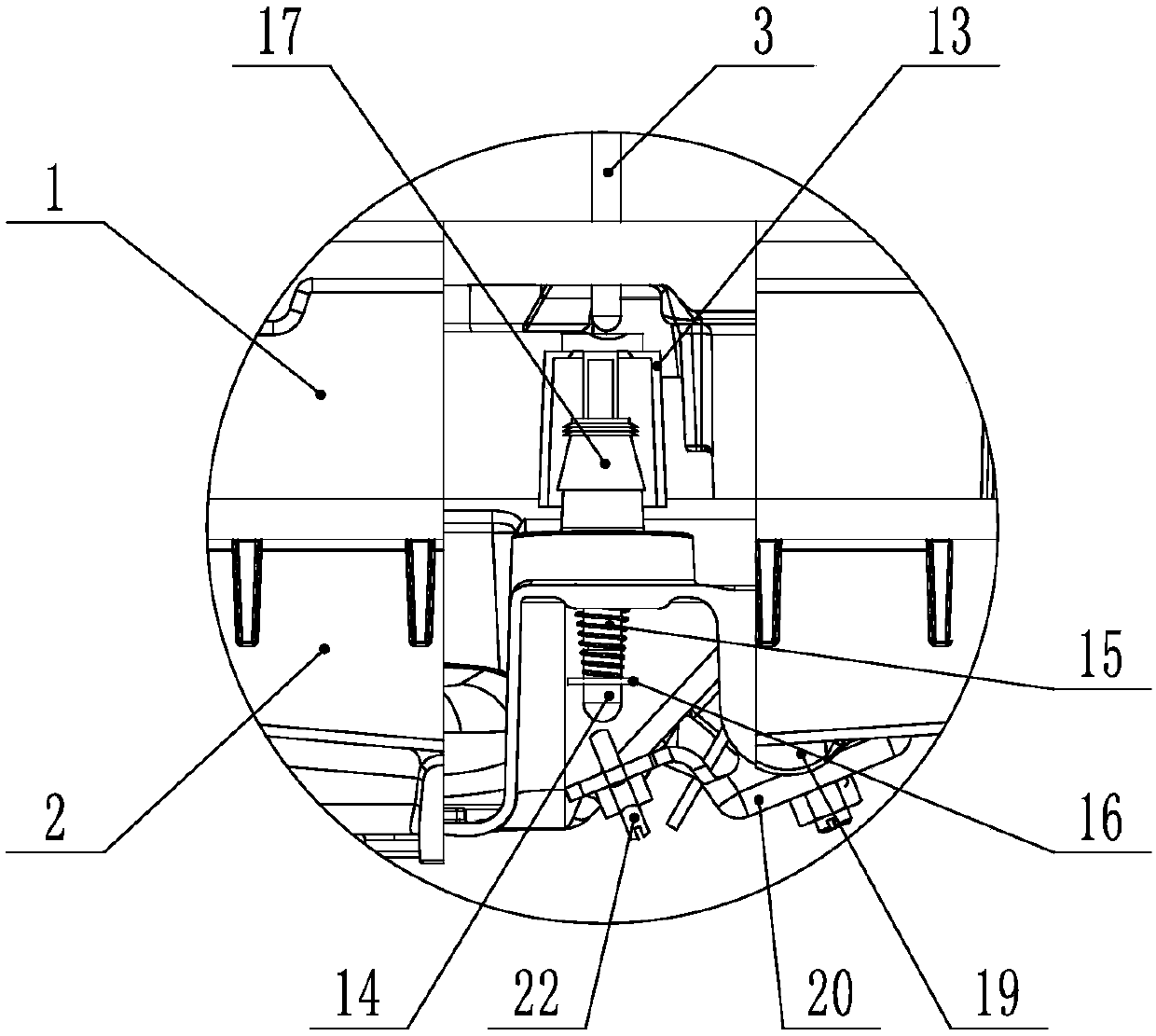

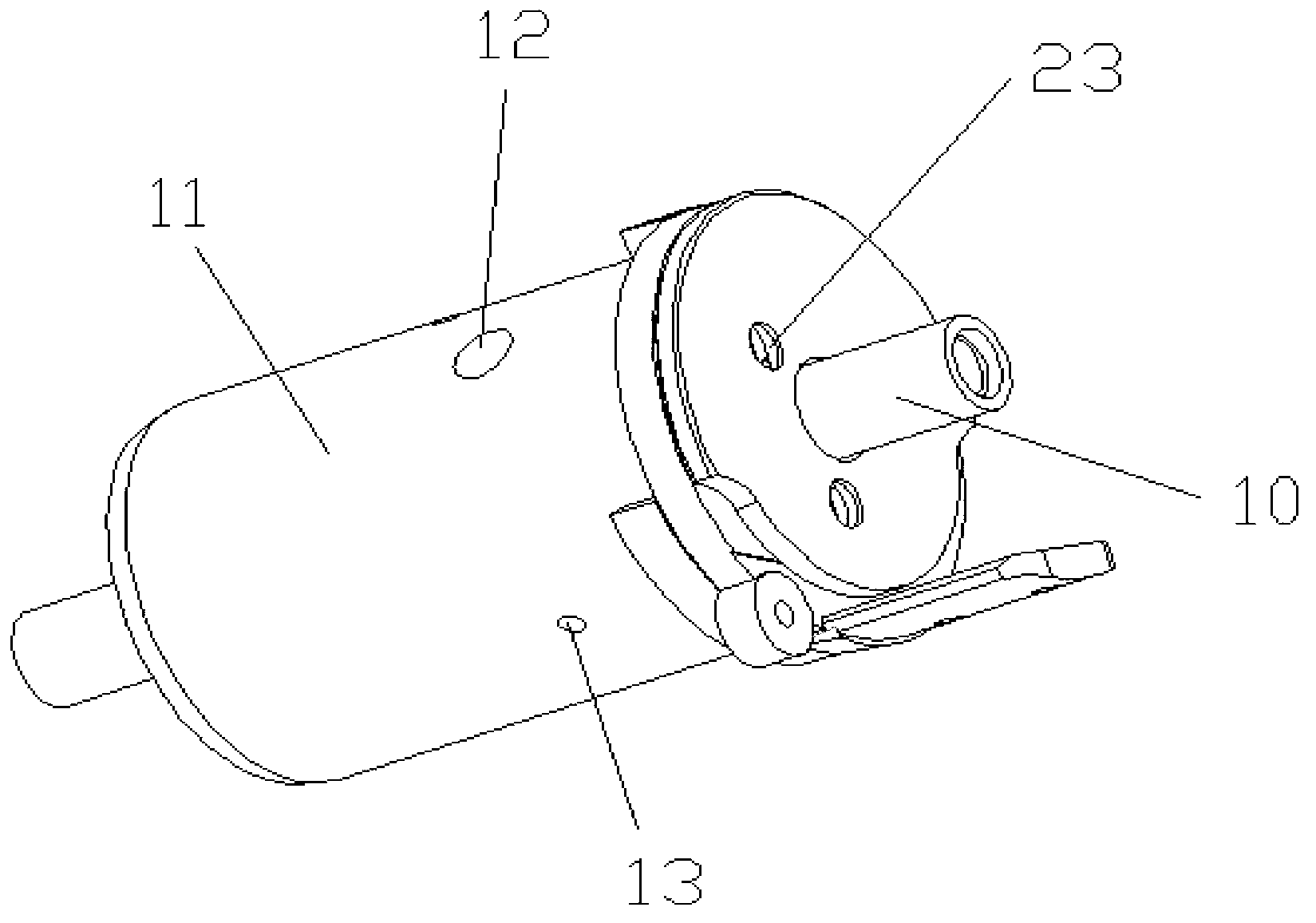

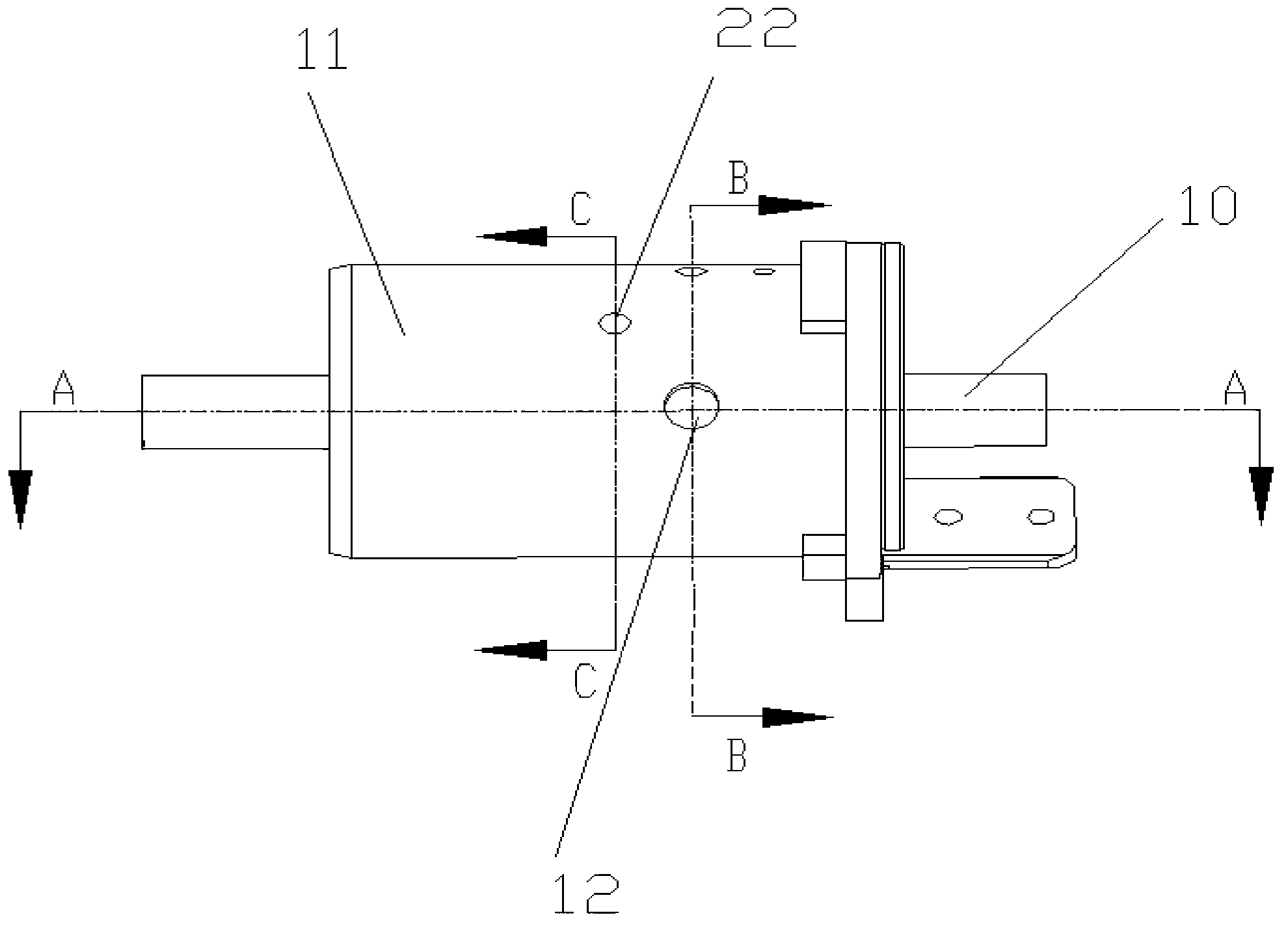

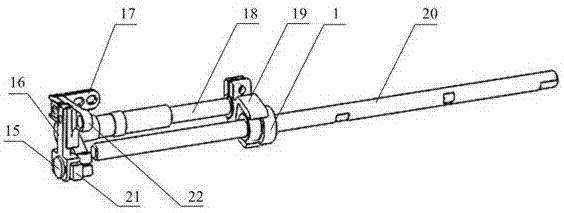

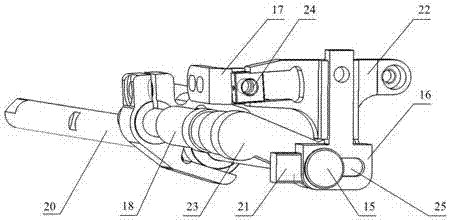

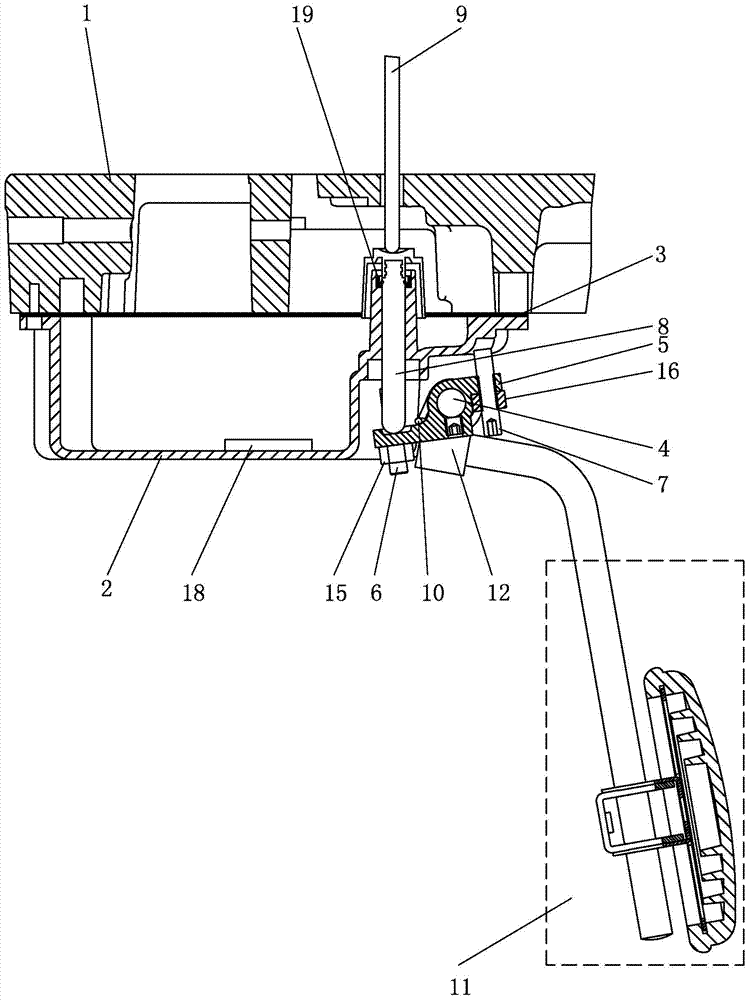

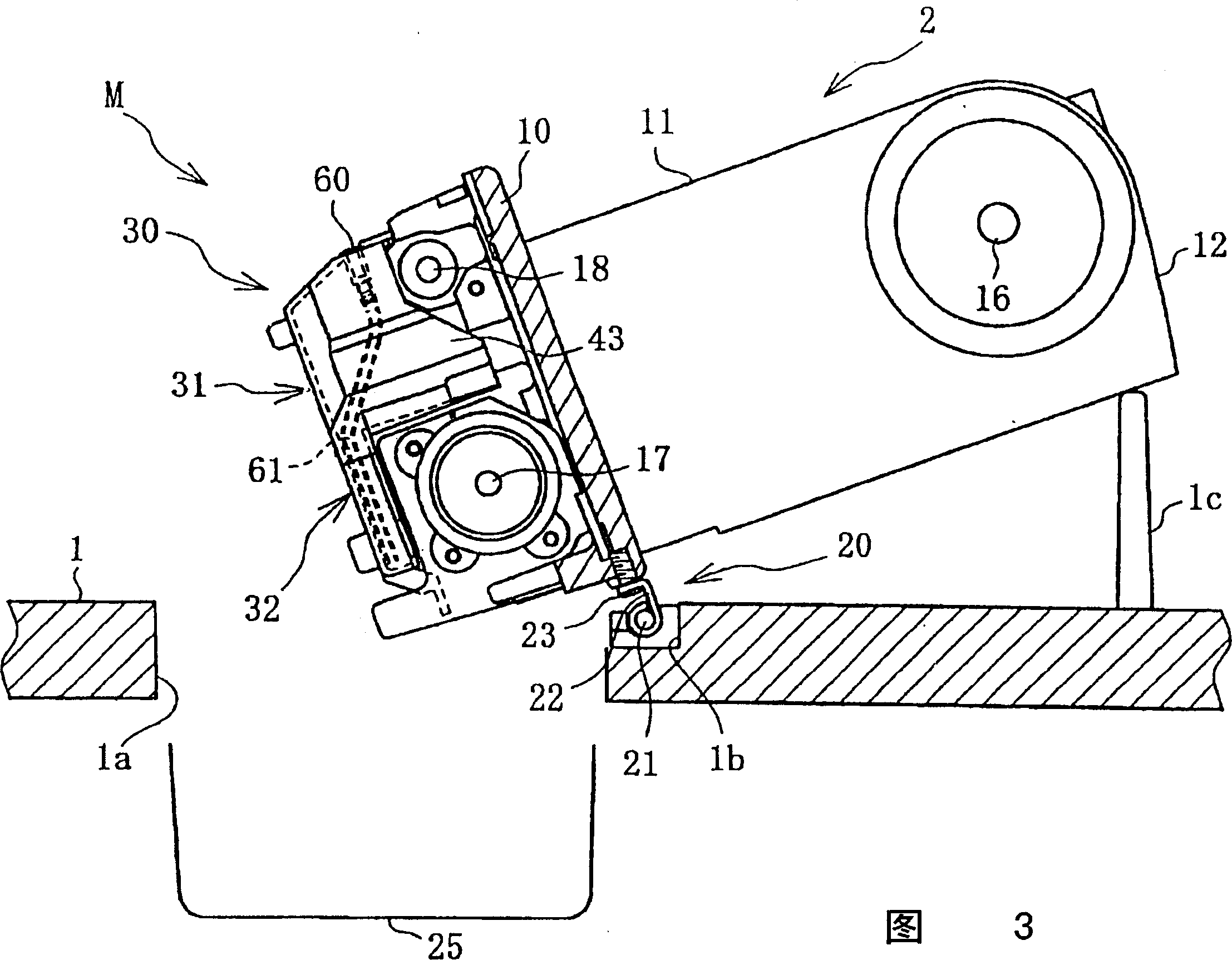

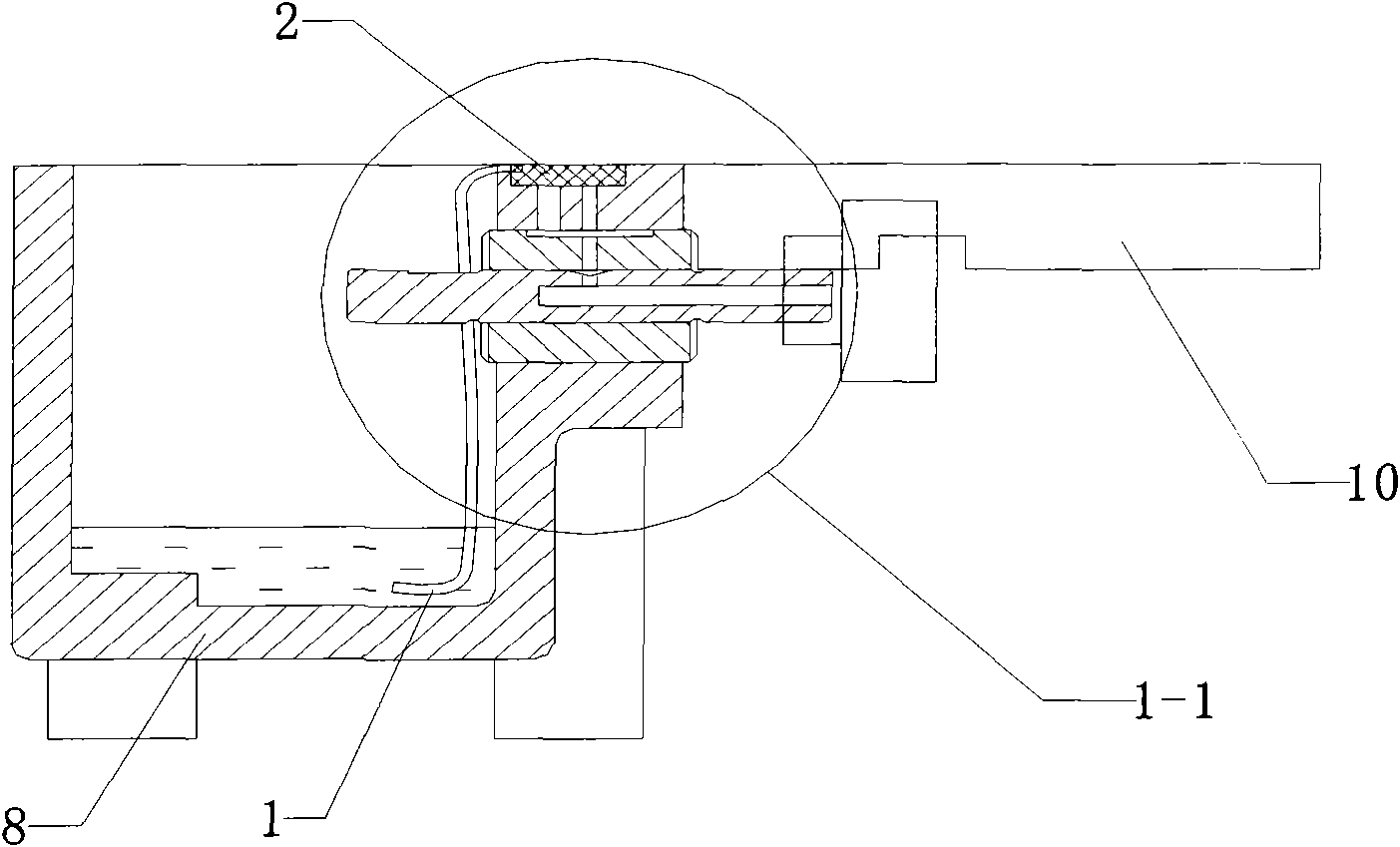

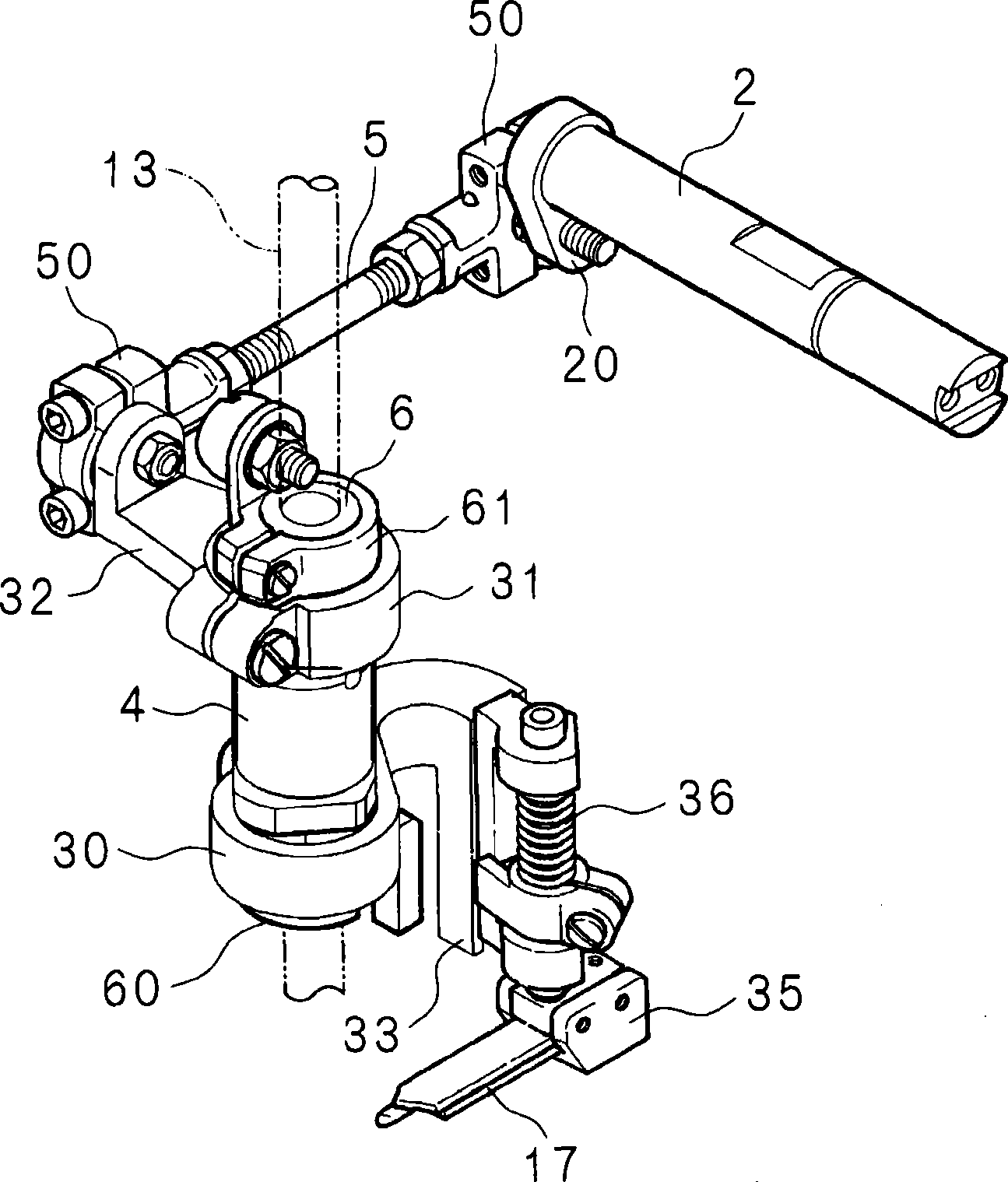

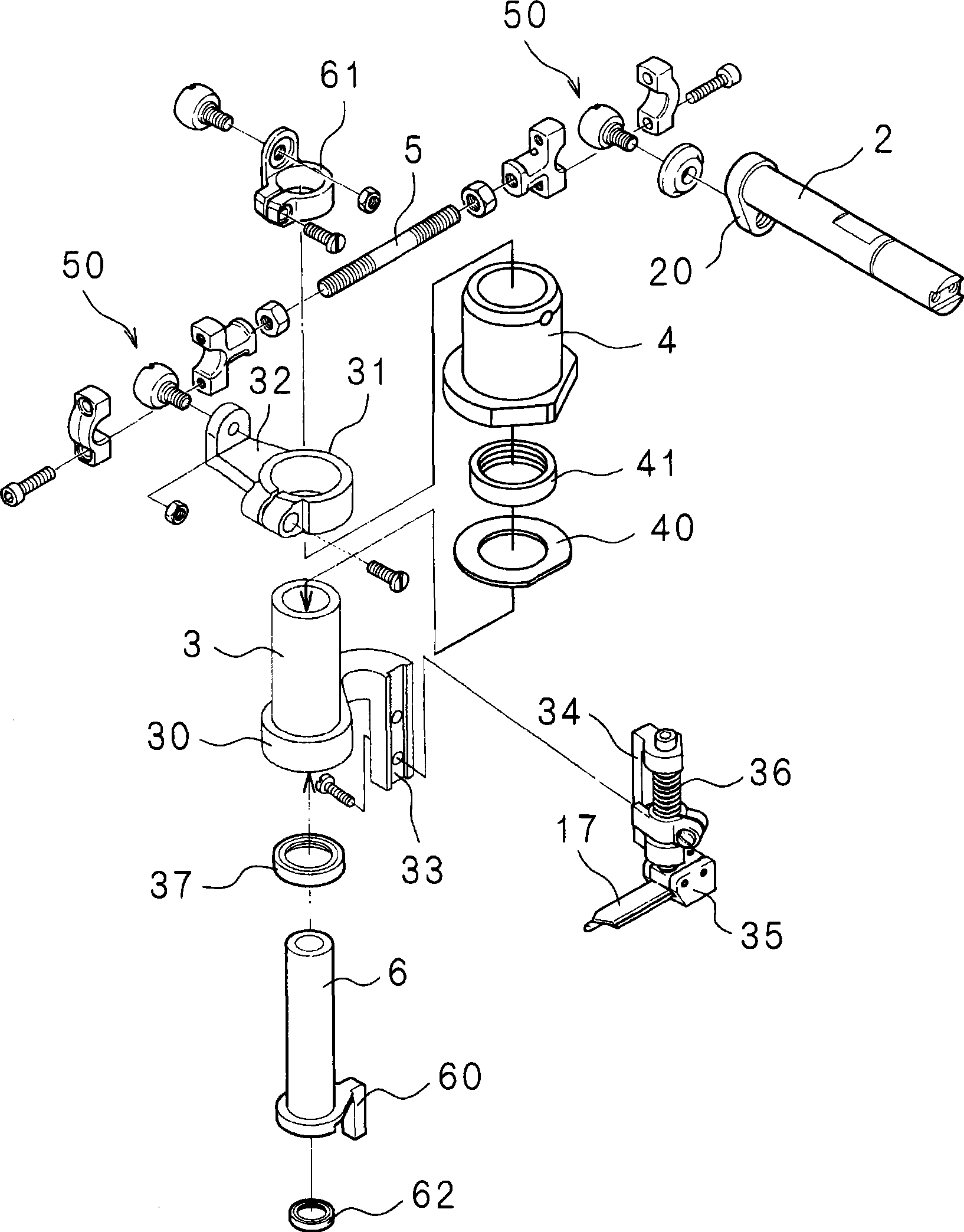

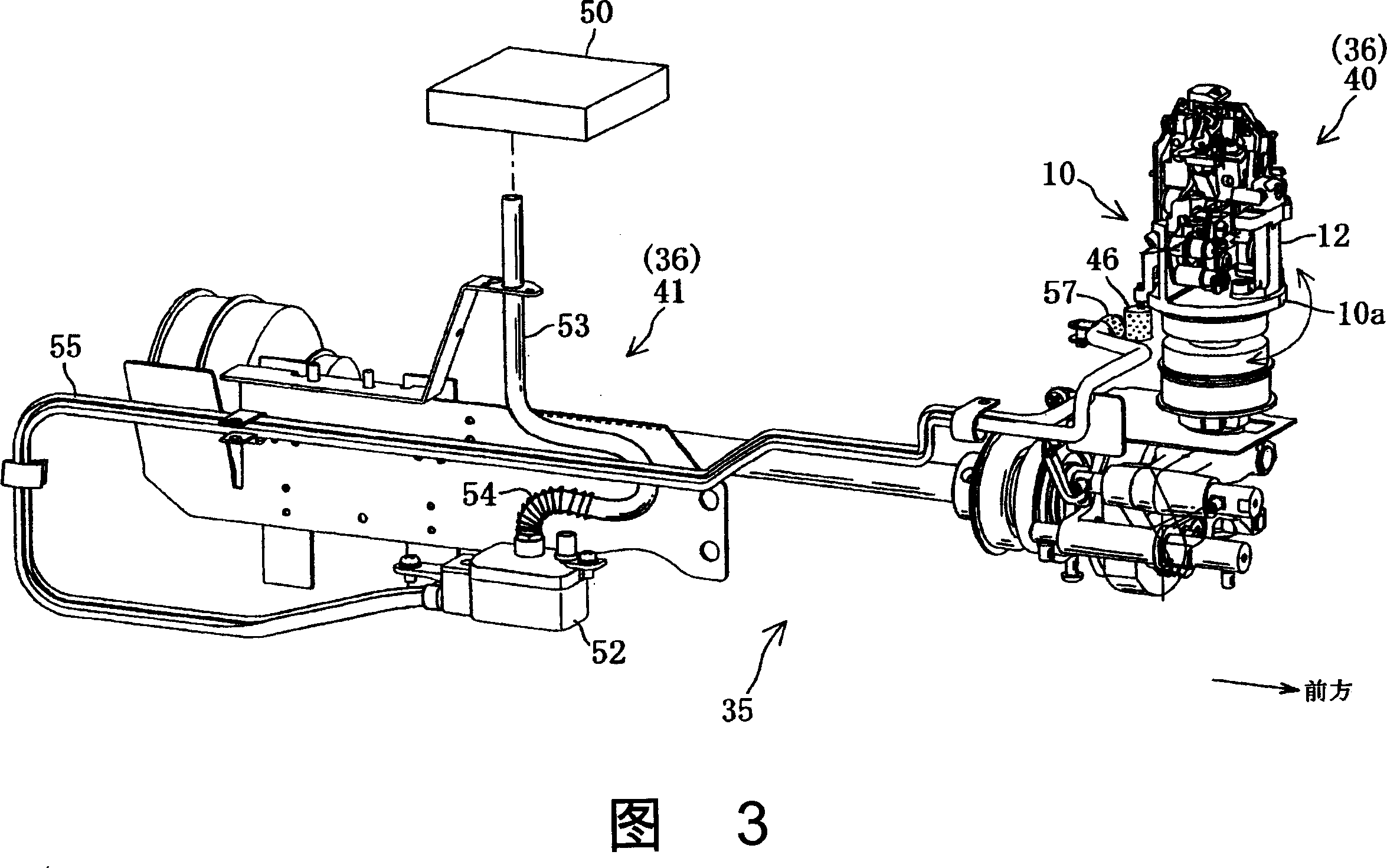

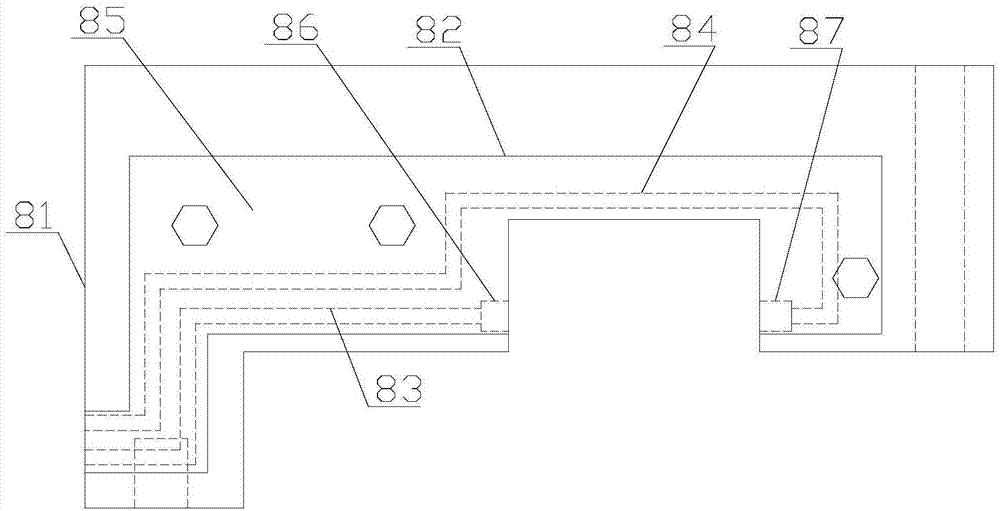

Knee-control presser foot lifting device of sewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to a knee-control presser foot lifting device of a sewing machine. The knee-control presser foot lifting device of the sewing machine comprises an oil box which is fixed on the base plane of a base plate. A presser foot lifting device which is connected with a presser foot mechanism and used for driving the presser foot mechanism to make presser foot lifting movement is arranged on a box body of the oil box. The presser foot lifting device is connected with a knee-control mechanism, the knee-control mechanism drives the presser foot lifting device to move so that the presser foot lifting movement can be achieved, and the knee-control mechanism and the presser foot lifting device are detachably connected. According to the knee-control presser foot lifting device of the sewing machine, the size of the oil box used for storing lubricating oil is small, the oil box is airtightly fixed on the base plate of the sewing machine, so that the lubricating oil is isolated inside the machine, the lubricating oil cannot leak or overflow along with overturning of the base plate, hence, lubricating oil pollution can be prevented, and the phenomenon that the lubricating oil overflows to pollute sewing cloth can be avoided; due to the fact that the knee-control mechanism and the presser foot lifting device are detachably connected, the presser foot lifting device is arranged on an oil receiver, when the machine is carried and overturned or knee-control presser foot lifting is of no need, a knee-control wrench can be dismounted, and thus the device can be used conveniently.

Owner:JACK SEWING MASCH CO LTD

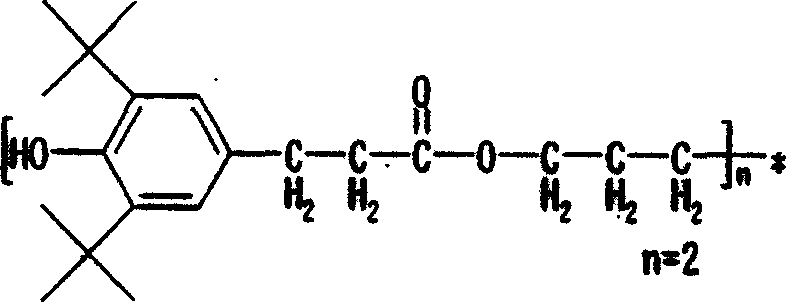

Lubricant composition for sewing machines

To provide a lubricant composition for sewing machines which excels in lubricity.The lubricant composition for sewing machines uses a single compound or component as a base oil in the lubricant composition composed of the base oil and additives to be encapsulated in a gap of the bearing surface opposite to the sliding surface of a direct acting shaft to support through a gap. (C)2004,JPO.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD +1

Lubricant composition for sewing machine

To provide a lubricant composition for a sewing machine having excellent lubricity and to prolong the life of various kinds of sliding members. A lubricant is sealed into a clearance of a bearing surface opposite through the clearance to a sliding surface of a member to be supported which is to be supported such as a needle shaft 7 and a bearing part 8. The lubricant composition for the sewing machine is obtained by compounding a base oil of the lubricant with 0.01-10 wt.% of aluminum oxide having 100-1,000 nm particle diameter and contains 0.1-15 wt.% of one or more kinds of oil-soluble additives selected from an organometallic compound, a boron compound, a phosphorus compound and a sulfur compound. The lubricant composition for the sewing machine may be a grease containing a thickener in addition to the oil-soluble additives. In this case, the amount of the thickener is preferably 10-20 wt.% and the thickener preferably has thixotropy.

Owner:BROTHER KOGYO KK

Oil box of sewing machine

The invention relates to an oil tank mounted on the sewing machine which has a sewing machine body for revolving by the center of horizontal axis shifted to the tilted position from the erected position, and includes an oil receiver mounted on the sewing machine body for storing the oil for lubrication and an oil container mounted on the oil receiver which can house all of the oil stored in the oil receiver when the sewing machine body is shifted to the tilted position from the erected position.

Owner:BROTHER KOGYO KK

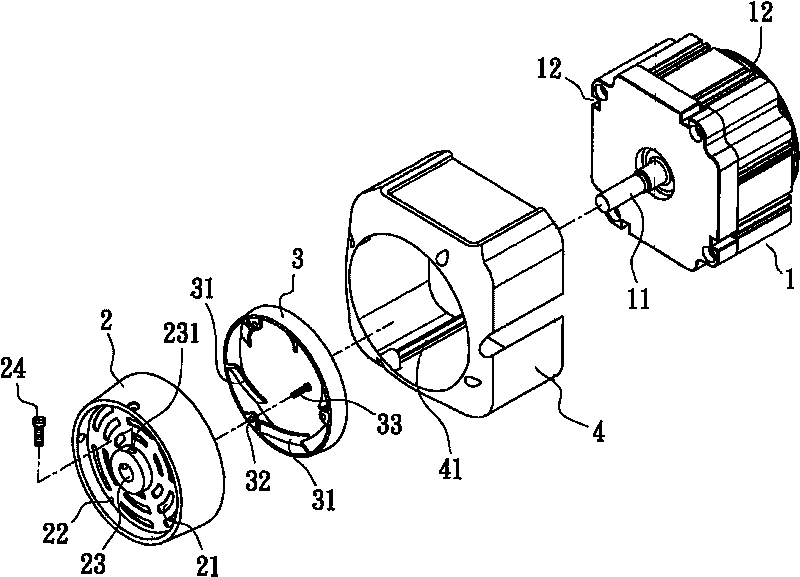

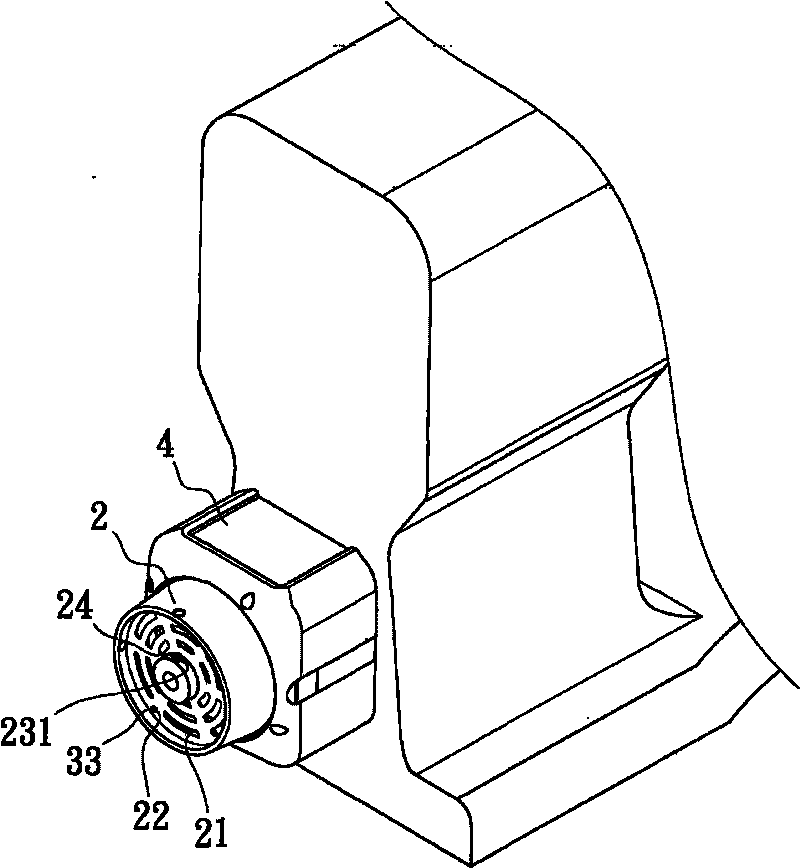

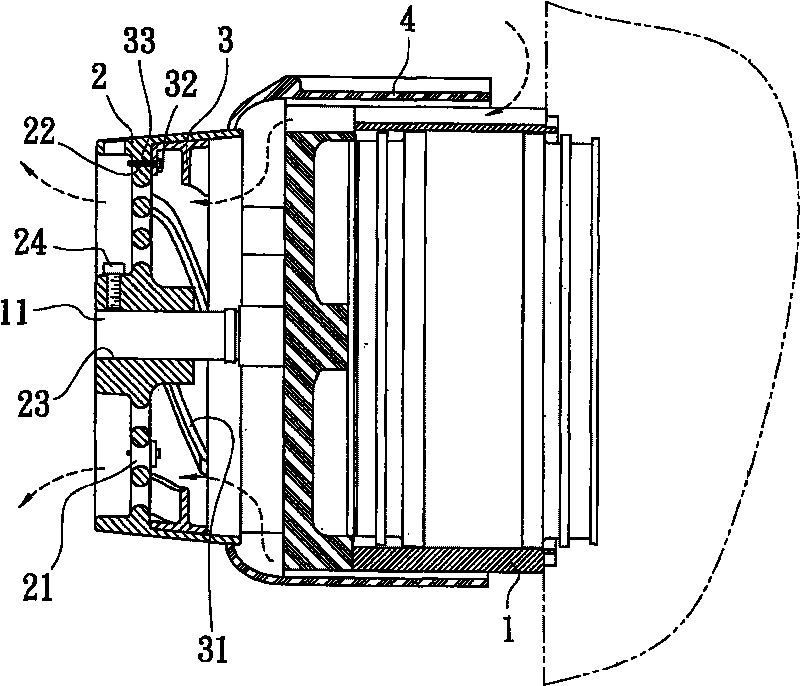

Direct-drive motor heat sink of industrial sewing machine

InactiveCN101705587AGuaranteed service lifeImprove cooling effectLubrication/cooling devicesSewing-machine control devicesDrive motorHeat sink

The invention relates to a direct-drive motor heat sink of an industrial sewing machine, wherein a hand wheel is assembled correspondingly at the back end of a main shaft of a direct-drive motor for supplying power to a sewing machine stand, a radiator fan is assembled at a part corresponding to the direct-drive motor in the interior of the hand wheel, and an outer shell is sleeved at the outside of the direct-drive motor to the hand wheel to form a diversion channel. Compared with the prior art, the invention disperses the high temperature generated by the operation of the direct-drive motor by the radiator fan through vents of the hand wheel, simultaneously ensures the diversion channel to form a cross-ventilated pipeline so as to realize the excellent heat radiating effect and ensure the service life of the direct-drive motor.

Owner:顾飞龙

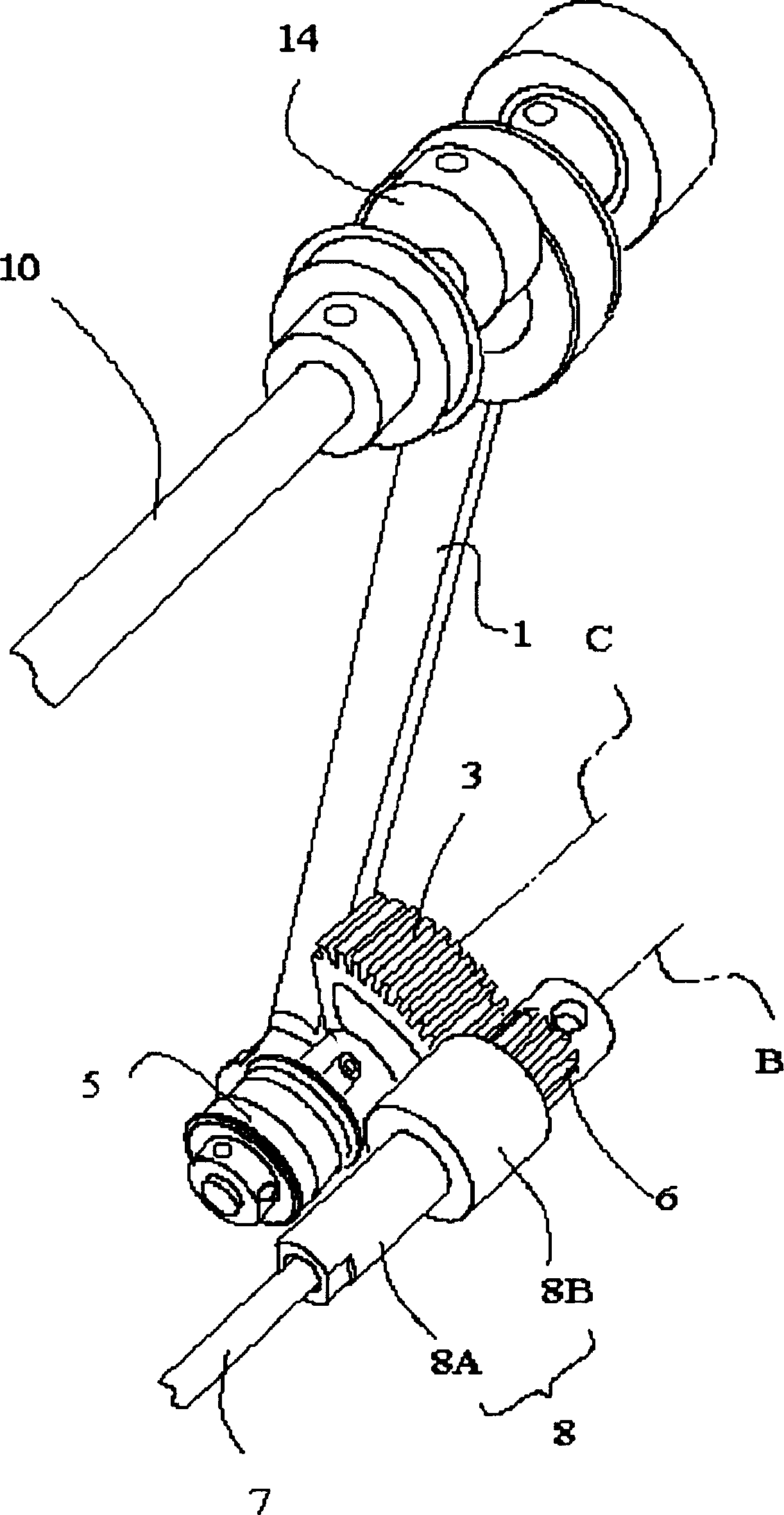

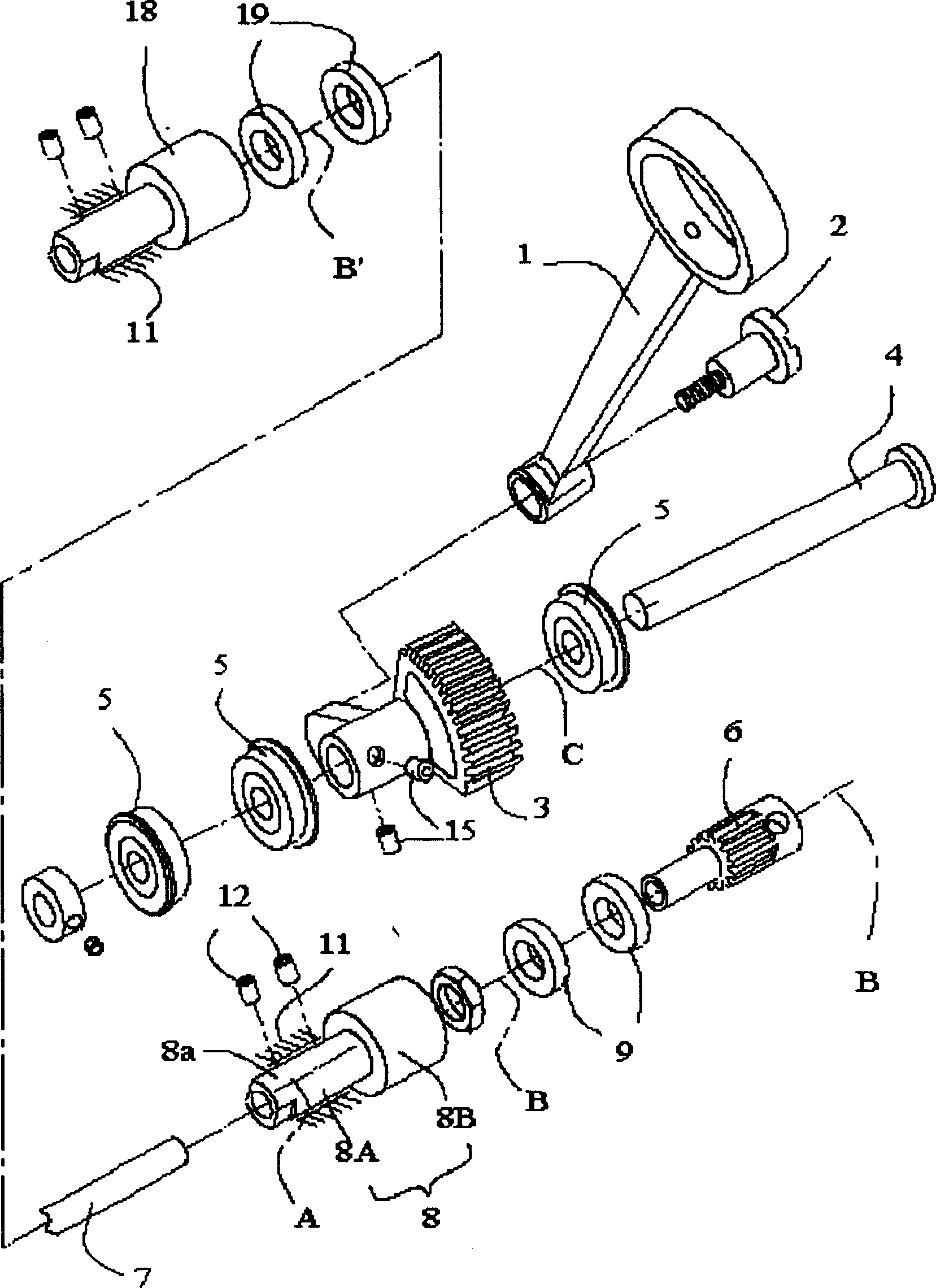

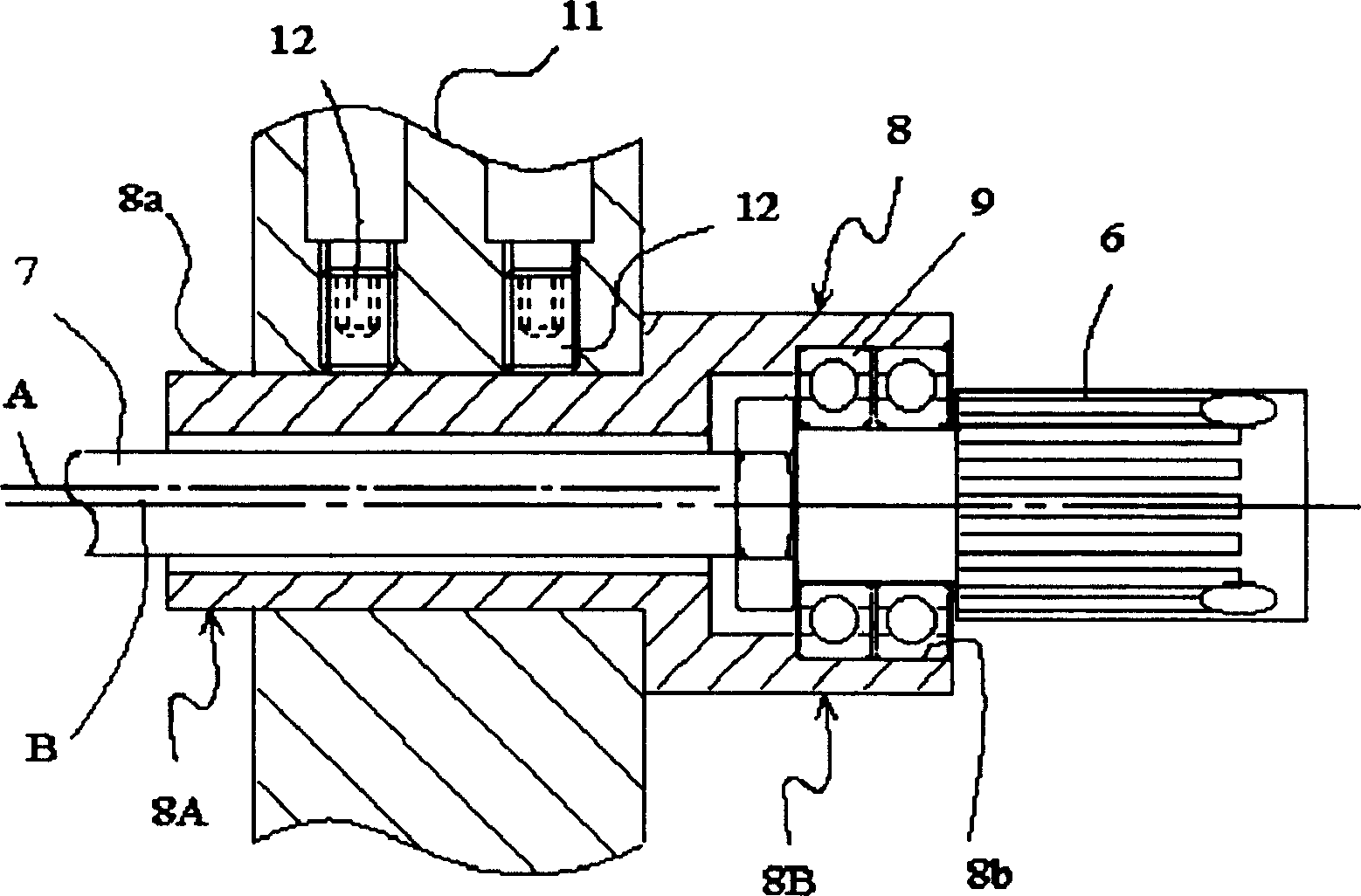

Lower shaft driving mechanism of sewing machine

The patent relates to a lower shaft driving mechanism without oil-feed structure in a sewing machine having a lower shaft performing rocking motion, which has a converting means 1 for converting the rotary motion of an upper shaft 10 to a rocking motion, a rocking rotator connected to the converting means and having a large pendulum gear 3 rockably rotating around a large pendulum shaft supported on a sewing machine frame, and a lower shaft 7 where a lower shaft gear 6 meshing with the large pendulum gear is fixed and rotary motion of the upper shaft is transmitted by both gears to rockably rotate. The present invention is characterized in that the mechanism has a bearing 8, the outer periphery of which is fixed to the sewing machine frame 11, and the gear side of the lower shaft is rotatably supported on the inner periphery thereof. The outer periphery of the bearing is formed cylindrical with eccentricity to the shaft center of the inner periphery, and the bearing where the lower shaft is passed is rotated with respect to the sewing machine frame to thereby adjust backlash of the large pendulum gear and the lower shaft gear.

Owner:JUKI CORP

Anti-oil leakage device of top bend needle mechanism

InactiveCN101381933ALong-term and smooth maintenance of lifting motion effectSmoothly maintain the effect of lifting movementLubrication/cooling devicesLubrication elementsFree rotationEngineering

The invention relates to an oil leak preventing device for an upwards curved needle mechanism. A columned upwards curved needle guiding body capable of being freely and rotationally inserted and kept on a circular hole formed on an upwards curved needle guiding component is formed with an upper communicating slotted hole and a lower communicating slotted hole orthogonal with a communicating hole for sliding and lifting of an upwards curved needle table, an oil seal ring elastically and glidingly contacting the outer peripheral face of the upwards curved needle table and provided with a labial part for scraping lubricating oil is inserted in the upper communicating slotted hole, and an oil suction ring capable of sucking and keeping the scraped residual lubricating oil is inserted in the lower communicating slotted hole, therefore, the oil leak preventing device can reliably and favorably exert scraping function of the residual lubricating oil, can reliably prevent the scraped residual lubricating oil from being attached to the outer peripheral face of the upwards curved needle table again to disperse upwards, and can stably maintain the oil link preventing function for a long term.

Owner:YAMATO SEWING MASCH MFG CO LTD

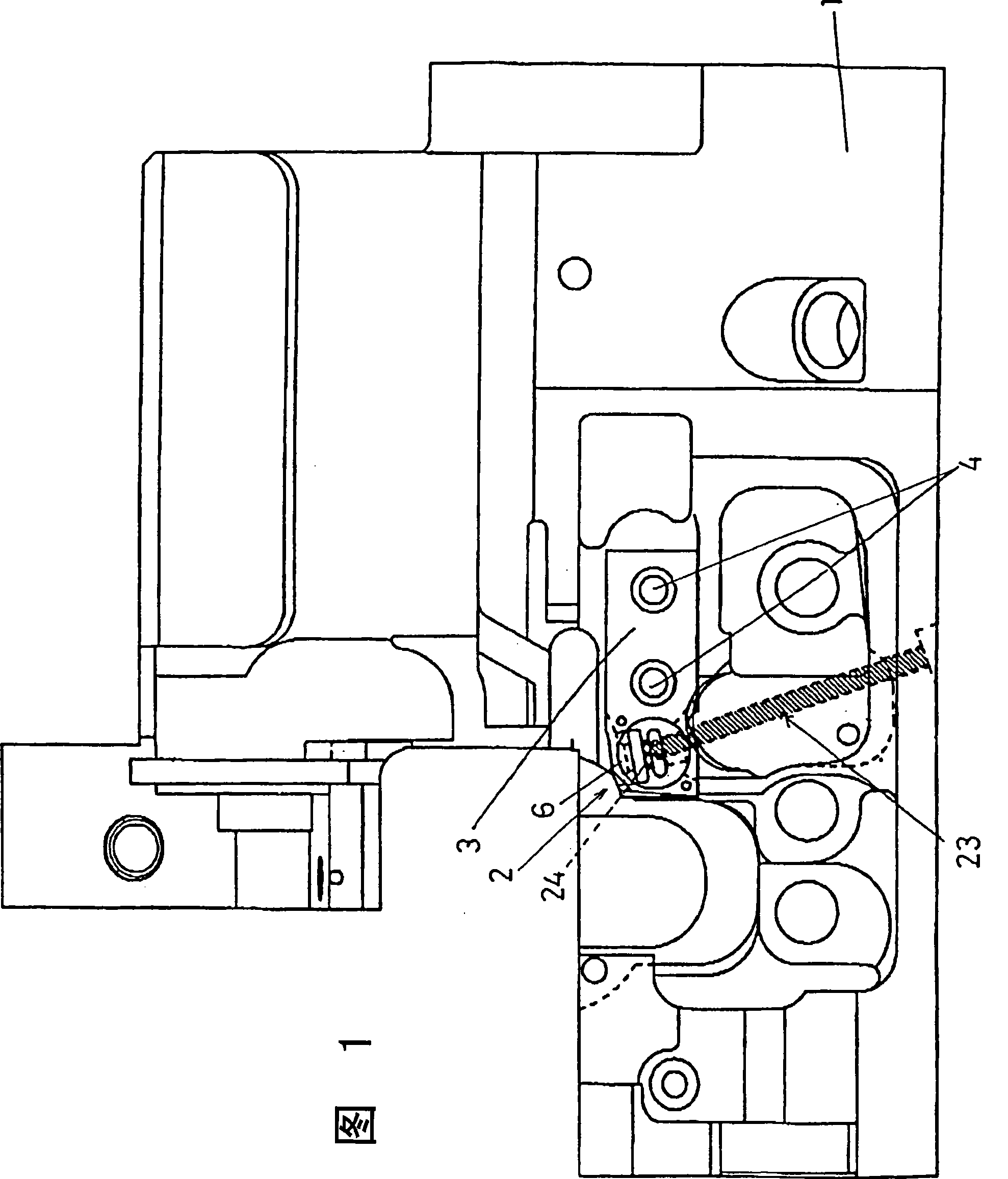

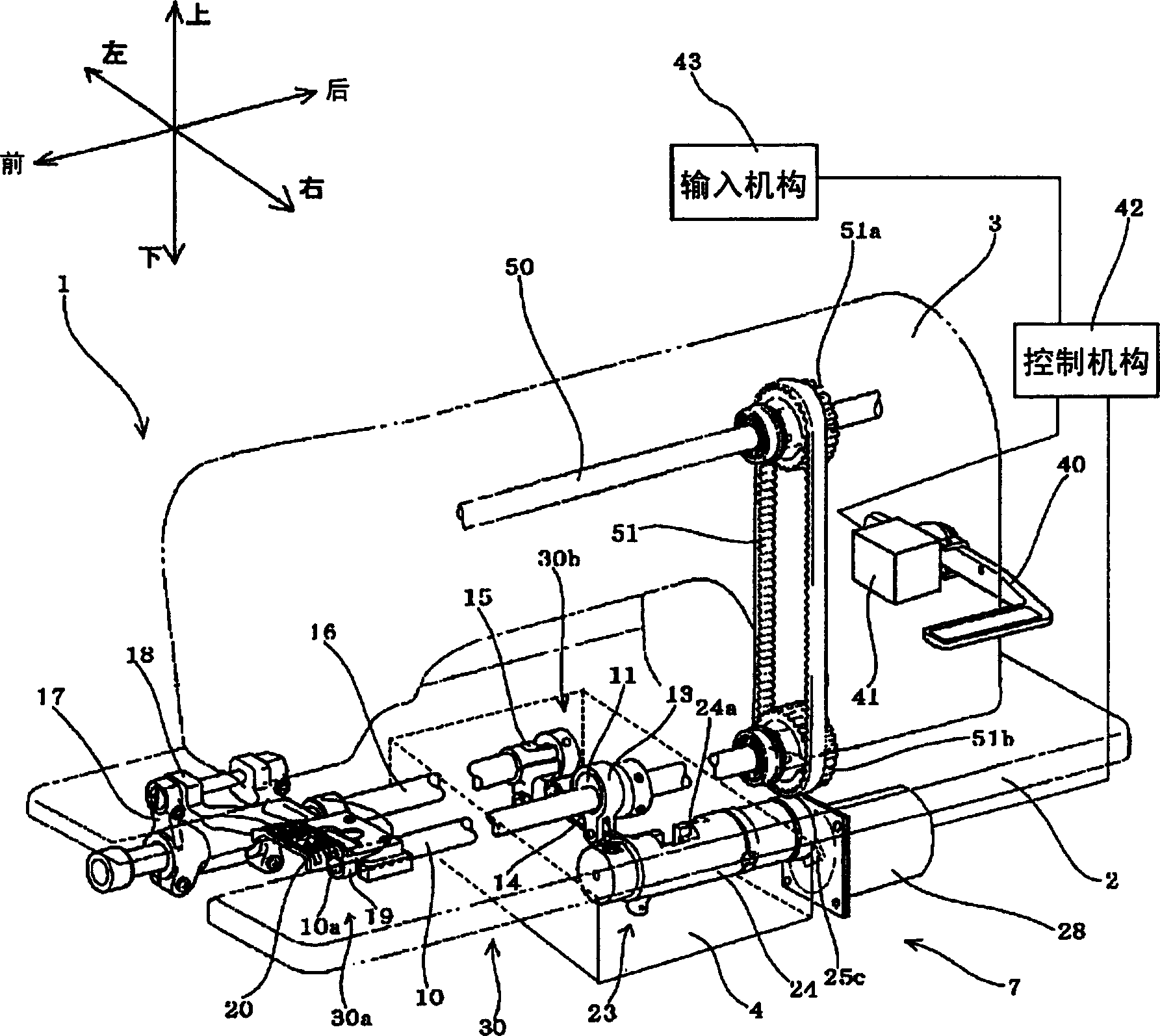

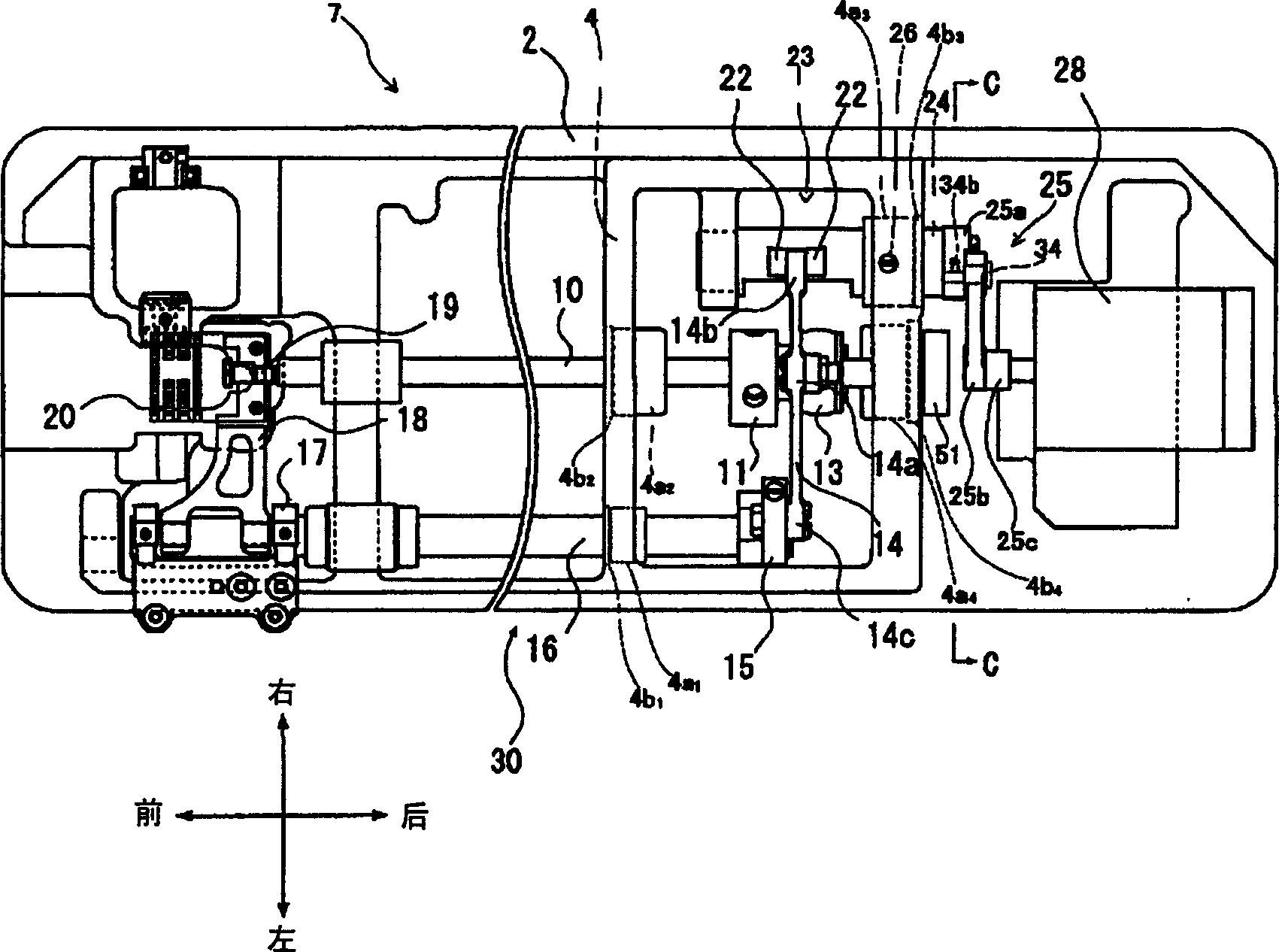

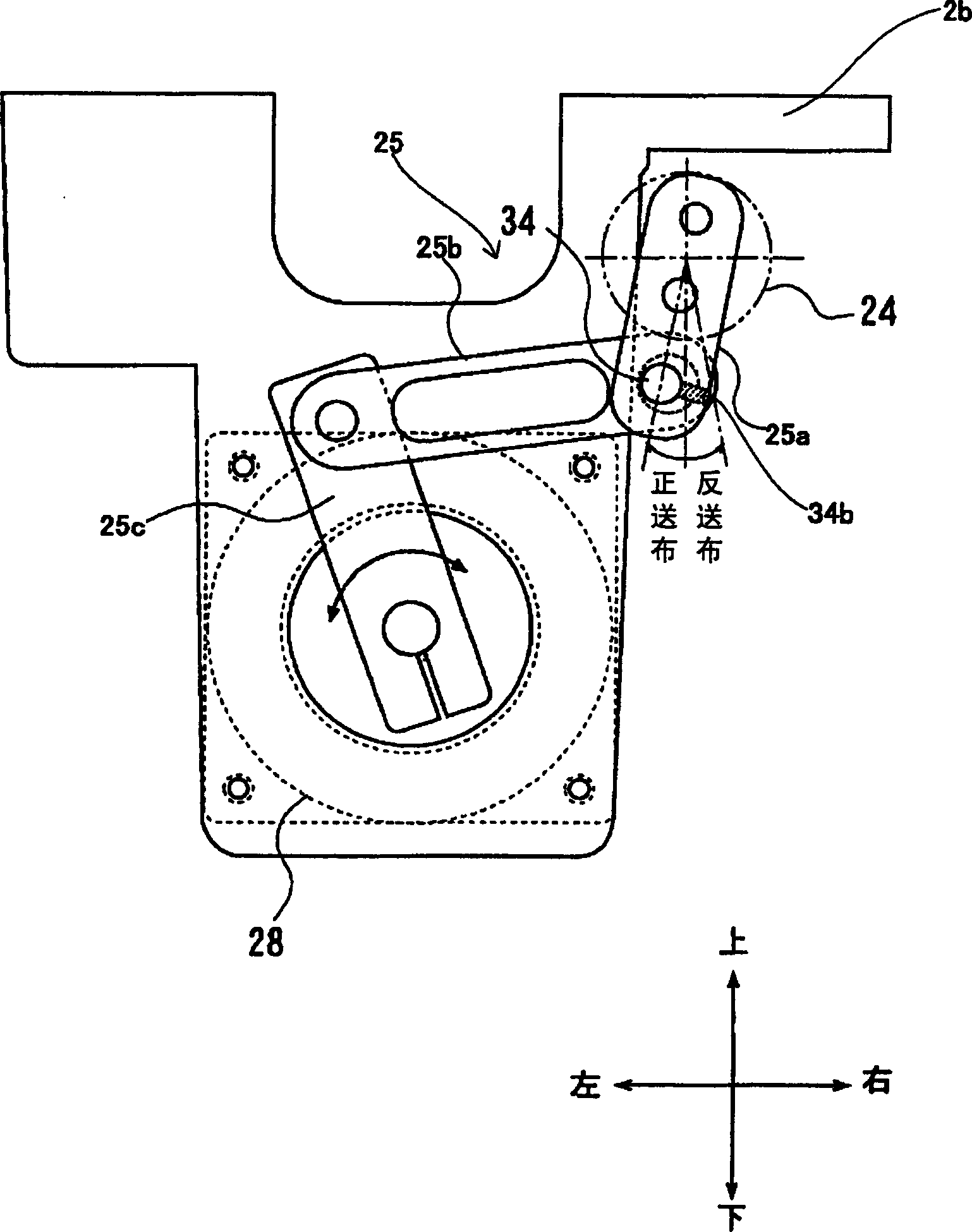

Cloth feeding mechanism of sewing machine

A horizontal feed mechanism 30b and a feed distance change means 23 of a cloth feeder 7 is provided in a closed lubricating chamber 4 separated from the outside. A pulse motor (a drive means) 28 actuating the feed distance change means 23 to change the feed distance is connected to a feed adjusting body 24 of the feed distance change means 23 via a link mechanism 25 and is fixed to the lower part of a sewing machine bed 2 outside the lubricating chamber 4. To provide a feeder capable of quietly changing an accurate feed distance even in a high-speed sewing time.

Owner:JUKI CORP

Lubrication structure for needle bar sleeve of sewing machine

InactiveCN102373585AAvoid accessModerate amount of oilLubrication/cooling devicesLubricationBiomedical engineering

The invention relates to a lubrication structure for a needle bar sleeve of a sewing machine. The sewing machine is provided with a machine head in which a needle bar module is installed, wherein the needle bar module comprises a vertical needle bar connected with a driving part and a needle bar sleeve connected at the lower end of a machine head shell and sleeved outside a needle bar. The lubrication structure comprises a needle bar sleeve main body, wherein a concentric needle bar sleeve with inner diameter reduced is arranged at the lower end of the needle bar sleeve main body; and an oil storage groove is arranged on the inner wall of the needle bar sleeve. The lubrication structure is characterized in that a wick is arranged in the oil storage groove. The lubrication structure has the following beneficial effects: the wick is arranged in the oil storage groove on the inner wall of the needle bar sleeve and most oil is controlled in the wick, so that the oil in a crack between the needle bar and the needle bar sleeve is moderate, is uniformly distributed and is not easy to leak; and oil absorption felts can be arranged at the upper and lower ends of the needle bar sleeve to absorb the redundant oil and prevent dust from entering, so that the whole structure has good lubrication effect and is pollution-free.

Owner:WUJIANG DEKELI TEXTILE PROD

Pollution-free lubrication system of sewing machine

InactiveCN101876127AAvoid pollutionImprove the lubrication effectLubrication/cooling devicesLubricationPollution

The invention relates to a pollution-free lubrication system of a sewing machine, which comprises a rotating shuttle part and a needle bar part, wherein the rotating shuttle part comprises an oil suction strand, an oil storage felt, a hollow rotating shuttle shaft and a high-speed rotating shuttle mechanism. The pollution-free lubrication system is characterized in that the inner cavity of the hollow rotating shuttle shaft is provided with a gas-oil mixture through hole, the oil storage felt is arranged at the top part of the upper oil tank body of a rotating shuttle sleeve, the bottom side of the oil storage felt is provided with an oil hole and a gas-oil mixture through hole, and the end part of the hollow rotating shuttle shaft is connected with the high-speed rotating shuttle mechanism; and the needle bar part comprises a needle bar, a needle bar sleeve, an oil storage tank and complex lithium grease, wherein the needle bar sleeve is arranged outside the needle bar, the oil storage tank is arranged at the upper end of the needle bar sleeve, and the complex lithium grease is arranged in the oil storage tank. The pollution-free lubrication system can effectively prevent plain lubrication oil from dropping along the need bar to pollute cloth, can be adapted to the lubrication effect reached at a high speed, and can maintain favorable sealing property in the high-speed moving process of the needle bar.

Owner:WUHAN AIWEI ANFANG TECH

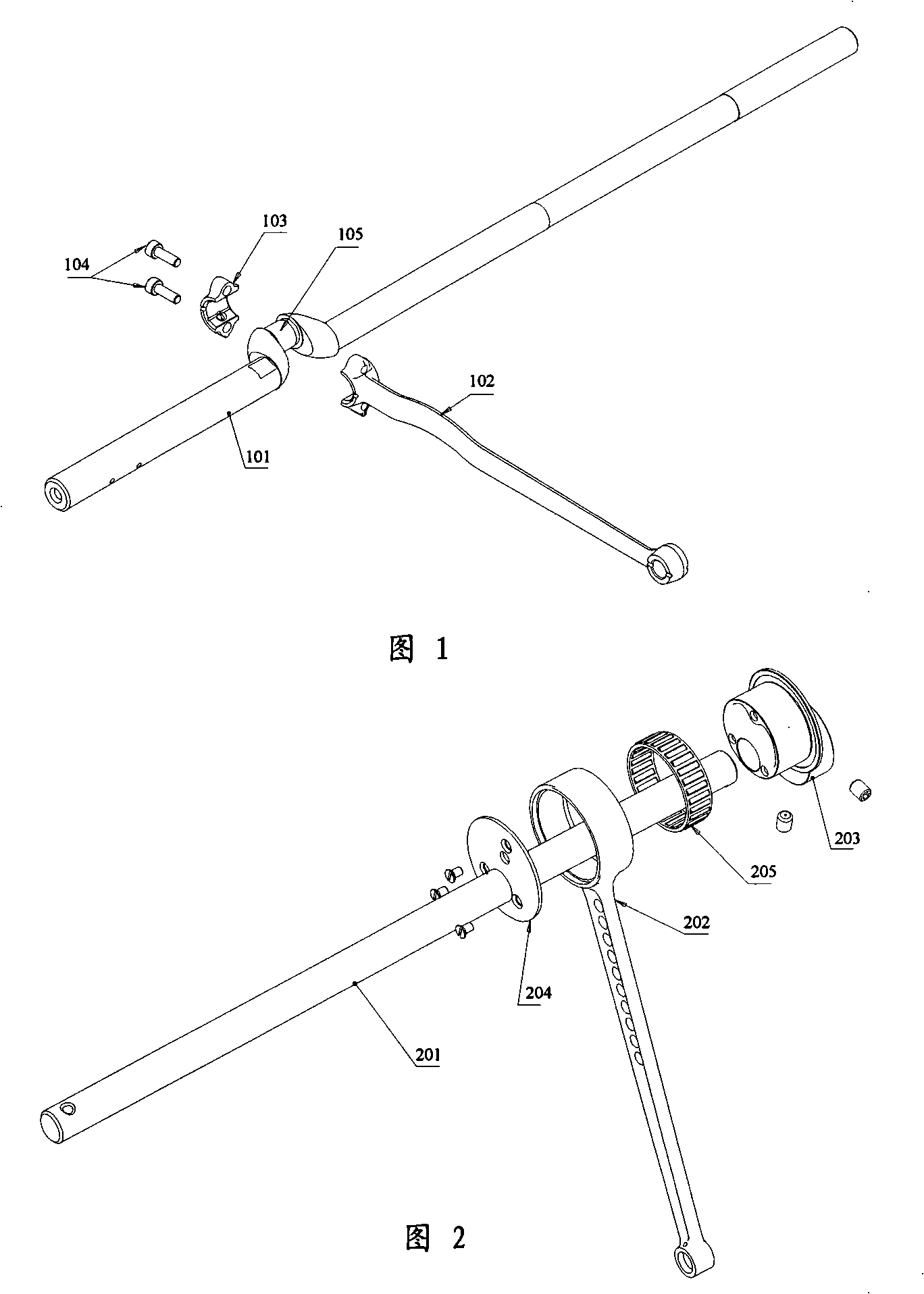

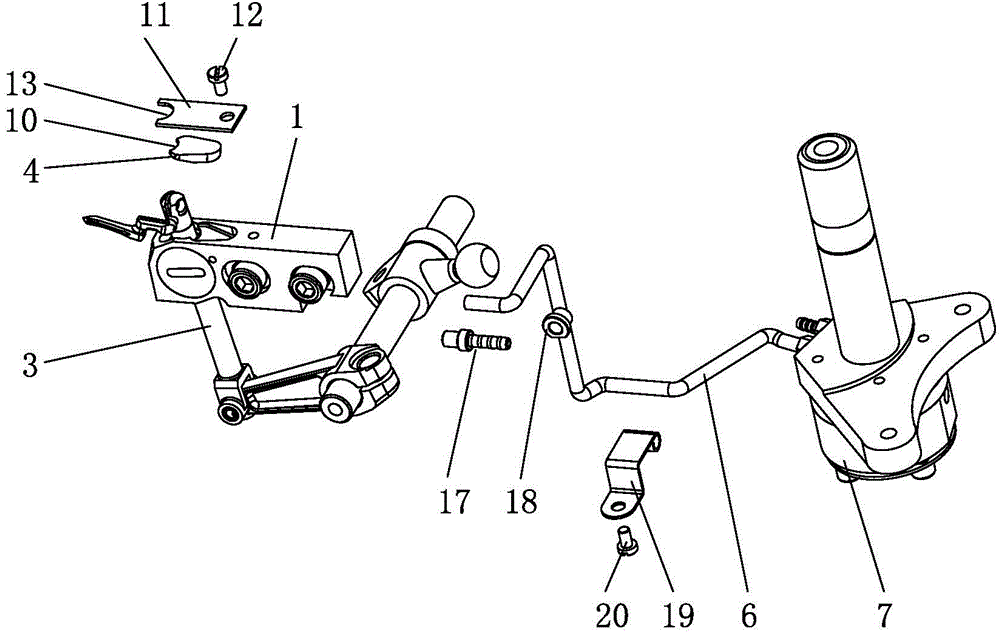

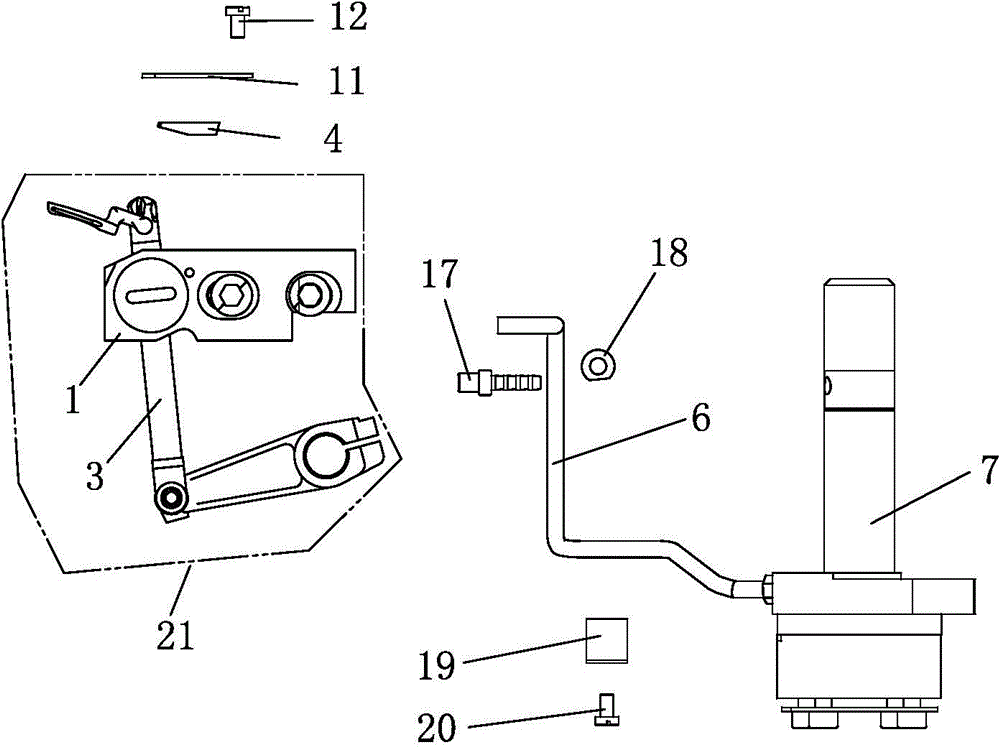

Driving device for cutter of sewing machine

ActiveCN101503846AChange the range of rotationFine-tuning the range of reciprocating motionLubrication/cooling devicesWorkpiece carriersReciprocating motionEngineering

The present invention provides a knife driving device of sewing machine. The device is installed with a transmission cylinder which penetrates the head lower wall at the bottom of sewing machine and is supported with a mode that the transmission cylinder can rotate around the central shaft. The transmission cylinder is embedded with a supporting bush of compression lever. The upper part of transmission cylinder positioned at the inner side of head part is connected with a knife pendulum shaft at the inner part of sewing machine arm. The lower part of transmission cylinder positioned outside the head part is installed with a movable blade. The reciprocating rotation of blade pendulum shaft at the inner part of sewing machine arm is transmitted to the transmission cylinder. Furthermore the reciprocating rotation of transmission cylinder is transmitted to a movable knife on the presser feet for reciprocating the movable blade. The inner part and outer part of head part are sealed with a sealing component which is installed at the internal circumstance and periphery of transmission cylinder. The transmission from the knife pendulum shaft to the movable knife is realized without damaging the sealing in and outside the head part. Furthermore the high-speed operation is realized.

Owner:YAMATO SEWING MASCH MFG CO LTD

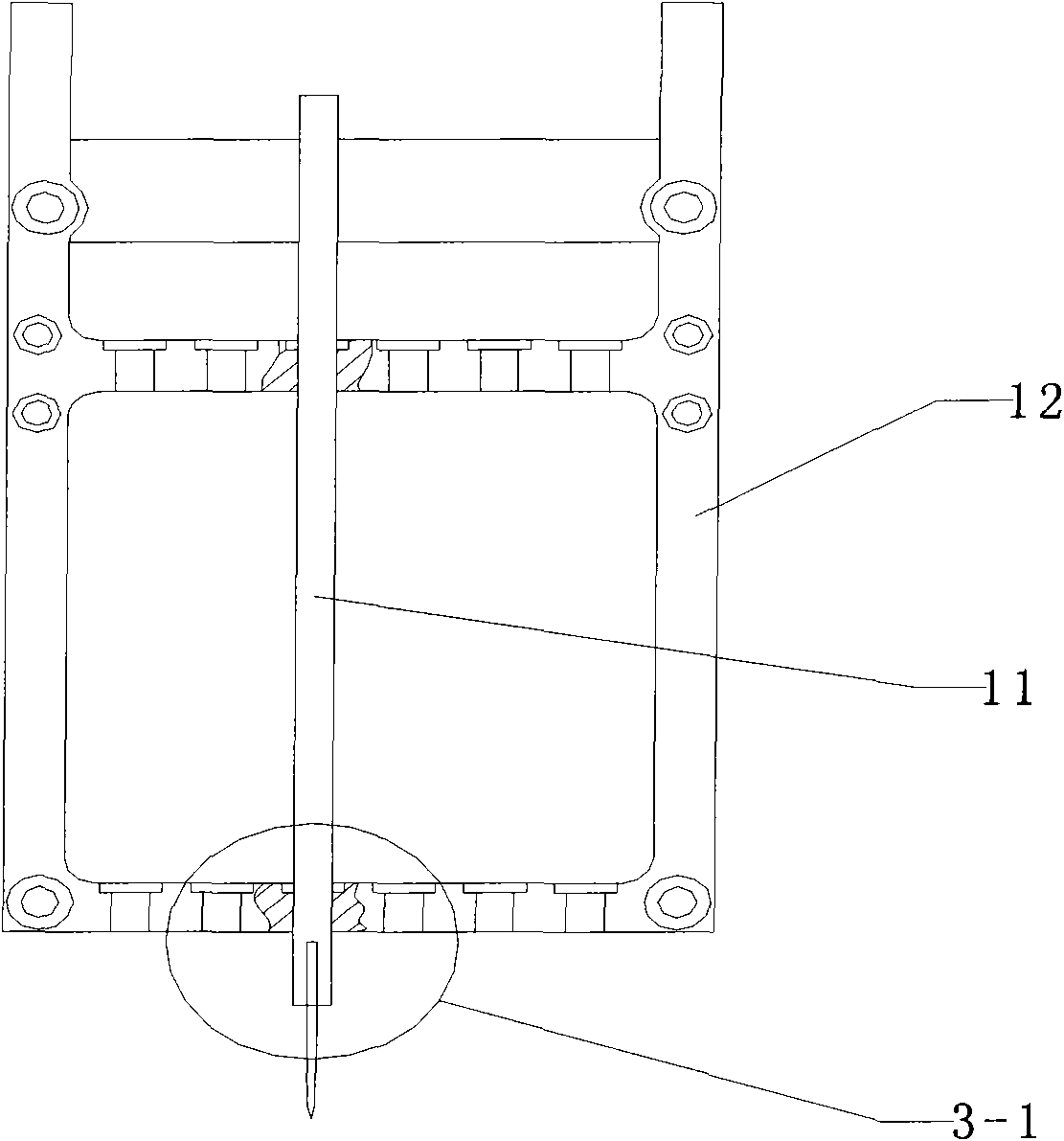

Forced oil return mechanism of upper looper slide bar of sewing machine

ActiveCN105274747AAvoid affecting the orderlyGood oil return effectLubrication/cooling devicesEngineeringReturn channel

The invention belongs to the technical field of sewing machines, and particularly to a forced oil return mechanism of an upper looper slide bar of a sewing machine. The forced oil return mechanism of the upper looper slide bar of the sewing machine comprises an upper looper slide bar seat, the upper looper slide bar in an upper looper slide bar hole of the upper looper slide bar seat, the upper looper slide bar seat is fixedly provided with oil absorption cotton, the oil absorption cotton contacts with and is connected to the upper lopper slide bar, the upper looper slide bar seat is provided with an oil return channel, the oil return channel is connected to an oil tube, the oil tube is connected to an oil pump, and the oil pump can make oil on the upper lopper slide bar forcedly return through the oil absorption cotton and the oil return channel. The forced oil return mechanism can make oil on the upper lopper slide bar forcedly return, oil stain can be prevented from being thrown away along with motion of the upper looper slide bar, so no oil stain splashes on the cloth, the cloth will not be polluted, order production cannot be affected. The forced oil return mechanism is good in oil return effect, simple in structure, low in cost and can be applied to the present sewing machine. The oil absorption cotton can be fixed to the upper looper slide bar seat through a cover plate, so the oil absorption cotton is convenient to mount and dismount, only the cover plate needs mounting / dismounting, and other parts do not need mounting / dismounting.

Owner:JACK SEWING MASCH CO LTD

Oil supply device for curving needle holder of sartorius

An oil supply device, the deposited oil in the grease-box is filtered to the second oil line in the supplying pipe and guided to the loopier foundation, and is moved to the first oil line which contacts in the circumference and rotates on the loopier foundation, the oil supply device also supply oil to a sliding plane that slides on the support platform of a support plate actuation cam plate which contacts the front section of the first oil line, thereby, oil can be supplied to the sliding plane of the support plate actuation cam plate that swings at high speed stably, the abrasion of the sliding plane can be reduced, sinter can be avoided, the durability of a loopier foundation of the sartorial can be improved.

Owner:BROTHER KOGYO KK

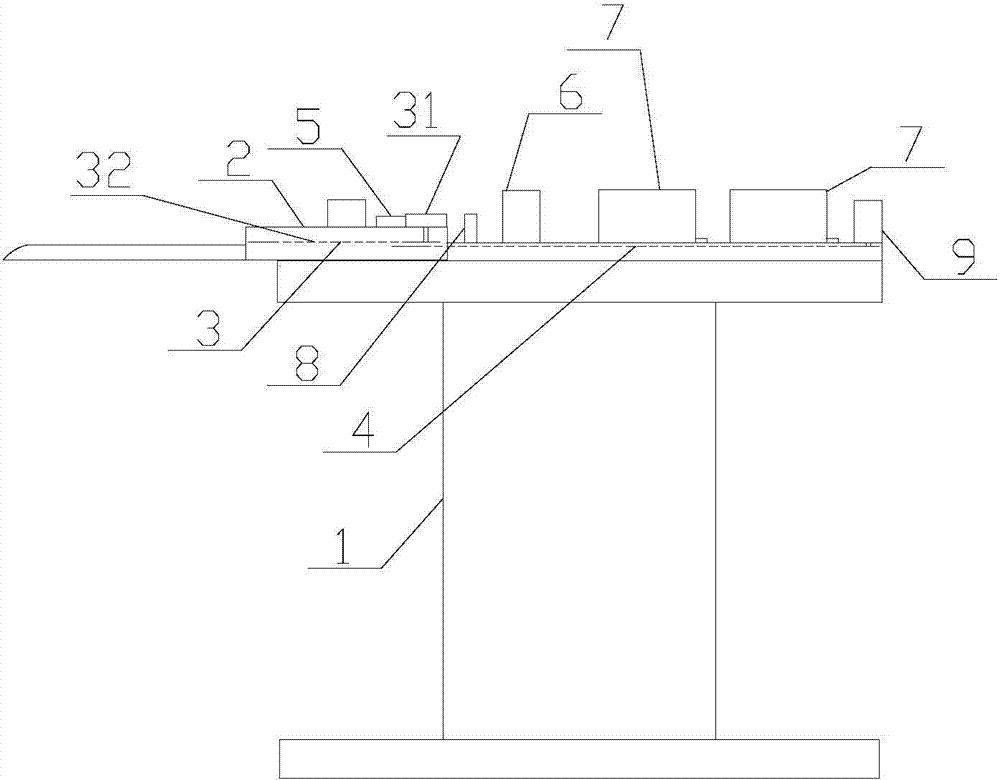

Straight sock looping machine

ActiveCN104727019AEasy accessGuaranteed aestheticsLubrication/cooling devicesWorkpiece carriersElectric machineryInductor

The invention discloses a straight sock looping machine. The straight sock looping machine comprises a machine frame, a guide device, a conveying chain device, a second conveying chain, a main motor, a cutter, lifting machine heads, a horseback-riding-type part and a second transmission case. The guide device and the conveying chain device are arranged at the front portion of a platform of the machine frame. The horseback-riding-type part, the cutter, the lifting machine heads and the second transmission case are sequentially arranged at the portion, behind the guide device, of the platform of the machine frame. The second conveying chain is arranged on the platform of the machine frame. The second transmission case is in transmission connection with the second conveying chain. The main motor is in transmission connection the conveying chain device, the cutter, the lifting machine heads and the second transmission case. By means of the straight sock looping machine, lubricating oil can be conveniently added, the normal service life of parts can not be influenced, the positioning accuracy can be guaranteed, disassembling and assembling can be convenient, and the maintenance cost can be reduced; in addition, the reliability of a light inductor fixedly installed on the horseback-riding-type part can be good, the attractiveness of the whole machine can be guaranteed, normal work can not be influenced, the adjustment gap of feeding guide rails can not be prone to being uneven, the occupied space can be small, and the structure can be compact.

Owner:ZHUJI SHIGAN KNITTING MACHINE

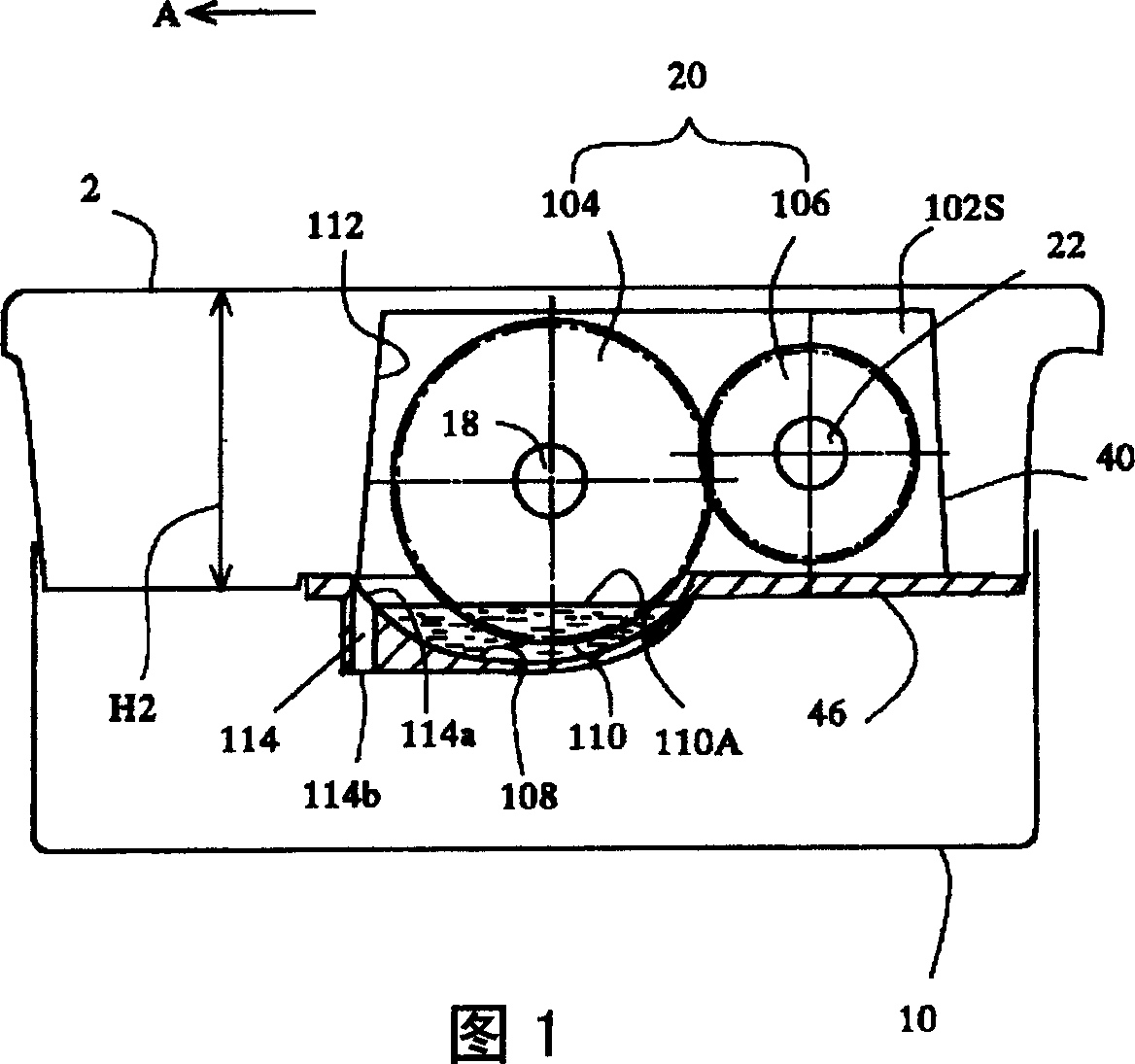

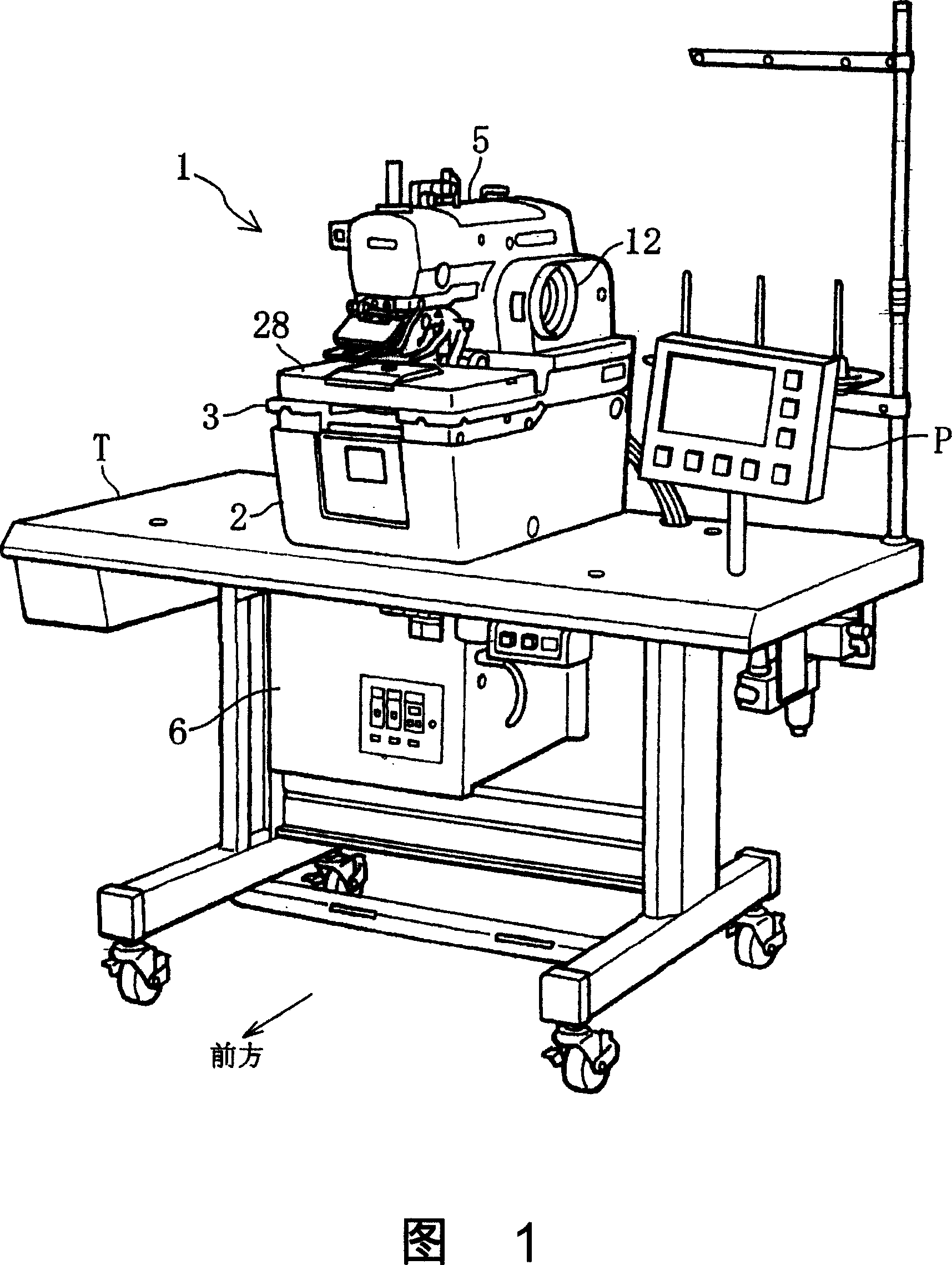

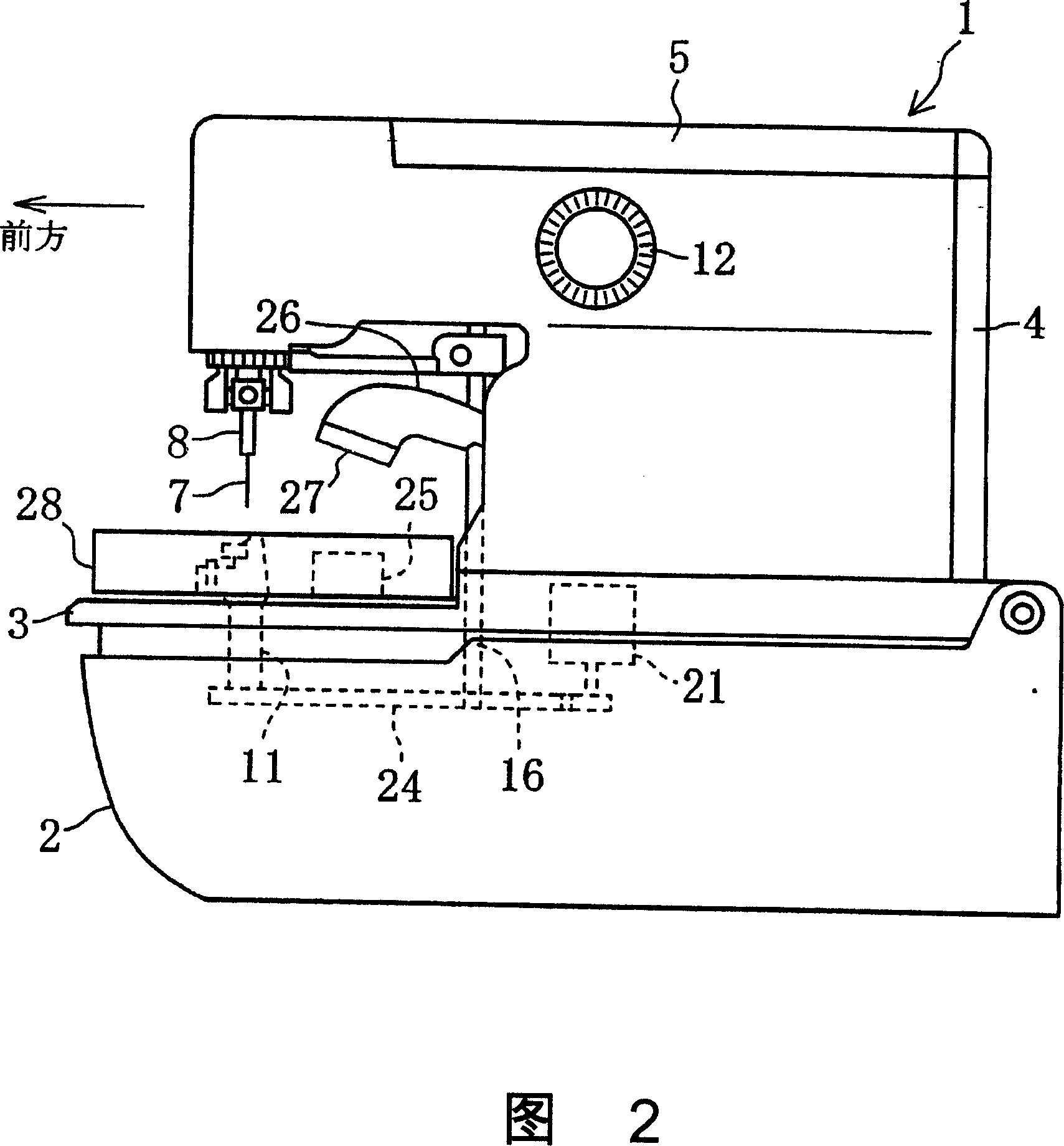

Sewing machines

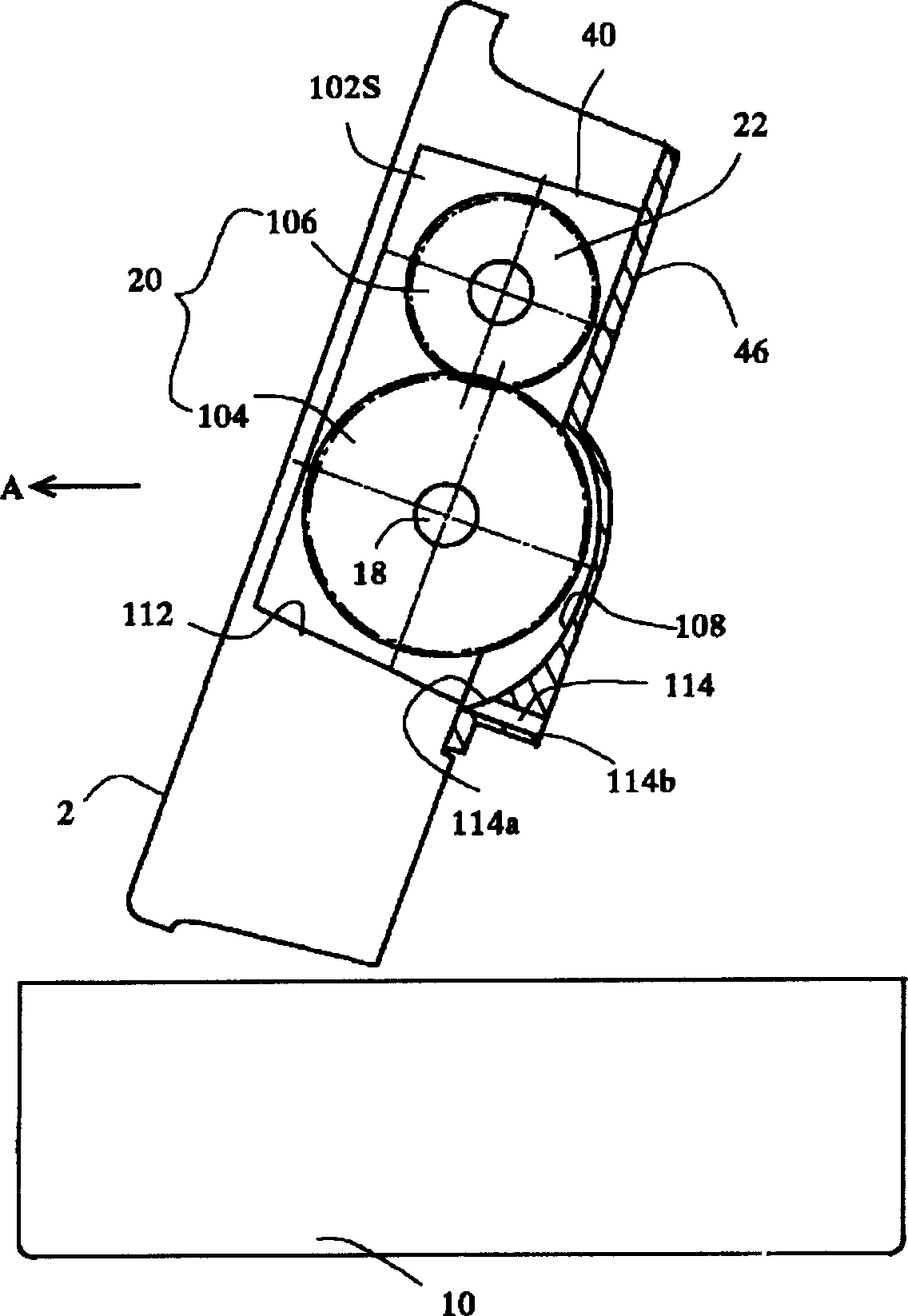

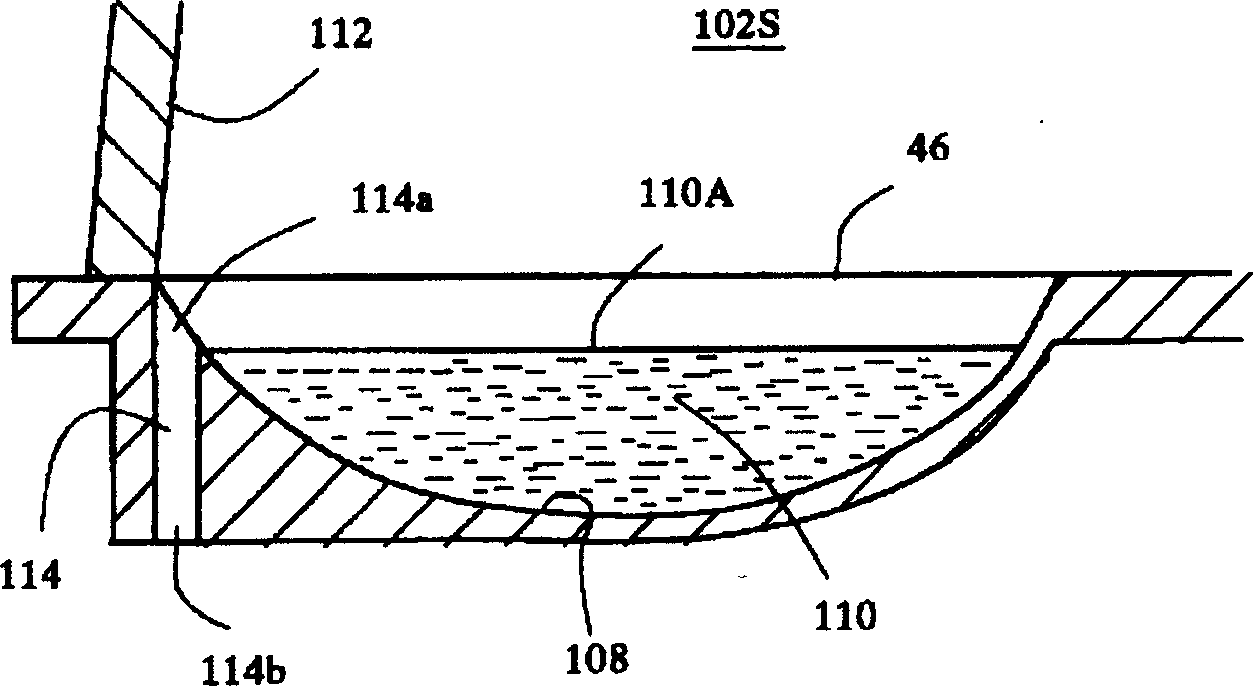

The invention provides a sewing machine which gets lubricants ejected into an oil pan to leave none thereof in a gear box when the sewing machine is levelled. In the sewing machine which is provided with a bed part 2, the oil pan 10 arranged below the bed part and a gear box 40 which is arranged within the bed part while housing a gear device 20 for transmitting driving forces of the lower shaft 18 to a hook drive shaft 22 and in which the gear box has an under cover 46 with a waste oil port 114 that is so formed as to let the lubricant 110 be ejected within the gear box to the oil pan 10, the waste oil port has an upper opening 114a bored into the gear box 40 and a lower opening 114b bored toward the side of the oil pan 10, the upper opening 114a of the waste oil port 114 is so positioned as to be higher than the lowest part of a space 102S within the gear box 40 when the sewing machine is standing while being down to the lowest of the space within the gear box when it is leveled.

Owner:JUKI CORP

Round-head keyhole sartorius

ActiveCN1924142AReliable and stable automatic oil supplyImprove wear resistanceLubrication/cooling devicesNeedle barsEngineeringTransfer mechanism

The round-head keyhole sartorius of the present invention includes: needle bar for fixing sewing needle, needle bar upping and downing mechanism for making the needle bar move up and down, needle-cyclical mechanism for making the needle bar swing, needle bar Rota table mechanism for making the needle bar rotate around its axis, and loopier bed turning mechanism for making the loopier bed which supports the loopier rotate synchronously with said needle bar, the sartorial is characterized in that, said needle bar upping and downing mechanism comprises: needle bar crank that moves with the arm shaft, and upping and downing transferring mechanism which can move with said needle bar crank and transfer the upping and downing drive force of the said needle bar crank to the needle bar, the round-head keyhole sartorial has lubricating oil supplying mechanism for supplying lubricating oil to plurality of gliding parts of the said upping and downing transferring mechanism.

Owner:BROTHER KOGYO KK

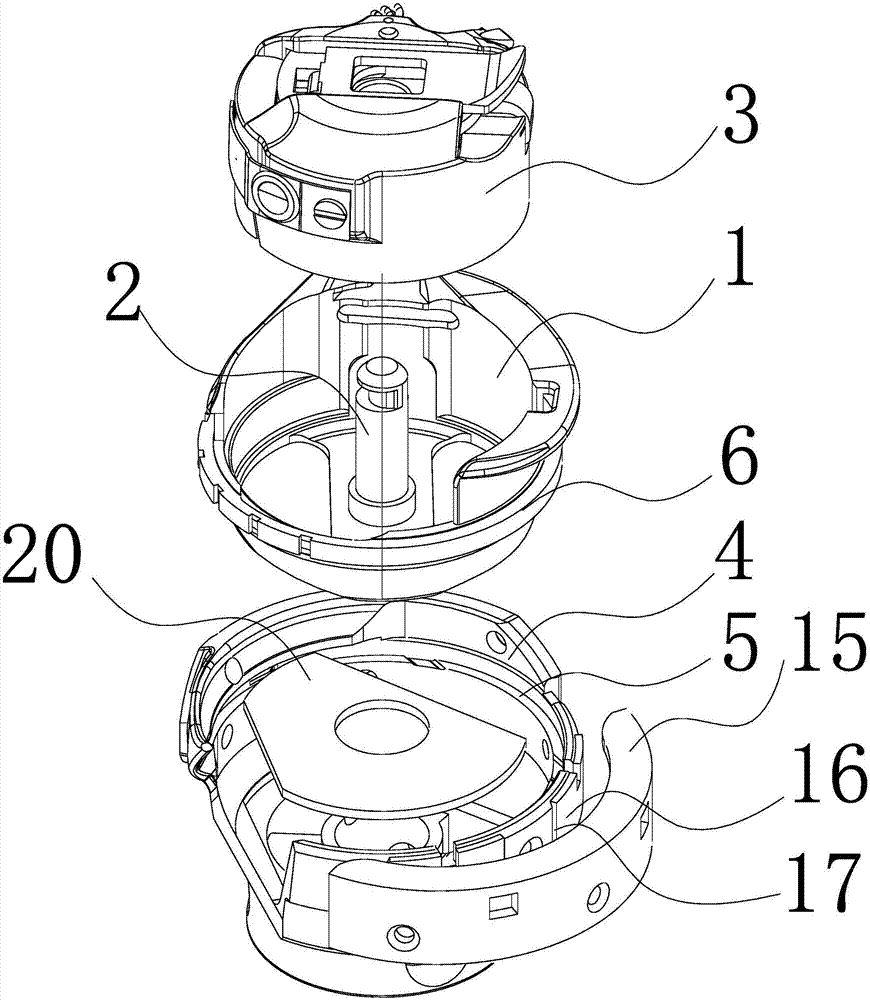

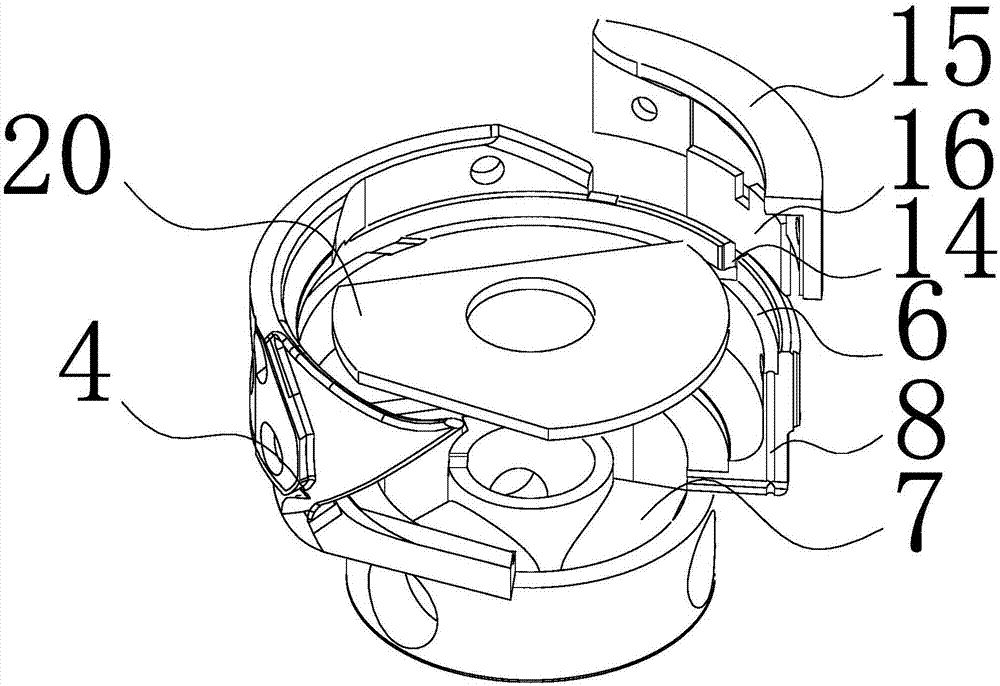

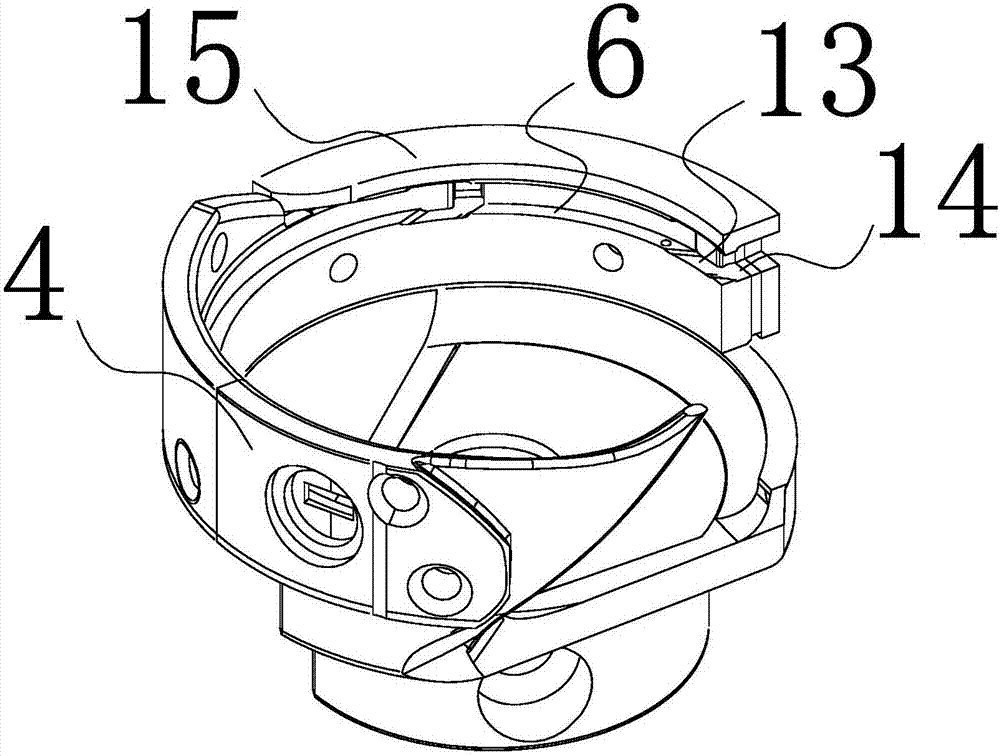

Novel sewing machine rotating shuttle structure

ActiveCN106968060ALong-term effective lubricationAvoid relative motionLubrication/cooling devicesLoop takersEngineeringSewing machine

The invention discloses a rotating shuttle structure, and provides a novel sewing machine rotating shuttle structure which has small abrasion between a shuttle race and a shuttle support, is fast in heat dissipation, guarantees that a rotating shuttle maintains normal work, and prolongs service life. The novel sewing machine rotating shuttle structure solves the technical problem in the prior art that friction resistance of a shuttle support guide rail and the shuttle race is big, the shuttle race guide rail and a rail table need to be lubricated and supplied with oil periodically, not only is the process complicated, but also the oil added amount is difficult to control, and the sewing quality is directly influenced. The novel sewing machine rotating shuttle structure comprises the shuttle support and a shuttle housing which is fixed on a shuttle support core at one end of the shuttle support, the other end of the shuttle support is covered with the shuttle race capable of rotating along the shuttle support core in a mutually matched mode, the inner annular surface of the shuttle race is provided with the rail table, the outer annular of the shuttle support is provided with the annular shuttle support guide rail, the shuttle support is supported on the rail table through the annular shuttle support guide rail, and keeps rotatable connection with the inner annular surface of the shuttle race, and the outer end face of the annular shuttle support guide rail is provided with multiple axial through holes connected to the rail table.

Owner:DONGYANG TAIJI PRECISION MFG

Heat dissipating method for sewing machine with direct-drive motor

The invention relates to a heat dissipating method for a sewing machine with a direct-drive motor. The heat dissipating method is characterized in that an adapter seat is correspondingly connected at a power input main shaft end of the head portion of the sewing machine, thus the direct-drive motor can be arranged though the adapter seat, and the adapter seat is a seat body with suitable thickness, so that a plurality of air intake groove holes can be formed in the outer periphery of the adapter seat. Thus, by utilization of a negative pressure phenomenon generated when the motor operates to drive a fan on a main shaft to rotate, cold air around is sucked in through the air intake grooves and then guided into a machine to be used for heat dissipation of the motor and internal components of the machine body.

Owner:顾飞龙

Lubricating device for needle bar of sewing machine

InactiveCN102337647ASimple structureReduce friction areaLubrication/cooling devicesBiomedical engineeringSewing machine

The invention relates to a lubricating device for a needle bar of a sewing machine, which comprises a vertical cylindrical needle bar arranged on the lower end of a handpiece shell and a cylindrical needle bar sleeve; the needle bar sleeve is connected to the handpiece shell and is sleeved at the outer side of the needle bar; an oil storage groove is arranged on the inner wall of the needle bar sleeve, and an oil injection hole is arranged in the upper part of the side face of a cylinder of the needle bar sleeve. The lubricating device is characterized in that the oil storage groove on the inner wall of the needle bar sleeve is helical with the axial line of the cylinder as a middle axle. The helical oil storage groove is used for reducing the friction area of the needle bar and the needle bar sleeve so as to reduce heat. Meanwhile, the helical groove is used as a flow channel for liquid lubricating grease to ensure that the grease is uniformly distributed within 360 degrees in the vertical and sectional directions of the axial line of the needle bar sleeve. The helical oil storage groove has a simple structure, and the upper end of the helical oil storage groove is arranged at the oil injection hole of the needle bar sleeve to conveniently inject oil.

Owner:吴江丰榖布艺整理厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com