Direct-drive motor heat sink of industrial sewing machine

A technology for industrial sewing machines and direct-drive motors, which is applied to sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of lack of heat dissipation, bulky, and unsatisfactory use design, and achieve the effect of ensuring service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

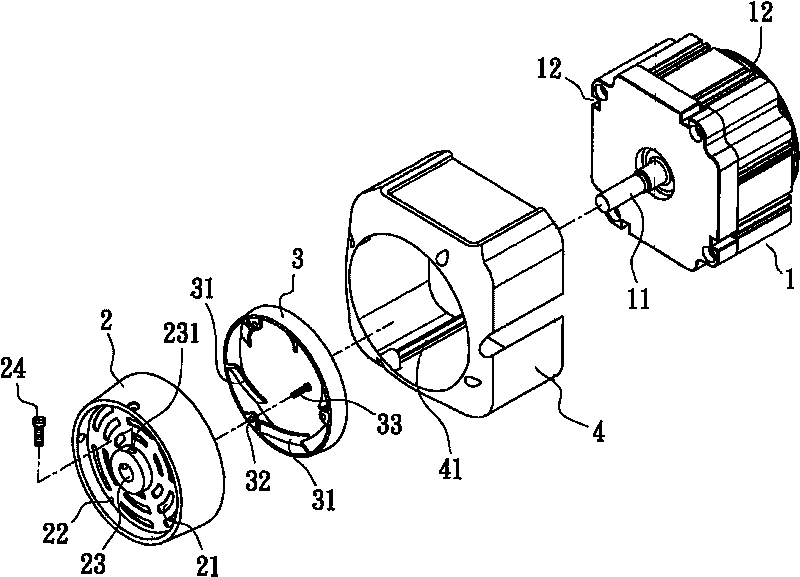

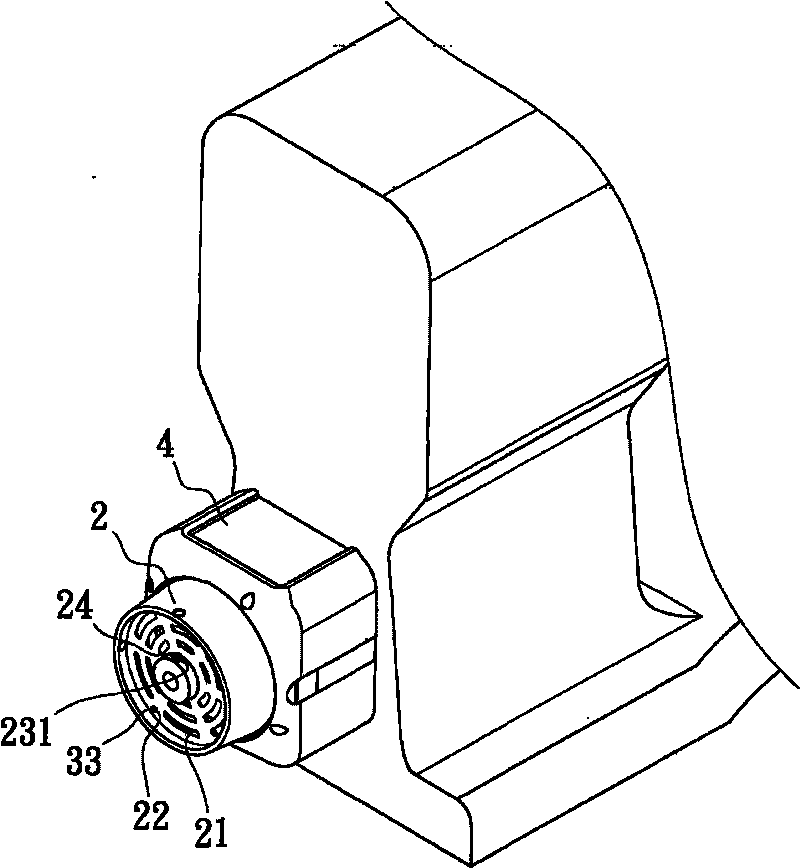

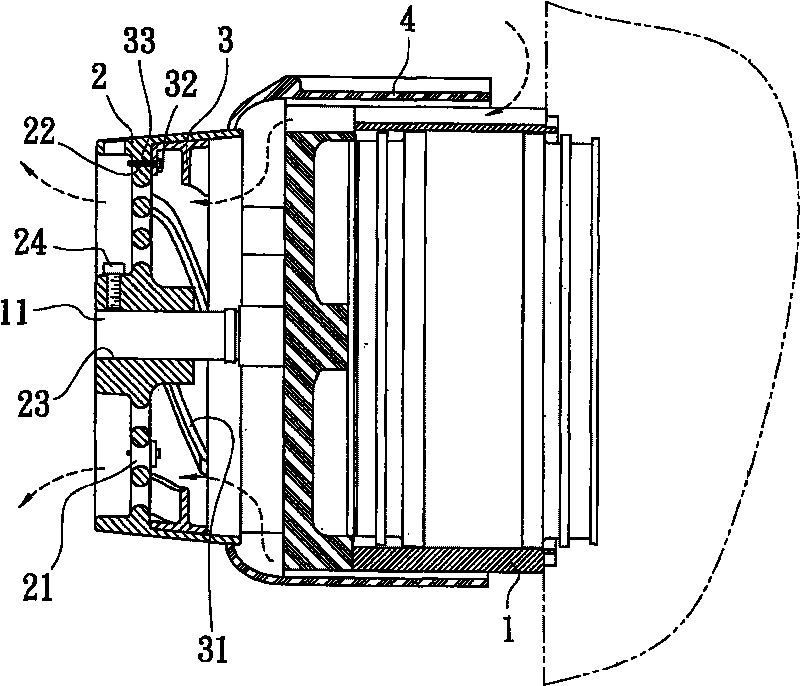

[0021] First, see Figure 1 ~ Figure 3 As shown, it is a three-dimensional disassembly, combination and combined sectional schematic diagram of Embodiment 1 of the direct drive motor cooling device of the industrial sewing machine of the present invention. Wheel 2, the center of the hand wheel 2 is provided with a through hole 23 which is nested with the main shaft 11, the periphery of the through hole 23 has a threaded hole 231 for a threaded part 24 to be screwed, and the side of the hand wheel 2 is provided with multiple exhaust Holes 21 and screw holes 22 are provided, and a heat dissipation fan 3 with guide vanes 31 is assembled correspondingly from the inside of the handwheel 2, and the screw hole 22 of the handwheel 2 corresponds to the inner surface of the heat dissipation fan 3. The perforated holes 32 are connected together by screws 33, and a shell 4 is set outside the direct drive motor 1 to connect to the hand wheel 2. The inside of the shell 4 is provided with a ...

Embodiment 2

[0024] see Figure 5 As shown, it is a schematic diagram of another embodiment of the direct-drive motor cooling device of the industrial sewing machine of the present invention. The difference from Embodiment 1 is that the direction of the deflector 31 of the cooling fan 3 is corresponding to when the direct-drive motor 1 is running. It can be designed to generate deflections. Therefore, when the main shaft 11 of the direct drive motor 1 is rotating, there are left and right rotations respectively, and the deflectors 31 of the cooling fan 3 are like figure 1 and Figure 5 The direction of the deflector 31 of the cooling fan 3 is different to correspond to the direct drive motor 1, and the hole 32 is used to correspond to the screw hole 22 of the hand wheel 2, and the screws 33 are assembled together to achieve Exhaust cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com