Rotary shuttle oil-supplying device

A technology for supplying oil to a rotary hook and a rotary hook shaft, which is applied in the field of sewing machines, can solve the problems of complex structure, increased cost, space occupied by an oil pump, etc., and achieves the effects of reducing manufacturing cost, saving space and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

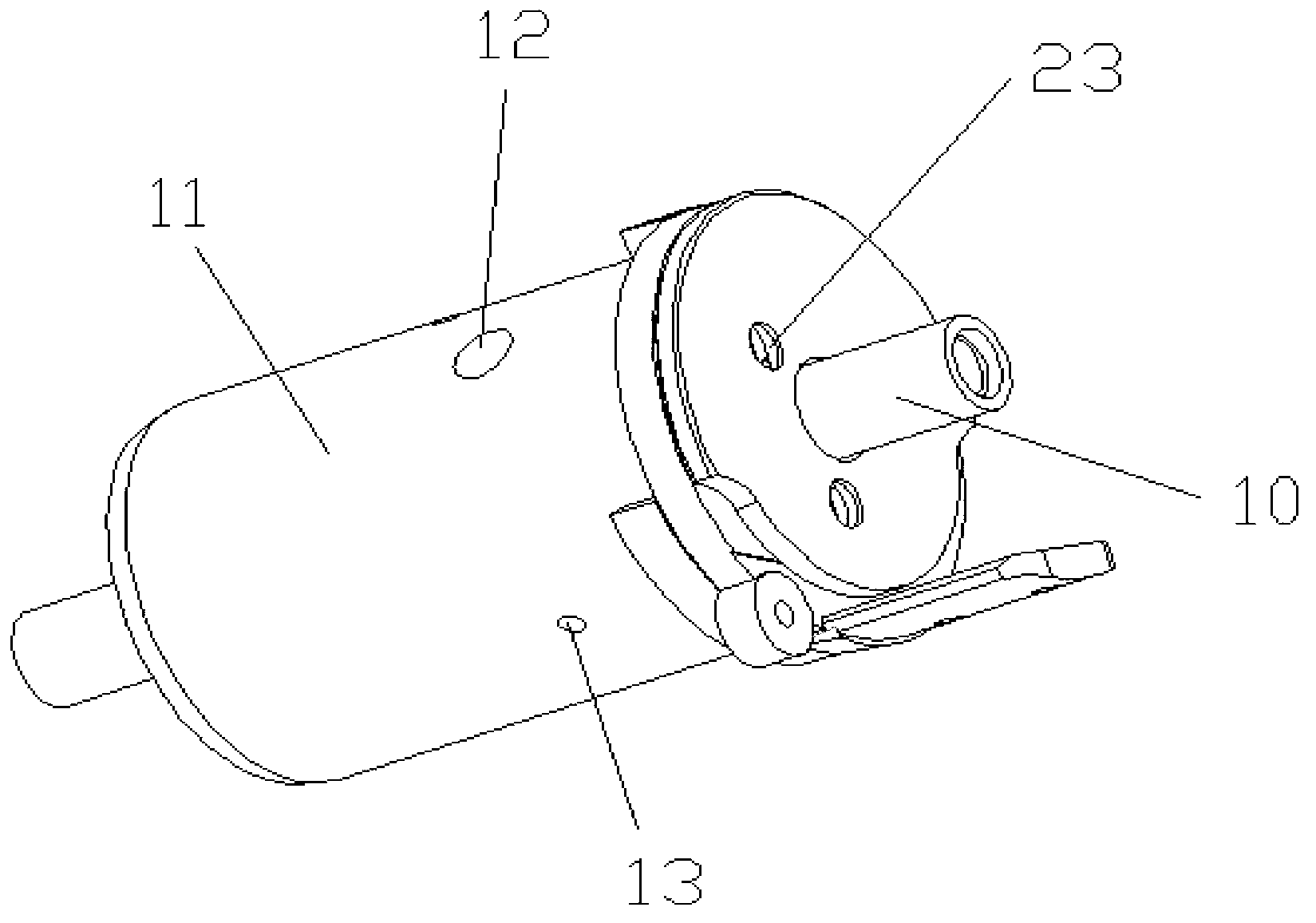

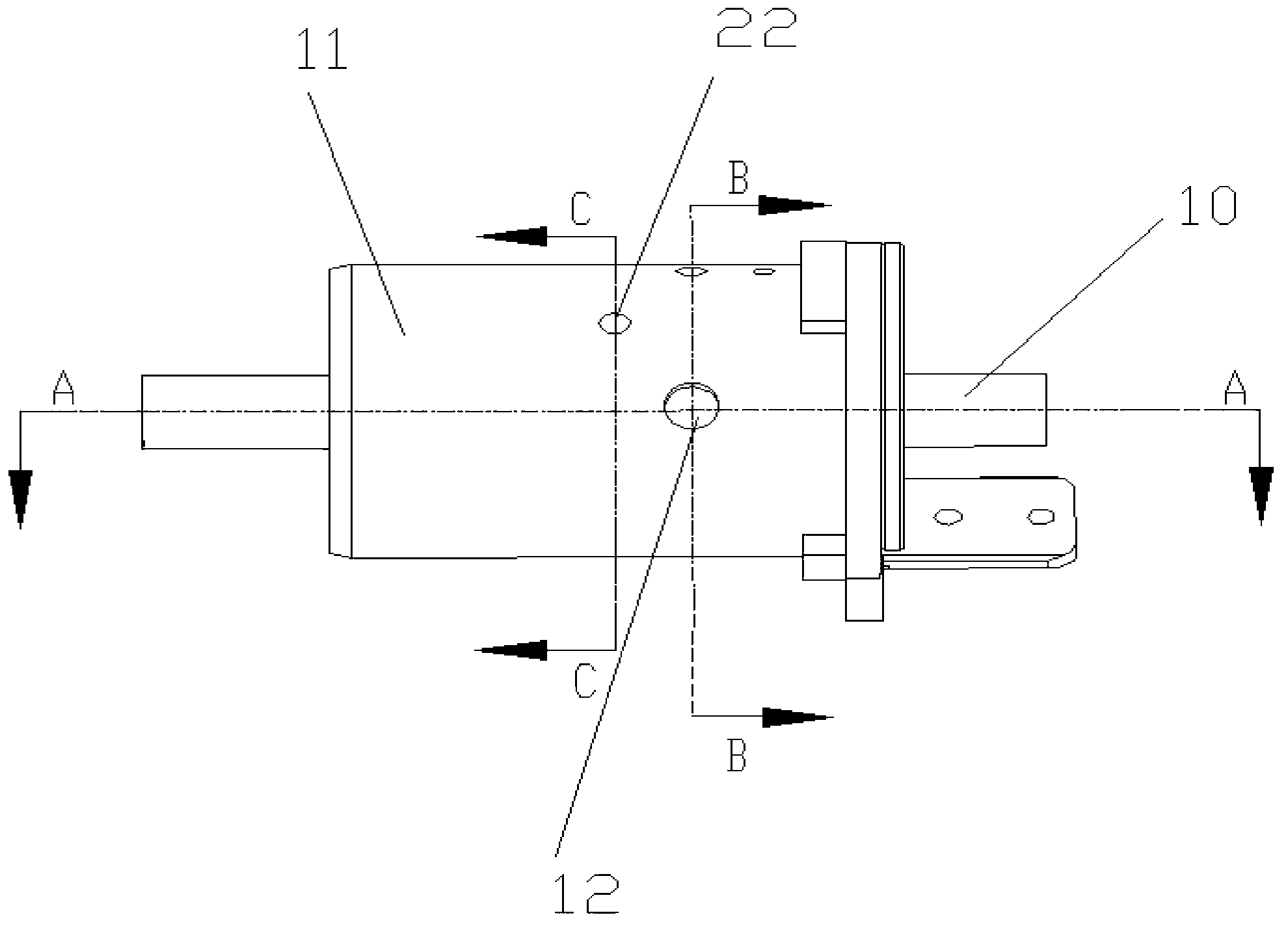

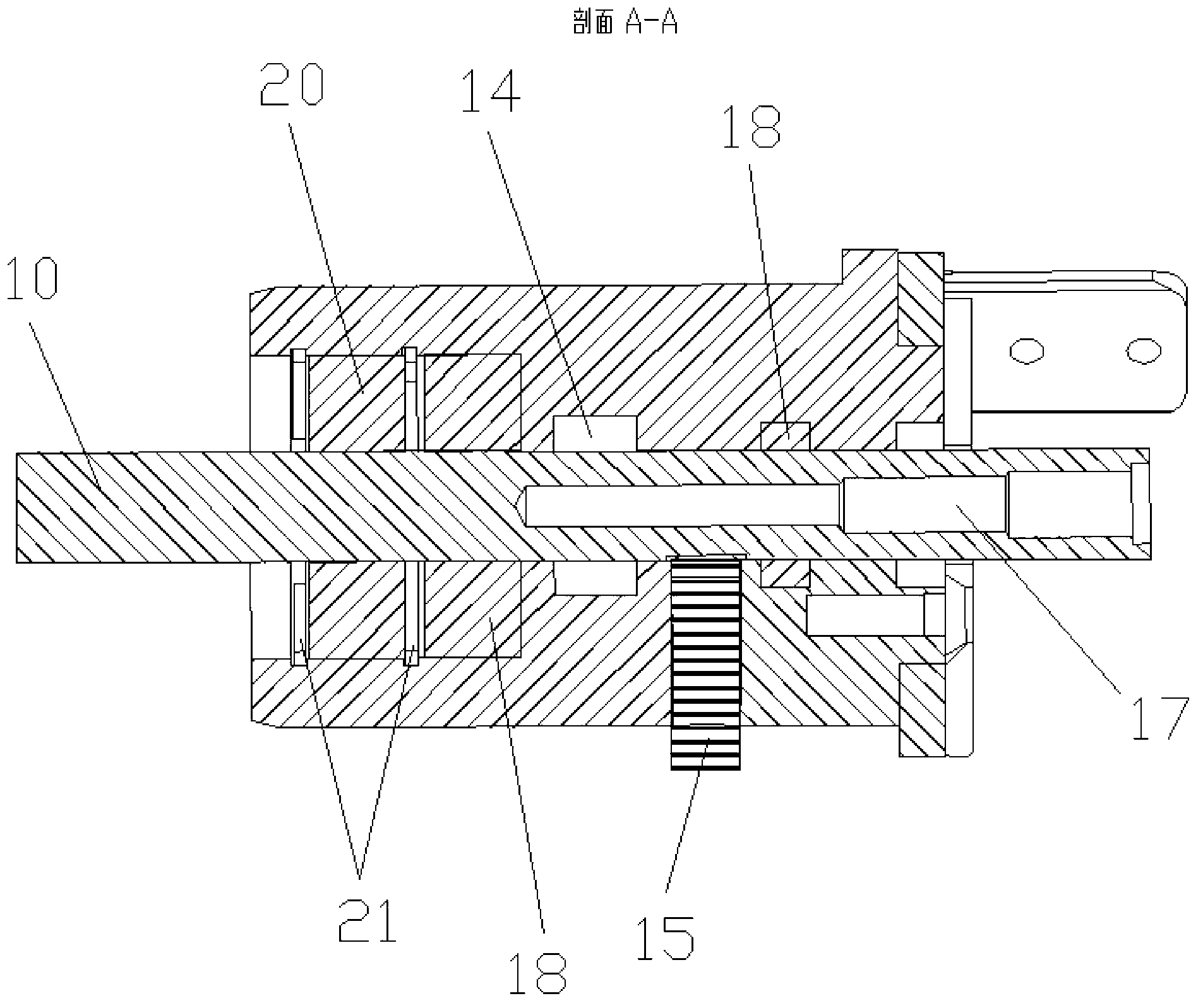

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —8: A rotary hook oil supply device, including a shaft sleeve 11 and a rotary hook shaft 10, the rotary hook shaft 10 runs through the shaft sleeve 11 and can rotate at a high speed in the shaft sleeve 11, wherein the rotary hook shaft 10 and the shaft The sleeve 11 is equipped with an oil pump mechanism, and the oil pumped by the oil pump mechanism supplies oil to the rotary hook through the oil delivery mechanism on the shaft sleeve 11 and the rotary hook shaft 10. The tail of the rotary hook shaft 10 is equipped with a bearing 20, and the bearing Circlips 21 are arranged on both sides of 20, and circlips 21 fix the bearing 20 to prevent the hook shaft 10 from moving axially; the outer diameter R of the bearing 20 is in interference fit with the inner diameter r of the shaft sleeve 11, and the inner diameter r1 of the bearing 20 is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com