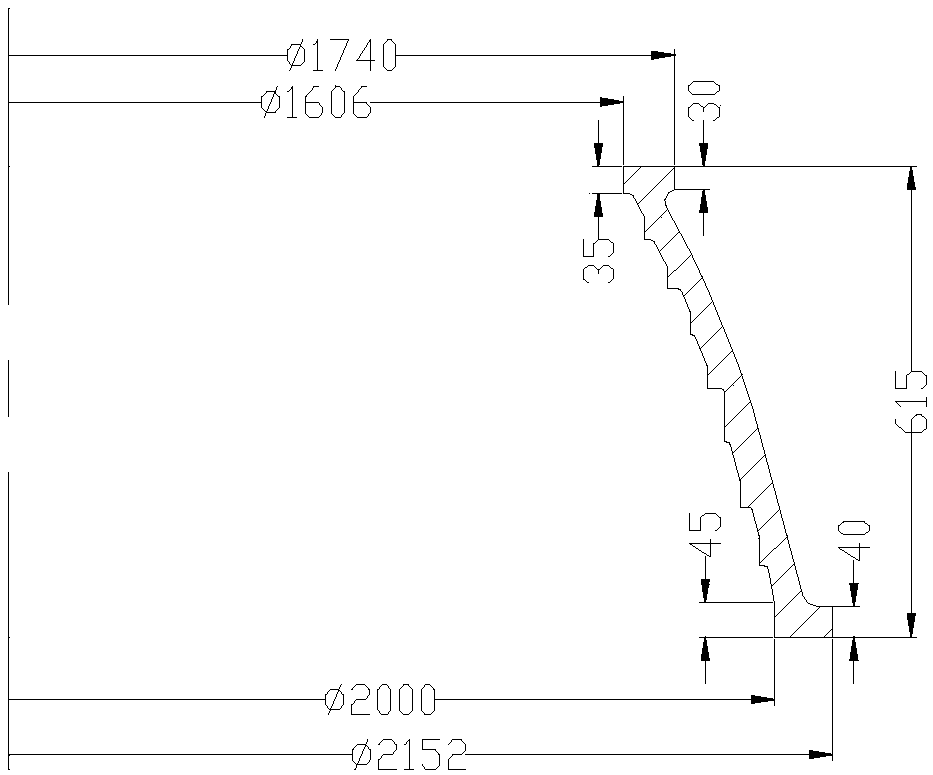

Manufacturing method of multi-step large-diameter casing ring forged piece

A manufacturing method and large-diameter technology, applied in metal rolling, metal processing equipment, etc., can solve the problems of high price, high processing cost, and large consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

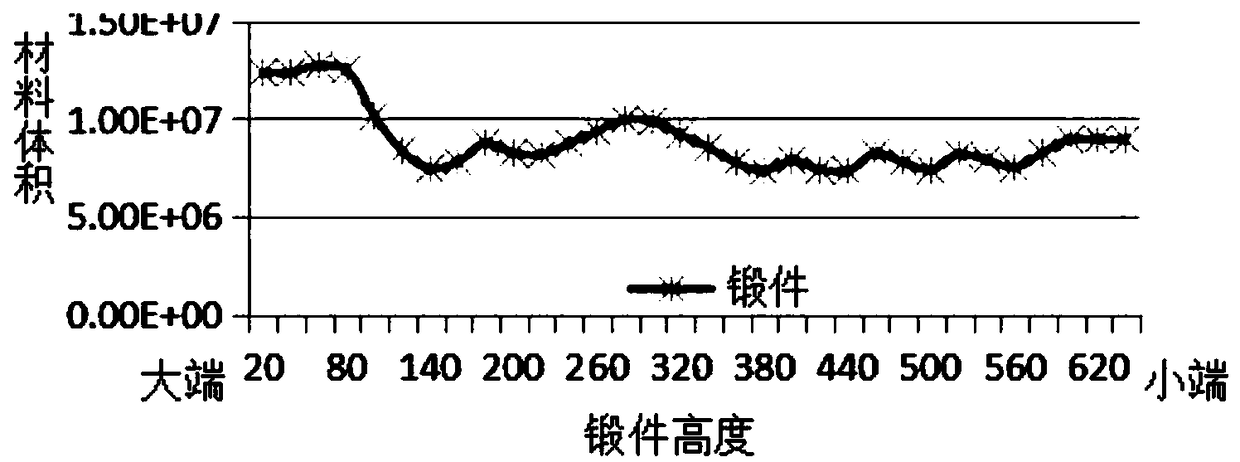

Method used

Image

Examples

Embodiment 1

[0029] (1) Select the WASPALOY rod-shaped raw material, carry out blanking, and then upset the raw material to make the length and thickness appropriate;

[0030] (2) Punch the raw material after upsetting, so that the center is opened;

[0031] (3) Horse-frame reaming is carried out on the raw material after punching, so that the size of the hole is suitable, the volume of the raw material is reasonably distributed, and a rectangular cross-section ring blank is obtained;

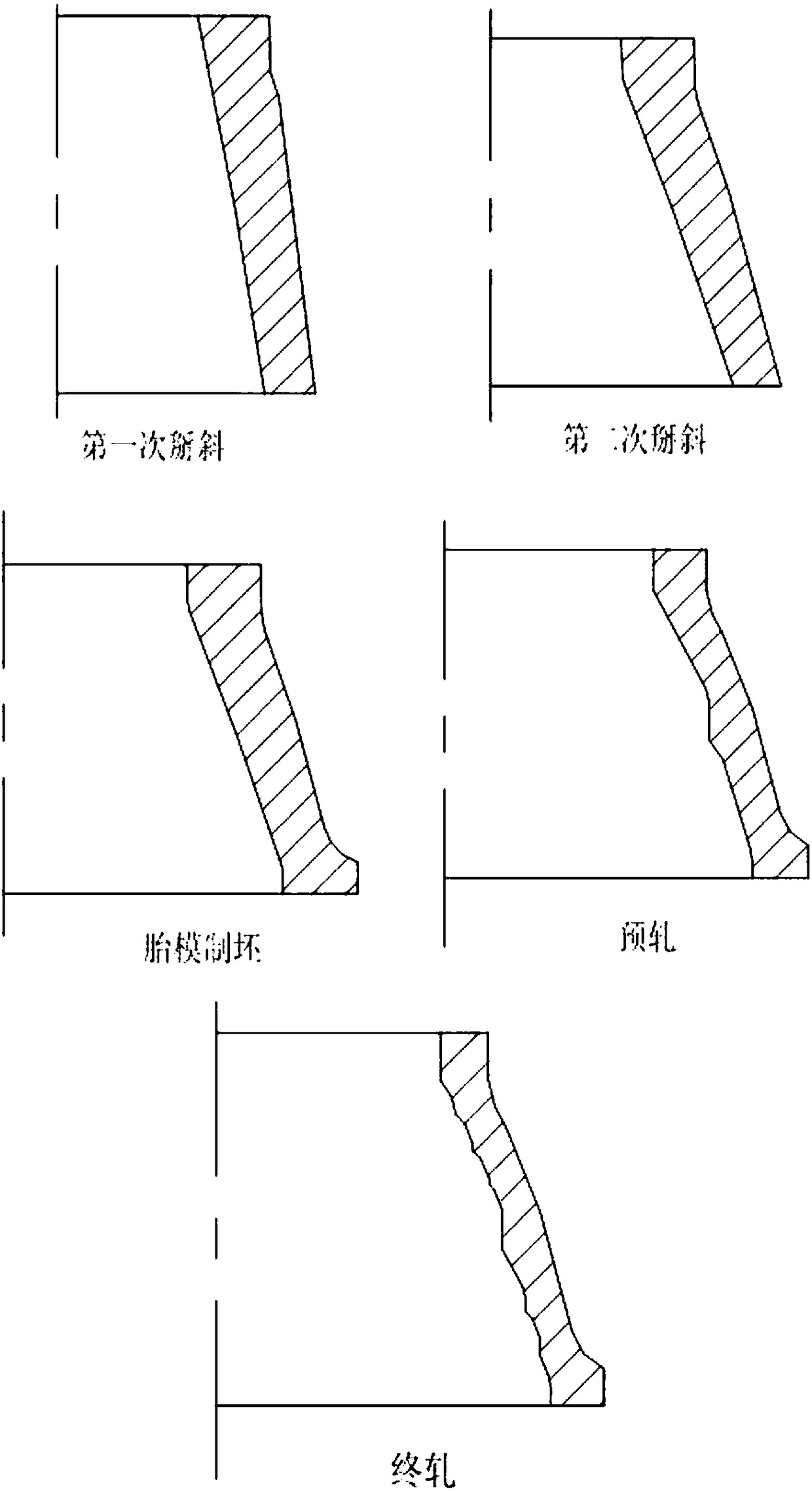

[0032] (4) Use a mold with a trapezoidal cross-section to punch in from the lower part of the ring blank, so that the side wall of the ring blank is inclined outward and becomes a bell shape;

[0033] (5) The ring blank is processed by using the method of tire mold blank making, and molds are set on the inside and outside of the ring blank, and then rolled, so that the shape of the ring blank is close to the shape of the final forging, so that the subsequent rolling is carried out smoothly;

[0034] (6) Us...

Embodiment 2

[0036] (1) Select GH738 rod-shaped raw material, carry out blanking, and then upset the raw material to make the length and thickness appropriate;

[0037] (2) Punch the raw material after upsetting, so that the center is opened;

[0038] (3) Horse-frame reaming is carried out on the raw material after punching, so that the size of the hole is suitable, the volume of the raw material is reasonably distributed, and a rectangular cross-section ring blank is obtained;

[0039] (4) Use a mold with a trapezoidal cross-section to punch in from the lower part of the ring blank, so that the side wall of the ring blank is inclined outward and becomes a bell shape;

[0040] (5) The ring blank is processed by using the method of tire mold blank making, and molds are set on the inside and outside of the ring blank, and then rolled, so that the shape of the ring blank is close to the shape of the final forging, so that the subsequent rolling is carried out smoothly;

[0041] (6) Use as at...

Embodiment 3

[0043] (1) Select the WASPALOY rod-shaped raw material, carry out blanking, and then upset the raw material to make the length and thickness appropriate;

[0044] (2) Punch the raw material after upsetting, so that the center is opened;

[0045] (3) Horse-frame reaming is carried out on the raw material after punching, so that the size of the hole is suitable, the volume of the raw material is reasonably distributed, and a rectangular cross-section ring blank is obtained;

[0046] (4) Use a mold with a trapezoidal cross-section to punch in from the lower part of the ring blank, so that the side wall of the ring blank is inclined outward and becomes a bell shape;

[0047] (5) The ring blank is processed by using the method of tire mold blank making, and molds are set on the inside and outside of the ring blank, and then rolled, so that the shape of the ring blank is close to the shape of the final forging, so that the subsequent rolling is carried out smoothly;

[0048] (6) Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com