Method for preventing great under-pressure distribution change in steel rolling process

A large, rolling-schedule technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as product shape and quality problems, avoid drastic changes, realize re-correction, and avoid performance inconsistencies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

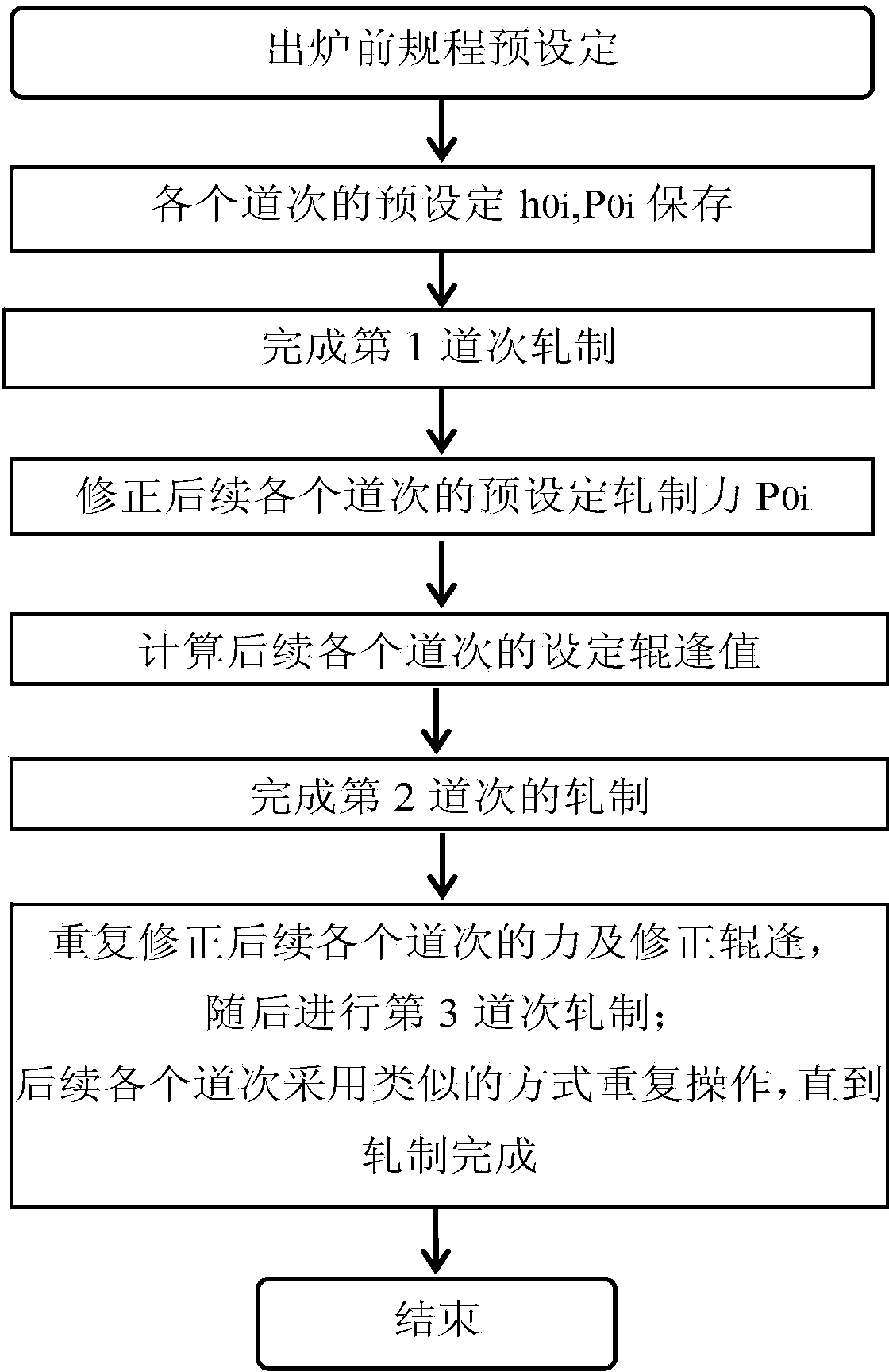

[0020] This embodiment is a method to avoid large changes in the distribution of the rolling process, the process is as follows figure 1 shown, proceed as follows:

[0021] (1) The operator uses the on-site secondary system to pre-calculate the rolling schedule, and records the calculated exit thickness h0i (i=1...n) and rolling force P0i (i=1...n) of each pass in the background (at this time For pre-calculation, it can be understood as pre-calculation of rolling force).

[0022] (2) After the steel is bitten in the first pass of rolling, according to the ratio γ1 of the actual rolling force P1 and the predicted rolling force P01 of the first pass, the rolling force P0i (i=2...n) of each subsequent pass is corrected.

[0023] γ1=P1 / P01; (after the first rolling pass); (1)

[0024] P0i=P0i*γ1(i=2...n) (2)

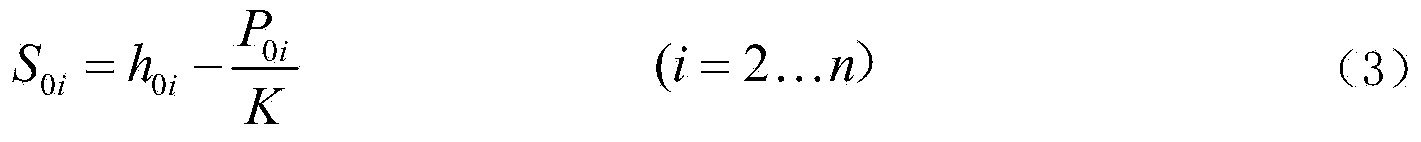

[0025] (3) According to the steel plate outlet thickness h0i (i=2...n) of the i-th pass preset in step (1) and the pre-calculated rolling force P0i (i=2...n) after step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com