Walking beam furnace high-level tapping automatic control method

A walking heating furnace, high-level technology, applied in the direction of heat treatment process control, heat treatment furnace, furnace, etc., can solve problems such as blank drop accident, collision with furnace door retaining wall, slab tilt, etc., to reduce burning loss , Improve production efficiency and stabilize the effect of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

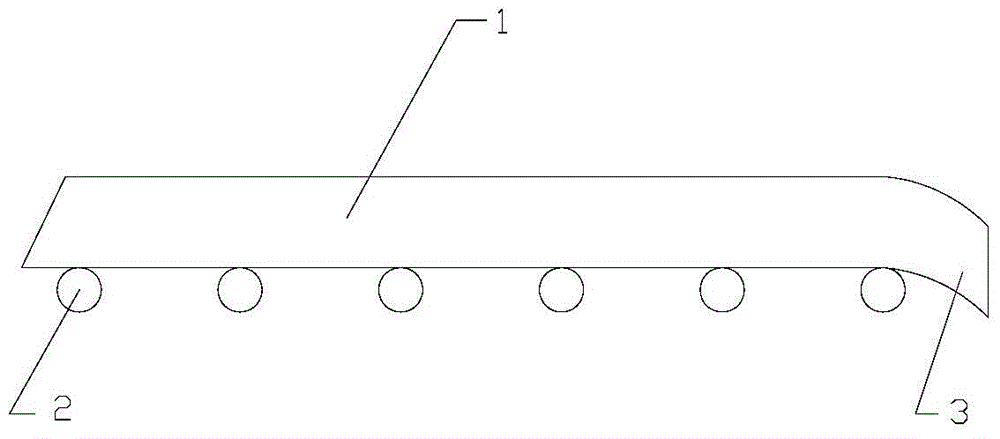

[0023] The length of the slab is 10800mm, and when the length of the slab is set to be 10500-10900mm in the second stage, the steel is tapped at the high position of the walking heating furnace.

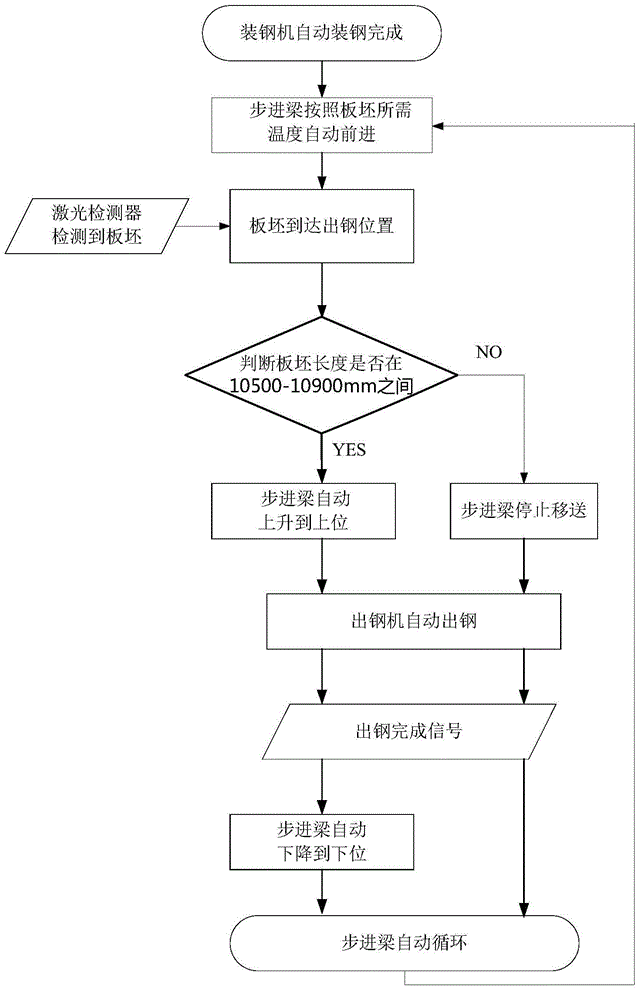

[0024] Such as figure 2 As shown, an automatic control method for high-level tapping of a walking heating furnace. When the laser detector at the discharge end detects that the slab reaches the tapping position, it is compared with the set value of 10500-10900mm. If the step is within the range of 10500-10900mm The beam enters and the steel is tapped at a high position automatically; the specific steps are as follows:

[0025] 1) Furnace loading, the steel loading machine automatically loads steel;

[0026] 2) The walking beam advances automatically according to the required temperature of the slab;

[0027] 3) The laser detector at the discharge end detects that the slab is in place;

[0028] 4) Determine whether the length of the slab is within the range of 10500-10900mm;

[0...

Embodiment 2

[0034] The length of the slab is 10000mm, and when the length of the slab is set to be 10500-10900mm in the second stage, the steel is tapped at the high position of the walking heating furnace.

[0035] Such as figure 2 As shown, an automatic control method for high-level tapping of a walking heating furnace. When the laser detector at the discharge end detects that the slab reaches the tapping position, it is compared with the set value of 10500-10900mm. If the step is within the range of 10500-10900mm The beam enters and the steel is tapped at a high position automatically; the specific steps are as follows:

[0036] 1) Furnace loading, the steel loading machine automatically loads steel;

[0037] 2) The walking beam advances automatically according to the required temperature of the slab;

[0038] 3) The laser detector at the discharge end detects that the slab is in place;

[0039] 4) Determine whether the length of the slab is within the range of 10500-10900mm;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com