Finish rolling stability control method

A technology of stability control and finish rolling, which is applied in the direction of rolling mill control device, rolling force/roll gap control, metal rolling, etc., can solve the problems of poor surface quality, large vibration fluctuation of rolling mill, poor shape, etc., and achieve improvement Stability, ensuring rolling stability, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

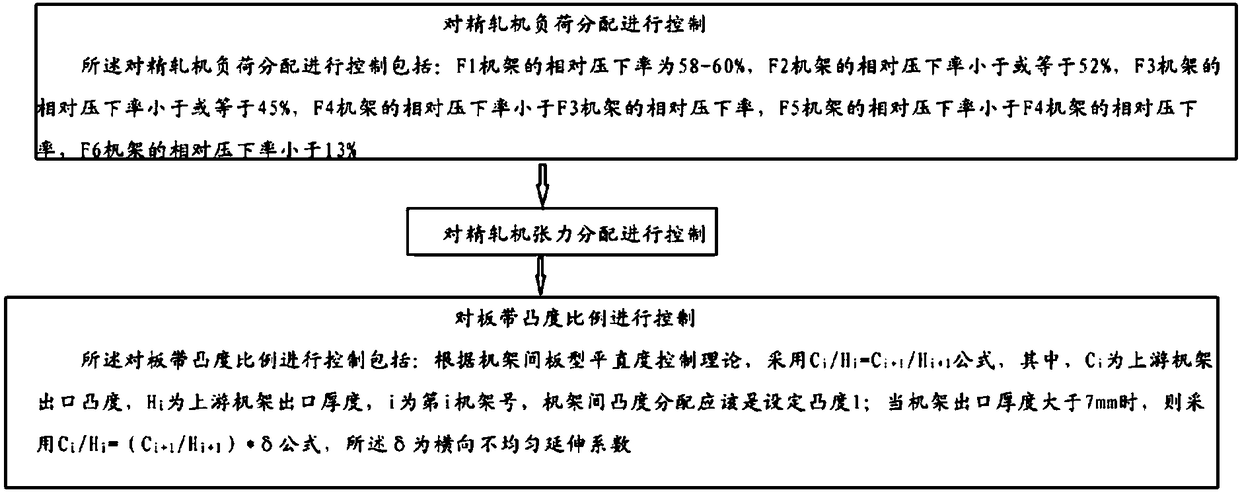

[0015] see figure 1 , a method for controlling stability of finish rolling provided in an embodiment of the present invention includes the following steps:

[0016] Step 1, controlling the load distribution of the finishing mill;

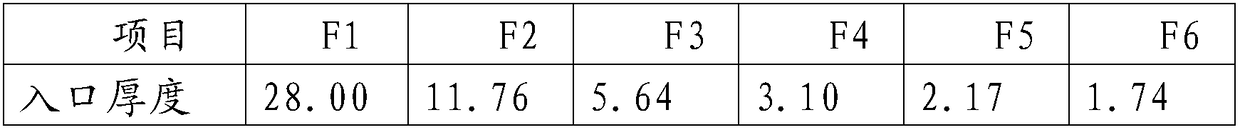

[0017] The control of the load distribution of the finishing mill includes: the thickness of the intermediate billet is less than or equal to 28mm, the relative reduction rate of the F1 frame is 58-60%, the relative reduction rate of the F2 frame is less than or equal to 52%, and the relative reduction rate of the F3 frame is less than or equal to 52%. The reduction rate is less than or equal to 45%, the relative reduction rate of the F4 frame is less than the relative reduction rate of the F3 frame, the relative reduction rate of the F5 frame is less than the relative reduction rate of the F4 frame, and the relative reduction rate of the F6 frame is The reduction rate is less than 13%.

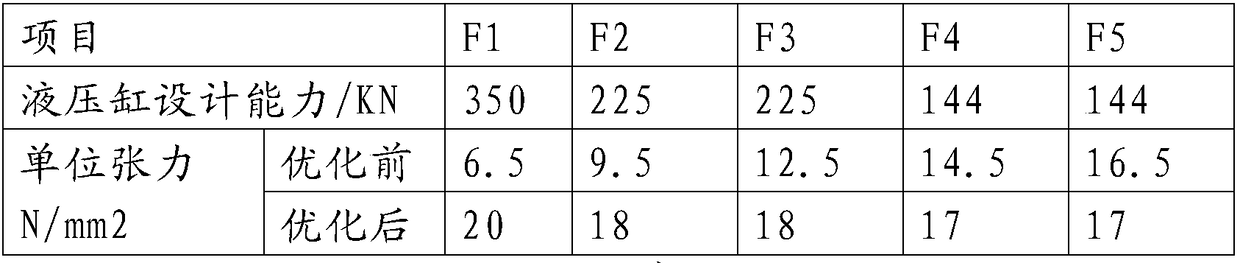

[0018] Step 2, control the tension distribution of the fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com