Patents

Literature

33results about How to "Fully refined grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

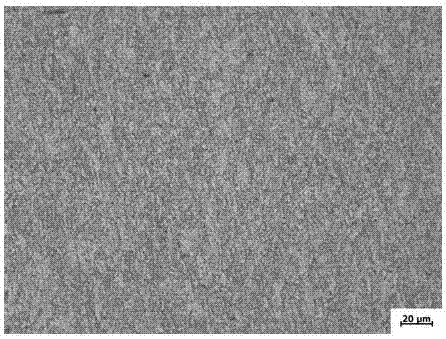

High-toughness non-tempering steel wire rod and preparation method thereof

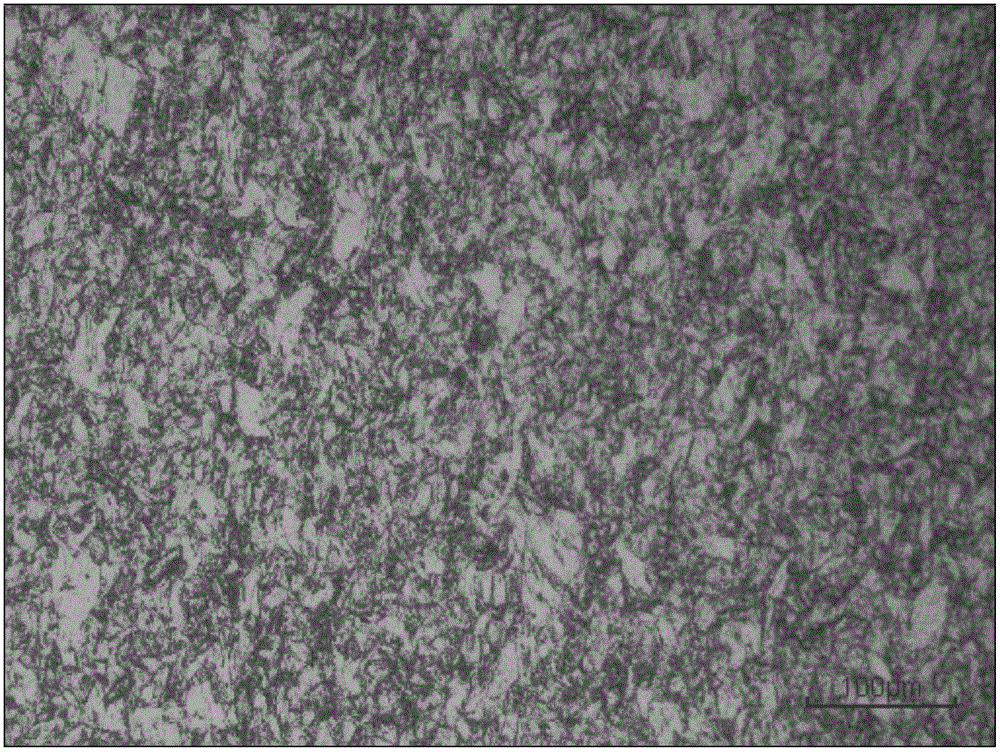

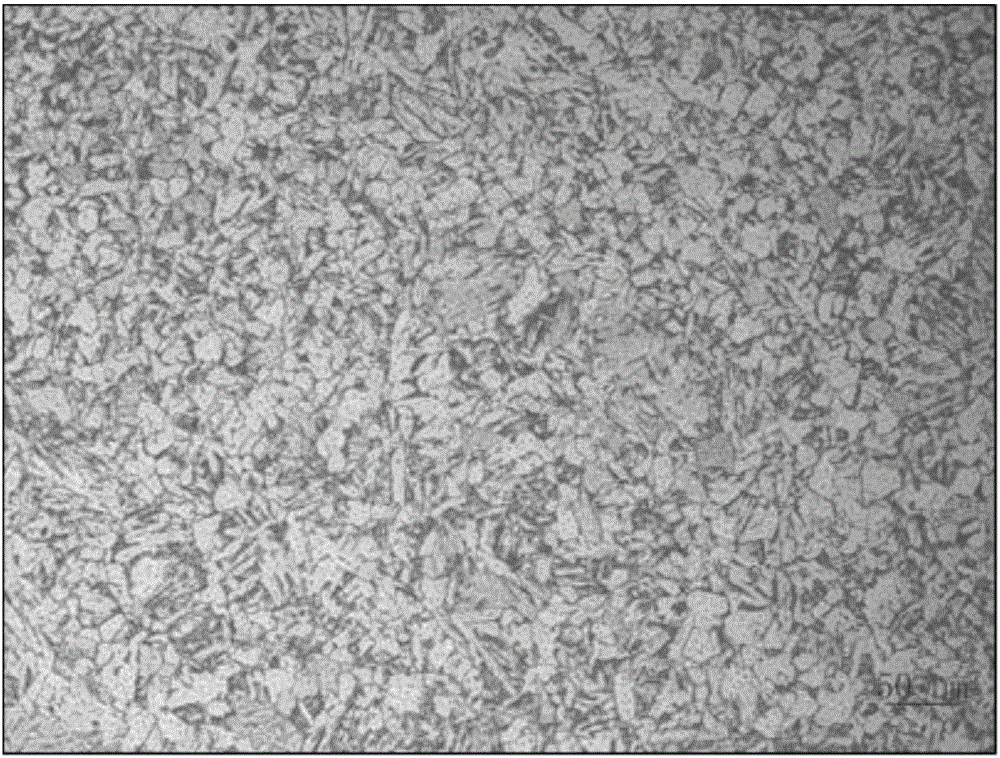

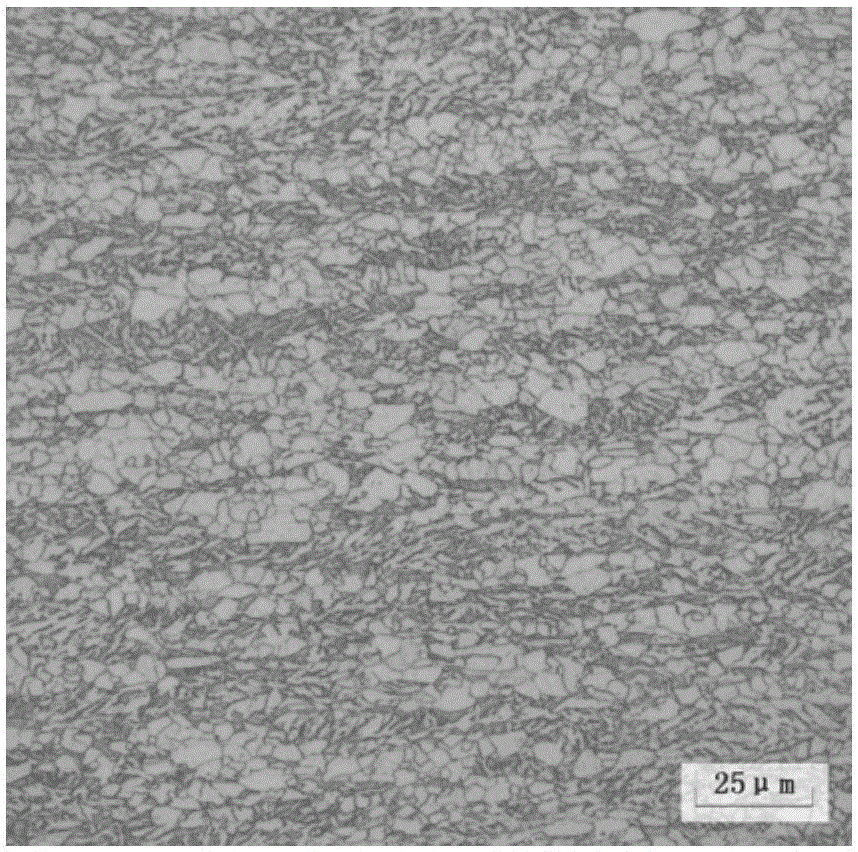

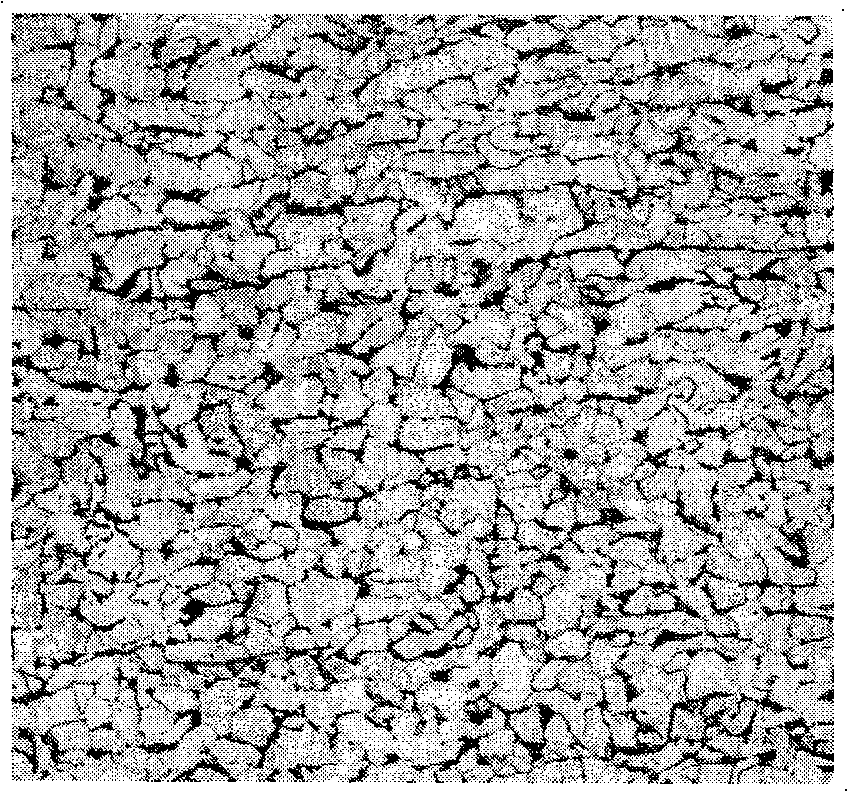

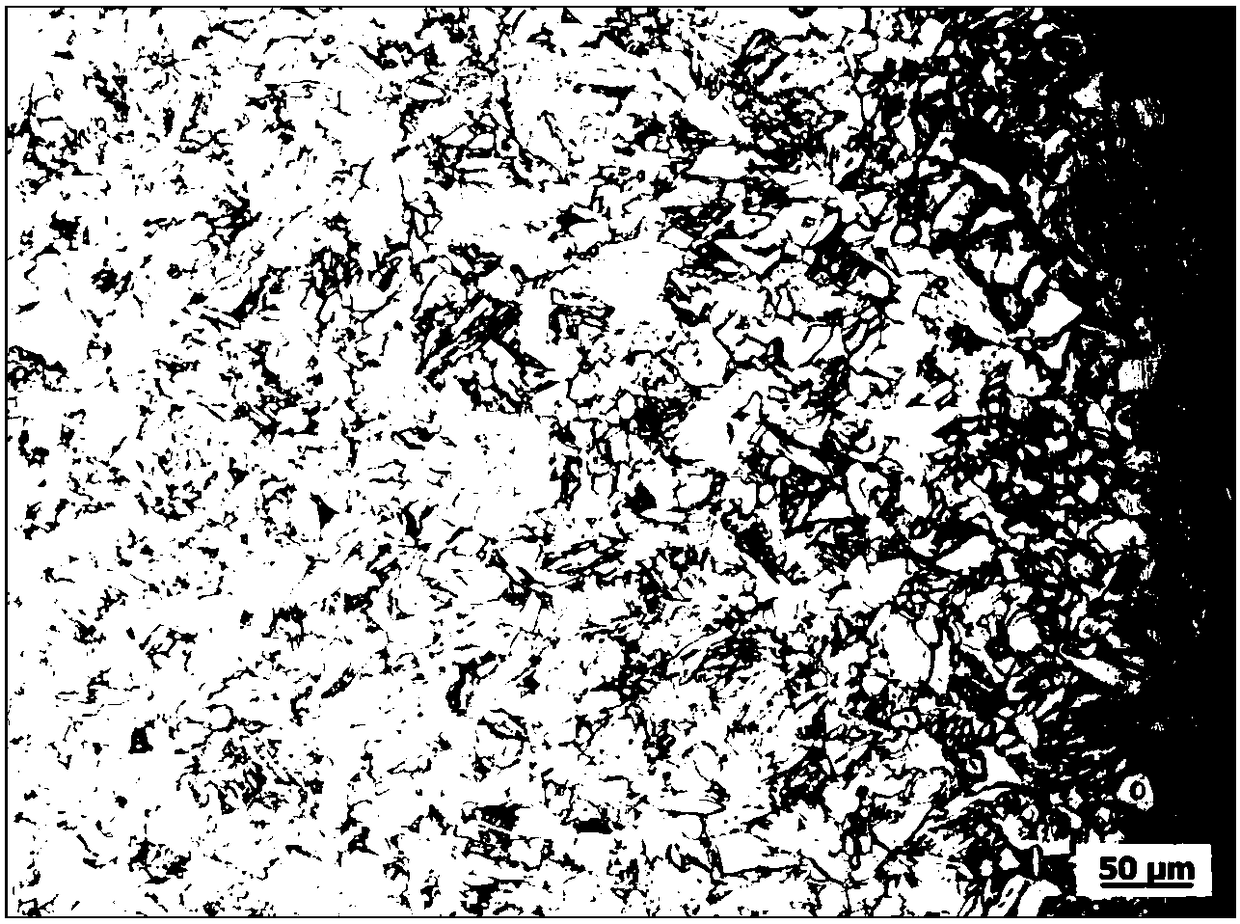

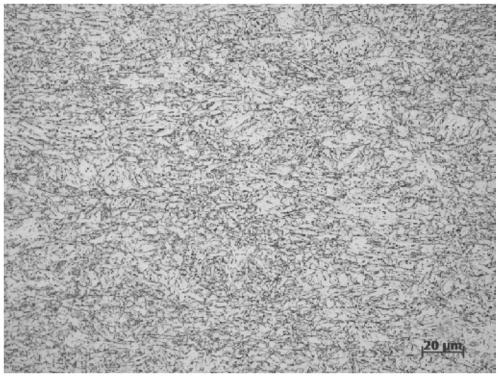

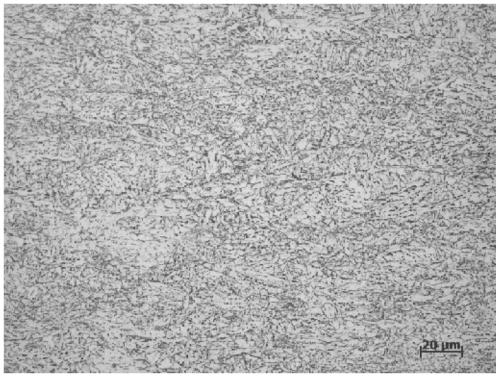

The invention discloses a high-toughness non-tempering steel wire rod and a preparation method thereof. The preparation method comprises processes of heating, rolling and cooling. The steel wire rod comprises the following chemical components in percentages by weight: 0.22-0.31% of C, 1.20-1.55% of Mn, 0.25-0.70% of Si, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.10-0.40% of Cr, 0.05-0.20% of V, 0.010-0.050% of Ti, 0.010-0.025% of N, 0.010-0.050% of Al, less than or equal to 0.25% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.10% of Mo, and the balance of Fe and inevitable impurity elements. The microstructure of the steel wire rod obtained by the method consists of ferrite and pearlite, the grain size is greater than level 7, the tensile strength is 750-850 MPa, reduction of area is greater than or equal to 40%, and impact toughness AkV is greater than or equal to 110J; strength and impact toughness are relatively high, and requirements of downstream customers on production of parts of automotive steering systems can be met; and meanwhile, quenching and tempering are omitted, and production and manufacturing costs are reduced.

Owner:XINGTAI IRON & STEEL

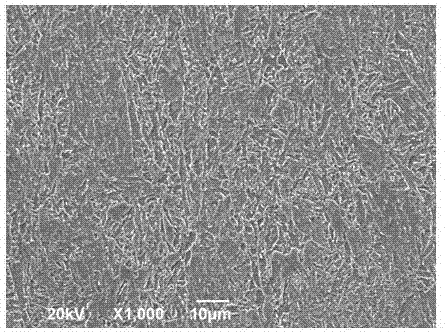

Low-temperature X80HD (High Density) large-deformation pipeline steel with great wall thickness and production method thereof

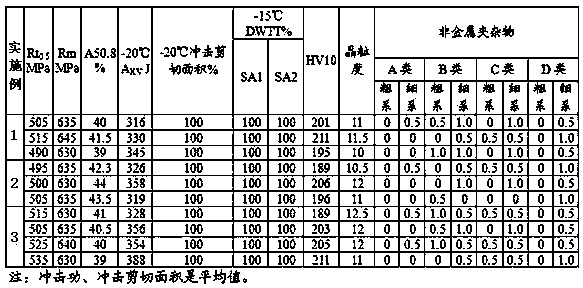

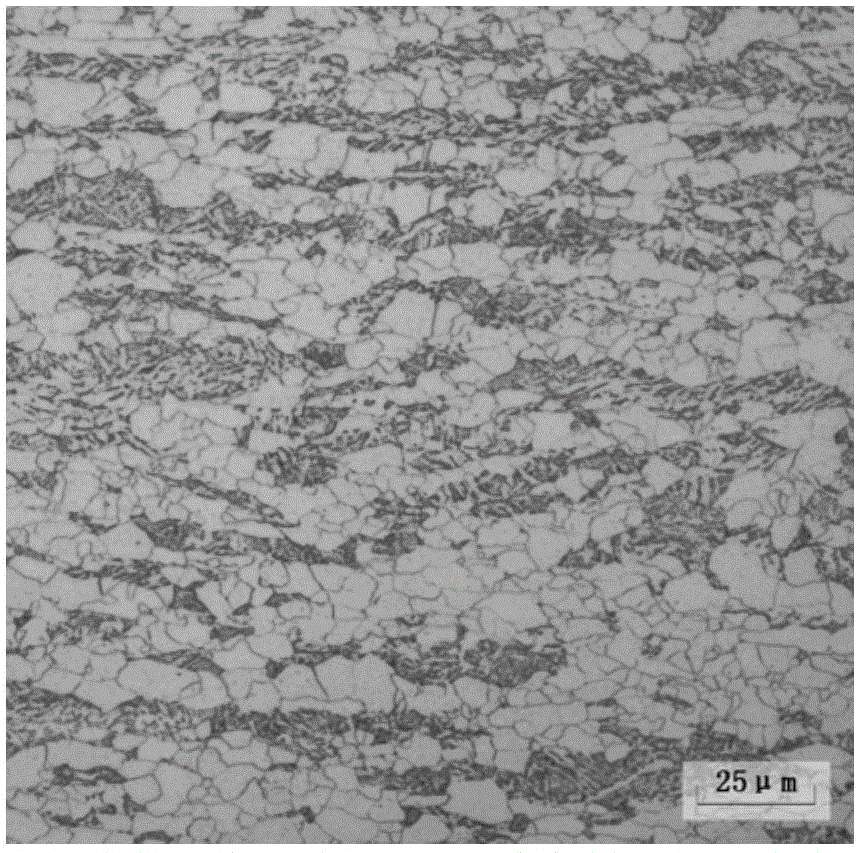

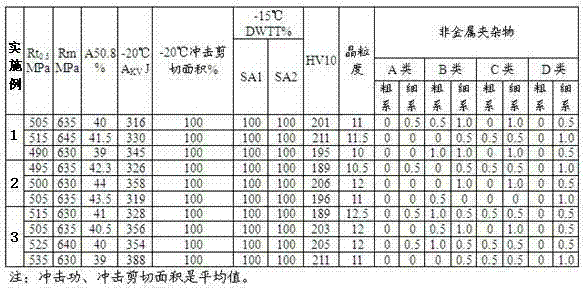

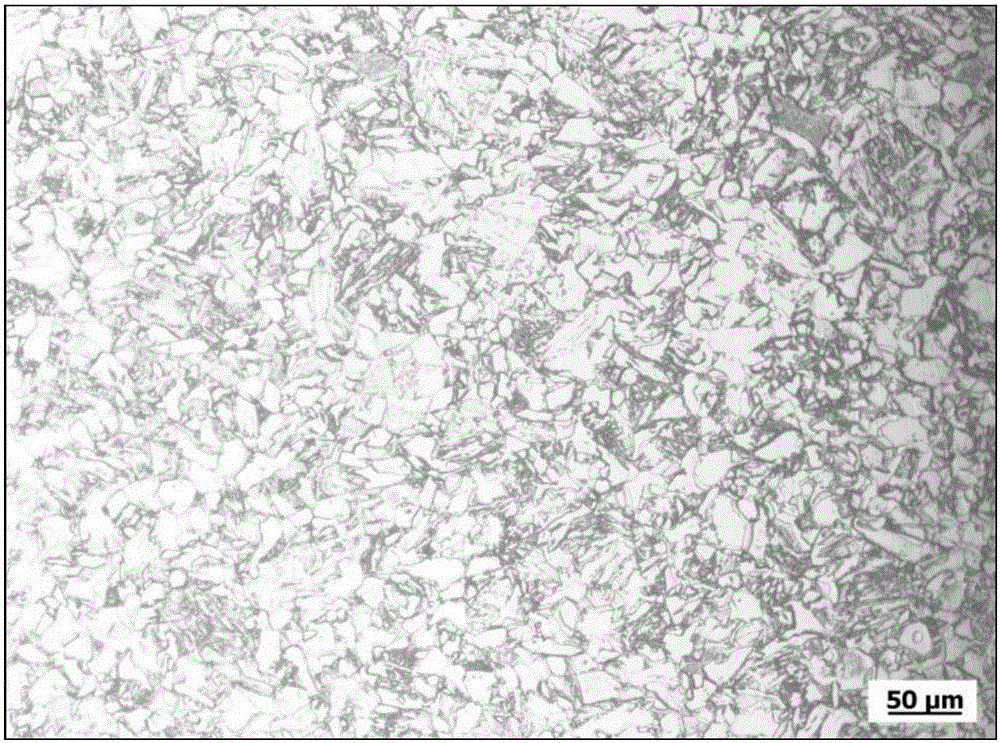

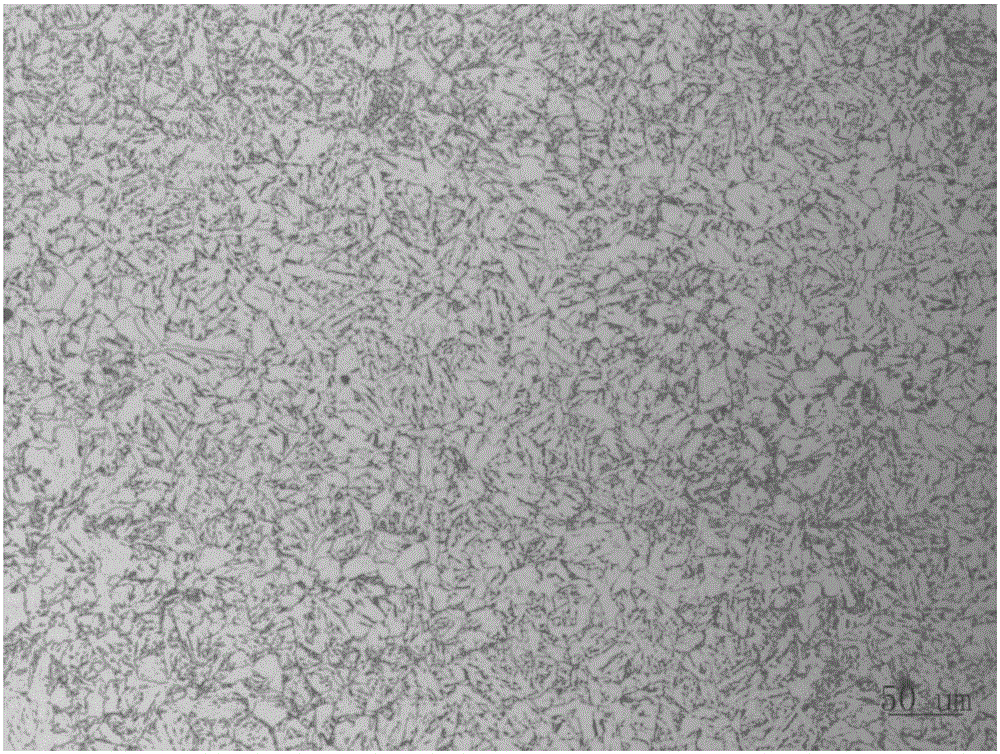

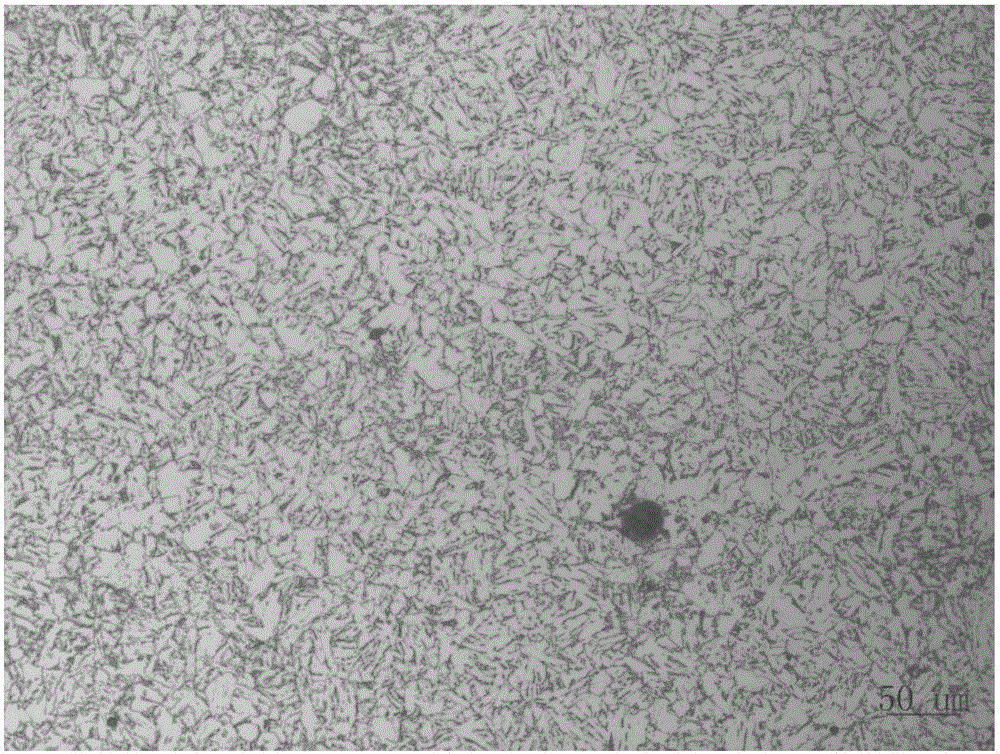

The invention discloses low-temperature X80HD (High Density) large-deformation pipeline steel with great wall thickness and a production method thereof, belonging to the technical field of medium-thickness plate production and longitudinal submerged arc welded tube production. A steel plate comprises the following chemical components in percentage by mass: not less than 0.04% and not greater than 0.09% of C, not greater than 0.35% of Si, not less than 1.5% and not greater than 1.85% of Mn, not greater than 0.012% of P, not greater than 0.004% of S, not less than 0.02% and not greater than 0.05% of Nb, not less than 0.008% and not greater than 0.025% of Ti, not less than 0.10% and not greater than 0.50% of Ni, not less than 0.10% and not greater than 0.45% of Cr, not less than 0.10% and not greater than 0.30% of Cu, not less than 0.10% and not greater than 0.35% of Mo, not less than 0.020% and not greater than 0.070% of Alt, not greater than 0.0005% of B, not greater than 0.0050% of Ca, and the balance of Fe and inevitable impurities. A preparation method of the steel plate comprises the processes such as converter smelting, external refining, continuous casting, heating, controlled rolling, relaxation phase change control and quick cooling; a texture of the rolled steel plate is ferrite, bainite and a little M / A (Martensite / Austenite), wherein ferrite content is 60%-85%, and bainite and M / A content is 15%-40%. The obtained X80HD large-deformation pipeline steel has high strength and toughness, a high work-hardening index, high uniform ductility, a low yield ratio and good deformation resistance.

Owner:SHOUGANG CORPORATION

Thick-specification acid-corrosion-resisting X65 pipeline steel plate and manufacturing method thereof

The invention discloses a thick-specification acid-corrosion-resisting X65 pipeline steel plate and a manufacturing method thereof. The yield strength of the steel plate is level 450MPa, a low-carbon and low-alloy composition design concept is adopted, the molten steel purity is improved through refining, the balled impurity form is processed through calcium, and production is performed through a controlled rolling and controlled cooling technology, so that the steel plate has the excellent HIC (hydrogen induced cracking) and SSCC (sulfide stress corrosion cracking) acid-corrosion resistance, and meanwhile, the steel plate is a product with excellent comprehensive properties such as the high strength, the high anti-crack toughness, the good weldability and the like.

Owner:JIGANG GRP

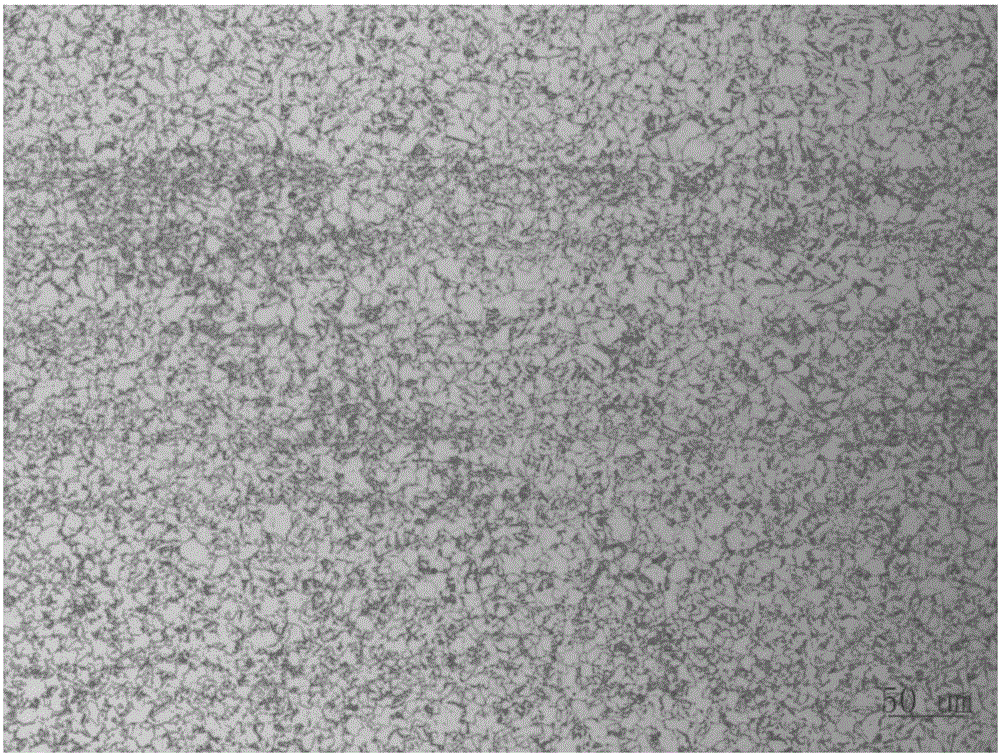

Low-crack sensitive pipe fitting steel plate used under low temperature condition and manufacturing method thereof

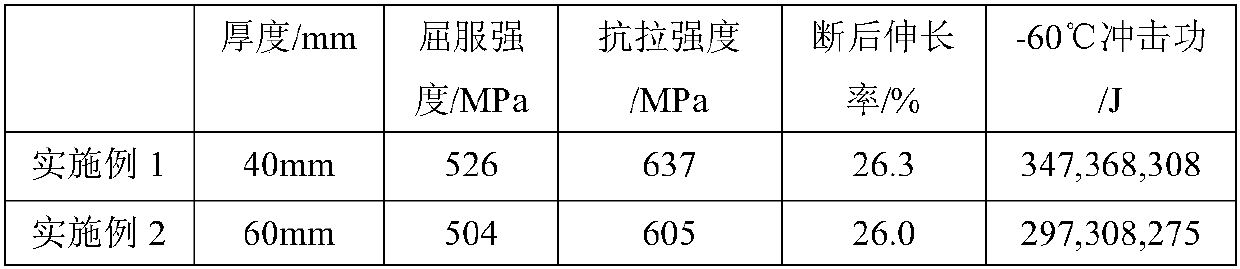

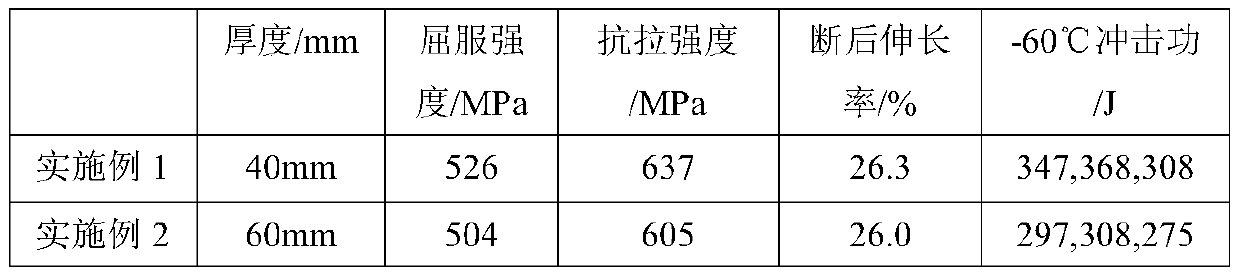

The invention relates to a low-crack sensitive pipe fitting steel plate used under a low temperature condition. The mechanical component (wt%) of the steel plate comprises 0.03-0.08 of C, 0.2-0.35 of Si, 0.9-1.6 of Mn, 0.02-0.04 of Al, 0.01-0.07 of Nb, 0.01-0.07 of V, 0.01-0.02 of Ti, less than or equal to 0.15% of Nb+V+Ti, less than or equal to 0.5 of Cr, less than or equal to 0.5 of Ni, less than or equal to 0.4 of Mo, less than or equal to 0.3 of Cu, less than or equal to 0.18 of Pcm and the balance Fe and inevitable impurities. The method sequentially comprises the steps of KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing, 370-450 mm thickness continuous casting blank continuous casting, continuous casting blank capping slow cooling, continuous casting blank checking and cleaning, casting blank heating, high-pressure water descaling, rolling, cooling, straightening and offline tempering. The steel plate structure is controlled to be a single tempered bainite structure, the grain size is within the range of 3-6 microns, and the steel plate has very excellent low-temperature toughness and can meet the use requirements of X70 pipeline steel underthe low-temperature condition of -60 DEG C.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

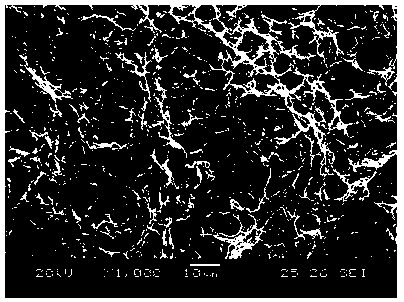

Method for casting Mg-Al-Zn based magnesium alloy with high strength and high tenacity

A method for casting high-strength and-toughness Mg-Al-Zn based Mg-alloy includes such steps as baking auxiliaries, proportional mixing, pre-heating tools, smelting Mg ingot, refining, modifying, laying aside while holding its temp, casting and solidifying. Said Mg-alloy contains Al (3-9 Wt %), Zn (3.5-9), Mn (0.15-1.0), Sb (0-2), and Al (rest).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

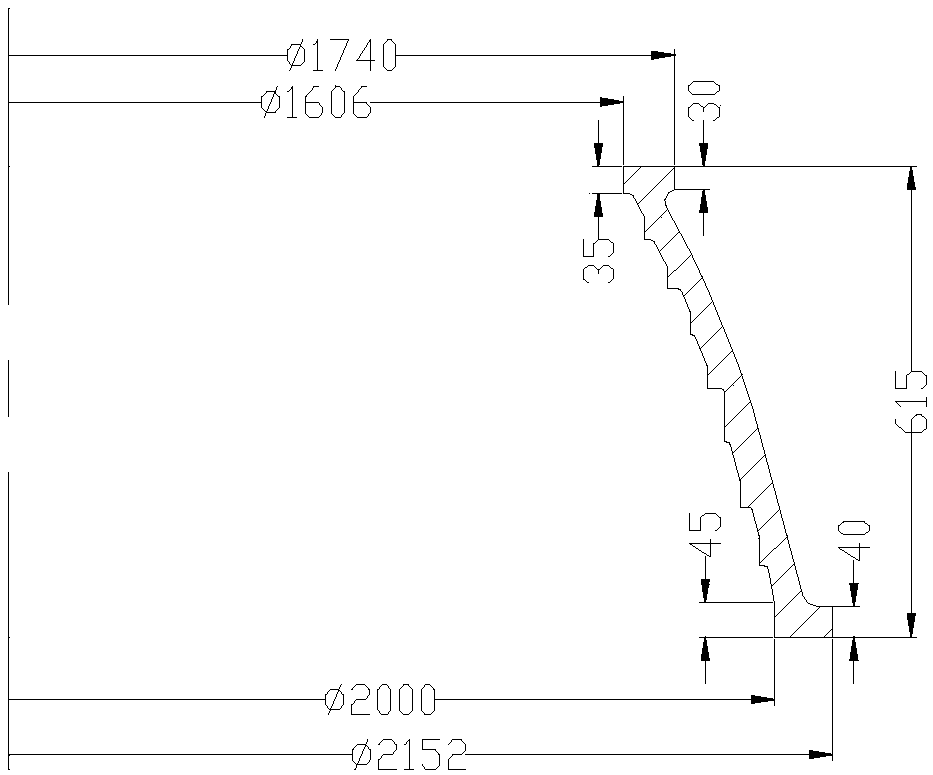

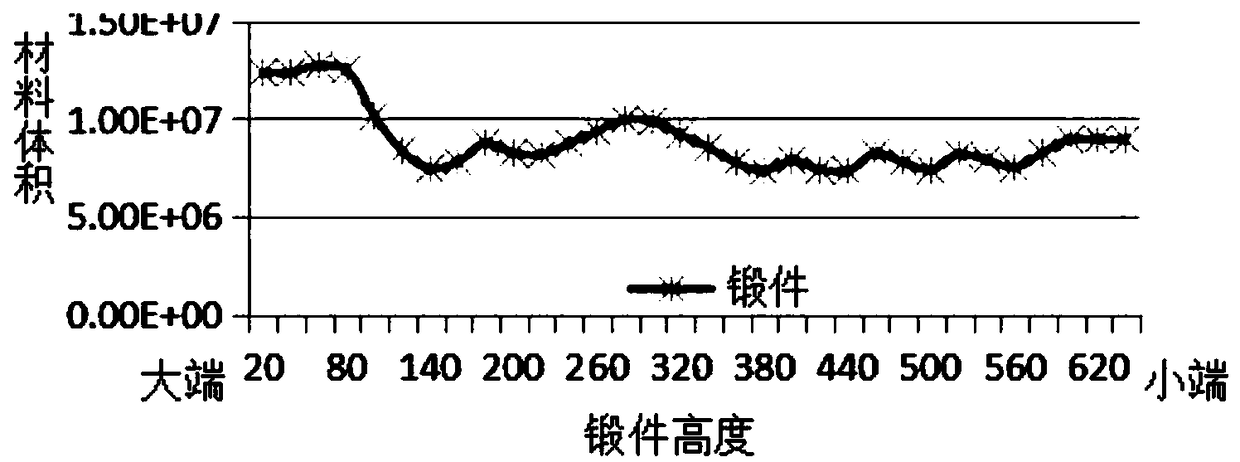

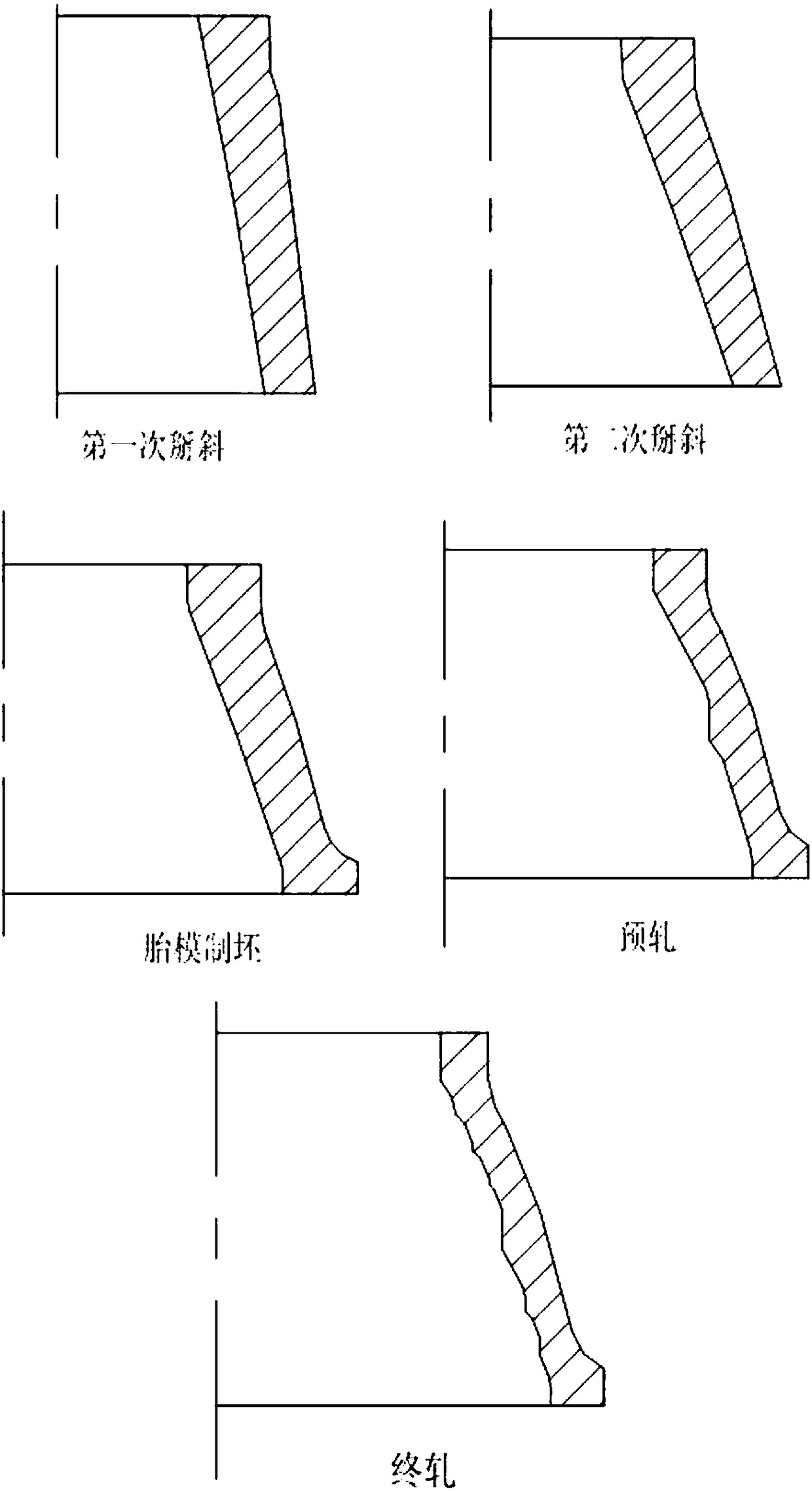

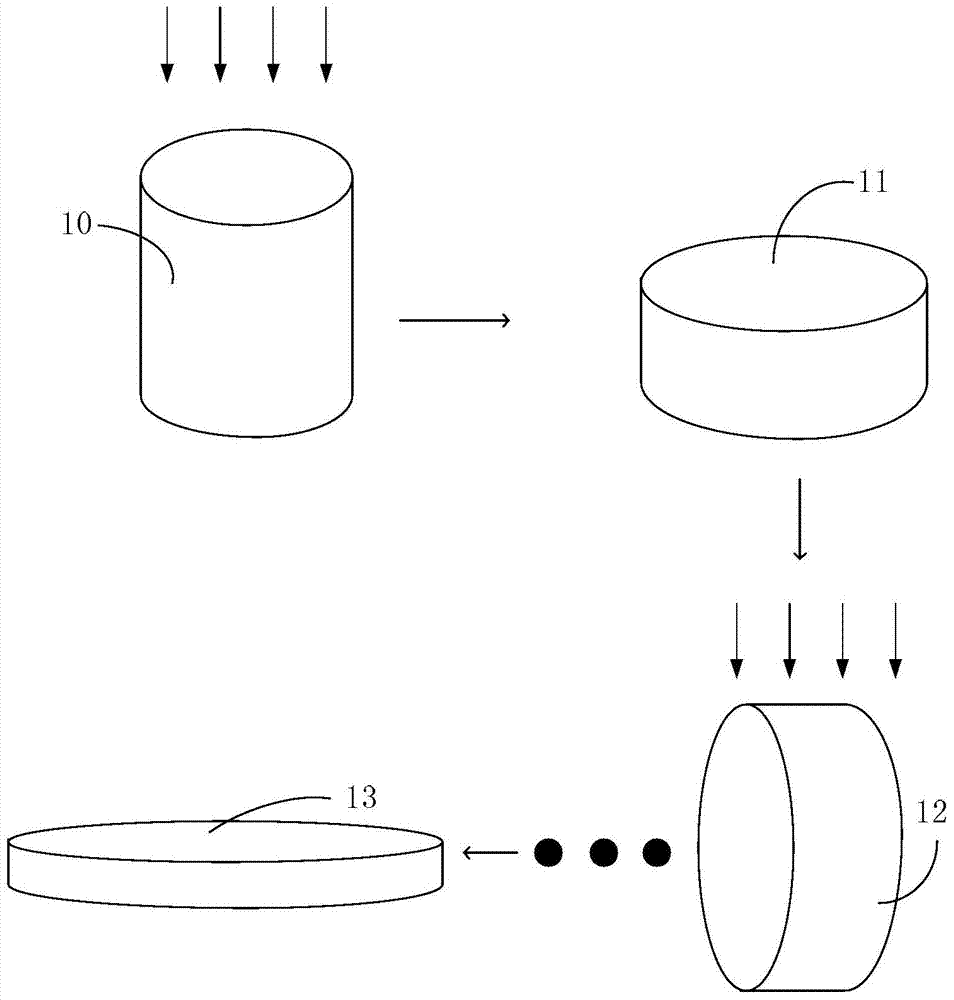

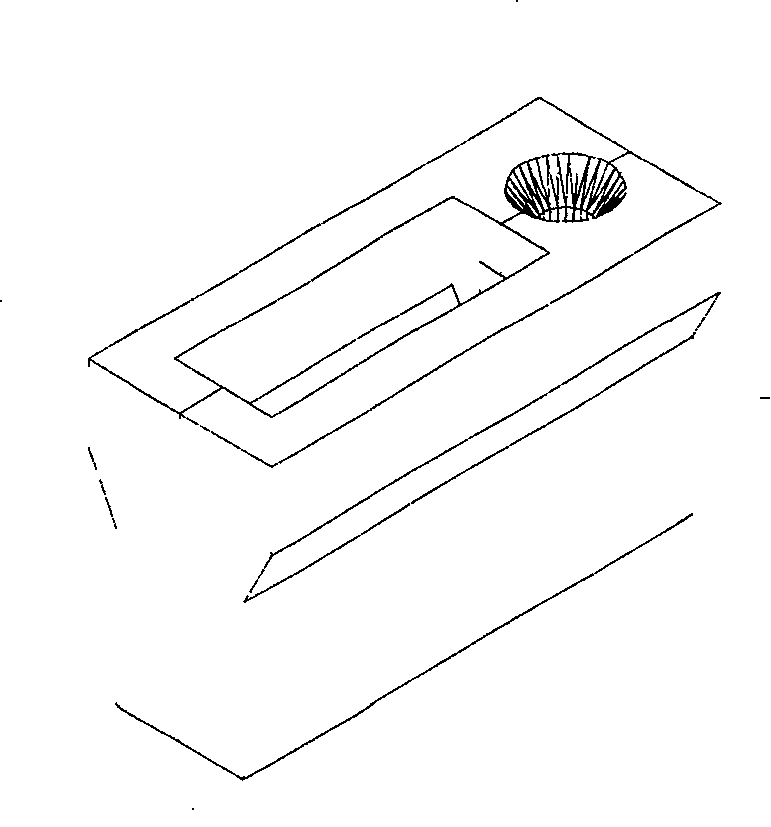

Manufacturing method of multi-step large-diameter casing ring forged piece

ActiveCN108246937AStable rolling processPrevent axial movementMetal rollingAbnormal shapedCrystallite

The invention relates to the technical field of special-shaped forged piece manufacturing technologies, in particular to a multi-step large-diameter casing ring forged piece and a manufacturing methodthereof. According to the multi-step large-diameter casing ring forged piece and the manufacturing method thereof, the casing ring forged piece is manufactured through processes of discharging, upsetting, punching, mandrel supporter reaming, inclining through breaking-off, forming die blanking, pre-rolling and rolling forming; the size distribution characteristic of a blank in the height direction meets the final forming requirements through upsetting, punching, mandrel supporter reaming, and forming die blanking; the large end of the blank is made to face downwards through a special structure, and rolling of the blank is ensured to be stable by loading from the position above a core roller die; the blank makes tight contact with the die by adjusting the size of the ring billet, and axialmoving of the blank is prevented; grains are refined by using high-temperature large deformation at the earlier stage, and the grains are kept to be unchanged by adopting low-temperature small deformation in the follow-up special-shaped blanking and forming process, so that the grains are fully refined; and finally, according to the manufacturing method of the multi-step large-diameter casing ring forged piece, rolling is stable, and the rolling precision of the forged piece can be well ensured.

Owner:GUIZHOU AVIATION TECHN DEV

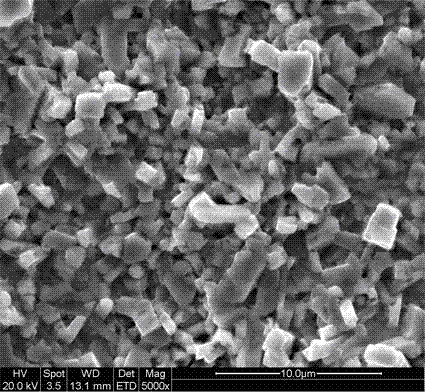

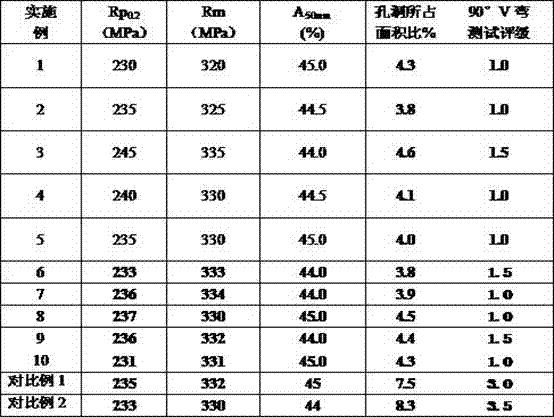

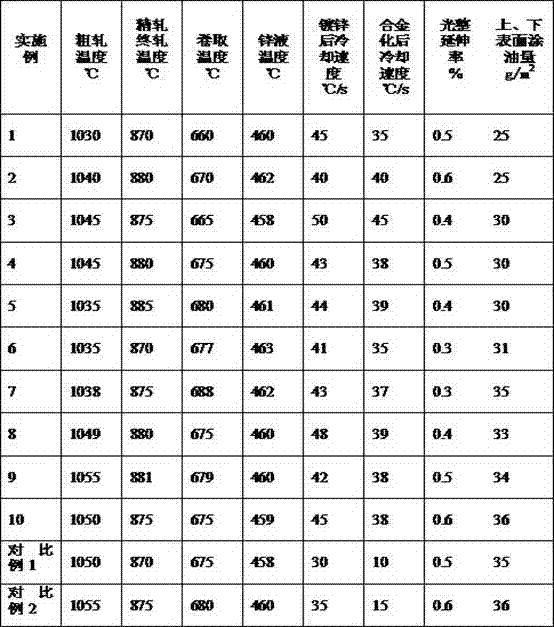

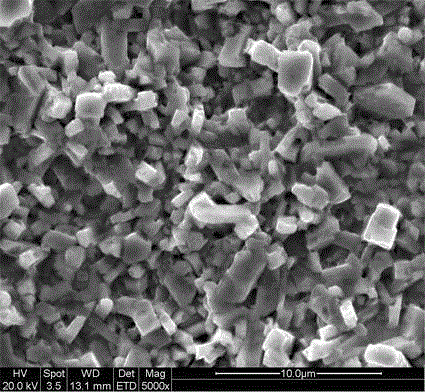

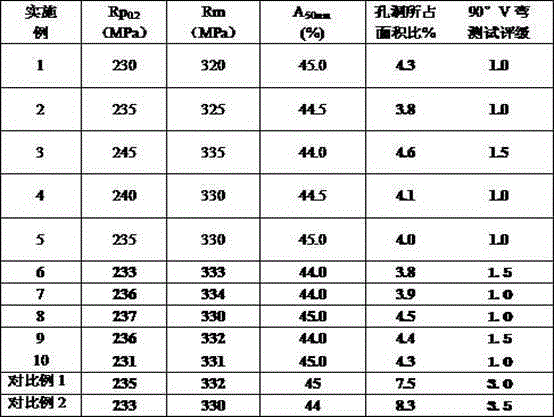

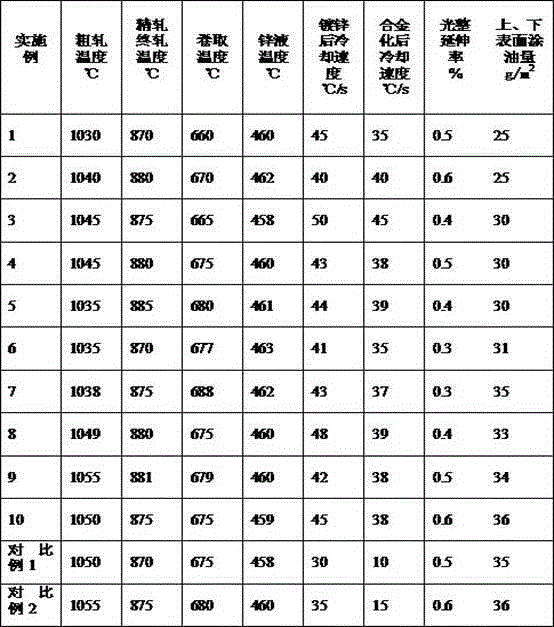

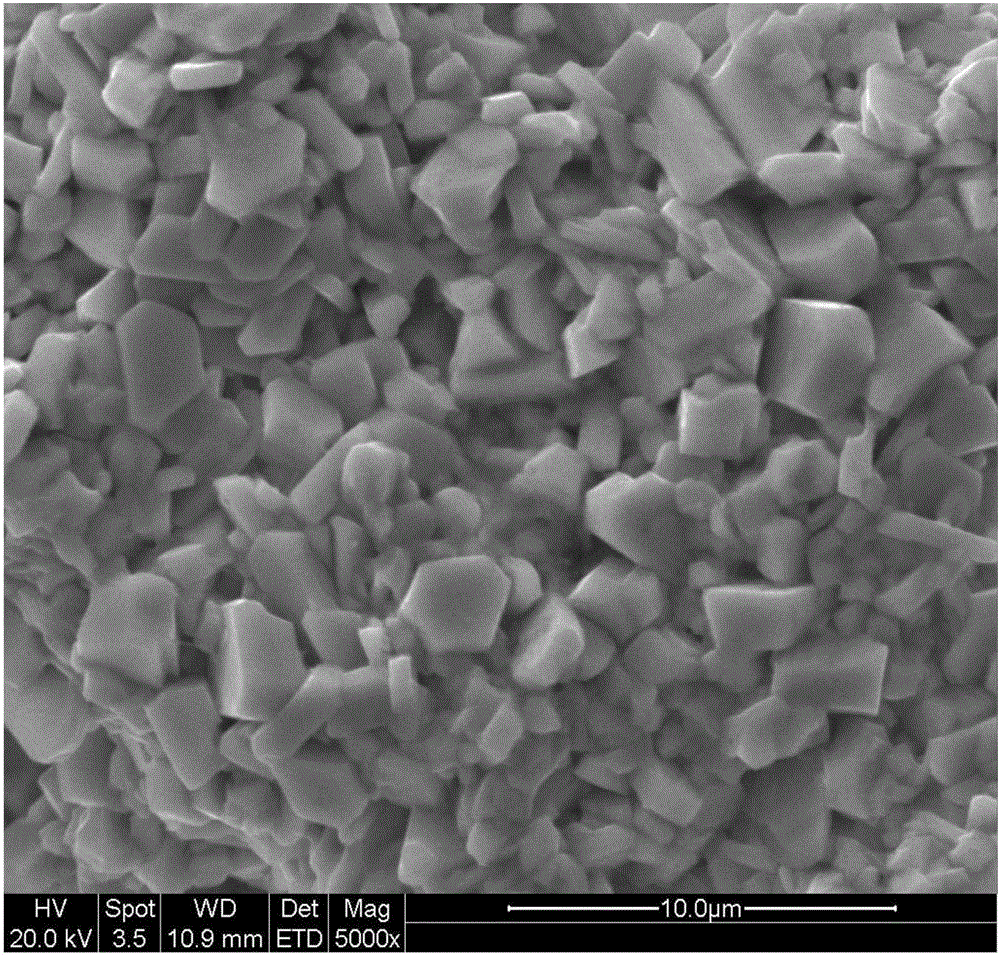

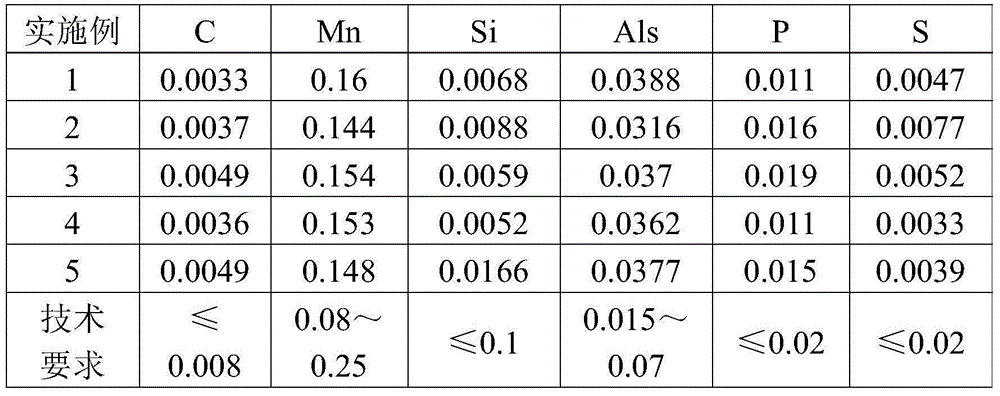

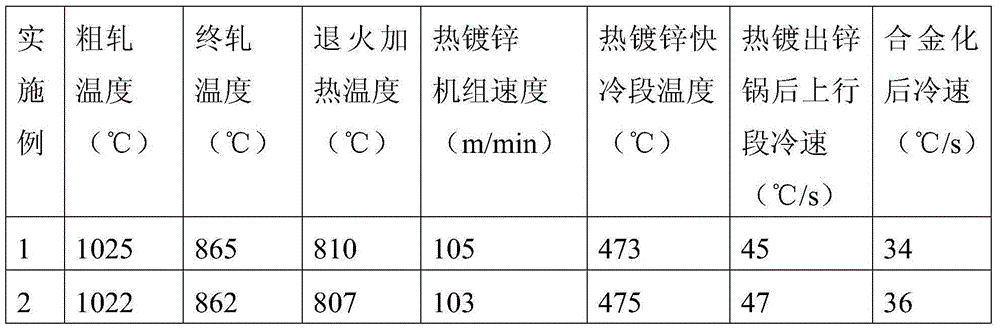

A production method of iron-zinc alloy coated steel plate with yield strength ≥ 220mpa

ActiveCN105274301BFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

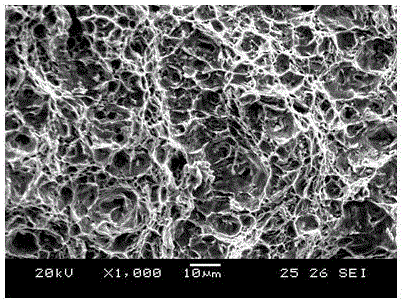

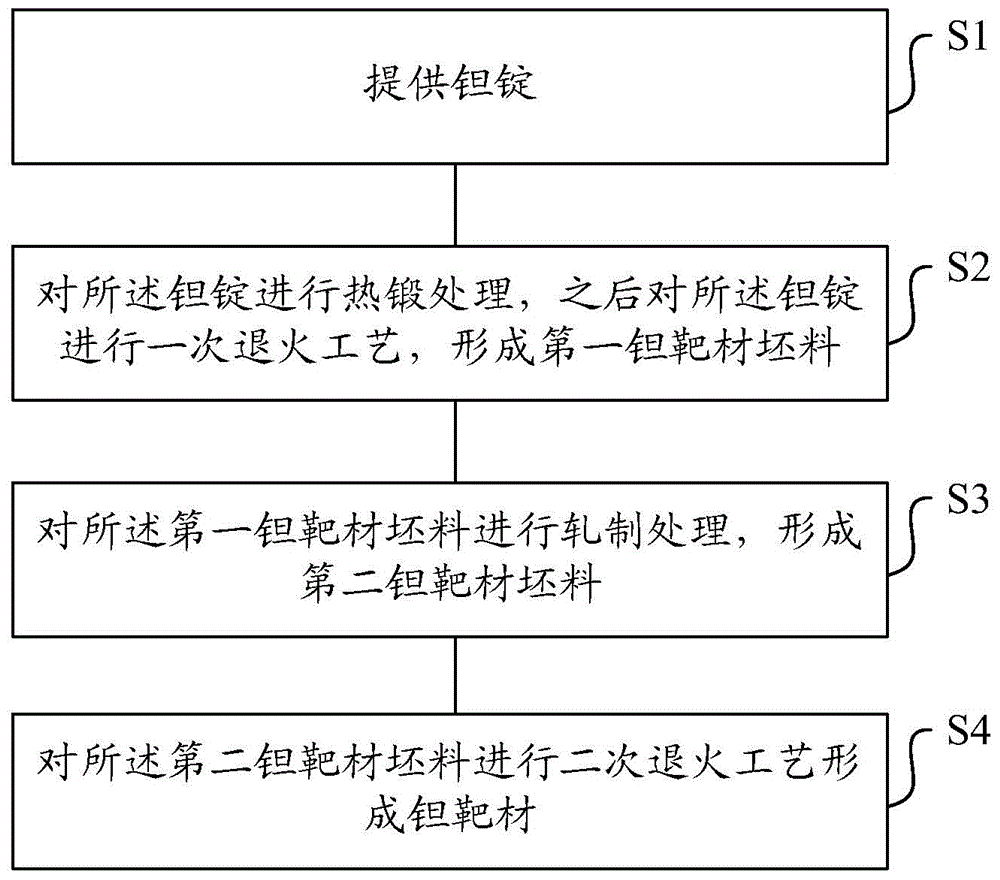

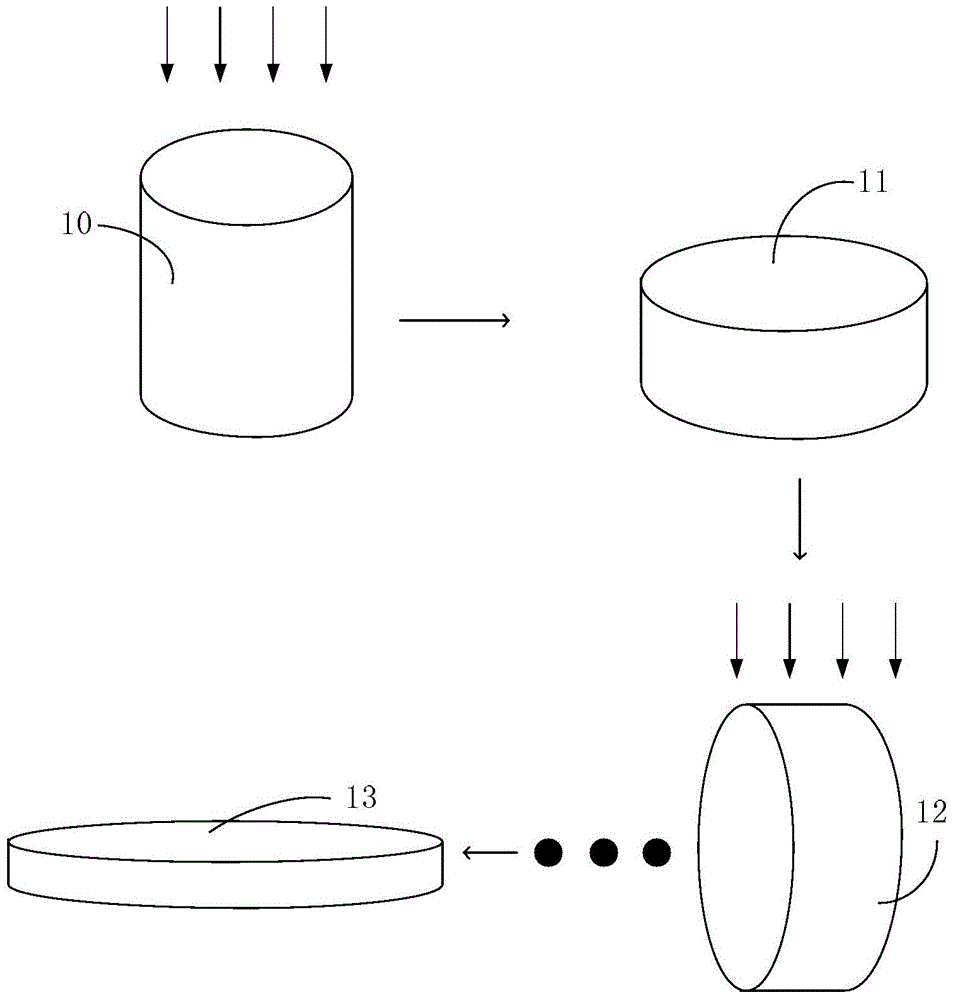

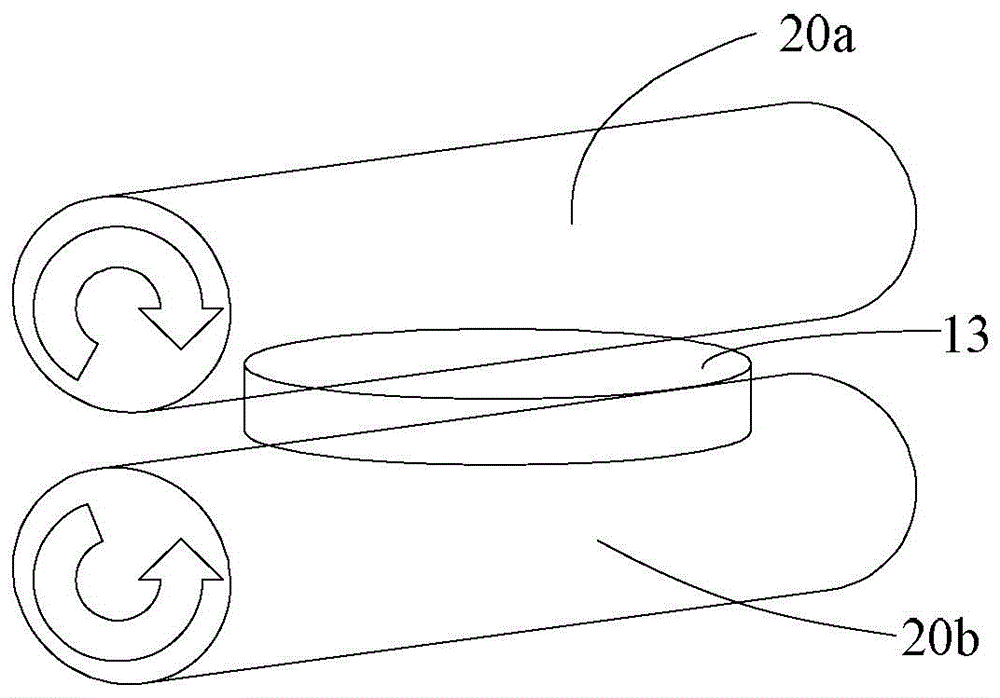

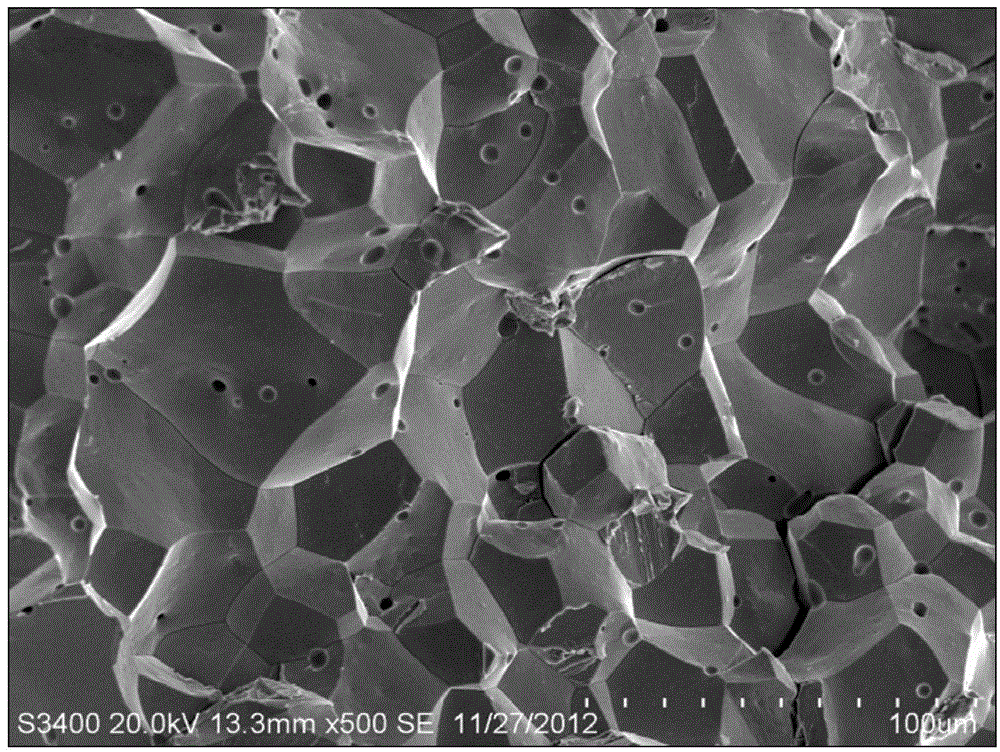

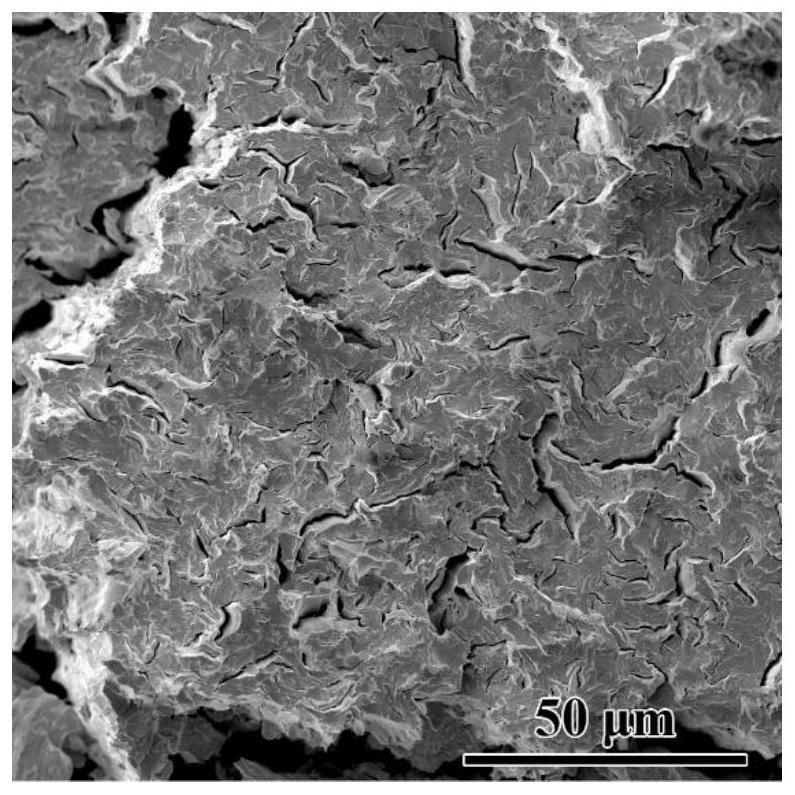

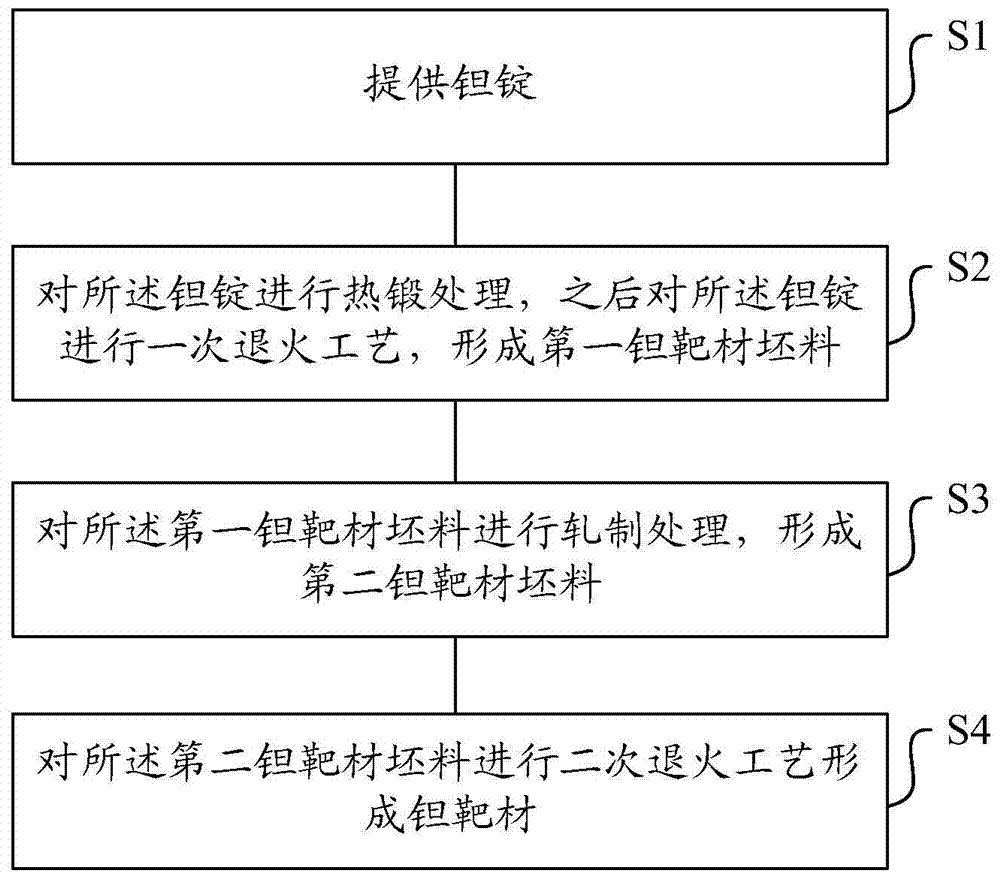

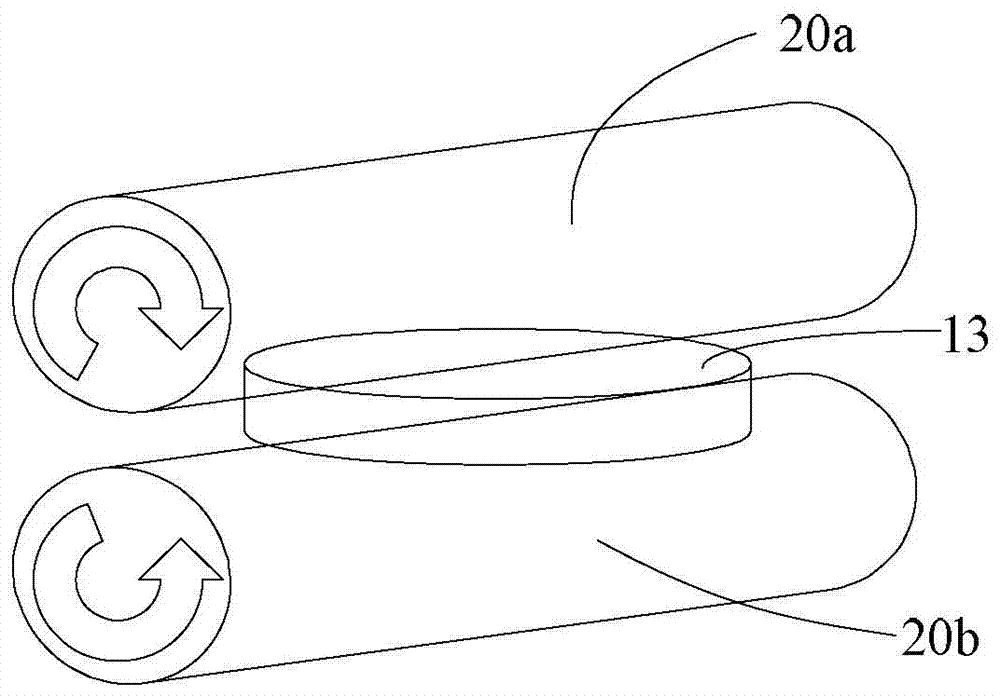

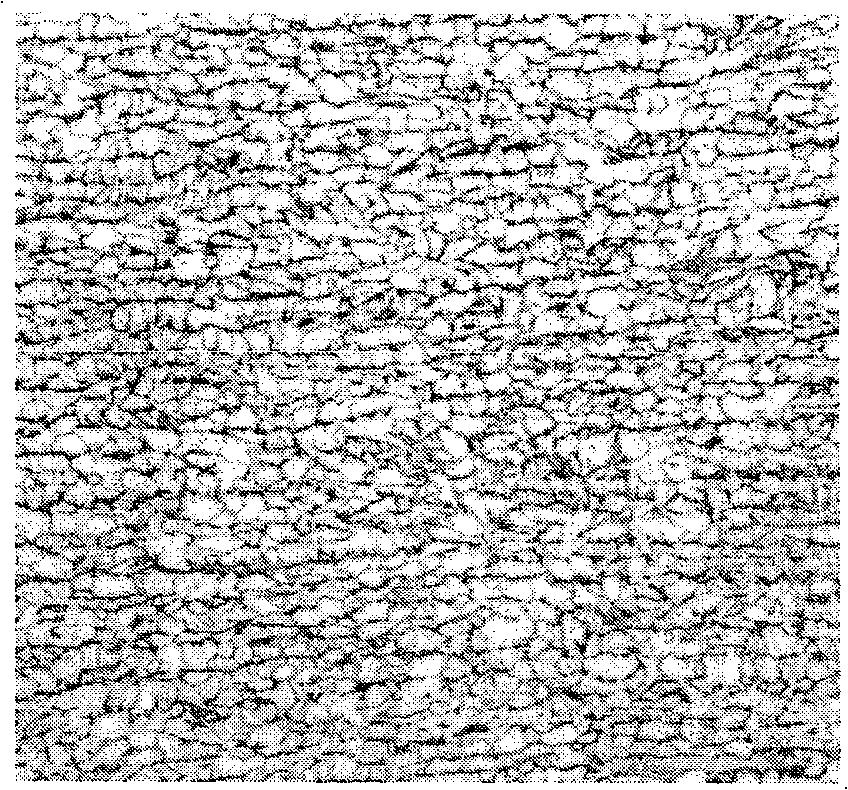

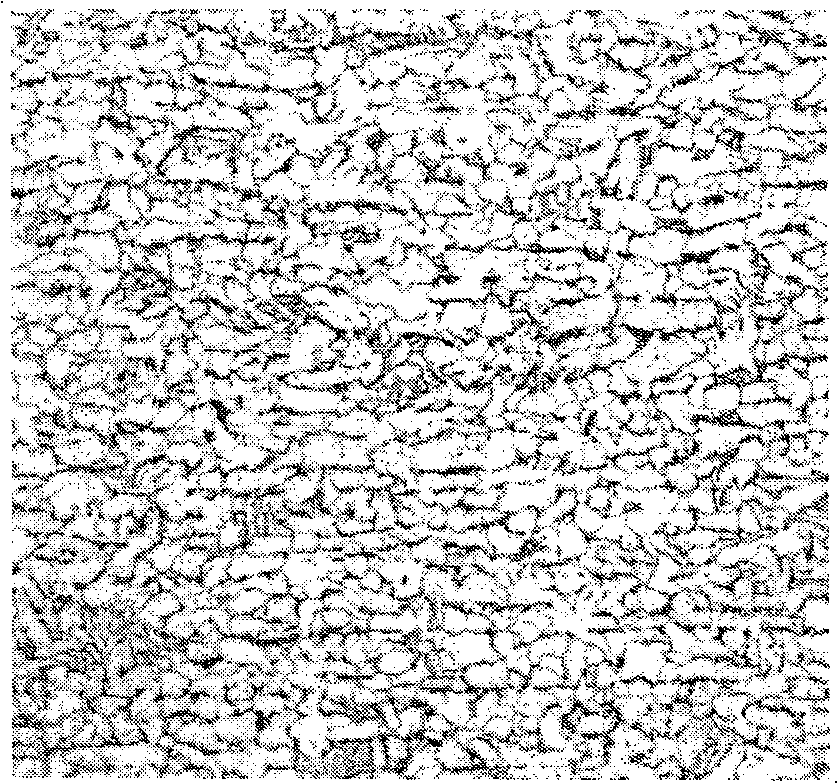

Method for manufacturing tantalum target material

ActiveCN104419901ASimple internal structureStress reliefVacuum evaporation coatingSputtering coatingIngotTantalum

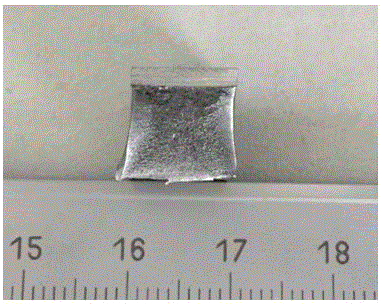

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Production method for low-yield-ratio high-strength medium-thickness steel plate

The invention discloses a production method of a low-yield ratio high-strength medium-thick steel plate. The chemical composition mass percentage of the steel is C=0.06-0.09, Si=0.2-0.4, Mn=1.3-1.8, Al=0.02-0.05, Cr=0.30~0.40, Nb≤0.05, Ti=0.015~0.025, Mo≤0.30, B≤0.0010, P<0.02, S<0.005, CEQ<0.45, Pcm<0.22, the process steps include rolling and heat treatment. The method of the present invention is used for rolling low-yield ratio high-strength medium-thick steel plates, especially high-strength steel medium-thick plates with a yield strength of 550 MPa for construction machinery, and finally obtains tempered strips through quenching and tempering process or TMCP+tempering process. The plate with bainite structure has a yield strength of more than 550MPa, a tensile strength of more than 680MPa, a yield ratio of less than 0.9, an elongation after fracture of more than 17%, and a full-thickness V-notch Charpy impact energy of more than 140J at -20°C. . And excellent performance after welding.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Tubular molybdenum target material preparation method

ActiveCN103978345ANo obvious sintering deformation phenomenonUniform and good surface qualityVacuum evaporation coatingSputtering coatingMaterials preparationMetal

The invention provides a tubular molybdenum target material preparation method. The method comprises the following steps: 1, molybdenum powder is compressed into a molybdenum tube blank; 2, a two-stage sintering process is adopted, and the molybdenum tube blank is subjected to sintering processing; 3, the molybdenum tube blank which is subjected to sintering processing is heated, and then is extruded and processed, and a tubular molybdenum target material is obtained after turning processing. According to the preparation method, cuttings are fewer, the production efficiency is high, the length of a molybdenum tube is adjustable, and the cost advantage is obvious; the production technological process is short, the metal loss is little, the comprehensive finished product rate is high, and the tubular molybdenum target material used for sputtering is conveniently, rapidly and largely produced.

Owner:JINDUICHENG MOLYBDENUM CO LTD

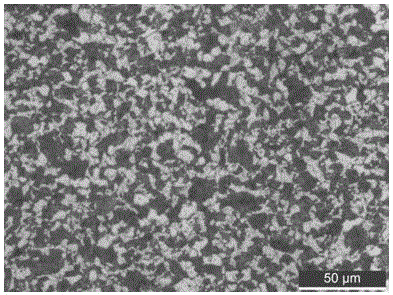

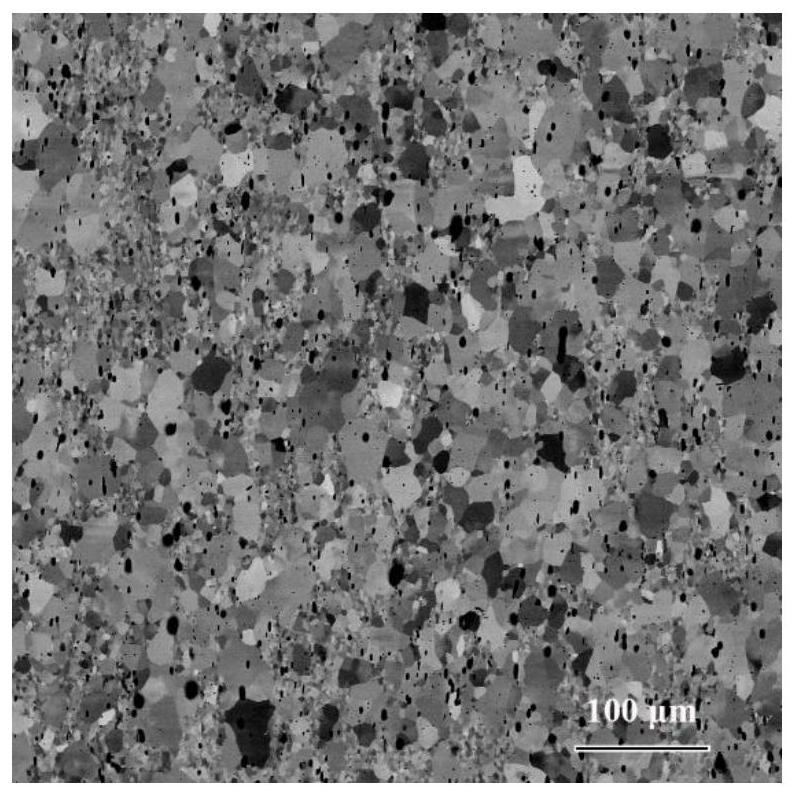

Tungsten (molybdenum) alloy with double-size grains, preparation method of tungsten (molybdenum) alloy and stirring tool for friction stir welding

ActiveCN113560565AHigh strengthImprove tensile plasticityIncreasing energy efficiencyNon-electric welding apparatusRheniumMetallic materials

The invention discloses a tungsten (molybdenum) alloy with double-size grains, a preparation method of the tungsten (molybdenum) alloy and a stirring tool for friction stir welding, and relates to the field of metal materials. The tungsten (molybdenum) alloy with the double-size grains is an alloy obtained by continuously preparing solid-solution-state powder prepared from tungsten (molybdenum) rhenium alloy powder, titanium powder and carbon powder; and in the tungsten (molybdenum) alloy with the double-size grains, the range of the small grains is controlled to range from 1.0 micrometer to 5.0 micrometers, the volume fraction of the small grains ranges from 40% to 70%, the size of the large grains is controlled to range from 20 micrometers to 100 micrometers, the ratio of the large grains ranges from 30% to 40%, and the average size of second-phase particles ranges from 20 nm to 50 nm. The tungsten (molybdenum) alloy with the double-size grains has the grains of two sizes, the high strength of the tungsten (molybdenum) alloy can be guaranteed through the thin and small equiaxed grains, channels can be provided for dislocation through the thick and large grains, the tungsten (molybdenum) alloy has the high tensile plasticity and toughness, and therefore the tungsten (molybdenum) alloy has the advantages of being high in strength and toughness at the same time.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

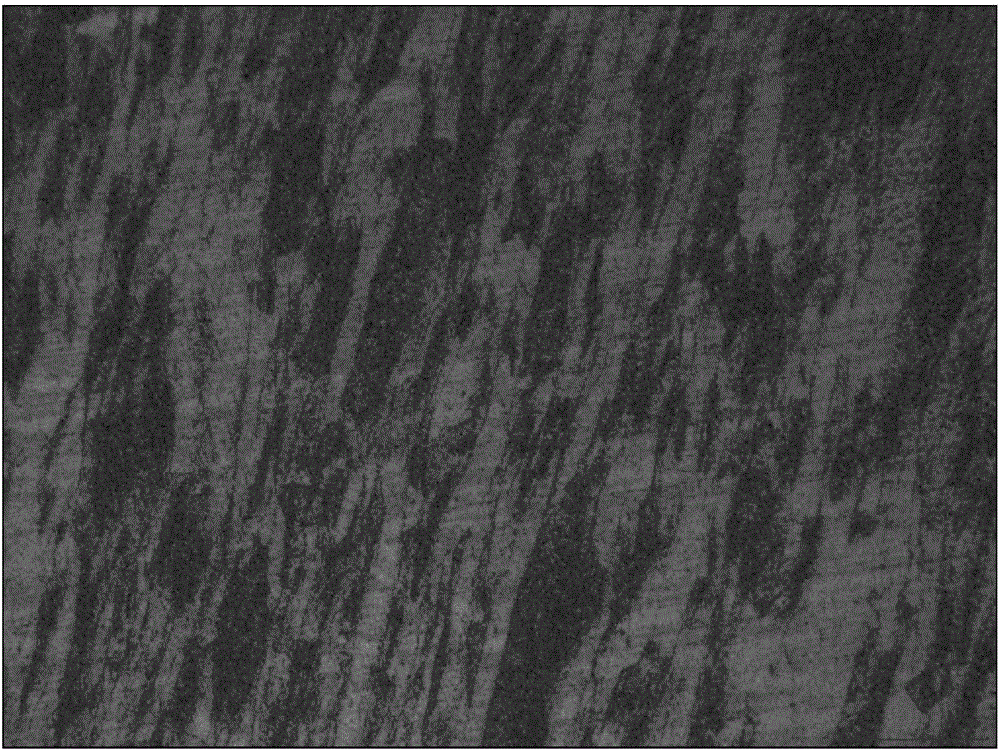

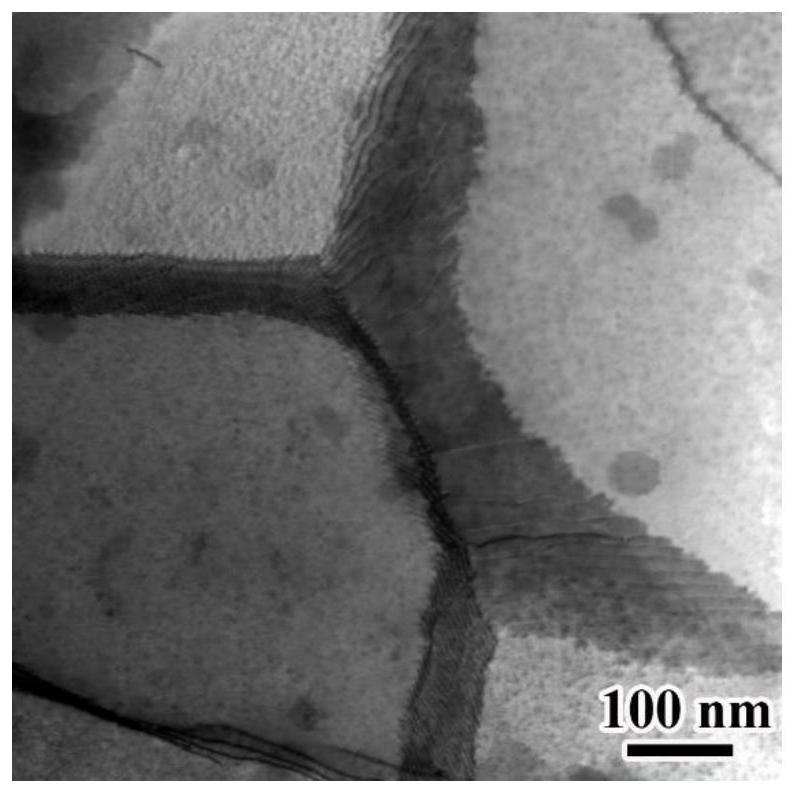

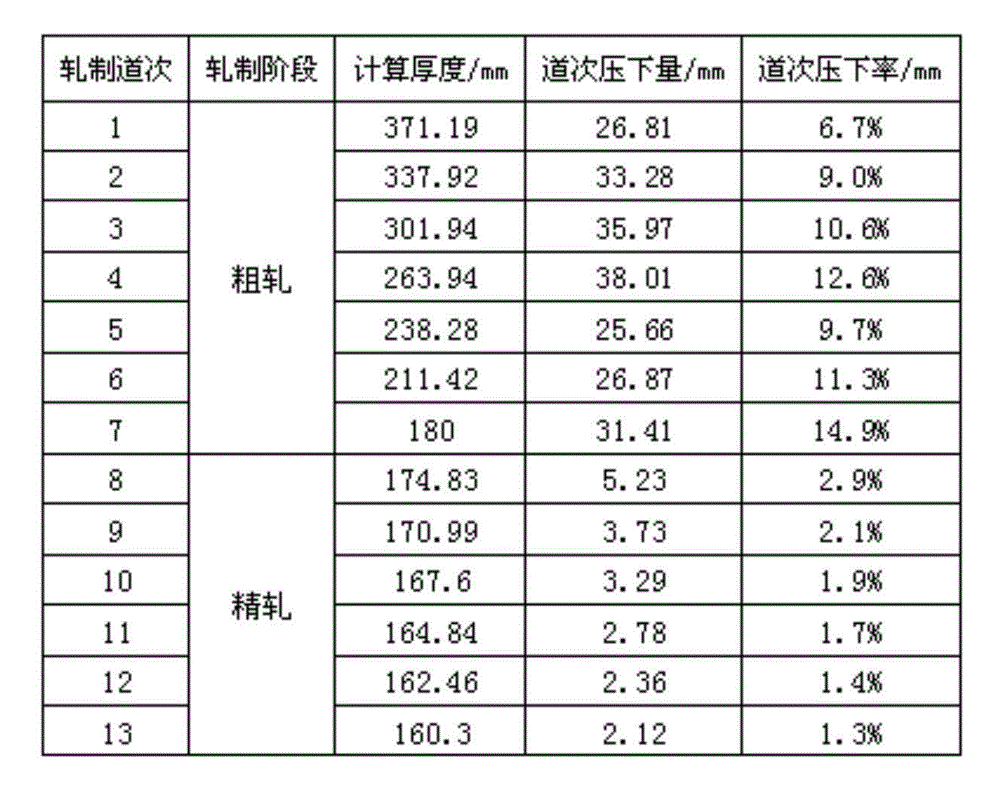

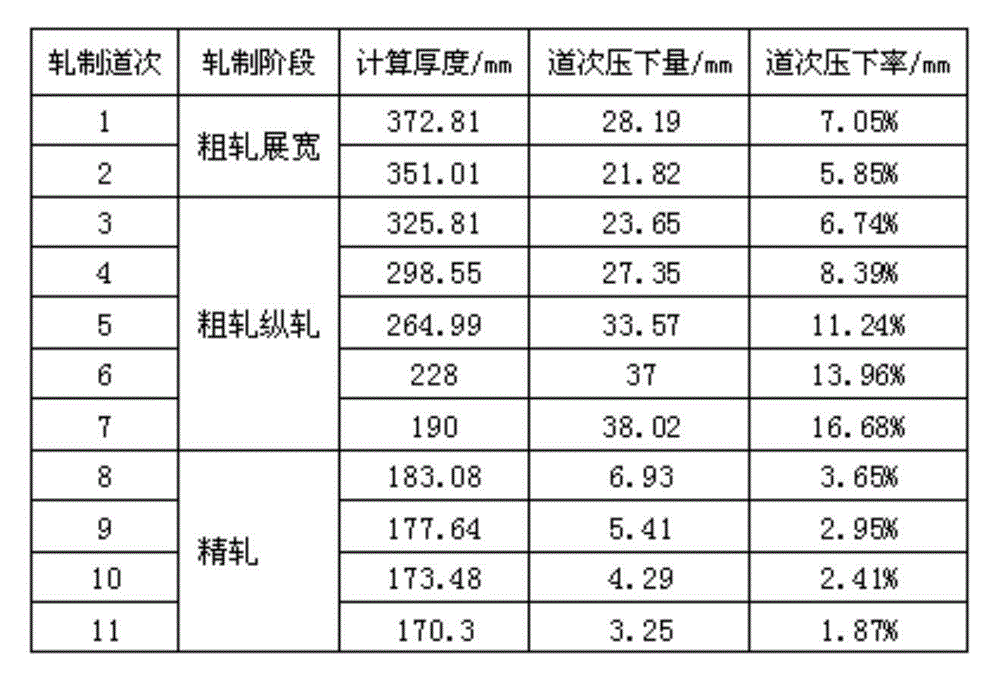

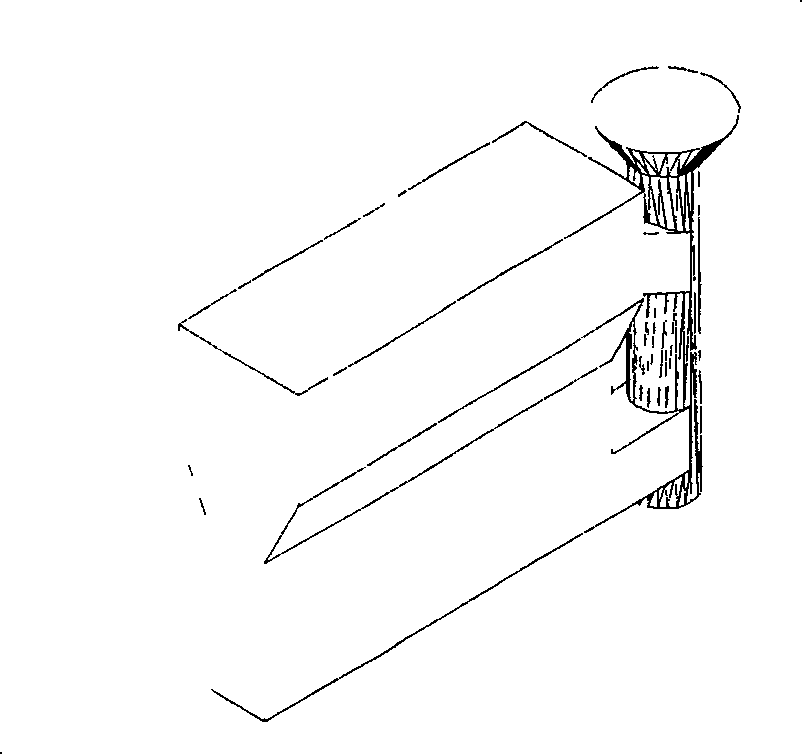

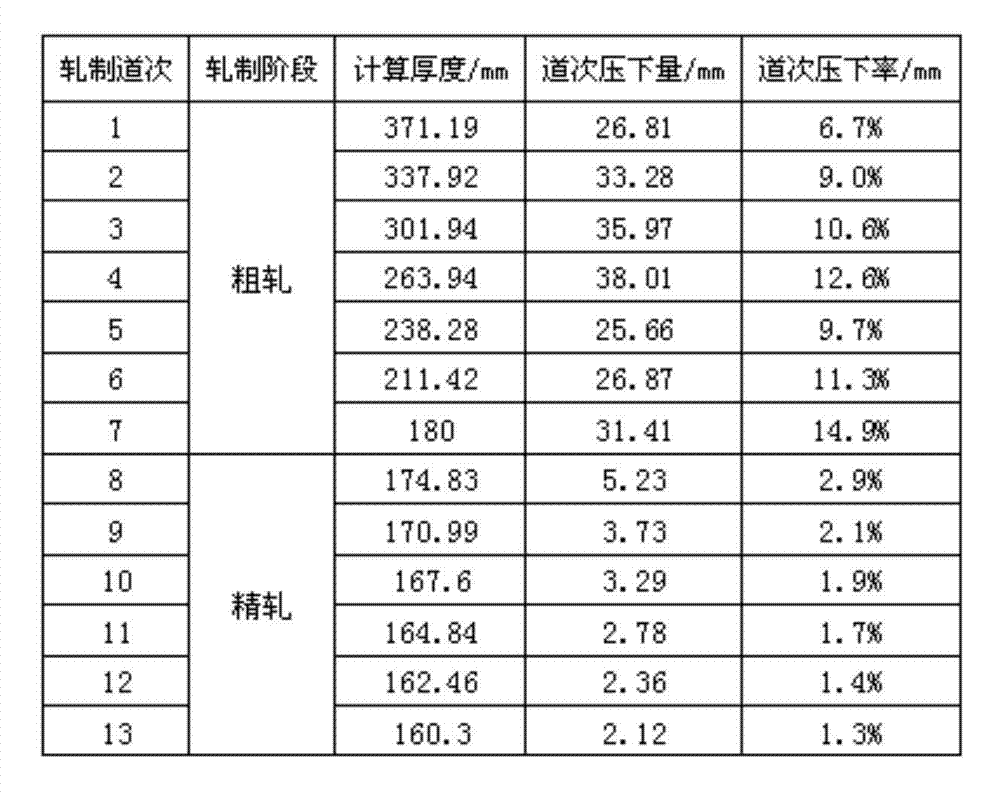

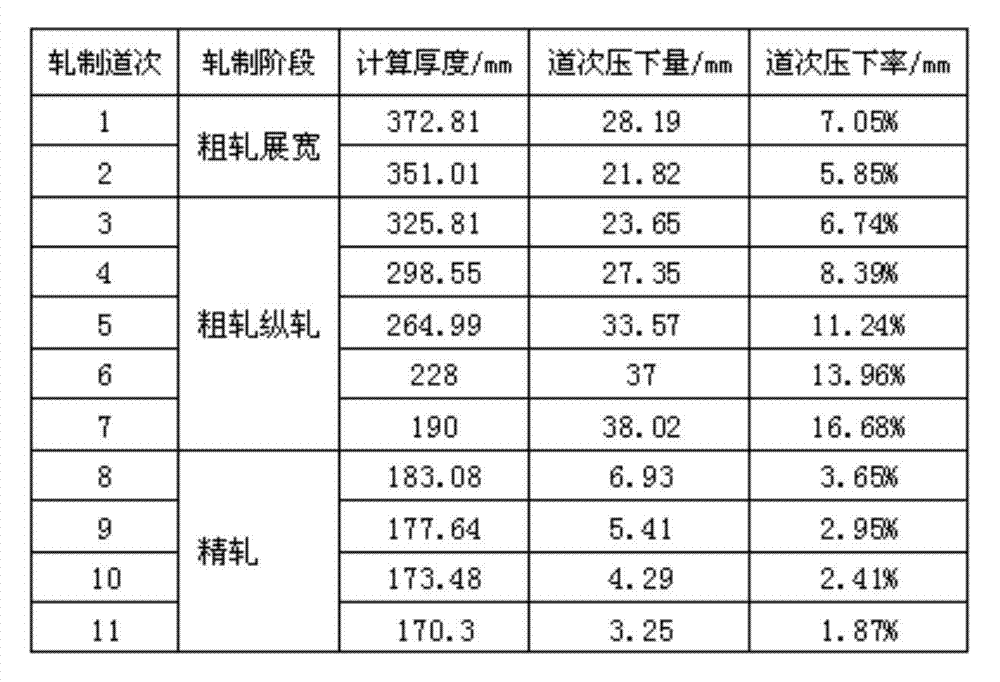

Double-stand rolling method for rolling super-thick steel plate by giving consideration to both plate shape and flaw detection performance

ActiveCN102909216AFully refined grainsImprove tissue performanceRoll force/gap control deviceMetal rolling arrangementsThick plateStrip mill

The invention discloses a double-stand rolling method for rolling a super-thick steel plate by giving consideration to both plate shape and flaw detection performance, and belongs to the technical field of rolling of medium-thick plates. Through reasonably selecting billet type, a roughing mill adopts a mode of direct longitudinal rolling, instead of rolling through broadening, meanwhile, the thickness of steel plates at a controlled temperature is added 15-20mm based on that of a target thickness, so as to ensure that the overall rolling reduction at rough rolling phase reaches maximum, crystal grains in core part of the steel plates are fully refined to improve organizational performance of the core part; the overall rolling reduction at a finishing mill is 15-20mm, which is completed through three to five passes of rolling, the rolling reduction at the last pass is approximately 2-5mm, little rolling reduction functions to flatten the shape of the steel plates, thereby guaranteeing the shape of the steel plates.

Owner:SHOUGANG CORPORATION

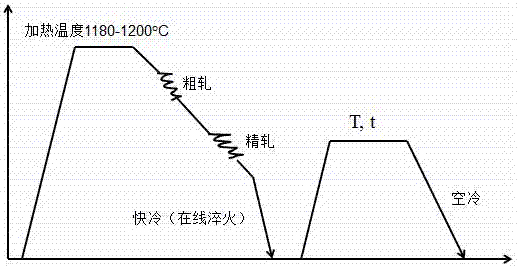

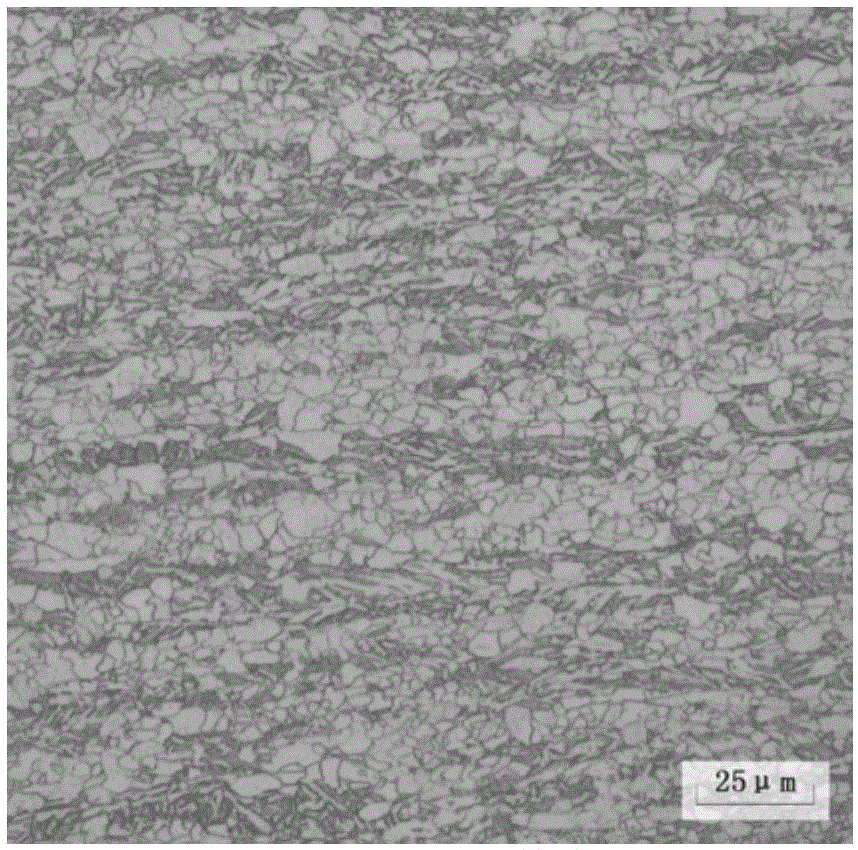

Manufacturing method of directly cold-drawn spring steel wire with excellent fatigue performance

ActiveCN102416411BFully refined grainsExtended service lifeFurnace typesHeat treatment process controlElectric arc furnaceVolumetric Mass Density

The invention discloses a manufacturing method of a directly cold-drawn spring steel wire with an excellent fatigue performance. In the method, the spring steel wire is obtained through heating twice for formation and a three-step controlled cooling process, and a large square continuous cast blank is obtained via an electric arc furnace (EAF), a low-frequency (LF) refining furnace and vapor density (VD) treatment and is subject to heat transfer, heating, blank opening with a 950 mill, reheating, controlled rolling and spinning. In the three-step controlled cooling process, the wire is cooledrapidly at an average cooling speed of 4-6 DEG C per second on the temperature section from spinning to arrival at a continuous annealing production line, is cooled slowly at an average cooling speedof 0.3-1.0 DEG C per second on the temperature section from the arrival at the continuous annealing production line to departure from the continuous annealing production line, and is then naturally cooled to the room temperature with air as a cooling medium after the departure from the continuous annealing production line, and thus the finished spring steel wire can be obtained. The spring steel wire not only has high plasticity, toughness and strength and excellent fatigue performance, but also has an excellent cold-drawing performance.

Owner:NANJING IRON & STEEL CO LTD

Method for producing iron-zinc alloy coated steel plate with yield strength being equal to or higher than 220 MPa

ActiveCN105274301AFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

Microalloying method capable of improving performance of steel for large heat input welding

The invention discloses a microalloying method capable of improving performance of steel for large heat input welding. The specific flow process of the production method comprises a converter steelmaking process, an LF refining process and a continuous casting process; according to the kind and the adding sequence of a deoxidizing agent in the LF refining process, Mo, Mn, Si, Nb, Al, Ca, Mg and Ti are included; the Al is adopted for final deoxidation, Mo-Nb-Mg-Ti alloying is carried out, the dispersive action of the MgO on Al2O3 and Ti2O3 serves as the foundation, dispersed, rich and small refractory oxides are formed to serve as cores, and generation of acicular ferrite in austenitic crystalline grains is promoted; on the other hand, a certain amount of Mo and Nb improve toughness of the steel while the grains are refined, and forming of pro-eutectoid ferrite of the grain boundary is restrained; in addition, part of small inclusion particles and carbon nitrogen carry out pinning on the austenite grain boundary, through several-aspect joint action, heat affected zone grains are fully refined, and the toughness of the steel is obviously improved; and the method is simple in control and low in production cost, and the steel for large heat input welding can be subject to large-scale production in an industrialization manner.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low temperature large wall thickness x80hd large deformation pipeline steel and its production method

Owner:SHOUGANG CORPORATION

Thick-specification acid-corrosion-resisting X65 pipeline steel plate and manufacturing method thereof

The invention discloses a thick-specification acid-corrosion-resisting X65 pipeline steel plate and a manufacturing method thereof. The yield strength of the steel plate is level 450MPa, a low-carbon and low-alloy composition design concept is adopted, the molten steel purity is improved through refining, the balled impurity form is processed through calcium, and production is performed through a controlled rolling and controlled cooling technology, so that the steel plate has the excellent HIC (hydrogen induced cracking) and SSCC (sulfide stress corrosion cracking) acid-corrosion resistance, and meanwhile, the steel plate is a product with excellent comprehensive properties such as the high strength, the high anti-crack toughness, the good weldability and the like.

Owner:JIGANG GRP

Mo-Nb-Ti-Mg steel smelting method for improving welding performance

InactiveCN106011361AImprove toughnessFully refined grainsManufacturing convertersSteelmakingMicroalloyed steel

The invention discloses a Mo-Nb-Ti-Mg steel smelting method for improving welding performance. The smelting method comprises the specific flowing processes of converter steelmaking, LF refining and continuous casting working procedures. Mo-Nb-Ti-Mg microalloyed steel chemically comprises, in percentage by mass, 0.06-0.08% of C, 1.25-1.60% of Mn, 0.010% or smaller of S, 0.025% or smaller of P, 0.20-0.40% of Si, 0.010-0.030% of Als, 0.060-0.080% of Mo, 0.010-0.020% of Ti, 0.002-0.005% of Mg, 0.020-0.035% of Nb and the balance of Fe and other unavoidable impurities. According to the Mo-Nb-Ti-Mg steel smelting method, Al final deoxidization is adopted for carrying out Mo-Nb-Ti-Mg microalloying, steel obdurability is obviously improved, control is simple, the production cost is low, and industrial mass production of steel for large heat input welding can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Production method of deep-drawing zinc-iron alloy plated steel plate with ductility higher than 38% and with compact plating structure

InactiveCN105177409AGuaranteed mechanical propertiesImproved chalking resistanceHot-dipping/immersion processesAlloyArea ratio

The invention discloses a production method of a deep-drawing zinc-iron alloy plated steel plate with a compact surface plating structure. The production method comprises the steps of molten iron desulphurization, converter smelting, alloying, continuous casting, heating, rolling and alloying continuous hot galvanizing. In the alloying continuous hot galvanizing process, after galvanizing and zinc pot delivery are carried out, the cooling speed of an upstream section is controlled to be higher than or equal to 40 DEG C / s, and the cooling speed is controlled to be higher than or equal to 30 DEG C / s after alloying. The deep-drawing zinc-iron alloy plated steel plate in which zinc-iron alloy plating surface grains are fine, distribution is even in size, the plating structure is compact (the area ratio of surface holes is smaller than or equal to 5%), and the surface is free of obvious microcracks is obtained on the premise that the mechanical performance of the steel plate is guaranteed. The anti-pulverization performance of the zinc-iron alloy plated steel plate is improved, the 60-degree V bending test grade reaches the first level, and the phenomena of pulverization and falling of a plating are not likely to happen in the steel plate punching molding process; and accordingly the purposes of quality and production of zinc-iron alloy plated steel plate workpieces are achieved.

Owner:武钢集团有限公司

Aluminum alloy, preparation method thereof and die casting

The invention relates to an aluminum alloy which comprises the following components including 0.9%-1.4% of iron, 0.5%-0.9% of magnesium, 0.2%-0.5% of manganese, 0.15%-0.3% of silver, 0.2%-0.3% of scandium, 0.3%-0.5% of yttrium and the balance aluminum. The invention further relates to a preparation method of the aluminum alloy. The invention also relates to a die casting which is made of the aluminum alloy.

Owner:惠州市田宇中南铝合金新材料科技有限公司

A kind of manufacturing method of tantalum target material

ActiveCN104419901BIncrease deformation rateUniform structureVacuum evaporation coatingSputtering coatingIngotBismuth

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

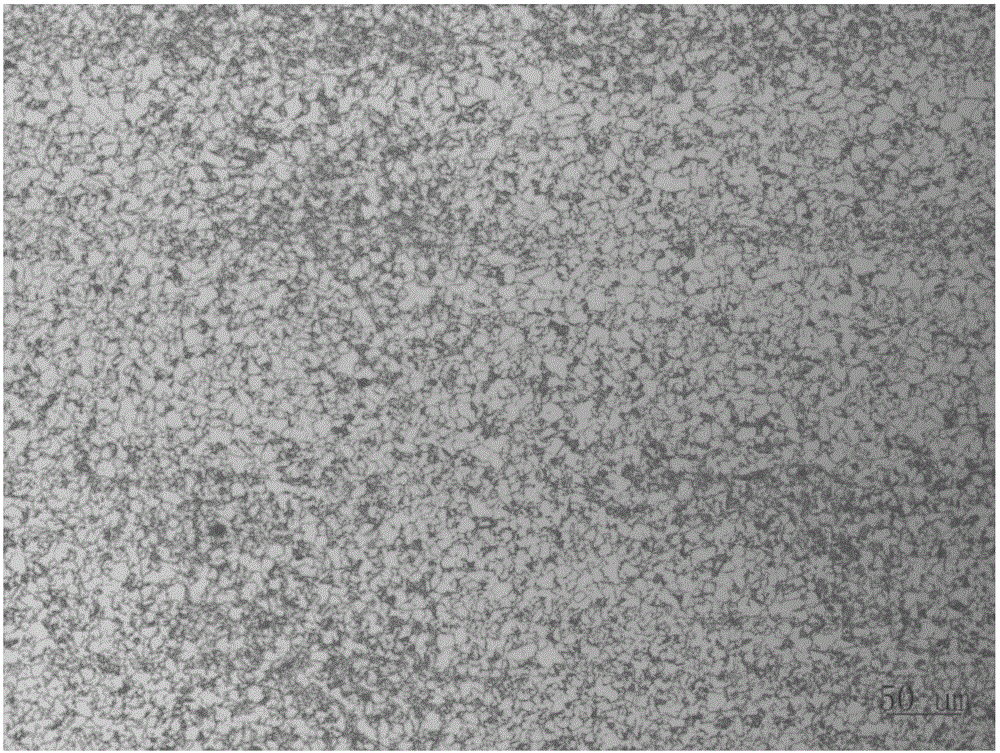

Method for producing wide and thick superfine-grain hot-rolled plate

InactiveCN100540707CIncrease temperatureIncrease spray coolingRoll mill control devicesMetal rolling arrangementsUltra fineMechanical property

The invention discloses a method for producing hot-rolled coils with wide and thick specifications and ultrafine grains. : ≤0.02%, S: ≤0.015%, the balance is Fe and unavoidable impurities, and the thickness of the coil is 8-14mm. The present invention appropriately increases the finishing rolling inlet temperature, increases the cooling capacity of the finishing rolling stand, and reasonably allocates the finishing rolling mill The amount of deformation in each pass of the frame is carried out in the non-recrystallized area of austenite; rapid cooling after rolling and coiling at a lower temperature can obtain ultra-fine ferrite and bainite multi-phase structure, iron The grain size of the element body is 3-6μm, and its mechanical properties are that the yield strength reaches more than 400Mpa, the tensile strength exceeds 520Mpa, and the elongation is greater than 28%. The steel does not contain special alloying elements, which can replace the low alloy steel of the same level, save alloy resources, and bring huge economic and social benefits to enterprises.

Owner:ANGANG STEEL CO LTD

High-strength toughness non-quenched and tempered steel wire rod and its preparation method

The invention discloses a high-toughness non-tempering steel wire rod and a preparation method thereof. The preparation method comprises processes of heating, rolling and cooling. The steel wire rod comprises the following chemical components in percentages by weight: 0.22-0.31% of C, 1.20-1.55% of Mn, 0.25-0.70% of Si, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.10-0.40% of Cr, 0.05-0.20% of V, 0.010-0.050% of Ti, 0.010-0.025% of N, 0.010-0.050% of Al, less than or equal to 0.25% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.10% of Mo, and the balance of Fe and inevitable impurity elements. The microstructure of the steel wire rod obtained by the method consists of ferrite and pearlite, the grain size is greater than level 7, the tensile strength is 750-850 MPa, reduction of area is greater than or equal to 40%, and impact toughness AkV is greater than or equal to 110J; strength and impact toughness are relatively high, and requirements of downstream customers on production of parts of automotive steering systems can be met; and meanwhile, quenching and tempering are omitted, and production and manufacturing costs are reduced.

Owner:XINGTAI IRON & STEEL

Method for casting Mg-Al-Zn based magnesium alloy with high strength and high tenacity

A method for casting high-strength and-toughness Mg-Al-Zn based Mg-alloy includes such steps as baking auxiliaries, proportional mixing, pre-heating tools, smelting Mg ingot, refining, modifying, laying aside while holding its temp, casting and solidifying. Said Mg-alloy contains Al (3-9 Wt %), Zn (3.5-9), Mn (0.15-1.0), Sb (0-2), and Al (rest).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Manganese zinc ferrite material with wide temperature, low power consumption and high magnetic permeability and preparation method thereof

ActiveCN108275992BWide operating temperature rangeIncreased power lossInorganic material magnetismInductances/transformers/magnets manufactureTransformerManganese

The invention discloses a wide temperature, low power consumption and high permeability manganese zinc ferrite material and a preparation method thereof. The material comprises a main component and adoping component, wherein the main component comprises the following components in percentage by mass: 55.8 to 58.7 percent of Fe2O3, 9.8 to 11.2 percent of ZnO, the balance of MnO, and the total amount is 100 percent. The material ensures that grains are sufficiently refined by relatively reducing the content of Fe2O3 in the main component and through a special doping technology, reduces the probability of irregular large grains, effectively improves the power consumption, meanwhile broadens the operating temperature range, has excellent properties of wide temperature, low power consumption and high permeability, is beneficial to the miniaturization of transformer devices, reduces the industrial scale production cost, and improves the operating efficiency.

Owner:南通三佳磁业有限公司

Thermal control and cold control process of ultralow-carbon fiber steel

The invention belongs to a heat-controlling-cooling process in the field of steel rolling, and is a heat-controlling-cooling process for ultra-low carbon fiber steel. The hot section is kept warm for a certain period of time; the rolling start temperature is controlled at 1070±20°C, and the rolling temperature is controlled after the pre-finishing rolling is completed, that is, the temperature is lowered to 910°C by water cooling, and the rolling is carried out in the finishing mill. After the finish rolling mill, the temperature of the wire rod is controlled at 850±10°C, and after the final rolling, the temperature of the wire rod is reduced to 880±10°C through a temperature control process, and finally enters spinning and forming; the final cover temperature is guaranteed to be ≤400°C, and the final coil is collected . The invention can improve the drawing performance of the product, ensure that the product has high ductility and drawing performance, and at the same time make the product have higher tensile strength.

Owner:NANJING IRON & STEEL CO LTD

Double-stand rolling method for rolling super-thick steel plate by giving consideration to both plate shape and flaw detection performance

ActiveCN102909216BFully refined grainsImprove tissue performanceRoll force/gap control deviceMetal rolling arrangementsSheet steelThick plate

The invention discloses a double-stand rolling method for rolling a super-thick steel plate by giving consideration to both plate shape and flaw detection performance, and belongs to the technical field of rolling of medium-thick plates. Through reasonably selecting billet type, a roughing mill adopts a mode of direct longitudinal rolling, instead of rolling through broadening, meanwhile, the thickness of steel plates at a controlled temperature is added 15-20mm based on that of a target thickness, so as to ensure that the overall rolling reduction at rough rolling phase reaches maximum, crystal grains in core part of the steel plates are fully refined to improve organizational performance of the core part; the overall rolling reduction at a finishing mill is 15-20mm, which is completed through three to five passes of rolling, the rolling reduction at the last pass is approximately 2-5mm, little rolling reduction functions to flatten the shape of the steel plates, thereby guaranteeing the shape of the steel plates.

Owner:SHOUGANG CORPORATION

Smelting method of mo-nb-ti-mg steel to improve weldability

InactiveCN106011361BImprove toughnessFully refined grainsManufacturing convertersSteelmakingDeoxidization

The invention discloses a Mo-Nb-Ti-Mg steel smelting method for improving welding performance. The smelting method comprises the specific flowing processes of converter steelmaking, LF refining and continuous casting working procedures. Mo-Nb-Ti-Mg microalloyed steel chemically comprises, in percentage by mass, 0.06-0.08% of C, 1.25-1.60% of Mn, 0.010% or smaller of S, 0.025% or smaller of P, 0.20-0.40% of Si, 0.010-0.030% of Als, 0.060-0.080% of Mo, 0.010-0.020% of Ti, 0.002-0.005% of Mg, 0.020-0.035% of Nb and the balance of Fe and other unavoidable impurities. According to the Mo-Nb-Ti-Mg steel smelting method, Al final deoxidization is adopted for carrying out Mo-Nb-Ti-Mg microalloying, steel obdurability is obviously improved, control is simple, the production cost is low, and industrial mass production of steel for large heat input welding can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Microalloying Method for Improving the Properties of High Energy Input Welding Steel

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of steel plate for low crack susceptibility pipe fittings used under low temperature conditions and its manufacturing method

ActiveCN108034885BMeet the requirements of steel for X70 grade pipe fittingsAchieve flatTemperingCrazing

The invention relates to a low-crack sensitive pipe fitting steel plate used under a low temperature condition. The mechanical component (wt%) of the steel plate comprises 0.03-0.08 of C, 0.2-0.35 of Si, 0.9-1.6 of Mn, 0.02-0.04 of Al, 0.01-0.07 of Nb, 0.01-0.07 of V, 0.01-0.02 of Ti, less than or equal to 0.15% of Nb+V+Ti, less than or equal to 0.5 of Cr, less than or equal to 0.5 of Ni, less than or equal to 0.4 of Mo, less than or equal to 0.3 of Cu, less than or equal to 0.18 of Pcm and the balance Fe and inevitable impurities. The method sequentially comprises the steps of KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing, 370-450 mm thickness continuous casting blank continuous casting, continuous casting blank capping slow cooling, continuous casting blank checking and cleaning, casting blank heating, high-pressure water descaling, rolling, cooling, straightening and offline tempering. The steel plate structure is controlled to be a single tempered bainite structure, the grain size is within the range of 3-6 microns, and the steel plate has very excellent low-temperature toughness and can meet the use requirements of X70 pipeline steel underthe low-temperature condition of -60 DEG C.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com