Method for casting Mg-Al-Zn based magnesium alloy with high strength and high tenacity

A high-strength technology for casting magnesium alloys, which is applied in the field of casting magnesium alloys, can solve problems such as low yields, and achieve the effects of low preparation costs, fully refined grains, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

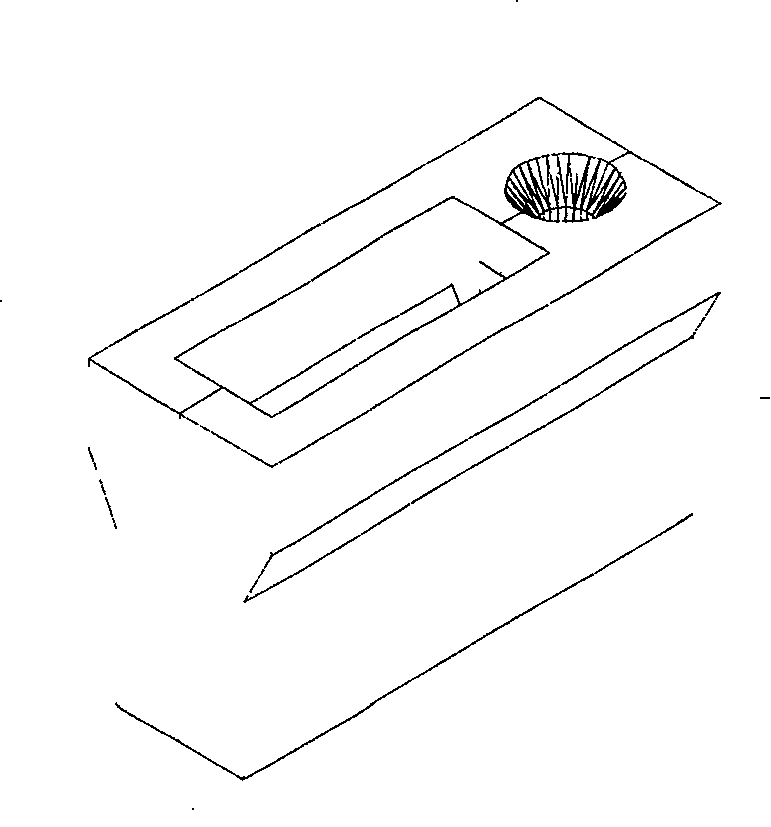

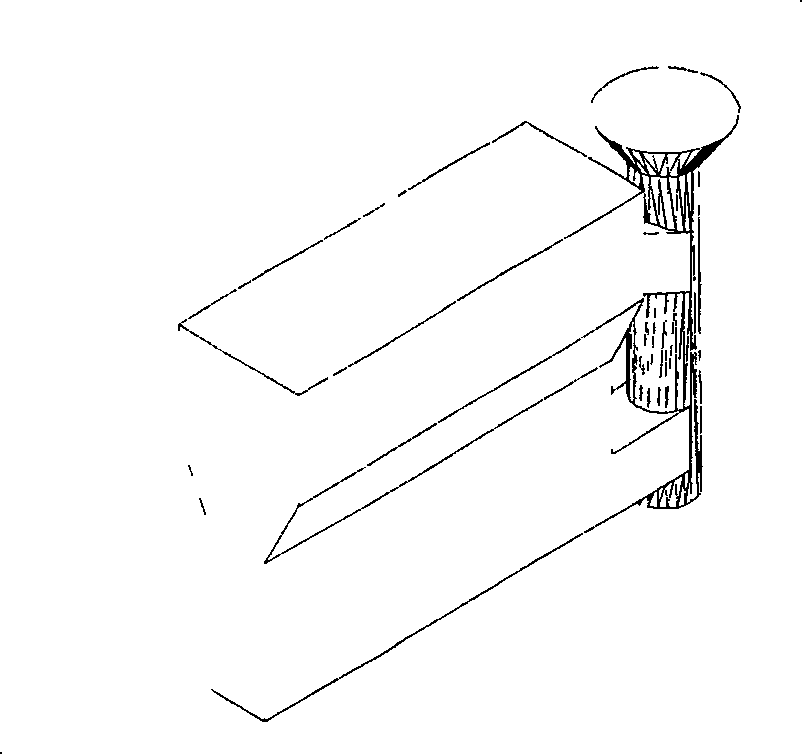

Image

Examples

Embodiment 1

[0042] The basic operation steps of the present embodiment 1 alloy are as follows:

[0043] I), alloy composition:

[0044] The alloy of Example 1 is prepared from commercially available high-purity raw materials. Its chemical composition was analyzed using inductively coupled plasma-atomic emission spectroscopy (ICP-AES) technique. The chemical composition of the alloy of Example 1 is shown in the table below.

[0045]

[0046] II), alloy smelting and casting molding:

[0047] The smelting work of Example 1 is carried out in a pit furnace, and the crucible is made of carbon steel; the casting of the alloy is completed in a metal mold. Among them, the manufacturers of RJ-2 covering / refining agent, RJ-1 washing flux and magnesite modification agent are Bohang Chemical Plant in Dashiqiao City, Liaoning Province. The detailed preparation process is as follows:

[0048] 1) Drying and preheating: the drying temperature of auxiliary materials (RJ-2 covering / refining agent, m...

Embodiment 2

[0067] The difference from Example 1 is:

[0068] The basic operation steps of the alloy in this embodiment are as follows:

[0069] I), alloy composition:

[0070]

[0071] II), alloy smelting and casting molding:

[0072] It is the same as the smelting and casting molding part in embodiment 1.

[0073] III), heat treatment of castings:

[0074] The specific conditions of the T61 heat treatment in Example 2 are the same as the heat treatment in Example 1.

[0075] IV), microstructure characterization

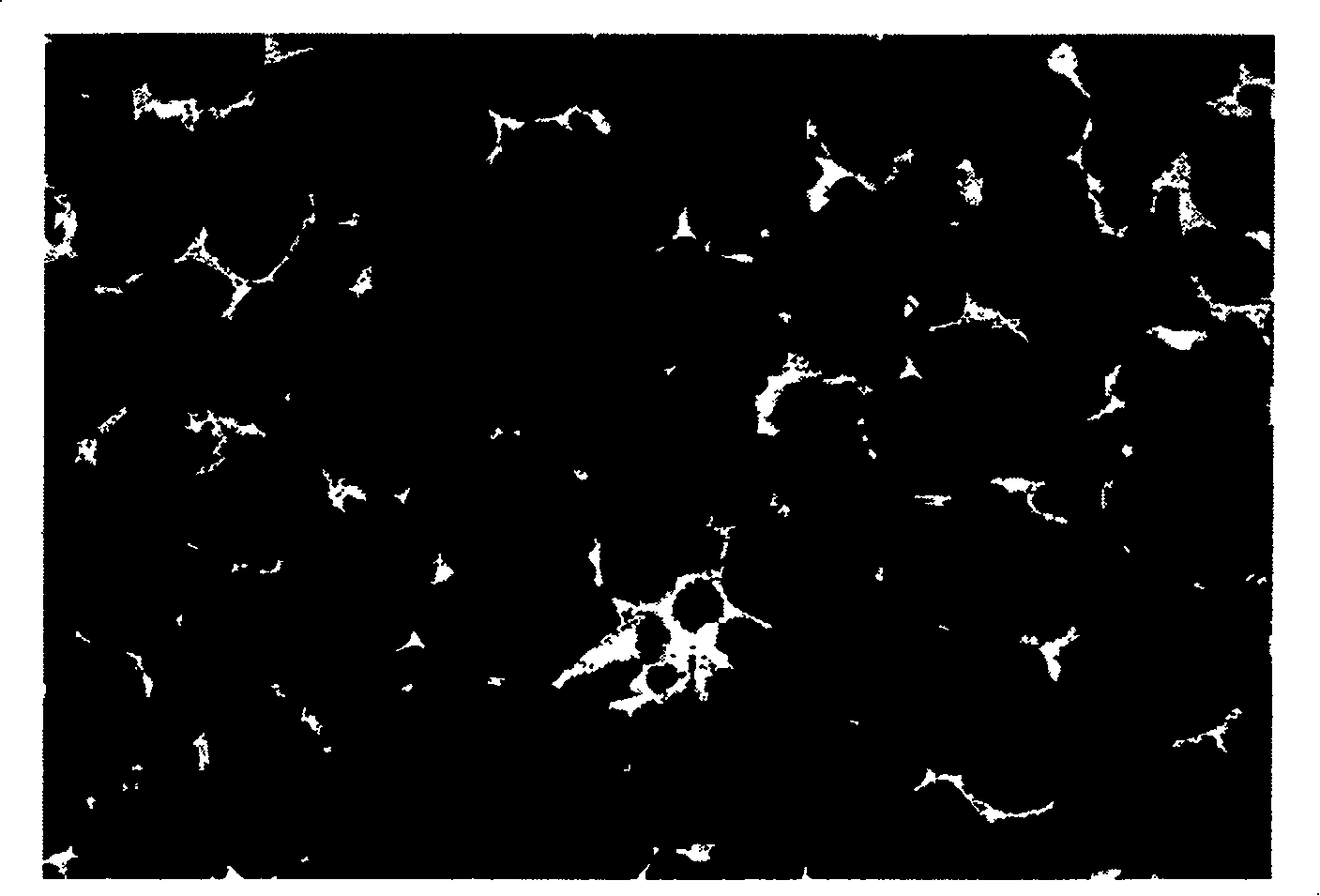

[0076] The sample preparation and characterization means for microstructure observation are the same as in Example 1. attached Image 6 It is the backscattered scanning electron microscope image of the alloy of Example 2 in the as-cast state. attached Figure 7 It is the backscattered scanning electron microscope picture of the T41 state embodiment 2 alloy. It can be seen from the above two figures that the crystal grains of the alloy in Example 2 have achieved a ve...

Embodiment 3

[0082] The difference from Example 1 is:

[0083] The basic operation steps of the alloy in this embodiment are as follows:

[0084] I), alloy composition:

[0085]

[0086] II), alloy smelting and casting molding:

[0087] It is the same as the smelting and casting molding part in embodiment 1.

[0088] III), heat treatment of castings:

[0089] attached Figure 9 It is the cooling curve of embodiment 3 alloy. It can be seen from the figure that the alloy of Example 3 has two temperature inflection points (375°C and 354°C) near the solidus line. According to the aforementioned heat treatment principles, two heat treatments, T61 and T62, were performed on the alloy of Example 3.

[0090]The T61 heat treatment is partly the same as the heat treatment in Example 1. The specific conditions of T62 heat treatment are: first pretreatment at 300°C for 2 hours, then set the heat treatment temperature at 340°C for 10 hours, finally set the heat treatment temperature at 365°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com