Microalloying Method for Improving the Properties of High Energy Input Welding Steel

A high-energy welding and micro-alloying technology, applied in the field of low-alloy steel manufacturing, can solve the problems of insufficient effect of promoting the formation of intragranular acicular ferrite, restricting the refinement of the structure of the heat-affected zone, etc., so as to achieve low production costs. , The effect of improving strength and toughness and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

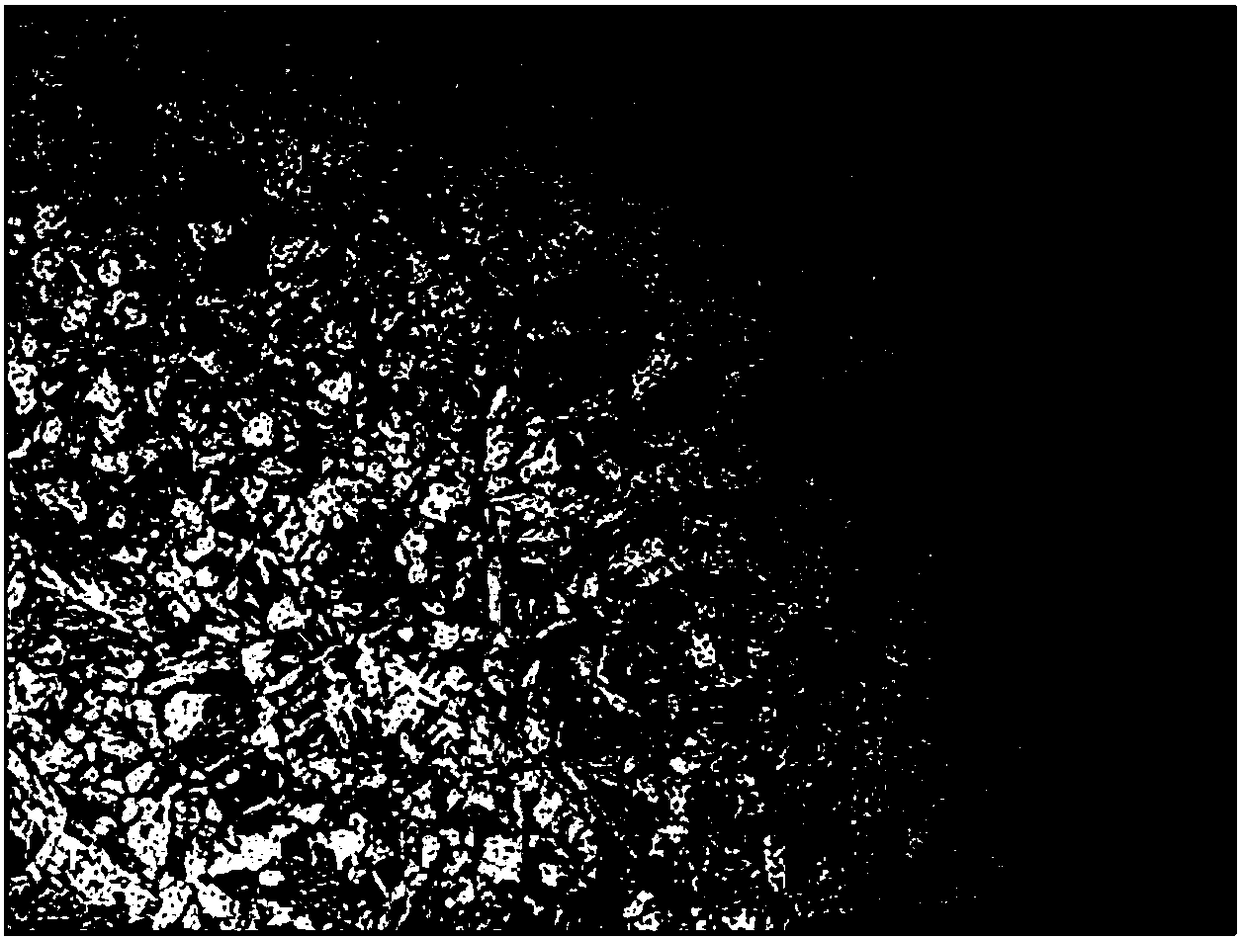

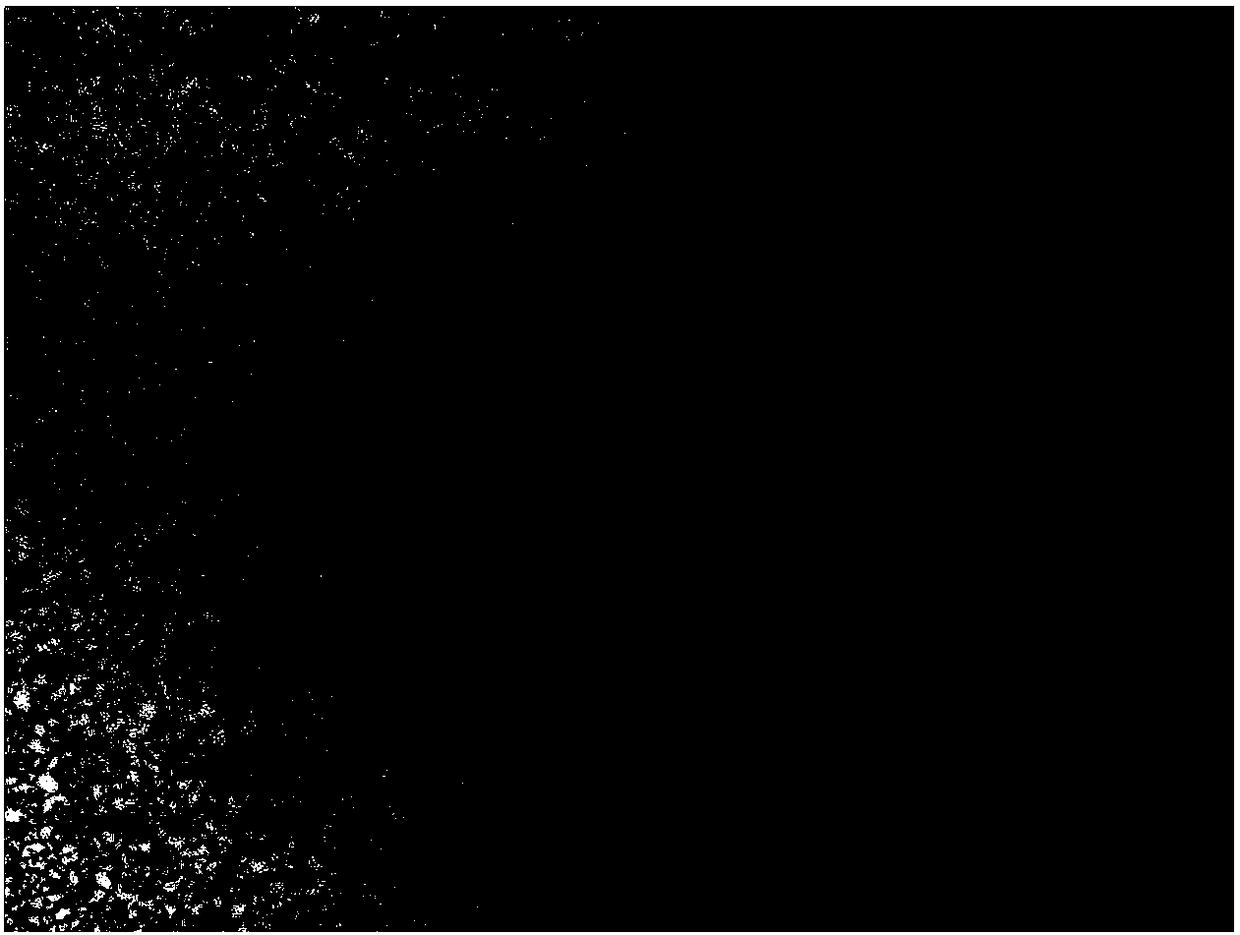

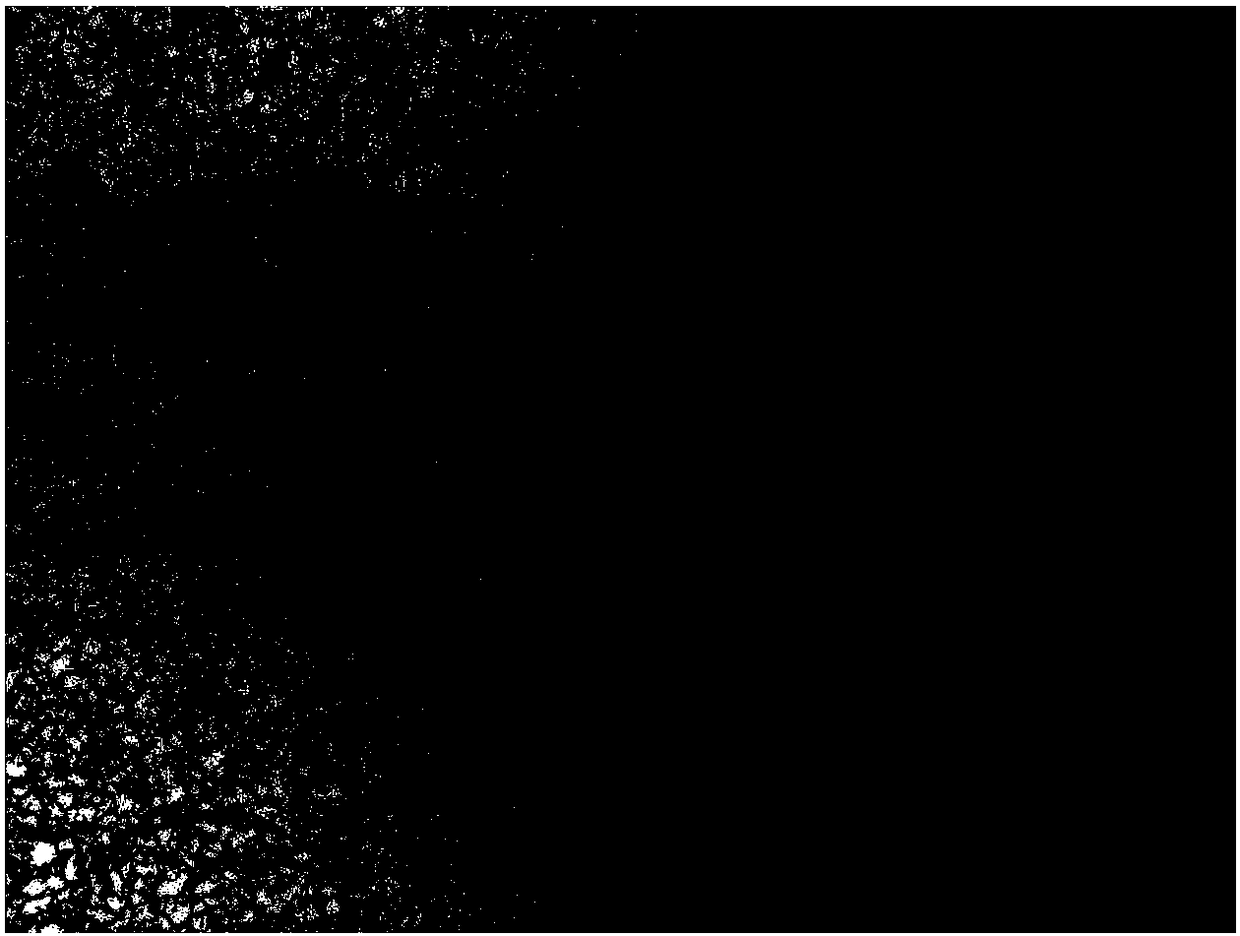

Image

Examples

Embodiment 1

[0040] A kind of Mo-Nb-Mg-Ti microalloying method that improves the performance of steel for high heat input welding, specifically as follows:

[0041] The process of smelting high-energy-input welding steel is 120t top-bottom combined blowing converter-120tLF ladle furnace refining-continuous casting.

[0042] Conditions of molten iron: molten iron [P]≤0.090%, [S]≤0.045%.

[0043] Converter: end target [C]=0.04~0.06%, [P]≤0.015%, [S]≤0.030%, [O]=500~800ppm, tapping temperature 1685℃, adding ferromolybdenum and manganese during tapping Iron, ferrosilicon, ferroniobium, ferroaluminum.

[0044] LF: The refining time is 40 minutes, and the net blowing time of argon after calcium treatment is 8 minutes. During the net blowing, the liquid surface of molten steel should not be exposed. The temperature of molten steel entering the station is 1585°C for the first furnace and 1580°C for the continuous pouring furnace. After entering the station, the feeding amount of the aluminum wi...

Embodiment 2

[0048] A kind of Mo-Nb-Mg-Ti microalloying method that improves the performance of steel for high heat input welding, specifically as follows:

[0049] The process of smelting high-energy-input welding steel is 120t top-bottom combined blowing converter-120tLF ladle furnace refining-continuous casting.

[0050] Conditions of molten iron: molten iron [P]≤0.090%, [S]≤0.045%.

[0051] Converter: end target [C]=0.04~0.06%, [P]≤0.015%, [S]≤0.030%, [O]=500~800ppm, tapping temperature 1680℃, adding ferromolybdenum and manganese during tapping Iron, ferrosilicon, ferroniobium, ferroaluminum.

[0052] LF: The refining time is 45 minutes, and the net blowing time of argon after calcium treatment is 10 minutes. During the net blowing, the liquid surface of molten steel should not be exposed. The temperature of molten steel entering the station is 1580°C for the first furnace and 1575°C for the continuous pouring furnace. After entering the station, the feeding amount of the aluminum w...

Embodiment 3

[0056] A kind of Mo-Nb-Mg-Ti microalloying method that improves the performance of steel for high heat input welding, specifically as follows:

[0057] The process of smelting high-energy-input welding steel is 120t top-bottom combined blowing converter-120tLF ladle furnace refining-continuous casting.

[0058] Conditions of molten iron: molten iron [P]≤0.090%, [S]≤0.045%.

[0059] Converter: end target [C]=0.04~0.06%, [P]≤0.015%, [S]≤0.030%, [O]=500~800ppm, tapping temperature 1670℃, adding ferromolybdenum and manganese during tapping Iron, ferrosilicon, ferroniobium, ferroaluminum.

[0060] LF: The refining time is 42 minutes, and the net blowing time of argon after calcium treatment is 6 minutes. During the net blowing, the liquid surface of molten steel should not be exposed. The temperature of molten steel entering the station is 1590°C for the first furnace and 1585°C for the continuous pouring furnace. After entering the station, the feeding amount of the aluminum wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com