Patents

Literature

67results about How to "Increase deformation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

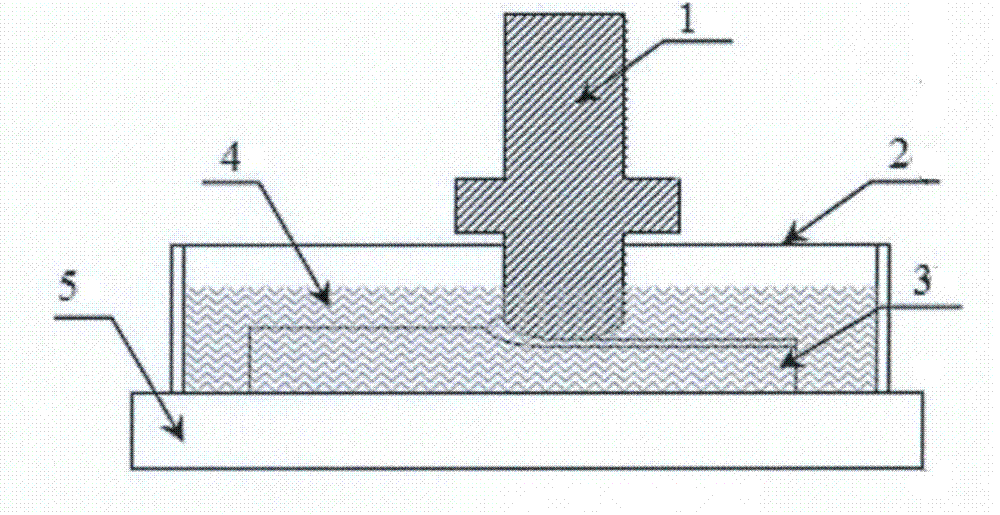

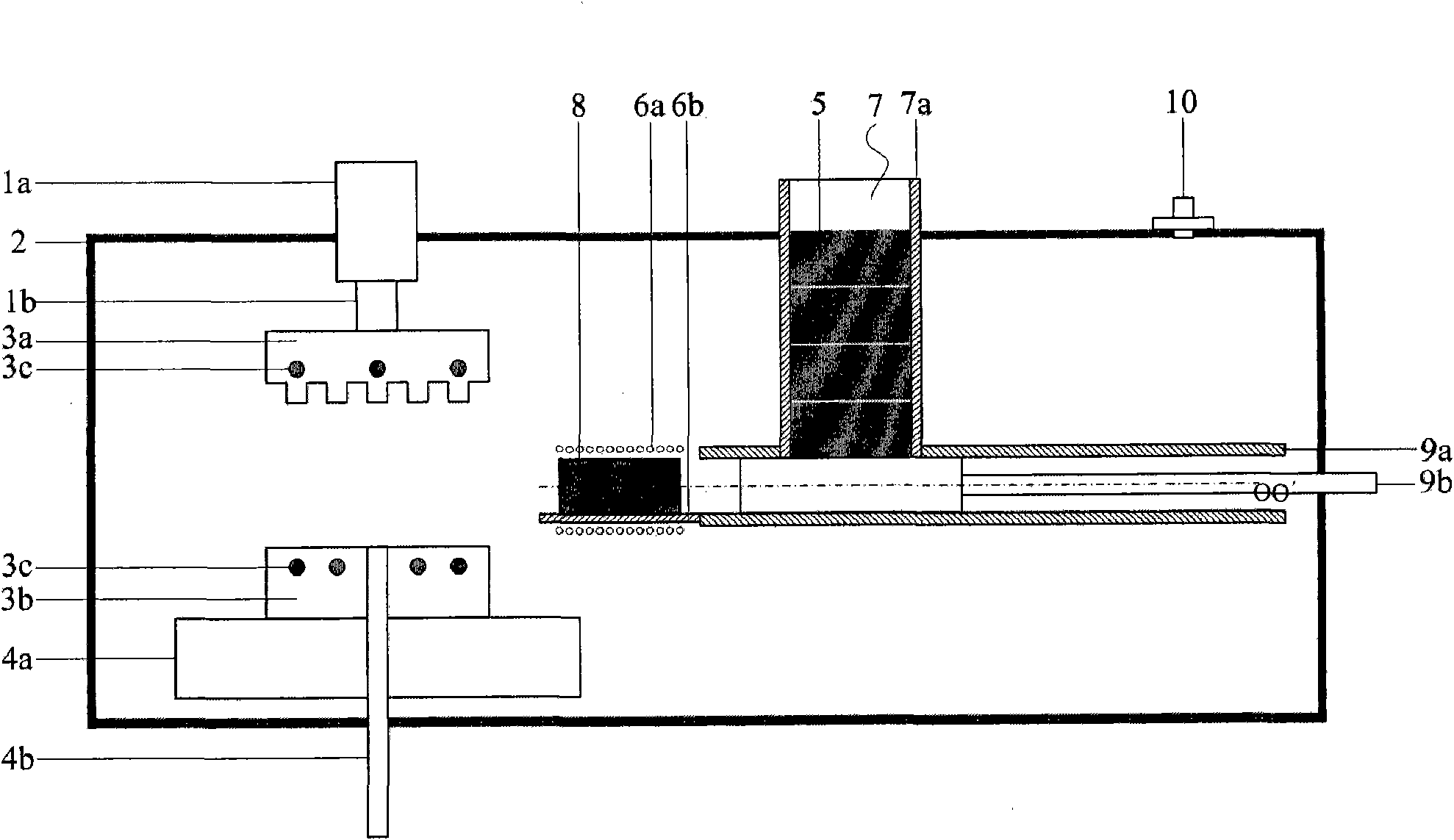

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

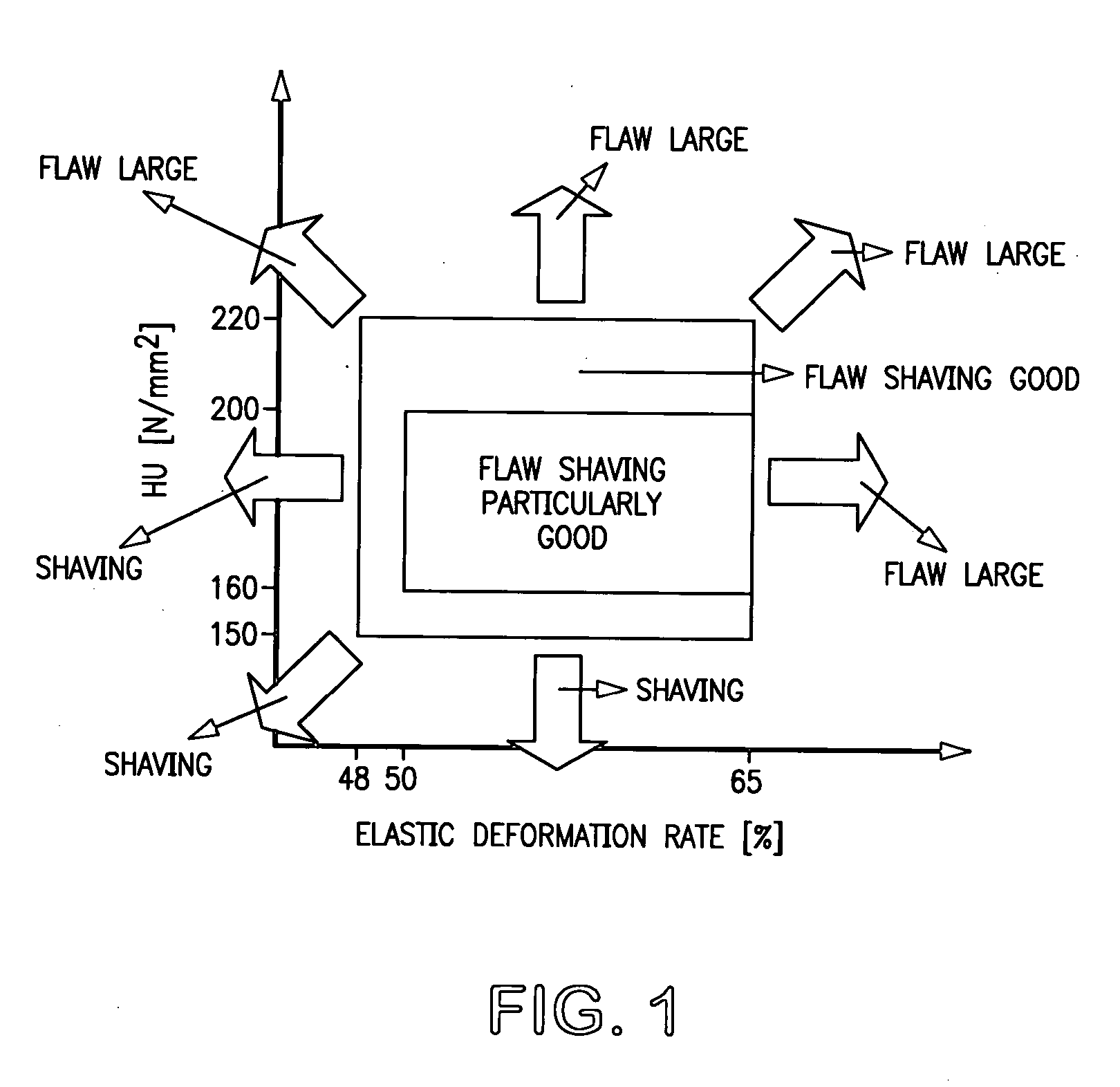

Electrophotographic apparatus

InactiveUS20050196196A1High deformation rateExcellent imageElectrographic process apparatusCoatingsTransfer systemHardness

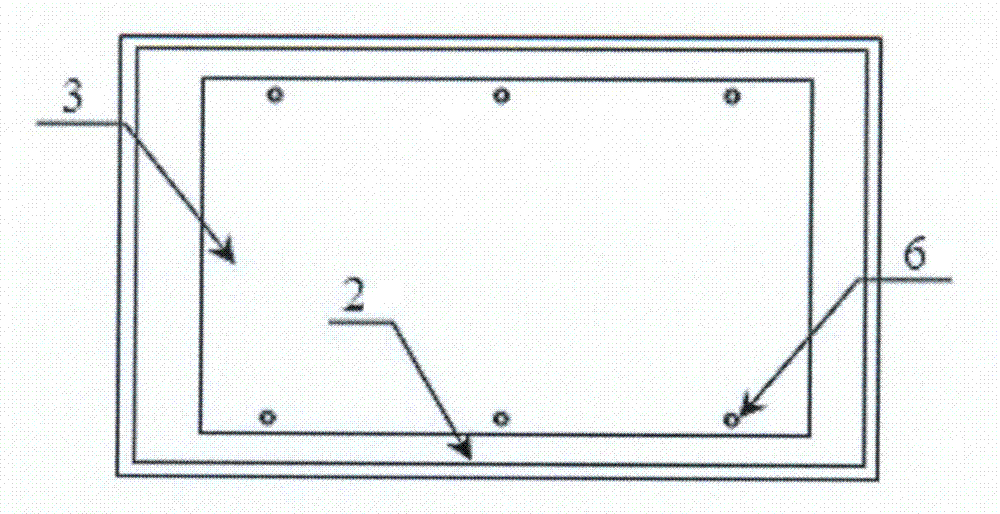

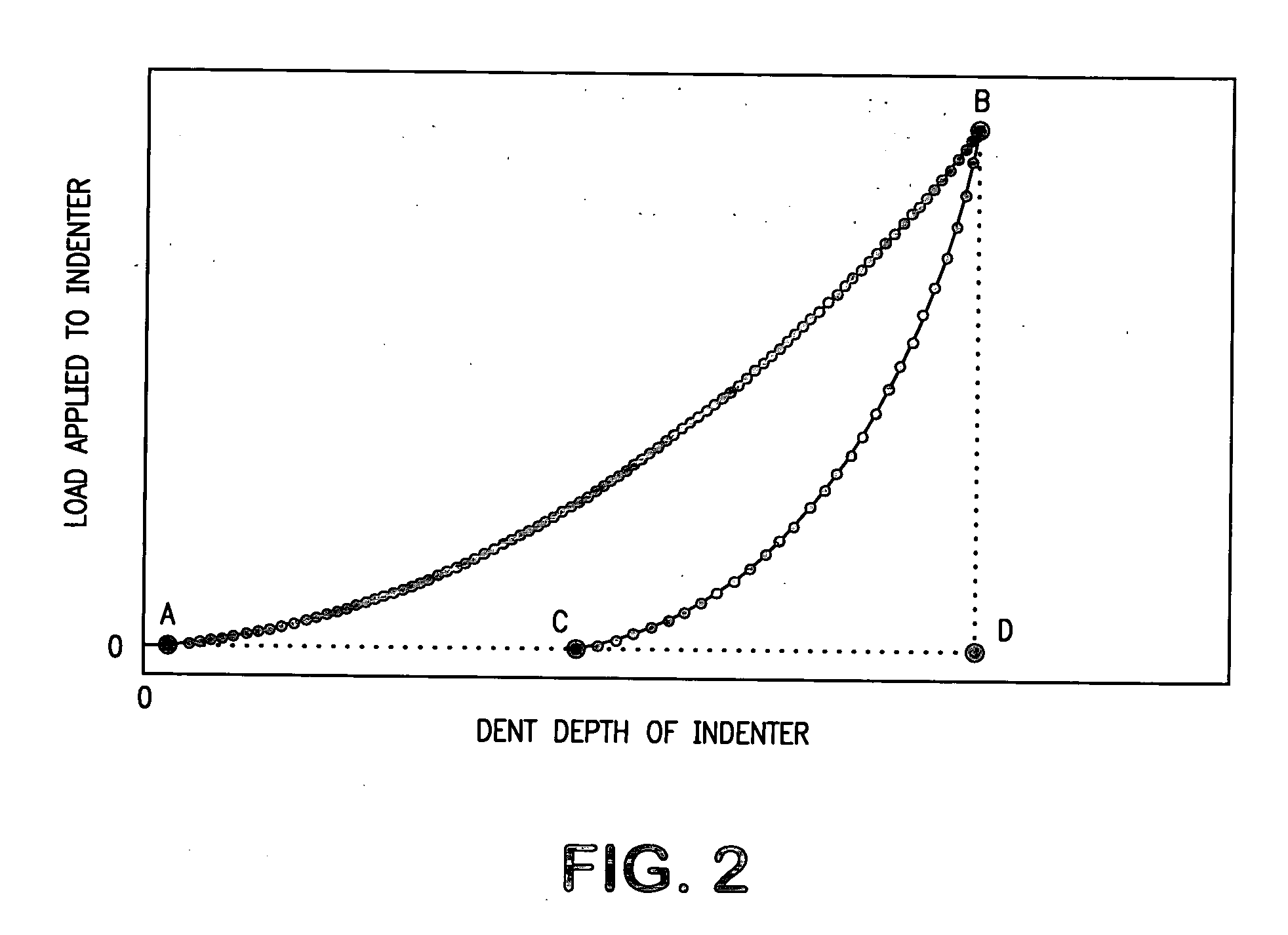

The present invention relates to an electrophotographic apparatus of an intermediate transfer system, in which: the surface of an electrophotographic photoreceptor has a universal hardness value (HU) of 150 N / mm2 or more to 220 N / mm2 or less, and an elastic deformation rate of 48% or more to 65% or less; the surface of an intermediate transfer body has a universal hardness value (HU) of 220 N / mm2 or less, and an elastic deformation rate of 50% or more; and the universal hardness value (HU) of the surface of the electrophotographic photoreceptor is greater than the universal hardness value (HU) of the surface of the intermediate transfer body.

Owner:CANON KK

Laser bending shaping method and device of light-wall conduit

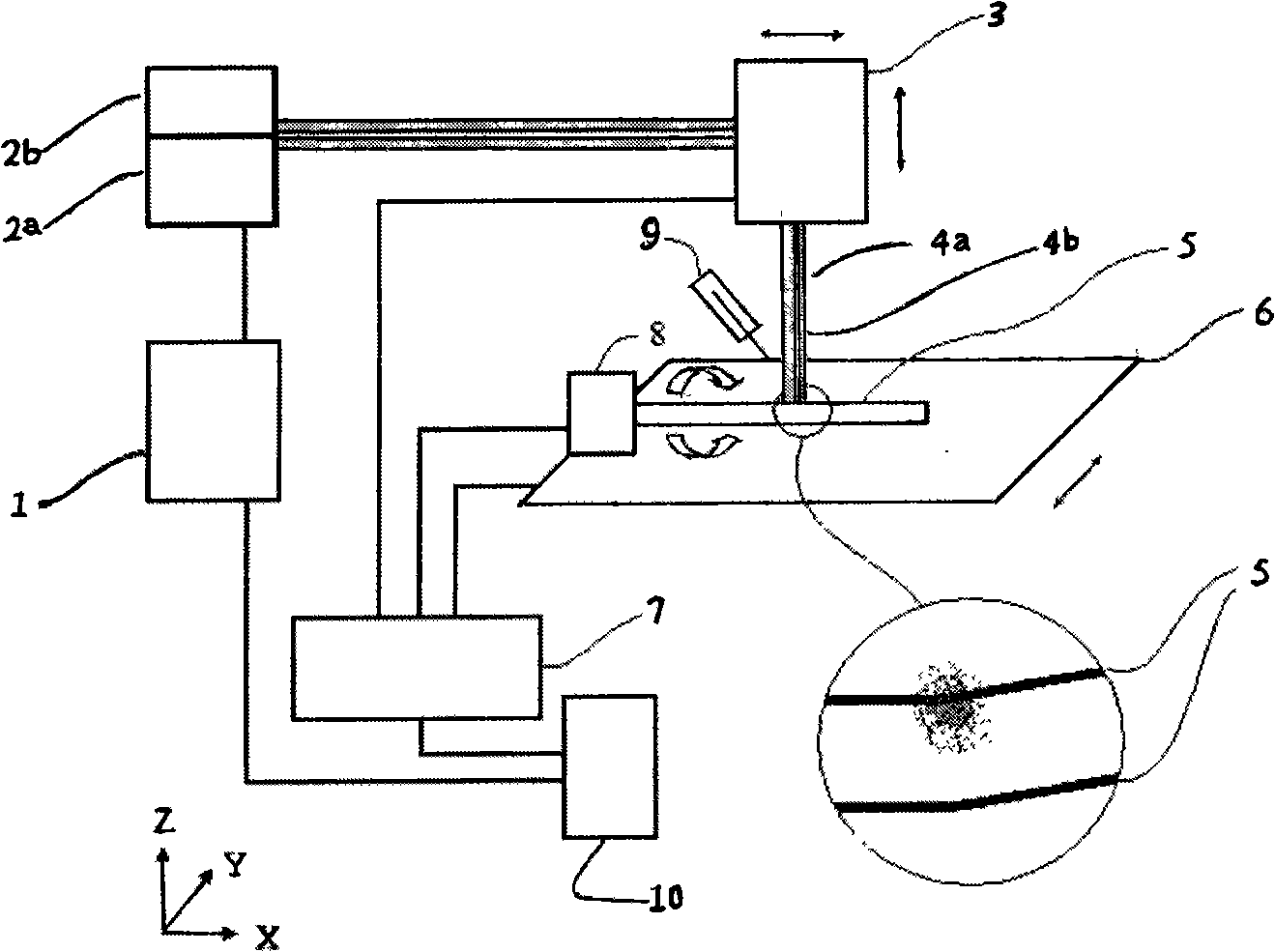

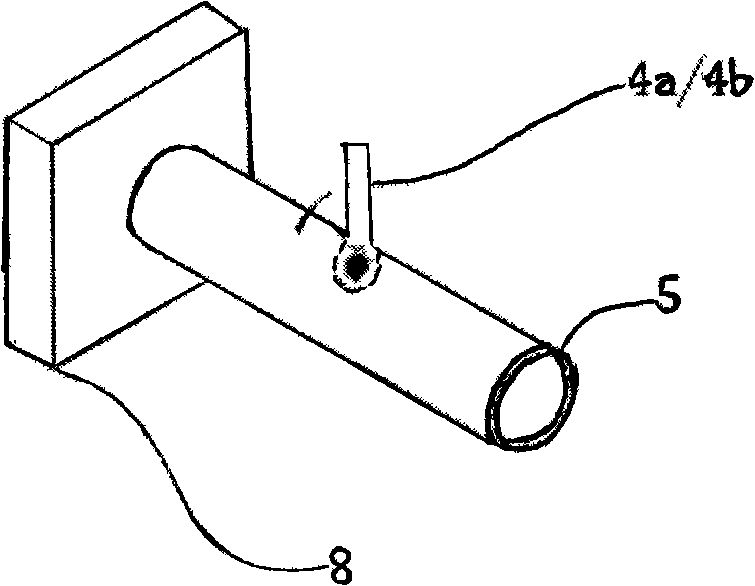

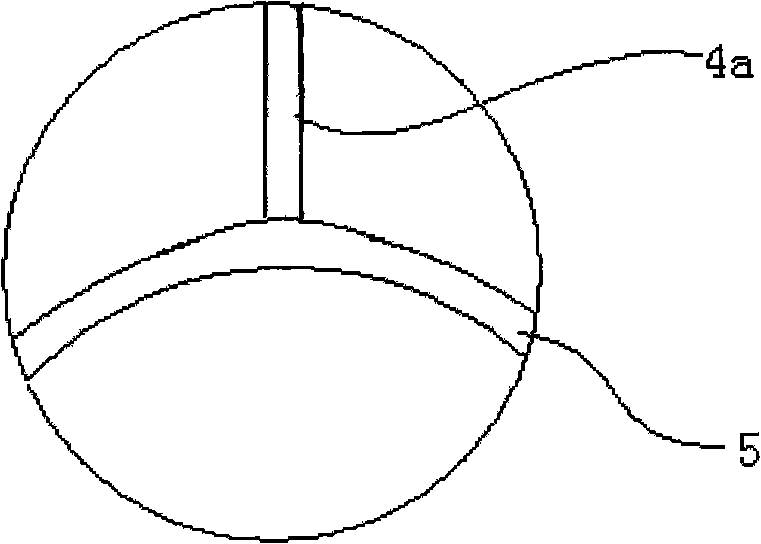

InactiveCN101332536AImprove fatigue lifeSmall bending radiusLaser beam welding apparatusControl systemTitanium

The invention discloses a laser bending forming method of a thin-walled tube and a special device used for realizing the method. The method adopts two laser beams to act on the thin-walled tube, wherein one laser beam is used for heating the thin-walled tube to soften the thin-walled tube and producing thermal stress along the thickness direction of the tube wall so as to cause the tube to bend and deform; the other laser beam forms a plasma on the surface of the tube, and further bends the thin-walled tube by the shock action produced by the plasma to obtain a fine grain structure. The special device for realizing the laser bending forming method of the thin-walled tube is composed of a laser generator system, a laser head system, a workbench system and a motion control system. By adopting the method, metal and alloy tubes made from steel, aluminum, copper, titanium and the like can be machined, which is a high-flexibility dieless forming technology.

Owner:SHANDONG UNIV

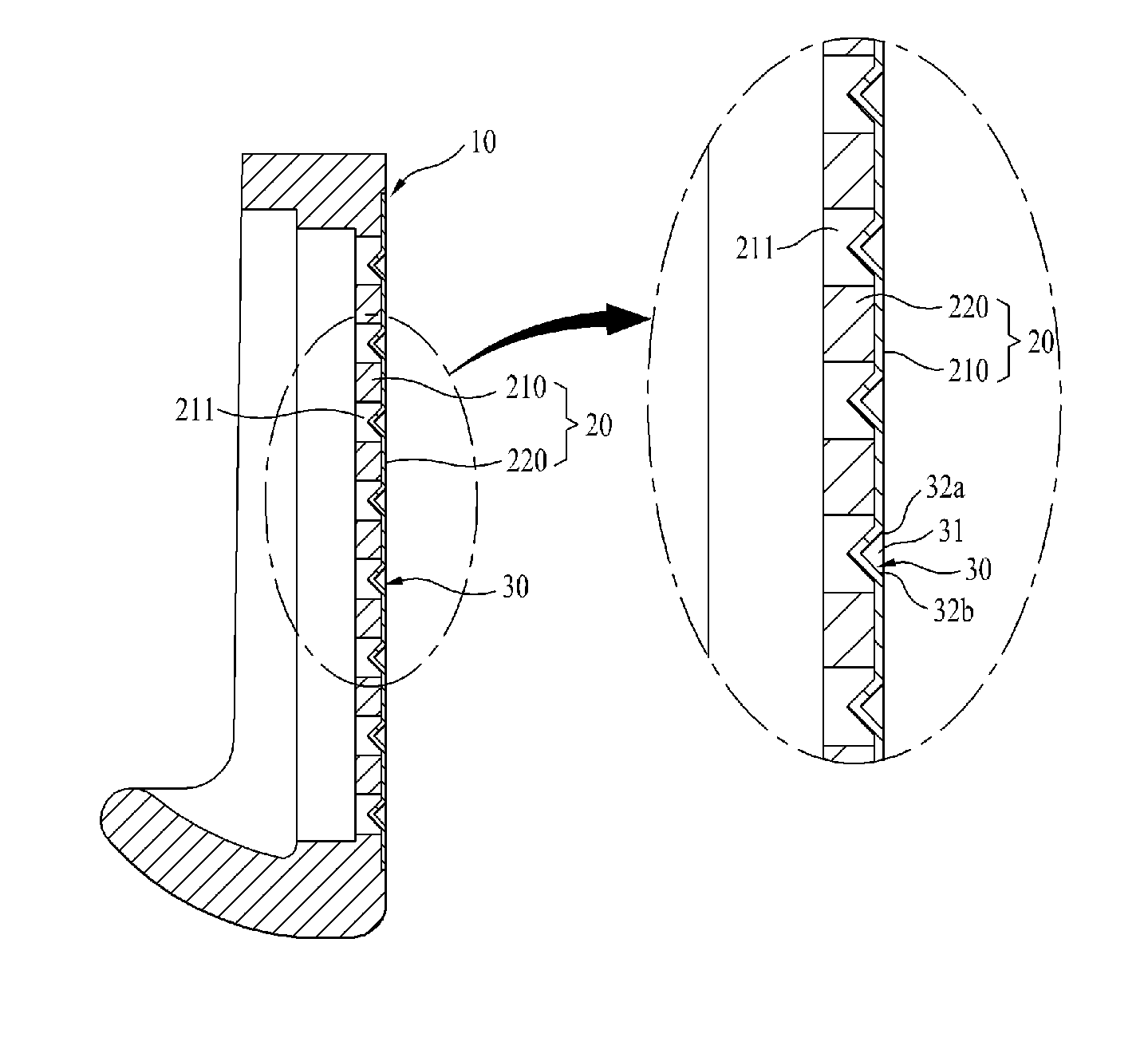

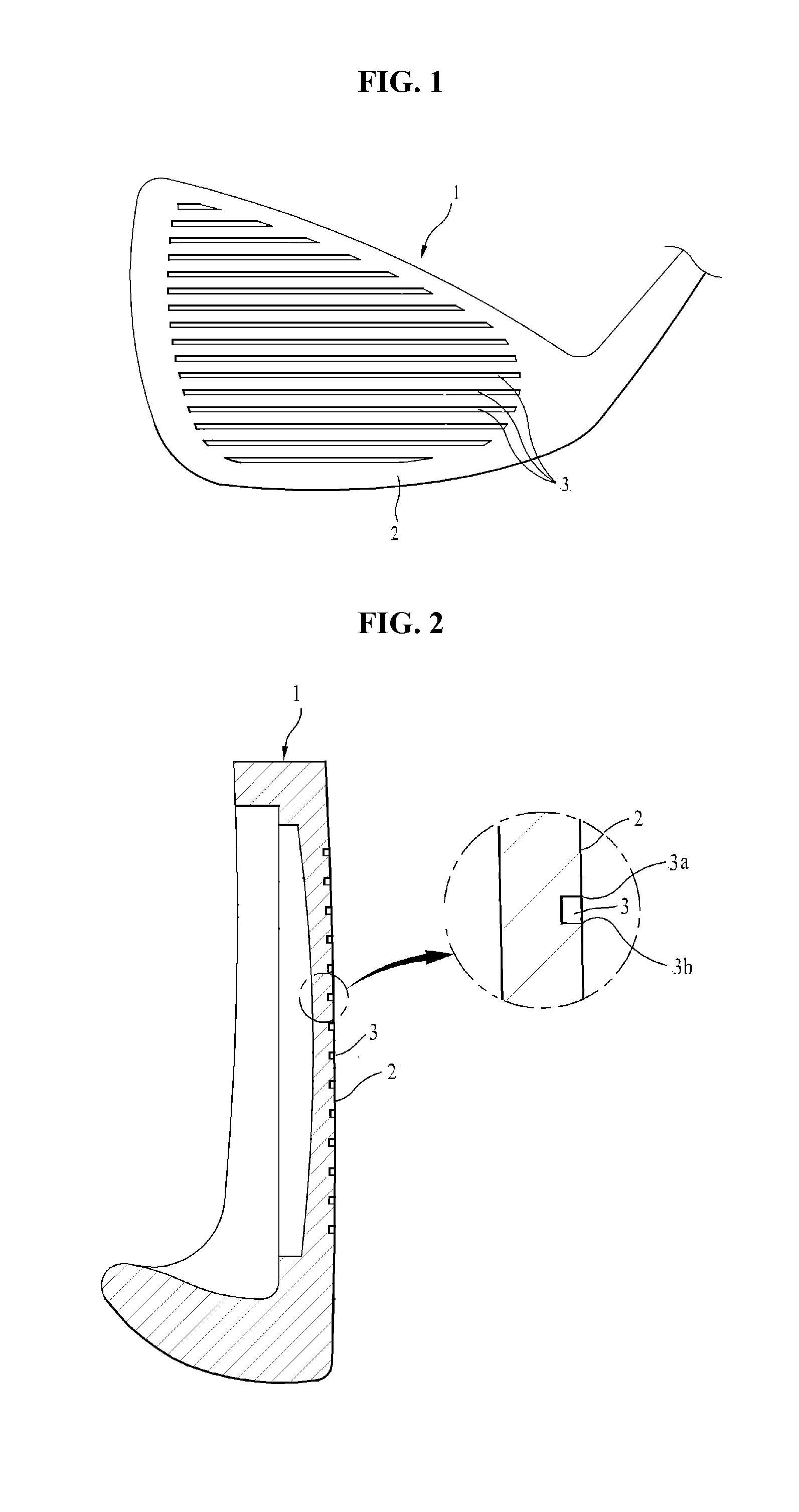

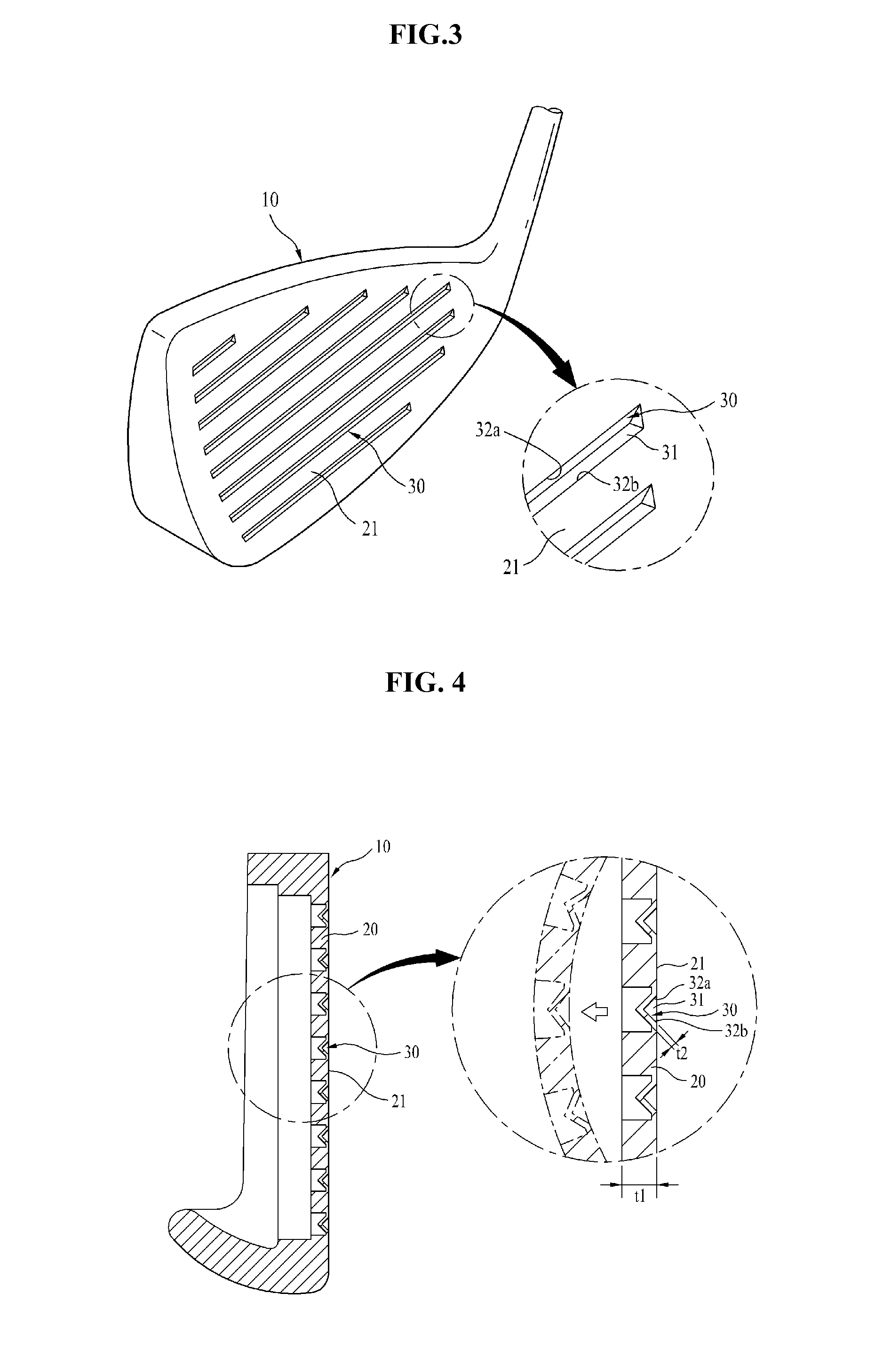

Golf Club Head

InactiveUS20120052979A1Easy elastic deformationIncrease elastic deformation rateGolf clubsRacket sportsSpinsEngineering

Disclosed is a golf club head including a variation part, which is easily flexible, formed at a striking surface of a head, and capable of increasing repulsive power caused by an elastic deformation rate of the striking surface upon striking a ball to improve a flying distance, and strengthening an elastic recovering force of corner parts formed by the variation part to further enhance stability in a ball-flying direction and a ball spin function.

Owner:KOREA NUCLEAR ENG

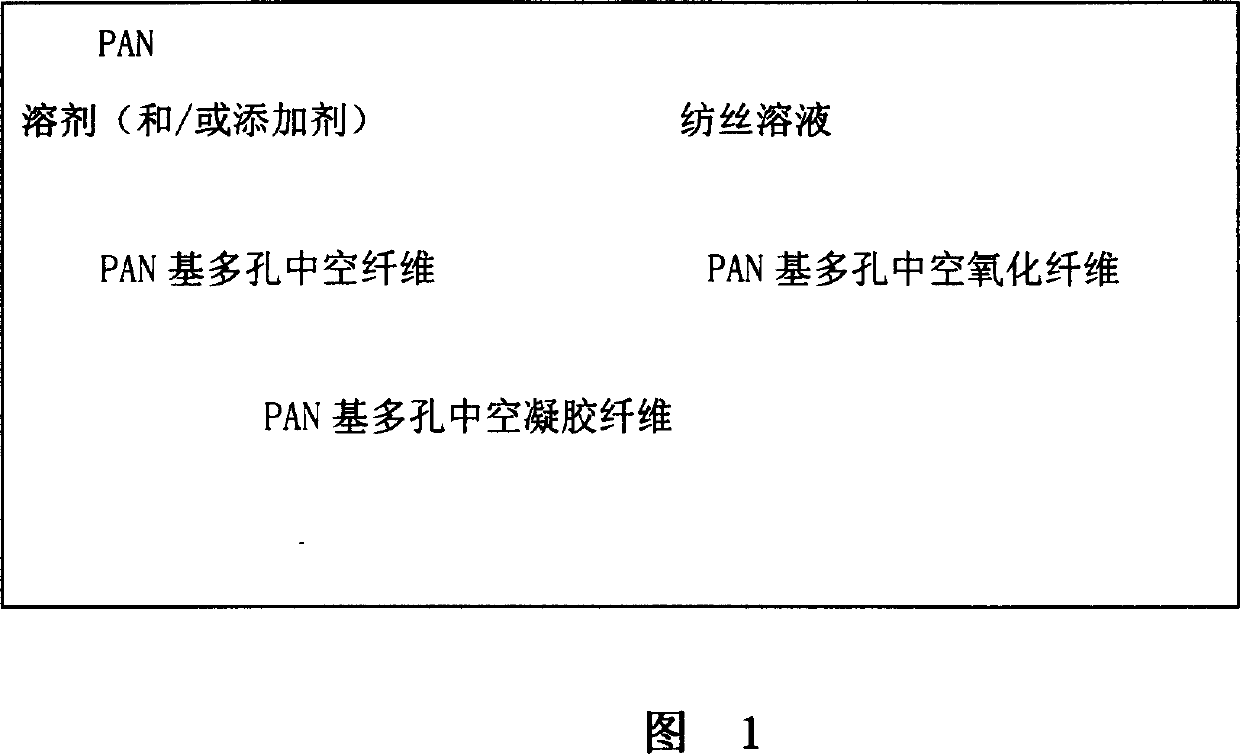

Stimulating responsiveness porous hollow gel fiber and its producing method

InactiveCN1587451AControl deformation rateHigh breaking strengthHollow filament manufactureMonocomponent synthetic polymer artificial filamentSolventHollow fiber membrane

The present invention relates to one kind of porous hollow gel fiber prepared with polyacrylonitrile (PAN) or its copolymer as material, and through compounding spinning solution with solvent, spinning to form porous hollow fiber and subsequent oxidation and saponification. The porous hollow gel fiber is pH and electric field sensitive and has great deformation rate, great shrinkage force, fast response speed and convenient operation.

Owner:DONGHUA UNIV

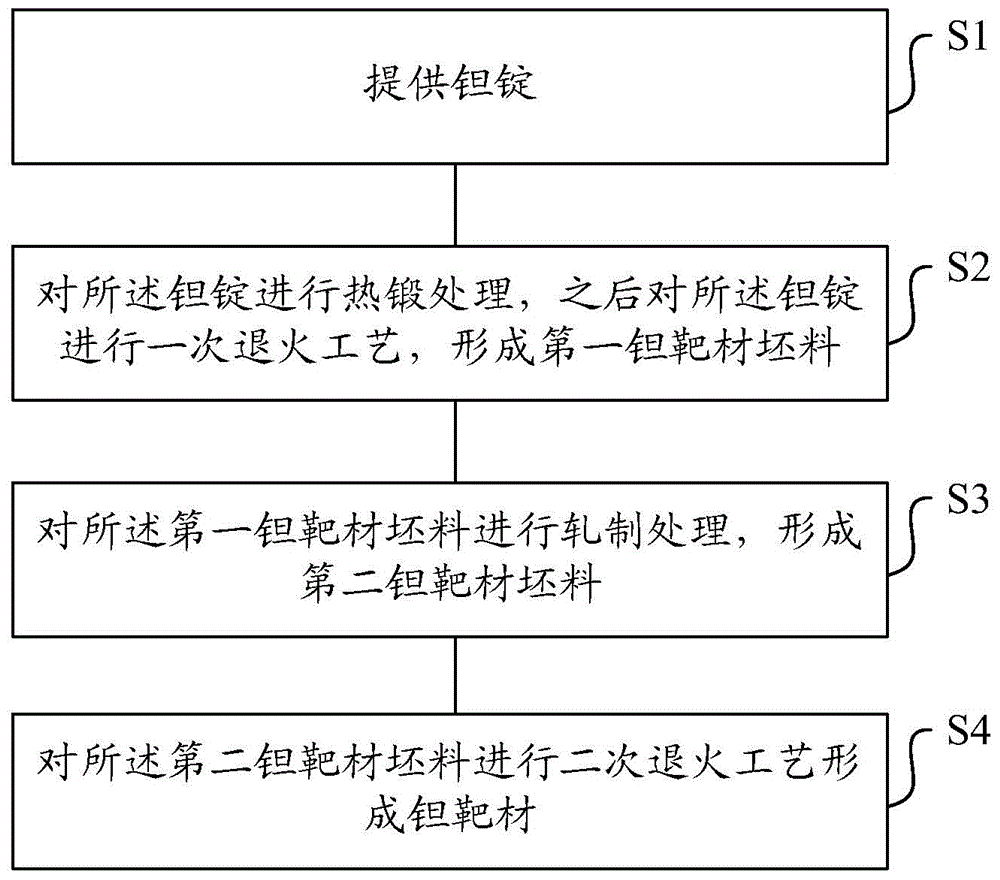

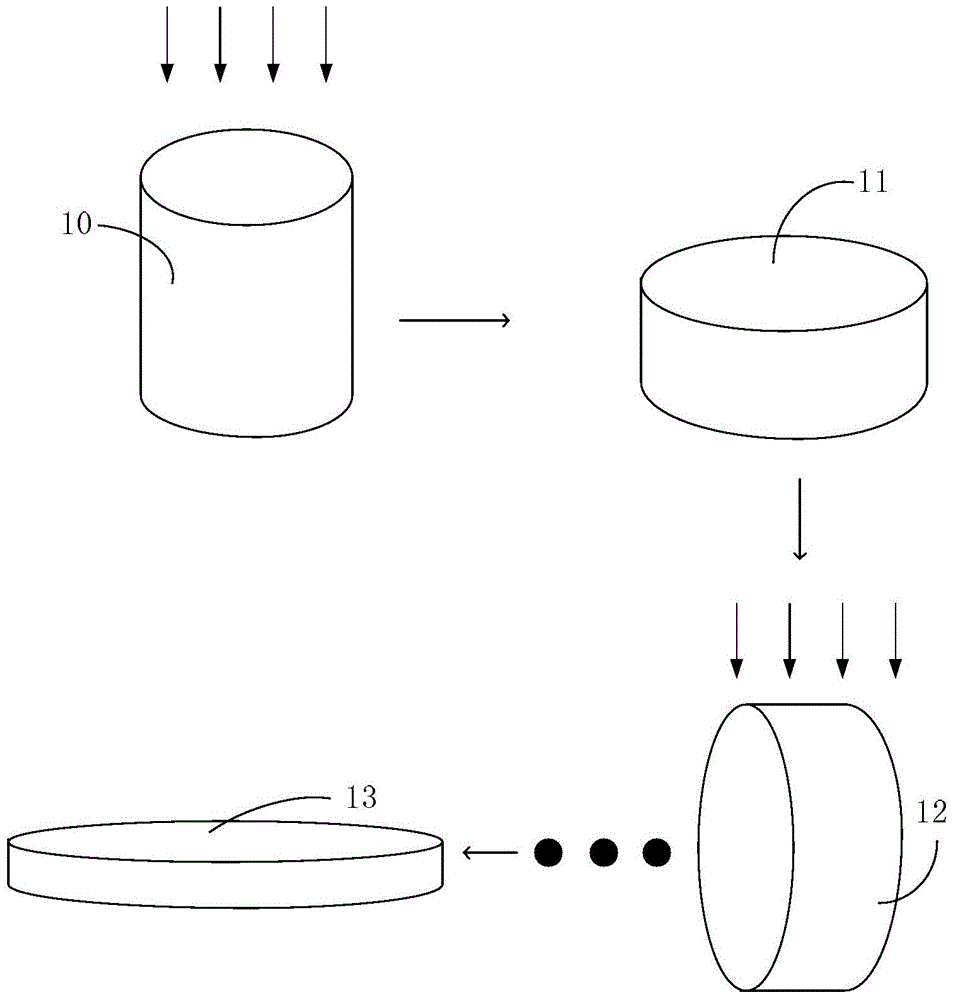

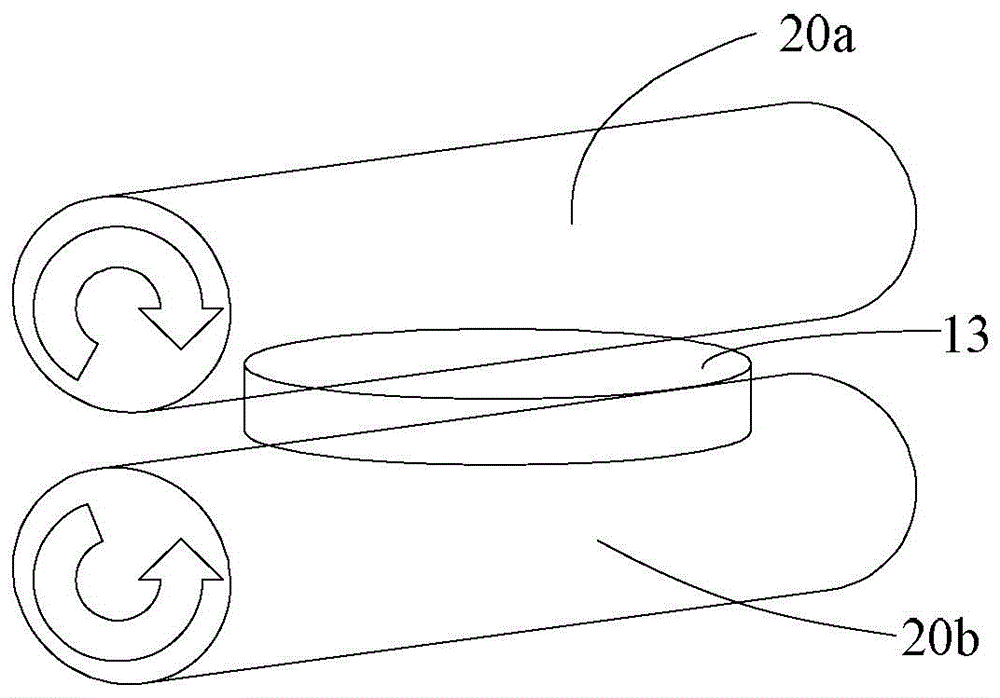

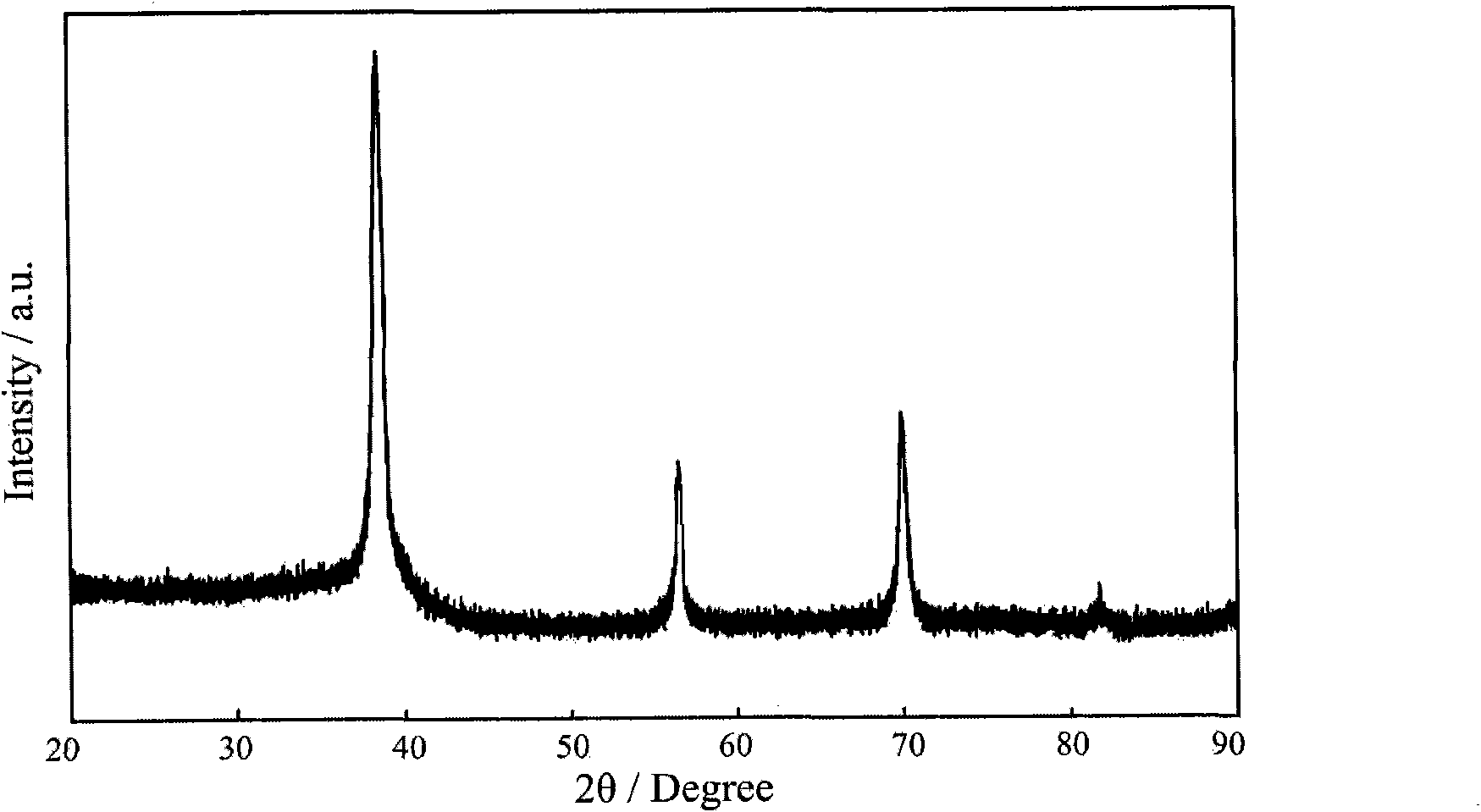

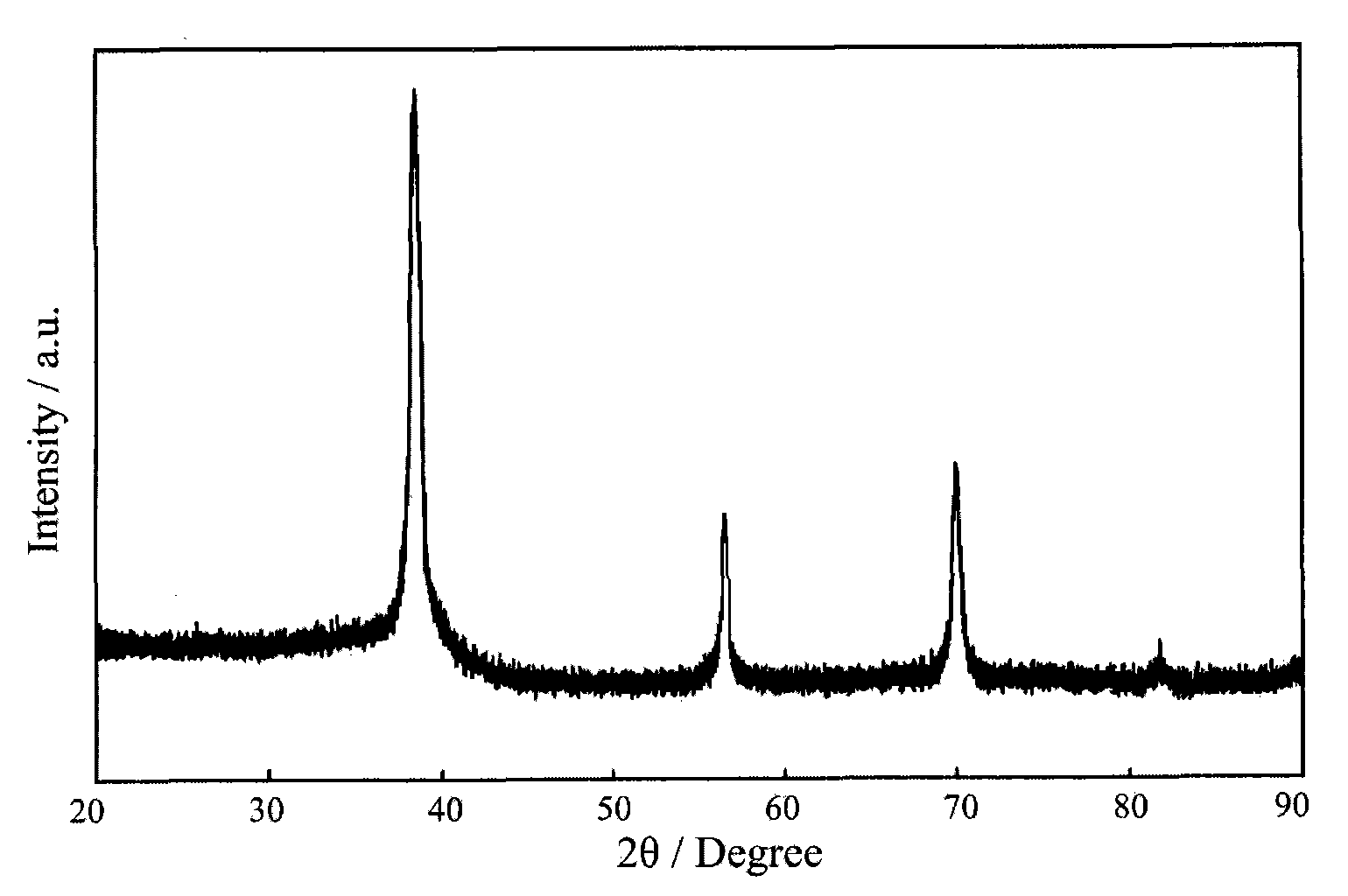

Method for manufacturing tantalum target material

ActiveCN104419901ASimple internal structureStress reliefVacuum evaporation coatingSputtering coatingIngotTantalum

The invention provides a method for manufacturing a tantalum target material. The method comprises the following steps: firstly, carrying out hot forging on a tantalum ingot and then carrying out first annealing on the hot-forged tantalum ingot to form a first tantalum target material billet; rolling the first tantalum target material billet to form a second tantalum target material billet; and carrying out second annealing on the second tantalum target material billet to obtain the tantalum target material. The tantalum target material formed according to the technical scheme has fine internal grains and uniform internal microstructure and thus the defects such as delamination inside the tantalum target material are effectively avoided, the sputtering rate of the tantalum target material and the quality of the formed tantalum film in the subsequent use process are improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

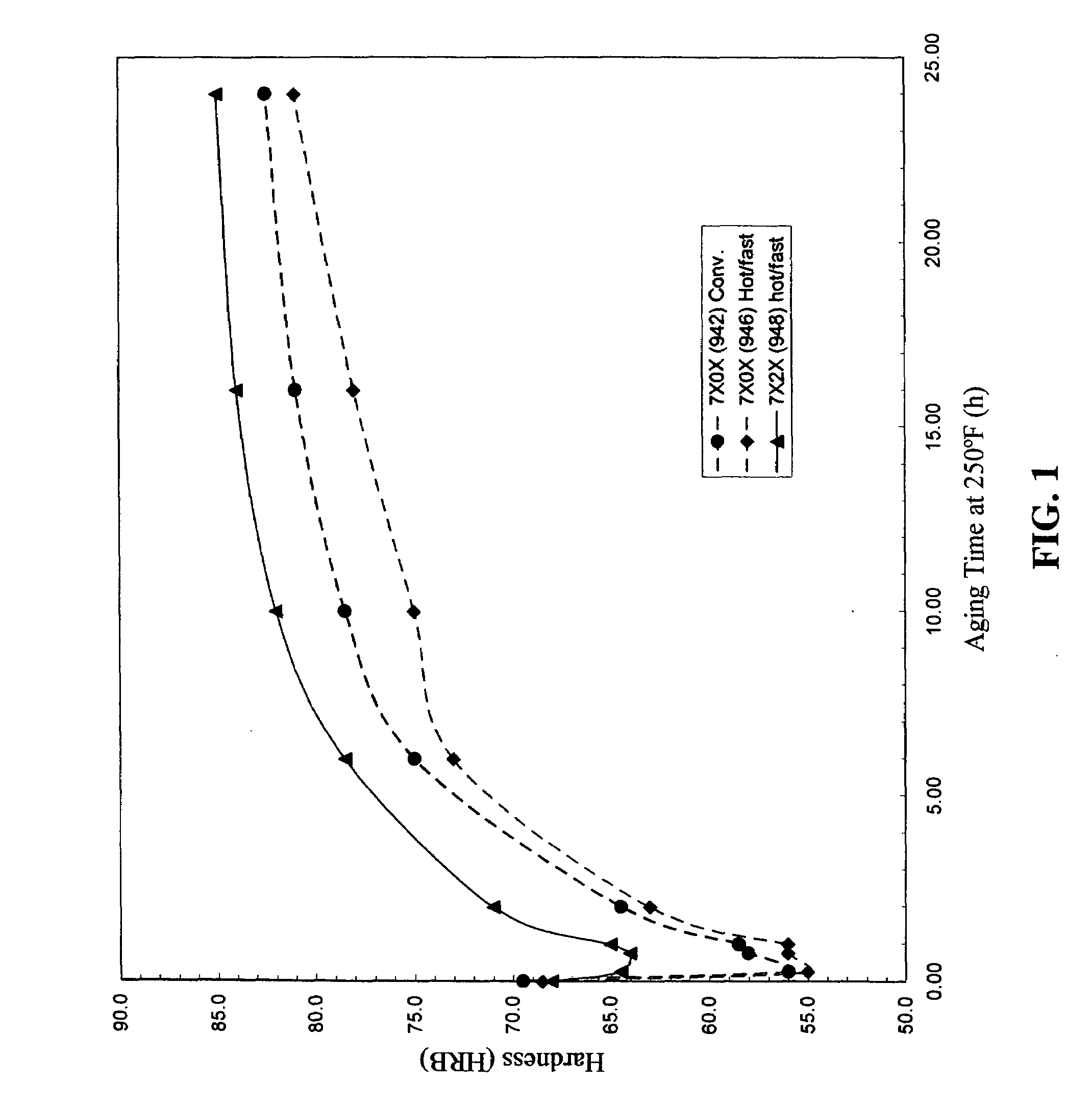

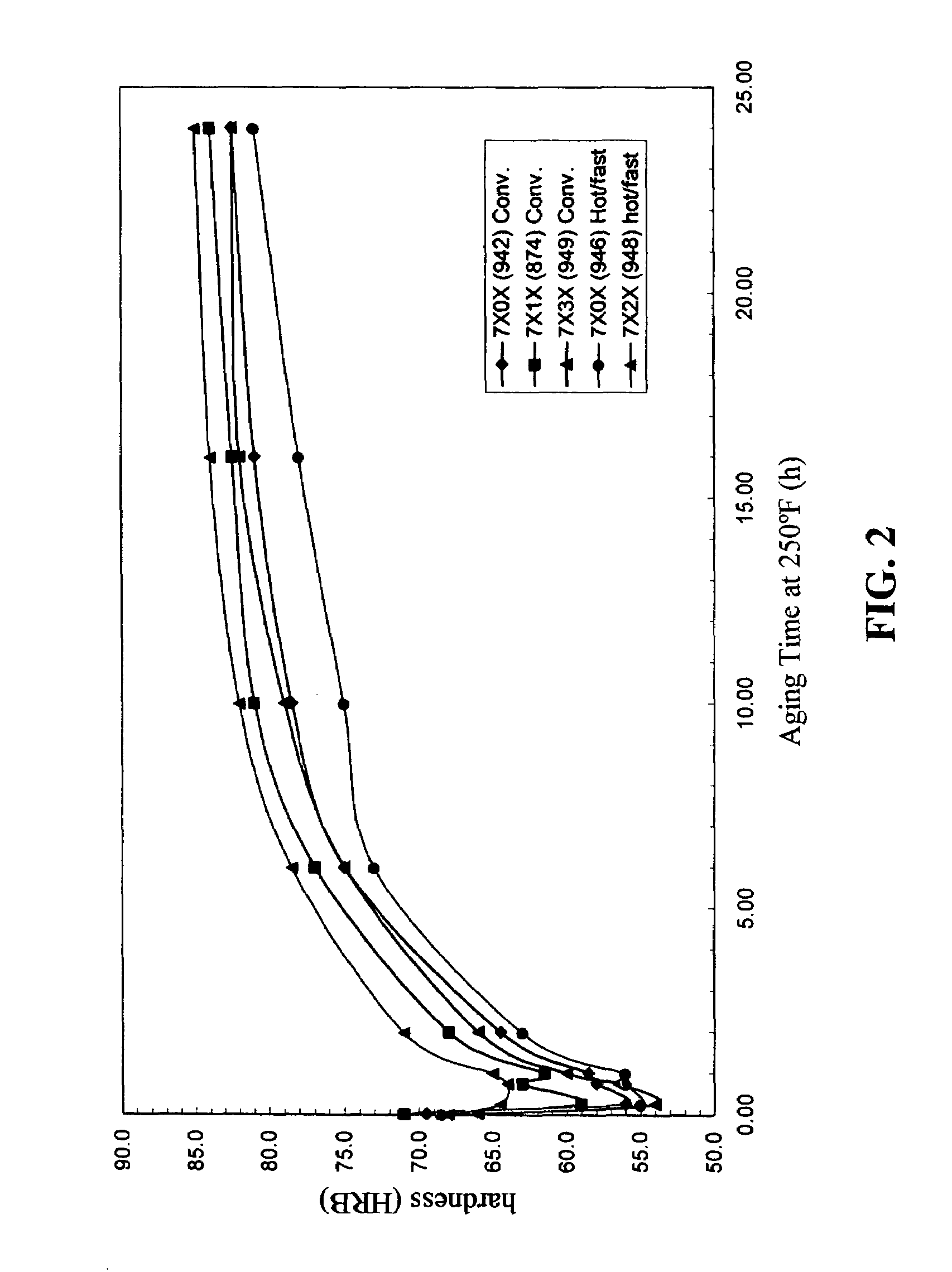

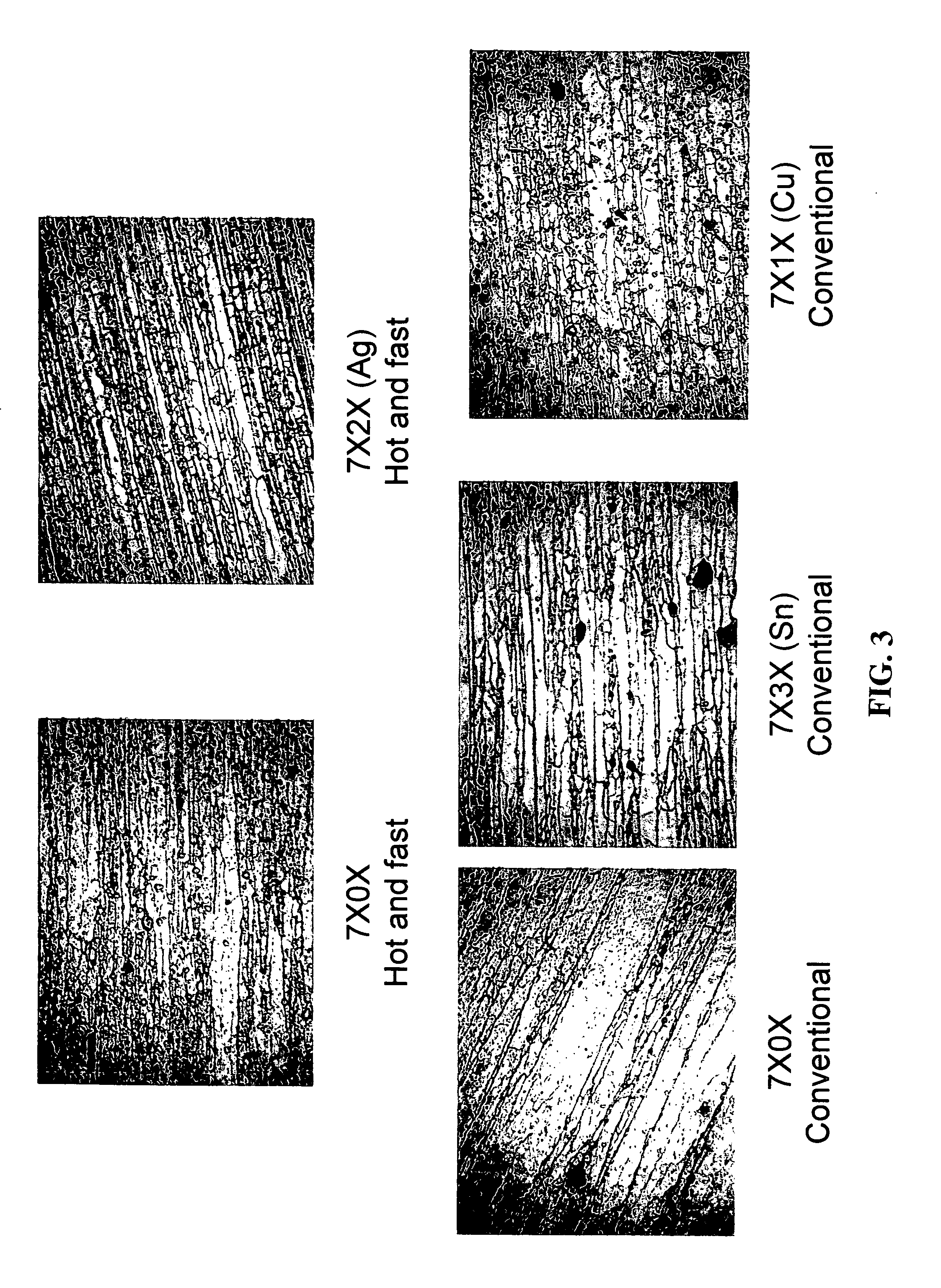

Aluminum-zinc-magnesium-scandium alloys and methods of fabricating same

Aluminum-zinc-magnesium-scandium alloys containing controlled amounts of alloying additions such as silver and tin are disclosed. The presence of Ag and / or Sn alloying additions improves fabrication characteristics of the alloys, such as the ability to be extruded at high temperatures and very high extrusion rates. The Al—Zn—Mg—Sc alloys may optionally include other alloying additions such as Cu, Mn, Zr, Ti and the like. The alloys possess good properties such as relatively high strength and excellent corrosion resistance. The alloys may be fabricated into various product forms such as extrusions, forgings, plate, sheet and weldments.

Owner:SURFACE TREATMENT TECH INC

Forming method of block-shaped amorphous composite material

The invention relates to a forming method of a block-shaped amorphous composite material, which is characterized by comprising the following steps: (1) selecting a block-shaped amorphous composite material which has the component purity greater than 99.3% and substrate components with strong glass forming capacity, preparing a high-purity block-shaped amorphous composite material, and cutting the block-shaped amorphous composite material into an ingot blank according to a forming part; (2) heating the ingot blank under gas protection at the speed of 0.5-50 DEG C / s to the liquidus temperature and the solidus temperature range of the block-shaped amorphous composite material, and insulating for 3-30 minutes; and (3) under pressure, filling a liquid-solid coexistent metal slurryinto a mold cavity at a deformation rate of 102-106s<-1>, and forcibly cooling for solidifying at the cooling speed of 1-200 DEG C / s while maintaining the pressure. The invention can obtain the metal slurry the second phase of which is uniformly distributed in the liquid phase, has low forming temperature, long service life of the mold and high production efficiency, improves the product performance, can be used for forming parts with complex forming shapes and thin walls, and can be widely applied to amorphous composite materials of Zr-series, Cu-series, Ti-series, La-series, Co-series and the like.

Owner:NANCHANG UNIV

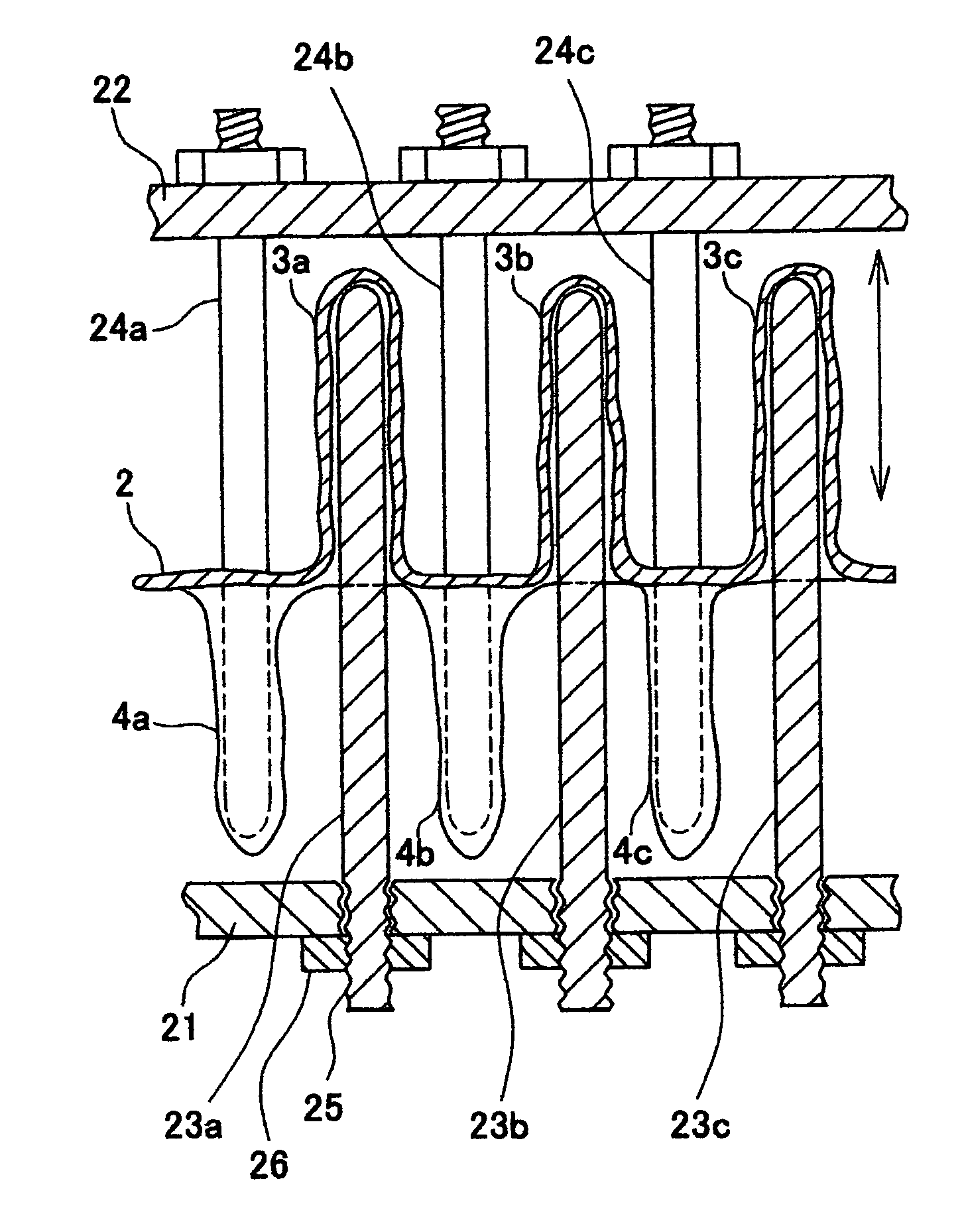

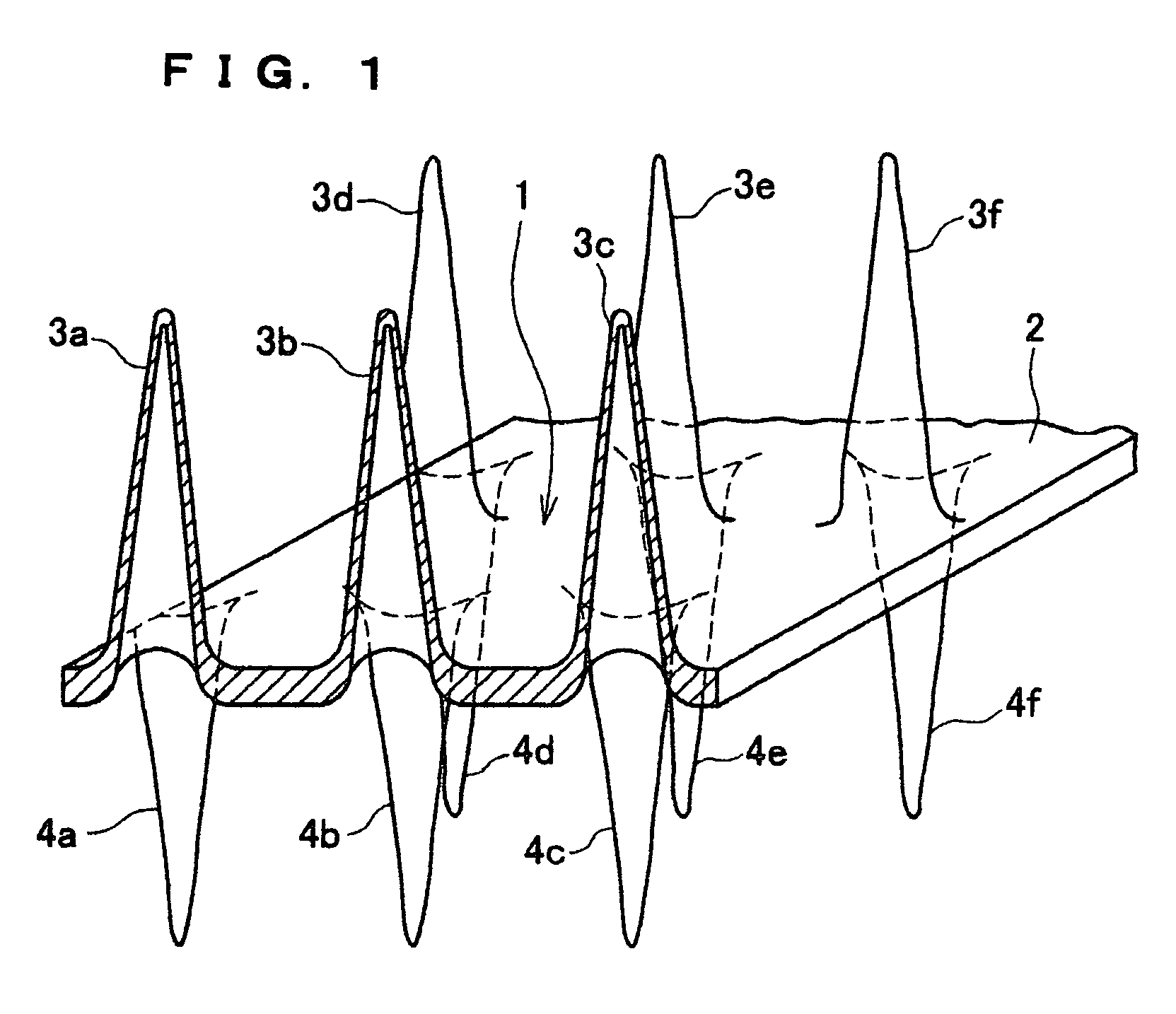

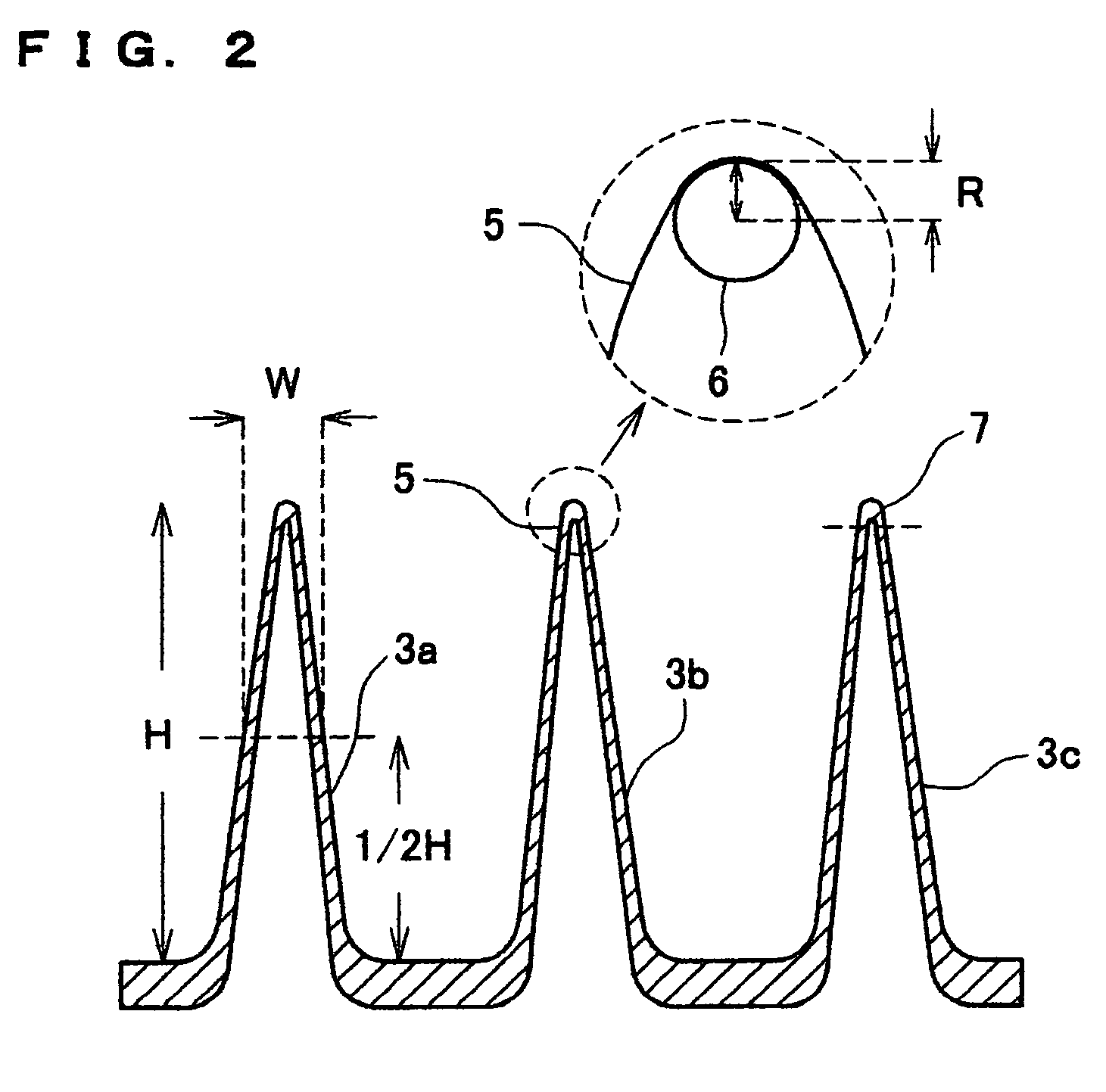

Three-dimensional structure and method and apparatus for manufacture thereof

InactiveUS7488169B2Reduce penetrationSave resourcesCeramic shaping apparatusDough shapingHigh resistanceBiomedical engineering

A three-dimensional structure, and a method and device for producing the structure, where the structure has pressure resistant characteristics despite its voluminous and elastic nature and has higher resistance to surface wear and mechanical dimensional stability than a foamed polyethylene sheet. The three-dimensional structure is characterized in that a resin sheet has needle-like projections on its both faces, each projection has a height (H) of 3 mm or more, the height (H) and a width (W) of the projection at the height of H / 2 has a relationship of H≧2.5 W, the projection has a hole in its tip, and the projections are joined to a sheet-like object at their tops. The method of producing the three-dimensional structure is characterized in that a large number of needle-like dies are integrated with a base plate, and a pair of the base plates are arranged so as to be opposed to each other, and a resin sheet is deformed when the pair of the base plates move parallel to each other so as to intrude into the resin sheet. Further, a method of continuously producing the three-dimensional structure is provided.

Owner:KAWAKAMI SANGYO CO LTD

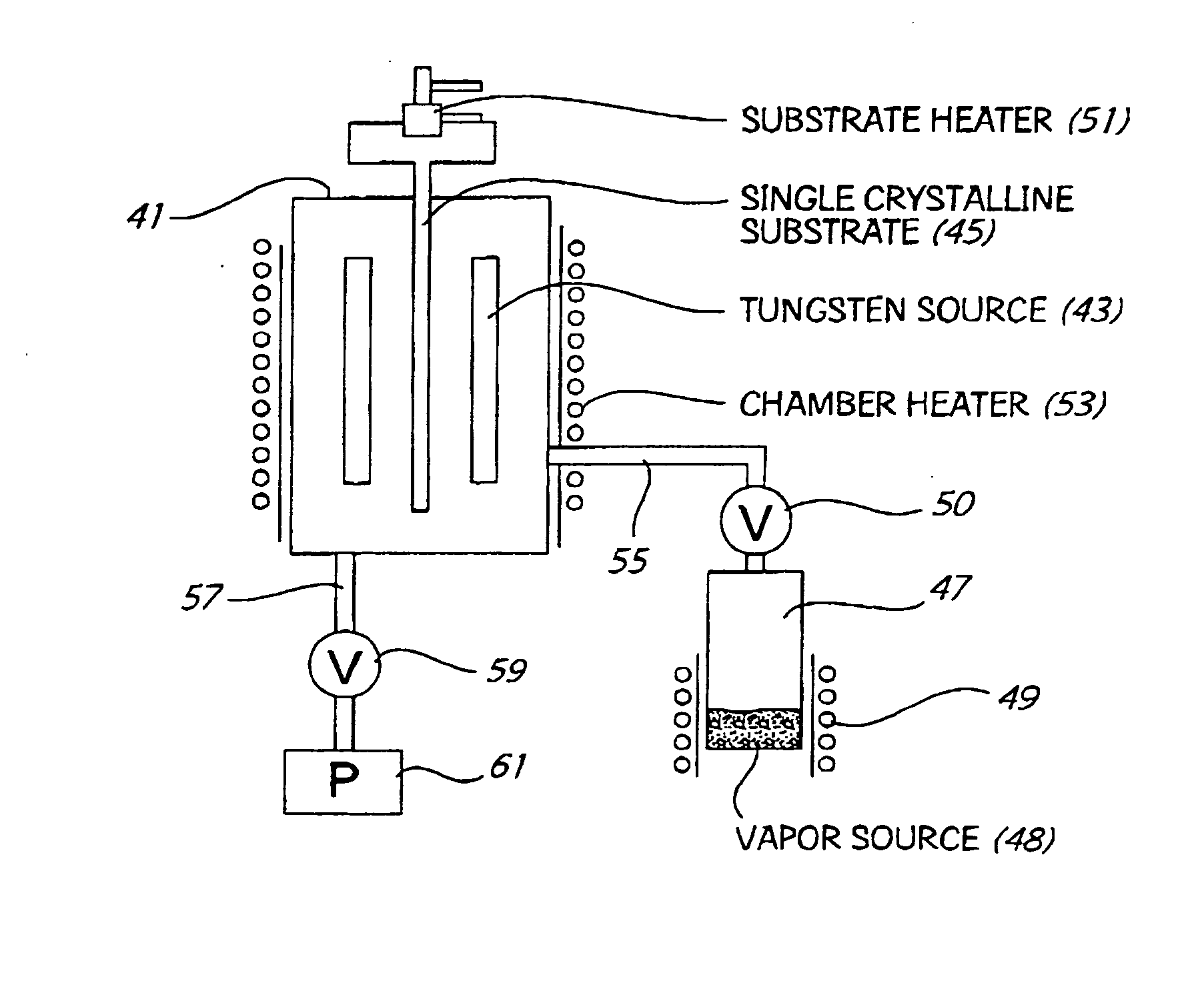

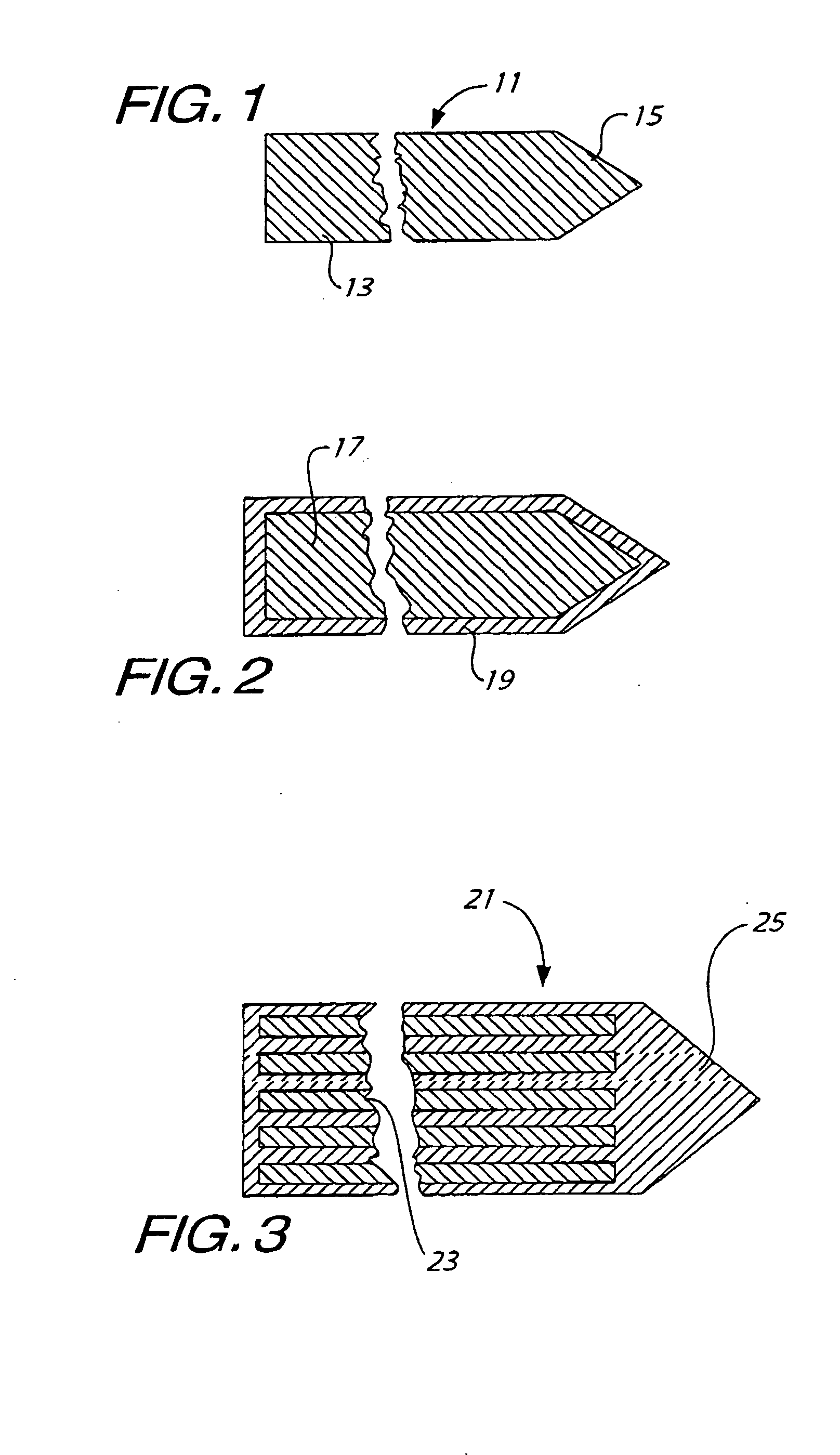

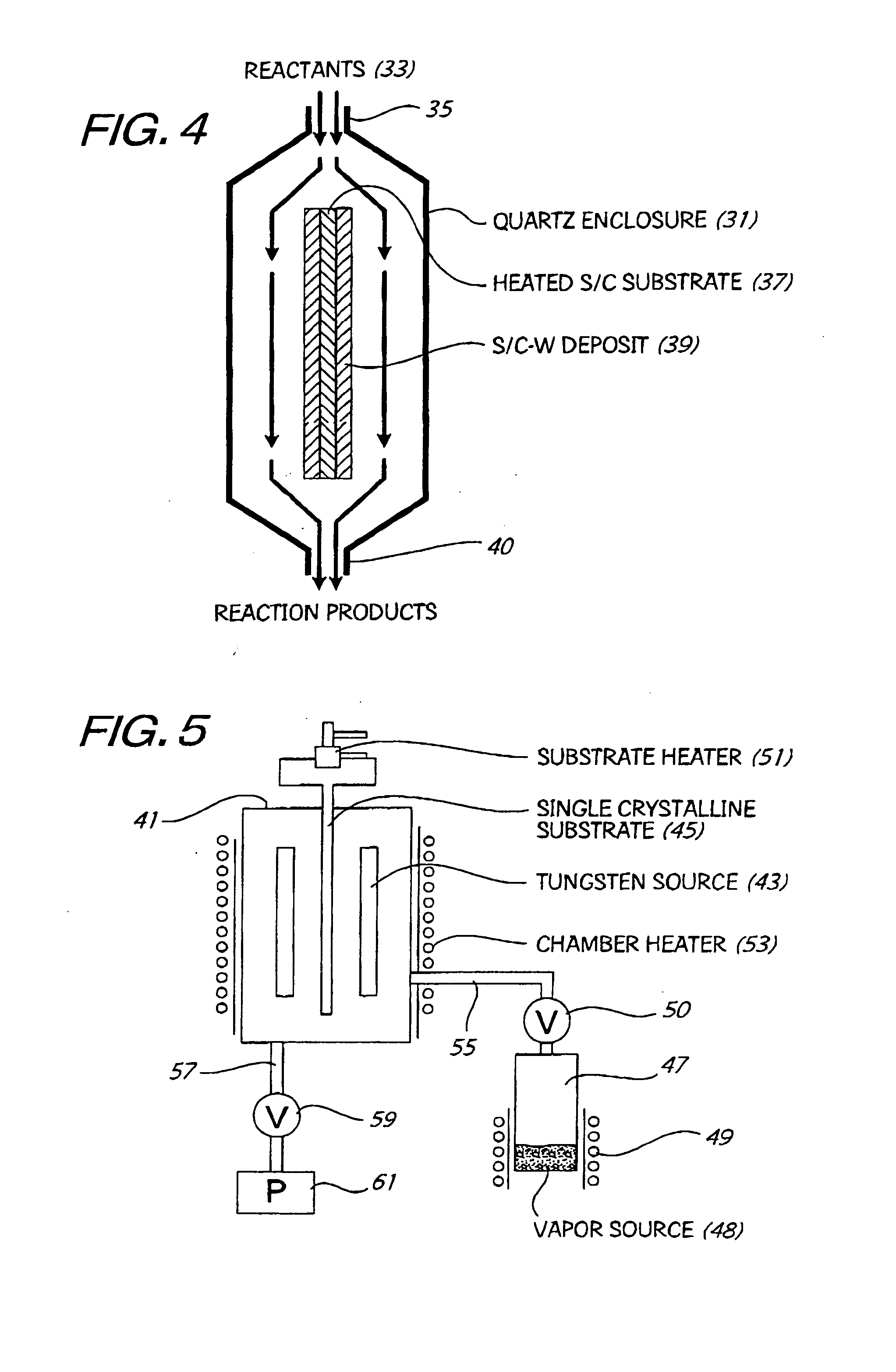

Single crystal tungsten penetrator and method of making

InactiveUS20050072498A1Minimizing creationEasy to useAmmunition projectilesPolycrystalline material growthRheniumHigh density

High density single crystal penetrators are made from tungsten or from alloys containing at least 90% tungsten, and a remainder of essentially tantalum, rhenium, niobium, molybdenum or a mixture thereof. The penetrator will generally be circular in cross-section and have a length to diameter ratio of at least about 10 to 1, with the single crystal body being aligned so the crystalline axis having the [100] orientation is parallel to the longitudinal axis of the penetrator. A penetrator having such desired crystalline characteristics can be formed by CVD about a heated substrate of body-centered cubic crystal material. One particularly efficient process utilizes static CVD in a closed chamber and employs a solid feedstock of polycrystalline tungsten material.

Owner:BEGG LESTER L

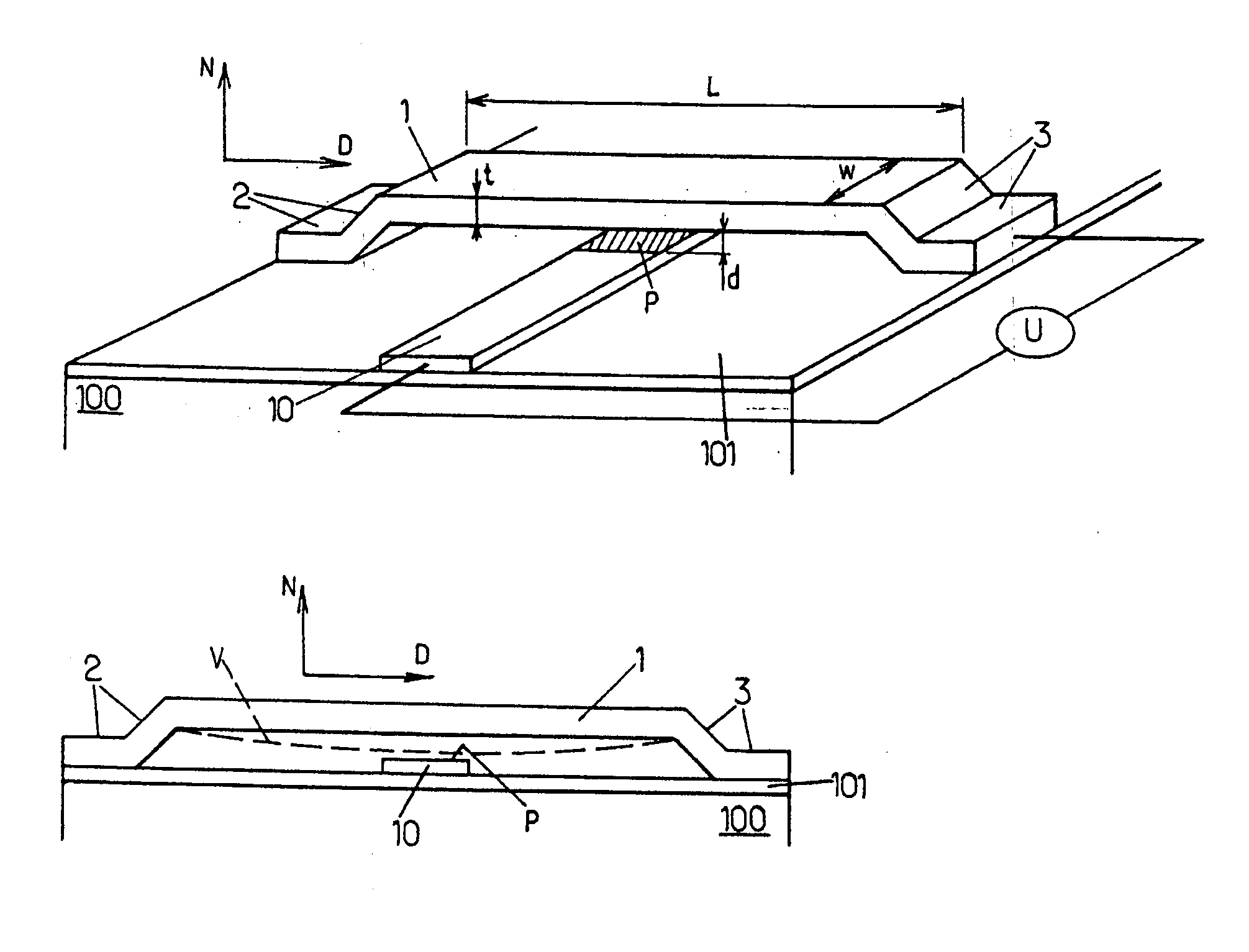

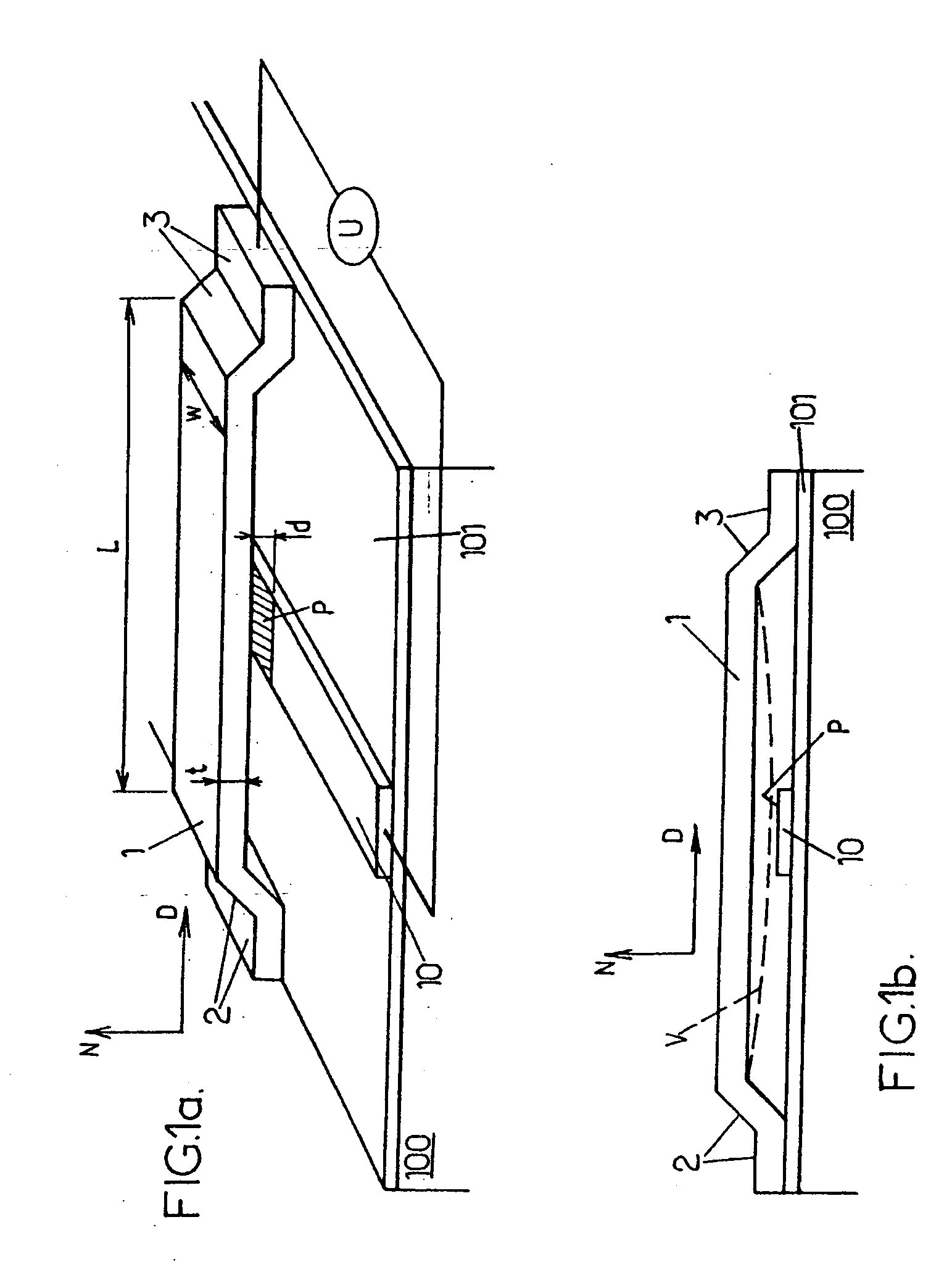

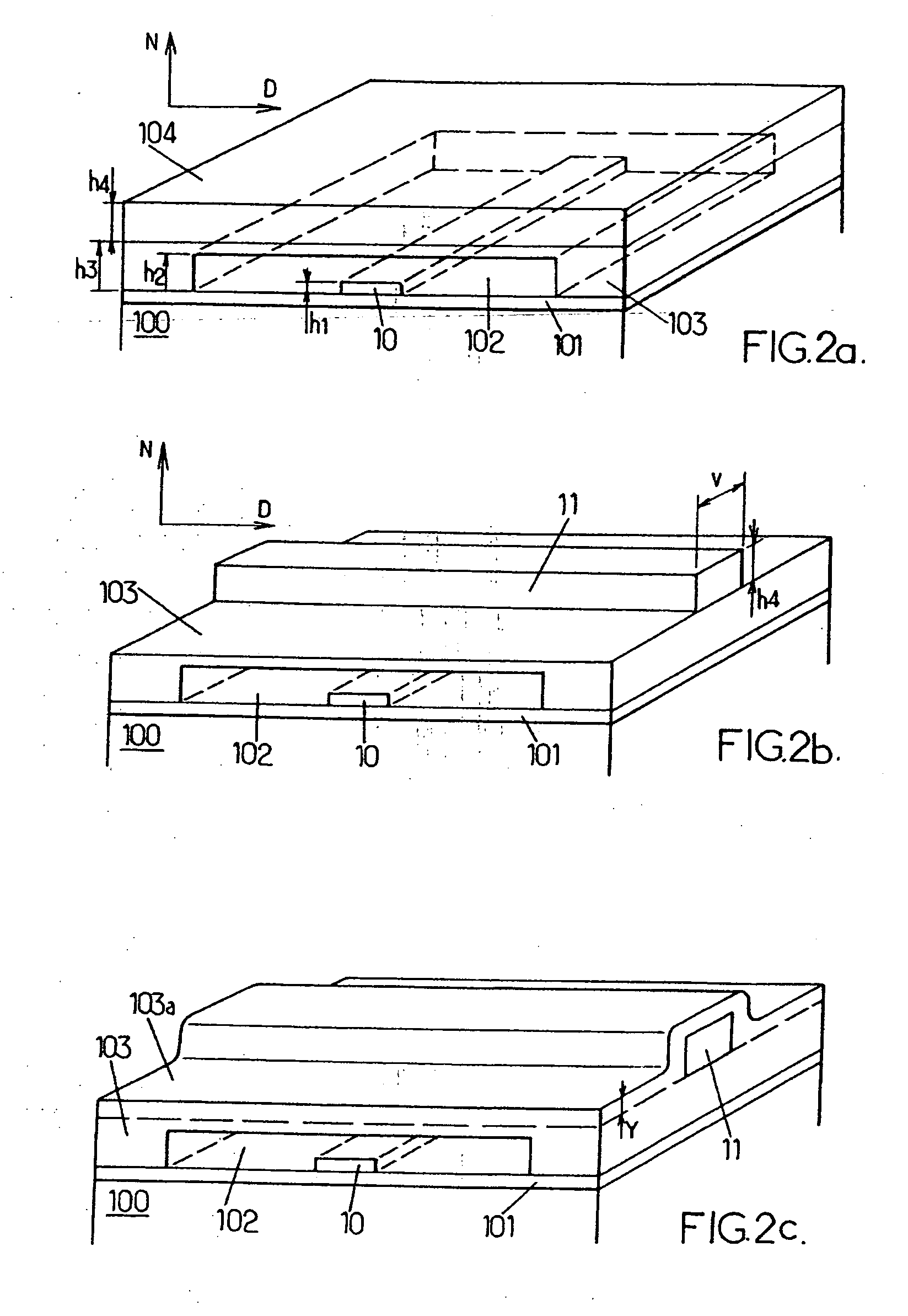

Microelectromechanical system comprising a beam that undergoes flexural deformation

InactiveUS20070035200A1Easy to produceIncrease deformation rateImpedence networksElectrostatic generators/motorsMicroelectromechanical systemsElectrostatic interaction

A microelectromechanical system comprises a beam and an electrode coupled to the beam via electrostatic interaction. The beam is designed to undergo elastic flexural deformation and has an approximately constant cross section. The beam consists of several flat faces that extend over the length of the beam, each having a thickness of less than an external dimension of the cross section. A flexural vibration frequency of the beam is then increased compared with a solid beam of the same external dimensions. Such a microelectromechanical system is suitable for applications requiring very short transition times, or for producing high-frequency oscillators and resonators.

Owner:STMICROELECTRONICS SRL +1

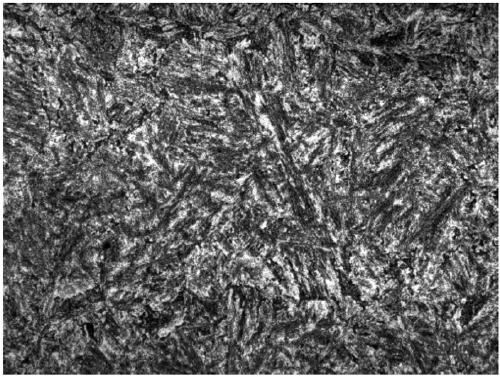

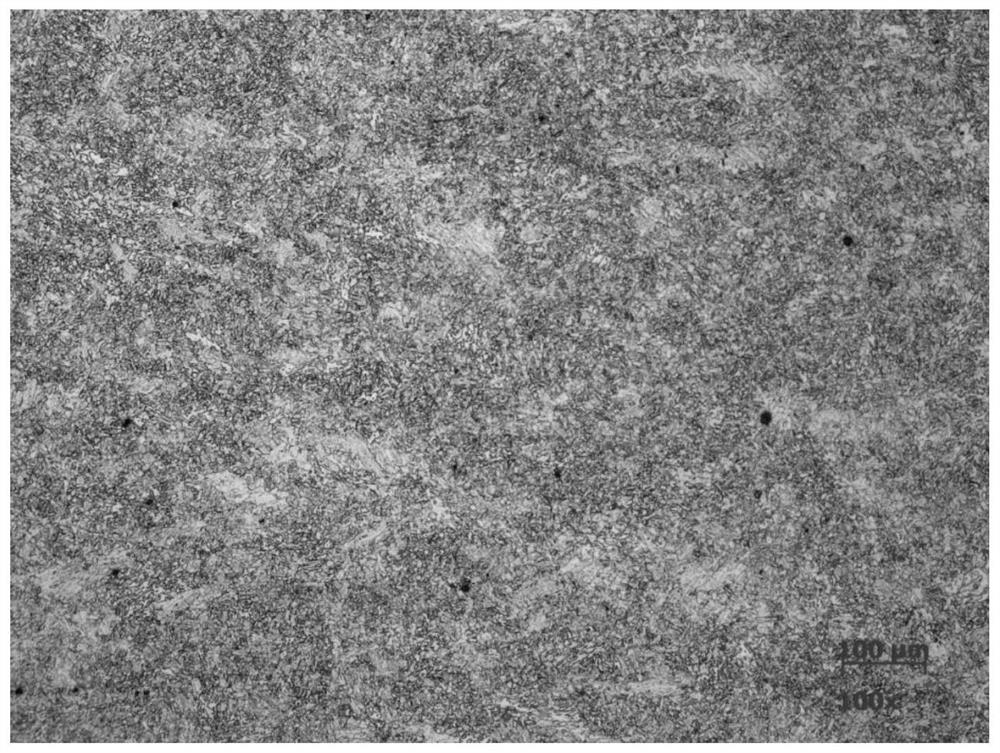

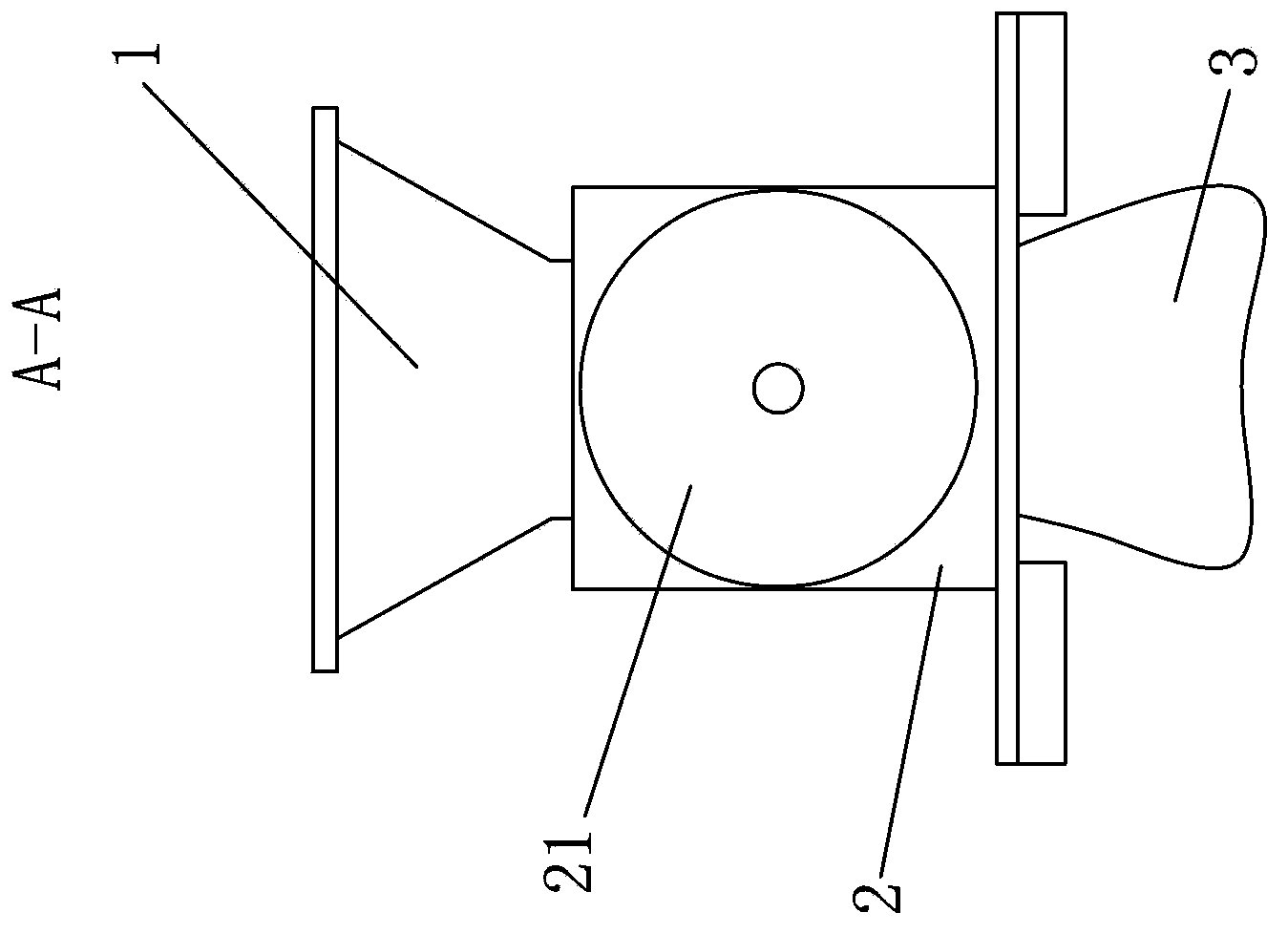

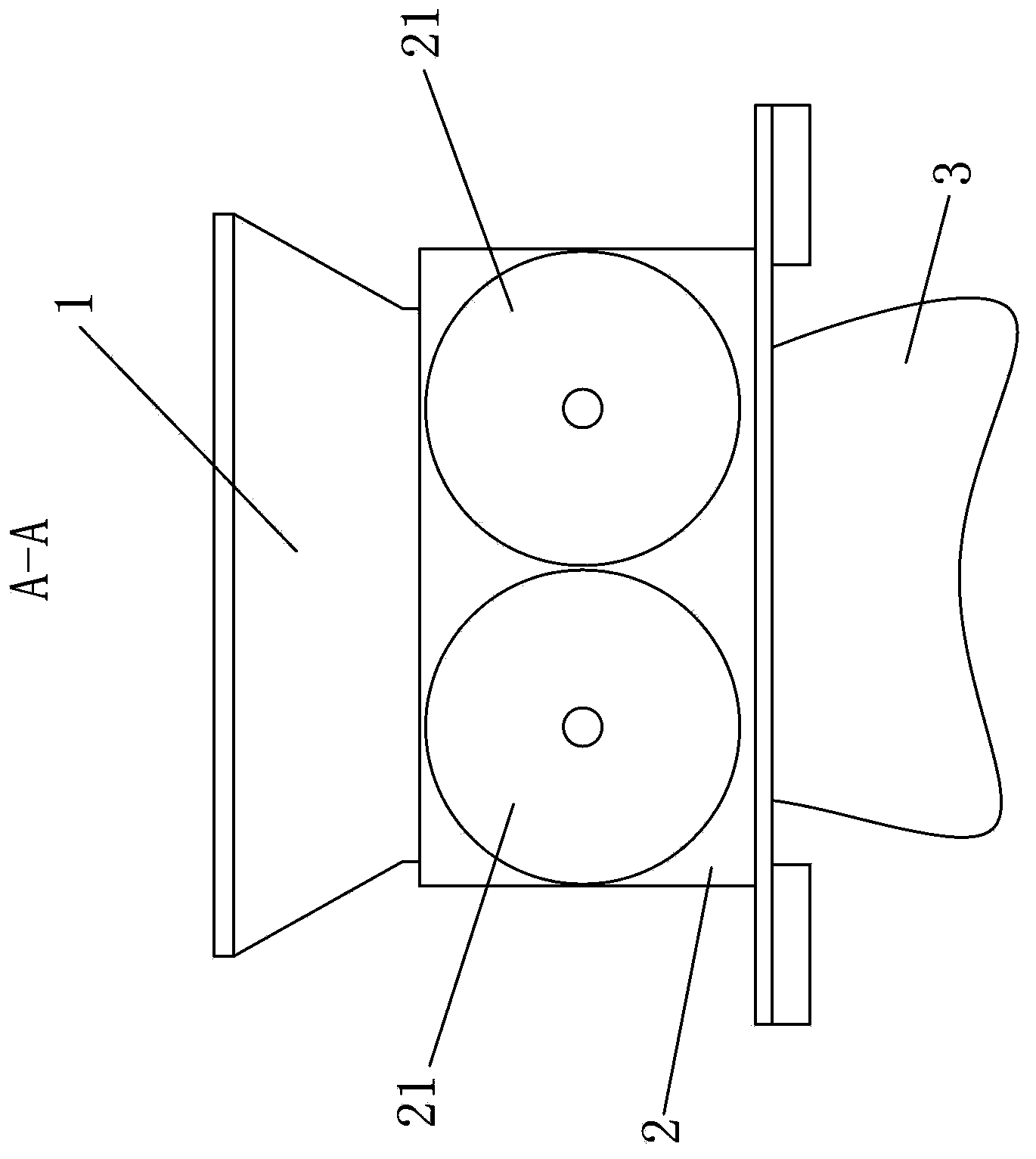

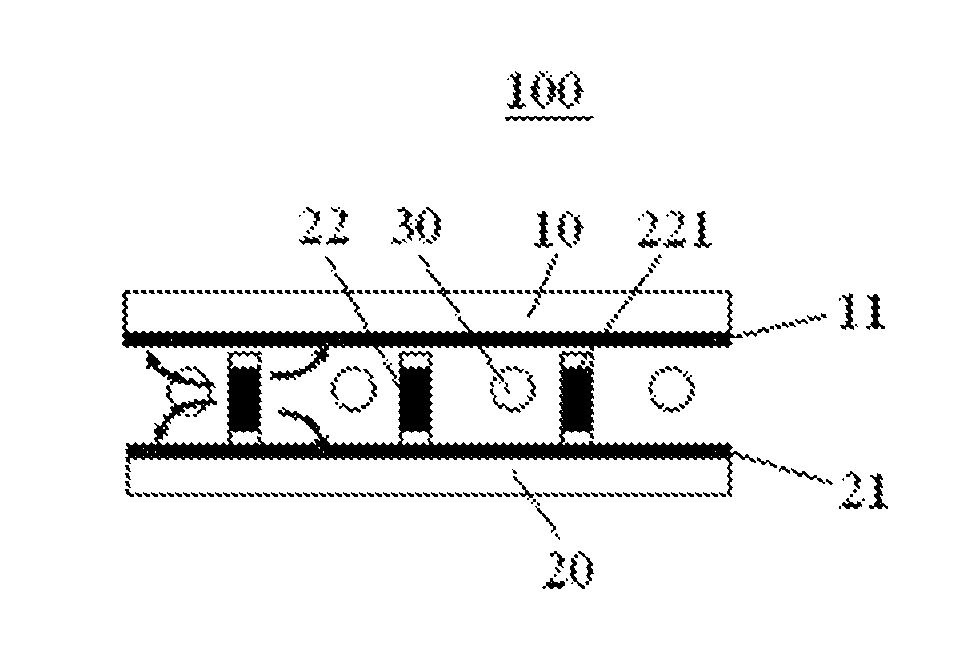

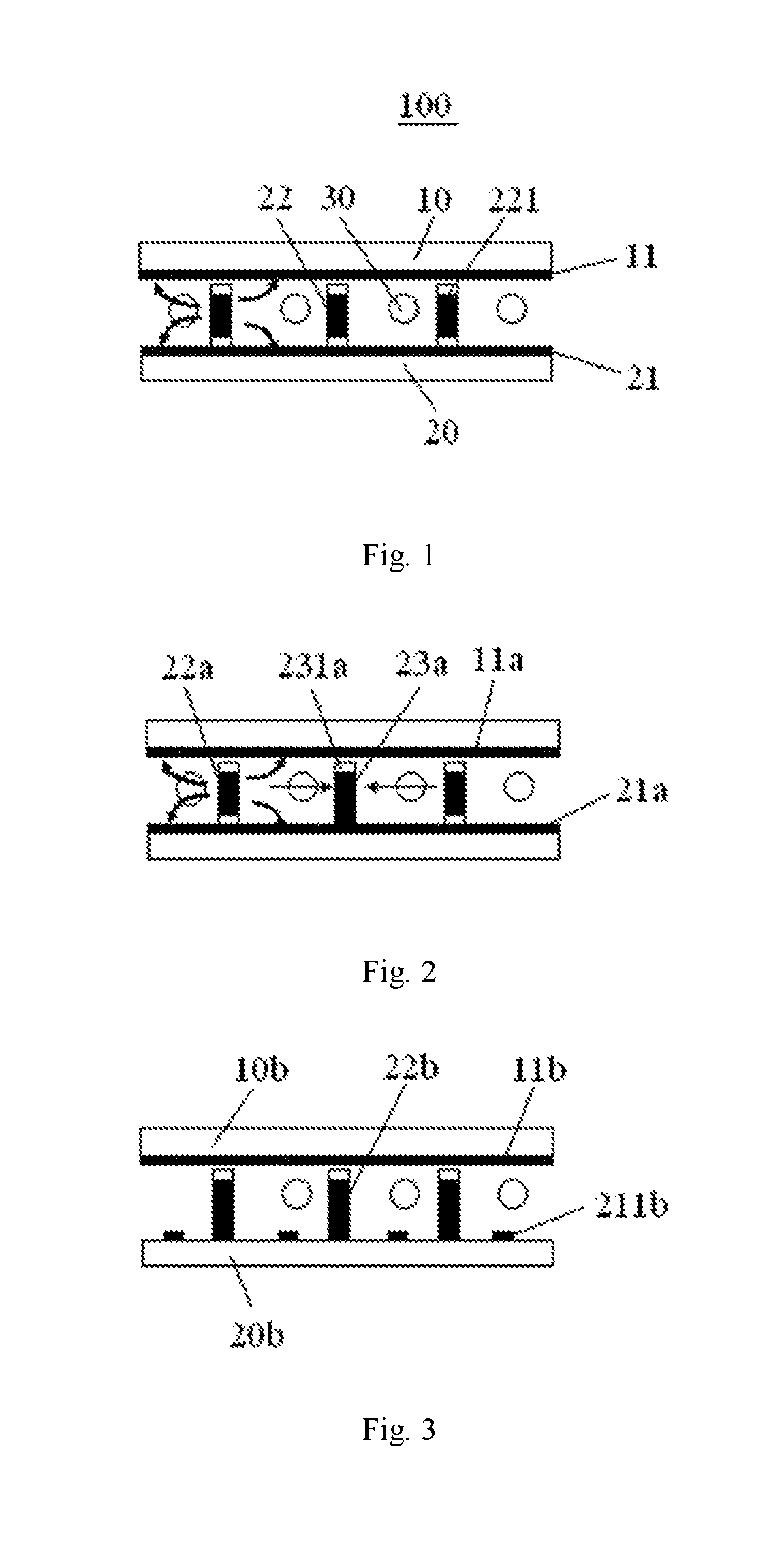

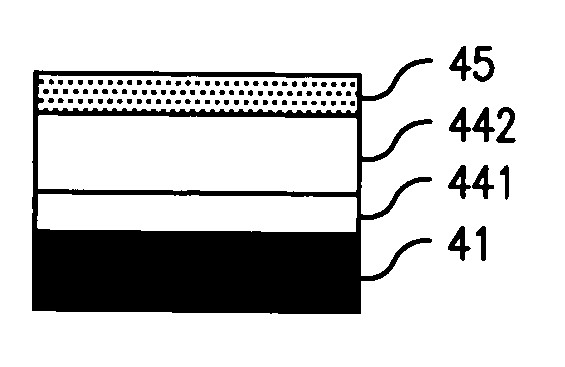

Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof

ActiveCN111058116AEasy to prepareEasy to operateArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsEngineeringBiology

The invention discloses a skin-core type poly(lactic acid) (PLA) / poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and a preparation method thereof, and belongs to the field of high polymer materials. The preparation method of the skin-core type PLA / PHBV composite fiber specifically includes the steps: 1, respectively drying the raw material PLA in a skin layer and a raw material PHBV in a core layer, wherein moisture content of the PLA and the PHBV is not more than 200 ppm; and 2, weighing the raw materials PLA and PHBV obtained in the step 1 according to a composite spinning ratio to perform compositely spinning, melting spinning, cross air blowing, applying oil, winding, online stretching, and thermoforming to obtain the skin-core type PLA / PHBV composite fiber, wherein the number of holes in a spinning plate used during a spinning process is 24-144. The material prepared according to the method is high in breaking strength, and can be applied to the fields of medical materials, agricultural textile, disposable goods and package materials.

Owner:JIANGNAN UNIV

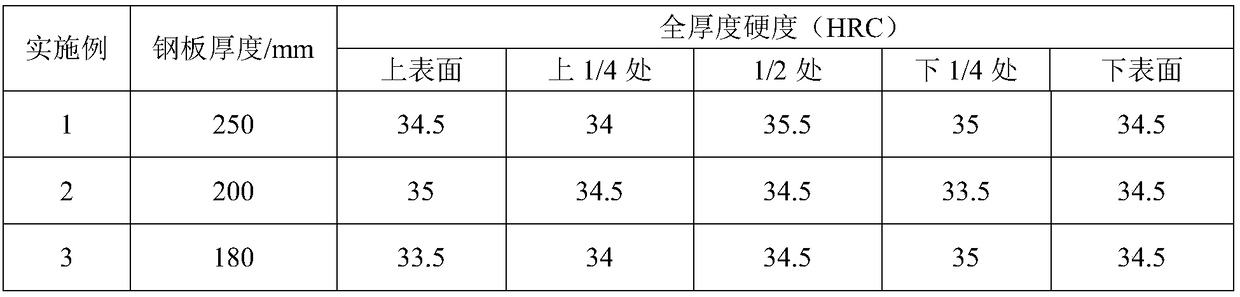

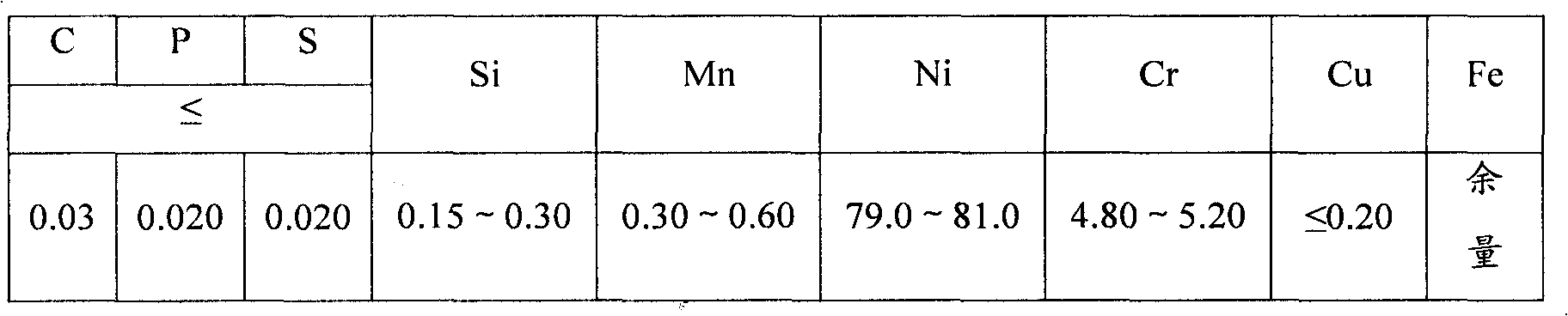

Continuous-casting production technology for low-compression-ratio high-flaw-detection-requirement SM4Gr2MnNi mould steel plate

ActiveCN109234495AQuality improvementHigh densityRoll force/gap control deviceFurnace typesSteelmakingReduction rate

The invention relates to a continuous-casting production technology for a low-compression-ratio high-flaw-detection-requirement SM4Gr2MnNi mould steel plate. The technology comprises the following processes: converter steelmaking, refining, vacuum degassing, 450 mm of a continuous casting blank, hot-sending, heating, blooming and rolling, heating, secondary rolling, heat-treatment, flaw detection,finishing, checking and storing. In the blooming and rolling process, through rapidly cooling the surface, strength of the surface is improved, and the situation that a core temperature of a blank material is higher than that of the surface is guaranteed, and deformation rate of a core is improved. A roughing mill single-machine-frame low-velocity high-reduction technology is used. In the blooming and rolling process, low-velocity high-reduction rolling is performed for 4-6 strokes, a single-stroke reduction amount is 30-60 mm, and a total reduction rate reaches 30% or more, and a blooming material is formed. Through a secondary rolling technology, internal quality of the steel plate is effectively improved, and a density of a material is improved. A maximum thickness of the produced SM4Gr2MnNi steel plate reaches 250 mm, a minimum compression ratio is 1.8, and the flow detection meets a NB / T 47013.3 I-level requirement.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

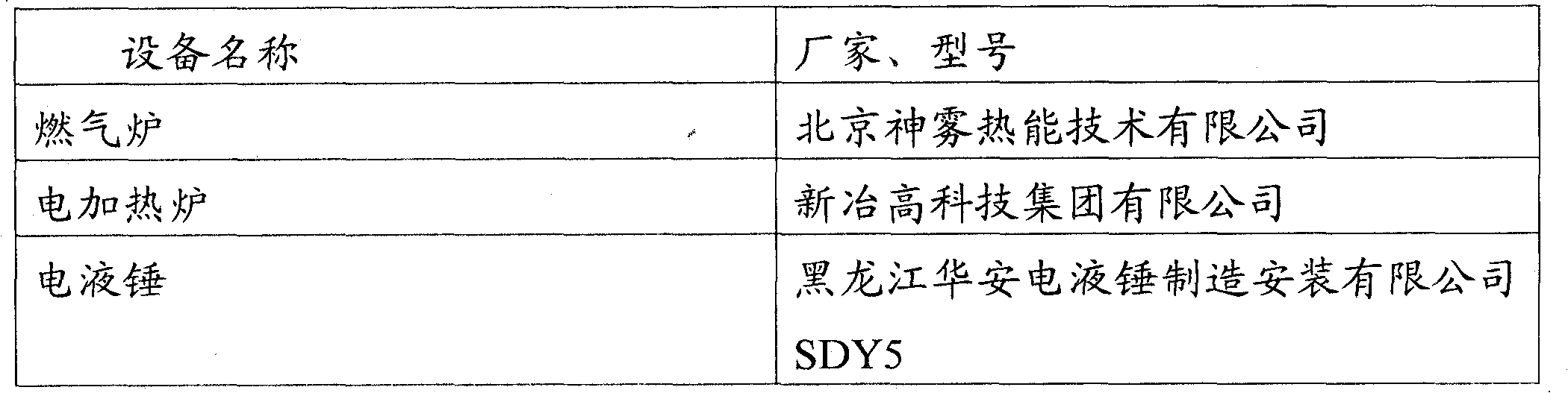

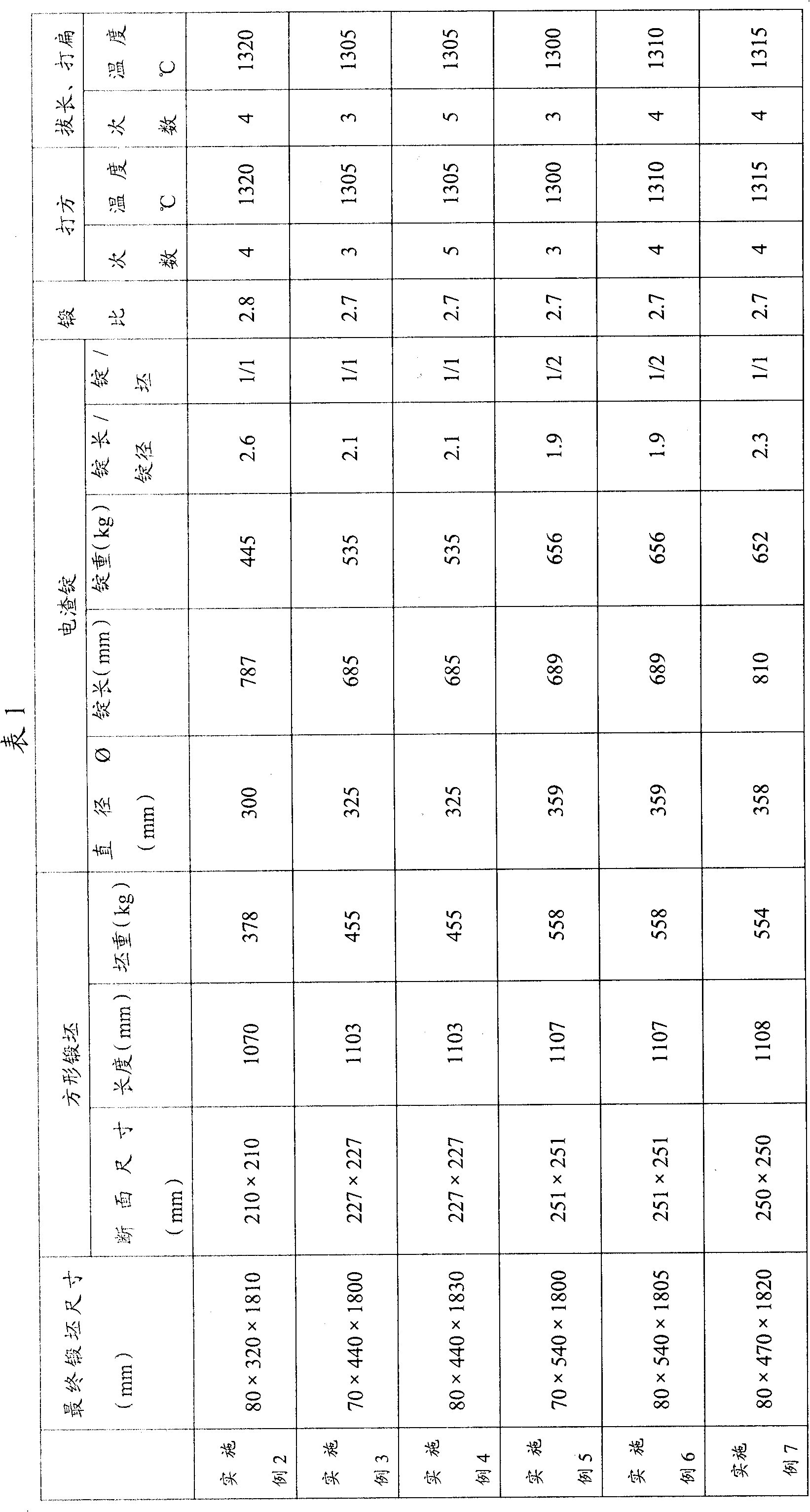

Free forging method for nickel-based magnetically soft alloy slab

The invention provides a free forging method for a nickel-based magnetically soft alloy slab. The free forging method for the nickel-based magnetically soft alloy slab sequentially comprises the following steps of: 1, arranging a spindle made from a nickel-based magnetically soft alloy into a heating furnace and heating the spindle to 1,300 to 1,320 DEG C; 2, performing upsetting and beating squaring forging on the spindle on forging equipment to obtain a square forged slab with the section size of (210-251)mm*(210-251)mm and the length of 1,070 to 1,108mm; 3, reheating the square forged slab to 1,300 to 1,320 DEG C in the heating furnace, and performing drawing-out and beating flattening operations on the forging equipment; and 4, reheating the forged slab obtained by the third procedure to 1,300 to 1,320 DEG C and performing beating flattening and finishing on the forging equipment to make the section size of the forged slab reach a final forged slab size and make the final forging temperature over 1,100 DEG C. The obtained forged slab has the size of (70-80)mm*(320-540)mm*(more than 1,800)mm and the aspect ratio of 4 to 7.7, and can meet the requirements of spaceflight, military industry and the like on wide slabs.

Owner:BERIS ENG & RES CORP

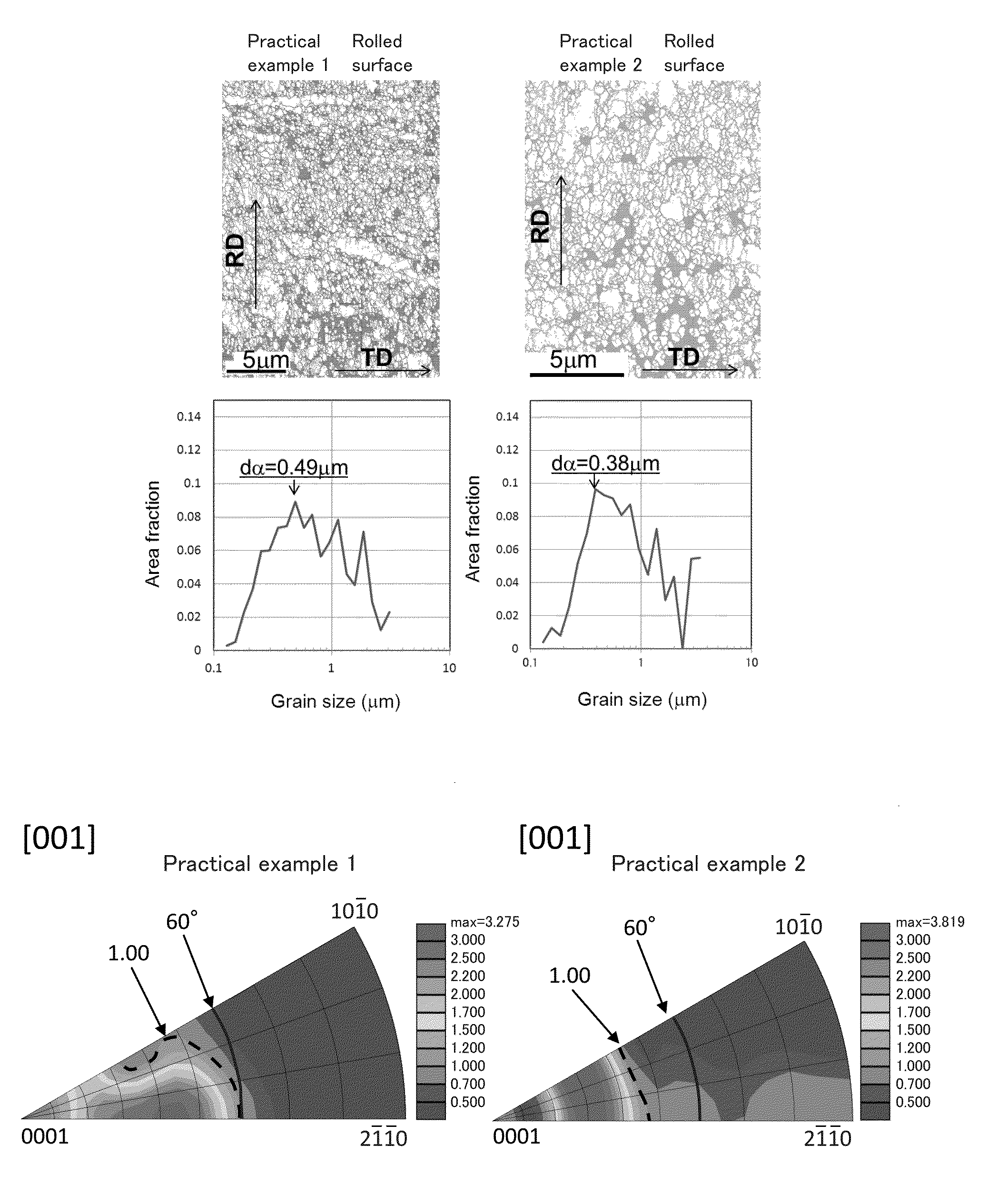

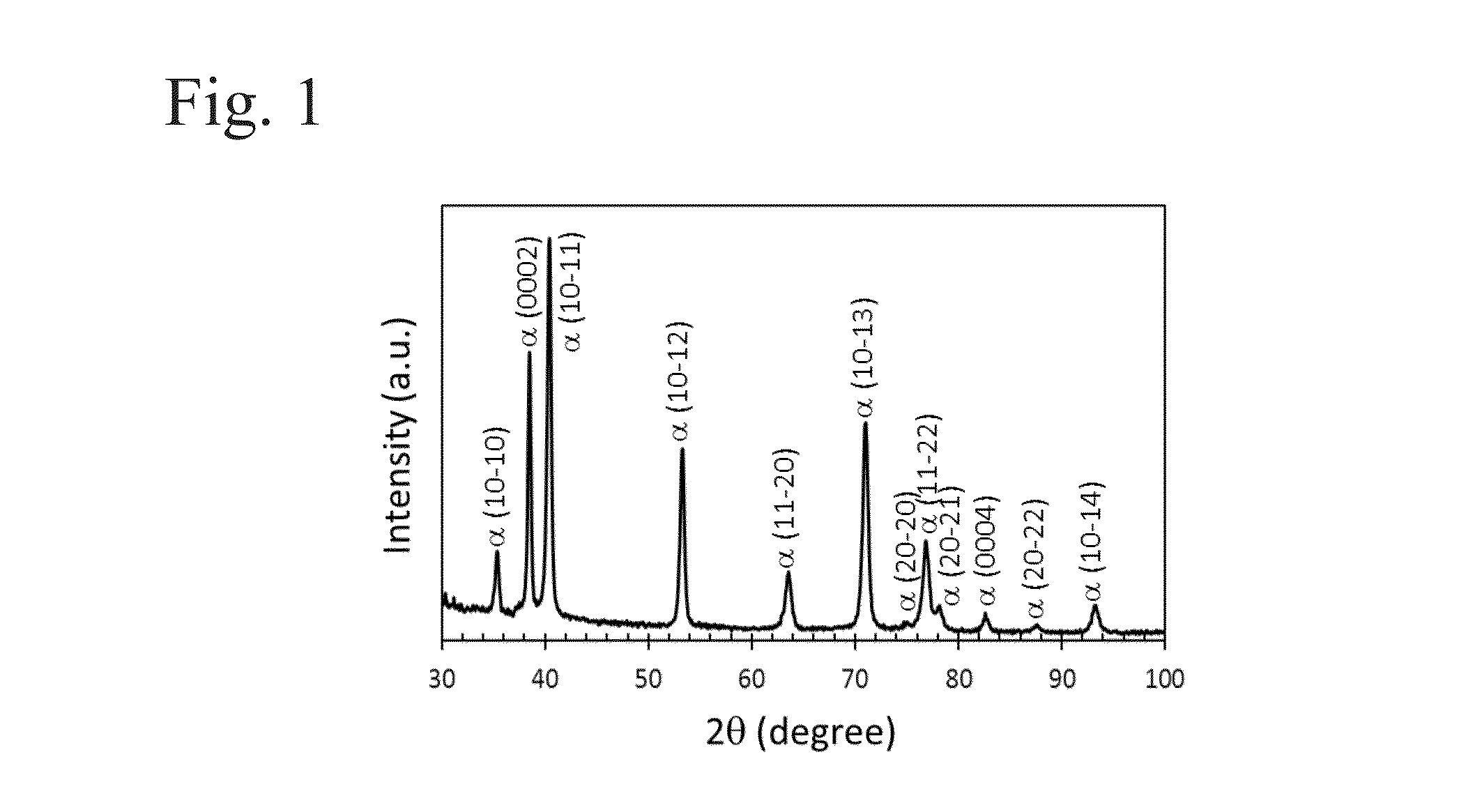

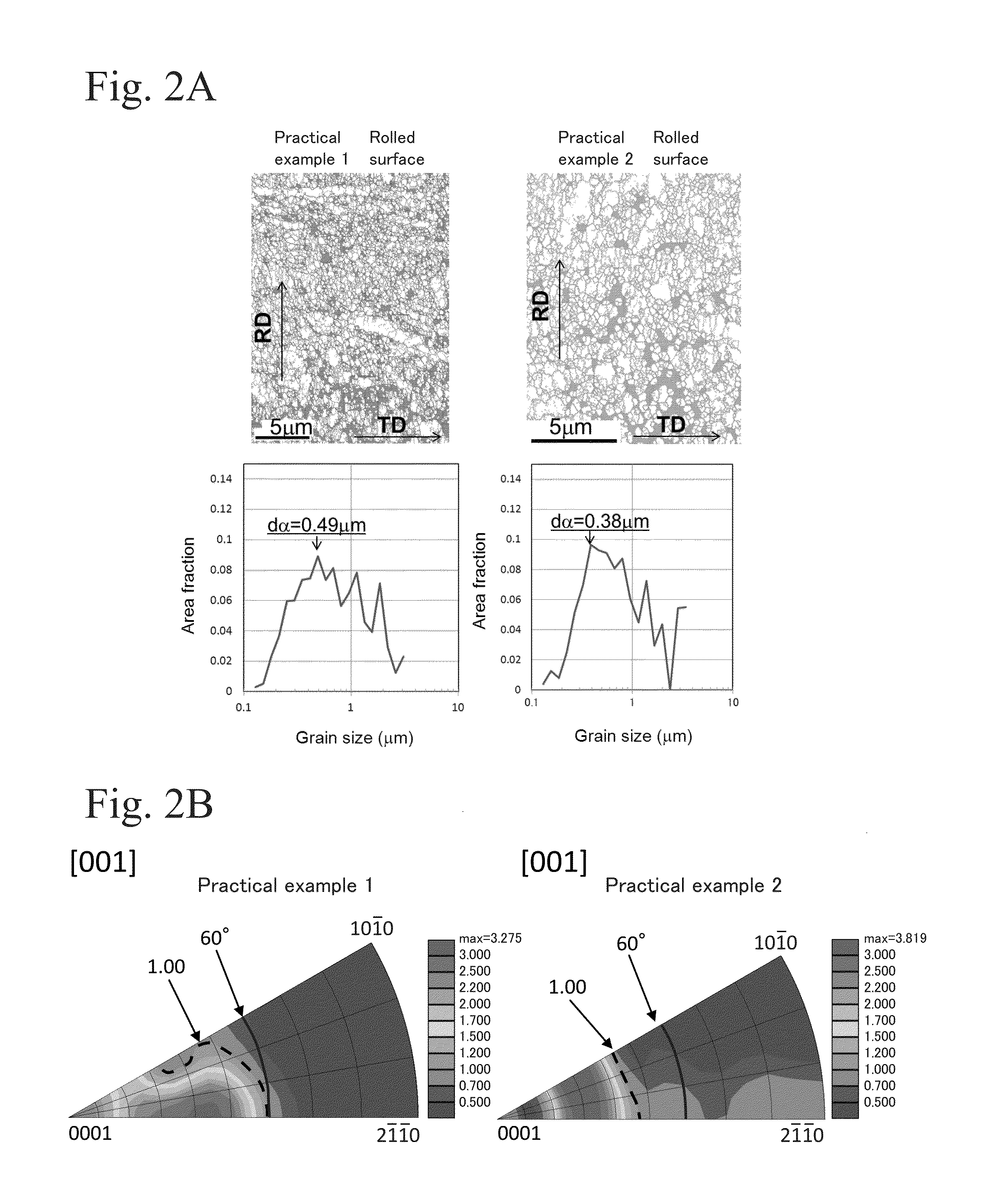

A+b type titanium alloy and production method therefor

The present invention provides an α+β type titanium alloy and a production method therefor, which has an ultrafine structure causing superplasticity under low temperatures and has a high deformation ratio compared to conventional α+β type Ti alloys. The alloy has an ultrafine structure made of equiaxial crystals in which an area ratio of crystals having a grain diameter of 1 μm or less is 60% or more, and maximum frequency grain diameter is 0.5 μm or less, wherein a portion in which the integration degree of plane orientation of the hexagonal close-packed crystal is 1.00 or more exists within a range of 0 to 60 degrees with respect to a normal line of a processed surface of the alloy.

Owner:NHK SPRING CO LTD +1

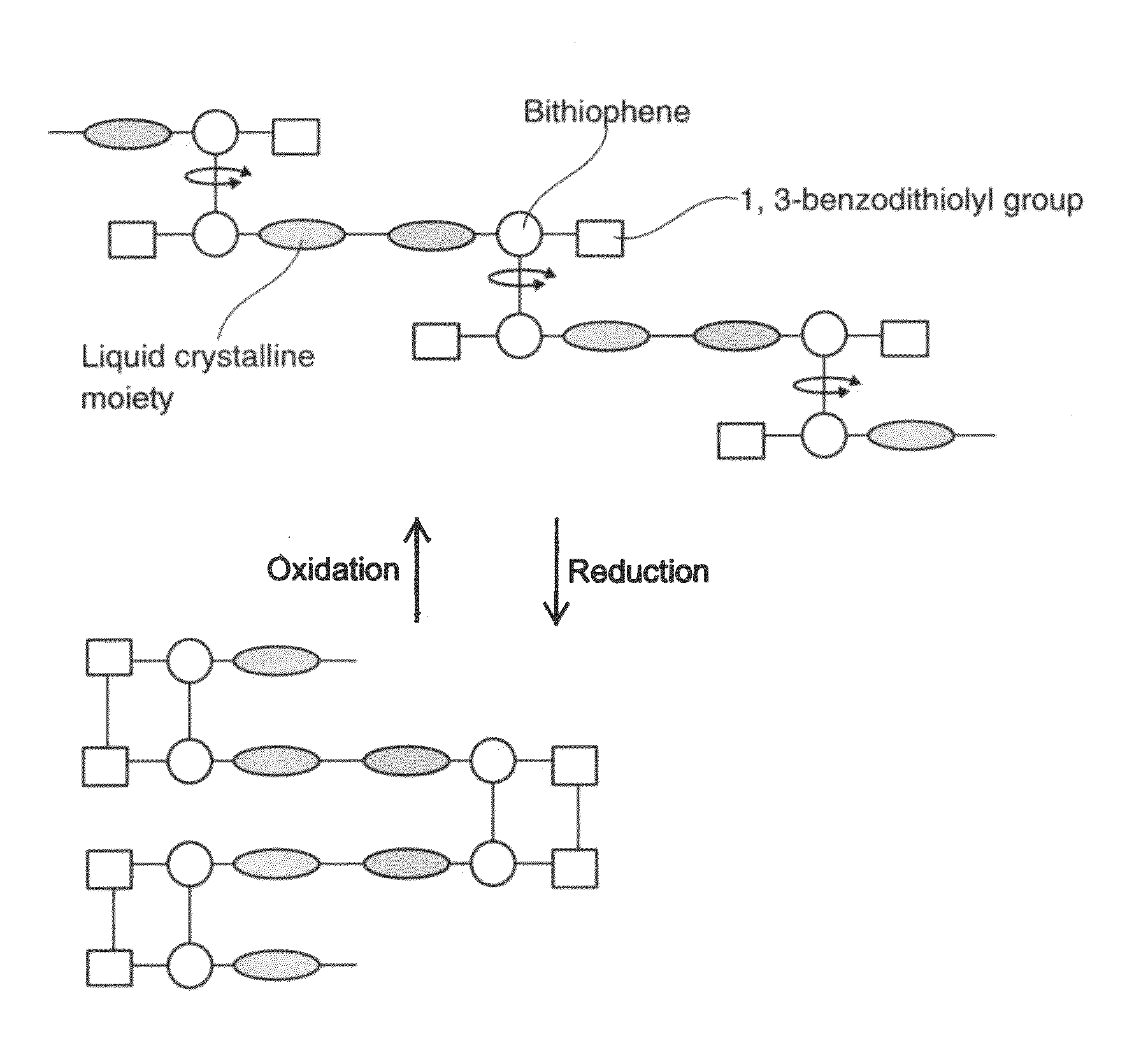

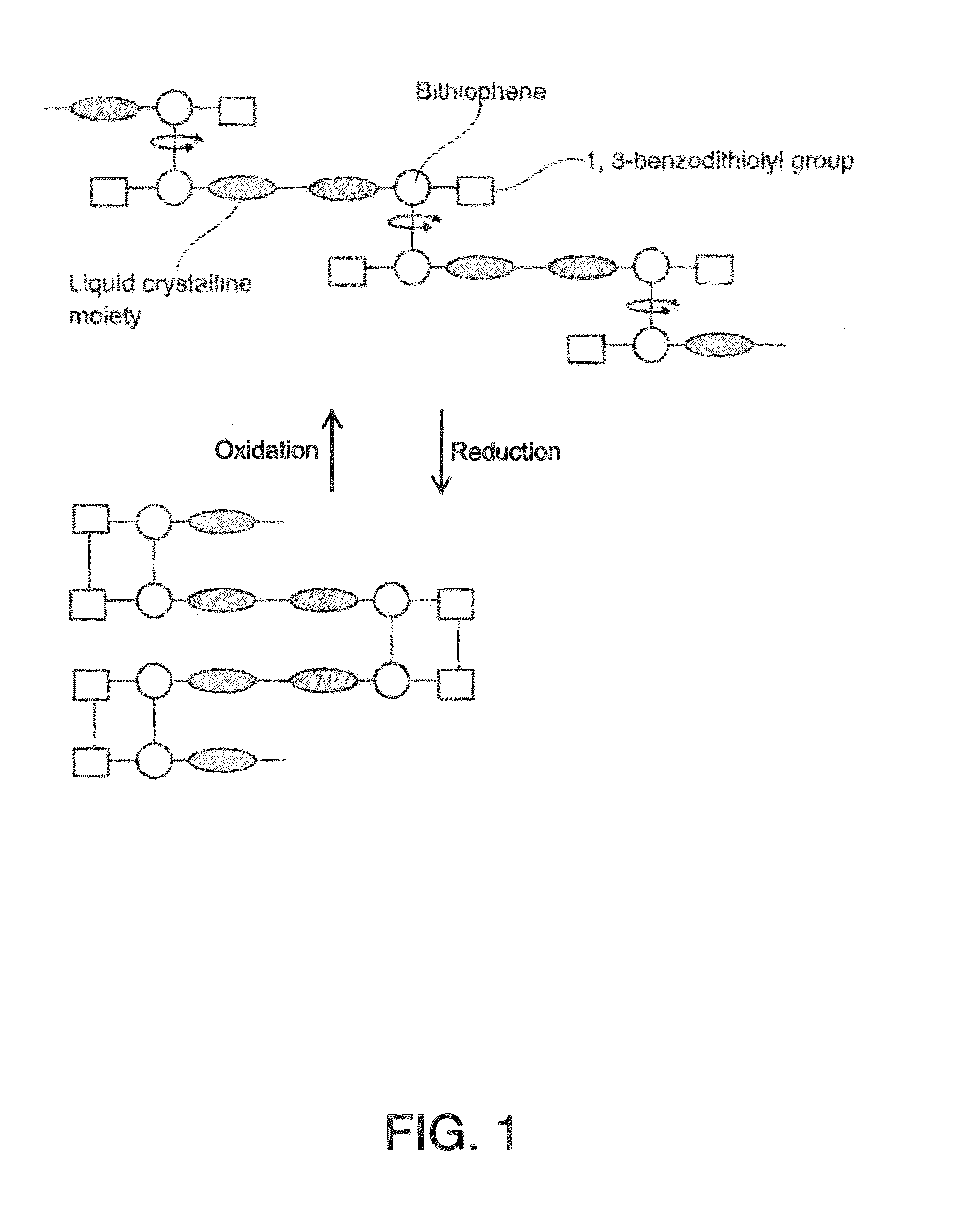

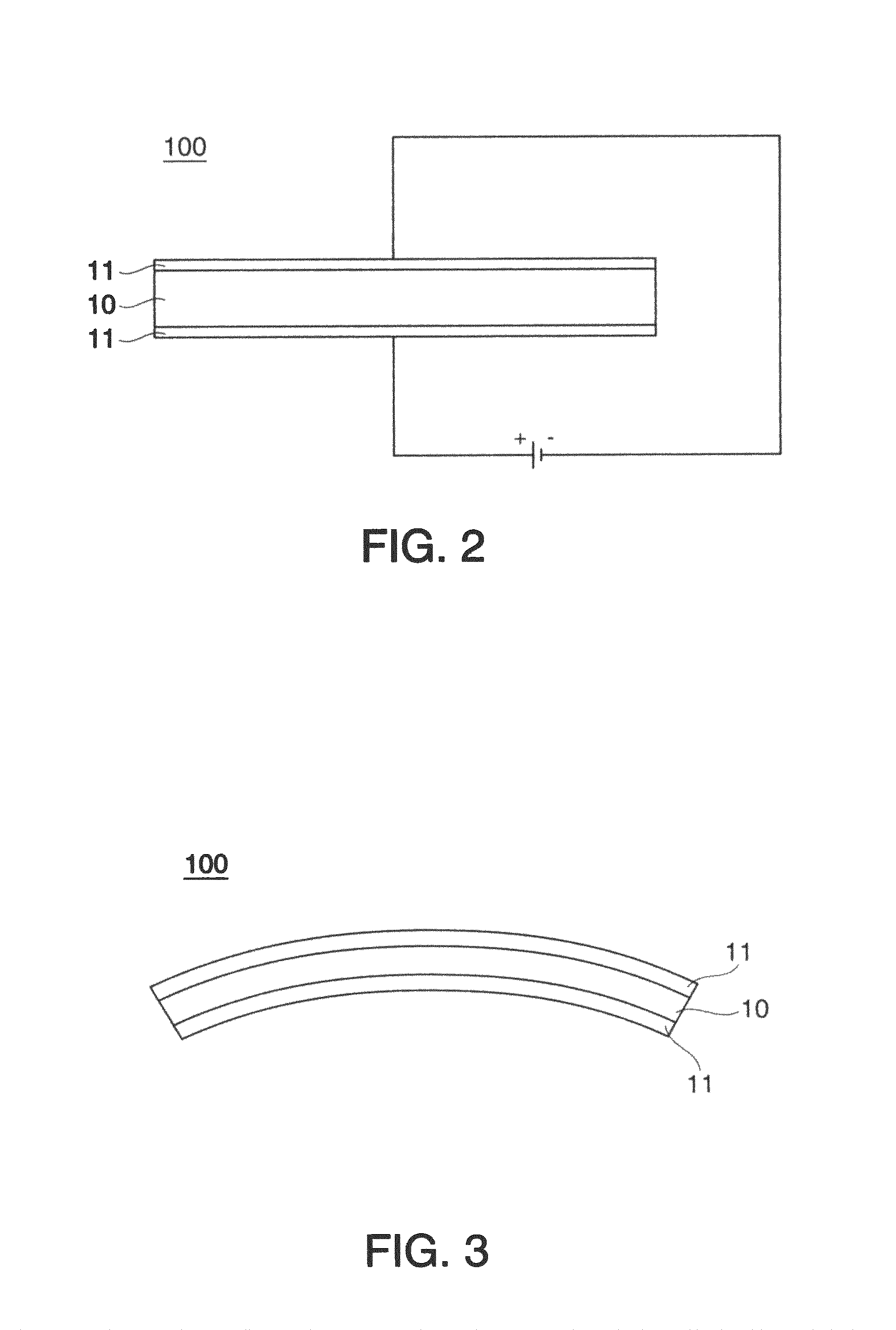

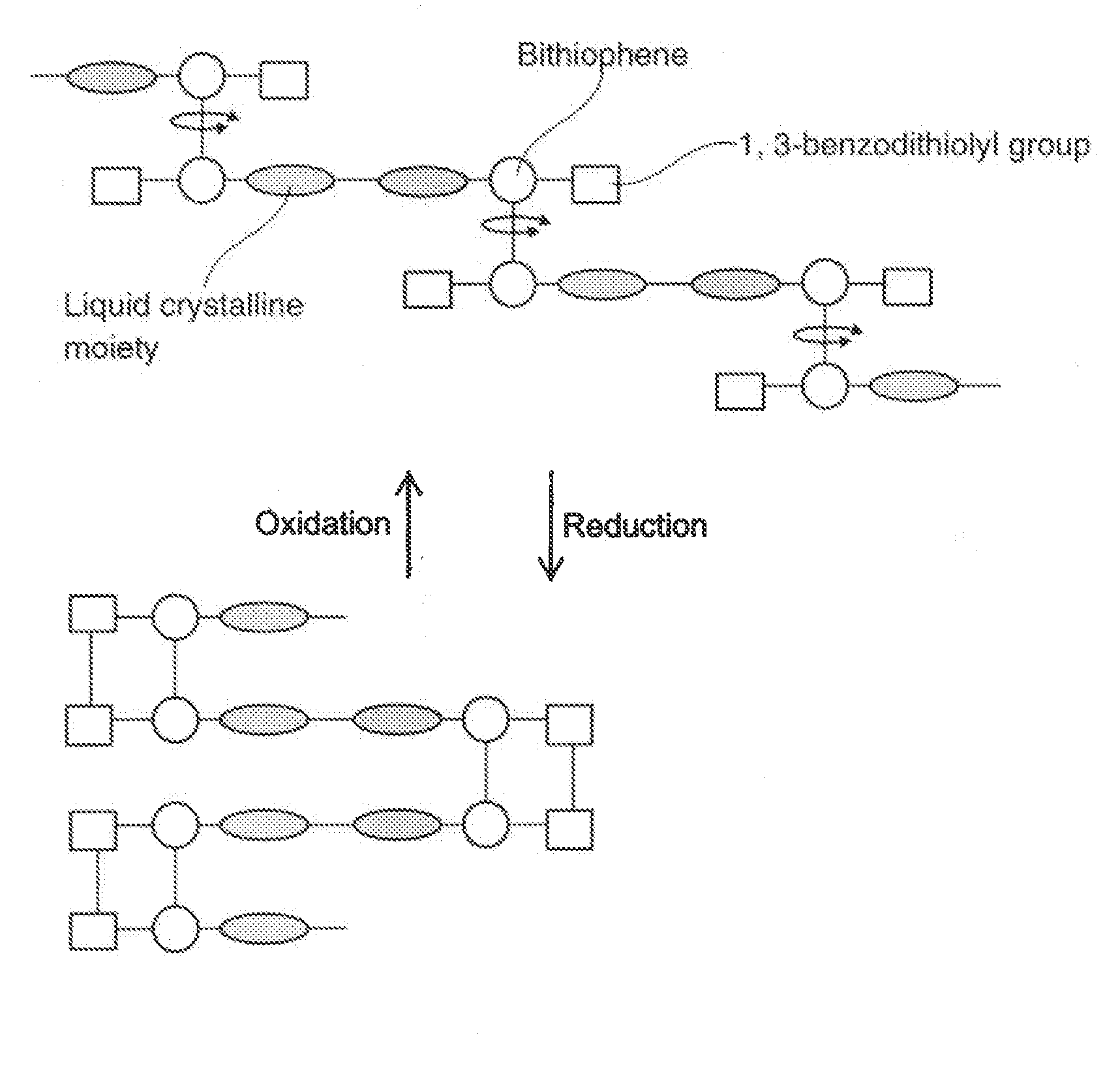

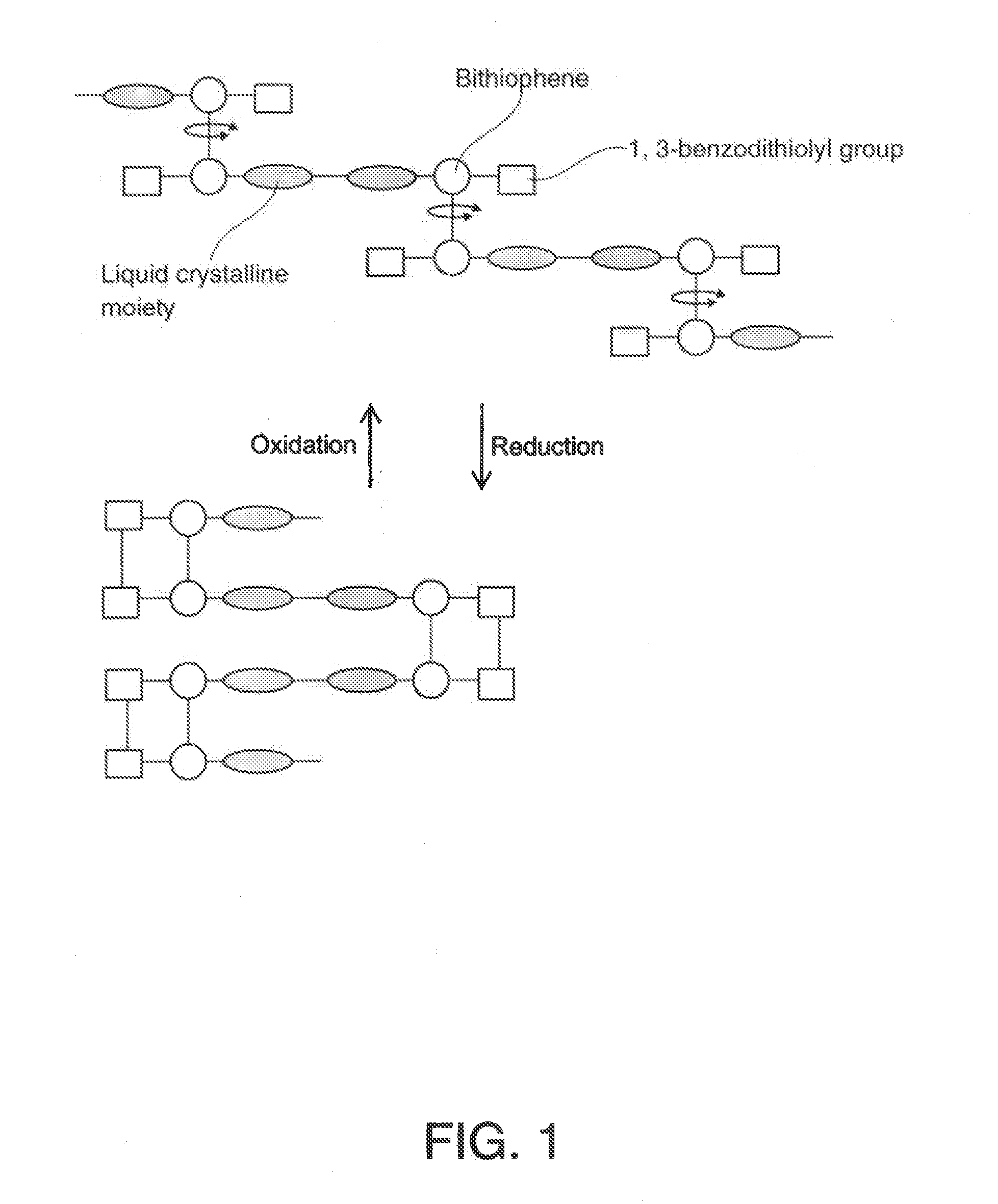

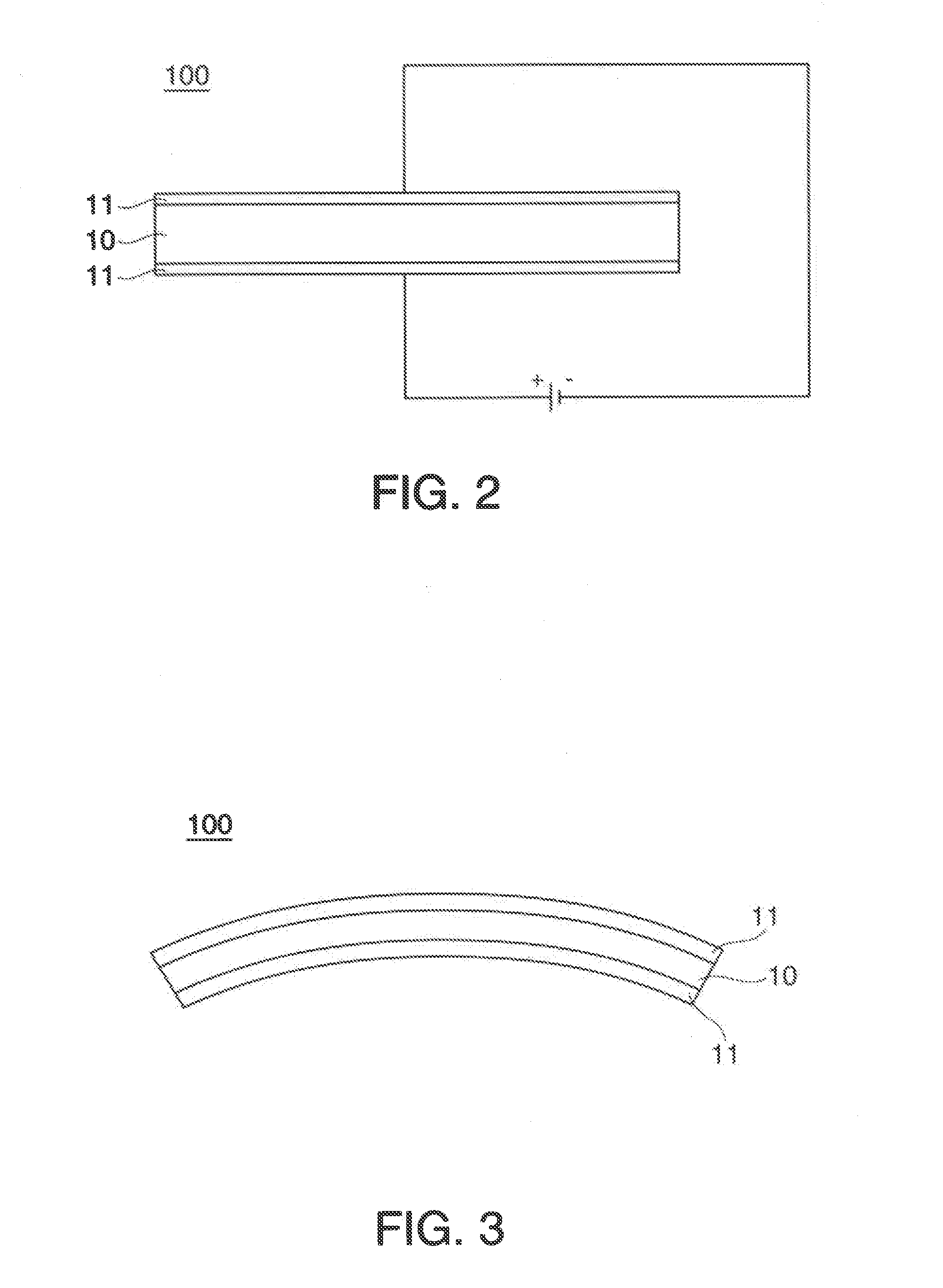

Stimuli responsive compound, stimuli responsive compound polymer, actuator and method for manufacturing stimuli responsive compound

InactiveUS8436117B2Increase deformation rateLiquid crystal compositionsOrganic chemistryCompound aStimuli responsive

A stimuli responsive compound includes: a unit A having bonds that function as rotation axes; a first unit B disposed at a first bonding section of the unit A; a second unit B disposed at a second bonding section of the unit A; a first unit C disposed at a third bonding section of the unit A; and a second unit C disposed at a fourth bonding section of the unit A. The first unit B bonds with the second unit B by oxidation-reduction reaction, and the first unit C and the second unit C have liquid crystallinity and include polymerizable functional groups.

Owner:SEIKO EPSON CORP

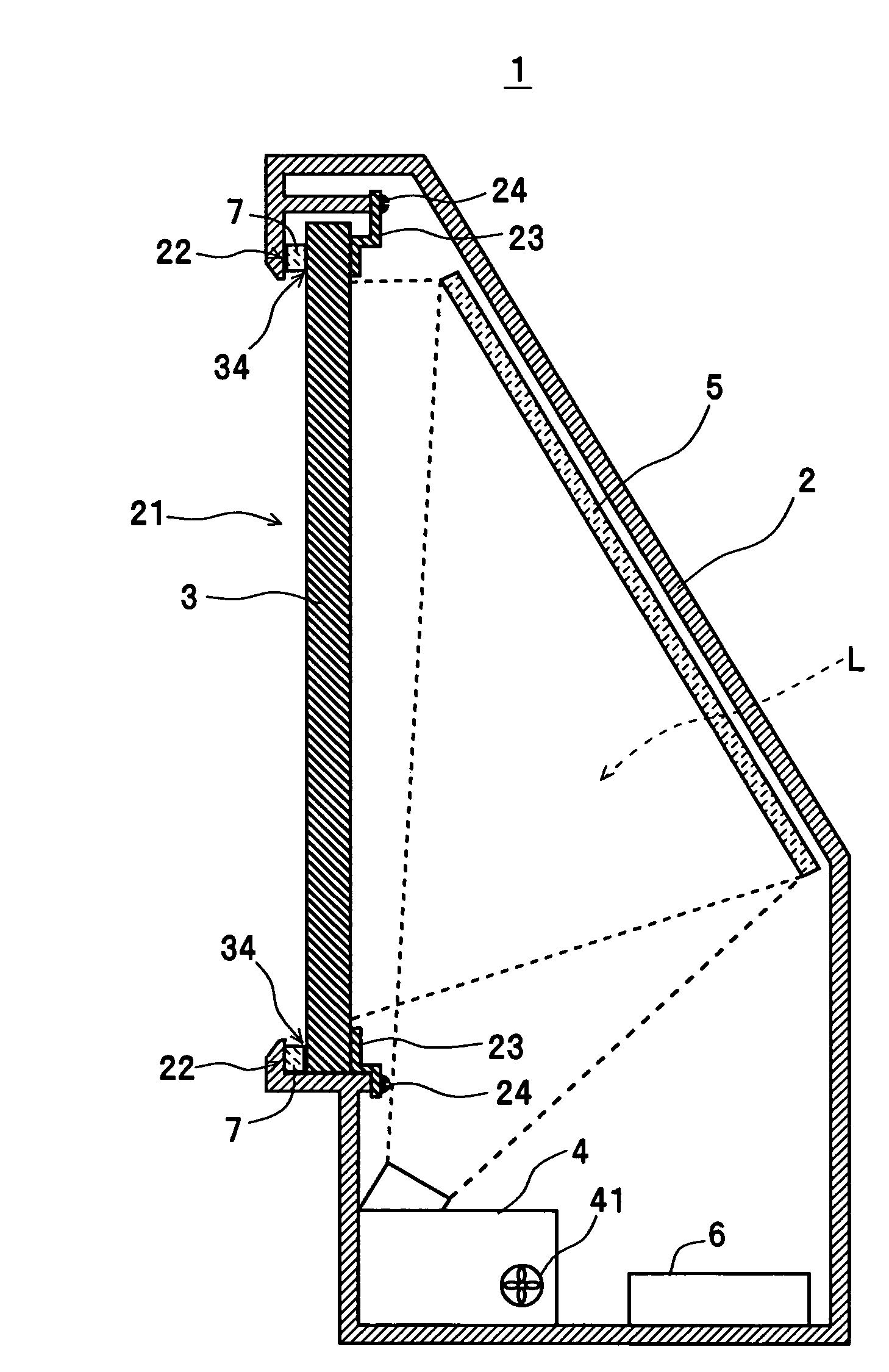

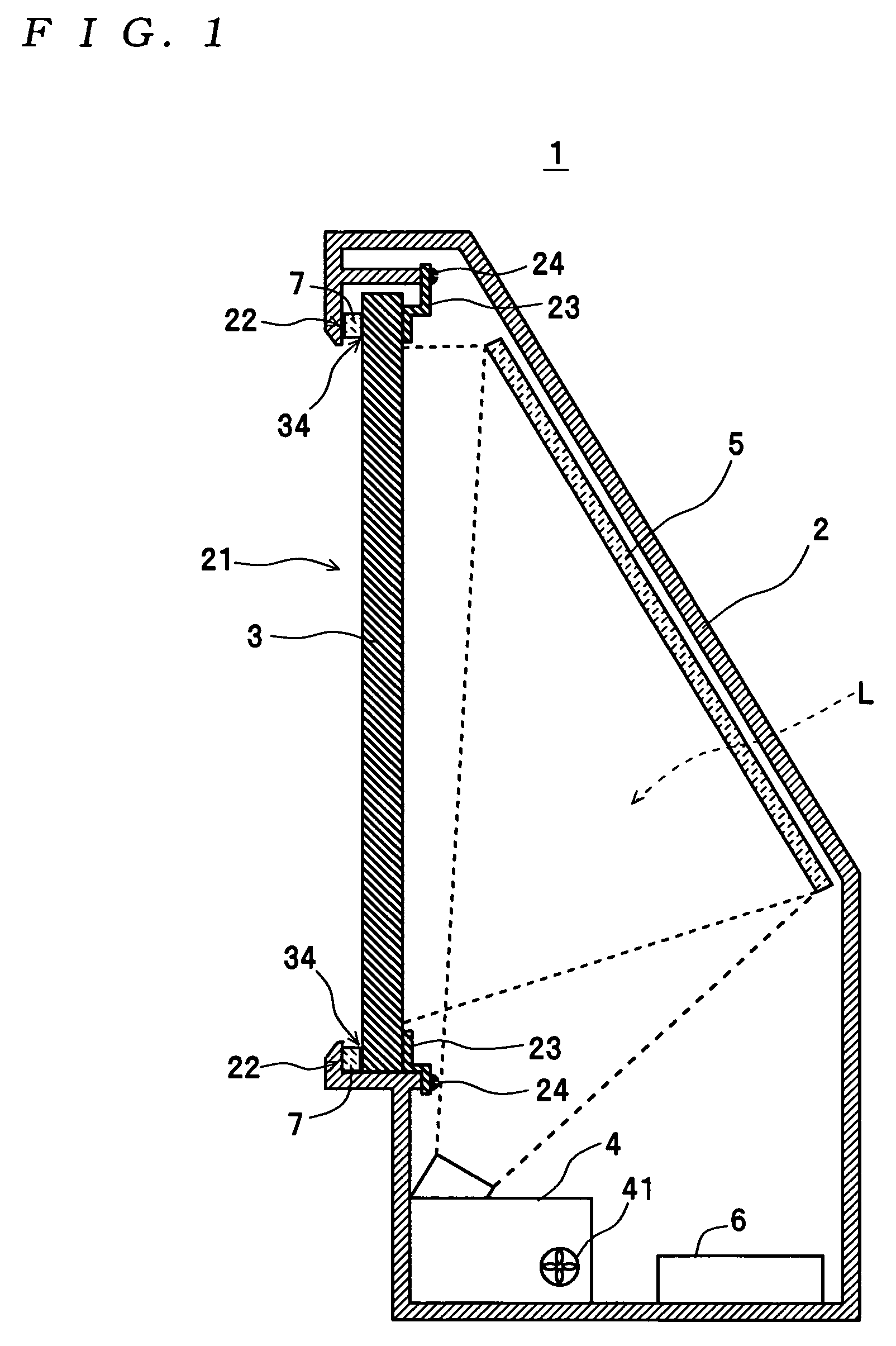

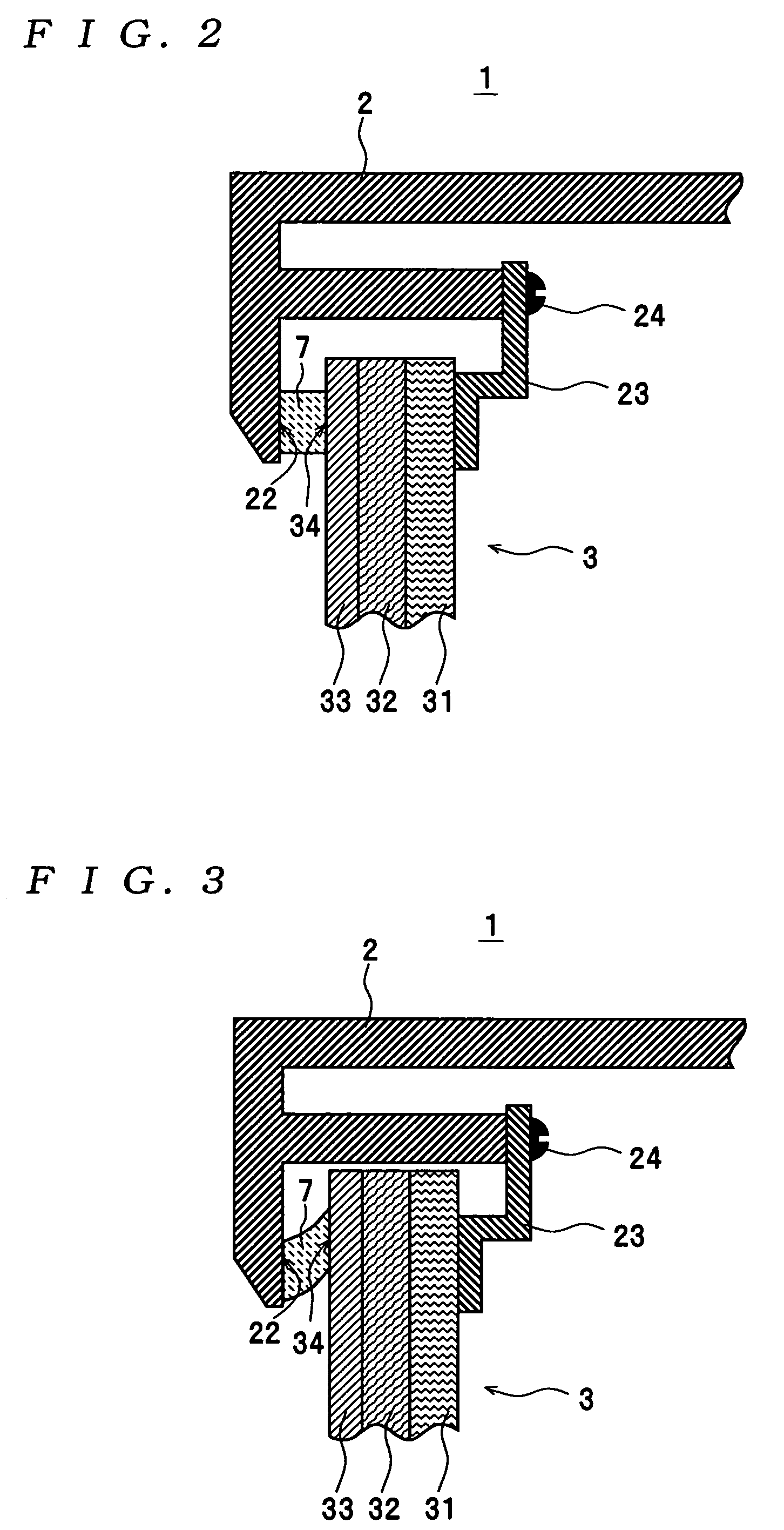

Rear projector

InactiveUS7215470B2Prevent dust depositionAvoid passingTelevision system detailsProjector focusing arrangementEngineeringElectrical and Electronics engineering

There is provided a rear projector capable of preventing entry of dust. A cabinet of the rear projector has a front side thereof formed with an opening. A screen panel slightly larger in size than the opening is attached to the front side of the cabinet such that the opening edge portion of the opening of the cabinet and the periphery of the screen panel are opposed to each other. The screen panel receives projection light projected from behind for image display, and thereby displays an image thereon. A projector unit is disposed within the cabinet, for projecting the projection light. A dust-proofing sealing member is disposed between the periphery of the screen panel and the opening edge portion, the screen panel is attached to the housing.

Owner:SEIKO EPSON CORP

Preparation method of flexible supercapacitor, and preparation method of electrode and diaphragm thereof

ActiveCN109461597AExcellent flexibility and processabilityAvoid edge lossHybrid capacitor separatorsHybrid/EDL manufactureCapacitanceEngineering

The invention relates to a preparation method of a flexible supercapacitor, and a preparation method of an electrode and a diaphragm thereof. The method comprises the following steps: designing the sizes of the electrode and the diaphragm, and customizing a forming mould, respectively loading a gel state electrode mixture and a gel state diaphragm mixture into the forming mould, pushing and extruding a gel state material from one side of the forming mould, after the gel state material is extruded from the other side to a fixed thickness, slicing the gel state material with the extruded fixed thickness by using a cut-off knife to obtain a flexible electrode and a flexible diaphragm, then stacking the flexible electrode and the flexible diaphragm to form a capacitor cell, and drying and packaging the capacitor cell to obtain the flexible supercapacitor. By adoption of the above method provided by the invention, the trimming loss of the flexible electrode and the flexible diaphragm in the cutting process is avoided; the flexible electrode has good tensile strength, high deformation rate and high electrical conductivity; the flexible diaphragm has good elasticity, large tensile strength and high deformation rate; and the flexible supercapacitor product has high production efficiency, good bending performance and wide electrochemical window.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

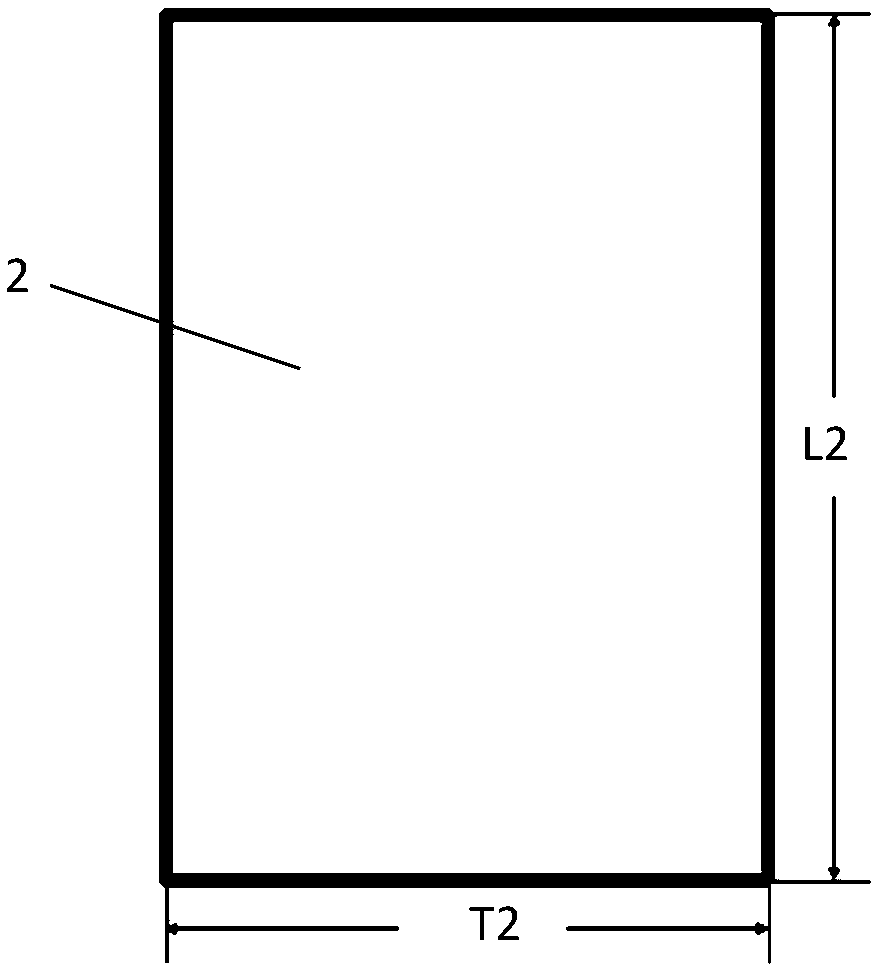

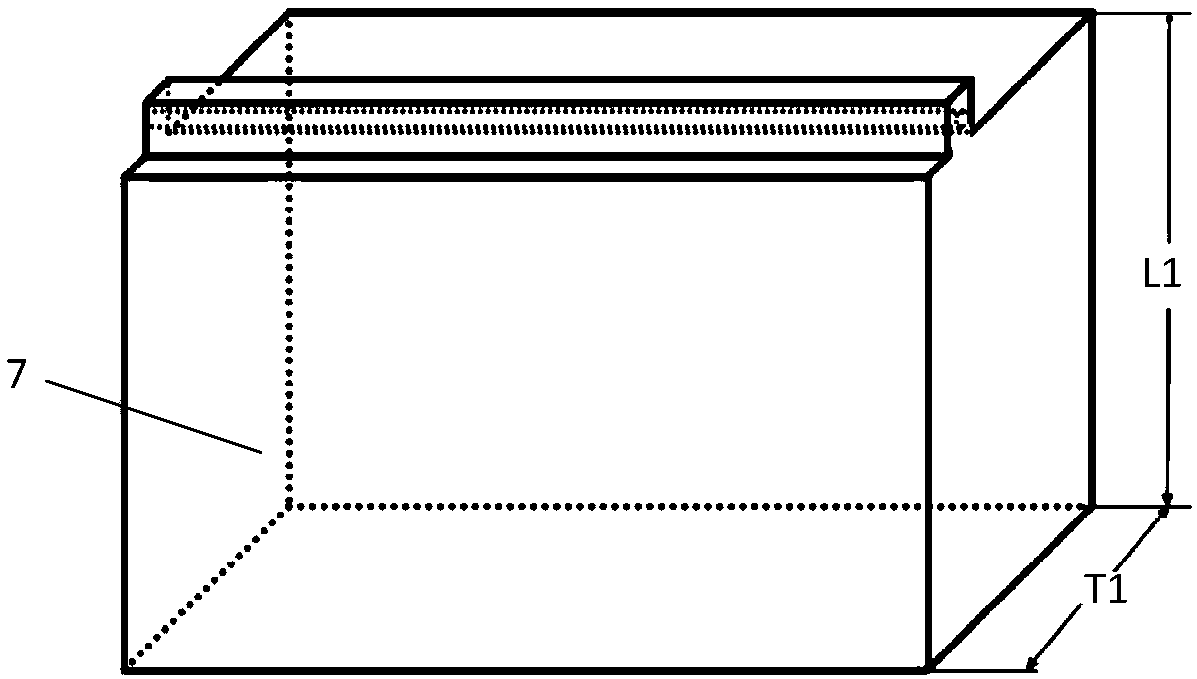

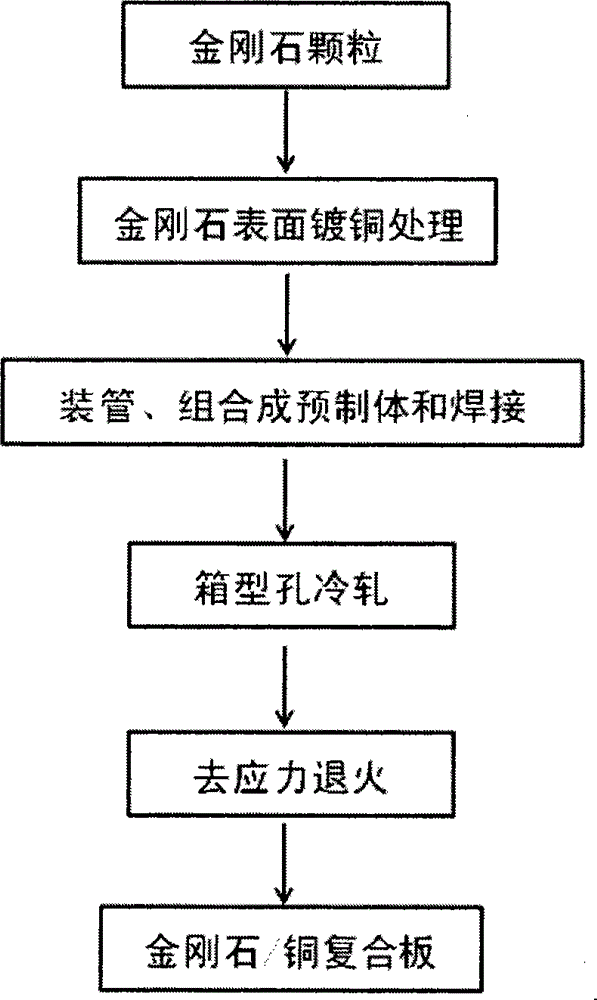

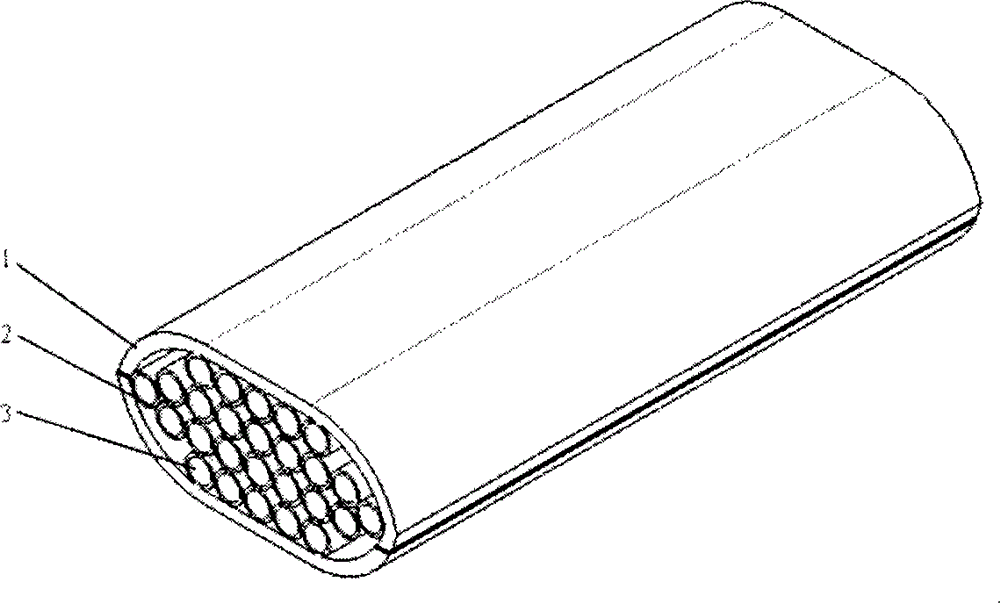

Boxy hole rolling method for large-sized high-thermal-conductivity diamond/copper composite board

InactiveCN104308465AOvercome difficult processing and forming problemsSolve processing problemsMetal rolling arrangementsCopper platingComposite plate

The invention discloses a boxy hole rolling method for a large-sized high-thermal-conductivity diamond / copper composite board. The method particularly comprises the following steps: uniformly placing diamond particles with copper-coated surfaces into thin-walled copper tubes with the external diameter of 2.5-3.5 mm; stacking the copper tubes into a bundle between an upper layer of copper sheets and a lower layer of copper sheets and welding the side edges of the two layers of copper sheets into a precast body; subjecting the prepared preform to multi-pass boxy hole cold rolling, and performing stress relieving at the temperature of 260-400 DEG C after each pass of rolling. Owing to the hardness difference between diamond and pure copper, in the rolling process, the diamond particles enter the copper matrix in an embedded manner. The boxy-hole pass rolling method has the advantages of uniform deformation, large deflection, capability of mass production and the like, and facilitates improvement on the production efficiency and reduction of the manufacturing cost. In the prepared diamond / copper composite board, the volume fraction of the diamond particles is 55-65%, and the thermal conductivity can reach more than 400W / (m.K). Therefore, a wide application prospect is achieved in the electronic encapsulation field.

Owner:UNIV OF SCI & TECH BEIJING

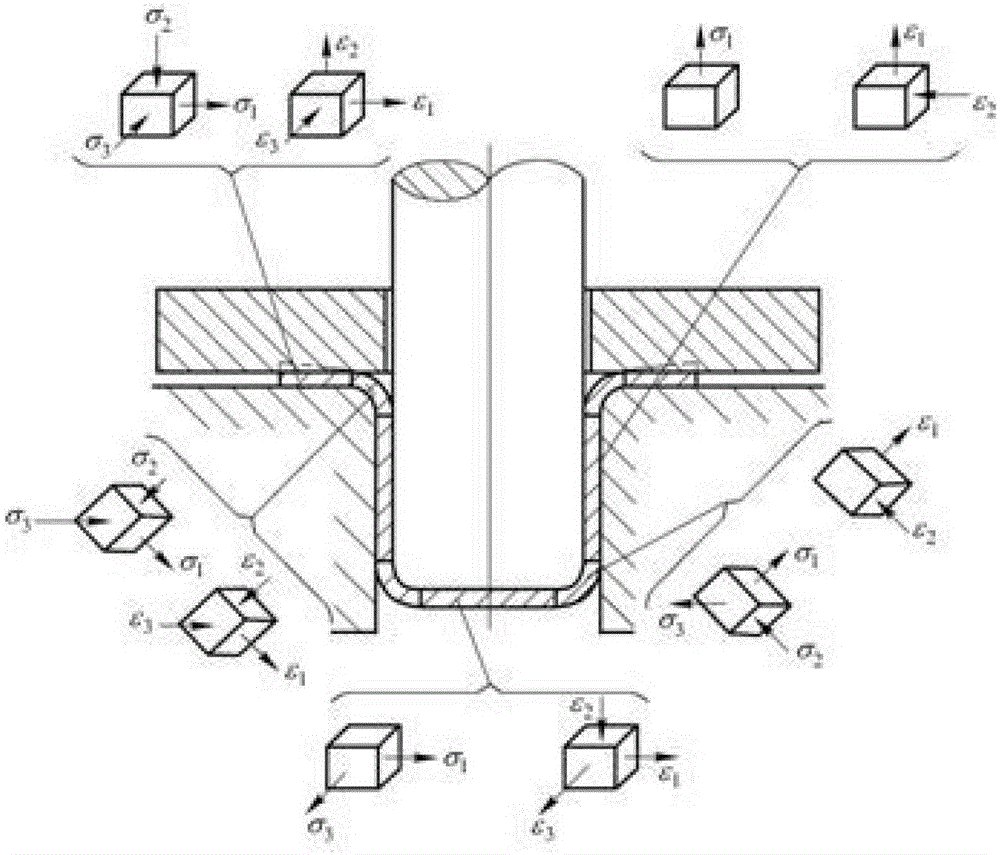

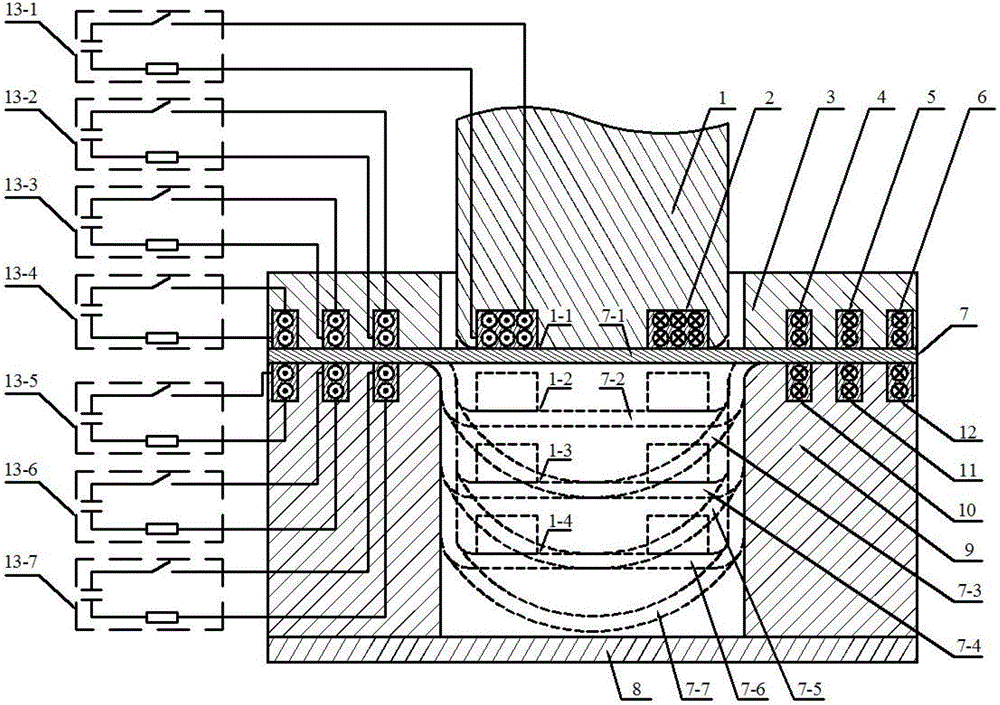

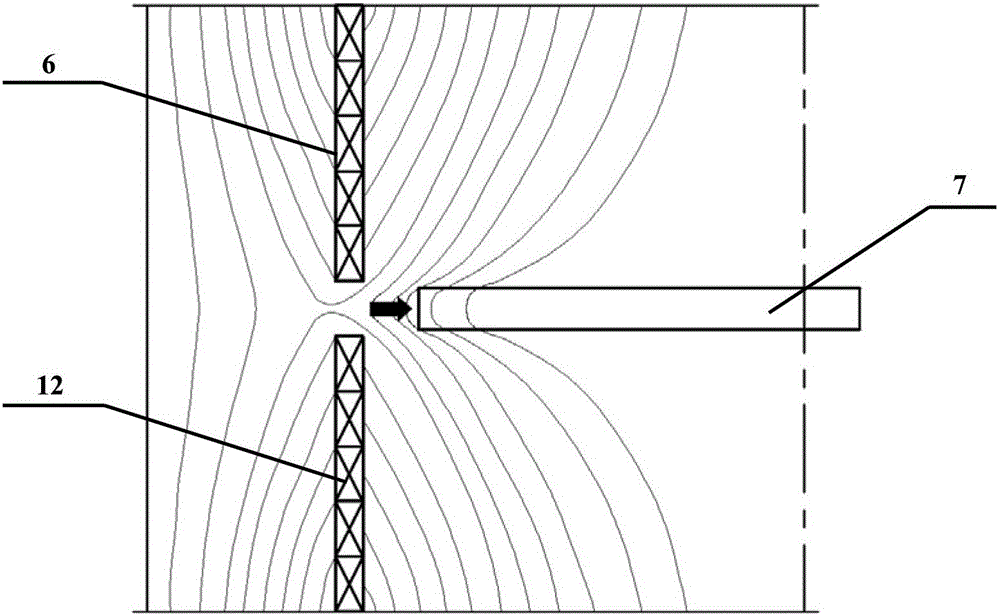

Electromagnetic pulse assisted progressive drawing method and device

InactiveCN103658297BChanging the state of stress and strainReduce tensile stressShaping toolsElectromagnetic pulseDeep drawing

The invention provides an electromagnetic pulse boosting type gradual deep drawing forming method. The electromagnetic pulse boosting type gradual deep drawing forming method comprises the steps that a sheet to be formed is placed between a female die and a male die; performing is conducted and the sheet to be formed is pressed into the female die, wherein the sheet to be formed is located at the bottom of the male die; electromagnetic force is applied to the portion, located at the bottom of the male die, of the sheet to be formed, and the sheet to be formed is pushed downwards; electromagnetic force is applied to the periphery of the sheet to be formed, the sheet to be formed is pushed to the center of the female die, and the sheet to be formed is made to flow into the female die; down force is applied to the male die so that the male die can move downwards, and therefore downward deep drawing is conducted on the portion, located on the lower portion of the male die, of the sheet to be formed; stamping deep drawing and electromagnetic pulse deep drawing are conducted repeatedly before deep drawing forming of the sheet to be formed is completed. According to the electromagnetic pulse boosting type gradual deep drawing forming method, the traditional male die forming technology and the electromagnetic pulse forming technology are combined, stamping deep drawing and electromagnetic pulse deep drawing are conducted alternately, and the depth of deep drawing forming of a cylindrical part is increased. The invention further provides an electromagnetic pulse boosting type gradual deep drawing forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

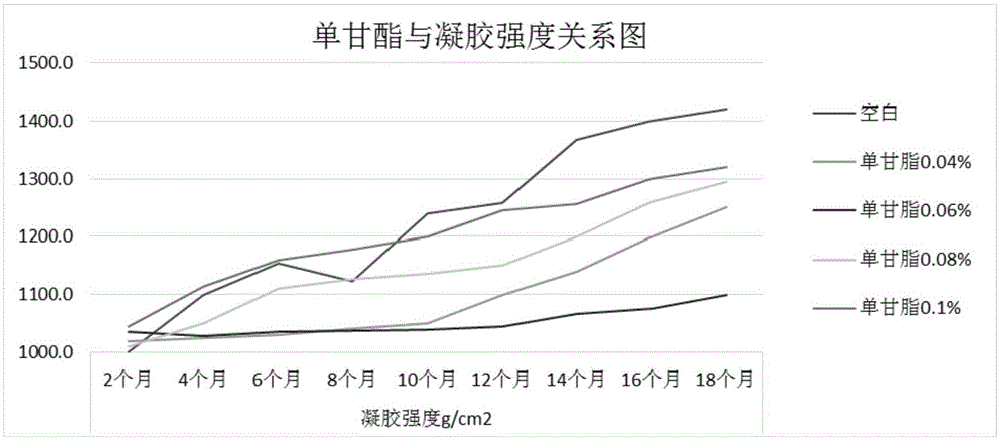

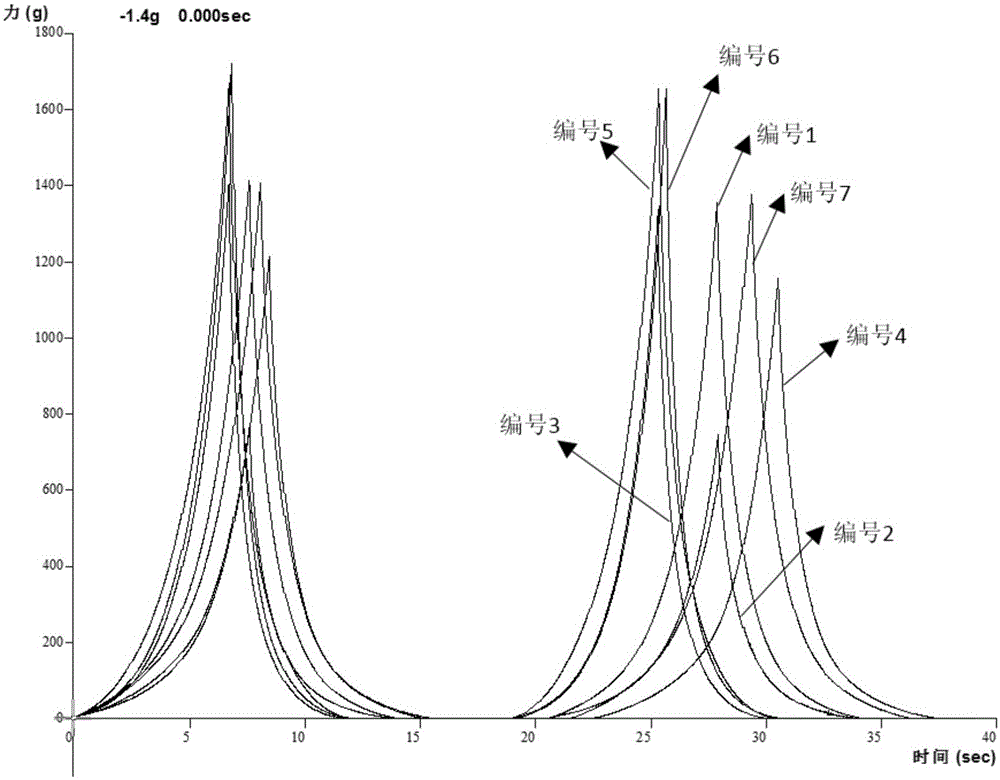

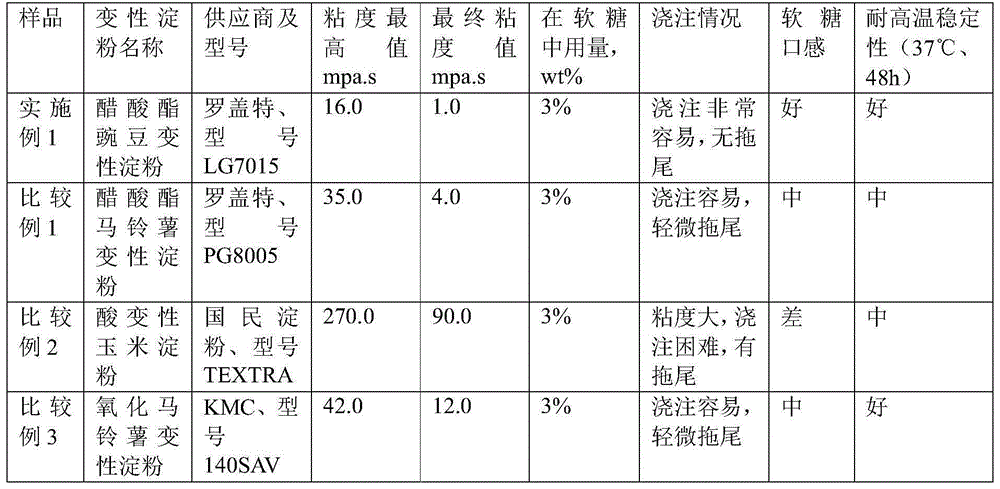

Functional mixed gel type soft sweets and manufacturing method thereof

InactiveCN106306295AIncrease melting point and deformation rateImprove thermal stabilityConfectionerySweetmeatsOrange juicePolydextrose

The present invention aims at providing functional mixed gel type soft sweets. The functional mixed gel type soft sweets comprise the following components: 6-7 wt% of gelatin, 1-5 wt% of acetate pea modified starch, 0.4-0.8 wt% of high methoxyl pectin, 20-30 wt% of xylitol, 32-48 wt% of polydextrose, 1-3 wt% of sorbitol solution, 0.5-1.5 wt% of DHA algal oil, 1-3 wt% of concentrated apple juice or concentrated orange juice, 2.2-2.5 wt% of citric acid solution at a concentration of 50 wt%, 0.3-0.5 wt% of sodium citrate buffer, and a small amount of natural essences and pigments. The present invention further provides a manufacture method of the functional mixed gel type soft sweets.

Owner:COFCO GROUP +1

12Cr2Mo1VR steel plate with low compression ratio and high flaw detection quality requirement for continuous casting billet forming and production process

The invention relates to a production process of 12Cr2Mo1VR with low compression ratio and high flaw detection quality requirement for continuous casting billet forming. The process route comprises converter steelmaking, LF refining, RH vacuum degassing, continuous casting, continuous casting billet heating, rolling, slow cooling, quenching and tempering, and the steel plate comprises the following chemical components in percentage by mass: 0.09-0.17% of C, less than or equal to 0.30% of Si, 0.30-0.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.010% of S, 2.00-2.50% of Cr, 0.80-1.20% of Mo, 0.25-0.35% of V, less than or equal to 0.003% of Sb, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As and the balance of Fe and inevitable impurity elements. According to the low-compression-ratio continuous casting process, on the premise that the 12Cr2Mo1VR steel plate with the high flaw detection requirement is obtained, the blank yield reaches 89% or above and is greatly improved compared with the static ingot yield, the production cost is reduced, and the production cycle is shortened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

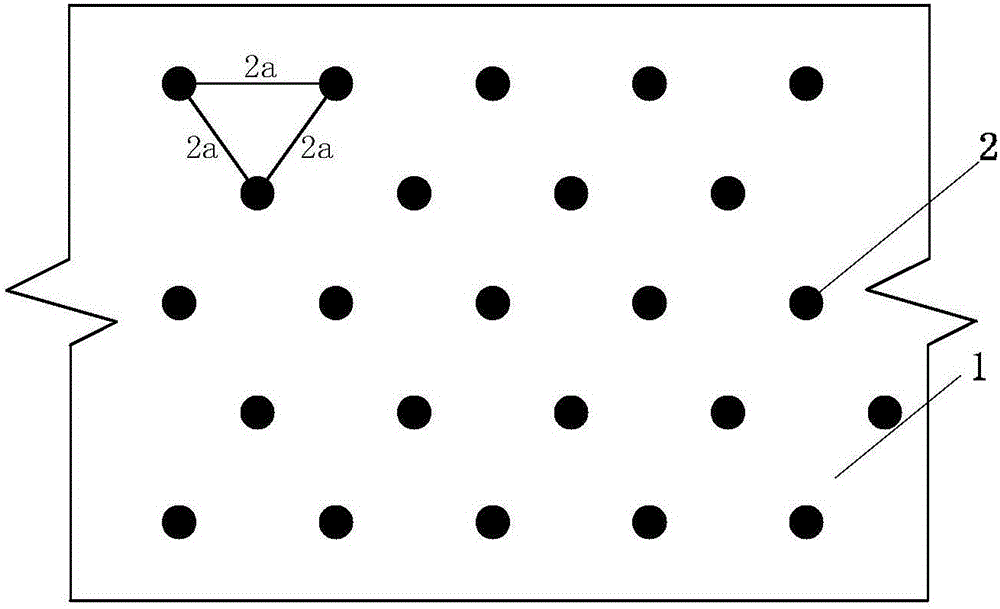

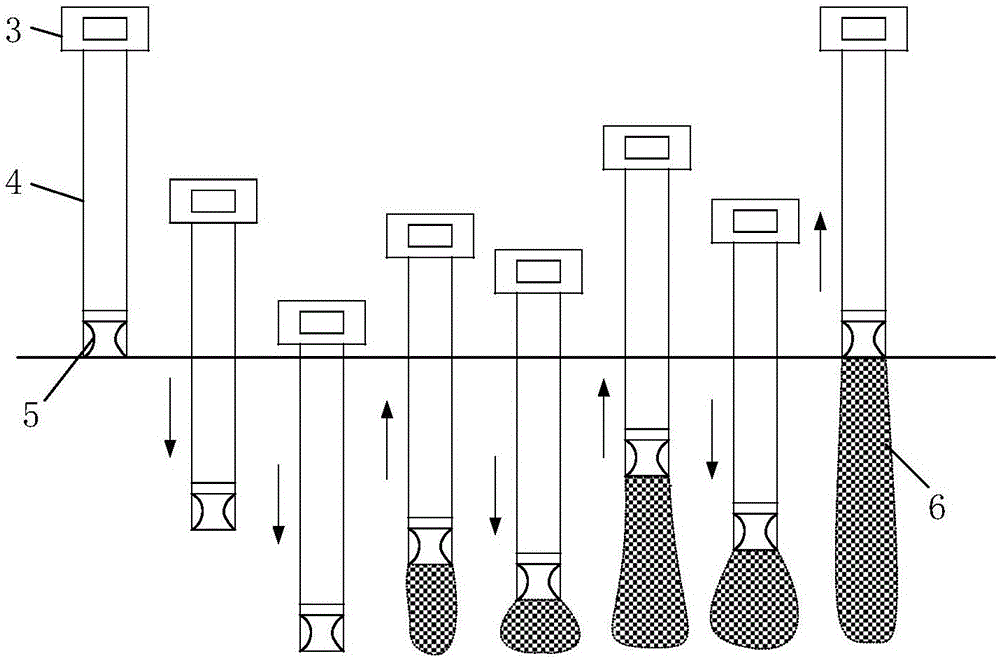

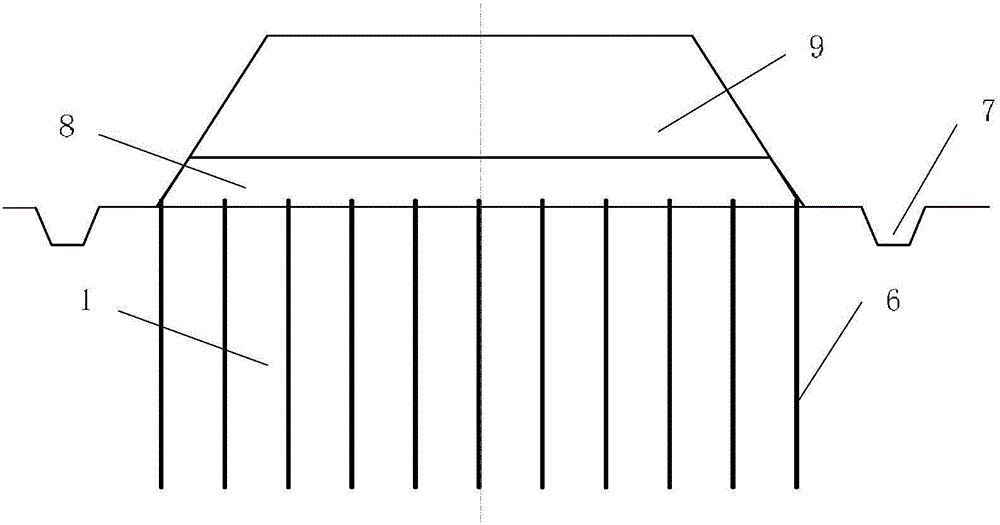

Method for treating peat soil foundation through preloading in combination with salt piles

The invention discloses a method for treating a peat soil foundation through preloading in combination with salt piles. The method for treating the peat soil foundation through preloading in combination with the salt piles is characterized in that the multiple salt piles with coarse sea salt as a core material are driven into the peat soil foundation; a horizontal drainage sand cushion is laid on the surface of the peat soil foundation; and a pre-load layer is constructed on the horizontal sand cushion layer. According to the method for treating the peat soil foundation through preloading in combination with the salt piles, through the ionizing effect of sodium chloride in the salt piles, pore water in the peat soil is driven to move towards the sodium chloride, a high-icon-concentration water film is formed on the surfaces of crystals in the dissolution process of the crystals, the electrostatic potential and the concentration potential generated around the water film can attract contra-ions in micropore water, so that the seepage speed of the micropore water into macropores is increased, and therefore the deformation rate of the peat soil in the whole drainage consolidation process is increased; and in addition, the salt piles driven into the peat soil foundation are similar like sand drains and can provide drainage channels for seeping out of a large amount of pore water in the peat soil layer in the preloading process, and therefore the efficiency of preloading treatment of the peat soil foundation is improved.

Owner:CHINA ROAD & BRIDGE +1

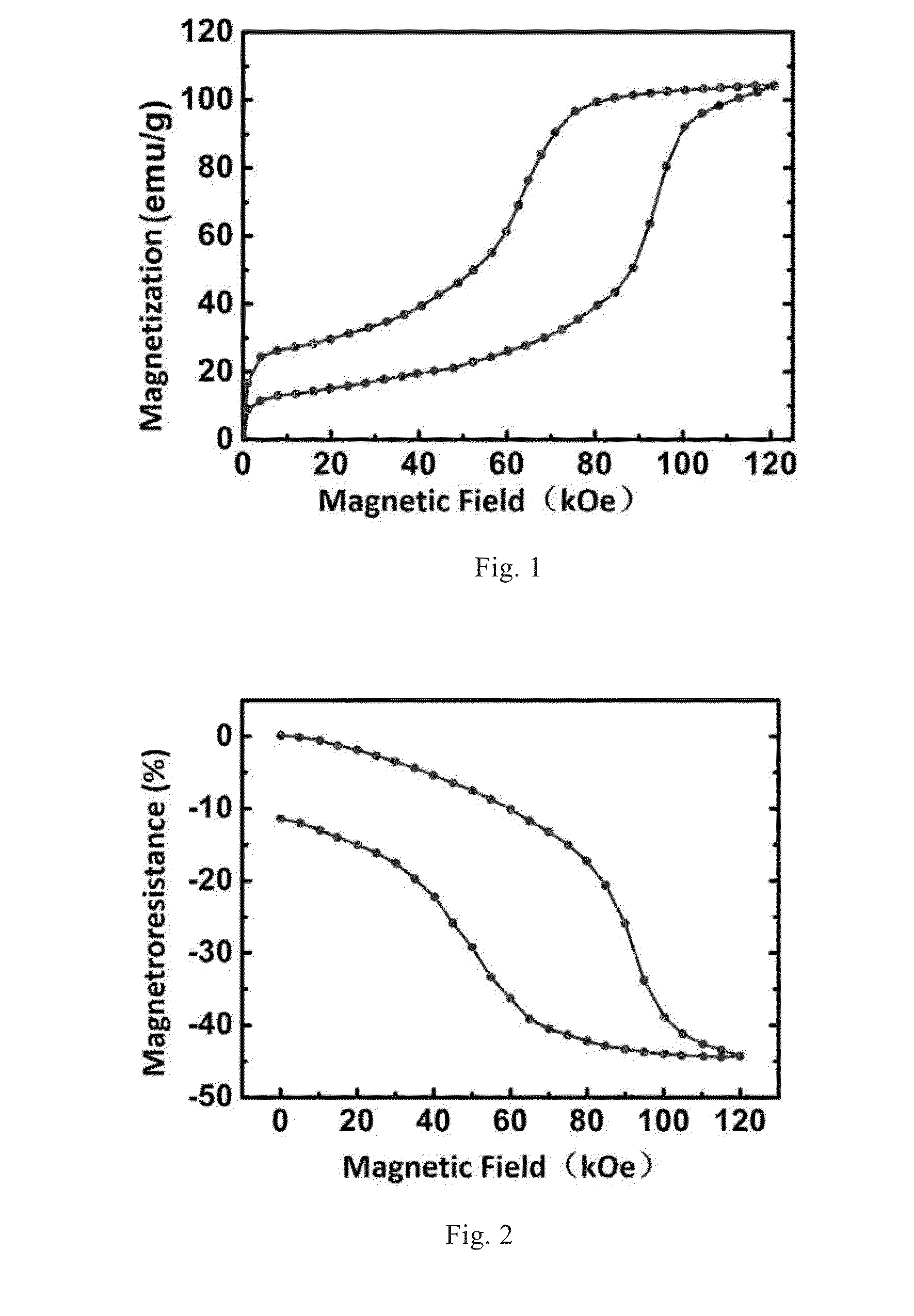

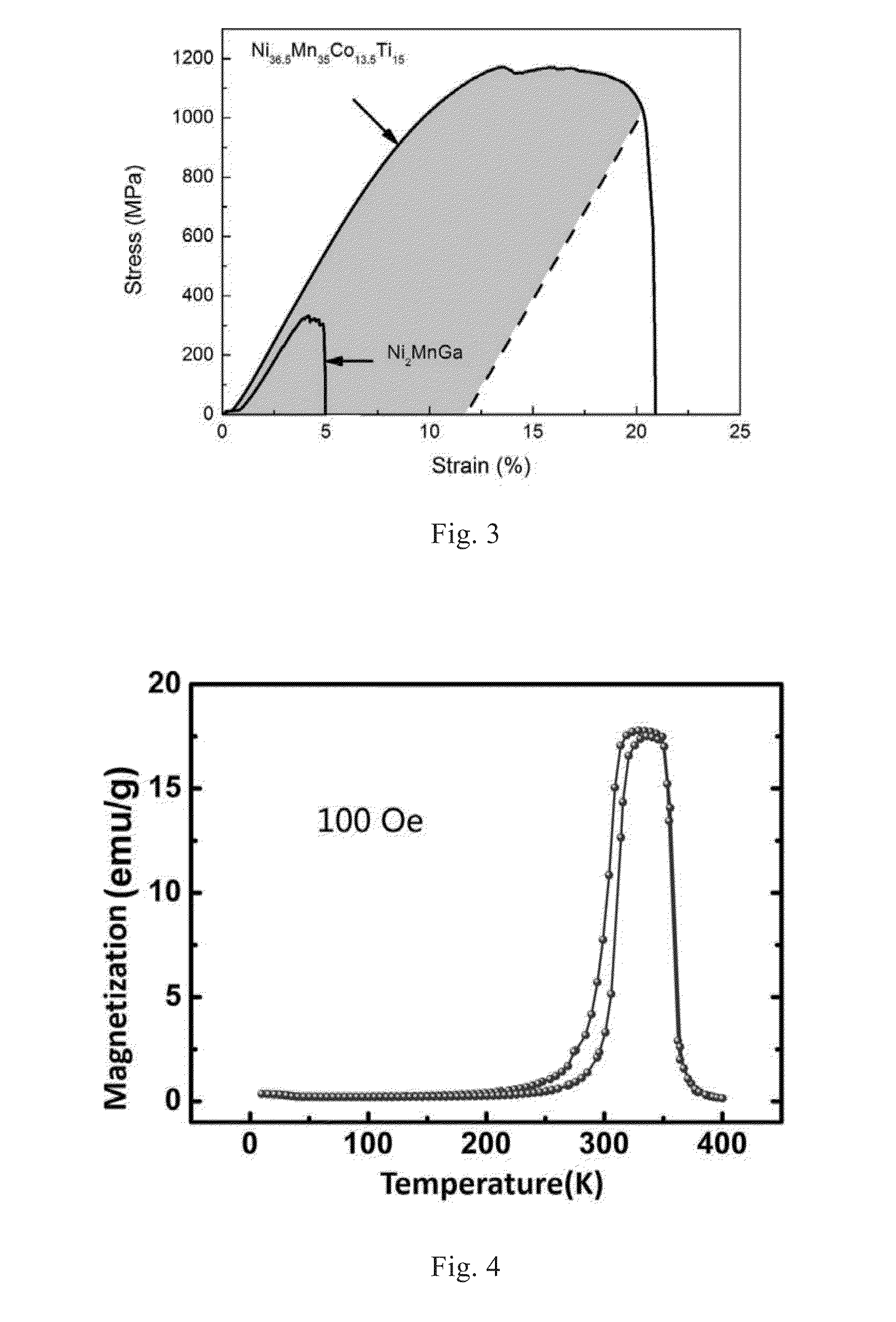

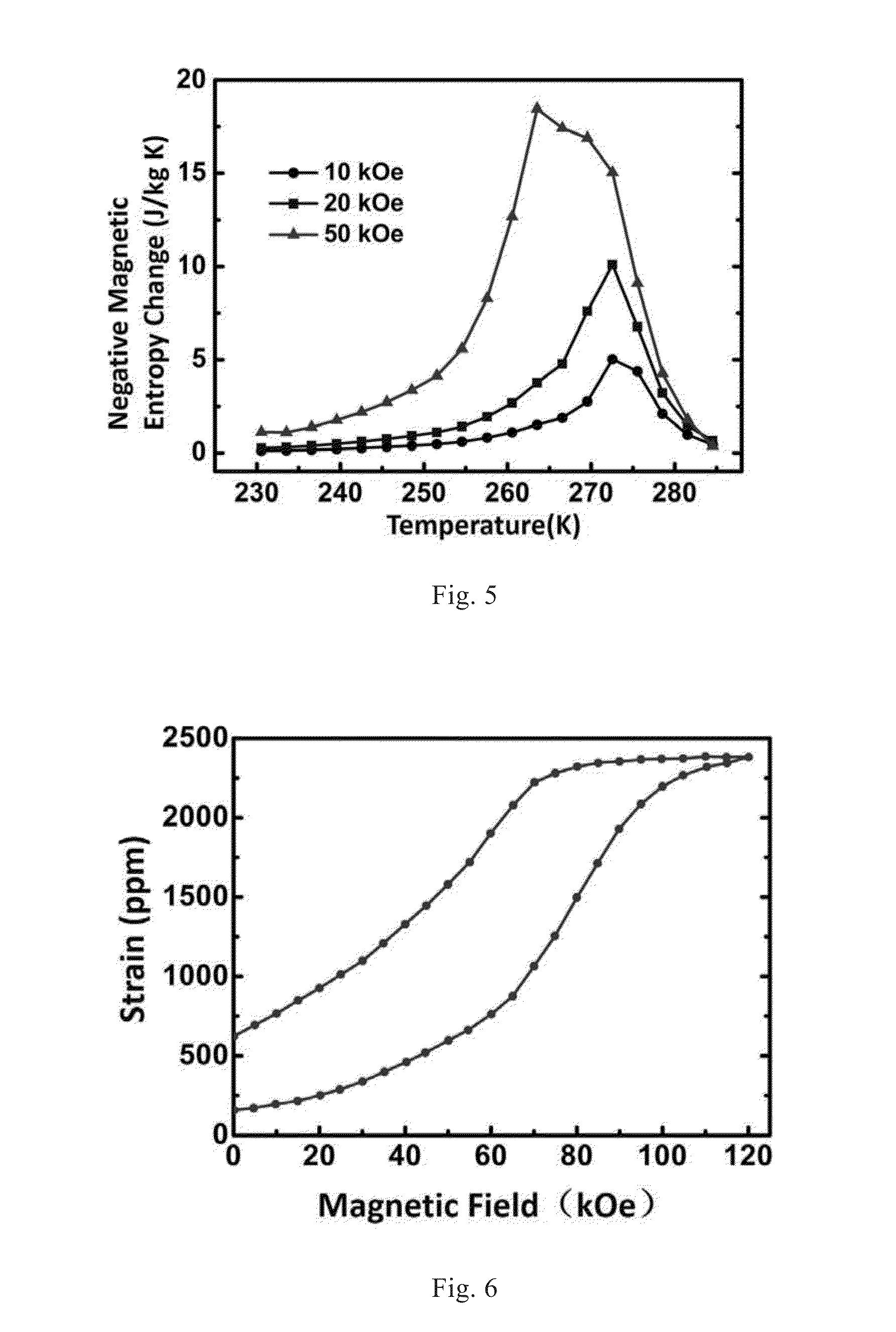

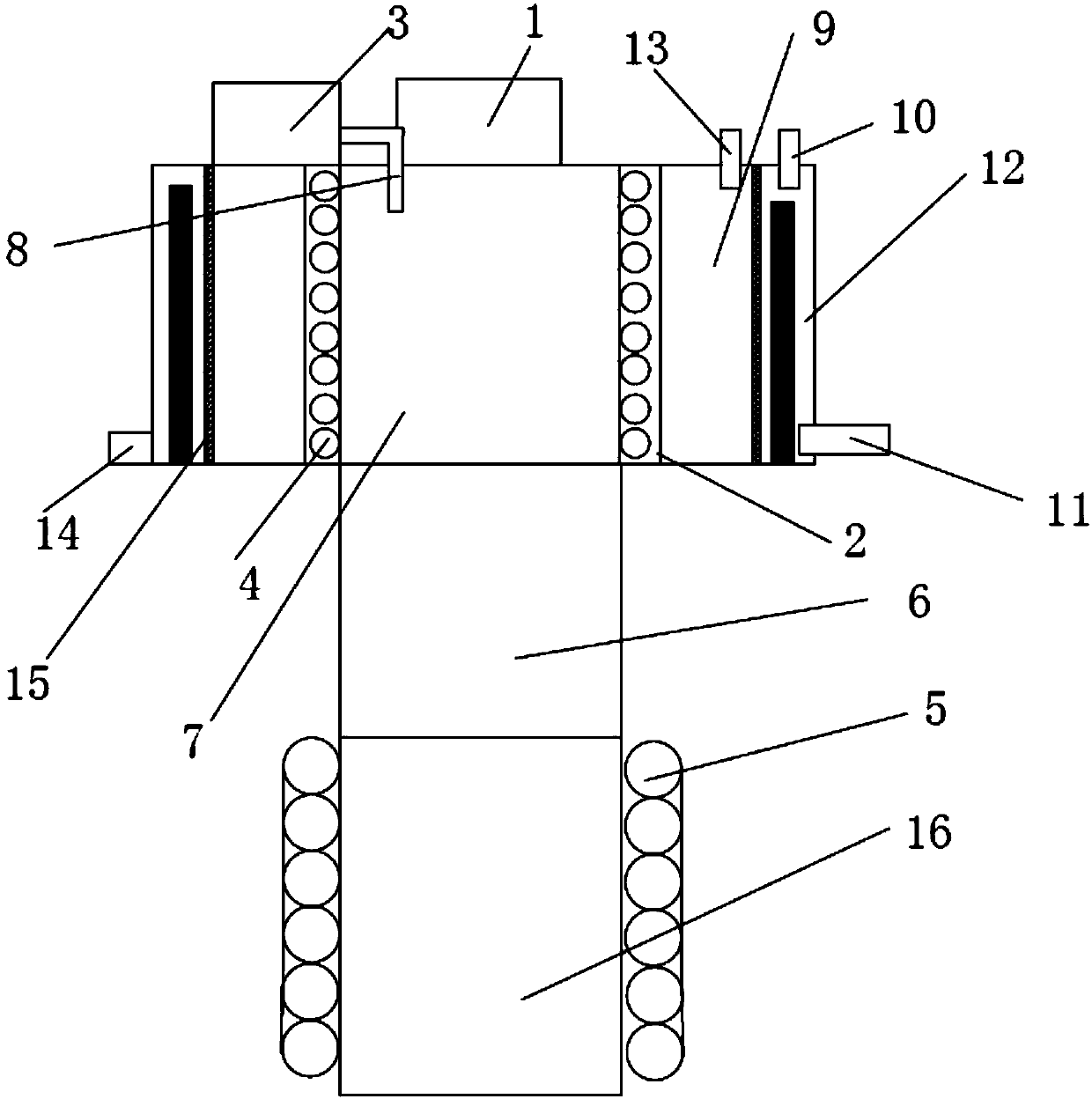

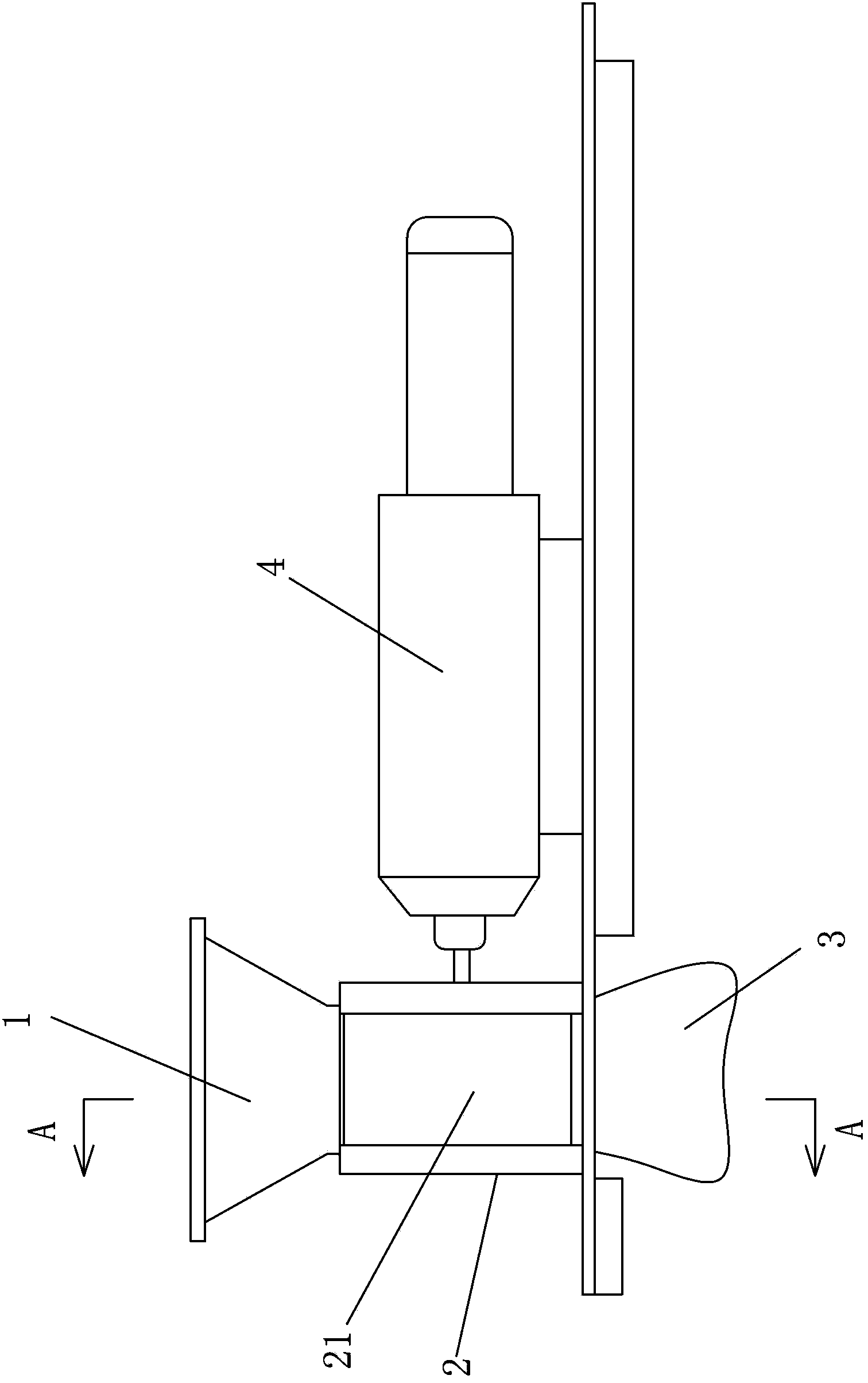

Magnetic phase-transformation material

ActiveUS20160256923A1Improve mechanical propertiesImprove toughnessMagnetic materialsMagnetic phaseMagnetic memory

A magnetic phase-transformation material with the formula Nia−mMnb−nCom+nTic is provided, wherein a+b+c=100, 20<a≦90, 5≦b<50, 5≦c≦30, 0≦m≦a, 0≦n≦b, 0<m+n<a+b, and wherein, any one or combination of a, b, c, m, n represent an atomic percentage content. The magnetic phase-transformation material has properties of high toughness, high deformation rate, ferromagnetism and magnetic field-driven martensitic phase transformation, which can be widely used in various fields including high-strength and high-toughness actuators, temperature and / or magnetic sensitive elements, magnetic refrigeration devices and equipments, magnetic heat pump devices, magnetic memories, micro-electromechanical devices and systems, and thermomagnetic power generators or transducers.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Light alloy magnetic ultrasonic casting and rolling integrated device and method

InactiveCN107716881AFast crystallizationLow cost productionMetal rolling arrangementsAlloyMaterials science

The invention discloses a light alloy magnetic ultrasonic casting and rolling integrated device and method. The device comprises a runner, a crystallizer, an ultrasonic generator, an induction coil, aroller and a straightening channel. A generating device of the ultrasonic generator extends into the crystallizer; the induction coil is arranged on the outer wall of an inner groove of the crystallizer; inner and outer cooling rooms are arranged on the outer side of the induction coil; the cooling rooms are of water-cooling structures with double channels; a cooling water inlet is formed in theupper end of the outer cooling room and a cooling water outlet is formed in the lower end; the inner cooling room is of an air cooling structure; an air inlet is formed in the upper end of the inner cooling room while an air outlet is formed in the lower end; a film layer, through which only wind can enter and water cannot be discharged, is arranged between the inner cooling room and the outer cooling room; the straightening channel is arranged at the outlet of the crystallizer, a discharge channel is arranged below the straightening channel and the roller is arranged out of the discharge channel for rolling a finished product into a panel. By combined cooling of air cooling and water cooling, the crystallizing speed of the light alloy crystals is fast, and the production cost is low.

Owner:南通聚星铸锻有限公司

Destructing device for disposable injection syringe

The invention provides a destructing device for a disposable injection syringe, which comprises a cavity, a charging hopper, a receiving hopper and a reducer, wherein a pressure wheel is arranged in the cavity, and the edge of the pressure wheel is tangent to the inner wall of the cavity; the charging hopper is connected with the upper part of the cavity and is communicated with the cavity; the receiving hopper is connected with the lower part of the cavity and is communicated with the cavity; the reducer is arranged on one side of the cavity and is connected with a rotating shaft of the pressure wheel; the power of the reducer is supplied by a motor to enable the reducer to drive the pressure wheel to rotate. According to the destructing device adopting a pressure wheel structure, a needle head and a needle tube of the injection syringe can be extruded in the cavity in opposite directions, so that the purpose of destructing the injection syringe radically can be achieved.

Owner:HARBIN MEDICAL UNIVERSITY

Blue phase liquid crystal display panel

ActiveUS9958740B2Reducing external drive voltageIncrease deformation rateNon-linear opticsEngineeringField strength

Disclosed is a blue phase liquid crystal display panel which includes an upper substrate and a lower substrate which are disposed opposite to each other, and blue phase liquid crystals provided between the upper substrate and the lower substrate. The upper substrate is provided with a first common electrode on a side facing the blue phase liquid crystals, and the lower substrate is provided with a second common electrode and a plurality of pixel electrodes on a side facing the blue phase liquid crystals. The pixel electrodes each extend towards the first common electrode, thus forming a horizontal electric field between the upper substrate and the lower substrate. According to the present disclosure, higher horizontal field intensity can be achieved so that the external drive voltage of the blue phase liquid crystals can be greatly decreased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

California red holothurian artificial breeding method

InactiveCN104430094AArtificial breeding is effectiveArtificial breeding is reliableClimate change adaptationAnimal feeding stuffConus californicusAquaculture

The invention discloses a California red holothurian artificial breeding method. The method includes: feeding maturity promoting feedstuffs into an aquaculture tank to cultivate holothurians, adding 1% spirulina liquid into the holothurian aquaculture tank when holothurian gonad index exceeds 15%, and well mixing for cultivation. By adoption the scheme for artificial breeding of California red holothurians, nutritional requirements of quick gonad development of the California red holothurians can be met by the maturity promoting feedstuffs in scientific proportion, and the maturity promoting feedstuffs effectively enable quick maturity of the holothurians; the spirulina liquid can effectively stimulate spermiation of male holothurians and ovulation of female holothurians to realize synchronicity of spermiation and ovulation so as to guarantee reliability in artificial breeding of the California red holothurians.

Owner:QINGDAO AGRI UNIV

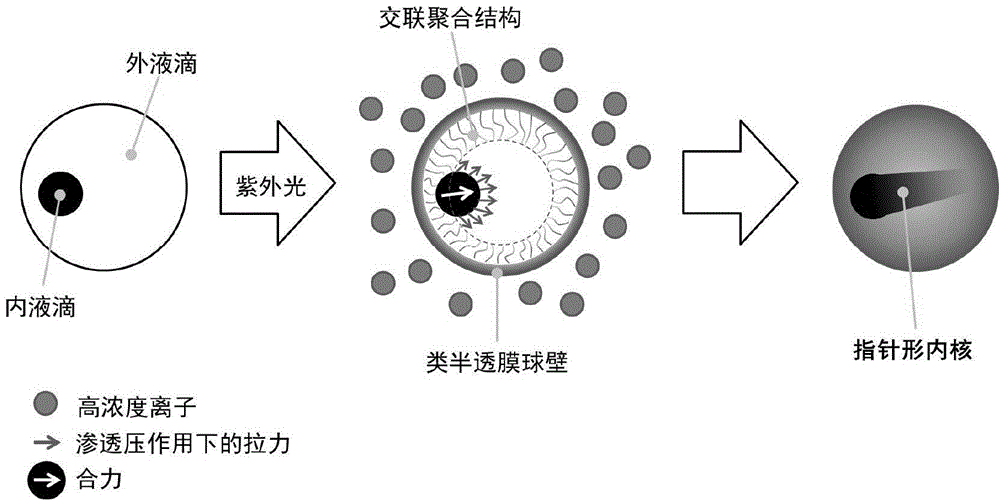

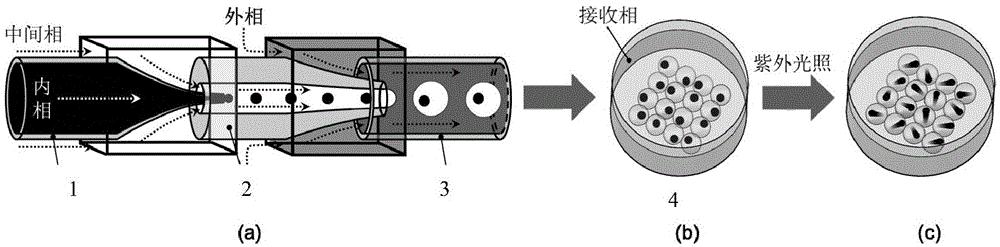

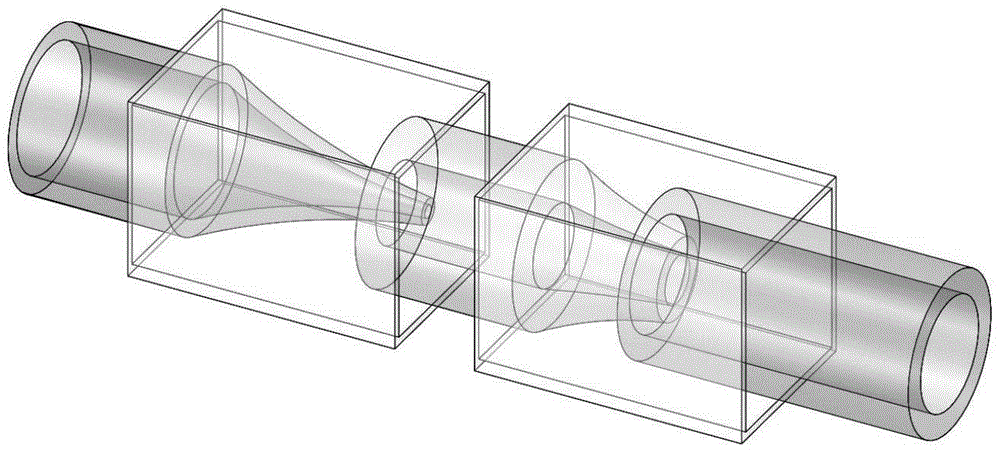

Microstress-induced reaction method and preparation method of pointer nuclear-shell microparticles using same

ActiveCN103979484AUniversalDirectionalDecorative surface effectsChemical vapor deposition coatingMicroparticleCore shell

Owner:EAST CHINA UNIV OF SCI & TECH

Stimuli responsive compound, stimuli responsive compound polymer, actuator and method for manufacturing stimuli responsive compound

InactiveUS20110196120A1Improve mobilityHigh degree of deformationLiquid crystal compositionsOrganic chemistryCompound aStimuli responsive

A stimuli responsive compound includes: a unit A having bonds that function as rotation axes; a first unit B disposed at a first bonding section of the unit A; a second unit B disposed at a second bonding section of the unit A; a first unit C disposed at a third bonding section of the unit A; and a second unit C disposed at a fourth bonding section of the unit A. The first unit B bonds with the second unit B by oxidation-reduction reaction, and the first unit C and the second unit C have liquid crystallinity and include polymerizable functional groups.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

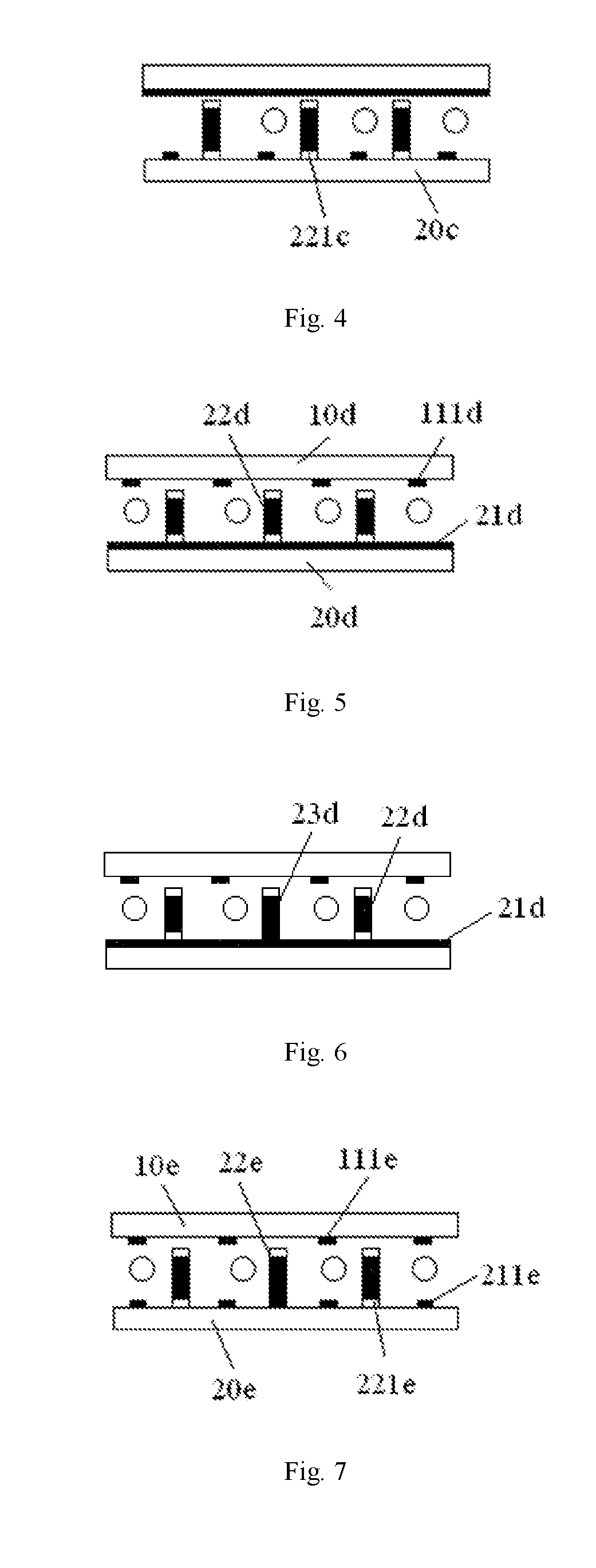

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000061.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000071.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000072.png)