Boxy hole rolling method for large-sized high-thermal-conductivity diamond/copper composite board

A high thermal conductivity, diamond technology, applied in the field of rolling forming, can solve the problems of affecting the performance, low density of composite materials, small size of composite materials, etc., and achieve the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

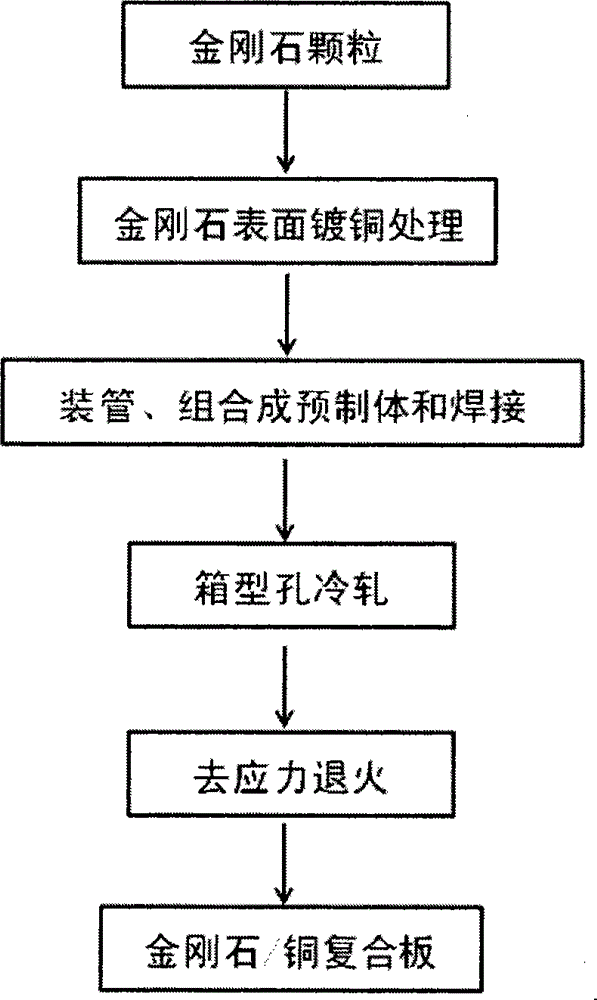

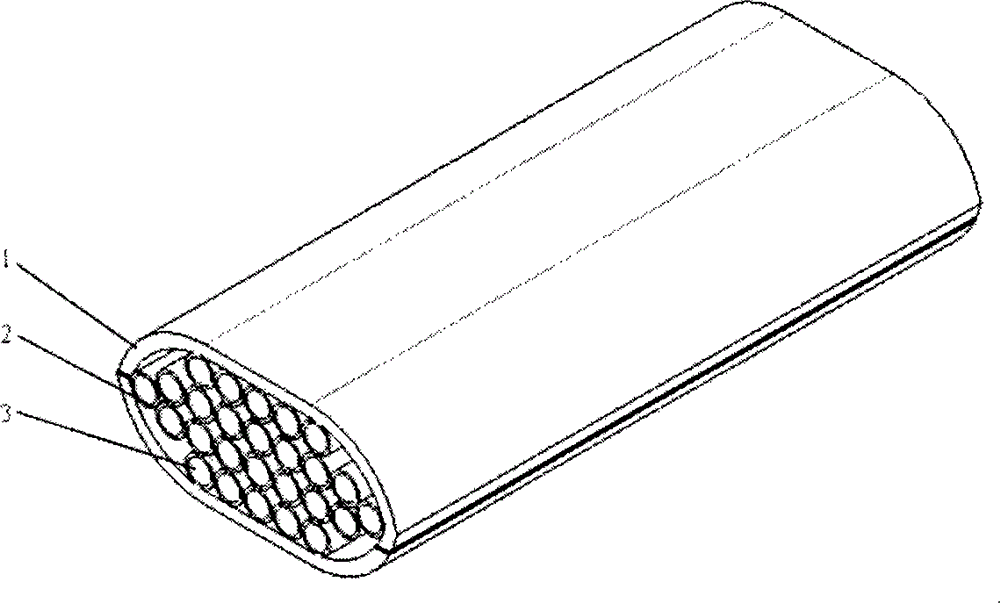

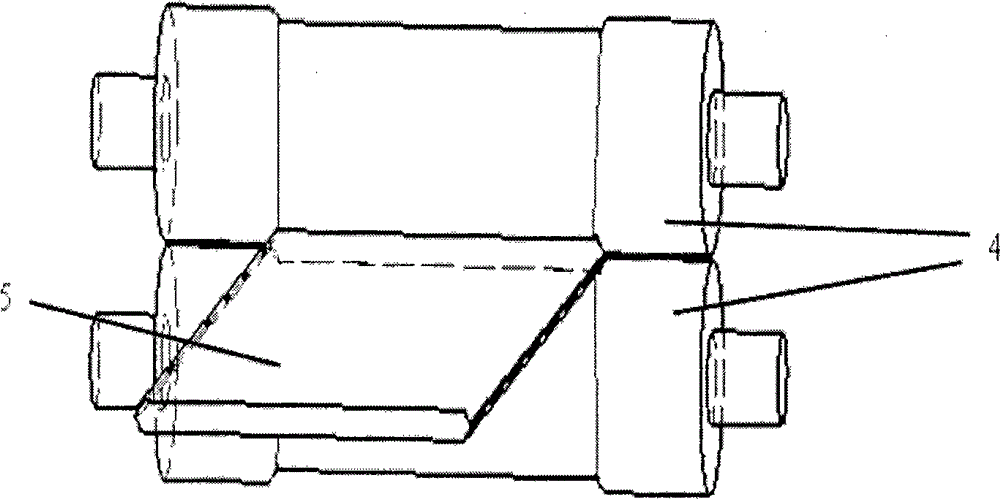

[0027] The preparation process of a high thermal conductivity diamond / copper composite board is shown in the attached figure 1 As shown, firstly, after the surface of the diamond particles is cleaned, a layer of pure copper coating is electroplated; secondly, the treated diamond / copper powder 2 is filled into a thin-walled pure copper tube 3 with an outer diameter of 2.5mm and an inner diameter of 2.0mm ; Then, 76 lengths of 100mm are filled with copper tubes 3 of diamond / copper powder evenly arranged between copper plates 1 of 100mm (long) * 32mm (wide) * 1mm (thick), as attached figure 2 As shown, the upper and lower copper plates 1 are welded into a prefabricated body 6 along the length direction by fusion welding, and the prepared prefabricated body 6 is as follows figure 2 Shown; Prefabricated body 6 is placed between the roll 4 of box hole rolling mill and carries out the cold rolling of seven passes, and rolling process is as image 3 with 4 As shown, the reductions...

Embodiment 2

[0029] The preparation process of a high thermal conductivity diamond / copper composite board is shown in the attached figure 1 As shown, first, after the surface of the diamond particles is cleaned, a layer of pure copper coating is electroplated; secondly, the processed diamond / copper powder 2 is filled into a thin-walled pure copper tube 3 with an outer diameter of 3mm and an inner diameter of 2.5mm; Then, 54 copper tubes 3 filled with diamond / copper powder with a length of 100mm are evenly arranged between copper plates 1 of 100mm (length) × 32mm (width) × 1mm (thickness), as attached figure 2 As shown, the upper and lower copper plates 1 are welded into a prefabricated body 6 along the length direction by fusion welding, and the prepared prefabricated body 6 is as follows figure 2 Shown; Prefabricated body 6 is placed between the roll 4 of box hole rolling mill and carries out the cold rolling of seven passes, and rolling process is as image 3 with 4 As shown, the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com