Method for preparing large diamond/copper composite plate through semi-solid continuous rolling

A diamond and semi-solid technology, applied in metal rolling and other directions, can solve the problems of small product size, affecting the structure and performance of composite materials, graphitization of diamond particles, etc., to improve air tightness and thermal conductivity, and avoid easy oxidation , the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

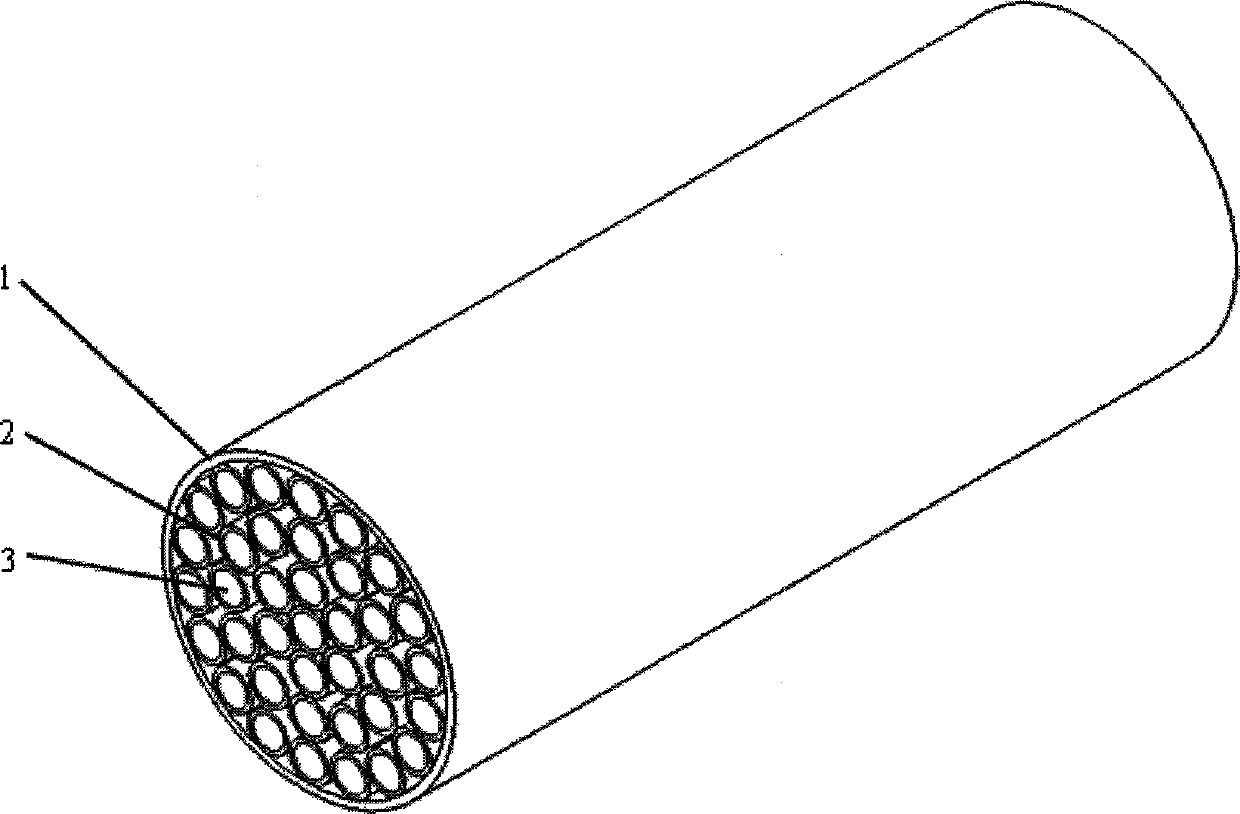

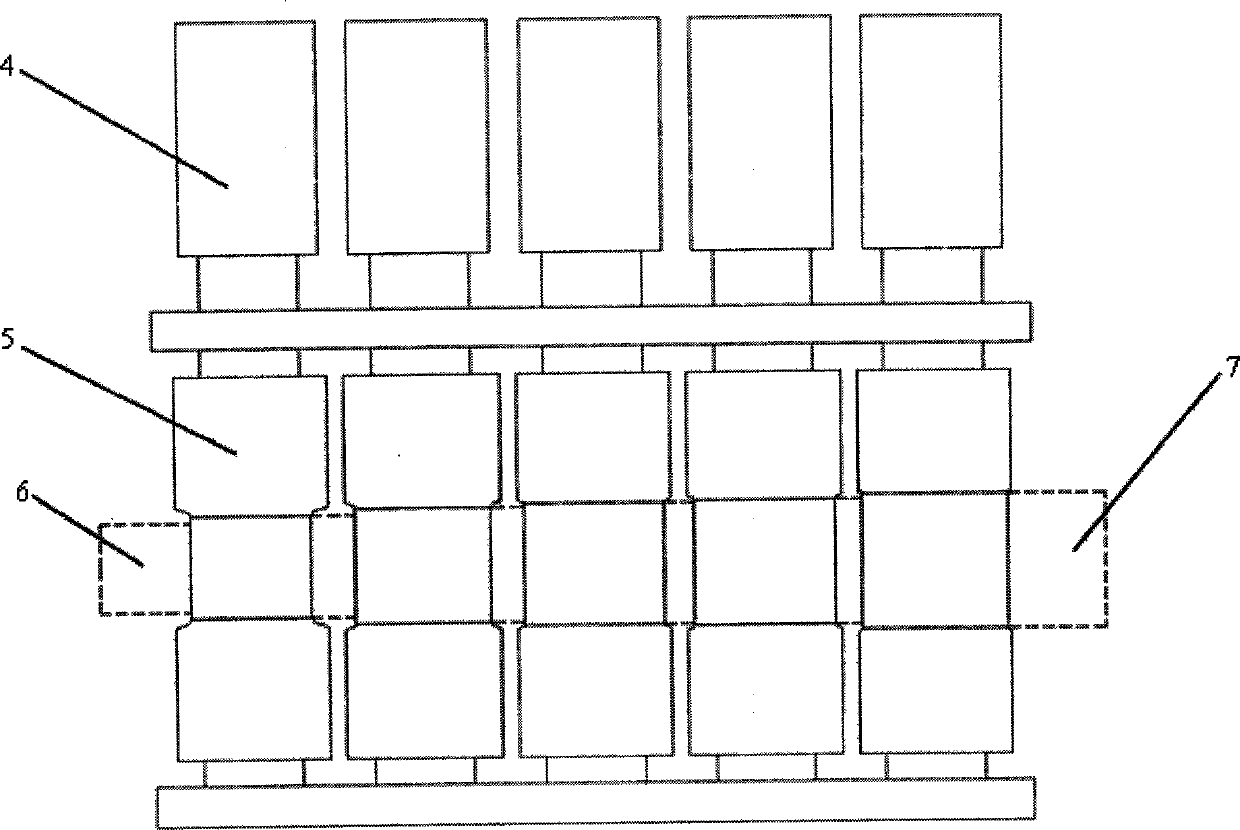

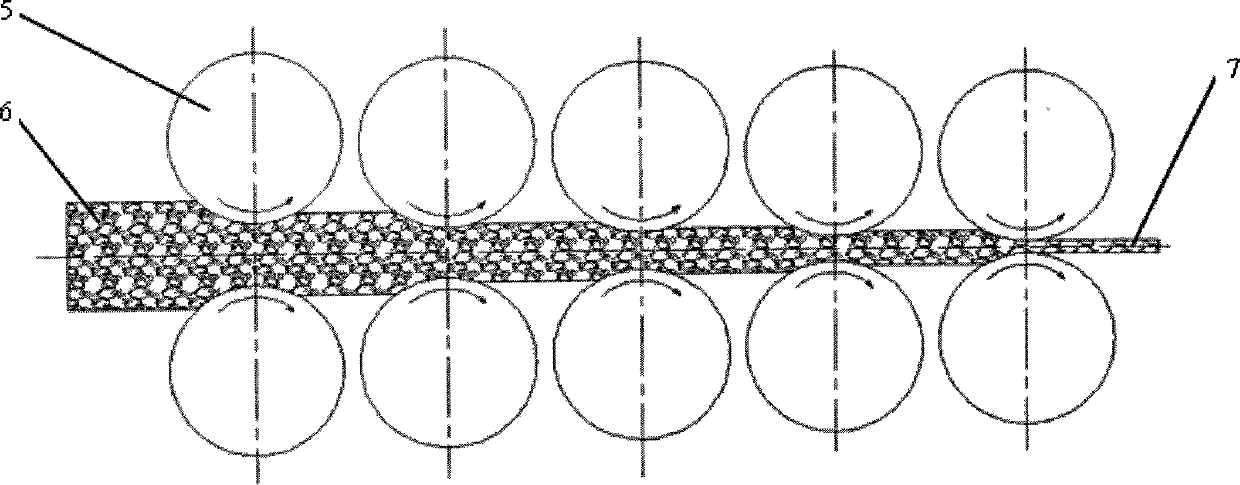

[0037]First, after the surface of the diamond particles is cleaned, a layer of pure copper is electroplated, and mixed evenly with CuZn31Al2 copper alloy powder with a volume fraction of 10%; secondly, the treated diamond / copper alloy mixed particles 3 are filled to an outer diameter of 2.5 mm, inner diameter of 2.0mm thin-walled pure copper tube 2, and seal the front and rear sections of the copper tube; One bundle is packed into a thin-walled circular copper tube 1 with an outer diameter of 16 mm and an inner diameter of 15 mm to form a cylindrical prefabricated body 6, such as figure 1 shown; then, press the preform into an ellipsoid of 50mm (length) × 20mm (width in the major axis direction) × 7mm (thickness in the minor axis direction) on a press and heat it to 955°C; then, the heated ellipsoid Placed between the rolls 5 of the box hole continuous rolling mill and carried out continuous rolling for five passes, the rolling process is as follows figure 2 and 3 As shown,...

Embodiment 2

[0039] First, after the surface of the diamond particles is cleaned, a layer of pure copper is electroplated, and mixed uniformly with CuZn31Al2 copper alloy powder with a volume fraction of 10%; secondly, the treated diamond / copper alloy mixed particles 3 are filled to an outer diameter of 3.0 mm, inner diameter of 2.5mm thin-walled pure copper tube 2, and seal the front and rear sections of the copper tube; One bundle is packed into a thin-walled circular copper tube 1 with an outer diameter of 16 mm and an inner diameter of 15 mm to form a cylindrical prefabricated body 6, such as figure 1 shown; then, the preform is pressed into an ellipsoid of 50mm (length) × 20mm (width in the major axis direction) × 7mm (thickness in the minor axis direction) on a press and heated to 965°C; then, the heated ellipsoid Placed between the rolls 5 of the box hole continuous rolling mill and carried out continuous rolling for five passes, the rolling process is as follows figure 2 and 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com