Method for manufacturing tantalum target material

A manufacturing method and technology for tantalum targets, which are applied in the field of tantalum target manufacturing, can solve the problems of serious delamination of tantalum targets and low internal deformation rate of tantalum ingots, so as to reduce process costs, improve internal structure, and avoid cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

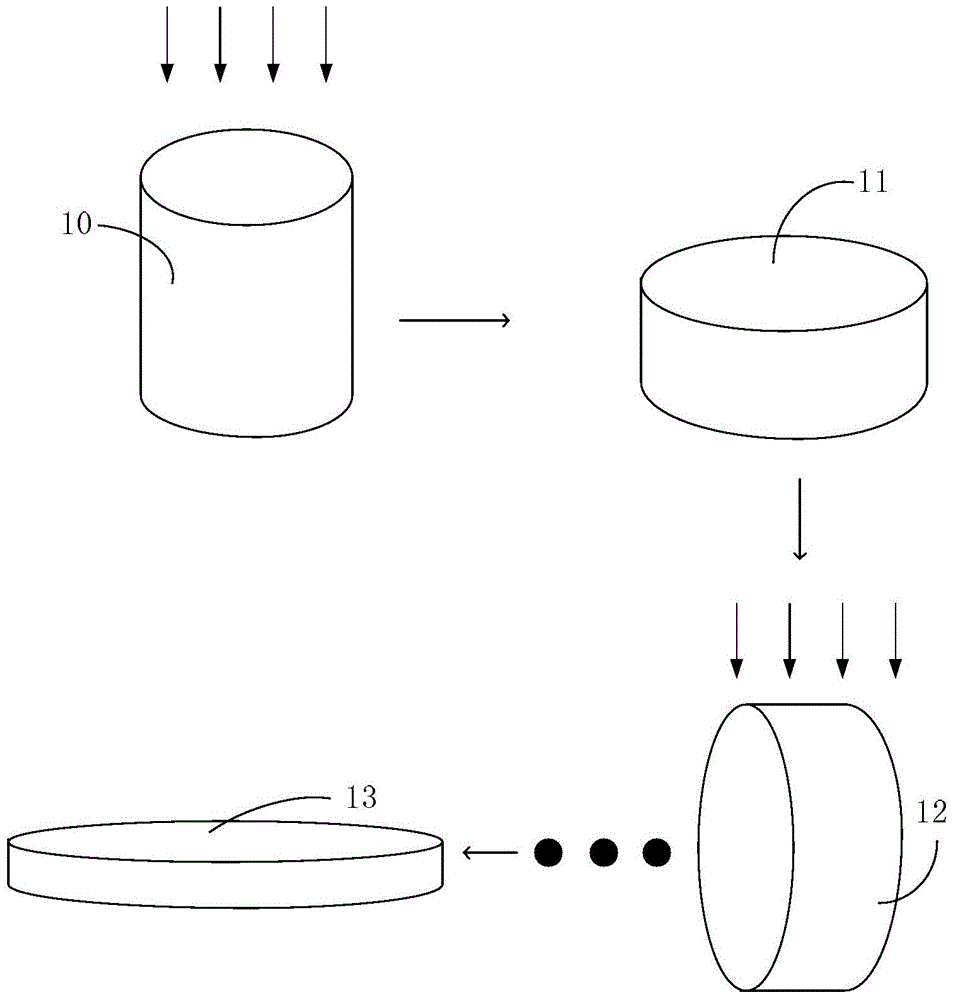

[0046] As mentioned in the background technology, based on the metal structure of tantalum metal itself, there will be obvious delamination inside the tantalum target formed by the traditional manufacturing process, which will affect the sputtering rate and stability of the target during the magnetron sputtering process , and thus reduce the film quality of tantalum thin films.

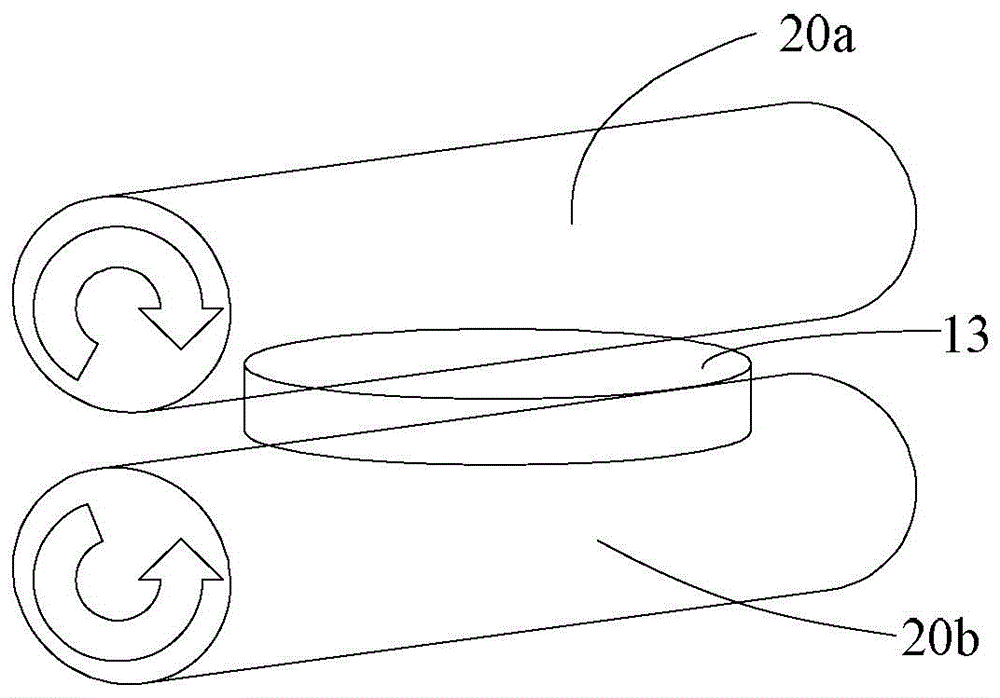

[0047] If the plastic deformation of the tantalum target is realized above the tantalum recrystallization temperature, the internal delamination phenomenon of the tantalum target can be alleviated, but the above-mentioned process requires high processing equipment such as hot rolling equipment, and the process conditions are harsh and difficult to operate. The yield rate of the tantalum target is low, and the above-mentioned process also greatly increases the production cost of the tantalum target.

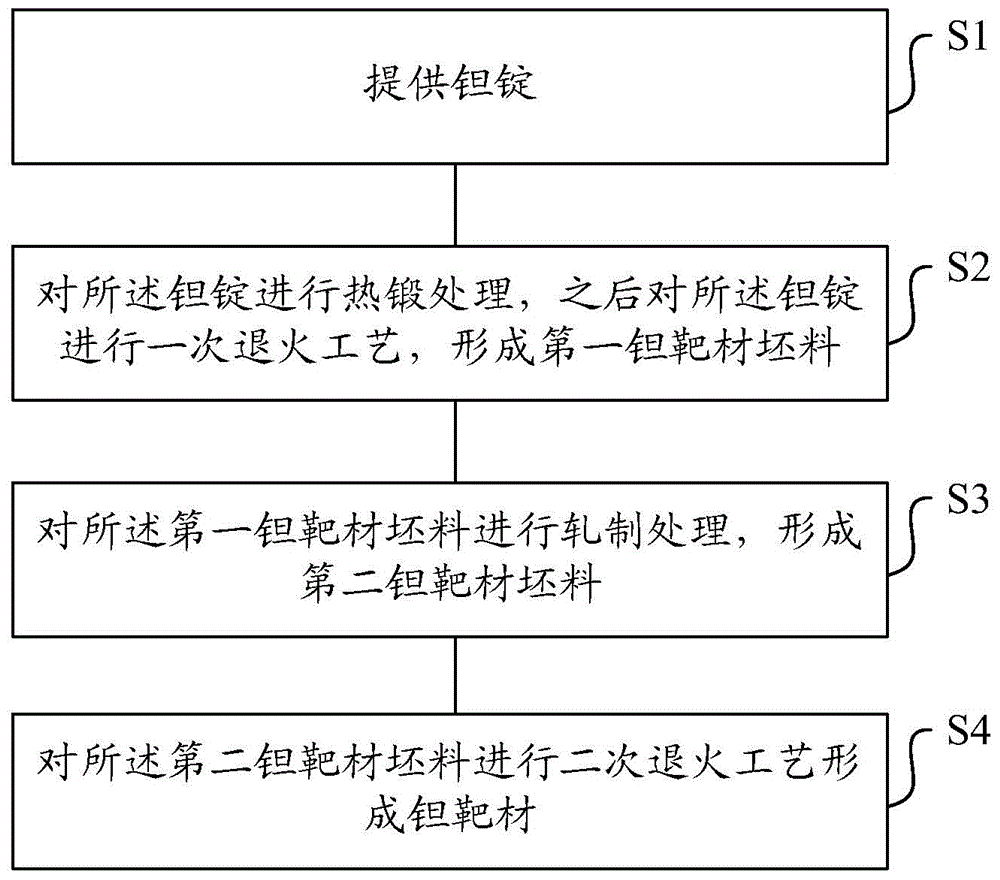

[0048] For this reason, the present invention provides a method for manufacturing tantalum targets. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com