Method for treating peat soil foundation through preloading in combination with salt piles

A technology of stacking preloading and ground foundation, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of accelerated pore water seepage, easy blockage of vacuum tubes, settlement and deformation, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for treating peat soil foundation with surcharge preloading combined with salt piles according to the present invention will be further described below in conjunction with specific examples, but the scope of protection of the present invention is not limited thereto.

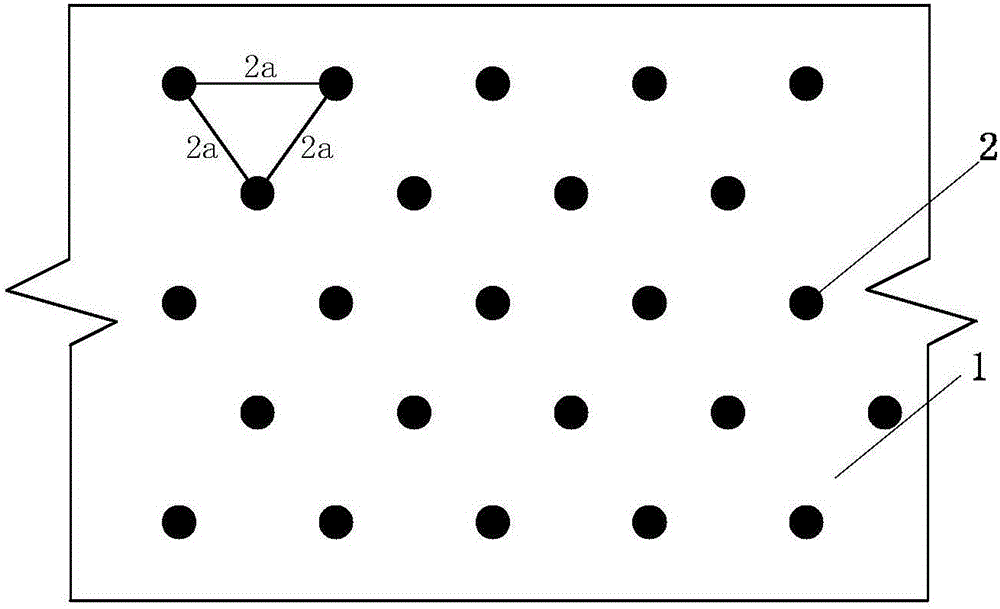

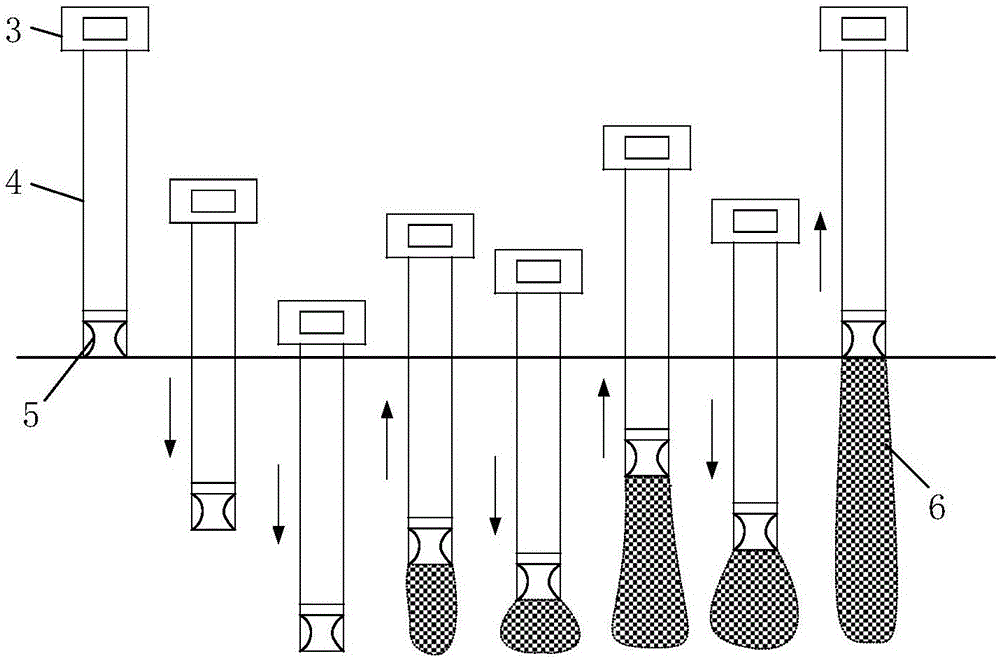

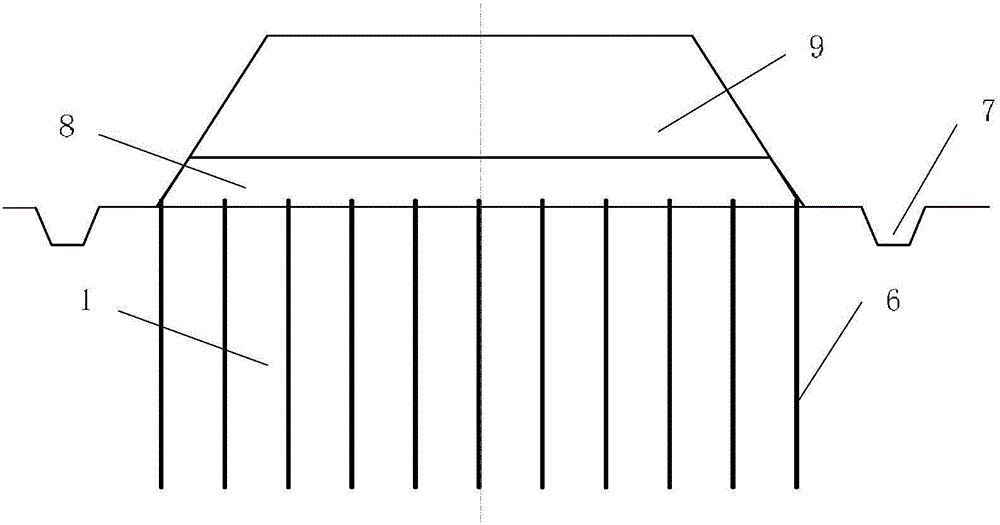

[0031] A method for treating peat soil foundations with surcharge preloading combined with salt piles. A number of salt piles are driven into the peat soil foundation, and the salt piles use coarse sea salt as the core material; a horizontal drainage sand cushion is laid on the surface of the peat soil foundation ; Construct the preloaded load layer above the horizontal sand cushion, the specific steps are as follows:

[0032] (1) according to the position and depth of the peat soil layer 1 to be treated given by the geological survey data, determine the penetration depth of the salt pile 6;

[0033] (2) Site leveling: the peat soil foundation 1 to be treated is leveled, and a drainage ditch 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com