Preparation method of flexible supercapacitor, and preparation method of electrode and diaphragm thereof

A supercapacitor, flexible technology, applied in the field of energy storage, can solve the problems of electrode and/or separator edge material loss, reduce monomer production efficiency, increase assembly process and other problems, achieve excellent flexibility and processing performance, good elasticity, avoid cutting The effect of edge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Add 300 grams of polymethyl acrylate, 150 grams of 1-butyl-3-methylimidazolium tetrafluoroborate, 450 grams of graphene, 50 grams of conductive carbon black, and 50 grams of polytetrafluoroethylene into a 5L internal mixer After mixing evenly in the medium, slowly add 2025 grams of water and continue mixing to form a gel electrode mixture;

[0042] 2) Add 300 grams of polymethyl acrylate, 150 grams of 1-butyl-3-methylimidazolium tetrafluoroborate, 450 grams of aluminum oxide powder, and 50 grams of polytetrafluoroethylene into a 5L internal mixer and mix well Afterwards, slowly add 1690 grams of water and continue to mix into a gel-state septum mixture;

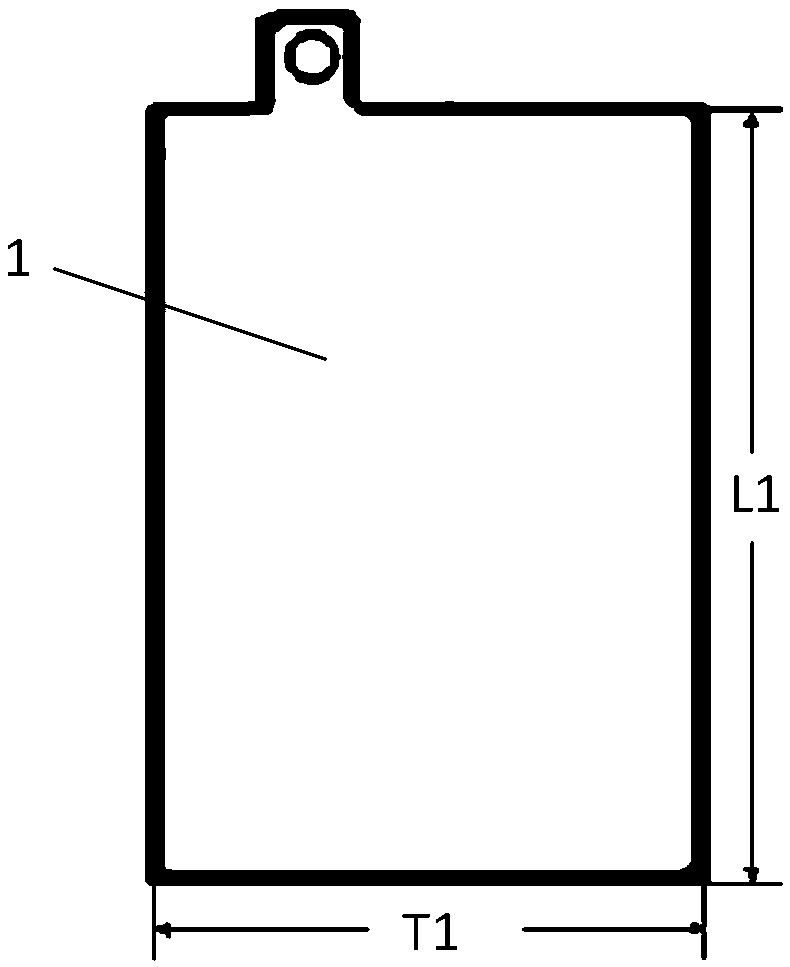

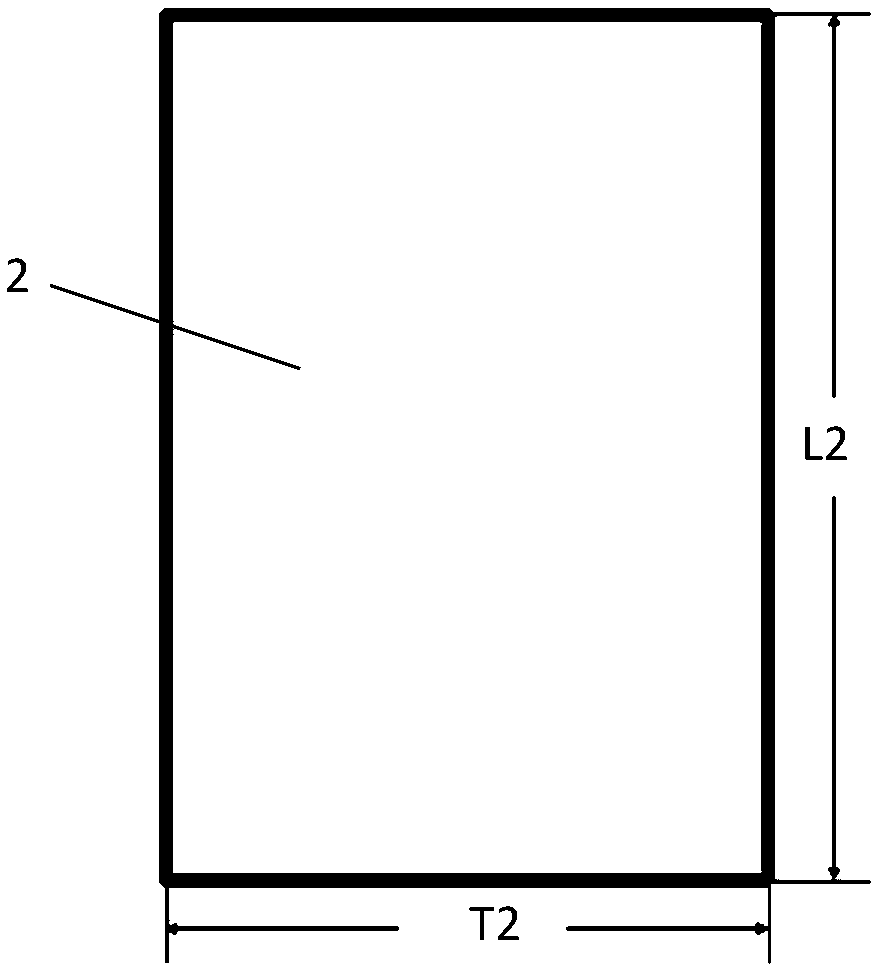

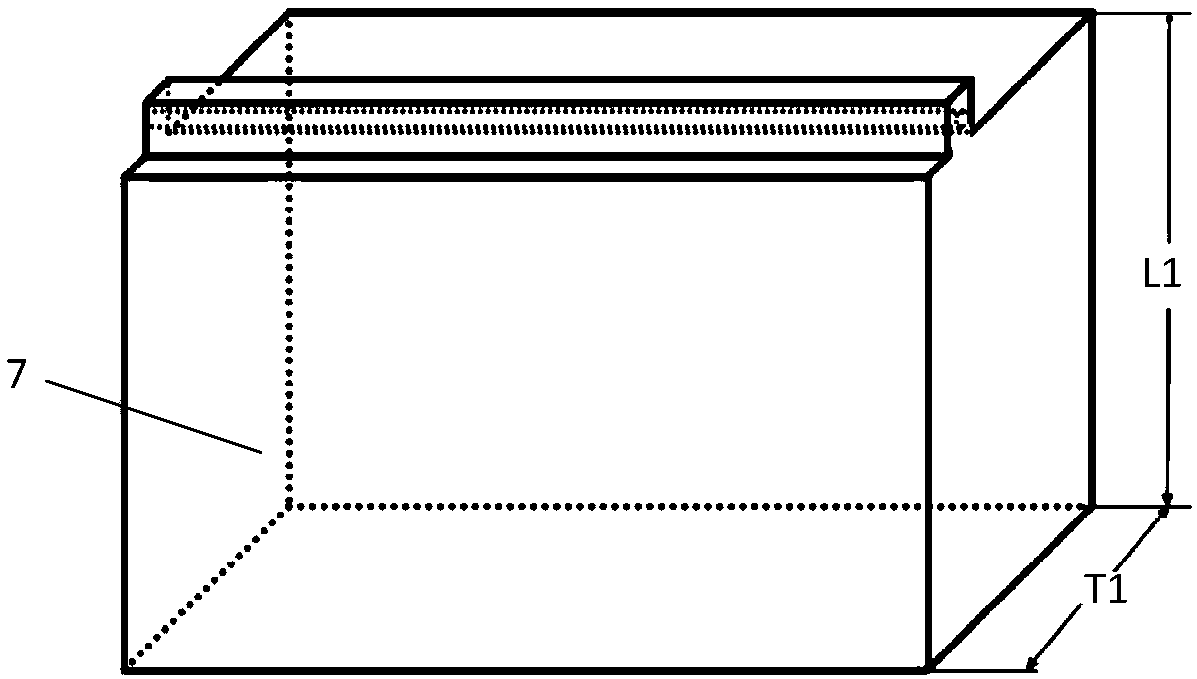

[0043] 3) According to the size of the electrode and diaphragm, respectively as figure 1 and figure 2 , to prepare the forming mold, respectively as image 3 and Figure 4 As shown, the gel electrode mixture and the gel state diaphragm mixture obtained in step 1) and step 2) are respectively put into the moldin...

Embodiment 2

[0047] 1) Add 300 grams of polymethyl acrylate, 150 grams of 1-butyl-3-methylimidazolium hexafluorophosphate, 450 grams of graphene, 50 grams of conductive carbon black, and 50 grams of polytetrafluoroethylene into a 5L internal mixer After mixing evenly, slowly add 2170 grams of acetonitrile to continue mixing to form a gel-state electrode mixture;

[0048] 2) Add 300 grams of polymethyl acrylate, 150 grams of 1-butyl-3-methylimidazolium hexafluorophosphate, 450 grams of aluminum oxide powder, and 50 grams of polytetrafluoroethylene into a 5L internal mixer and mix evenly , slowly add 1810 grams of acetonitrile and continue to mix into a gel-state septum mixture;

[0049] All the other 3), 4), and 5) steps are the same as in Example 1.

Embodiment 3

[0051] 1) 300 grams of polymethyl acrylate, 150 grams of 1-ethyl-3-picoline bis(trifluoromethylsulfonyl)imide, 450 grams of graphene, 50 grams of conductive carbon black, 50 grams of polytetrafluoroethylene Add vinyl fluoride to a 5L internal mixer and mix evenly, then slowly add 1960 grams of acetonitrile and continue mixing to form a gel-state electrode mixture;

[0052] 2) Add 300 grams of polymethyl acrylate, 150 grams of 1-butyl-3-picoline bis(trifluoromethylsulfonyl)imide, 450 grams of aluminum oxide powder, and 50 grams of polytetrafluoroethylene After mixing evenly in the 5L internal mixer, slowly add 1620 grams of acetonitrile to continue mixing to form a gel-state diaphragm mixture;

[0053] All the other 3), 4), and 5) steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com