Electromagnetic pulse assisted progressive drawing method and device

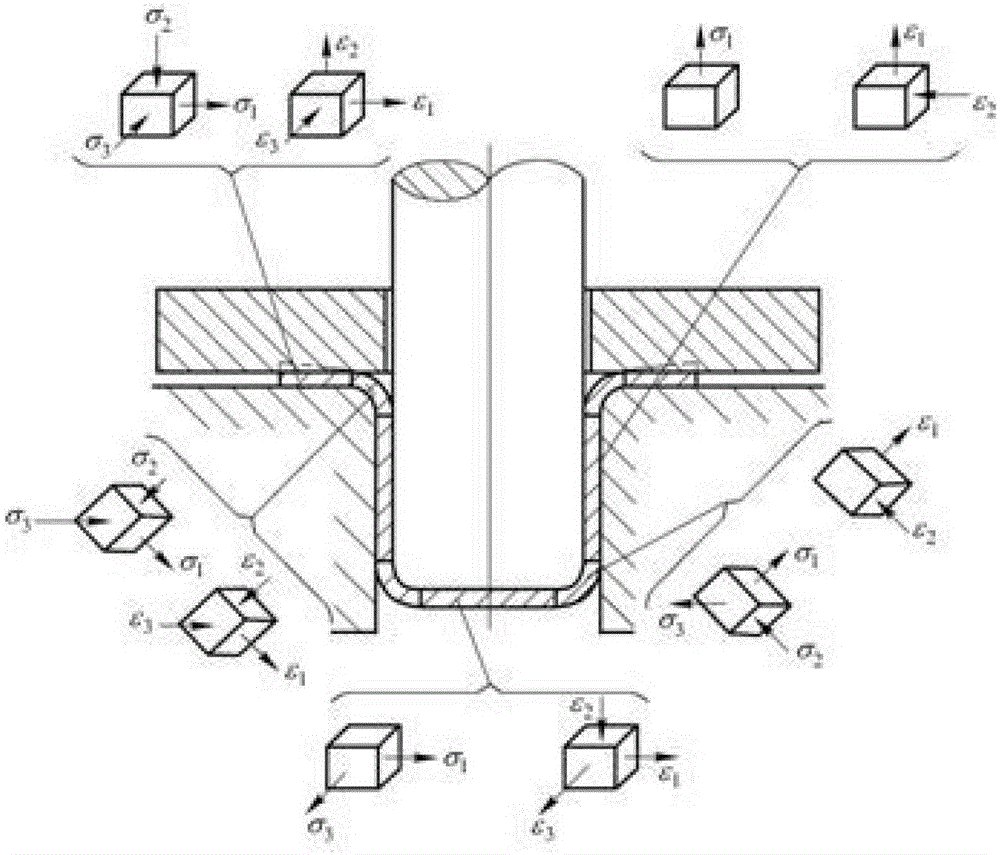

An electromagnetic pulse boosting and incremental forming technology, which is applied in the field of material plastic forming, can solve the problems of unreasonable force state of deep drawing forming and single electromagnetic deep drawing forming height of drawing crack, so as to overcome the drawing crack defect and improve the forming limit. , easy to shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

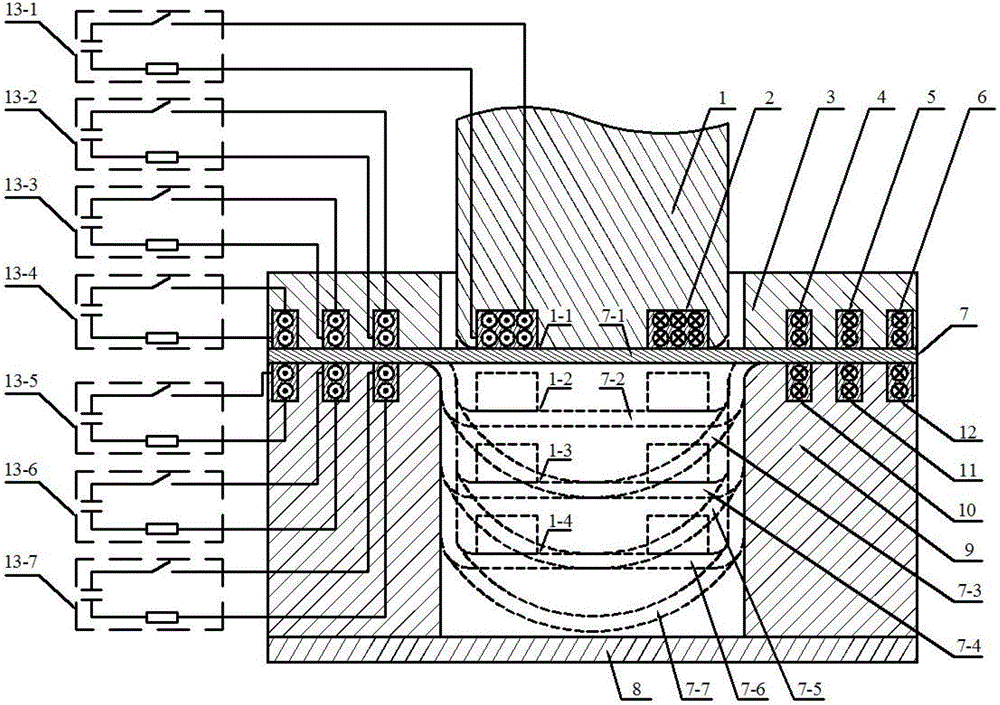

[0055] Such as Figure 2-4 Shown is the electromagnetic pulse-assisted progressive drawing forming device of the present invention, including a punch 1, a die 9, a blank holder 3, a drawing coil 2, three booster coil groups and a power supply system; the punch 1 Matched with the die 9, the drawing coil 2 is embedded in the die 1; the blank holder 3 is movably arranged on the die 9 and is located on the periphery of the die 1, and is used to press the blank 7 to be formed on the die 9; die 9 is fixedly installed on the base 8. Of course, the base 8 may not be provided in the present invention.

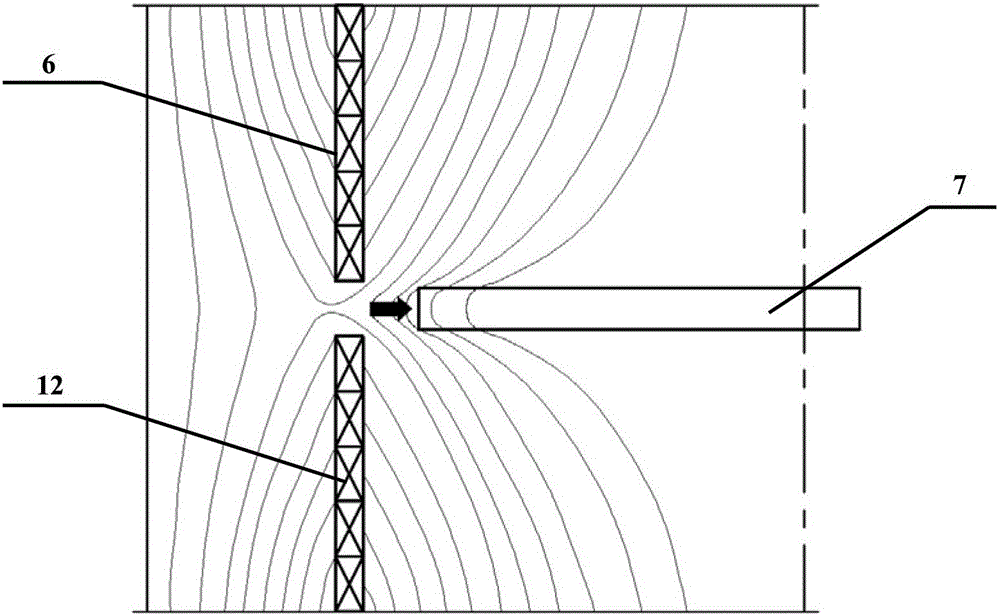

[0056] Each booster coil group includes an upper booster coil and a lower booster coil corresponding to the upper and lower positions. In this embodiment, the first upper booster coil 6 and the first lower booster coil 12 form the first booster coil group. The second upper booster coil 5 and the second lower booster coil 11 constitute the second booster coil group, the third upper boo...

Embodiment 2

[0061] Using the electromagnetic pulse-assisted progressive drawing forming device described in Embodiment 1, the method for drawing and forming specifically includes:

[0062] First, place the blank 7 to be formed between the blank holder 3 and the die 9, at this time the blank 7 to be formed is located at the initial blank position 7-1, the lower end of the punch 1 is located at the first punch position 1-1, Keep the edge of the blank 7 to be formed aligned with the inner edges of the first upper booster coil 6 and the first lower booster coil 12, as Figure 9a Shown; Charge the energy storage capacitors of the first power supply subsystem 13-1, the fourth power supply subsystem 13-4, and the fifth power supply subsystem 13-5 respectively, and when the charging voltage reaches the forming voltage, disconnect the charging circuit; Simultaneously close the switches in the first power supply subsystem 13-1, the fourth power supply subsystem 13-4, and the fifth power supply subs...

Embodiment 3

[0064] Such as Figure 5 Shown is the electromagnetic pulse-assisted progressive drawing forming device of the present invention, which includes a punch 1, a die 9, a blank holder 3, a drawing coil 2, three booster coil groups and a power supply system. Except for the power supply system, its structure is exactly the same as that of the first embodiment, and will not be repeated here.

[0065] The power supply system includes a plurality of power supply subsystems, namely the first power supply subsystem 13-1, the second power supply subsystem 13-2, the third power supply subsystem 13-3, and the fourth power supply subsystem 13-4. Each power supply subsystem includes a power supply, an energy storage capacitor, a voltage divider resistor and a switch connected in series in sequence.

[0066] The drawing coil 2 is connected to the first power supply subsystem 13-1, and after the first upper booster coil 6 is connected in series with the first lower booster coil 12, it is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com