Patents

Literature

47results about How to "Overcome cracking defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

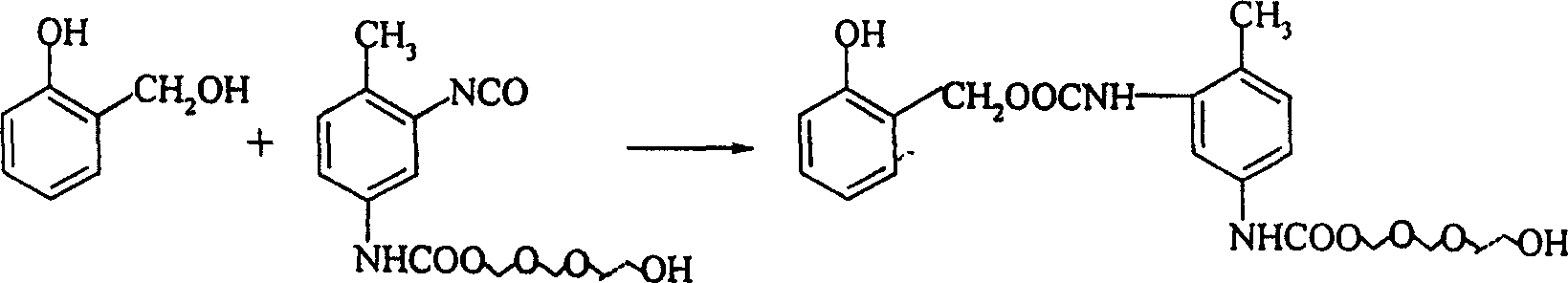

Method of preparing phenolic foam insulation material via foaming at normal temp

This invention relates to a method to produce phenolic foam heat preserving materials by ordinary-temperature foaming, is which phenol formaldehyde is adopted as raw materials and anhydrous polyethylene oxide sorbitan mono-oleate, aluminium hydroxide, pentane and composite acid curing agent are added. It has the characteristics that auxiliary agents and reinforcing modifiers can be also added in the raw materials; the ingredients added into the phenol formaldehyde raw materials have proportions as follows: 4~8 shares of polyethylene oxide sorbitan mono-oleate, 0.1~20 shares of auxiliary agents, 0.5~25 shares of reinforcing modifiers, 0~80 shares of aluminium hydroxide, 6~20 shares of pentane and 8~20 shares of composite acid curing agent, counting in 100 mass shares of phenol formaldehyde. In this invention, ordinar-temperature preparation of phenolic foam heat preserving materials above 0 deg. C can be realized. The phenolic foam heat preserving materials prepared have excellent properties; they help save energy and can be applied in spot construction, and therefore, they are promising materials.

Owner:SHANGHAI INST OF TECH +1

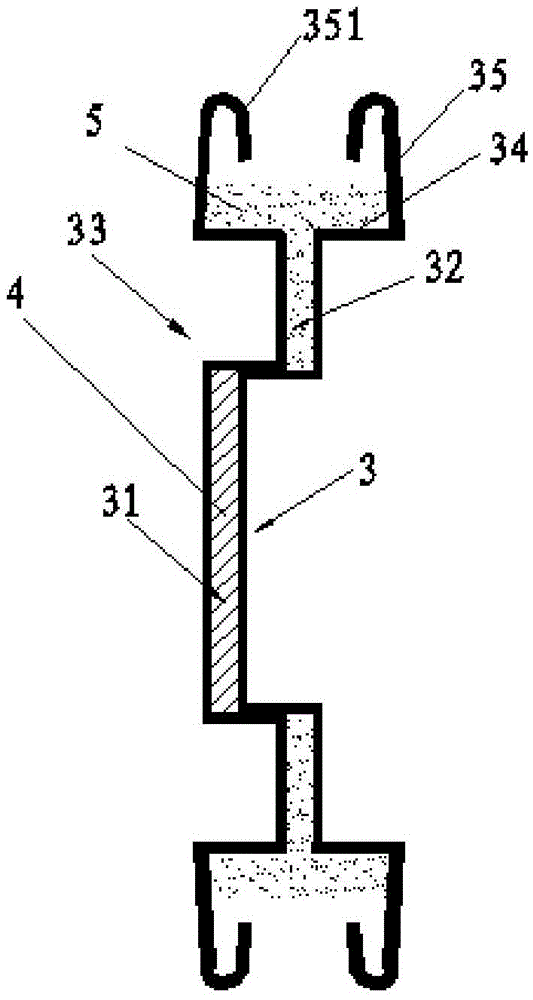

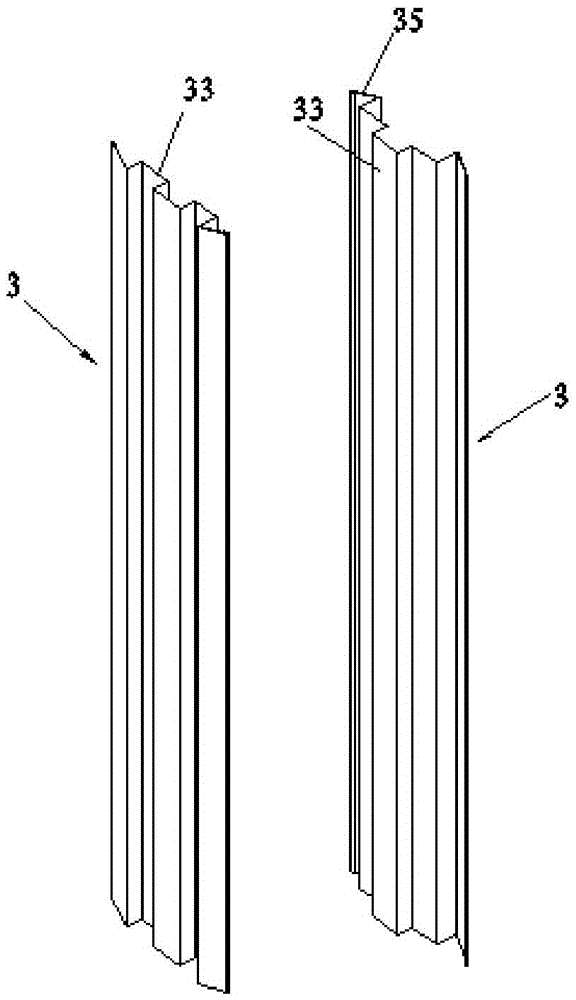

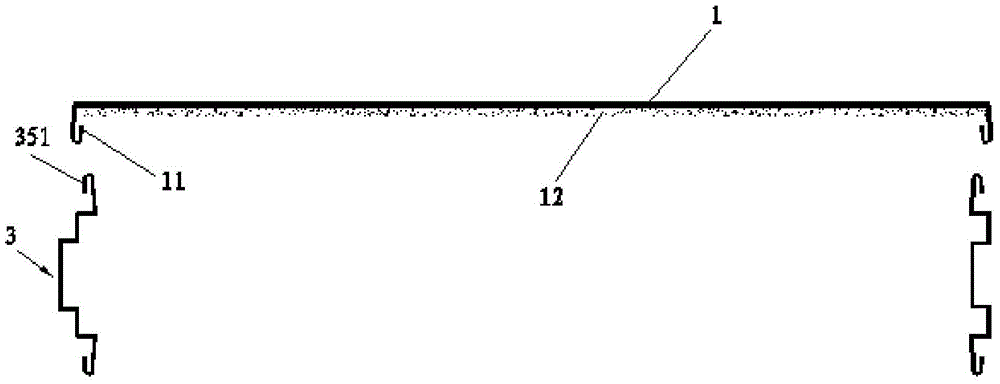

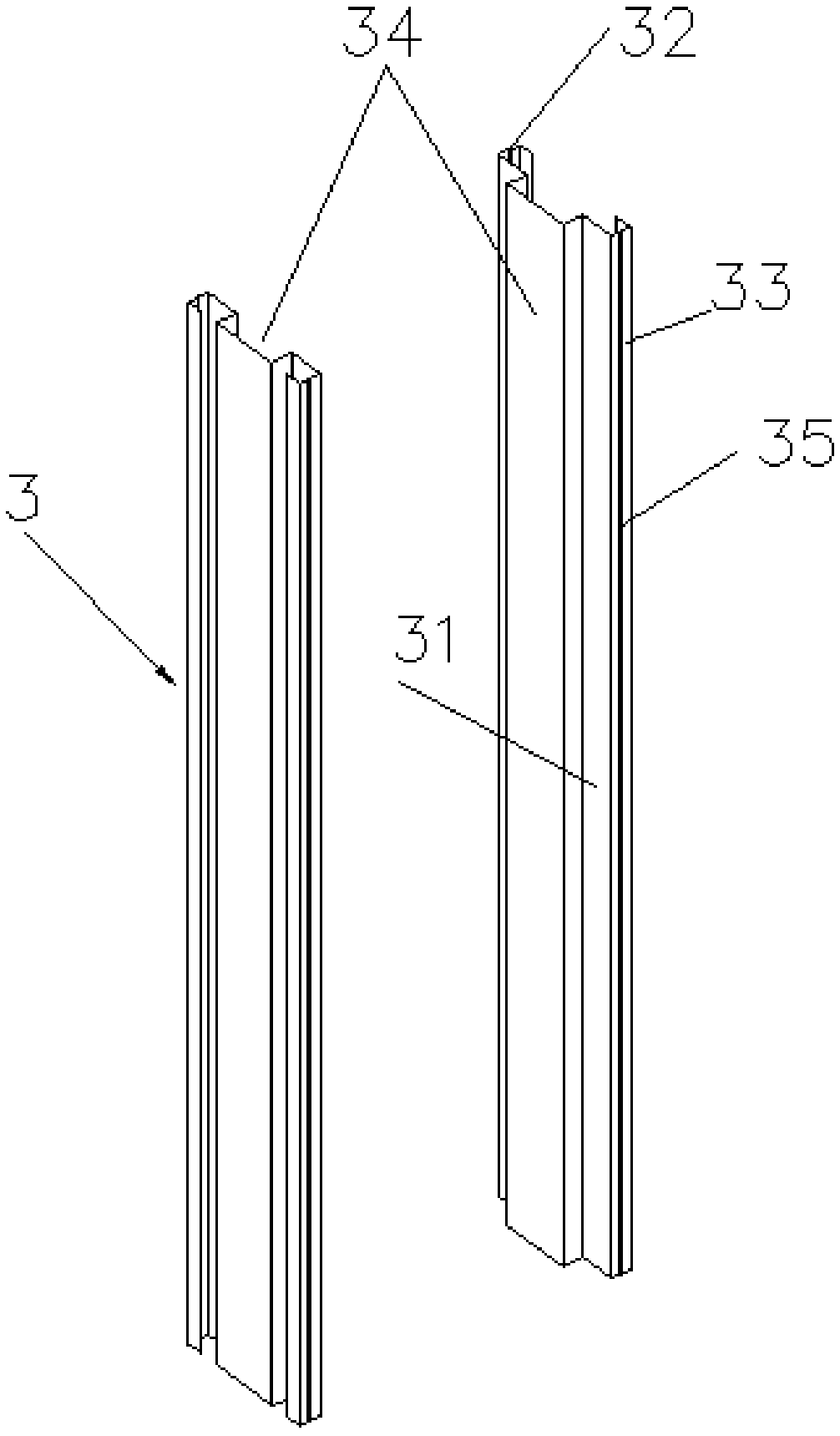

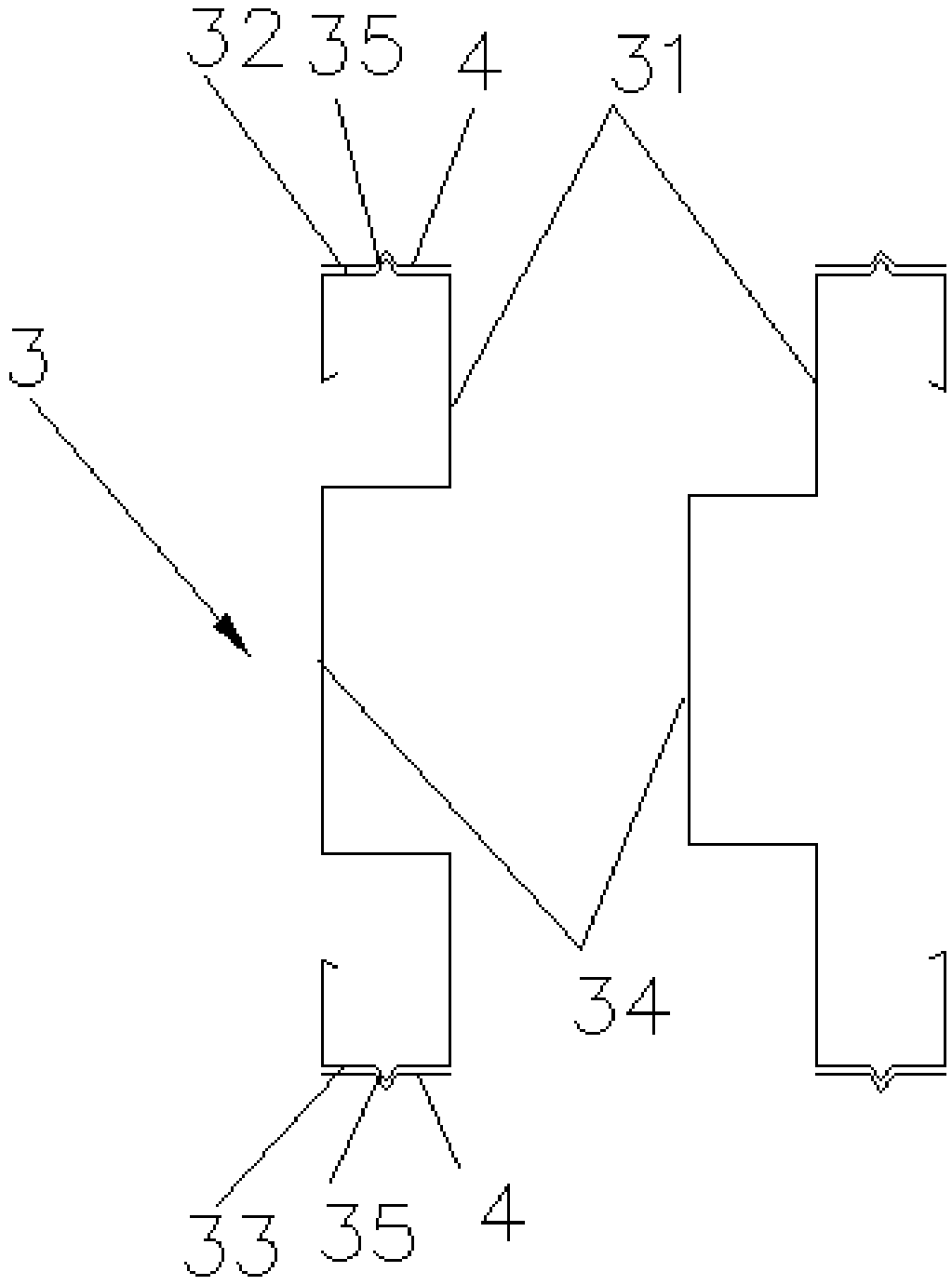

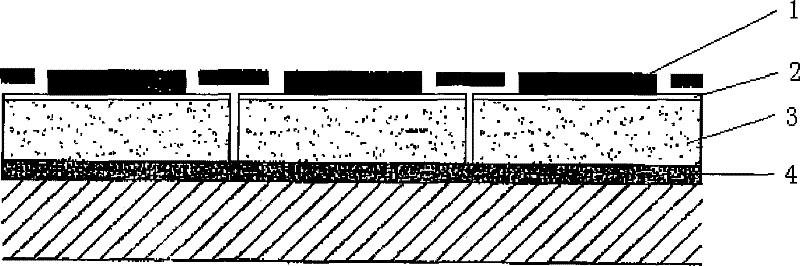

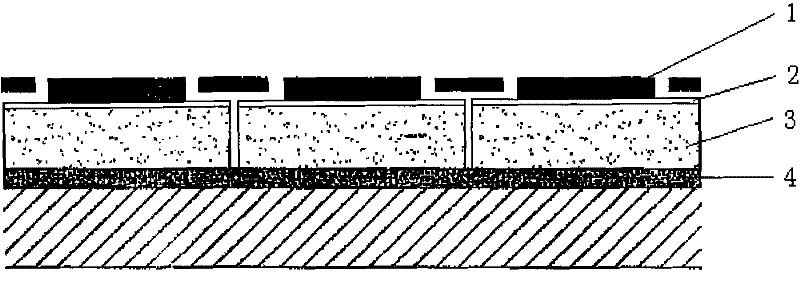

Frame and formwork integrated partition wallboard with telescopic slab joints

The invention provides a frame and formwork integrated partition wallboard with telescopic slab joints. The partition wallboard comprises a frame and a wallboard body connected with the frame. The wallboard body comprises two surface layers and a filling layer between the two surface layers. The partition wallboard is characterized in that a frame strip of the frame is a keel with a concave-convex butt joint part located on the outer side face of the keel perpendicular to the wallboard body, and the concave-convex butt joint parts of adjacent keels of two wallboards with frames are matched so that the two wallboards with the frames can be in butt joint; after the two wallboards with the frames are in butt joint, gaps are reserved between the concave-convex butt joint parts of the two adjacent keels to from a closed space and semi-closed spaces, the semi-closed spaces are located on the two sides of the closed space and communicated with space on the outer side of the outer surfaces of the wallboards, the closed space is filled with a slab joint adhesive rubber strip, and the semi-closed spaces are filled with slab joint filling adhesives. The wallboard is light, high in strength, good in sound insulation, heat isolation, fireproof and heat preservation effect, and capable of overcoming the defect that joints between steel structures, between a steel beam and a wallboard, between a steel column and a wallboard and between wallboards are prone to crack.

Owner:YUNNAN BANZHU TECH CO LTD

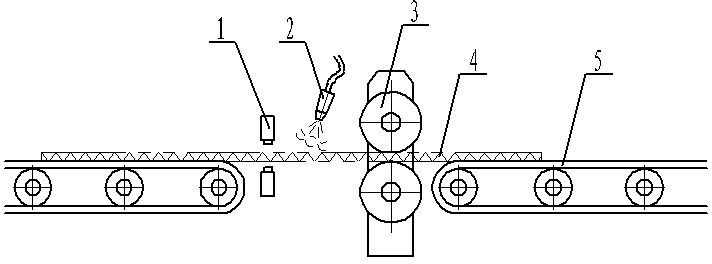

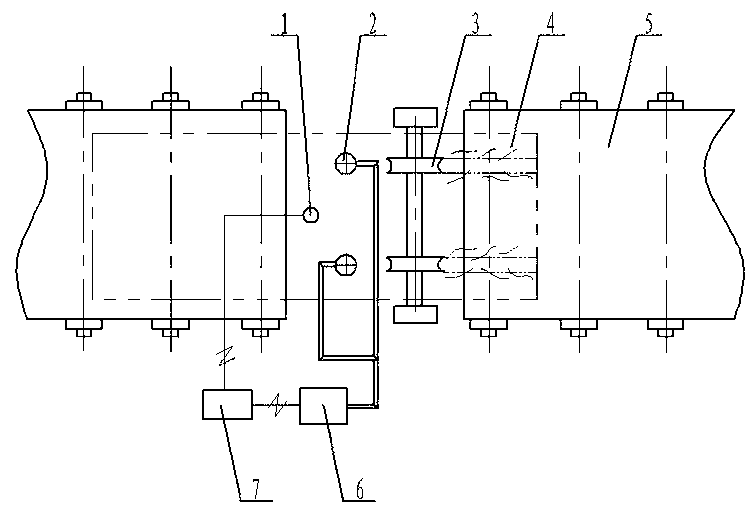

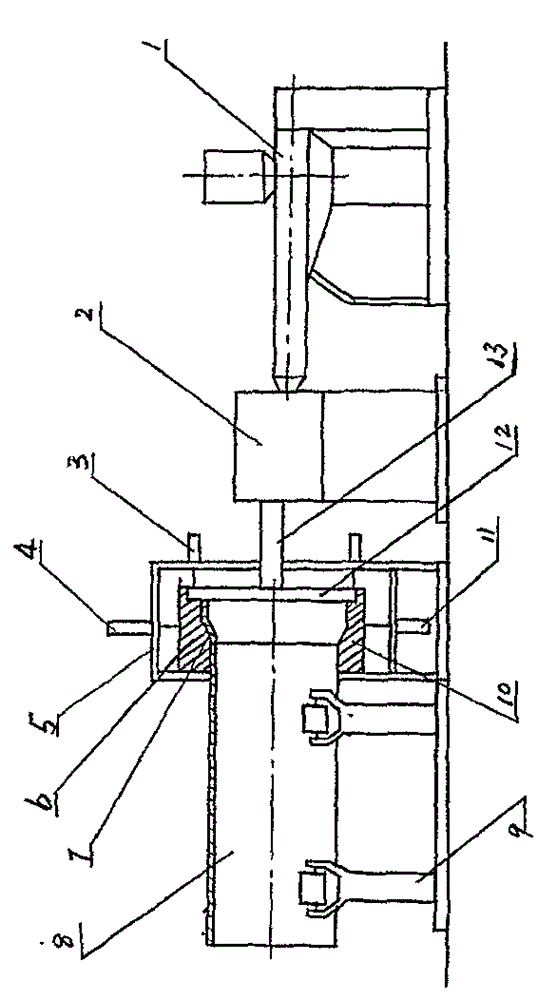

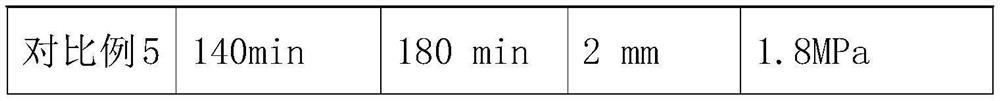

Improved structure of corrugated paperboard production line

InactiveCN103231548AOvercome cracking defectsSolve the compressive strengthMechanical working/deformationCardboardCompressive resistance

The invention discloses an improved structure of a corrugated paperboard production line and belongs to production devices of corrugated cases. The improved structure of the corrugated paperboard production line aims at preventing cracks from generating on the paperboard close to indentation lines. The improved structure of the corrugated paperboard production line comprises a conveyor and a marking press, a nozzle (2) is respectively fixed at the position higher than the conveyor (5) in front of two indentation wheels (3) of the marking press, and the nozzles (2) are respectively communicated with a spraying device (6) through pipelines; a photoelectric sensor (1) electrically connected a controller (7) is arranged in front of the nozzles (2), and the controller (7) is electrically connected with the spraying device (6). The improved structure of the corrugated paperboard production line thoroughly overcomes the shortcomings that paper boards are crisp and can be cracked nearby the indentation lines, and solves the problem that indexes of compressive strength, puncturing strength and the like can drop easily caused by large paperboard moisture.

Owner:GUIZHOU WAIMAO SHENCAI PACKING CO LTD

Method for preparing heat-insulation materials from nano-silica filled non-graphitized carbon foam

The invention provides a method for preparing heat-insulation materials from nano-silica filled non-graphitized carbon foam, and relates to a method for applying non-graphitized carbon foam to the preparation of heat-insulation materials. The method solves the problem that the prior aerogel is poor in mechanical properties and cannot be used as independent blocks. The method comprises: allowing mixture of tetraethyl orthosilicate, deionized water and absolute ethanolto react to 10 to 15 minutes under acidic and alkaline conditions respectively; soaking obtained alcogel in tetraethyl ortho-silicate ethanol solution; washing the obtained product with deionized water to obtain SiO2 sol-gel; immersing non-graphitized carbon foam in the SiO2 sol-gel; drying the obtained product; and obtaining nano-silica filled non-graphitized carbon foam heat-insulation composite material. The heat-insulation material obtained by the method can be used as independent blocks, is strong in mechanical properties compared with aerogel, and has the heat-insulation temperature between 1,200 and 1,300 DEG C.

Owner:HARBIN INST OF TECH

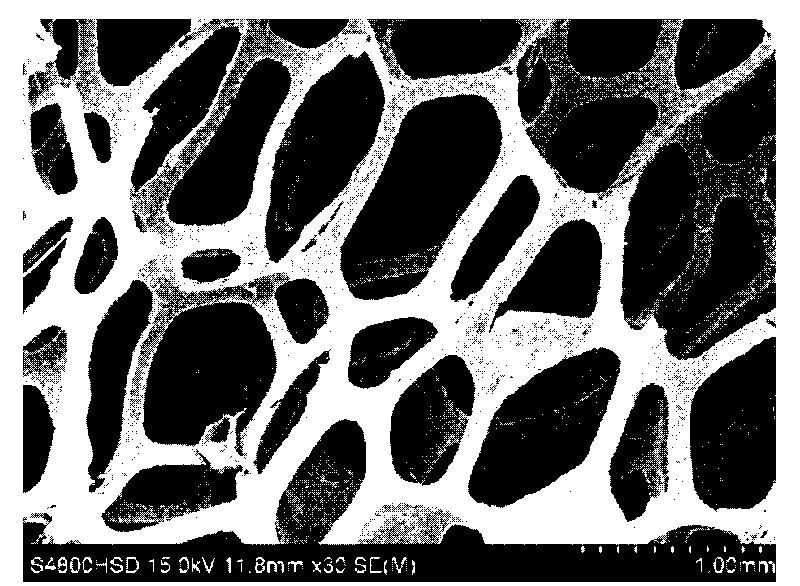

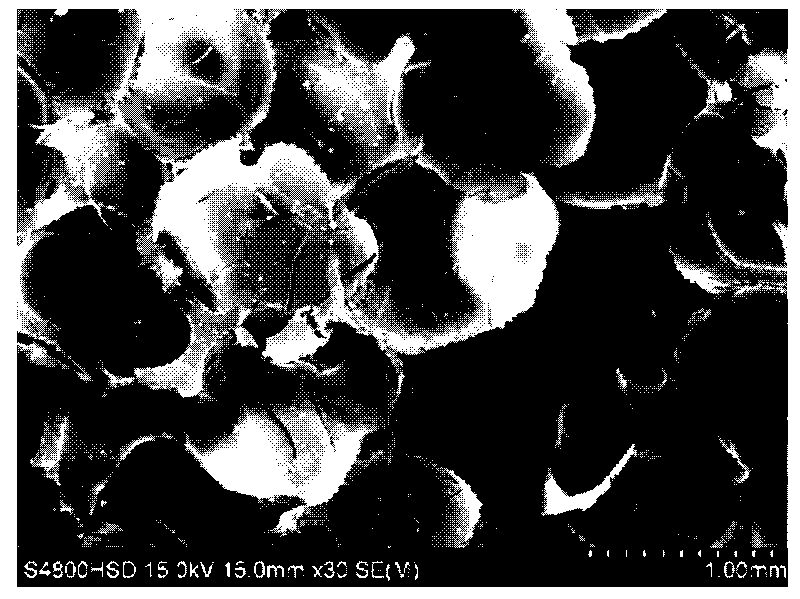

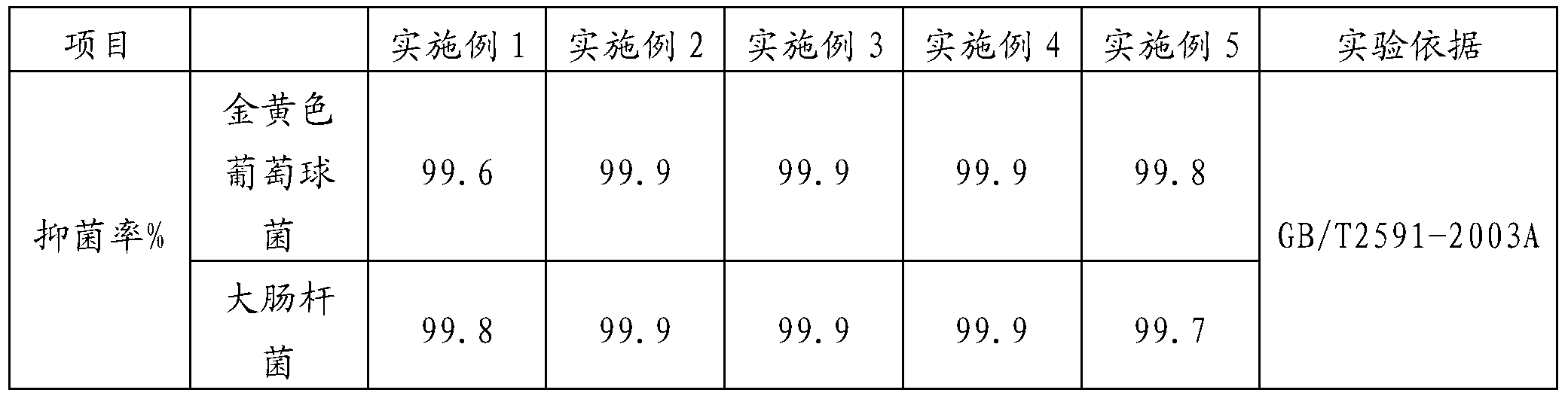

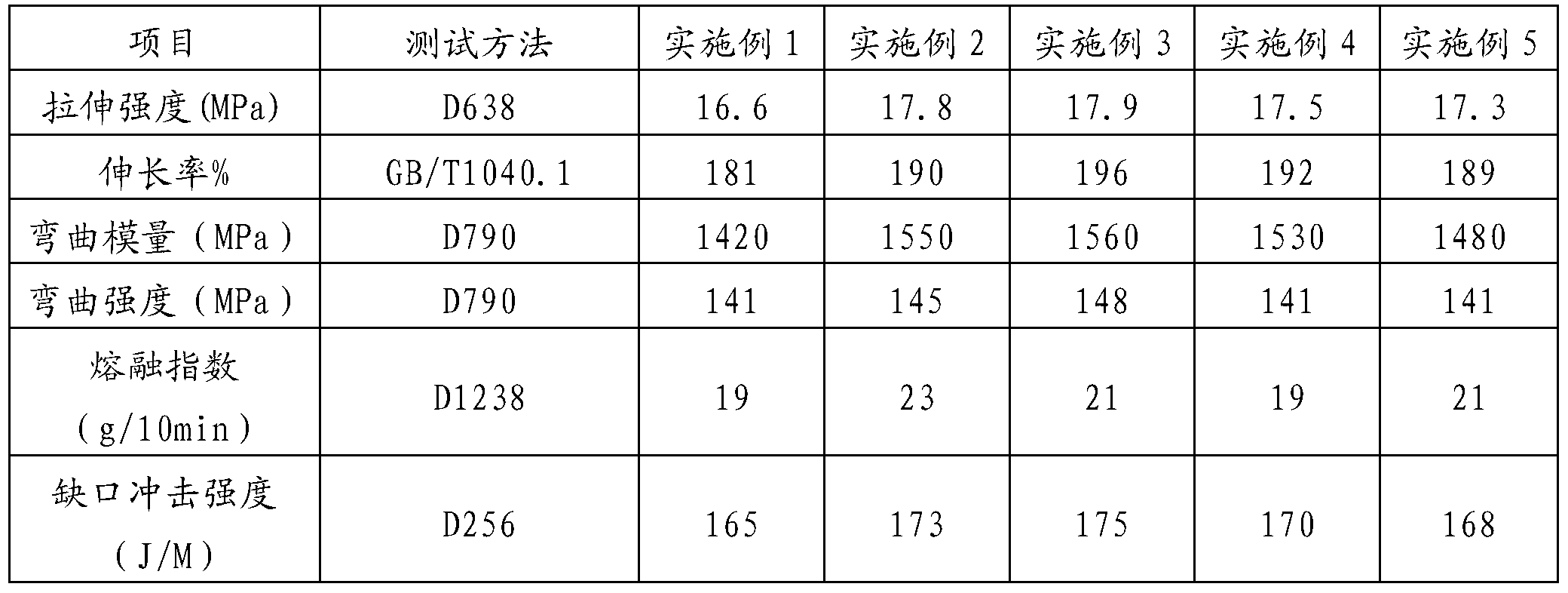

ABS (acrylonitrile butadiene styrene)/PA (polyamide) composite antibacterial pipe and preparation method thereof

InactiveCN103304952AOvercoming low toleranceOvercome cracking defectsPolyesterThermoplastic elastomer

The invention discloses an ABS (acrylonitrile butadiene styrene) / PA (polyamide) composite antibacterial pipe and a preparation method thereof. The composite antibacterial pipe comprises the following components in parts by weight: 60-80 parts of ABS, 25-40 parts of PA, 5-20 parts of polyester thermoplastic elastomer, 1-6 parts of nano-silver powder, 0.5-5 parts of ammonium dihydrogen phosphate, 2-5 parts of 2, 6-tributyl-4-methylphenol, 1-4 parts of diester thiodipropionate, 6-15 parts of chlorinated polyethylene, 0.5-1.2 parts of stearic acid and 5-10 parts of titanium dioxide. The prepared composite antibacterial pipe has not only good tolerance, but also good antibacterial effect.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Preparation method of nano-silica compacted concrete

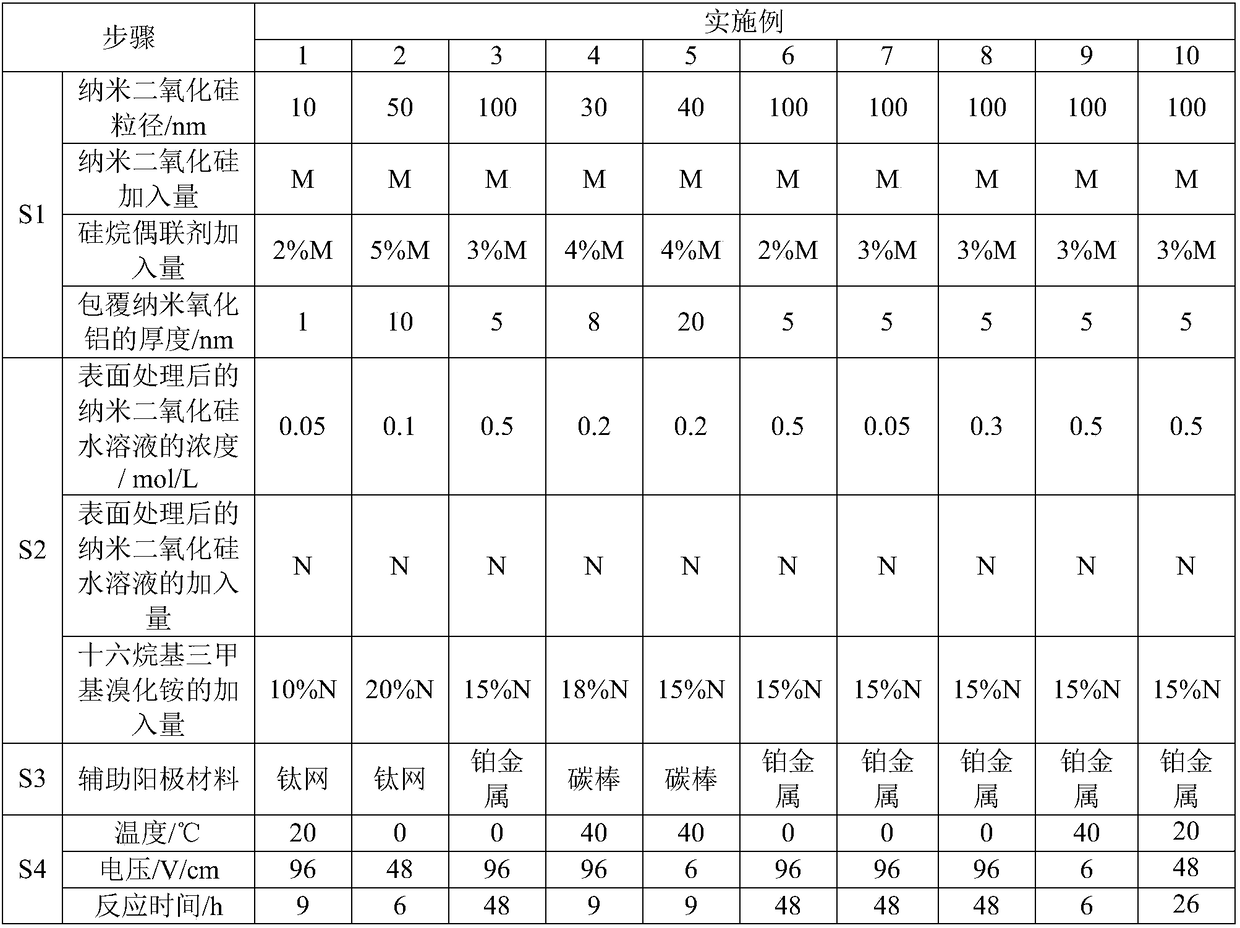

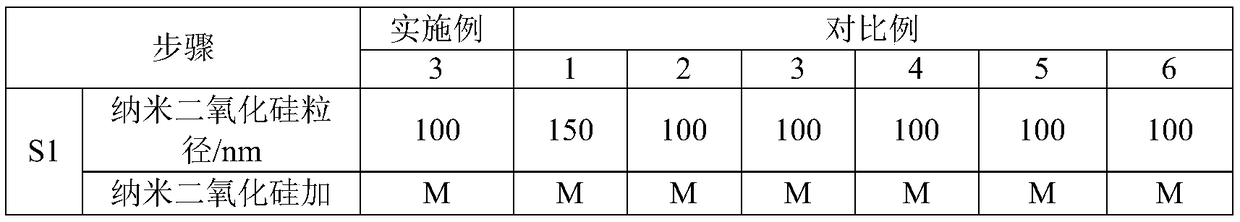

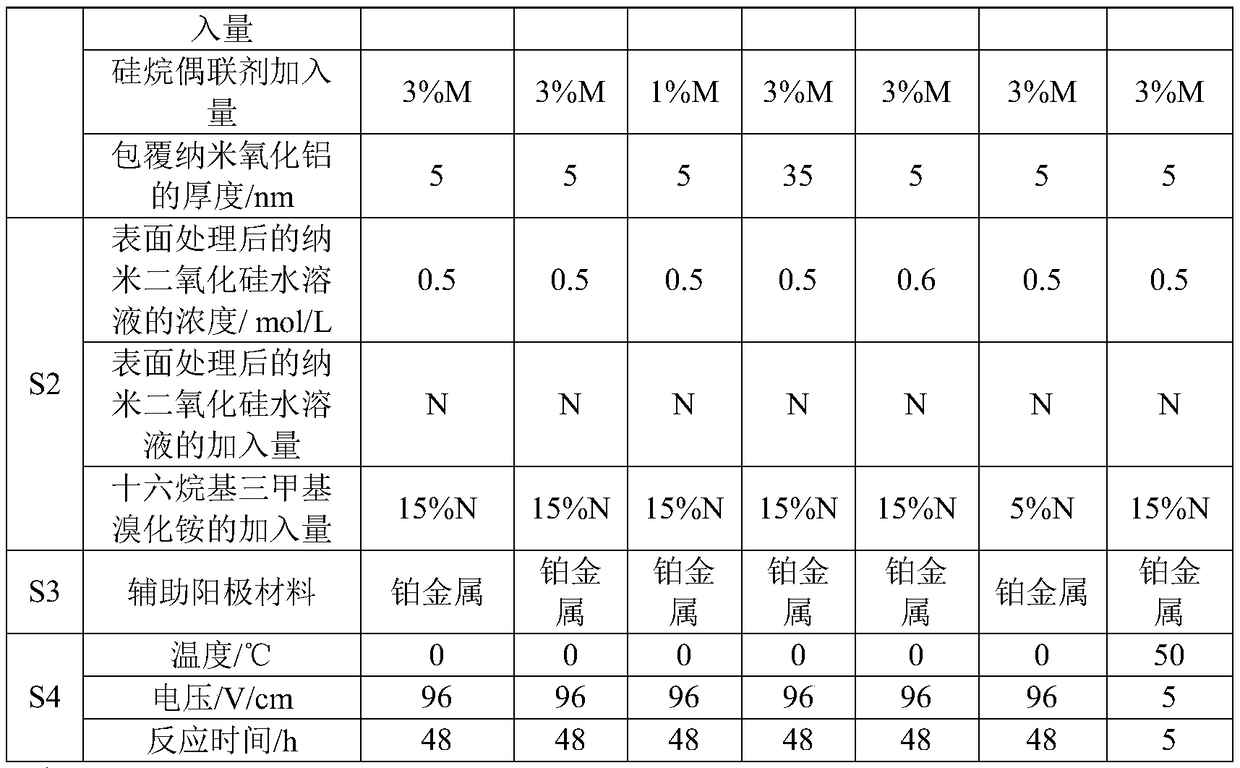

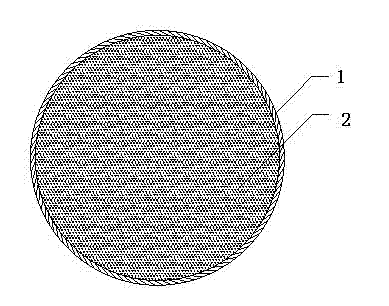

The invention discloses a preparation method of nano-silica compacted concrete. The preparation method comprises the following steps: preparing nano-silica of which the surface is coated with nano-alumina into a nano-silica aqueous solution with the concentration of 0.05 to 0.5 mol / L and injecting the nano-silica aqueous solution into an electrolytic cell; putting a concrete specimen with built-insteel bars into the electrolytic cell, connecting the steel bars into a power supply cathode, arranging an auxiliary anode parallel to the concrete specimen outside the concrete specimen and connecting the auxiliary anode into a power supply anode; under the condition of 0 to 4 DEG C, applying 6 to 96 V / cm impressed voltage between the power supply cathode and the power supply anode in the S3 andthen electrifying. According to the method disclosed by the invention, by taking the nano-silica as a raw material and applying an external electric field, the nano-silica enters pores of the concrete through electrophoresis drive; by utilizing C-S-H gel generated through reacting the nano-silica solution with calcium hydroxide, the pores in the concrete are filled to obtain compacted concrete, and further the durability of the concrete is improved.

Owner:HOHAI UNIV

Glass reinforced plastic pipe concrete member

InactiveCN102808476ABenefit from potential advantagesOvercome cracking defectsStrutsSolid waste managementEngineeringAlkali–silica reaction

The invention relates to compound pipes, in particular to a glass reinforced plastic pipe concrete member amongst the compound pipes. The glass reinforced plastic pipe concrete member comprises a steel pipe filled with glass concrete. The glass reinforced plastic pipe concrete member has the advantages that waste glass is applied to concrete filled steel tubes, the steel tubes provide tightening force for core glass concrete, the defect of expansion cracking of the glass concrete due to alkali-silica reaction is overcome; the core concrete generate different degrees of contraction stresses to cause cracking of the concrete, adding expanding agent to the concrete filled steel tubes to compensate the contraction stress of the core concrete conventionally is an existing way, the contraction stress of the concrete can be compensated to a certain degree by expansive force of the glass concrete caused by alkali-silica reaction of the glass concrete, and potential advantages of the waste glass can be given to play.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

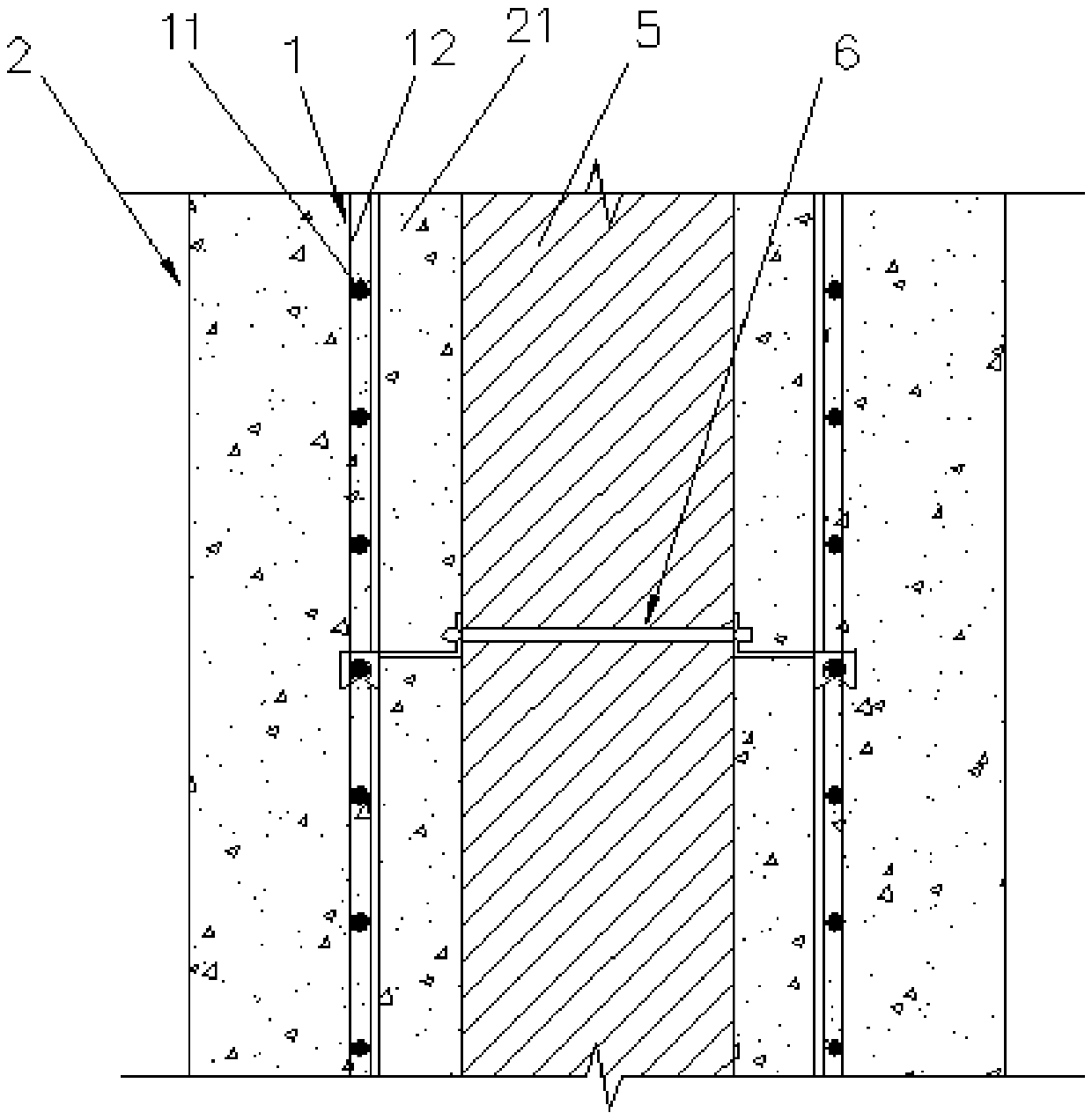

Bridge-cut-off concrete composite partition wall and manufacturing method thereof

PendingCN108678233AReduce labor intensityOvercome cracking defectsWallsClimate change adaptationSurface layerKeel

The invention provides a bridge-cut-off concrete composite partition wall and a manufacturing method thereof. The partition wall comprises a metal side frame, reinforcement nets and a wall surface layer, wherein four frame strips of the metal side frame are keels which are provided with concave-convex abutting parts; protruded ribs are arranged on the left side surface and the right side surface of each keel; the ribs are welded to the reinforcement nets which cover the left side and the right side of the metal side frame; heat insulation coating layers cover at least the outer surfaces of theleft side surfaces and the right side surfaces of the keels; connecting clamping parts penetrate the two reinforcement nets and flame-retardant lightweight filling plates to realize connection of thereinforcements and the flame-retardant lightweight filling plates, and intervals are formed between the reinforcement nets and the flame-retardant lightweight filling plates, and thus lightweight concrete for forming the wall surface layer fills the intervals after flowing through the reinforcement nets. The bridge-cut-off concrete composite partition wall is simple in production processes, convenient and quick to mount; and the working intensity of workers can be reduced; the production efficiency is improved; the defects of empty shells and cracking of a wall body are overcome; the good fireproofing, heat preserving, noise insulating and heat insulating effects are achieved; in addition, the used materials are energy saving, emission reducing, waste utilizing, green and environmentallyfriendly.

Owner:唐元元

High-strength sausage casing and preparation method thereof

InactiveCN107549269AHigh activityIncreased mechanical strength and tensile strengthSausage casingsGlycoproteinChemistry

The invention discloses a high-strength sausage casing. The high-strength sausage casing comprises the following components of 0.2-0.4 part of transglutaminase, 16-20 parts of collagen, 2-4 parts of wood ear polysaccharide, 5-6 parts of glycerine and 13-18 parts of water. The invention further discloses a preparation method of the high-strength sausage casing. The high-strength sausage casing hasthe beneficial effects that oligosaccharide chains of bioactive peptides and wood ear polysaccharide form glycoprotein through covalent bonds. The glycoprotein can improve the activity of the transglutaminase, and further promote gamma-carboxylic acid amide groups and other amino acid residues in amino acid residues of collagen casings to be subjected to a crosslinked action, and through the covalent bond, firm network structures are formed. The mechanical strength and the tensile strength of the collagen casing are notably improved, and the defect that the casing is easy to crack in the cooking process is overcome.

Owner:浦江县泰如食品科技有限公司

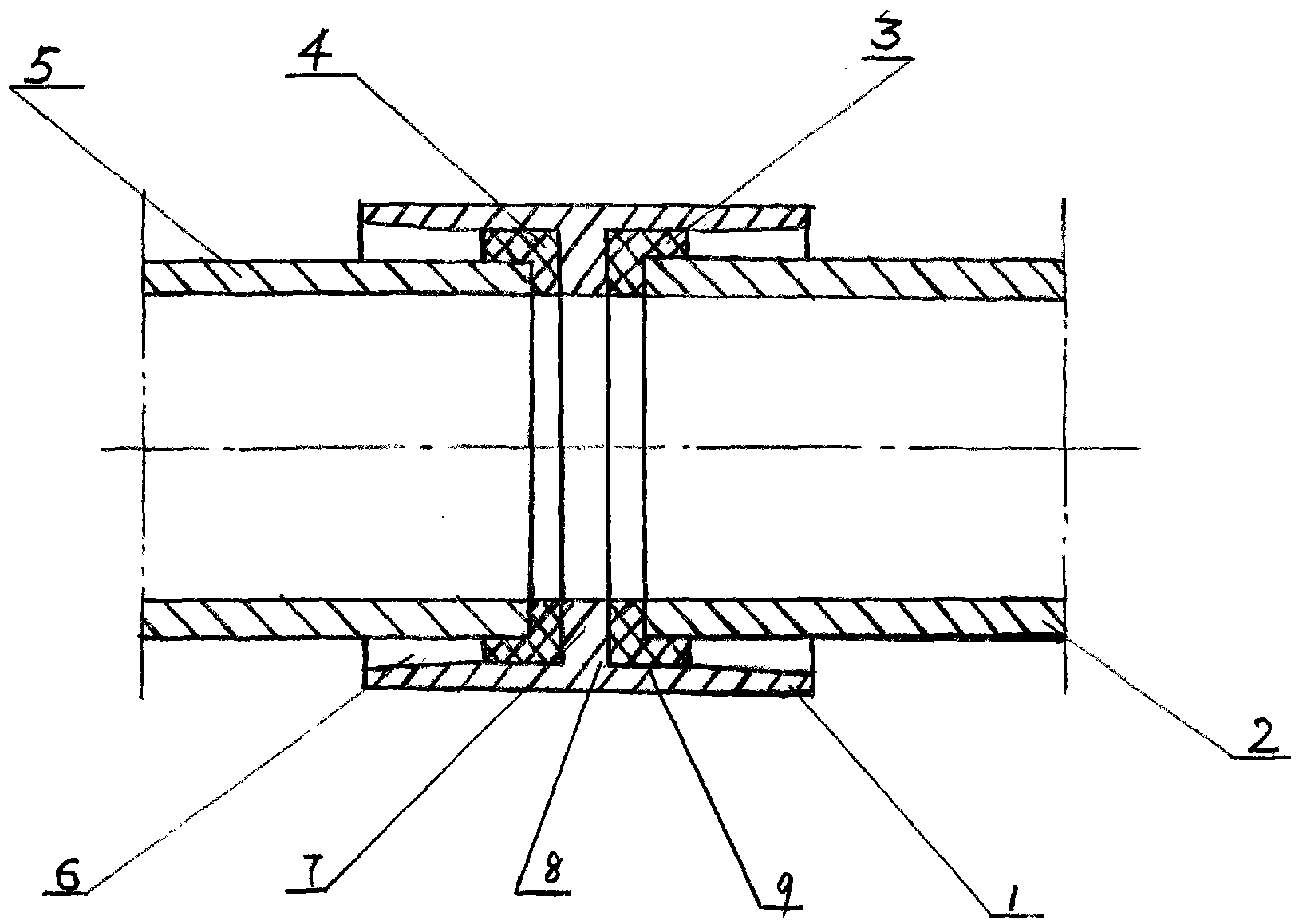

Butting pipe sleeve of plastic socket pipes and connection of plastic socket pipes

InactiveCN102384328AOvercome deformationOvercome cracking defectsPipe connection arrangementsEngineeringUltimate tensile strength

The invention discloses a butting pipe sleeve of plastic socket pipes and a connection of the plastic socket pipes. The butting pipe sleeve comprises a structure in which sealing washers and the plastic socket pipes are arranged and is characterized in that a circular ring conjoined with a butting pipe sleeve outer wall is arranged in the middle of an inner cavity of the circular butting pipe sleeve outer wall; and holes at the two ends of the butting pipe sleeve are respectively horn mouths. In the connection of the plastic socket pipes, the ends of the two plastic socket pipes are respectively sleeved into the basin-shaped sealing washers; and when the plastic socket pipes sleeved into the sealing washers pass through the horn mouths, the sealing washers are compressed by the horn mouths and enter a straight pipe section of the butting pipe sleeve, so that the bottom surfaces of the sealing washers are respectively pressed against with the two side surfaces of the circular ring. When the two plastic socket pipes are connected with each other, the defects that the connecting strength of an electric hot-melting belt is not uniform, and the pipes are easy to deform and crack are overcome. The plastic socket pipes are suitable for construction in the various environments, are particularly suitable for operation in the water environment, are convenient to connect, have lower cost and reduce the labor intensity of operators.

Owner:SHANGHAI JIUTONG PLASTIC PROD

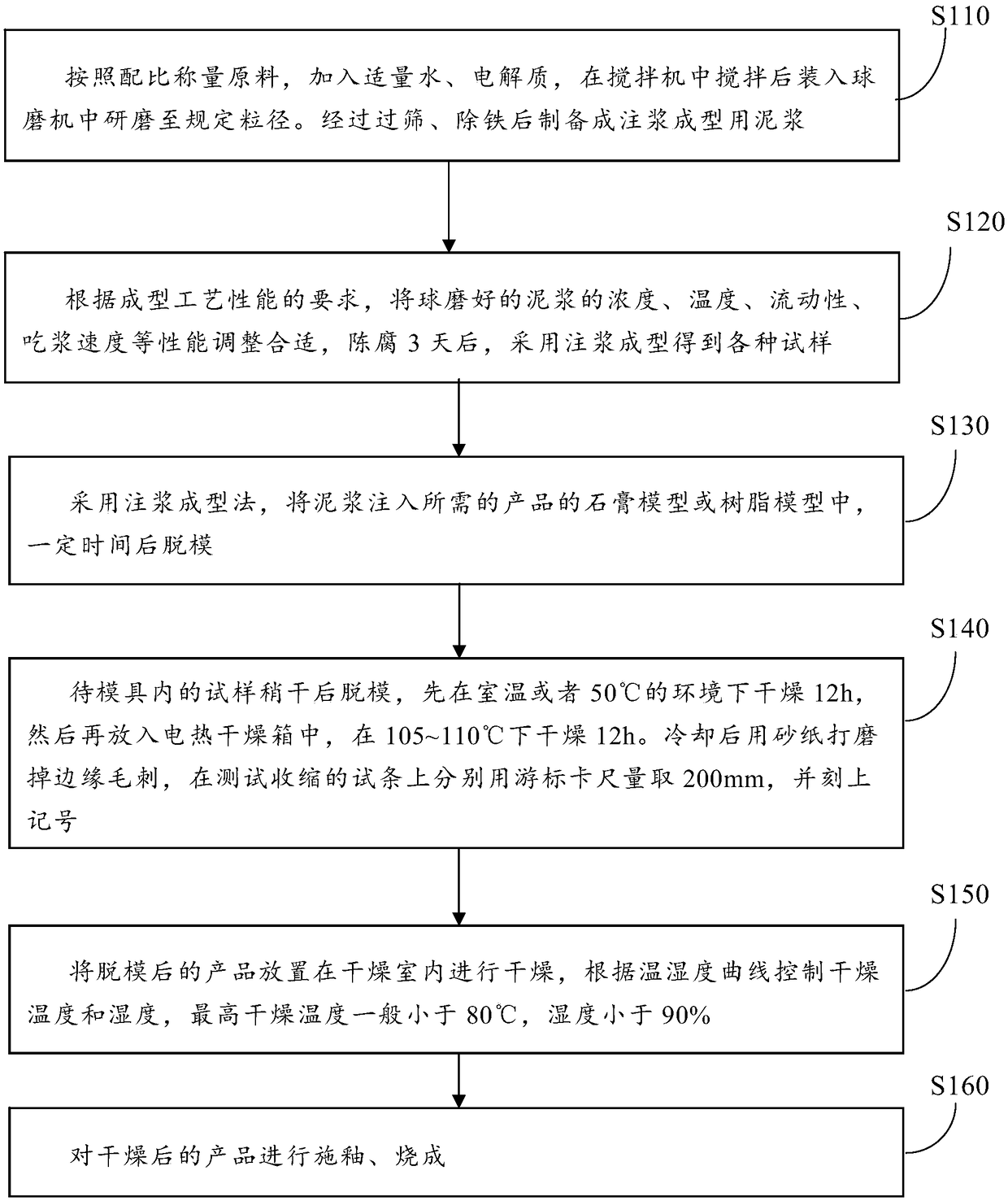

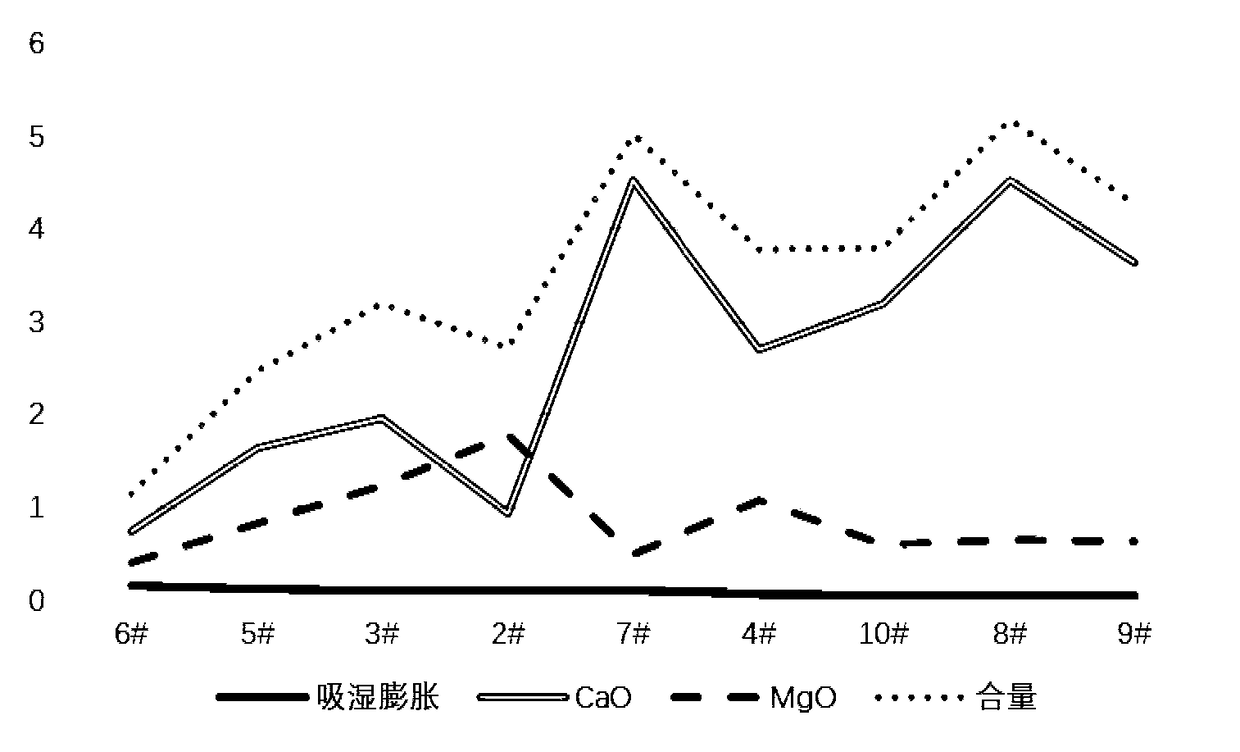

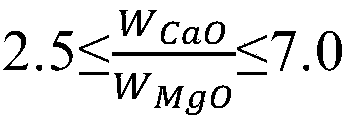

Earthen sanitary ware blank and preparation method thereof

PendingCN108975865AResolve shrinkageSmall overall deformationCeramic materials productionClaywaresThermal expansionQuartz

The invention provides an earthen sanitary ware blank and a preparation method thereof. A proper quantity of raw materials such as kaolin and quartz are introduced; the crystalline phase content of mullite, quartz and the like in the blank is controlled; the glass phase content of potassium oxide and sodium oxide is reduced; the high-temperature plastic deformation is reduced; the low deformationof earthen sanitary ceramics is realized. The thermal expansion coefficient of the blank at 200 to 300 DEG C is regulated, so that the thermal expansion coefficient of the blank is matched with the thermal expansion coefficient of glaze. The problem that the earthen sanitary ware blank cannot overcome shrinkage and great deformation is solved, so that the earthen sanitary ware does not use engobeand does not generate glaze checking; qualified products are produced according to an earthen sanitary ware production method.

Owner:平潭海创智汇科技有限公司

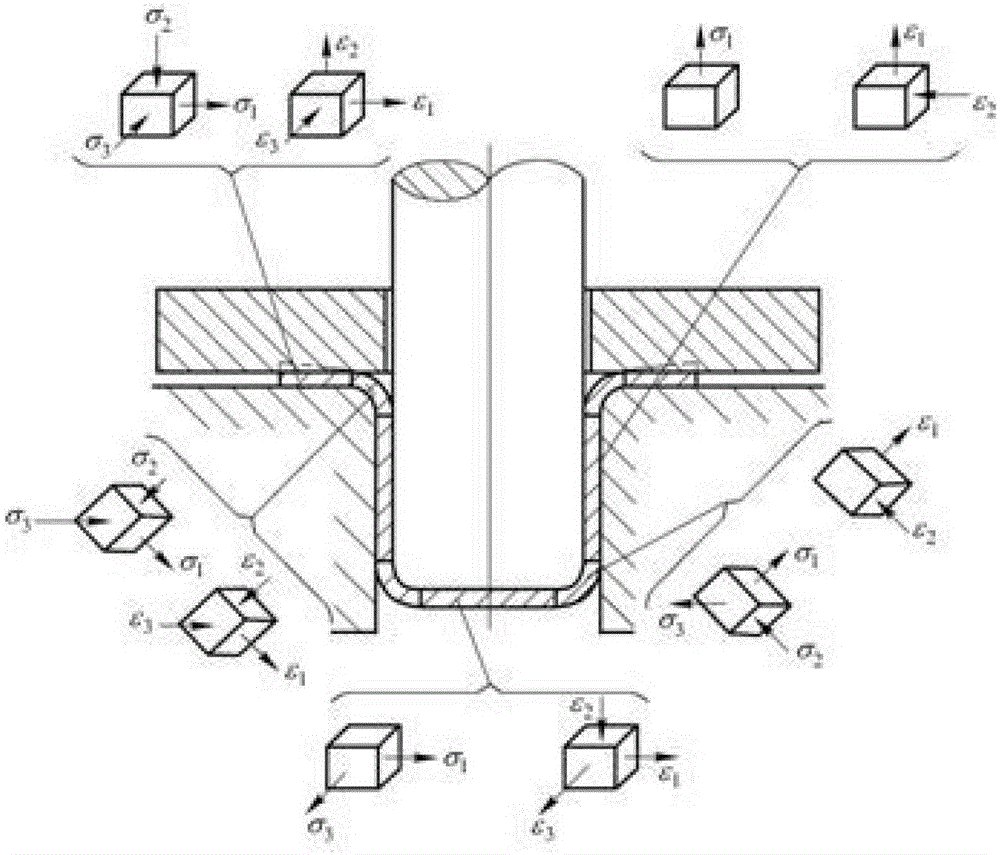

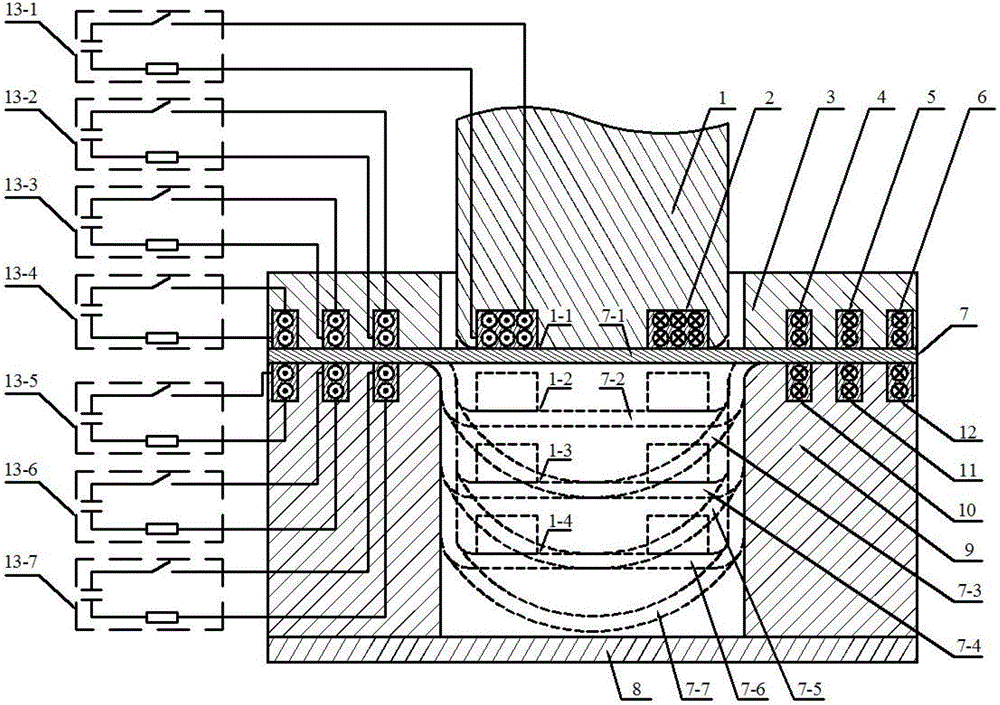

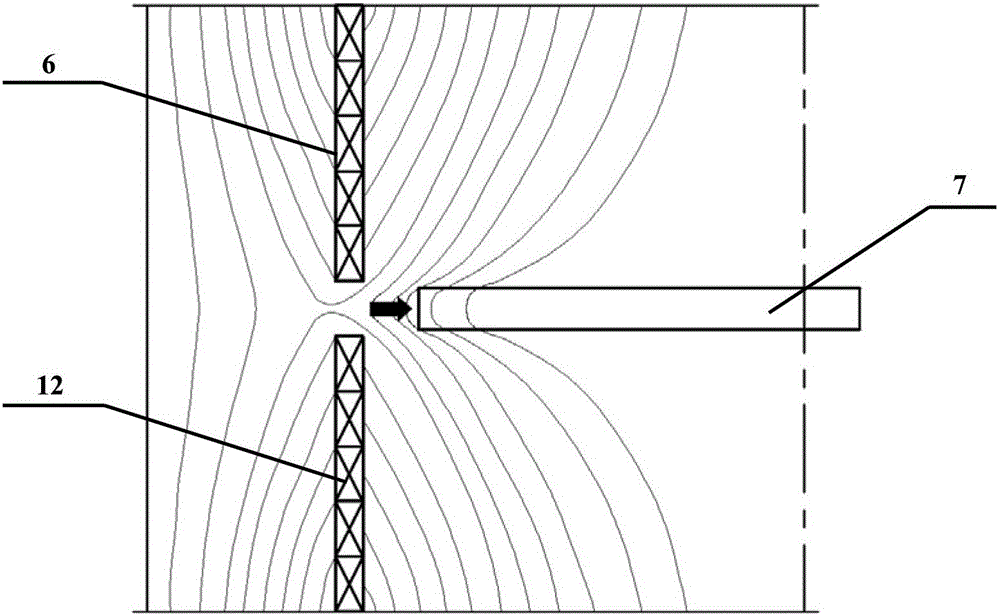

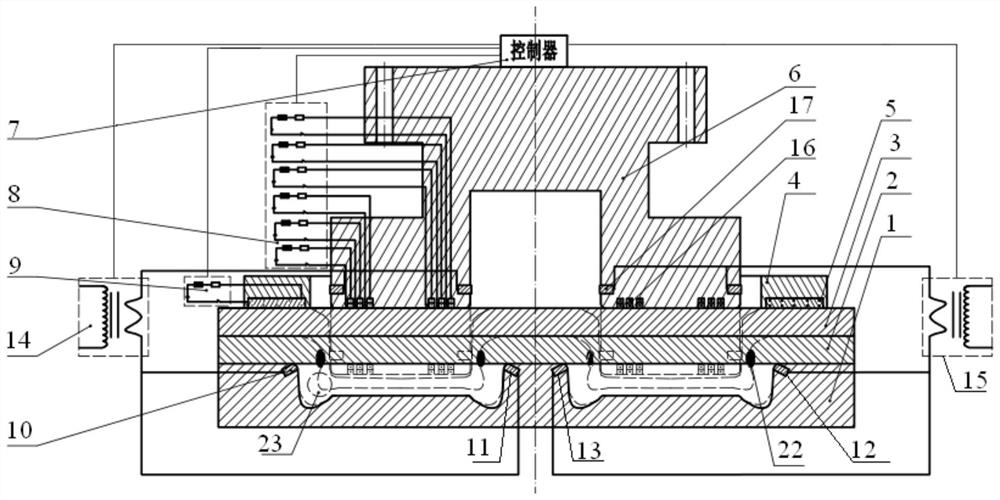

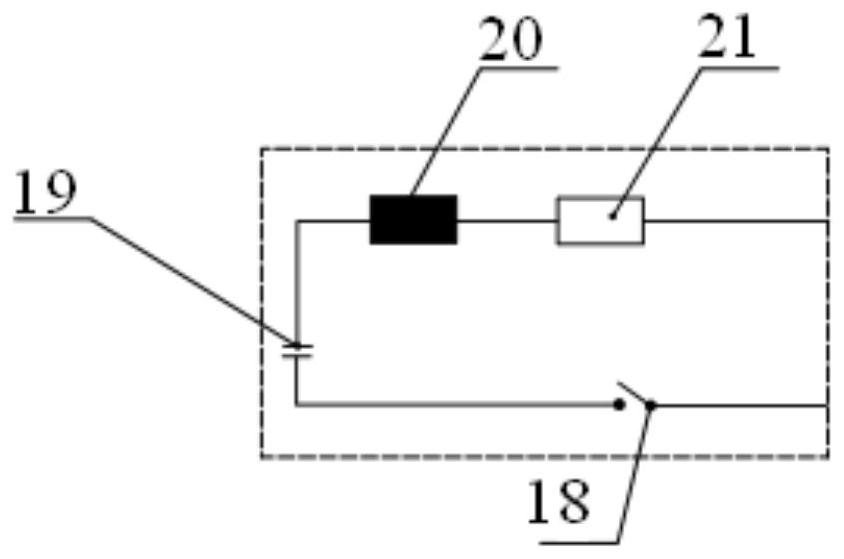

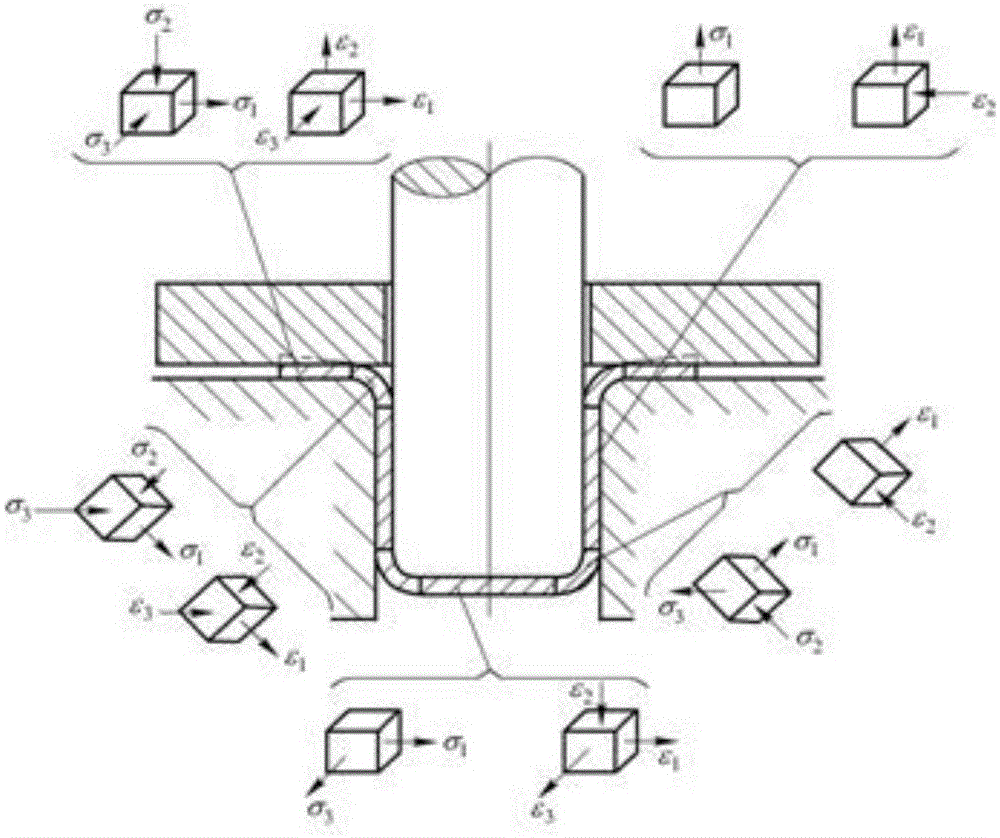

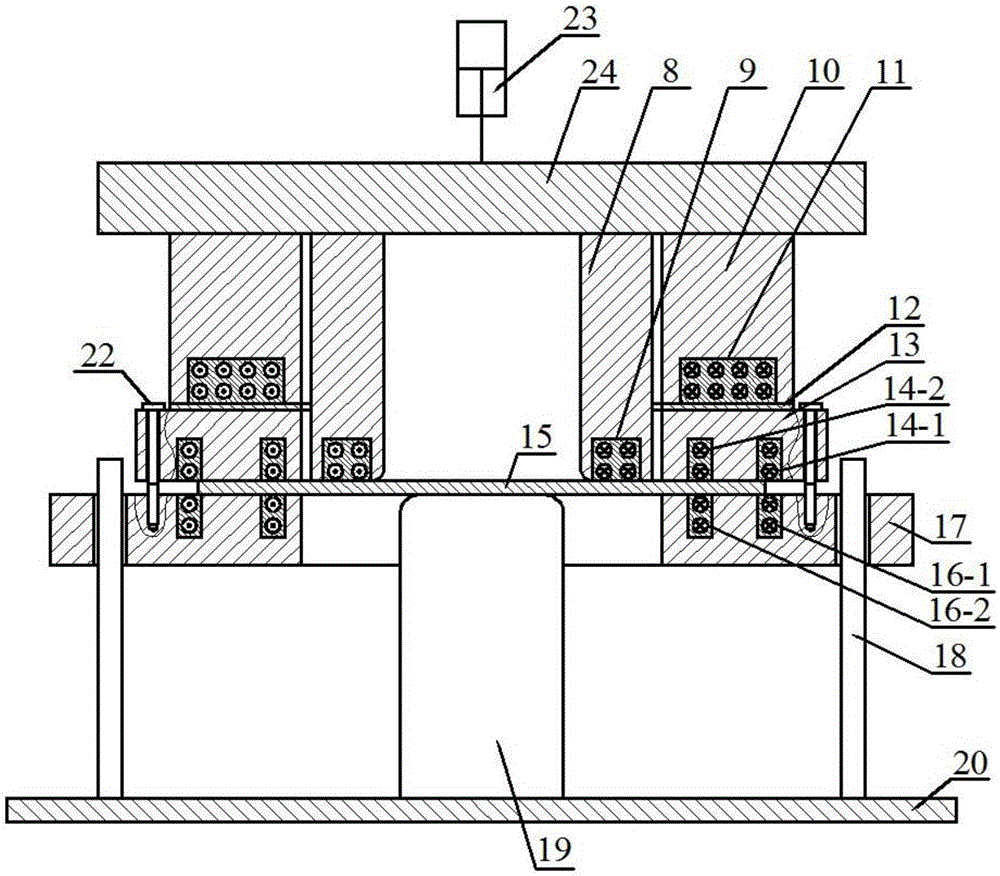

Electromagnetic pulse assisted progressive drawing method and device

InactiveCN103658297BChanging the state of stress and strainReduce tensile stressShaping toolsElectromagnetic pulseDeep drawing

The invention provides an electromagnetic pulse boosting type gradual deep drawing forming method. The electromagnetic pulse boosting type gradual deep drawing forming method comprises the steps that a sheet to be formed is placed between a female die and a male die; performing is conducted and the sheet to be formed is pressed into the female die, wherein the sheet to be formed is located at the bottom of the male die; electromagnetic force is applied to the portion, located at the bottom of the male die, of the sheet to be formed, and the sheet to be formed is pushed downwards; electromagnetic force is applied to the periphery of the sheet to be formed, the sheet to be formed is pushed to the center of the female die, and the sheet to be formed is made to flow into the female die; down force is applied to the male die so that the male die can move downwards, and therefore downward deep drawing is conducted on the portion, located on the lower portion of the male die, of the sheet to be formed; stamping deep drawing and electromagnetic pulse deep drawing are conducted repeatedly before deep drawing forming of the sheet to be formed is completed. According to the electromagnetic pulse boosting type gradual deep drawing forming method, the traditional male die forming technology and the electromagnetic pulse forming technology are combined, stamping deep drawing and electromagnetic pulse deep drawing are conducted alternately, and the depth of deep drawing forming of a cylindrical part is increased. The invention further provides an electromagnetic pulse boosting type gradual deep drawing forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

Centering mechanism for hot melting of socket insertion type plastic pipe and pipe connecting sleeve

The invention relates to a centering mechanism for hot melting of a socket insertion type plastic pipe and a pipe connecting sleeve. The centering mechanism is characterized in that the end of a screw rod is movably fixed and connected with an umbrella head provided with uniformly distributed umbrella rib head grooves, the umbrella head is movably connected with umbrella ribs through connecting pins, the screw rod is connected with a screw sleeve provided with uniformly distributed umbrella rib installing grooves through screw threads, one support ends of the umbrella ribs are movably fixed in the corresponding umbrella rib grooves through connecting pins, the other support ends of the umbrella ribs are respectively and movably fixed in the umbrella rib installing grooves arranged on the screw sleeve through pins, and through the pins, a centering claw is movably fixed in a groove of a centering claw groove arranged at the top ends of the umbrella ribs. Compared with the prior art, the centering mechanism has the advantages that the effect of maintaining the consistency between the axis of the pipe connecting pipe and the socket insertion type plastic pipe can be effectively reached, so the defects that the connecting intensity of the electric heating melting belt is nonuniform, and the pipe can easily deform and crack can be overcome. The socket insertion type plastic pipe formed by the socket insertion pipe plastic pipe and the pipe connecting sleeve through hot melting is applicable to the construction in various environments, and the engineering schedule is improved.

Owner:SHANGHAI JIUTONG PLASTIC PROD

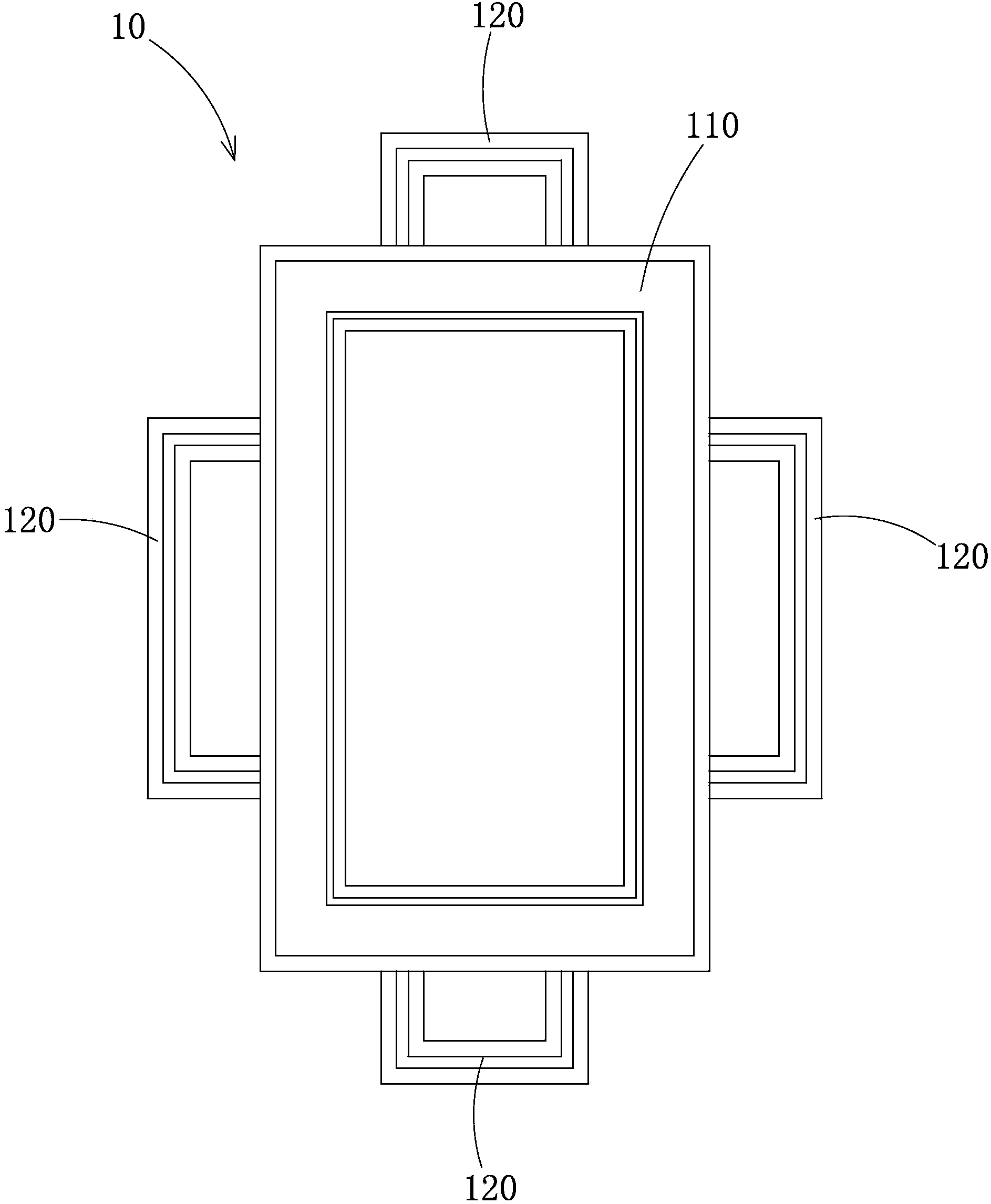

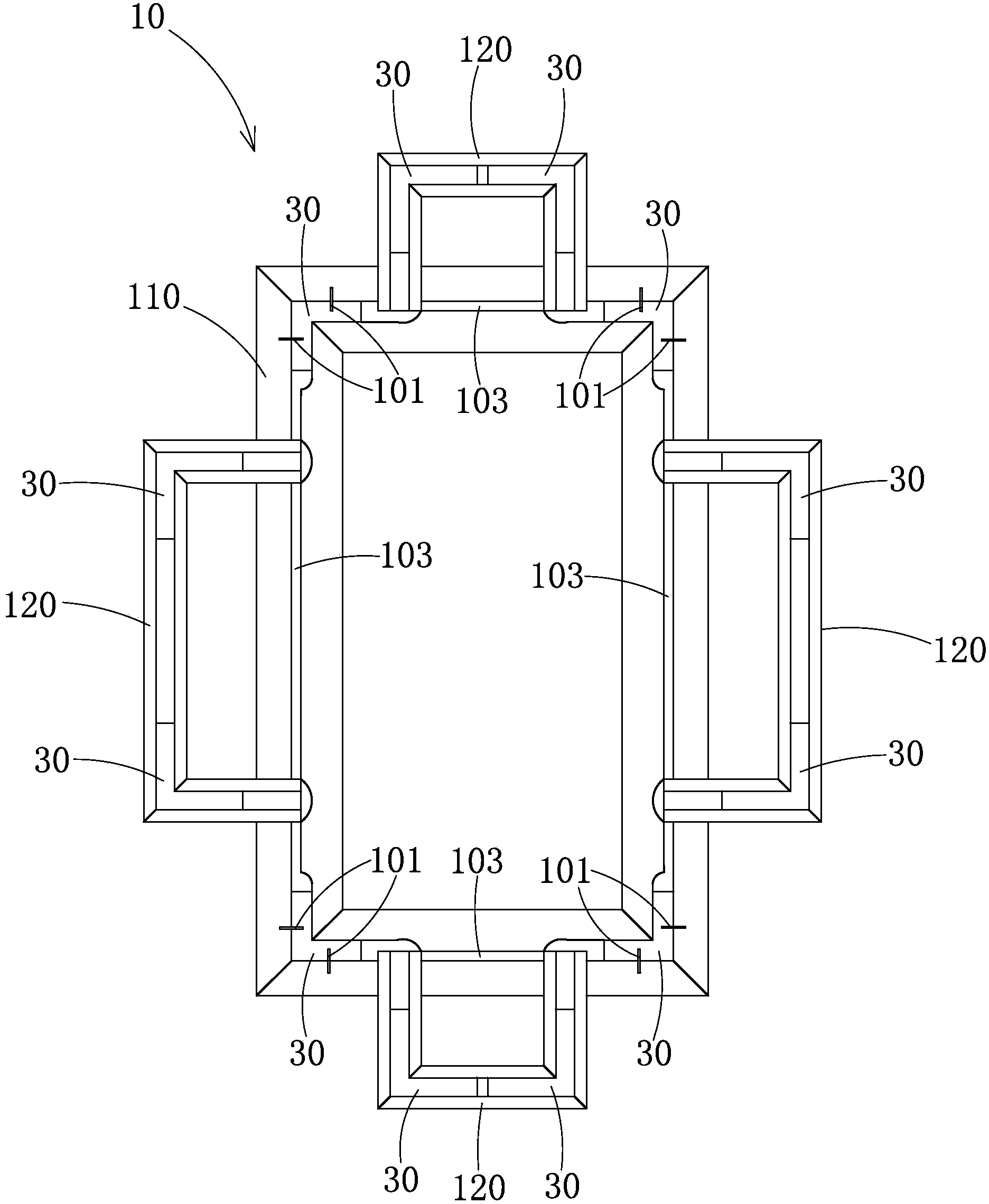

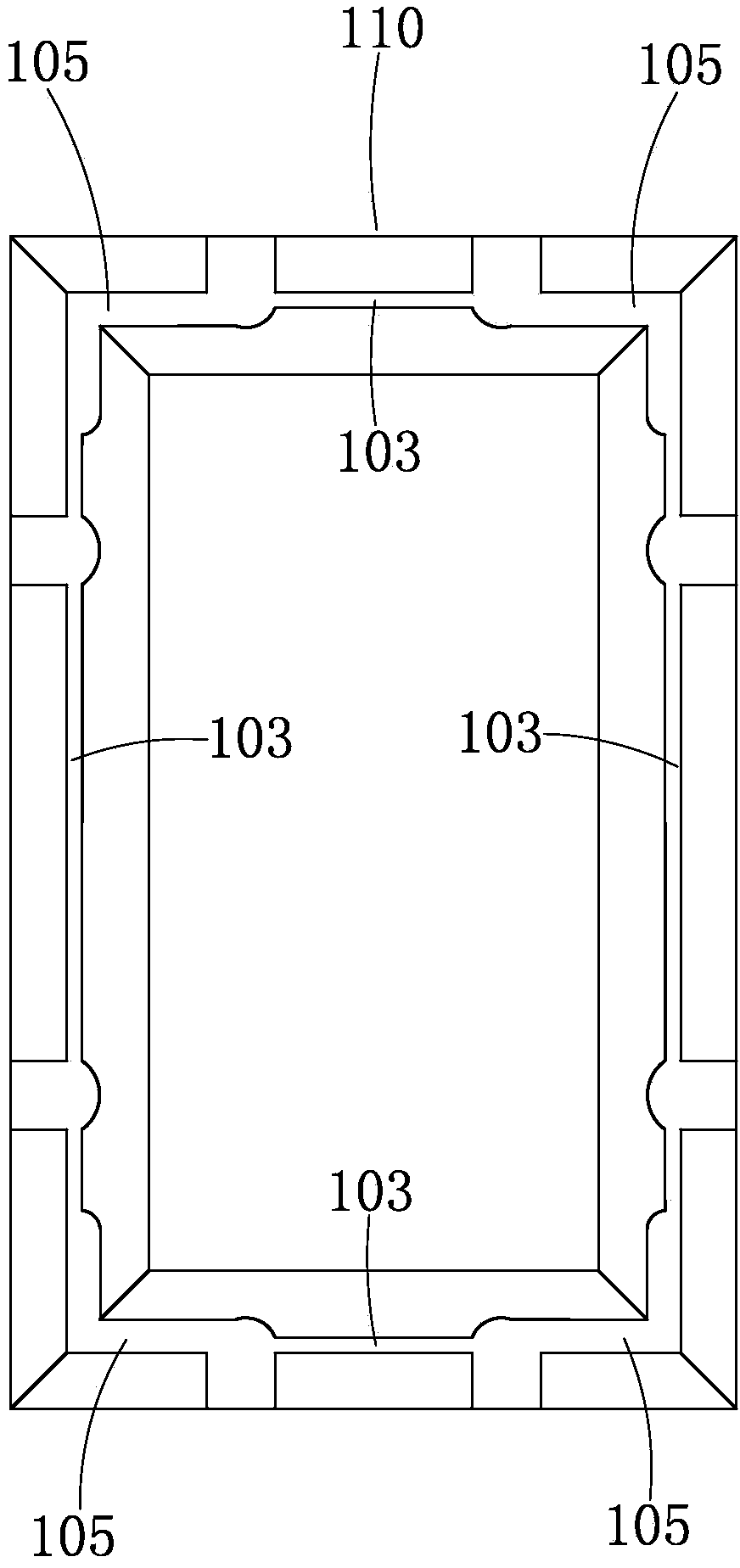

Decorative moulding assembly and construction method thereof

ActiveCN103510685AImprove installation speedImprove installation accuracyBuilding material handlingSurface layerBuilding construction

Provided are a decorative moulding assembly and a construction method thereof. The decorative moulding assembly comprises a decorative moulding (10), clamps (40) which can be fixed on a wall and a formwork (50) which can fix the clamp (40) on the wall and then be taken off. A decorative surface layer which covers a joint coats the front surface of the decorative moulding (10), clamping grooves (103) which allow the clamps (40) to be clamped are formed in the back surface of the decorative moulding (10), the formwork (50) is provided with clamp holes (501) which are matched with the clamps (40) in dimension, and the positions of all the clamp holes (501) in the formwork (50) are in one-to-one correspondence with the mounting positions of the clamps (40) on the clamping grooves (103). The mounting positions of the clamps on the wall can be accurately positioned in a one-time mode only by the way that the clamps are mounted aiming at the clamp holes of the formwork, accordingly, the mounting position of the decorative moulding can be accurately positioned, the mounting precision and the construction precision of the decorative moulding are improved, the construction period is shortened, and the dependency on the technical level of construction people and labor cost are lowered.

Owner:SHENZHEN JIANYI DECORATION GROUP

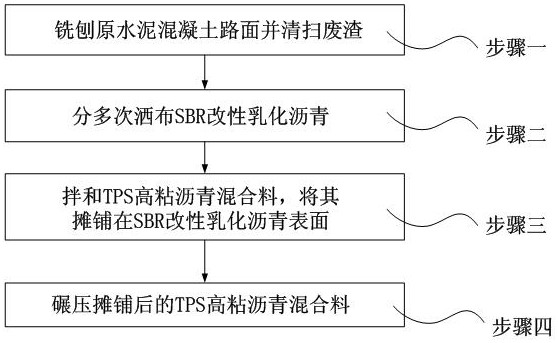

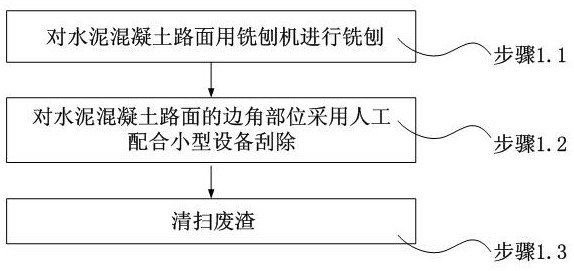

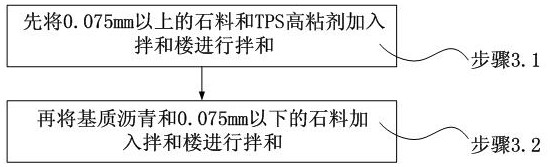

Construction process for changing cement concrete pavement into asphalt pavement

PendingCN111996876AImprove featuresImprove adhesionIn situ pavingsRoads maintainenceBitumen emulsionRoad surface

The invention provides a construction process for changing a cement concrete pavement into an asphalt pavement. The construction process comprises the following steps step 1, milling an original cement concrete pavement and cleaning waste residues; step 2, spreading SBR modified emulsified asphalt on the milled cement concrete surface for multiple times, wherein a spreading amount of starting, stopping and joints is slightly greater than the normal spreading amount during spreading; step 3, mixing a TPS high-viscosity asphalt mixture and paving the mixture on the surface of the SBR modified emulsified asphalt, wherein a paving starting speed is slightly lower than a normal paving speed during paving; and step 4, rolling the paved TPS high-viscosity asphalt mixture, wherein the TPS high-viscosity asphalt mixture starts to be rolled in a high-temperature state and cannot be repeatedly rolled in a low-temperature state. Due to a fact that the TPS high-viscosity asphalt has an excellent viscosity characteristic and an adhesion capacity, the TPS high-viscosity asphalt surface layer is adopted as an additional paving layer of the cement concrete pavement, a defect that the asphalt pavement is prone to cracking is overcome, a pavement bearing capacity is improved, and pavement safety and durability are enhanced.

Owner:陕西路桥集团有限公司

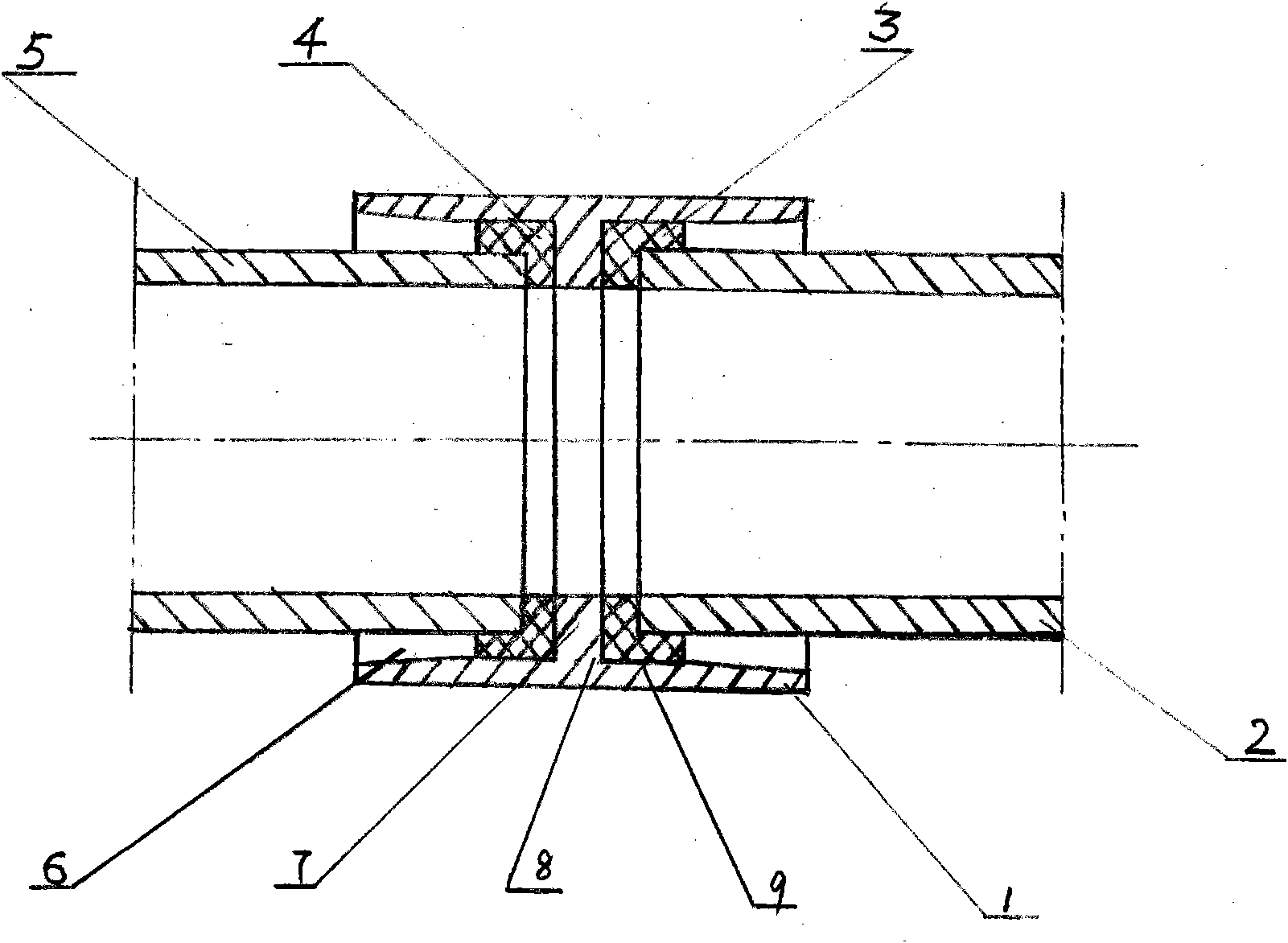

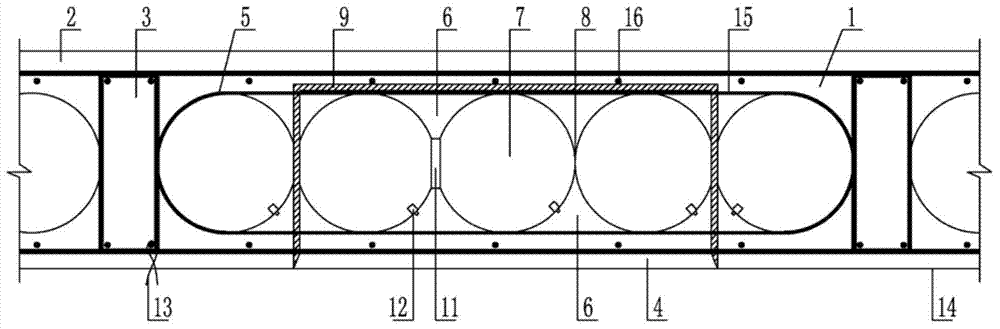

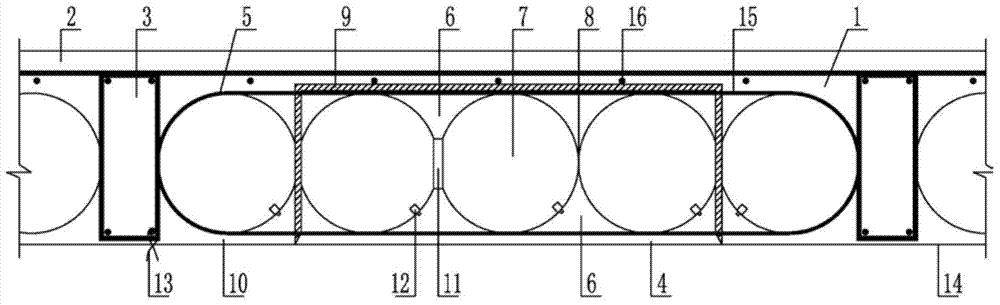

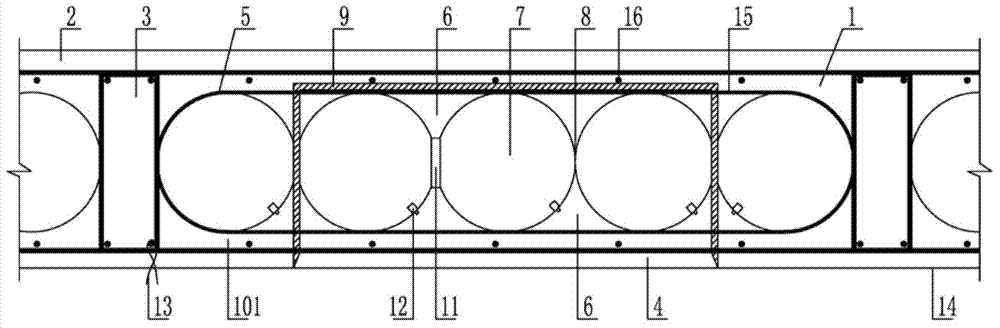

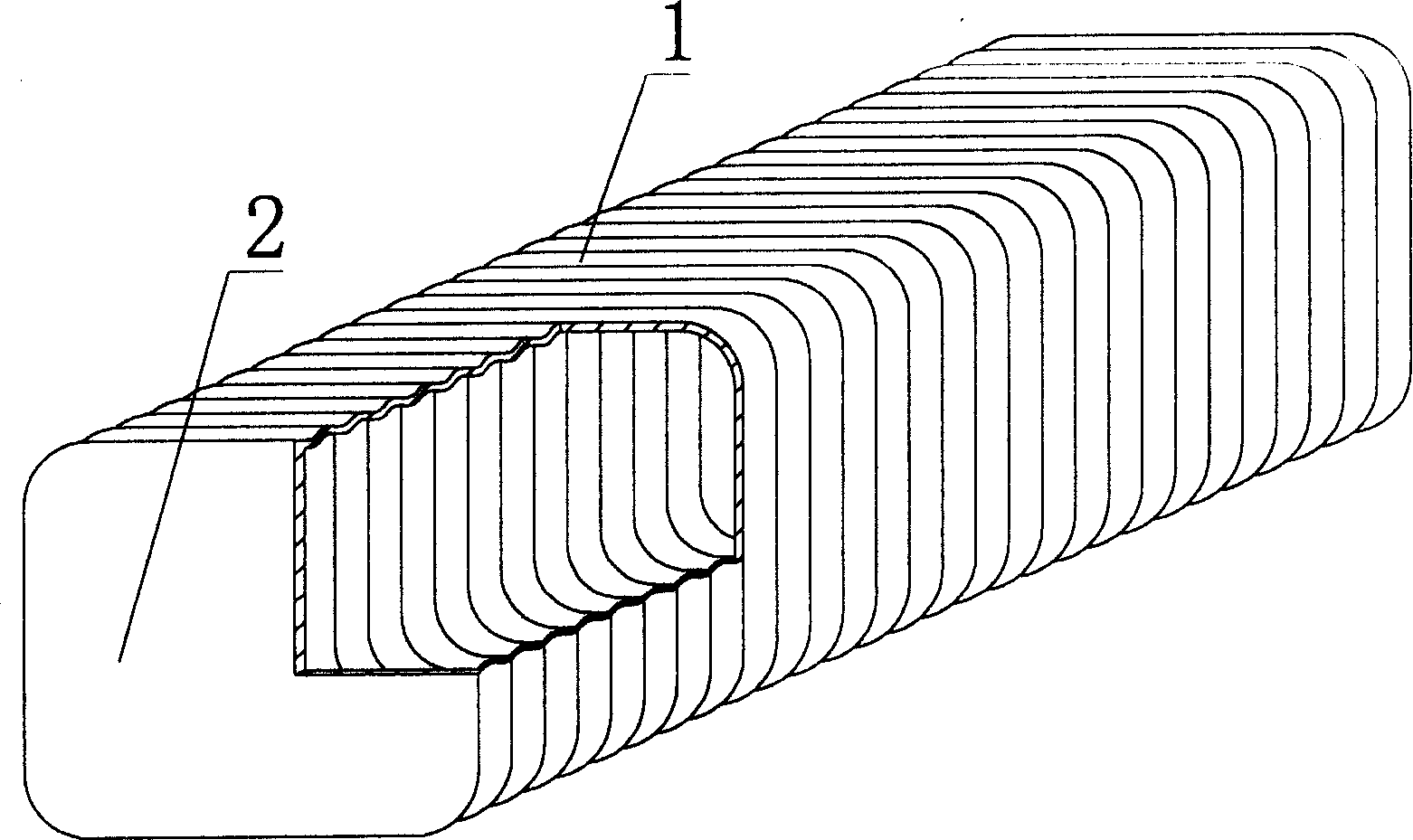

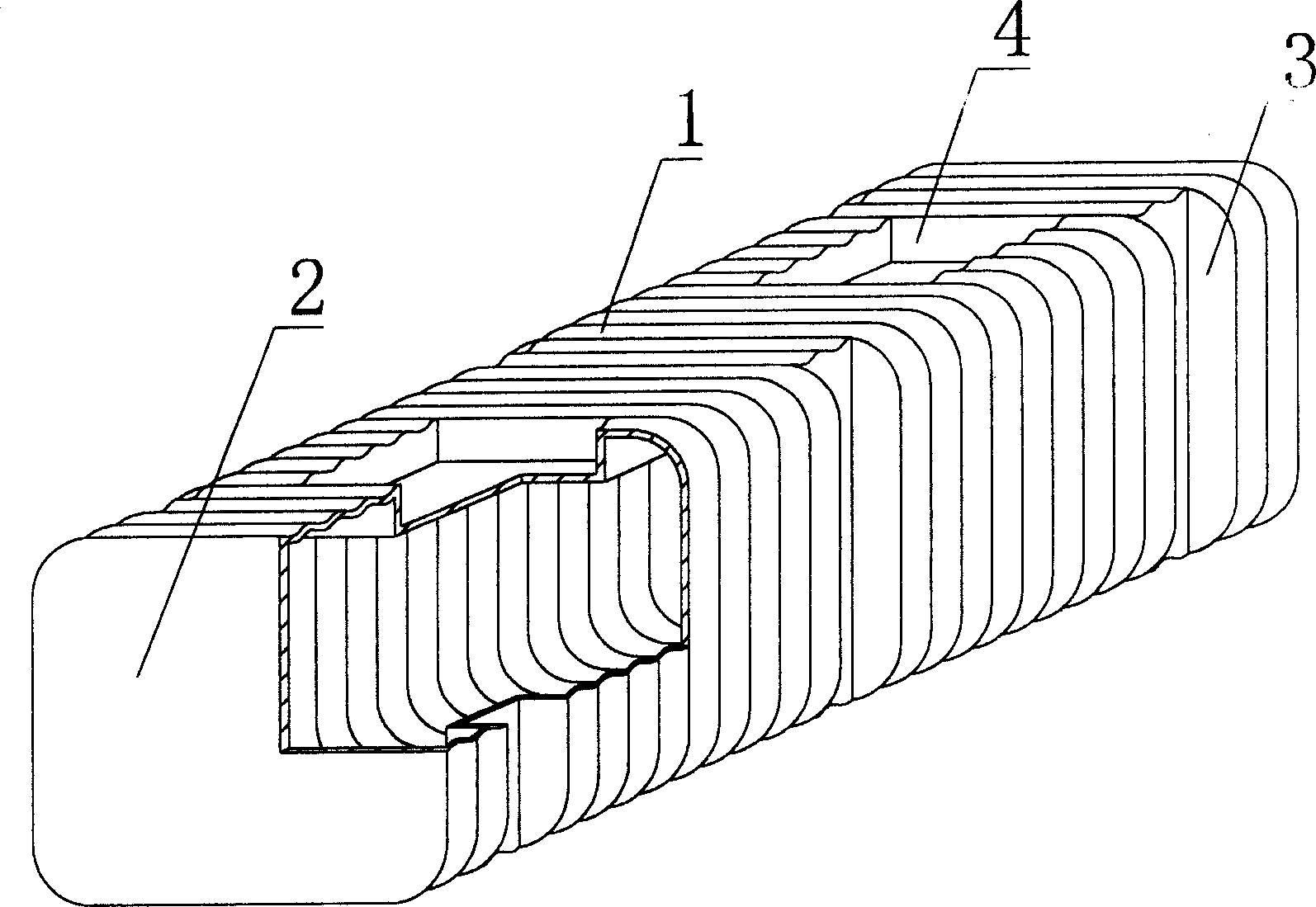

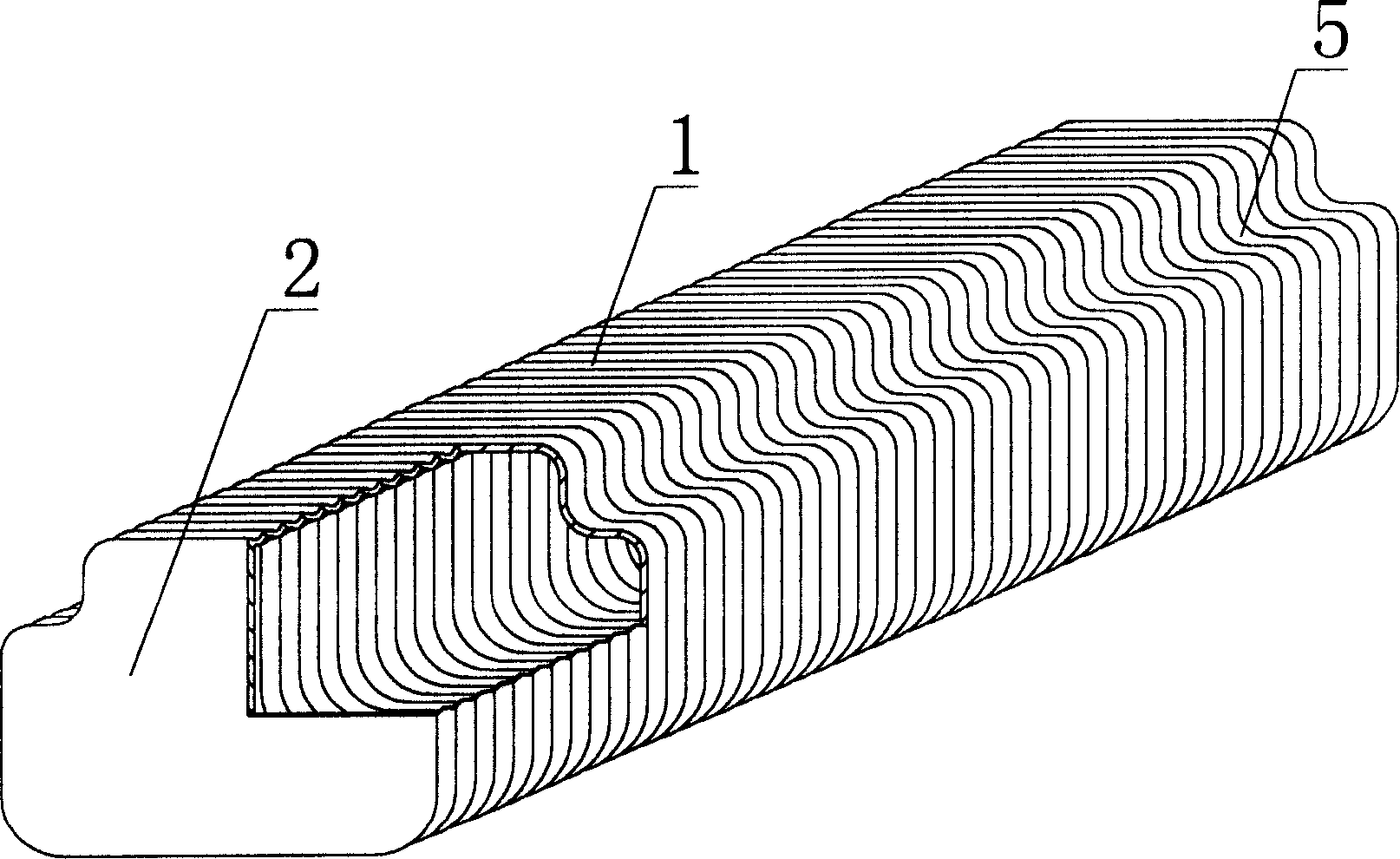

Construction method for crack-resistant cast-in-situ hollow floor

ActiveCN103541480AOvercome cracking defectsClose contactFloorsBuilding material handlingGas-filled tubeSteel tube

The invention provides a construction method for a crack-resistant cast-in-situ hollow floor. The crack-resistant cast-in-situ hollow floor comprises a top flange plate (2), beams (3), a bottom flange plate (4) and combined filling members (5) placed in a floor ribbed beam gridding. The construction method includes casting wavy bottom flange concrete after reserving and pre-burying of pipelines, and then casting the beams and top flange concrete to construct the hollow floor (1). The inner surfaces of the top flange plate (2) and the bottom flange plate (4) are in a wavy shape (6). The value of the wave crest is larger than 50mm. The combined filling members are formed by more than three gas filled tubes (7) in parallel combination, and adjacent bonding portions (8) of the gas filled tubes are in close contact. The length of each single tube is as same as the width (51) of the combined filling members (5) when the combined filling members (5) are in parallel combination. The sum of the diameters of multiple tubes is as same as the length (52) of the combined filling members (5), and the ratio of the length (52) to the width (51) is not less than 0.7. The gas filled tube combined filling members (5) act with a steel tube supporting and separating component (9); the gas filled tubes are fully utilized, and the defects of punching resistance and cracking in the prior art are overcome according to features of the tubes; cost of the floor can be saved, convenient and rapid construction is realized, and the structure of the floor is more reasonable.

Owner:王本淼

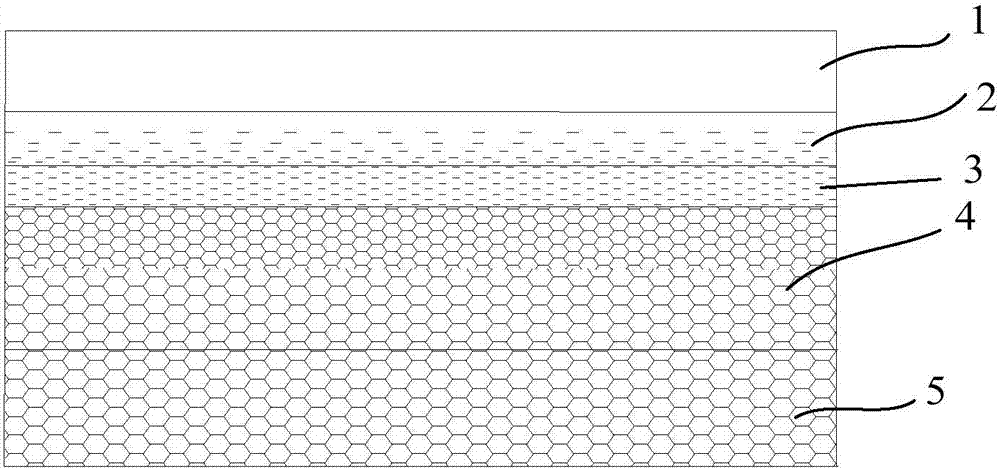

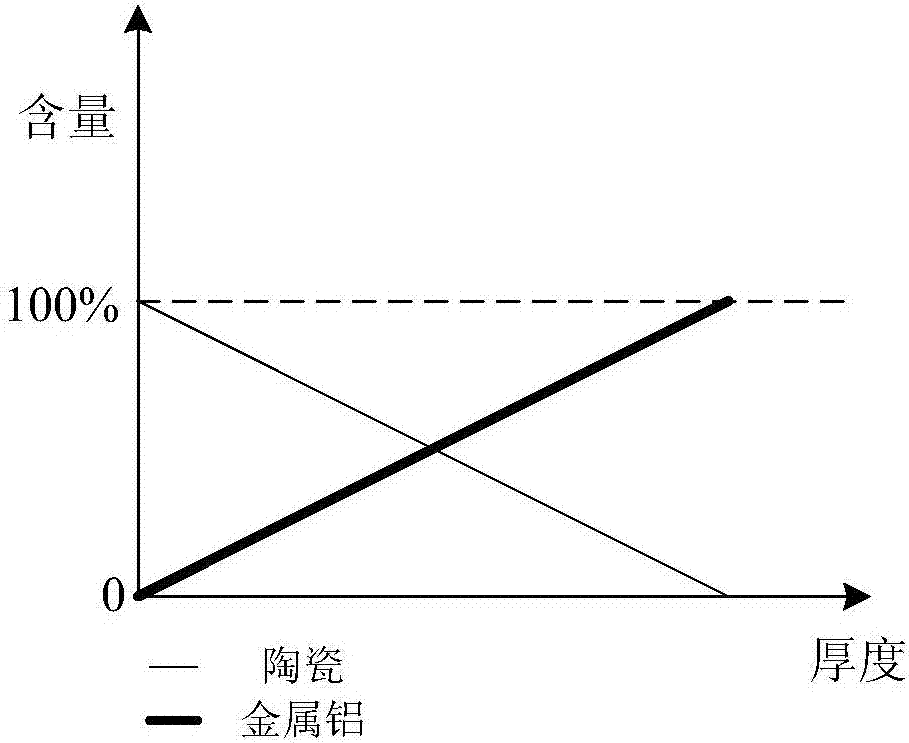

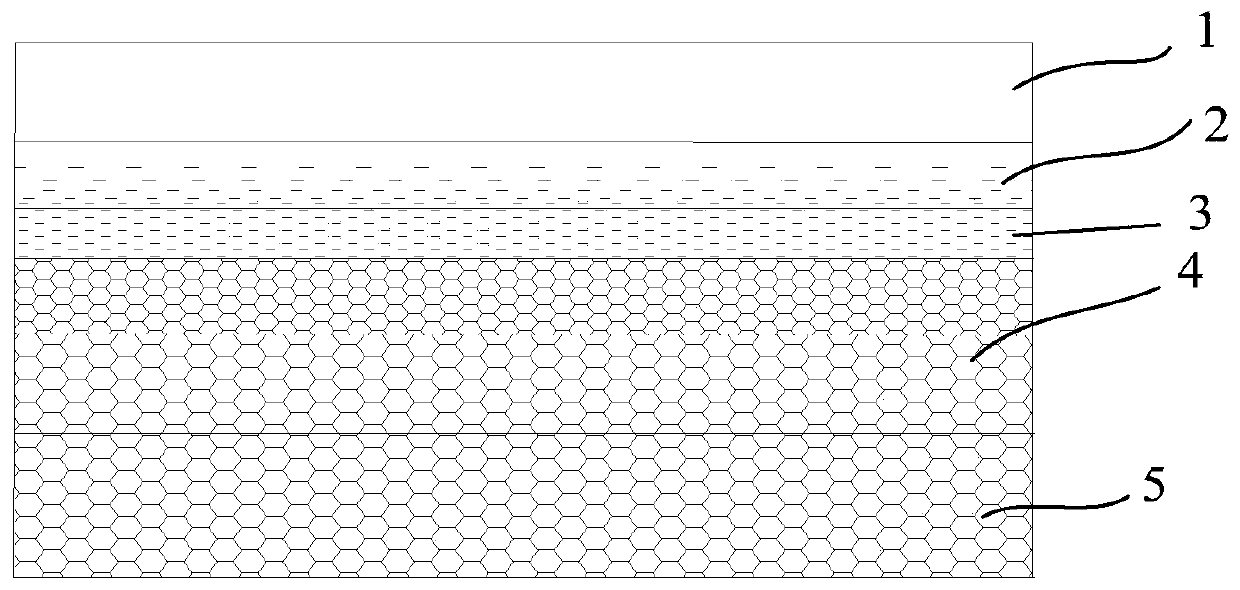

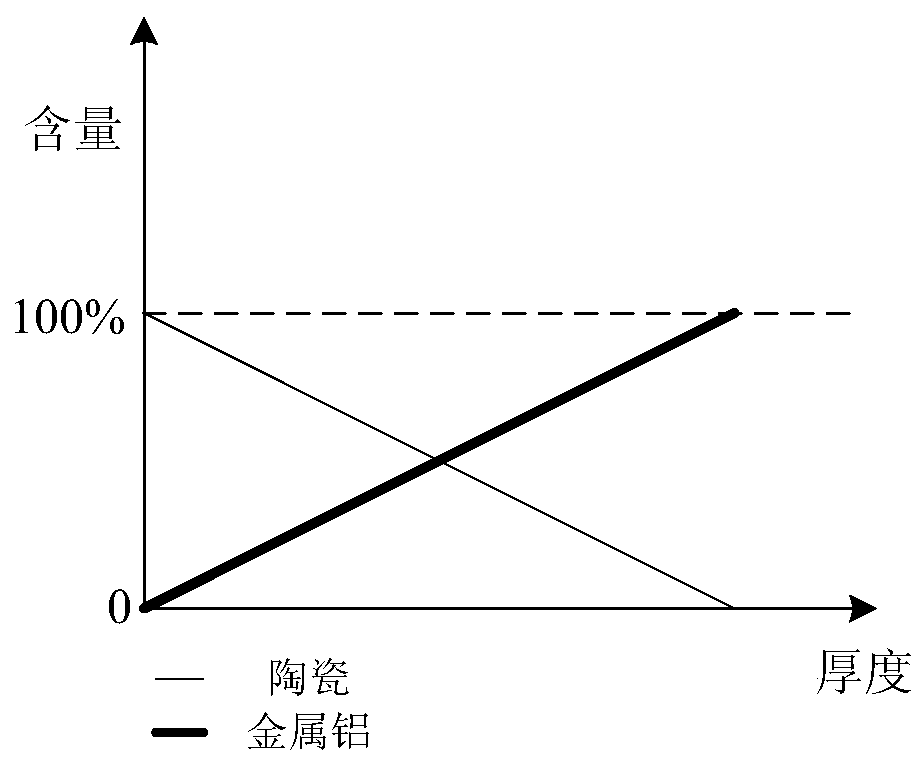

Light impact-resistant protection plate

ActiveCN107152888ALow densityOvercome stressProtective equipmentArmour platesStress concentrationMetallic aluminum

The invention discloses a light impact-resistant protection plate. The light impact-resistant protection plate comprises a ceramic layer, a ceramic-aluminum gradient layer which is jointed with the ceramic layer and foam aluminum buffer layers , wherein the side, jointed with the ceramic layer, of the ceramic-aluminum gradient layer is a first side; the side, jointed with the foam aluminum buffer layers, of the ceramic-aluminum gradient layer is a second side; and from the first side to the second side, the content of ceramic in the ceramic-aluminum gradient layer is gradually decreased to 0% from 100%, and the content of metallic aluminum is gradually increased to 100% from 0%. The weight of the light impact-resistant protection plate is obviously lowered; gradient gradual transition is realized at joint positions of various materials in the impact-resistant protection plate due to the ceramic-aluminum gradient layer, so that defects of stress concentration and cracking which easily happen at a interface between the ceramic and the metallic aluminum under a high impact load in the prior art are overcome. The invention further discloses a manufacture method for the light impact-resistant protection plate.

Owner:UNIV OF SCI & TECH OF CHINA

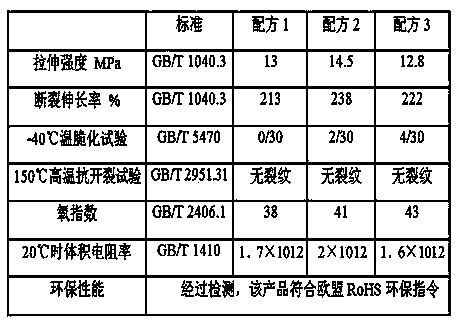

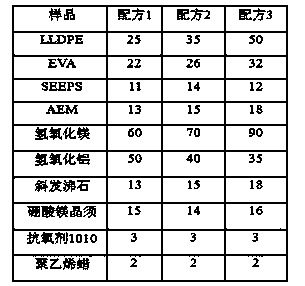

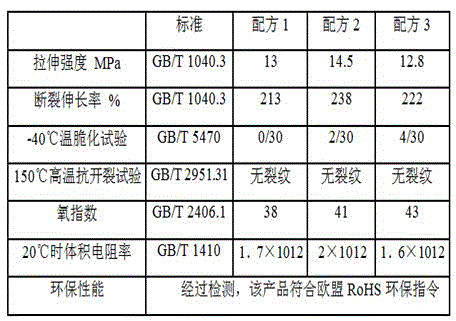

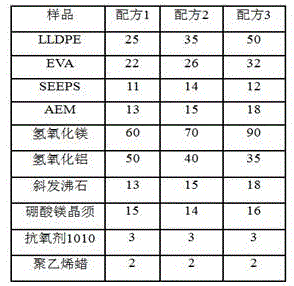

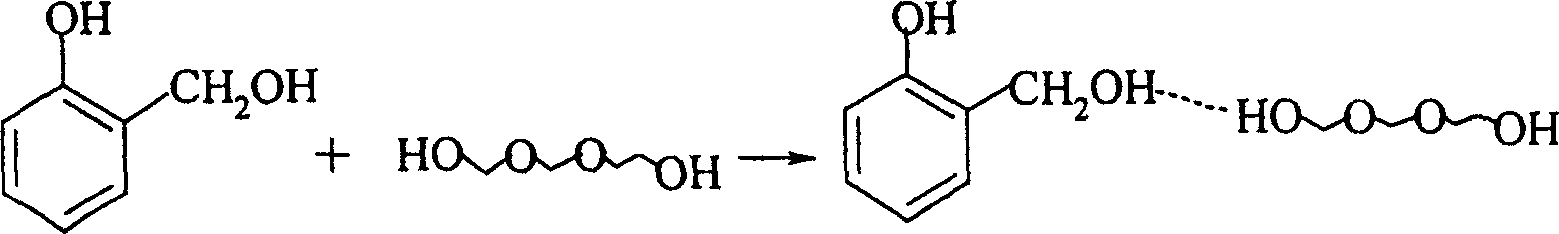

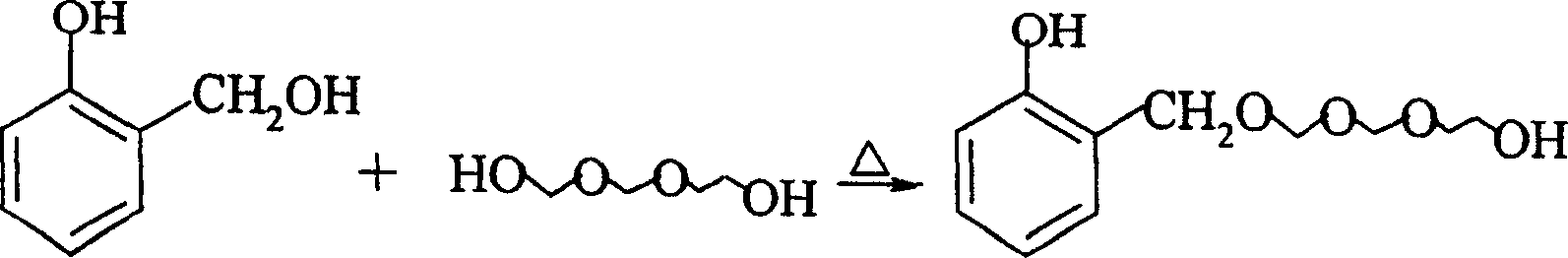

Cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material with thermoplasticity and preparation method thereof

ActiveCN103965540AOvercome cracking defectsStructurally supplePlastic/resin/waxes insulatorsInsulated cablesAntioxidantSmoke

The invention discloses a cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material with thermoplasticity and a preparation method thereof, and belongs to the technical field of cables. The cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material is prepared from the following components in parts by weight: 20-60 parts of linear low density polyethylene (LLDPE), 20-40 parts of ethylene vinyl-acetate copolymer (EVA), 10-20 parts of styrenic block copolymer (SEEPS), 10-20 parts of alpha-ethylmescaline (AEM), 50-100 parts of magnesium hydrate, 20-50 parts of aluminum hydroxide, 10-20 parts of clinoptilolite, 10-20 parts of borate whisker, 1-5 parts of antioxidant and 2-6 parts of lubricating agent. The method comprises the following steps: firstly, adding the borate whisker, the clinoptilolite and 1% of silane coupling agent to a high-speed mixer and mixing; adding the residual components to the high-speed mixer, and then extruding and pelletizing the mixture in a two-stage pelletizer. The cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material meets the requirements of an embrittlement experiment at low temperature of minus 40 DEG C and a crack-resistant experiment at high temperature of 150 DEG C, and furthermore has excellent flame retardant property.

Owner:BAOSHENG SCI & TECH INNOVATION +1

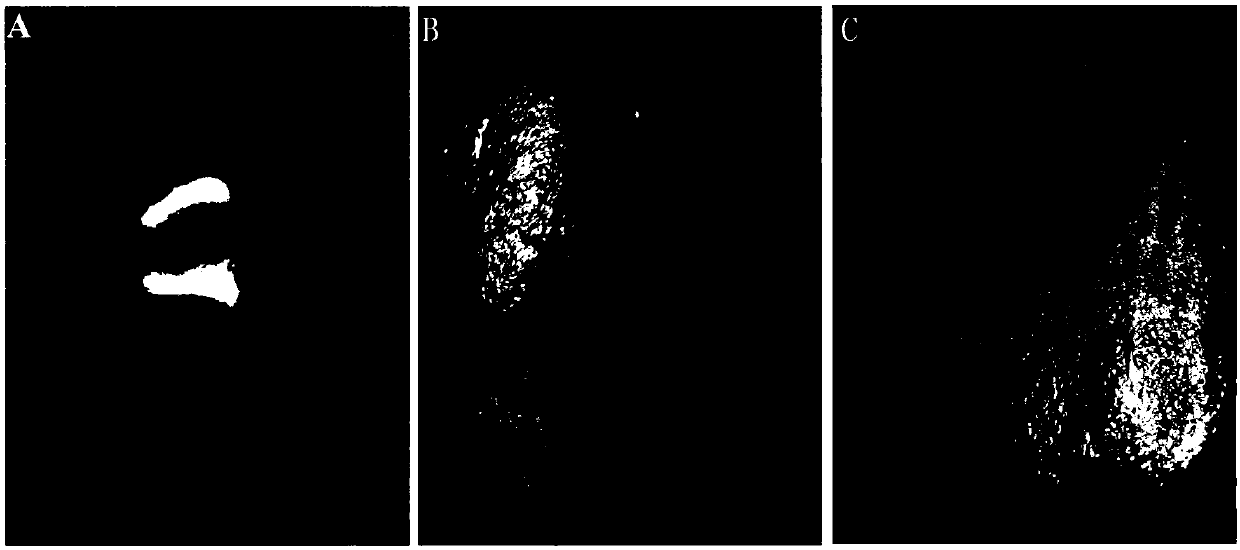

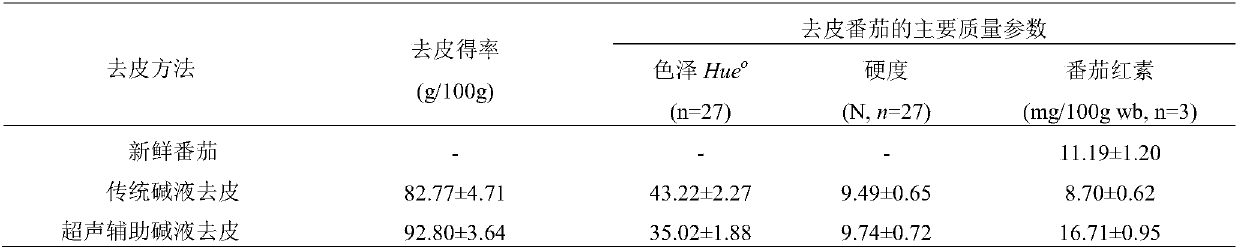

Ultrasonic-assisted lye tomato peeling method and product

InactiveCN109549062AReduce processing timeOvercome cracking defectsFood scienceUltrasonic assistedMedicine

The invention relates to an ultrasonic-assisted lye tomato peeling method and a product, and belongs to the technical field of agricultural product processing. The method combines lye treatment and ultrasonic treatment for tomato peeling; process conditions of the lye treatment and ultrasonic treatment are properly set, so that final tomatoes can not only achieve 100% peeling rate and 90% of the peeling yield, but also have most of the tomato red layer and lycopene retained; and the peeled tomatoes are obviously superior to the tomatoes obtained by traditional lye peeling in color and nutrients. Compared with traditional lye treatment, the method reduces the amount of chemical reagents and shortens the treatment time of tomatoes in lye; compared with an existing power ultrasonic peeling method, the method reduces ultrasonic temperature, and overcomes the drawbacks that the existing ultrasonic treatment is insufficient to crack the tomato skin. The method is suitable for industrial production and has great promotion value.

Owner:SOUTHWEST UNIVERSITY

Socket and spigot type plastic pipe fusion welding device for conveying media through pressure

InactiveCN106142496AOvercoming uneven connection strengthOvercome deformationTubular articlesEngineeringHeat fusion

The utility model relates to a socket-type plastic pipe welding device for pressure conveying medium. The whole device is arranged in the order of extruder, hot melt material storage barrel, feeding pipe, mold frame and support. There are upper mold and lower mold in the mold base, and a sealing plate is provided on one side of the upper mold and lower mold. , the inner side of the sealing plate is fixed with a mold core, the mold core moving cylinder fixed on one side of the mold base is connected with the sealing plate, the upper mold moving cylinder fixed on the mold base is connected with the upper mold, and the lower mold fixed under the mold base moves The cylinder is connected with the lower mold; when the socket tube is connected with the socket head, the defects of uneven connection strength of the electric heating belt and easy deformation and cracking of the pipe are overcome. The hot-melt connection between the socket pipe and the generated socket plug is firm, and the socket-type plastic pipe formed is suitable for operation in various environments. The relative cost of the project is low, and at the same time, the labor intensity of the operators is reduced, and the project progress is improved.

Owner:SHANGHAI JIUTONG PLASTIC PROD

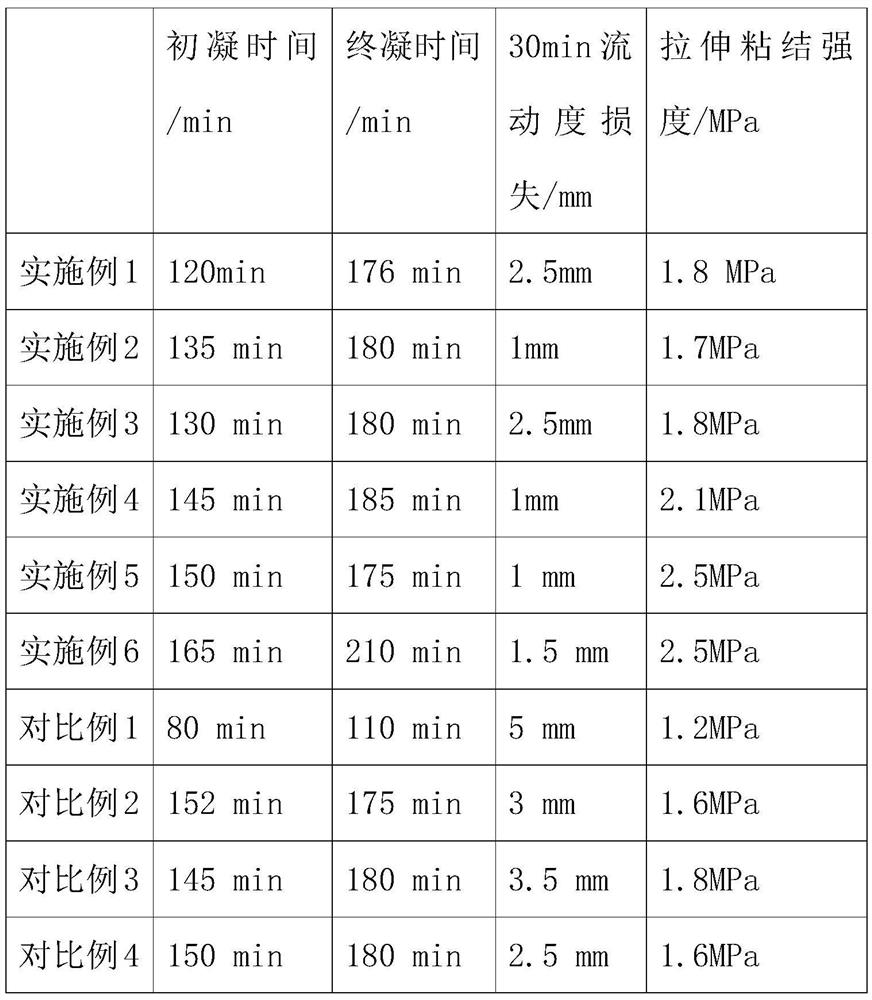

Moisture-resistant sound-insulation gypsum-based self-leveling mortar

ActiveCN112794729AImprove moisture resistanceIncrease the elastomerSolid waste managementCeramicwareElastomerPolymer science

The invention relates to the technical field of gypsum mortar preparation, and particularly, relates to a moisture-resistant sound-insulation gypsum-based self-leveling mortar comprising a main material, an auxiliary material resin and an additive, wherein the auxiliary material resin is mainly a polyolefin elastomer, and the addition amount of the auxiliary material resin is 4-6 wt% of the weight of the main material. By optimizing the components of the mortar, adding the auxiliary material resin and controlling the addition amount, the moisture resistance of the mortar is improved, the defects that hollowing and cracking are prone to occurring are overcome, the weight is relatively small, construction is facilitated, the daily ground paving area can reach 800-1000 m<2>, and the foot feeling comfort is poor.

Owner:长兴欧立亚新型建材有限公司

Steel tube machining method with high yield

InactiveCN107138533AQuality improvementHigh yieldMetal rolling arrangementsWaste productSaponification

The invention relates to the field of steel pipe preparation, and discloses a steel pipe processing method with a high yield. The continuous casting billet is used as a raw material, and the following steps are followed in sequence: heating, piercing, surface machining, annealing, pickling, phosphating, and saponification , Rolling preheating, rolling, cooling, the steel pipe produced will not crack, the quality is high, the yield is high, and the production cost is low; the piercing temperature is related to the piercing rate and the cracking degree of the steel pipe, and the appropriate piercing temperature can ensure the piercing efficiency. Avoid cracking of the steel pipe, and also avoid the production of waste products. The annealing process of the present invention can overcome the defect that the inner or outer surface of the steel pipe is easy to crack. Since the steel pipe billet is first put into the furnace and kept at 750-760°C, the steel pipe and The temperature in the furnace is consistent, and then staged annealing treatment and cooling are performed to stabilize the performance of the tube billet.

Owner:射洪县才伦建材有限责任公司

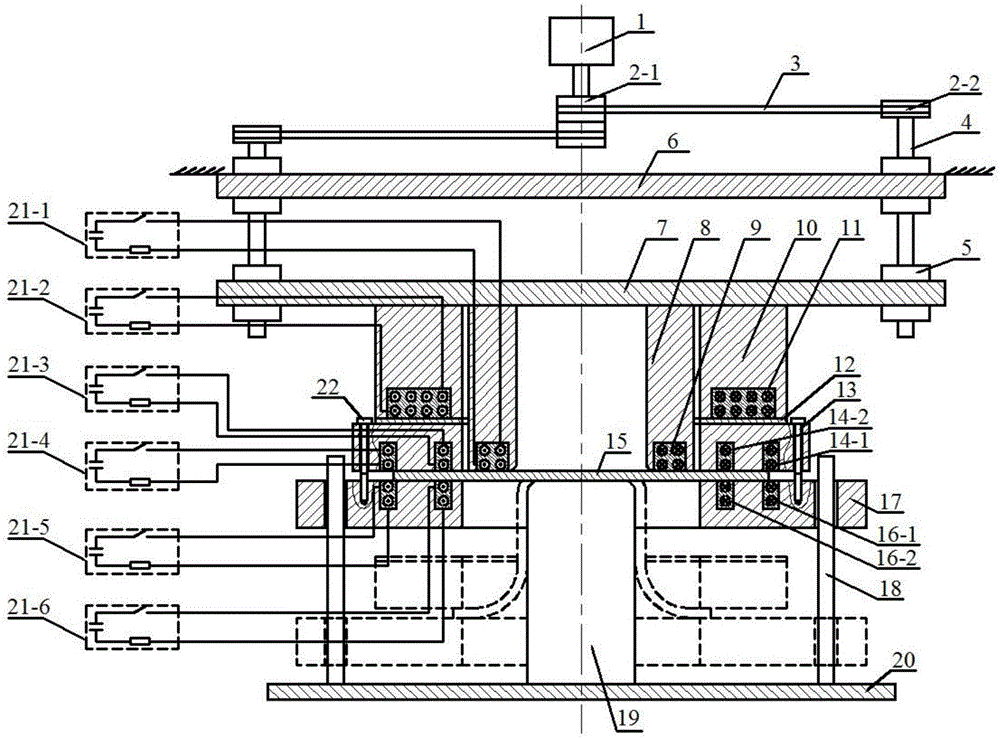

Punchless rivetless connection device and method combined with multi-energy field

The present invention provides a multi-energy field composite punchless rivetless connection device and method. A groove is provided, a tapered protrusion is provided in the middle of the die, the top of the die is provided with a first sheet metal and a second sheet metal; Above the second metal sheet, a ring-shaped binder coil is embedded in the binder ring. The multi-energy field composite non-punching type rivetless connection device and method of the present invention does not need to use a punch, and by organically unifying the magnetic field, electric field, and plastic mechanics field, and the joint action of multiple fields, four The two ring-shaped mechanical lock structures of the solder joints improve the microstructure, improve the material flow during the rivetless joint process, reduce the stress concentration on the neck of the rivetless joint, and significantly improve the mechanical properties of the joint, with high reliability and efficiency Higher and easier to operate.

Owner:CENT SOUTH UNIV

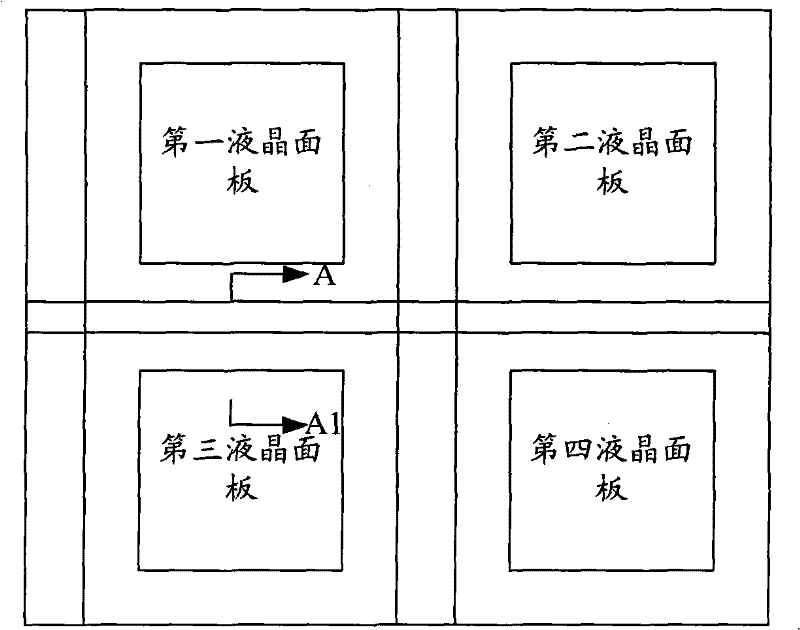

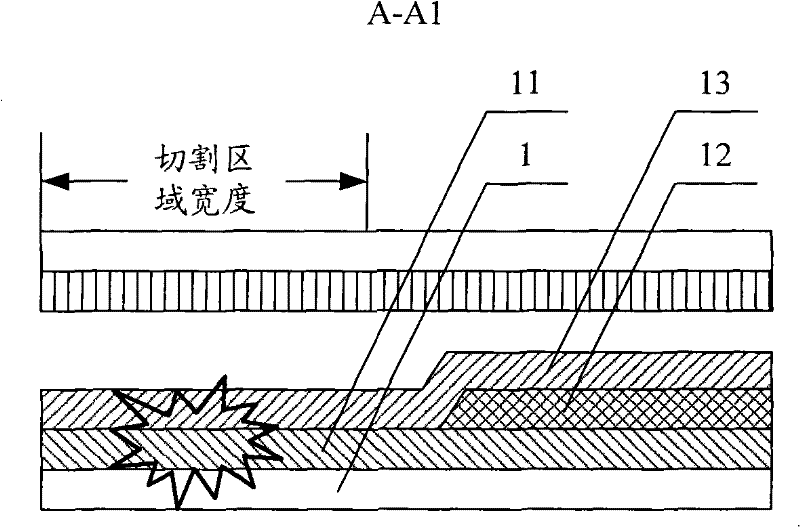

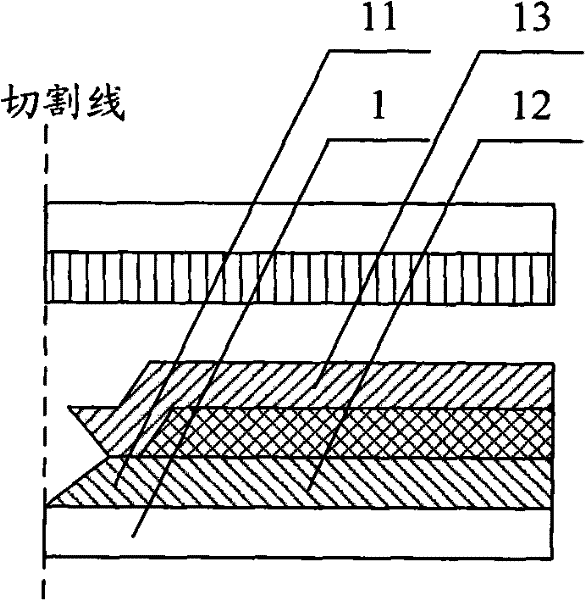

Array substrate and manufacturing method thereof and liquid crystal panel and manufacturing method thereof

ActiveCN101826488BOvercome breakageOvercome cracking defectsSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneMaterials science

The invention relates to an array substrate and a manufacturing method thereof and a liquid crystal panel and a manufacturing method thereof. The array substrate comprises a display area and a non-display area, wherein the non-display area comprises a cutting area and other areas, the other areas are provided with a double-layer structure which is formed by a grid insulation film and a passivation film, and the cutting area exposes the substrate. During the cutting process, the defects such as the breakage or fracture of the grid insulation film and the passivation film can be effectively overcome.

Owner:BOE TECH GRP CO LTD +1

A thermoplastic cold-resistant, crack-resistant, halogen-free, low-smoke, flame-retardant polyolefin sheath material and preparation method thereof

ActiveCN103965540BImprove low temperature resistanceLow smoke densityPlastic/resin/waxes insulatorsLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material with thermoplasticity and a preparation method thereof, and belongs to the technical field of cables. The cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material is prepared from the following components in parts by weight: 20-60 parts of linear low density polyethylene (LLDPE), 20-40 parts of ethylene vinyl-acetate copolymer (EVA), 10-20 parts of styrenic block copolymer (SEEPS), 10-20 parts of alpha-ethylmescaline (AEM), 50-100 parts of magnesium hydrate, 20-50 parts of aluminum hydroxide, 10-20 parts of clinoptilolite, 10-20 parts of borate whisker, 1-5 parts of antioxidant and 2-6 parts of lubricating agent. The method comprises the following steps: firstly, adding the borate whisker, the clinoptilolite and 1% of silane coupling agent to a high-speed mixer and mixing; adding the residual components to the high-speed mixer, and then extruding and pelletizing the mixture in a two-stage pelletizer. The cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material meets the requirements of an embrittlement experiment at low temperature of minus 40 DEG C and a crack-resistant experiment at high temperature of 150 DEG C, and furthermore has excellent flame retardant property.

Owner:BAOSHENG SCI & TECH INNOVATION +1

Method of preparing phenolic foam insulation material via foaming at normal temp

This invention relates to a method to produce phenolic foam heat preserving materials by ordinary-temperature foaming, is which phenol formaldehyde is adopted as raw materials and anhydrous polyethylene oxide sorbitan mono-oleate, aluminium hydroxide, pentane and composite acid curing agent are added. It has the characteristics that auxiliary agents and reinforcing modifiers can be also added in the raw materials; the ingredients added into the phenol formaldehyde raw materials have proportions as follows: 4~8 shares of polyethylene oxide sorbitan mono-oleate, 0.1~20 shares of auxiliary agents, 0.5~25 shares of reinforcing modifiers, 0~80 shares of aluminium hydroxide, 6~20 shares of pentane and 8~20 shares of composite acid curing agent, counting in 100 mass shares of phenol formaldehyde. In this invention, ordinar-temperature preparation of phenolic foam heat preserving materials above 0 deg. C can be realized. The phenolic foam heat preserving materials prepared have excellent properties; they help save energy and can be applied in spot construction, and therefore, they are promising materials.

Owner:SHANGHAI INST OF TECH +1

Metal corrugated thin wall stuffing mold tube

InactiveCN1532362AImprove anti-corrosion performanceIncreased durabilityFloorsReinforced concreteUltimate tensile strength

The thin wall corrugated metal pipe as stuffing mold includes one stuffing mold pipe and end plugs and features that the cross section of the stuffing mold pipe is quadrange with rounded angles. When the stuffing mold pipe is used in hollow floor board, the in-situ cast concrete rib formed between stuffing mold pipes has the shape of arc transitional rectangle, which has less consumption of concrete, small dead weight, good antiseismic performance superior to in-situ concrete rib formed with circular corrugated pipe. The present invention has high strength, high deformation and vibration resistance, convenient construction and transportation, and other features. The present invention is suitable for use in in-situ cast hollow beam-less reinforced concrete floor board as well as roofing, base board, wall and hollow bridge.

Owner:邱则有

Waterproof heat insulating brick and manufacturing and construction methods thereof

InactiveCN101660334BGood weather resistanceImprove waterproof performanceRoof covering using slabs/sheetsRoof covering using tiles/slatesBrickInorganic materials

The invention discloses a waterproof heat insulating brick, which consists of a brick body; the brick body consists of a rigid waterproof layer, a flexible waterproof layer and a heat insulating layer; the heat insulting layer is positioned on the lower part of the brick body, and is filled with a heat insulating material and cement; the flexible waterproof layer is arranged on the heat insulating layer, and is made of a polyethylene polypropylene waterproof material; the rigid waterproof layer is arranged on the flexible waterproof layer, and consists of concrete and admixtures; in the concrete, fine sand and pebbles are mixed in a mass ratio of 30-45:100 into gravel; and the mass ratio of the cement to the gravel is 1:2-2.5, and the mass ratio of water to the cement is 45-60:100. Inorganic materials are combined with organic materials, a characteristic of the inorganic materials of high strength is combined with the characteristics of the organic materials of good drawing force and strong waterproof performance, and a layer of heat insulating material is added, so the brick body with strong weather fastness, excellent waterproof performance and heat insulating function is formed.

Owner:任太平

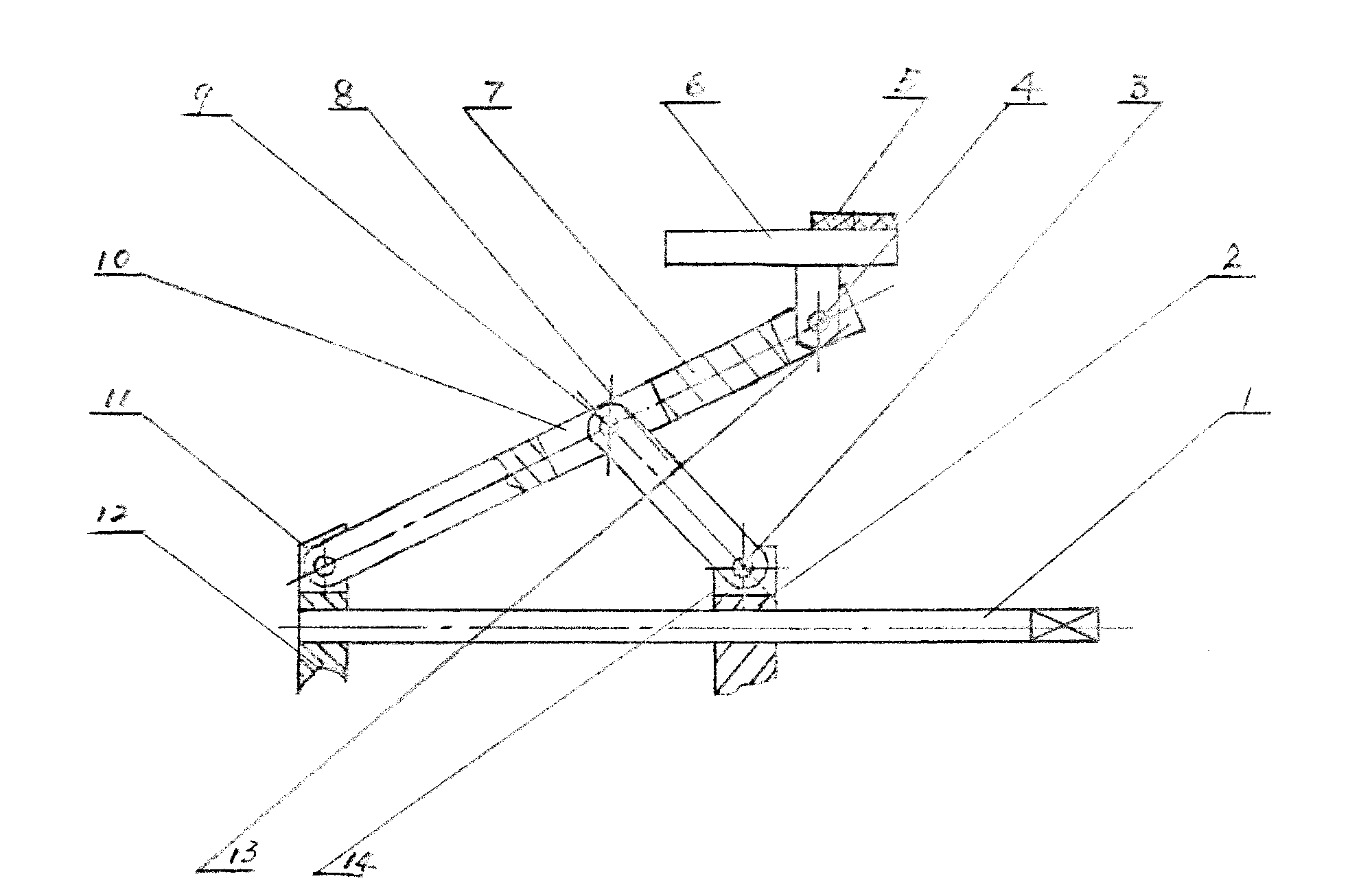

Annular electromagnetic pulse progressive reverse drawing forming method and device for metal sheet

InactiveCN103722067BChanging the state of stress and strainReduce tensile stressElectromagnetic pulseDeep drawing

The invention provides a metal plate annular electromagnetic pulse progressive reverse drawing forming method. The method includes the steps that a to-be-formed plate is placed between a female die and a male die; the periphery of the female die is provided with a clamping plate, and the periphery of the male die is provided with a supporting frame; pre-forming force is exerted on the to-be-formed plate; electromagnetic force is exerted to push the to-be-formed plate and the clamping plate downwards; electromagnetic force is exerted on the periphery of the to-be-formed plate, and the to-be-formed plate is pushed horizontally towards the center of the female die, so that the to-be-formed plate flows into the female die and reverse drawing forming is achieved; lower pressure is exerted to drive the female die to move downwards, and the to-be-formed plate at the bottom of the female die is squeezed into a gap between the female die and the male die, so that reverse drawing forming of the plate is achieved; reverse drawing and electromagnetic pulse drawing are repeatedly carried out on the female die and the male die until reverse drawing forming is finished. According to the method, forming limits can be substantially increased, and the forming depth of a cylindrical element is increased. The invention further provides a metal plate annular electromagnetic pulse progressive reverse drawing forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

A lightweight impact-resistant protective plate

ActiveCN107152888BLow densityOvercome stressProtective equipmentArmour platesStress concentrationMetallic aluminum

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com