ABS (acrylonitrile butadiene styrene)/PA (polyamide) composite antibacterial pipe and preparation method thereof

A composite antibacterial and stage technology, applied in the field of ABS/PA composite antibacterial pipe and its preparation, can solve the problems of rigidity decrease, bacteria can not be inhibited or killed, and easy to break, so as to overcome low tolerance and good inhibition And kill bacteria, overcome the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of ABS / PA composite antibacterial pipe, is made up of the following components by weight:

[0030] ABS60 copies

[0031] PA25 copies

[0032] Polyester thermoplastic elastomer 5 parts

[0033] Nano silver powder 1 part

[0034] 0.5 parts of ammonium dihydrogen phosphate

[0035] 2,6-tributyl-4-methylphenol 2 parts

[0036] Thiodipropionate diester 1 part

[0037] Chlorinated polyethylene 6 parts

[0038] 0.5 parts of stearic acid

[0039] Titanium dioxide 5 parts

[0040] The above-mentioned composite antibacterial tube is prepared according to the following steps:

[0041] (1) Mixing: Weigh according to the weight of each component, and fully mix in a mixer, the mixing temperature is 40°C, the speed is 80 rpm, and the time is 15 minutes;

[0042] (2) Extrusion: use extruder for extrusion, control five temperature stages, the first temperature stage is 200°C, the second temperature stage is 220°C, the third temperature stage is 250°C, the fourth temperat...

Embodiment 2

[0045] A kind of ABS / PA composite antibacterial pipe, is made up of the following components by weight:

[0046] ABS63 copies;

[0047] PA30 copies;

[0048] 8 parts of polyester thermoplastic elastomer;

[0049] 3 parts of nano-silver powder;

[0050] 1.2 parts of ammonium dihydrogen phosphate;

[0051] 2 parts of 2,6-tributyl-4-methylphenol;

[0052] 2 parts of diester of thiodipropionate;

[0053] Chlorinated polyethylene 8 parts.

[0054] 0.6 parts of stearic acid;

[0055] 6 parts of titanium dioxide.

[0056] The above-mentioned composite antibacterial tube is prepared according to the following steps:

[0057] (1) Mixing: Weigh according to the weight of each component, and fully mix in a mixer, the mixing temperature is 52°C, the speed is 90 rpm, and the time is 15 minutes;

[0058] (2) Extrusion: use extruder for extrusion, control five temperature stages, the first temperature stage is 210°C, the second temperature stage is 230°C, the third temperature stage...

Embodiment 3

[0061] A kind of ABS / PA composite antibacterial pipe, is made up of the following components by weight:

[0062] ABS70 copies;

[0063] PA32 copies;

[0064] 13 parts of polyester thermoplastic elastomer;

[0065] 3 parts of nano-silver powder;

[0066] 2.5 parts of ammonium dihydrogen phosphate;

[0067] 4 parts of 2,6-tributyl-4-methylphenol;

[0068] 3 parts of diester of thiodipropionate;

[0069] Chlorinated polyethylene 12 parts.

[0070] 1 part stearic acid;

[0071] 7 parts of titanium dioxide.

[0072] The above-mentioned composite antibacterial tube is prepared according to the following steps:

[0073] (1) Mixing: Weigh according to the weight of each component, and fully mix in a mixer, the mixing temperature is 55°C, the speed is 100 rpm, and the time is 20 minutes;

[0074] (2) Extrusion: Use extruder for extrusion, control five temperature stages, the first temperature stage is 200-230°C, the second temperature stage is 220-260°C, and the third temperat...

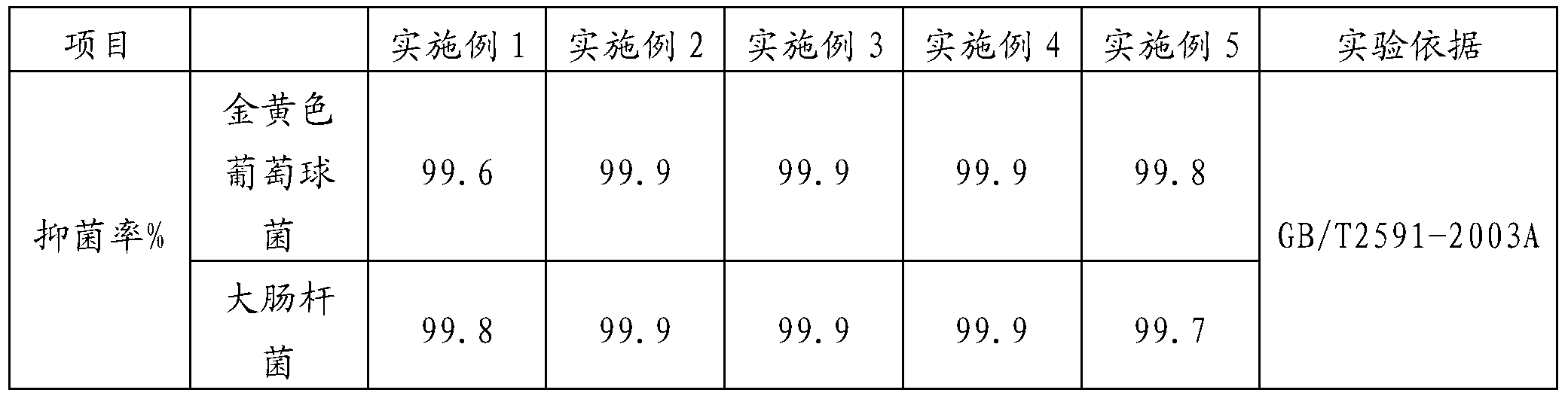

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com