Patents

Literature

39results about How to "Good antibacterial performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

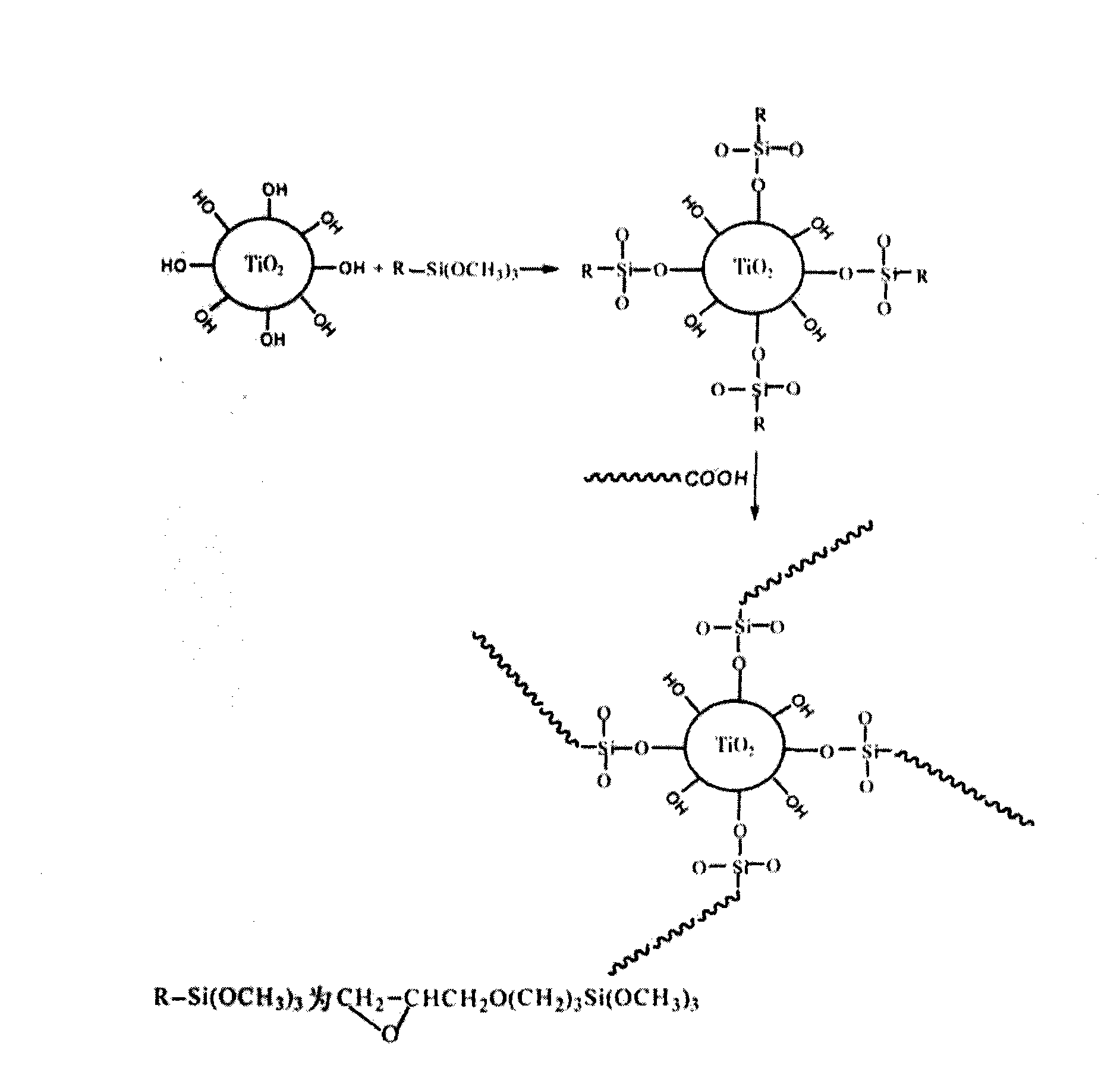

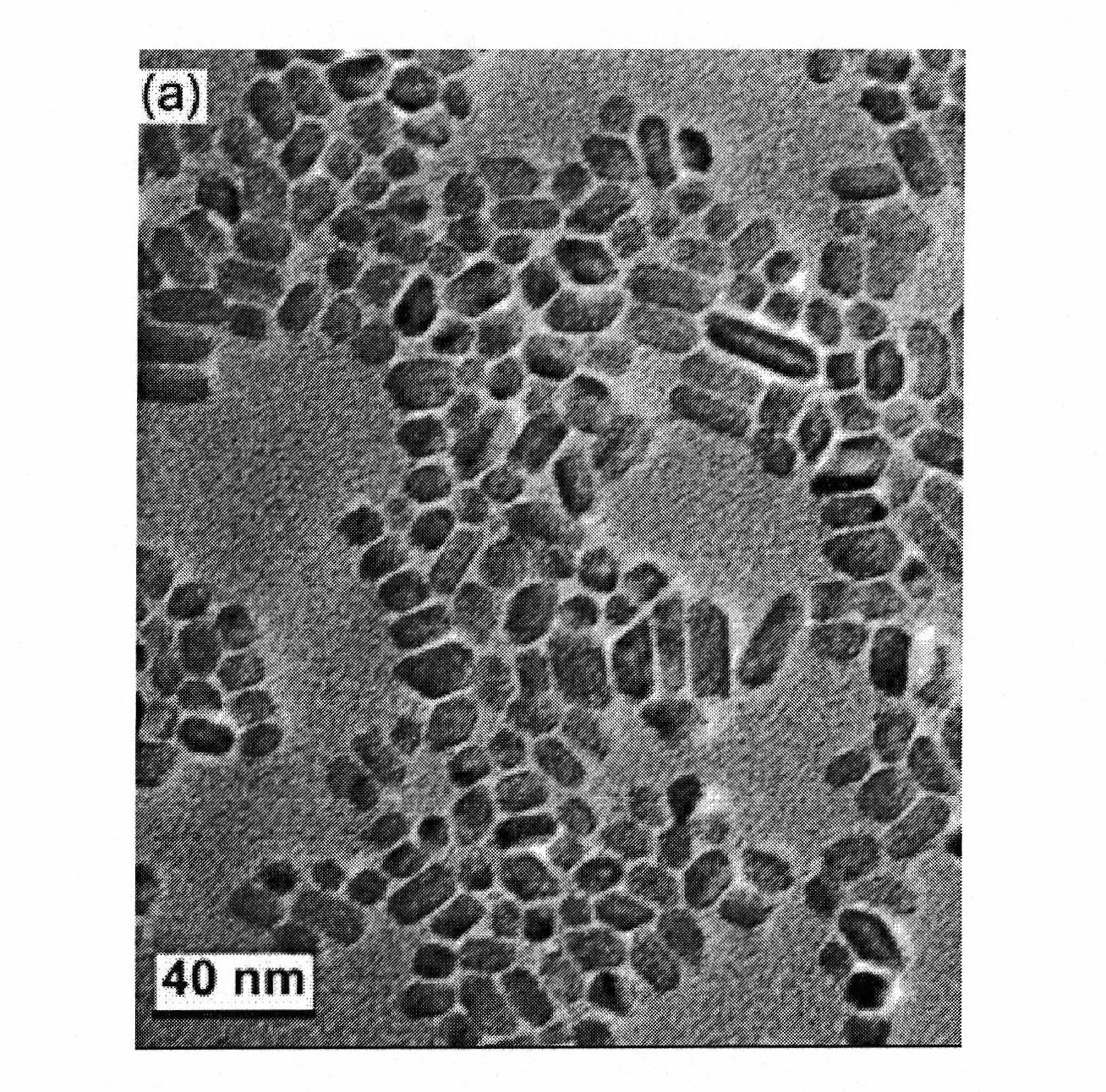

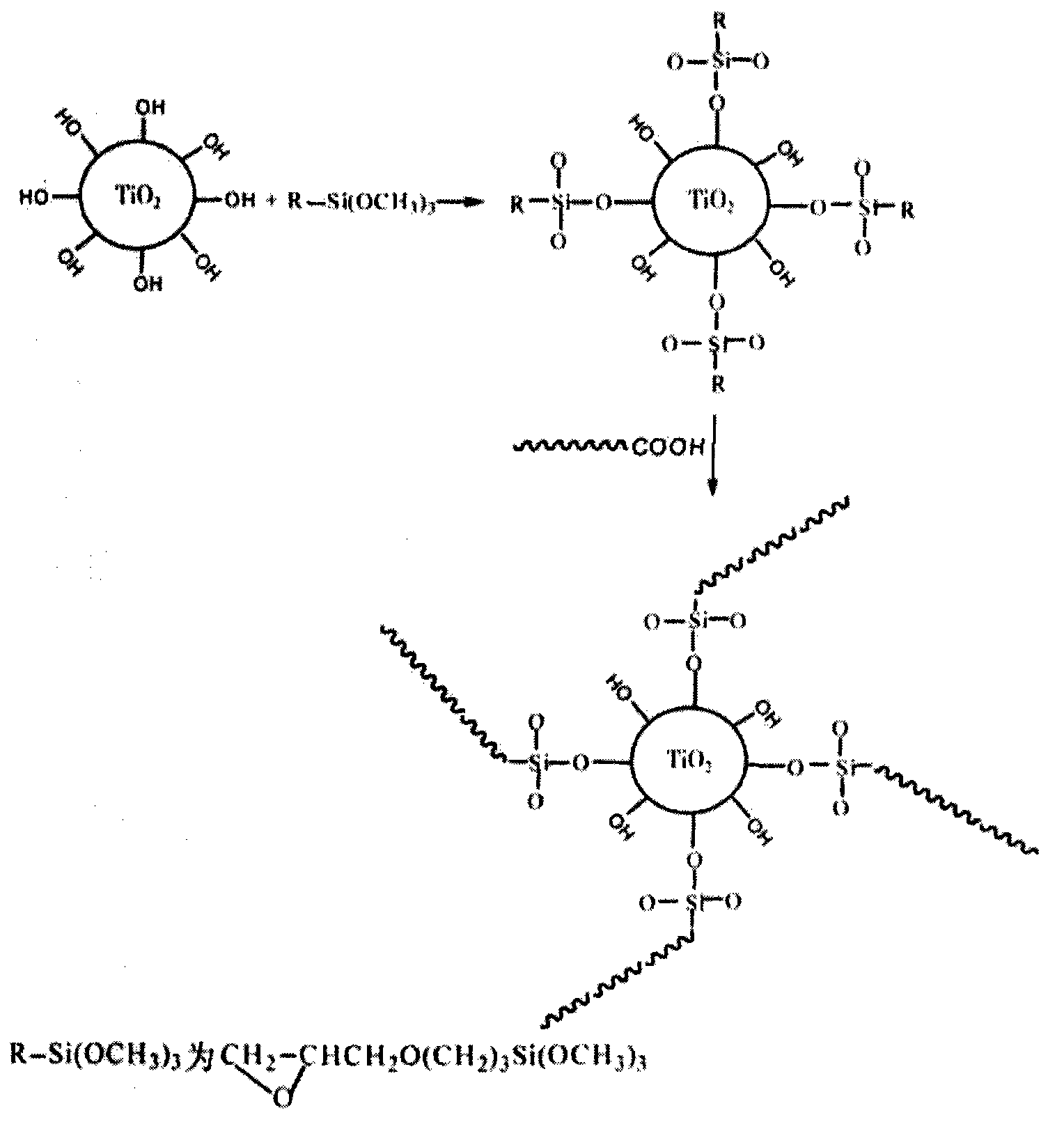

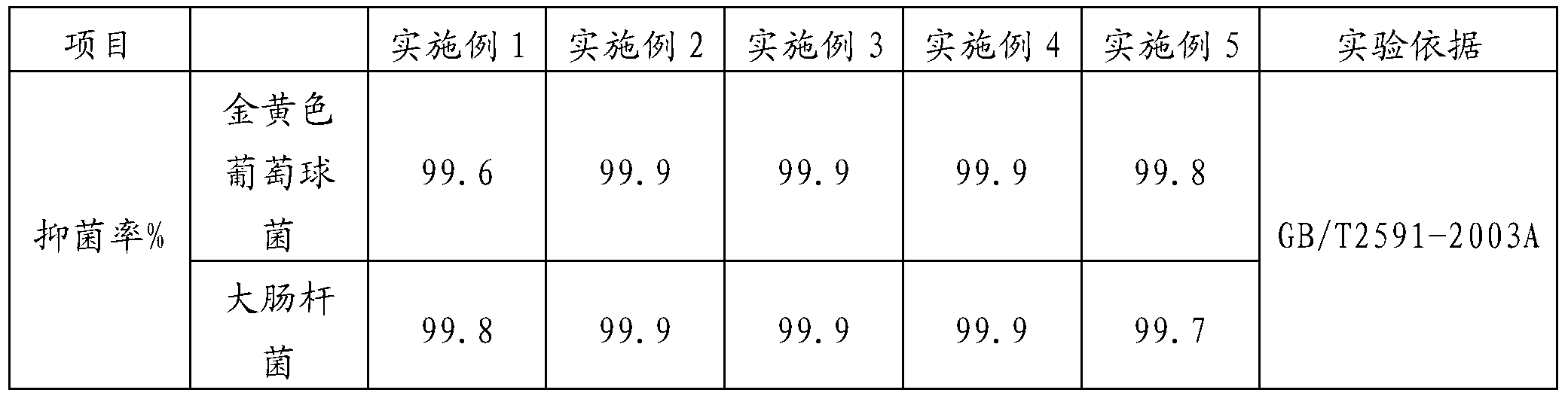

Method for preparing finishing agent of modified nano titanium dioxide coating layer of electromagnetic shielding fabric

InactiveCN101768853AImprove performanceNot easy to reuniteMagnetic/electric field screeningFibre treatmentCross-linkUltraviolet

The invention relates to a method for preparing a finishing agent of a modified nano titanium dioxide coating layer of an electromagnetic shielding fabric. The technical problem of the invention to be solved is that the method for preparing the finishing agent of the modified nano titanium dioxide coating layer of the electromagnetic shielding fabric is provided, so that the electromagnetic shielding fabric has excellent performance of ultraviolet ray resistance, antibacterium, self-cleaning and the like, and the original characteristic of low surface resistance can be maintained at the same time. The technical scheme for solving the problem is that nano TiO2 is modified by a special process, and then the modified nano TiO2 is mixed uniformly with resin and a cross-linking agent according to the proportion, so that the finishing agent of the modified nano titanium dioxide coating layer of the electromagnetic shielding fabric is obtained. The invention can be used for the textile industry of the electromagnetic shielding fabric.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Bacterial cellulose composite dressing

ActiveCN103480028AHigh mechanical strengthStrong tear resistanceBiochemical fibre treatmentMicroorganism based processesWound dressingAntibiotic Y

The invention relates to a bacterial cellulose composite dressing, which is prepared by soaking a composite material composed of bacterial cellulose and non-woven fabrics or woven fabrics in an antibiotics-containing water solution. The bacterial cellulose composite dressing is prepared by following steps: choosing bacterial strains capable of secreting bacterial cellulose to made into a seed mash, then evenly dropwise adding the seed mash on non-woven fabrics or woven fabrics, which have been subjected to a sterilization treatment, adding a small amount of fermentation culture medium for cultivation of 12 to 48 hours, then adding fermentation culture medium, cultivating for 3 to 6d, taking out the fermentation products, and finally subjecting the fermentation products to a purifying treatment so as to obtain the bacterial cellulose composite non-woven fabrics or woven fabrics. The preparation method has the advantages of simple technology, and convenient operation, and is capable of preparing bacterial cellulose wound dressings with various functions according to the needs.

Owner:钟春燕

Production method of medical packaging paper with high bacteria blocking performance

InactiveCN105256642AGood antibacterial performanceQuality improvementReinforcing agents additionPaper/cardboardPolyesterPolyacrylamide

The invention relates to a production method of medical packaging paper with high bacteria blocking performance. The production method comprises following steps: polyester microfibers with the length of 1-2 mm and the width of 0.3-3 mu m are selected and dispersed in water firstly; then aluminum sulfate is added and mixed uniformly, CMC (carboxymethyl cellulose) is added and stirred for 5 min, and the mixture is uniformly mixed; bleached softwood chemical pulp and bleached hardwood chemical pulp are beaten until the beating degree is 16-35 degree SR and are mixed uniformly; modified polyester microfibers are added to the pulp and uniformly mixed; then the wet strength agent PAE, cationic starch and AKD are added, water is added, the mixture is diluted until the concentration is 0.1%-1.0%, cationic polyacrylamide is added and mixed uniformly, the product is subjected to papermaking, squeezing, drying, surface sizing and calendering on a paper machine, and the medical packaging paper with high bacteria blocking performance is prepared. With adoption of the method, the bacteria blocking performance of the medical packaging paper is improved, the medical packaging paper keeps good breathability, and the quality of the medical packaging paper is improved.

Owner:ZHEJIANG SCI-TECH UNIV

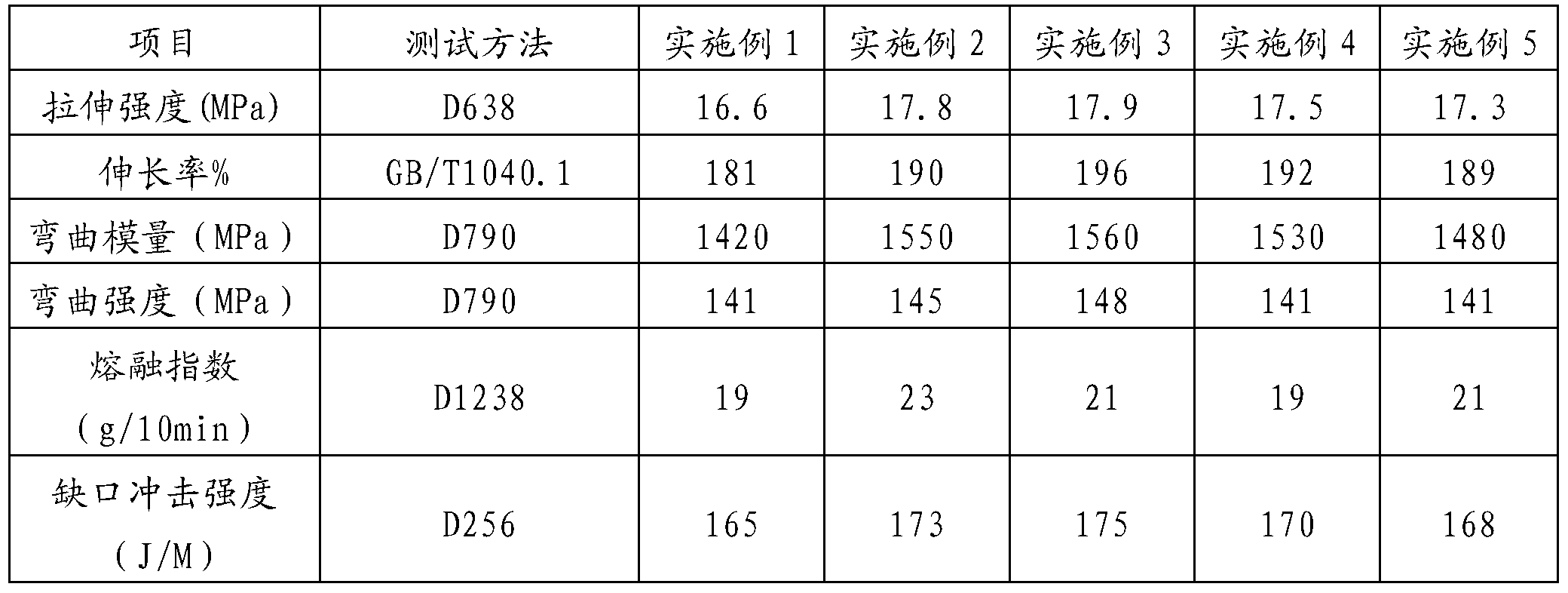

ABS (acrylonitrile butadiene styrene)/PA (polyamide) composite antibacterial pipe and preparation method thereof

InactiveCN103304952AOvercoming low toleranceOvercome cracking defectsPolyesterThermoplastic elastomer

The invention discloses an ABS (acrylonitrile butadiene styrene) / PA (polyamide) composite antibacterial pipe and a preparation method thereof. The composite antibacterial pipe comprises the following components in parts by weight: 60-80 parts of ABS, 25-40 parts of PA, 5-20 parts of polyester thermoplastic elastomer, 1-6 parts of nano-silver powder, 0.5-5 parts of ammonium dihydrogen phosphate, 2-5 parts of 2, 6-tributyl-4-methylphenol, 1-4 parts of diester thiodipropionate, 6-15 parts of chlorinated polyethylene, 0.5-1.2 parts of stearic acid and 5-10 parts of titanium dioxide. The prepared composite antibacterial pipe has not only good tolerance, but also good antibacterial effect.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

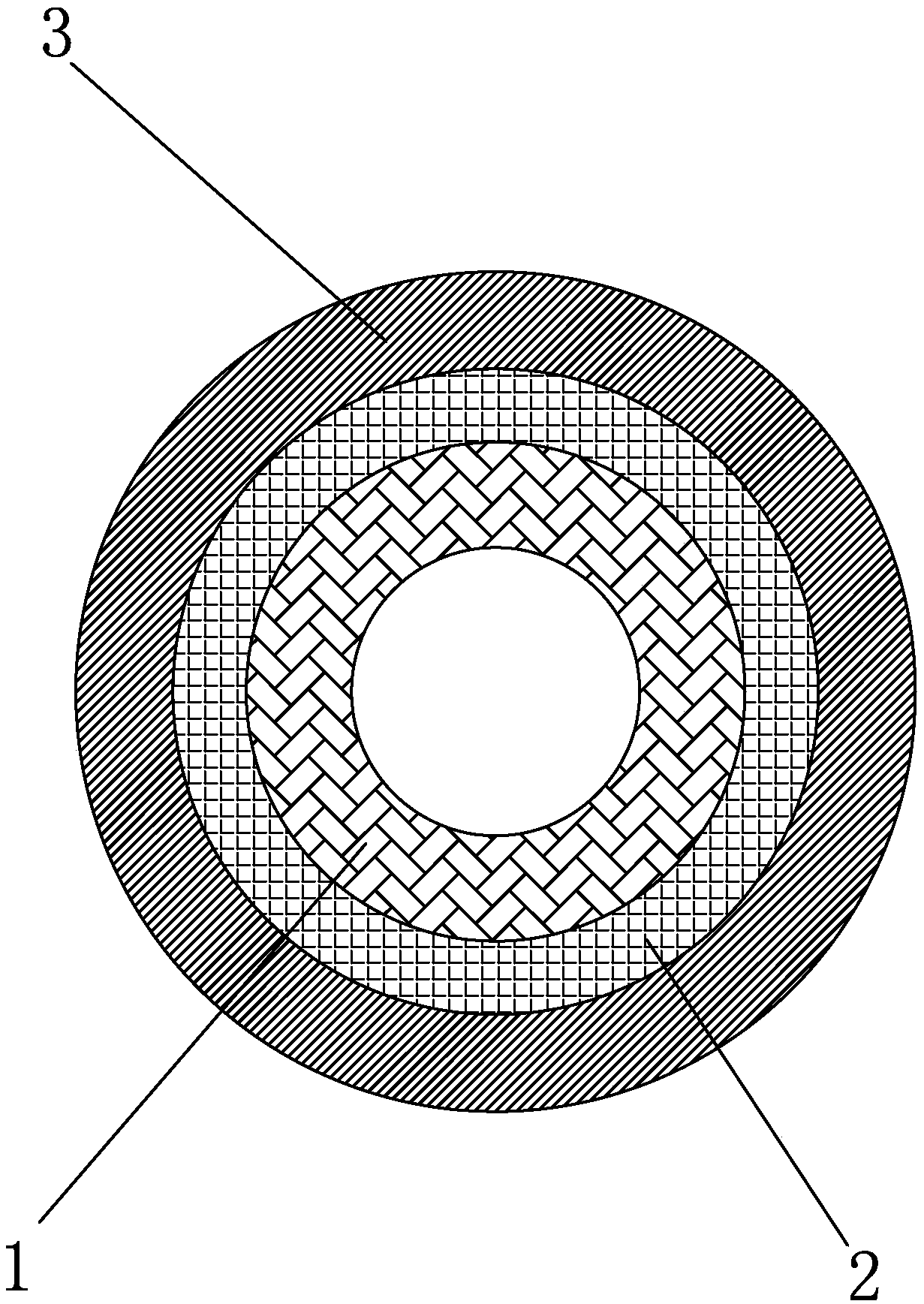

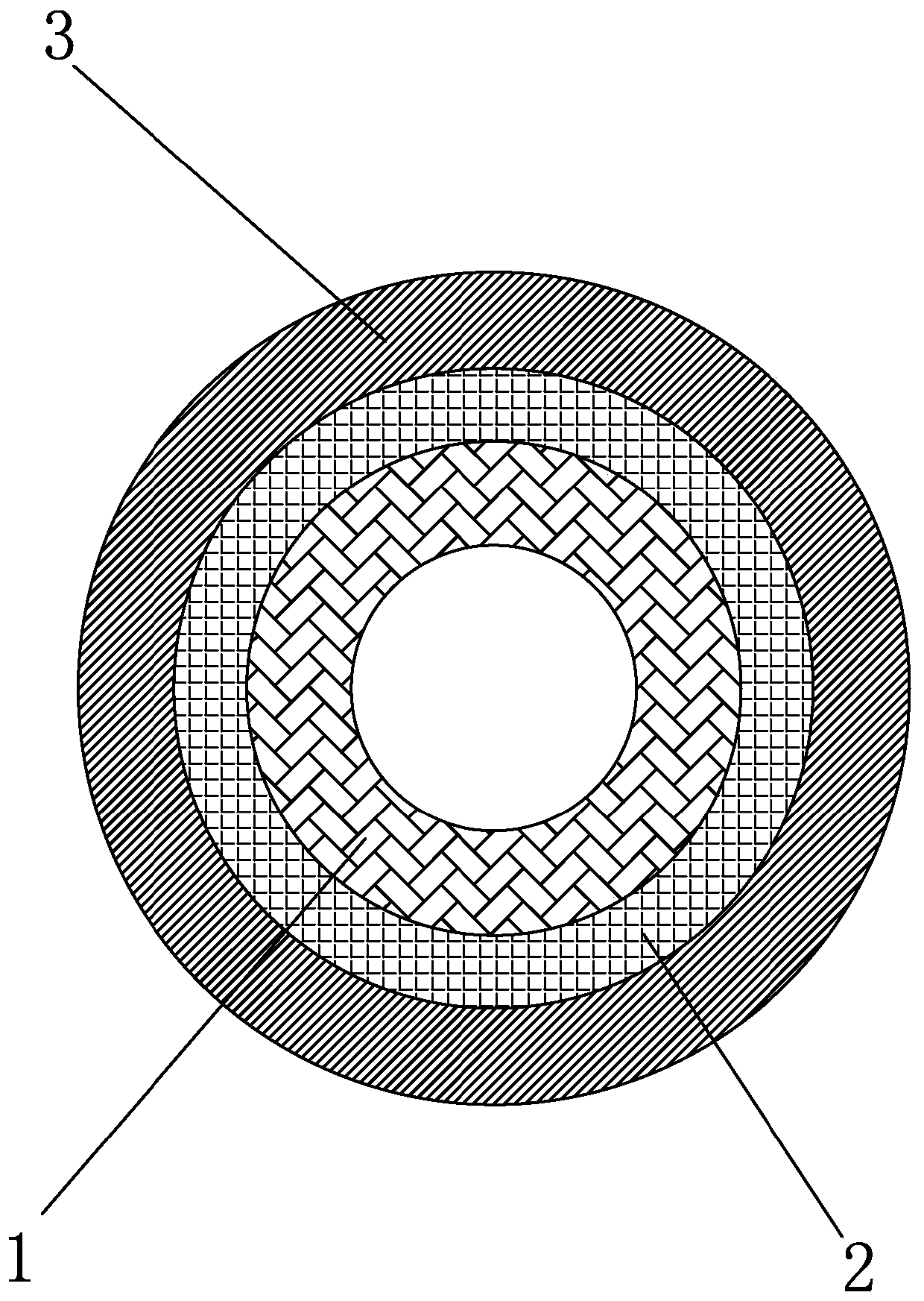

Hollow soft antibacterial yarn

PendingCN109183225AImprove breathabilityGood air permeability, good antibacterial and deodorizing propertiesYarnYarnCarbon fibers

The invention discloses a hollow soft antibacterial yarn. The yarn includes a yarn body, wherein the yarn body is of a sheath core structure, the yarn body is a hollow yarn, an inner portion is a hollow core, the yarn body sequentially includes a bamboo charcoal fiber layer, a coffee carbon fiber layer and a colored cotton fiber layer from the inside to the outside in the radial direction of the yarn body, the hollow core of the yarn body is formed through hydrolysis of a core yarn made of the water-soluble vinylon fiber, the bamboo charcoal fiber layer is formed by spirally winding raw bamboofibers, the bamboo charcoal fiber layer is internally filled with silver nano particles, the coffee carbon fiber layer is formed through spirally covering the coffee carbon fiber outside the bamboo charcoal fiber layer, and the colored cotton fiber layer is formed by spirally covering the colored cotton fiber outside the coffee carbon fiber layer. The yarn is advantaged in that the hollow yarn structure is utilized, the bamboo charcoal fiber layer and the coffee carbon fiber layer are arranged internally, and the yarn is super soft and super fluffy, has good warmth keeping effect, breathability, good antibacterial and deodorizing performance, the bright color and no dye need and can realize environmental protection and energy saving.

Owner:苏州璟珮新材料科技有限公司

Production method of heat-sealing self-adhesive medical dialyzing paper

ActiveCN110939009AImprove surface bond strengthHigh bonding strengthWater-repelling agents additionPulp beating methodsProcess engineeringSizing

The invention discloses a production method of heat-sealing self-adhesive medical dialyzing paper. The production method comprises the following steps: pulping a pulp; pulping; preparing materials; forming on a net; squeezing and dehydrating; drying and surface sizing; drying, transferring and coating; calendaring and coiling; rewinding and packaging to obtain a finished product. According to themedical dialyzing paper prepared by the method, the indexes of air permeability and bonding strength can meet the use requirements of the medical industry, the production of base paper and an adhesivelayer is completed in a papermaking machine in one time, the medical dialyzing paper is directly used for manufacturing medical packaging paper plastic bags, the equipment, labor and transportation cost can be saved, and the efficiency is greatly improved.

Owner:安徽华邦古楼新材料有限公司

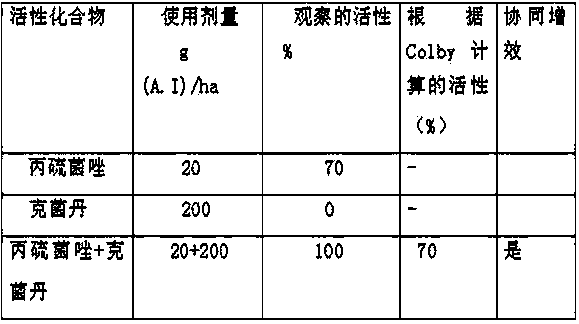

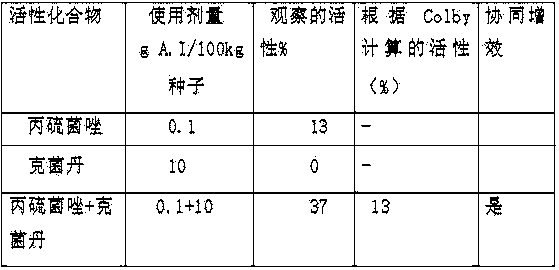

Sterilizing active ingredient composition

ActiveCN103461362AGood antibacterial performanceGood stimulating effectBiocideFungicidesTreatment effectCaptan

The invention relates to a sterilizing active ingredient composition, and particularly relates to the sterilizing active ingredient composition comprising prothioconazole and captan. The sterilizing active ingredient composition is characterized by comprising compounds prothioconazole and captan, and the weight ratio of the active compounds prothioconazole to captan is1:100-100:1. Due to binary compounding of the prothioconazole and captan, the prevention and therapy effects of the sterilizing active ingredient composition are improved, the bacteriocidal spectrum is enlarged, and the sterilizing active ingredient composition can be used for preventing and curing fungus and germ on frumentum, fruits, vegetables, and industrial crops.

Owner:JIANGSU ROTAM CHEM

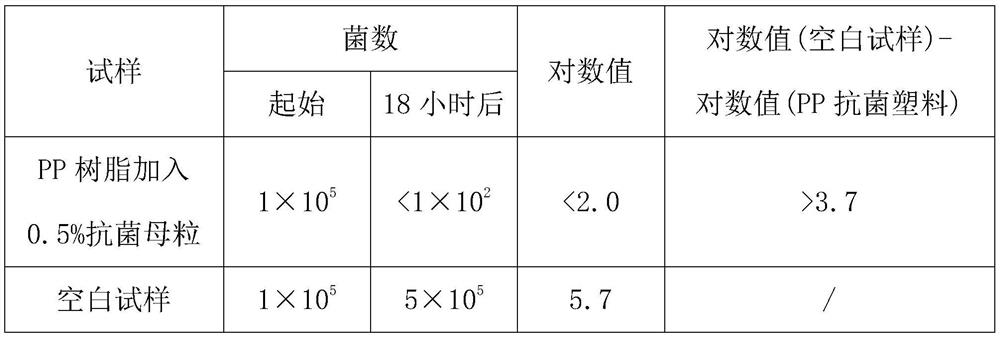

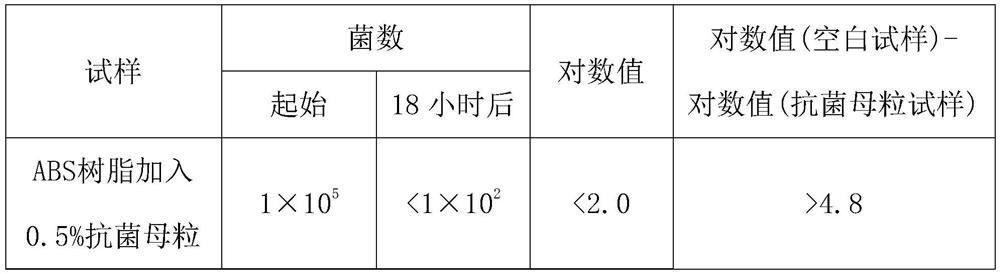

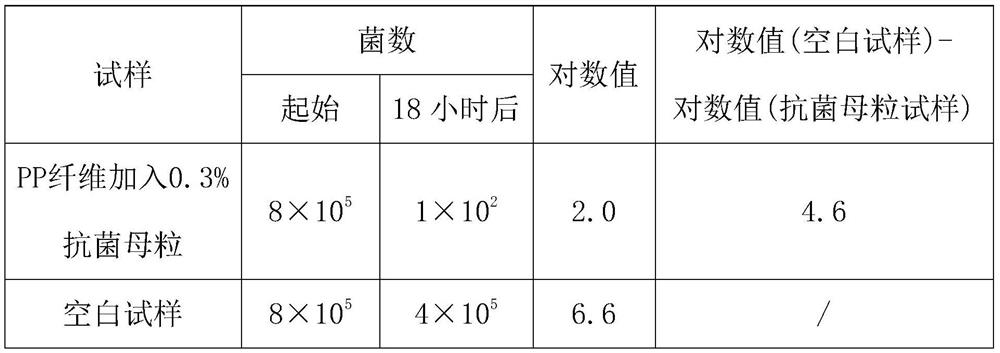

Antibacterial master batch and antibacterial plastic

PendingCN113354898AInhibitory activityKill bacteriaMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentDamp environmentChemistry

The invention belongs to the technical field of plastic materials, and discloses an antibacterial master batch and antibacterial plastic, the antibacterial master batch comprises the following components by weight: 1-5 parts of a silver-loaded antibacterial agent, 1-5 parts of a dispersant, 1-3 parts of a nano ultraviolet light absorber, 1-5 parts of nano titanium dioxide, and 25-45 parts of carrier resin. The antibacterial plastic comprises a resin raw material and antibacterial master batches. And the antibacterial master batch accounts for 0.3-1% of the total mass of the antibacterial plastic. The antibacterial master batch has a good antibacterial effect no matter in a dark and humid environment or in a sunshine irradiation environment. Meanwhile, the antibacterial master batch also has an anti-ultraviolet effect. The antibacterial master batch with an extremely low proportion is added into the resin raw materials, so that the antibacterial plastic product has excellent antibacterial effect and still has excellent antibacterial performance after being washed and soaked in warm water.

Owner:惠州市适合颜料塑胶制品有限公司

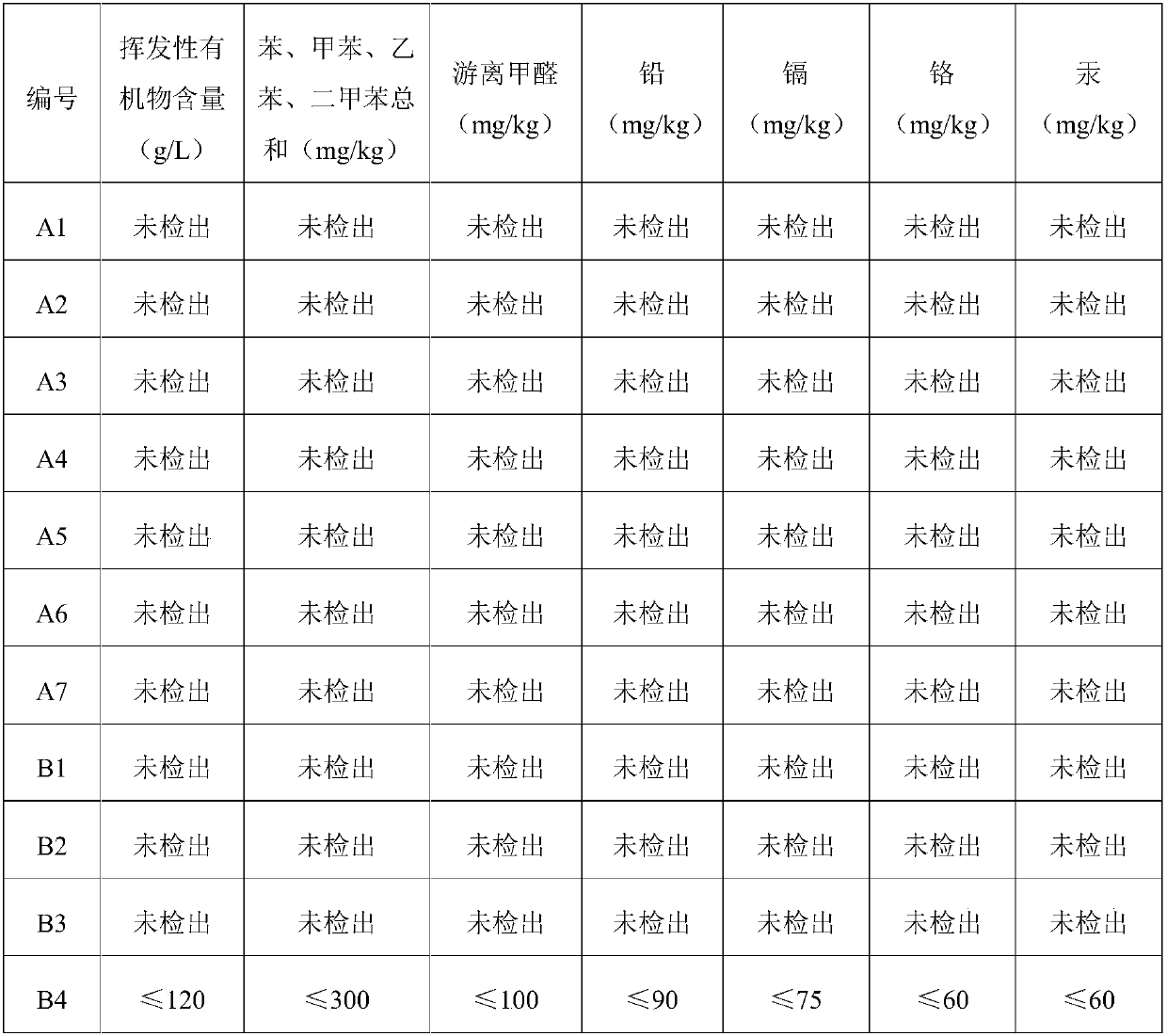

Inorganic interior wall paint and preparation method thereof

InactiveCN109575658AImprove diffusivityGuaranteed stabilityAntifouling/underwater paintsAlkali metal silicate coatingsEmulsionPotassium silicate

The invention provides an inorganic interior wall paint and a preparation method thereof. The preparation method comprises, mixing nanometer potassium silicate and water to obtain a nanometer potassium silicate solution; adding silane coupling agent into the nanometer potassium silicate solution to obtain modified nanometer potassium silicate; mixing titanium dioxide and inorganic paint into the modified nanometer potassium silicate to obtain a powder paint precursor; with existence of solvent, mixing silicon dioxide and polyacrylate to obtain a silicon emulsion; mixing the powder paint precursor, the silicon emulsion, processing auxiliaries and water to obtain the inorganic interior wall paint. The applied inorganic paint powder is at least composed of at least one of montmorillonite, kaolin, bentonite and attapulgite. The preparation method of the inorganic interior wall paint can improve the stability, and under the premise of ensuring the advantage of high environmental protectionproperty, can avoid aggregation to further improve the application performance.

Owner:杭州琻泰环境科技有限公司

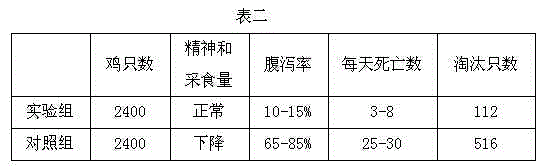

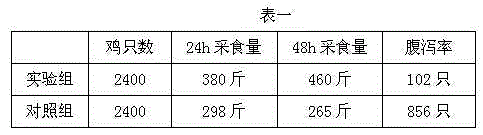

Compound fermented traditional Chinese medicine for preventing and treating chicken salmonellosis

InactiveCN104547187AGood antibacterial performanceImprove immunityAntibacterial agentsDigestive systemFermentationDiarrhea

The invention discloses a compound fermented traditional Chinese medicine for preventing and treating chicken salmonellosis. The compound fermented traditional Chinese medicine is prepared from the following components in parts by weight: 45-60 parts of Chinese pulsatilla root, 20-40 parts of atractylodes macrocephala, 10-30 parts of coptis, 10-30 parts of phellodendron amurense, 5-15 parts of clove, 5-20 parts of agastache, 40-60 parts of dandelion, 10-30 parts of radix sophorae flavescentis, 2-15 parts of gentian, 10-30 parts of purslane, and 5-20 parts of radix paeoniae alba. The traditional Chinese medicine composition is prepared by the following steps: smashing the components in ultrasound; adding fermented culture medium and compound bacteria liquid; conducting enclosed anerobic fermentation at 36-37 DEG C for 12-14 h; adding a stabilizer in the fermented product; conducting vacuum low-temperature drying. The traditional Chinese medicine composition prepared from microbe fermentation acts with the microbe, is converted into components easy to be ingested and utilized by bodies, accelerates treating speed, improves curative effect, and micro-ecology environment of bodies, improves animal food return rate and performance trait, is used for preventing and treating chicken salmonellosis, can effectively relieve the symptom of diarrhea of chicken, eliminates or remarkably relieves inflammatory pathological injury of gastrointestinal tracts and cloaca, relieves potential safety hazards caused by chemical drugs, and improves safety of pharmacy.

Owner:河南天纳图生物科技有限公司

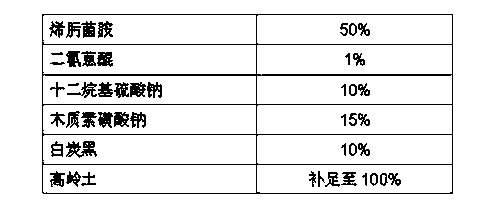

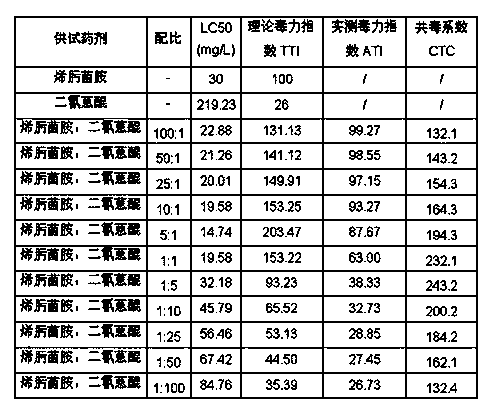

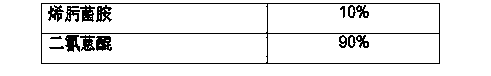

Bactericidal composition

ActiveCN105475357ADelay drug resistanceHigh bactericidal activityBiocideFungicidesFluopicolideSulfate

The invention provides a bactericidal composition comprising active components of fluopicolide and copper calcium sulfate with a weight ratio of 1:100-100:1. According to the invention, fluopicolide and copper calcium sulfate are subjected to binary compounding, such that the composition has a significant synergistic effect in controlling crop diseases caused by fungi and bacteria. With binary compounding, bactericidal spectrum is expanded; the doses of the two components are reduced; and the risk of pathogen drug resistance is reduced.

Owner:JIANGSU ROTAM CHEM

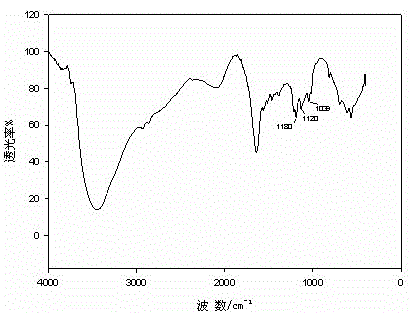

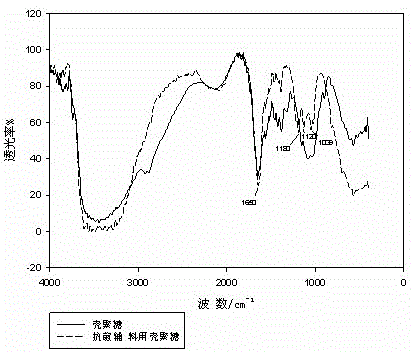

Production method of silk bamboo cotton towel

InactiveCN101113545AAvoid damageLuxury appearanceFibre treatmentWoven fabricsCellulose fiberEngineering

The invention discloses a manufacturing method of a silk-bamboo-cotton towel, comprising cotton blending, spinning, bleaching and dyeing, post-treatment, and sewing and classification. The method is characterized in that: 1) cotton blending: wherein, spun silk accounts for 22 percent of the total weight of blending cotton, bamboo fibre accounts for 36 percent, cotton fiber accounts for 42 percent; 2) spinning: after spinning, the cotton fiber is distributed in the outer layer, the spun silk is distributed in the middle, and the bamboo fibre is distributed in the inmost layer; 3) bleaching and dyeing technology processing; 4) post-treatment: a hydrophilic softener is adopted for post-treatment. The invention solves the problems of bleaching, dyeing and post-treatment technologies of blending products, in particular to that of the blending products of protein fiber and cellulose fiber, and solves the contradict that a technique being suitable for processing cotton can damage silk fiber and a technique being suitable for processing silk can not ensure the water absorption of cotton.

Owner:LOFTEX CHINA LTD

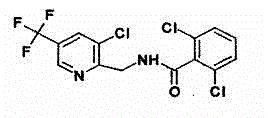

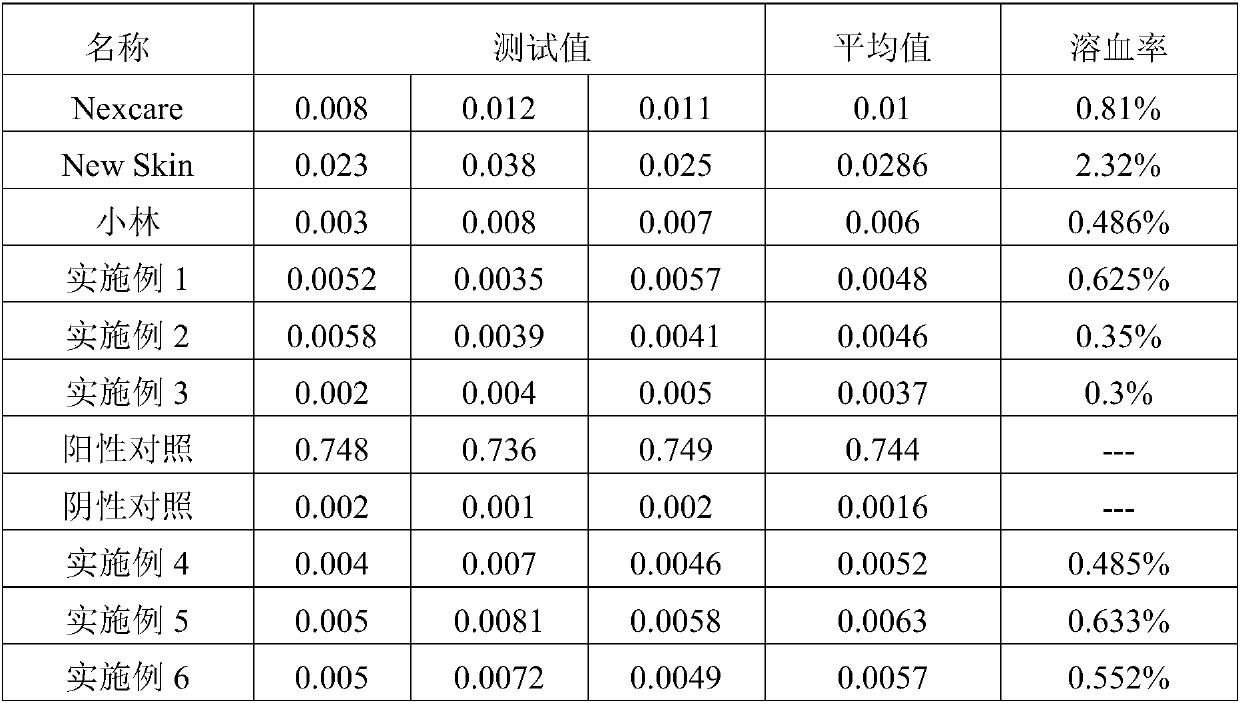

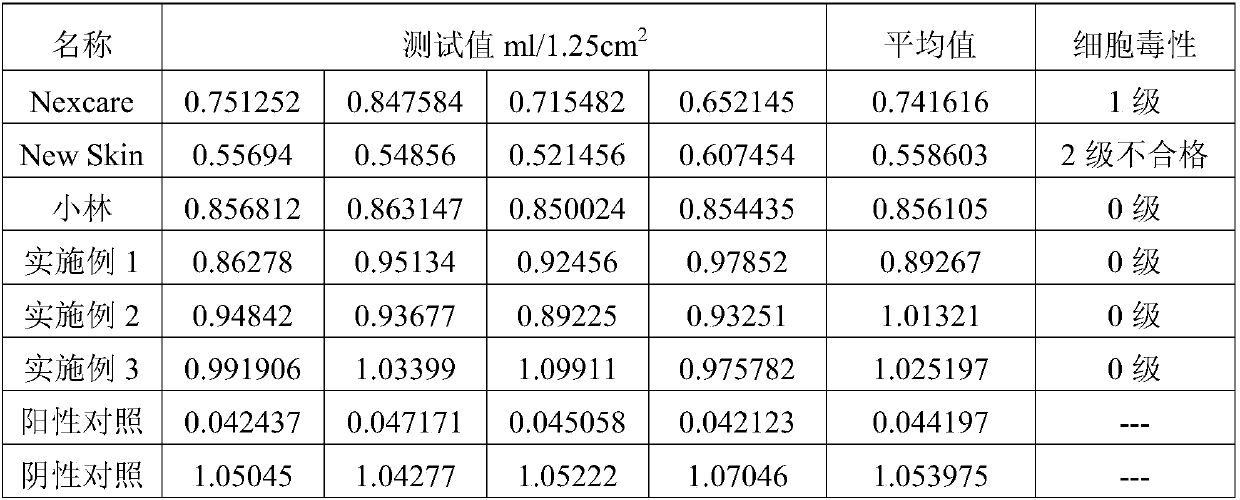

Liquid band-aid and preparation method thereof

InactiveCN107693840AImprove protectionAvoid water resistanceBandagesSurgical operationBioactive glass

The invention provides a liquid band-aid and a preparation method thereof. The liquid band-aid consists of a film-forming agent, a solvent and bio-active glass. According to an embodiment, the liquidband-aid provided by the invention has functions of preventing wound infection, protecting wounds and water-proofing; and the liquid band-aid is applicable to protection of scratched and surgically sutured sites, skin allergy, scratched hangnails, cracks, chapped skin, small tool marks, scratched parts due to mosquito bites, rapid removal of blood crusts, scars and the like.

Owner:BEIJING NATON INST OF MEDICAL TECH CO LTD +1

Self-sterilizing aviation paper-plastic composite garbage bag and preparation method thereof

InactiveCN107364214AHigh mechanical strengthGood antibacterial performanceBio-packagingRefuse receptaclesAviationMolded pulp

The invention discloses a self-sterilizing aviation paper-plastic composite garbage bag and a preparation method thereof. The preparation method comprises: (1) pounding raw wood pulp, bamboo leaves, pine leaves and other components, mixing the pounded components and lime water, mixing, cooking to obtain a paper pulp, washing the paper pulp, bleaching, beating, taking out the paper, carrying out pressing drying, and baking the paper to prepare antibacterial paper M1; (2) mixing a polycarbonate resin, a phenol formaldehyde resin and other components, carrying out heat treatment to obtain a melt M2, extruding, molding, and processing to form a film M3; and (3) heating the film M3, coating the surface of the antibacterial paper M1 to form a plastic layer so as to prepare composite paper, and processing the composite paper into the self-sterilizing aviation paper-plastic composite garbage bag. According to the present invention, the prepared self-sterilizing aviation paper-plastic composite garbage bag has advantages of good mechanical strength and good antibacterial performance, such that the long-term sterile use of the garbage bag in aviation can be ensured.

Owner:WUHU BLUE SKY ENG PLASTIC CO LTD

A kind of chitosan hydrogel for antibacterial dressing and preparation method thereof

InactiveCN103920180BGood antibacterial performanceNo drug resistance problemAbsorbent padsBandagesCross-linkPolyhexamethyleneguanidine hydrochloride

The invention discloses a chitosan hydrogel for an antibacterial dressing and a preparation method thereof. The chitosan hydrogel for the antibacterial dressing comprises, by weight, 2 to 6 parts of chitosan, 5 to 20 parts of a water-soluble monomer, 1 to 5 parts of an antibacterial agent polyhexamethyleneguanidine hydrochloride, 0.015 to 0.1 part of a cross-linking agent, 1 to 5 parts of a condensing agent, 1 to 5 parts of an activator, 0.1 to 0.5 part of an initiator and 109 to 145 parts of dimethyl sulfoxide. The preparation method comprises the following steps: introducing a carboxyl group on chitosan in the manner of free radical polymerization; subjecting the carboxyl group introduced on chitosan and the antibacterial agent polyhexamethyleneguanidine hydrochloride to an amidation reaction by using the condensing agent and the activator; and uniformly mixing chitosan for the antibacterial dressing with the cross-linking agent and pouring an obtained mixture into a die for a reaction so as to obtain the hydrogel with good drug resistance, good antibacterial property, a lasting antibacterial effect, high water absorption and good mechanical properties.

Owner:SHANGHAI INST OF TECH

Vortex-spun antibacterial medical yarn

InactiveCN111218740AImprove breathabilityGood air permeability, good antibacterial and deodorizing propertiesYarnYarnPolymer science

The invention discloses a vortex-spun antibacterial medical yarn. The vortex-spun antibacterial medical yarn comprises a yarn body; the yarn body is of a sheath-core structure; the yarn body is a hollow yarn, the interior is provided with a hollow yarn core, and the yarn body is provided with a bamboo charcoal fiber layer, a coffee carbon fiber layer and a colored cotton fiber layer in sequence from inside to outside in the radial direction of the yarn body; the hollow yarn core of the yarn body is formed by hydrolyzing a core yarn prepared from water-soluble polyvinyl alcohol fibers; the bamboo charcoal fiber layer is formed by spiraling natural bamboo fibers; the bamboo charcoal fiber layer is filled with silver nanoparticles; the coffee carbon fiber layer is formed by spirally coating the bamboo charcoal fiber layer with coffee carbon fibers; and the colored cotton fiber layer is formed by spirally coating the coffee carbon fiber layer with colored cotton fibers. The vortex-spun antibacterial medical yarn adopts the hollow yarn structure, is internally provided with the bamboo charcoal fiber layer and the coffee carbon fiber layer, has super softness and super fluffiness, and isgood in heat retention property and air permeability, good in bacteria resistance and deodorization performance, bright in color, dyeing-free, environment-friendly and energy-saving.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

Production method of medical artificial skin

InactiveCN107362393ASimple production processEasy and practical to processProsthesisEnvironmentally friendlyOrganic solvent

The invention discloses a production method of a medical artificial skin. The method comprises the following steps: according to steps A-E, feeding a component A and a component B of injecting and forming liquid silicone rubber according to a certain mass ratio under a certain condition, separately mixing the component A and the component B with purified water uniformly at first, then mixing the component A and the component B uniformly under a certain condition, feeding the mixture into a slobbering machine and carrying out slobbering film forming, curing and evaporating at the specifically selected temperature and for a specifically selected time, and then carrying out steps such as puncturing, slitting and rolling to obtain the finished medical artificial skin. The method is simple, convenient and practical, is short in preparation period and high in efficiency, does not use organic solvents in a production process, is safe and environmentally friendly, meanwhile can provide a wet environment for a wound to facilitate healing of the wound, and is not adhered to the wound when used, so that pain of a patient when the medical artificial skin is changed is relieved; and moreover, the produced medical artificial skin is good in resistance of bacteria and breathability.

Owner:江西高大生物医疗科技有限公司

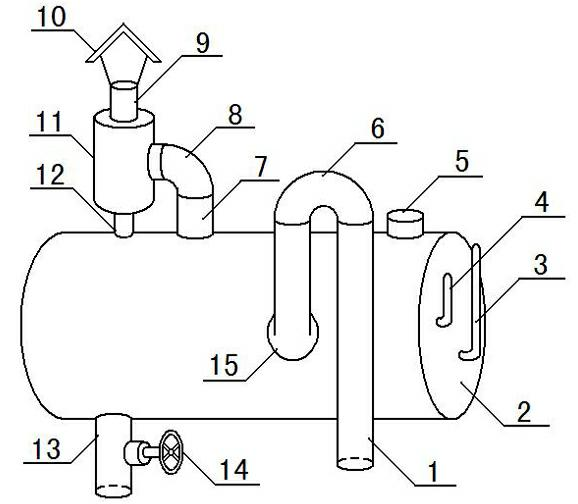

Novel chimney purifier

InactiveCN102085442AAchieve purificationEasy to handleUsing liquid separation agentBlowoff valveReflux

A novel chimney purifier relates to a chimney environmental protection purifier, and purifying liquid is stored in a gas dissolving tank which is provided with a liquid feeding port, an exhaust gas inlet pipe and a mist outlet duct, wherein the mist outlet duct is arranged at upper portion of the gas dissolving tank, the mist outlet duct leads to a mist purification pot which is provided with an air purification pipe at top and a residual liquid reflux pipe at bottom. The residual liquid reflux pipe leads to the gas dissolving tank; the bottom of the gas dissolving tank is provided with a discharge pipe; and the top of the discharge pipe is provided with a blowoff valve. In addition, the interface of the exhaust gas inlet pipe in the gas dissolving tank is arranged under the liquid level; the highest location of the exhaust gas inlet pipe exceeds the liquid level in the gas dissolving tank; and the purifying liquid is edible vinegar. The invention possesses the following substantial effects: the novel chimney purifier is arranged in the central section of a chimney to treat exhaust gas effectively, and possesses functions of dust removal, and smoke elimination. The invention possesses simple structure, low production cost and use cost, and convenience for design, making, and popularization.

Owner:张合存

Bactericidal plastic-wood material composition, bactericidal plastic-wood product and production method of bactericidal plastic-wood product

InactiveCN106009981AGood antibacterial performanceImprove the use environmentAntifouling/underwater paintsPaints with biocidesEmulsionPolyvinyl acetate

The invention discloses a bactericidal plastic-wood material composition, a bactericidal plastic-wood product and a production method of the bactericidal plastic-wood product. The composition comprises a plastic-wood matrix and bactericidal coating applied to the outer surface of the plastic-wood matrix. The bactericidal coating comprises water, polyvinyl acetate emulsion, poly(vinyl alcohol), ethylene glycol, nanosilicon dioxide, CMIT and sodium benzoate. Specifically, to 100 parts of water by weight, there are 30-70 parts of polyvinyl acetate emulsion, 10-30 parts of poly(vinyl alcohol), 20-50 parts of ethylene glycol, 5-15 parts of nanosilicon dioxide, 0.1-2 part of CMIT and 0.1-1 part of sodium benzoate. According to the design, the composition is bactericidal; and invasion of bacteria to the composition is weak even in an environment full of bacteria.

Owner:芜湖昊轩环保新材料有限公司

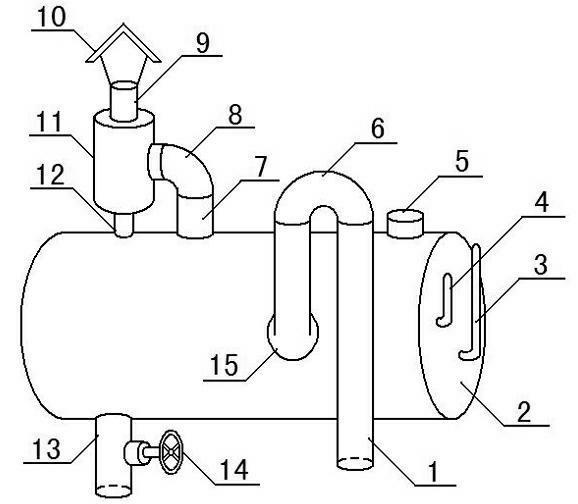

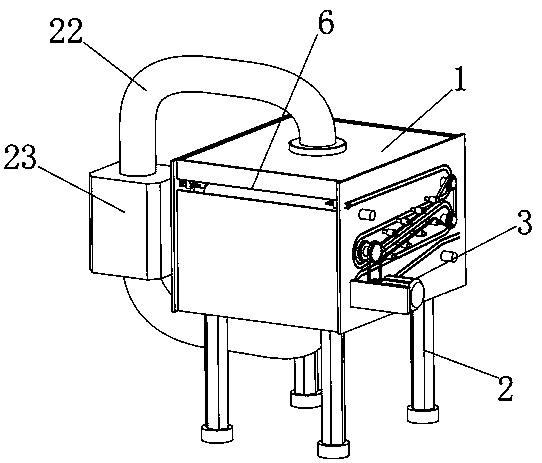

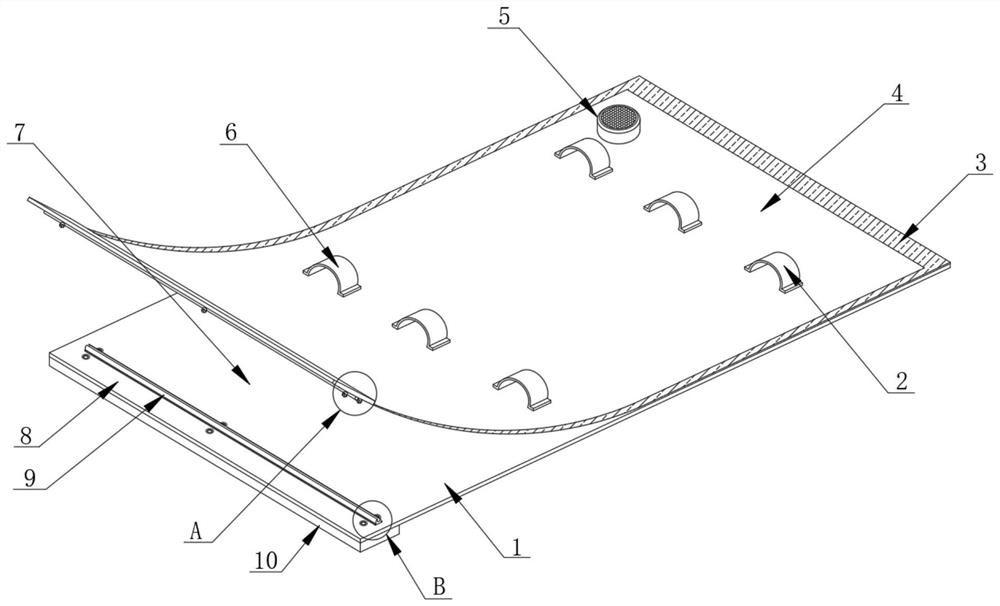

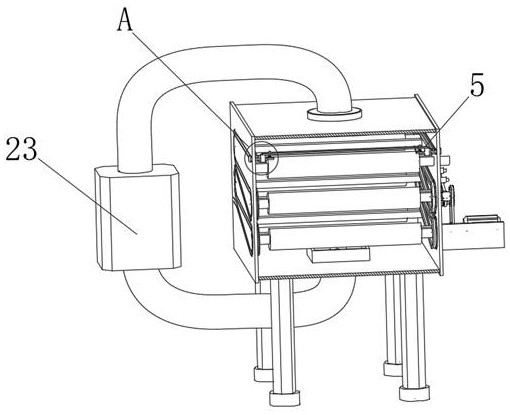

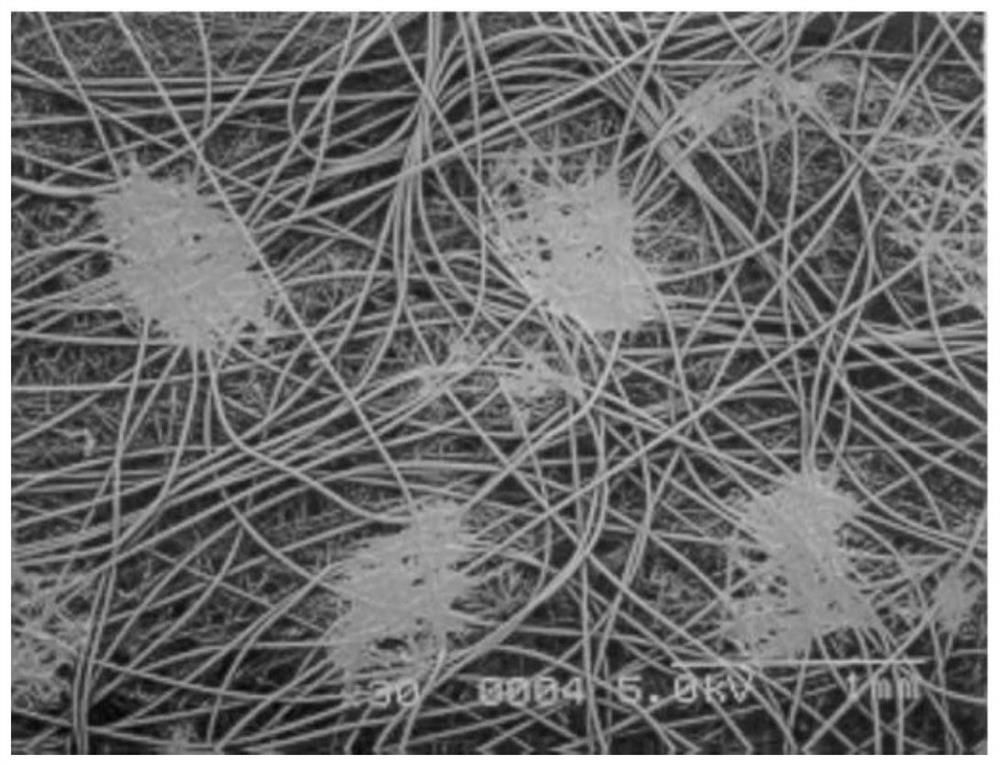

Micro-aperture medical packing paper surface drying device and slurry proportion and beating process

ActiveCN110205857AImprove breathabilityAdd channelPulp beating methodsPaper/cardboardPorosityScanning electron microscope

The invention discloses a micro-aperture medical packing paper surface drying device and slurry proportion and beating process. Coniferous wood and hardwood are used as main raw materials, wherein a fiber ratio of the coniferous wood to the hardwood is that the coniferous wood is 75%-85% and the hardwood is 15%-25%, the coniferous wood and the hardwood are separately beaten, microstructures of paper, raw materials and the like are timely analyzed through an imported scanning electron microscope, and then surface glue applying and drying operation are carried out. According to the invention, novel technical means are used to carry out in-depth analysis and research on products and raw materials in a research process, an advanced imported scanning electron microscope is introduced, fiber type selection is studied by means of determining the amount of porosity of paper through microstructure analysis of the paper, the raw materials and the like, and the consumption of hardwood fibers is increased by 6%-10%, thereby improving the uniformity of the pore size distribution of dialysis paper. The cumulative distribution of pore size range from 0.23 [mu]m to 3.2 [mu]m is more than 90%, andthe maximum pore size is less than 5.0 [mu]m, which can effectively block the penetration of bacteria.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

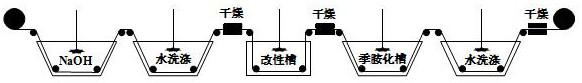

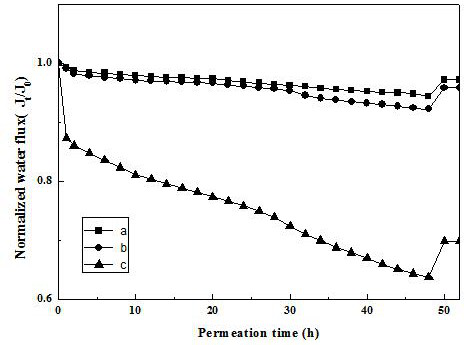

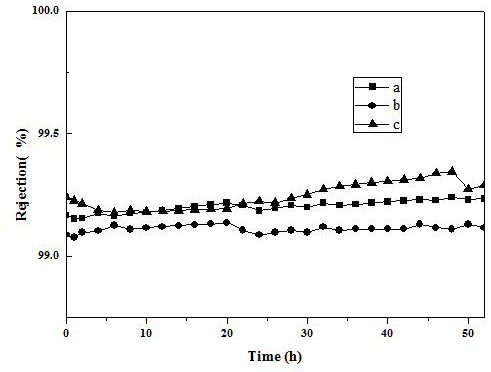

Preparation method of cellulose acetate reverse osmosis membrane surface-modified by quaternary ammonium salt

InactiveCN113171686ALow permeate flux attenuationExtended service lifeMembranesGeneral water supply conservationCellulose acetateReverse osmosis

The invention belongs to the field of functional modification of reverse osmosis membranes, and particularly relates to a preparation method of a cellulose acetate reverse osmosis membrane surface-modified by quaternary ammonium salt. The cellulose acetate reverse osmosis membrane surface-modified by quaternary ammonium salt integrates the advantages of reliability, high desalination characteristic, microbial erosion resistance and the like, has stable separation membrane process, low failure rate, a wider application scope, low main operation pressure, low energy consumption, large flux, high water yield, pollution resistance, stable operation, high desalination rate at high flow rate, high mechanical strength and long service life, can play a role under low operation pressure and can tolerate the influence of chemical or biochemical action. The quaternary amine group cellulose acetate reverse osmosis membrane is prepared by introducing quaternary amine groups, so the hydrolysis resistance and the oxidation resistance of the membrane are improved; and the membrane is positively charged by the quaternary amine groups, so the metal cation pollution resistance of the membrane is improved, and the quaternary amine group cellulose acetate reverse osmosis membrane has good practical and economic values.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

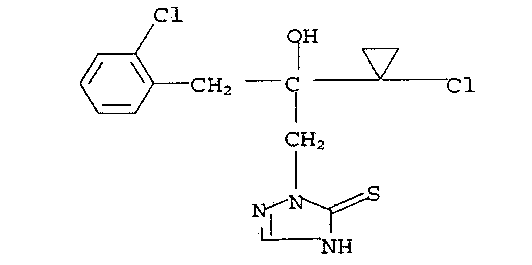

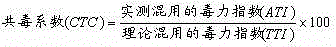

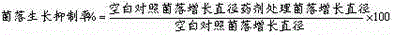

Plant disease preventing and treating composition

ActiveCN105076155AEffective microbicidal activityUninfectedBiocideFungicidesOrysastrobinPathogenic bacteria

The invention relates to a plant disease preventing and treating composition and also relates to a method for preventing and treating pathogenic bacteria of plants. The plant disease preventing and treating composition contains Orysastrobin represented by a formula I shown in the description and Tetraconazole, wherein the weight ratio of Orysastrobin to Tetraconazole is (1: 100) to (100: 1). Orysastrobin and Tetraconazole are subjected to binary compounding and act on the pathogenic bacteria and / or environment therefor, or the plants, plant parts, seeds, soil, areas, materials or spaces, so that the plant disease preventing and treating composition can be used for preventing and treating fungi and bacteria on cereals, beans, fruits, vegetables, cotton and ornamental plants and achieves the effect of synergism. The composition containing Orysastrobin and Tetraconazole can be used for treating seeds of plants needing protection.

Owner:JIANGSU ROTAM CHEM

Medical paper-plastic bag with high bacterial resistance

InactiveCN112793909AClosed tightlyAvoid the problem of weak gap bondingBagsSacksStructural engineeringProcess engineering

The invention relates to the technical field of medical paper-plastic bags, in particular to a medical paper-plastic bag with high bacterial resistance, a second surface layer is arranged above a first surface layer, three connected side edges of the first surface layer and the second surface layer are sealed through heat sealing edges, and openings are formed in the other side edges of the first surface layer and the second surface layer. The sealing device is novel in design, the environment-friendly effect can be achieved through repeated utilization, cost waste is reduced, the auxiliary sealing mechanism can enable an opening to be closed more tightly, the problem that gap bonding is not firm easily due to long-time opening and closing of mother and child sealing strips is solved, the sealing performance is improved, repeated use is convenient, internal gas can be emptied through the gas discharging mechanism, and the sealing effect is improved. And the stored instruments can be conveniently fixed through the object fixing assembly, the problem that bacteria enter the paper-plastic bag due to air leakage caused by the fact that the instruments pierce the paper-plastic bag is solved, and the overall bacterium blocking performance is improved.

Owner:安徽和美瑞医用包装材料有限公司

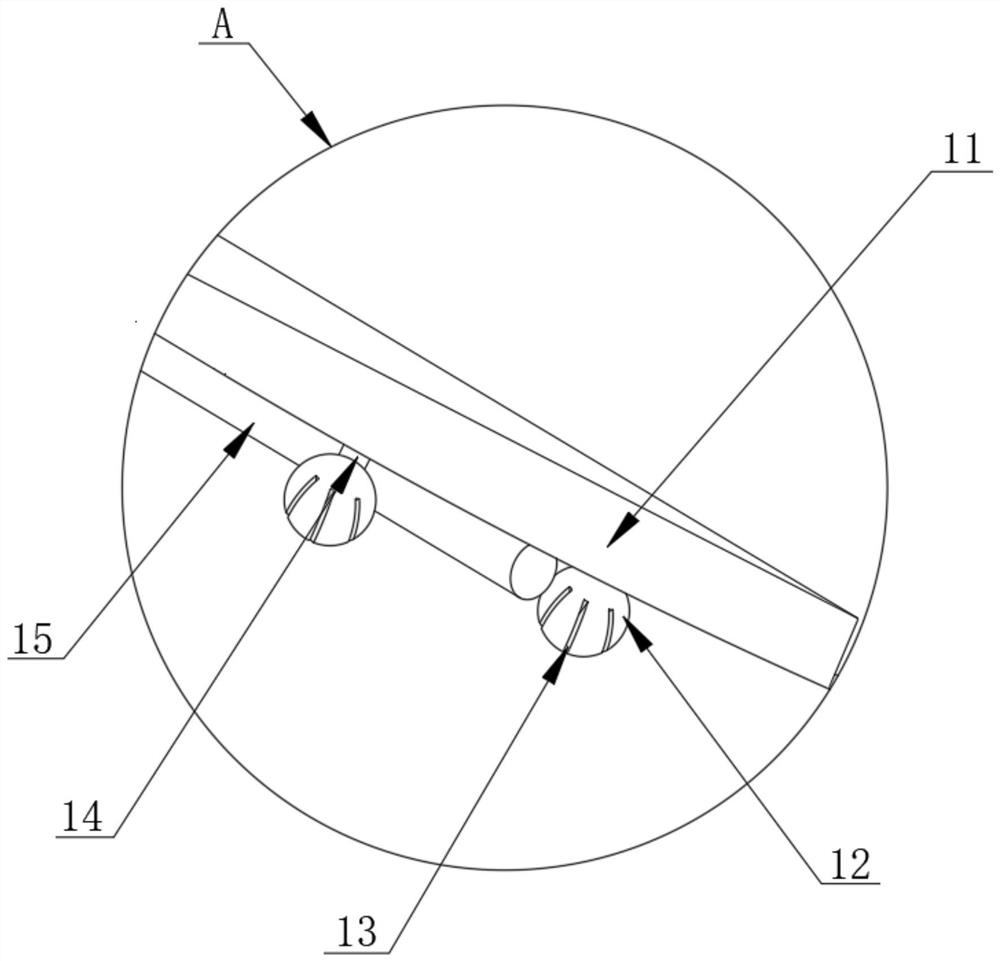

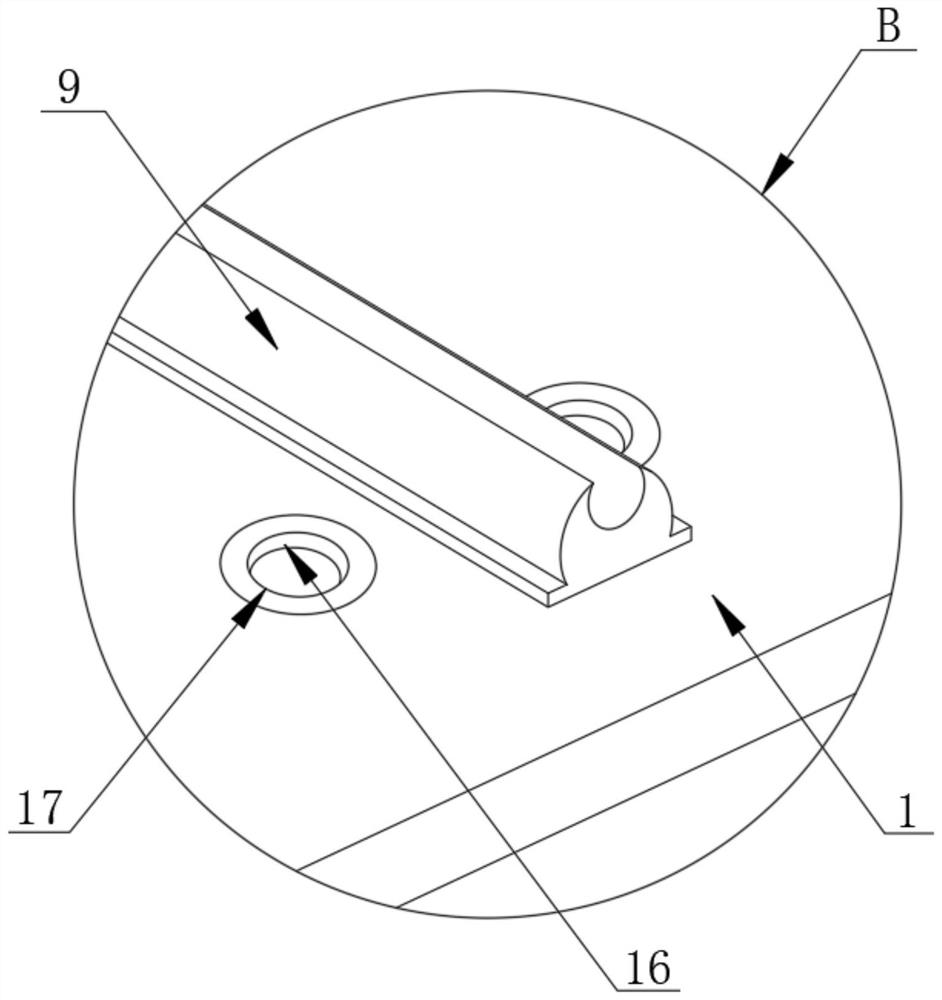

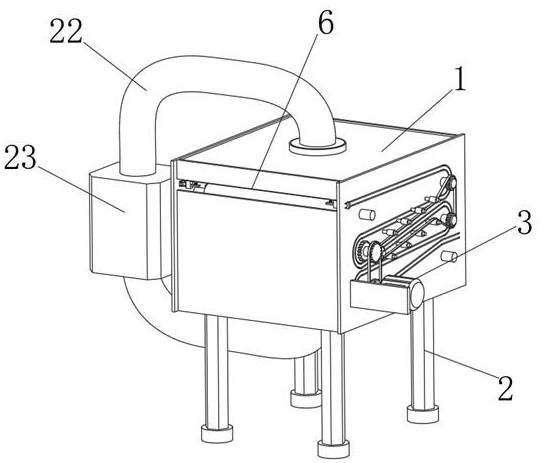

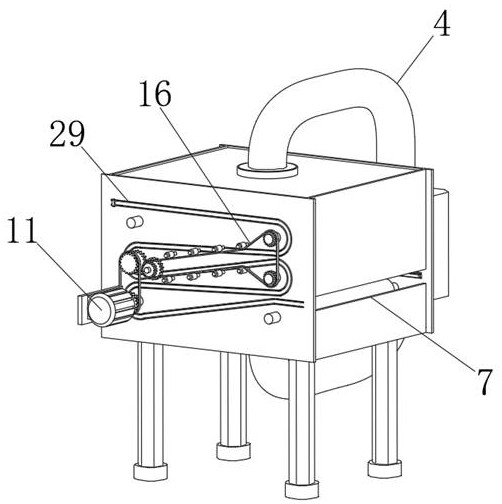

A microporous medical packaging paper surface drying device

The invention discloses a micro-aperture medical packaging paper surface drying device, which uses coniferous wood and broad-leaved wood as main raw materials, and the fiber ratio of leafy wood and broad-leaved wood is 75%-85% for coniferous wood and 15% for broad-leaved wood. %‑25%, and then separately beat the coniferous wood and hardwood raw materials, and analyze the microstructure of paper and raw materials through imported scanning electron microscopes in time, and then perform surface sizing and drying operations. This invention adopts new technology In-depth analysis and research on products and raw materials in the research process, the introduction of advanced imported scanning electron microscopes, through the microstructure analysis of paper, raw materials, etc., and the determination of paper porosity and other means to study fiber selection, the hardwood fiber The dosage has been increased by 6%-10%, thereby improving the uniformity of the pore size distribution of the dialysis paper. The cumulative distribution of the 0.23μm-3.2μm pore size range is more than 90%, and the maximum pore size does not exceed 5.0μm, which can effectively block the penetration of bacteria.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Bacterial cellulose composite dressing

ActiveCN103480028BGood biocompatibilityHigh biosecurityBiochemical fibre treatmentMicroorganism based processesWound dressingAntibiotic Y

Owner:钟春燕

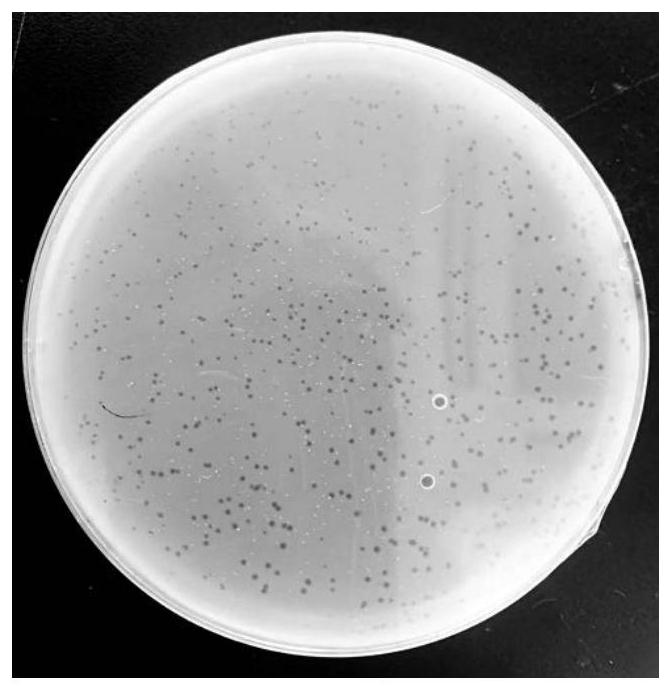

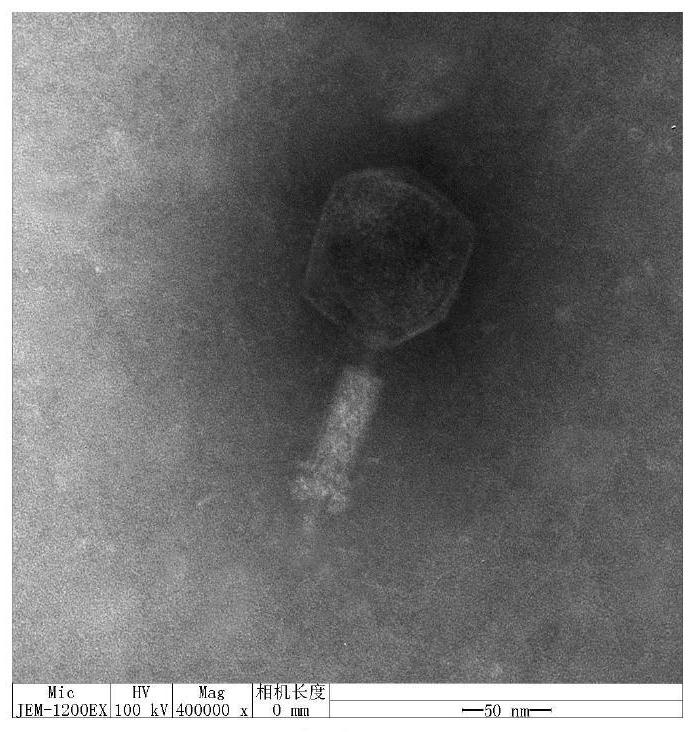

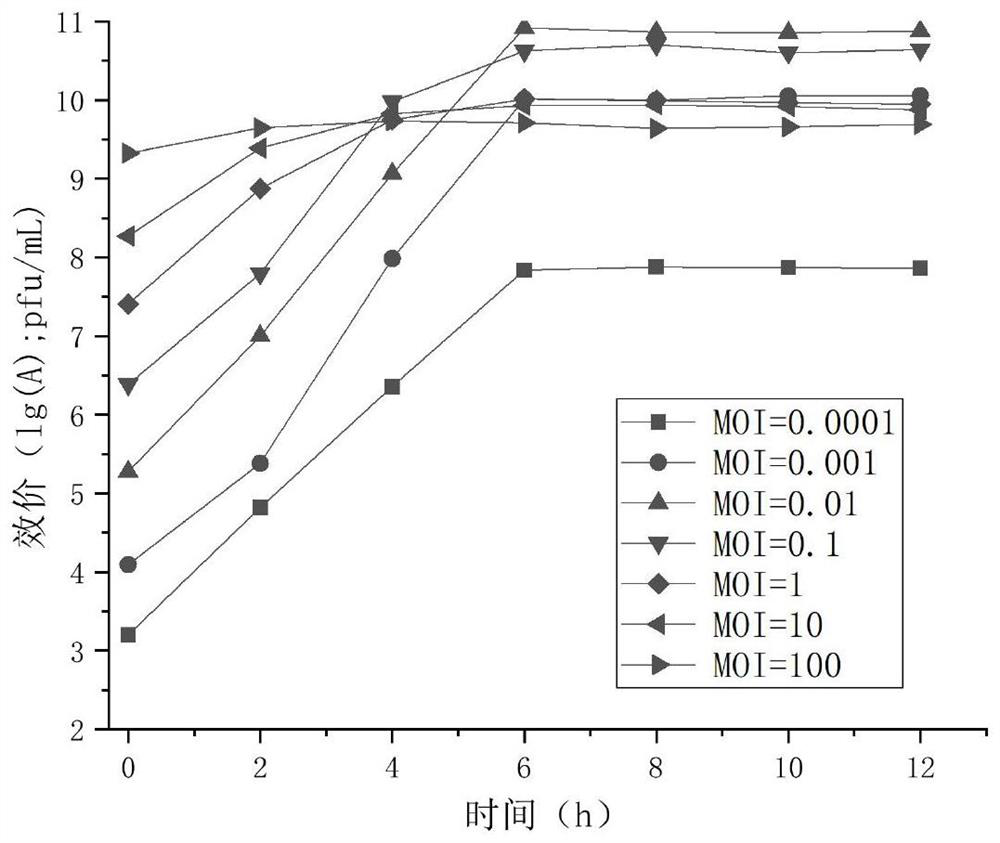

Vibrio alginolyticus bacteriophage GVA-P21 with high fermentation rate and lasting bacteriostasis and application thereof

PendingCN114703149AImprove fermentation rateHas cracking effectAntibacterial agentsViral/bacteriophage medical ingredientsVibrio alginolyticusVibrion

The invention provides a vibrio alginolyticus bacteriophage GVA-P21 with high fermentation rate and lasting bacteriostasis and application thereof, the preservation number of the vibrio alginolyticus bacteriophage is CCTCC NO: M20211480, and the vibrio alginolyticus bacteriophage is named as GVA-P21, the vibrio alginolyticus bacteriophage GVA-P21 is high in fermentation efficiency, when MOI is 0.01, the titer reaches 8.24 * 10 < 10 > PFU / mL after 6 h of culture, the cracking rate of 355 strains of pathogenic vibrio alginolyticus is as high as 95.5%, and the vibrio alginolyticus bacteriophage GVA-P21 can be used for preparing the vibrio The vibrio alginolyticus bacteriophage GVA-P21 has a long-time antibacterial effect on vibrio alginolyticus, and is more obvious than that of other bacteriophages on the vibrio alginolyticus, so that the vibrio alginolyticus bacteriophage GVA-P21 has good prevention and treatment effects on diseases caused by the vibrio alginolyticus in aquaculture.

Owner:武汉格瑞农生物科技有限公司

Production method of silk bamboo cotton towel

InactiveCN101113545BAvoid damageLuxury appearanceFibre treatmentWoven fabricsCellulose fiberEngineering

Owner:LOFTEX CHINA LTD

Preparation method of bacterial cellulose composite chitosan moist antimicrobial dressing

ActiveCN103120803BMaintain the three-dimensional nano-network structureHigh mechanical strengthAbsorbent padsNon-woven fabricsAnhydrous ethanolMedical equipment

The invention discloses a preparation method of a bacterial cellulose composite chitosan moist antimicrobial dressing, and relates to medical equipment and the technical field of a preparation of the medical equipment. The preparation method comprises the following steps that a seed mash prepared from activating a strain is dropped on a non-woven fabric or a woven fabric, and a small amount of fermentation culture media are added to be cultured for 12 to 48 hours, then the fermentation culture media are supplemented, and culturing is carried out for 3 to 6 days, and a fermentation product is taken out, the fermentation product is purified to obtain a bacterial cellulose composite non-woven fabric or a woven fabric membrane material, and an electrostatic spinning method is used for ejecting a chitosan solution from a spinneret, trickles of the ejected chitosan solution are ejected to the bacterial cellulose composite non-woven fabric or the woven fabric membrane material containing anhydrous ethanol and / or water, finally the bacterial cellulose composite chitosan moist antimicrobial dressing is obtained after the bacterial cellulose composite non-woven fabric or the woven fabric membrane material containing anhydrous ethanol and / or water is treated. The preparation method disclosed by the invention is simple and easy in preparation processes, convenient to operate, and low in cost, and the prepared moist antimicrobial dressing can cure chronic unhealed traumas, pressure acute refractory wounds, burns, and a large area of soft tissue defects and / or infections.

Owner:钟春燕

Bactericide composition and application thereof

ActiveCN103704214AGood fungicidal performanceGood antibacterial performanceBiocidePlant growth regulatorsFruit treeActive component

The invention provides a bactericide composition and application thereof and relates to a bactericide composition containing SYP-1620 and dithianon and application thereof. The bactericide composition contains active components including the SYP-1620 and the dithianon in a weight ratio of 1:100 to 100:1. According to the bactericide composition and the application thereof, the SYP-1620 and the dithianon are subjected to binary compounding so that the bactericide composition has a synergistic bactericide effect and particularly has protruding prevention effects on scab, anthracnose, brown leaf rust and gummy stem blight of wheat, rice, fruit trees, vegetables and flower crops. Meanwhile, the composition of the SYP-1620 and the dithianon can be used for improving the content of chlorophyll of crops.

Owner:JIANGSU ROTAM CHEM

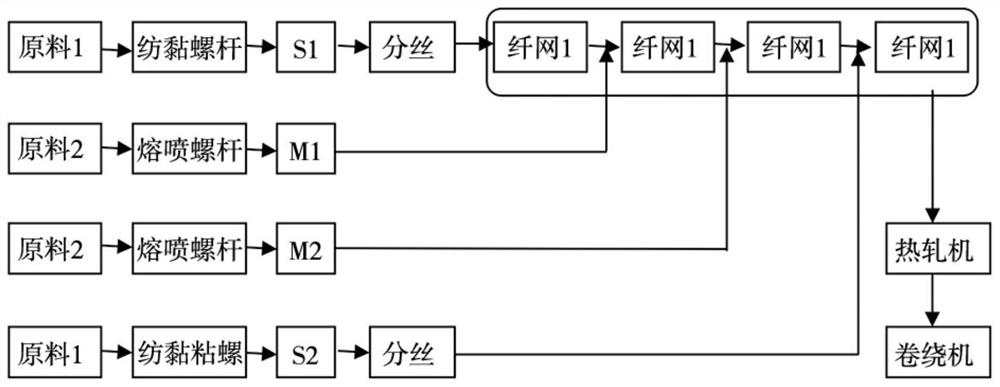

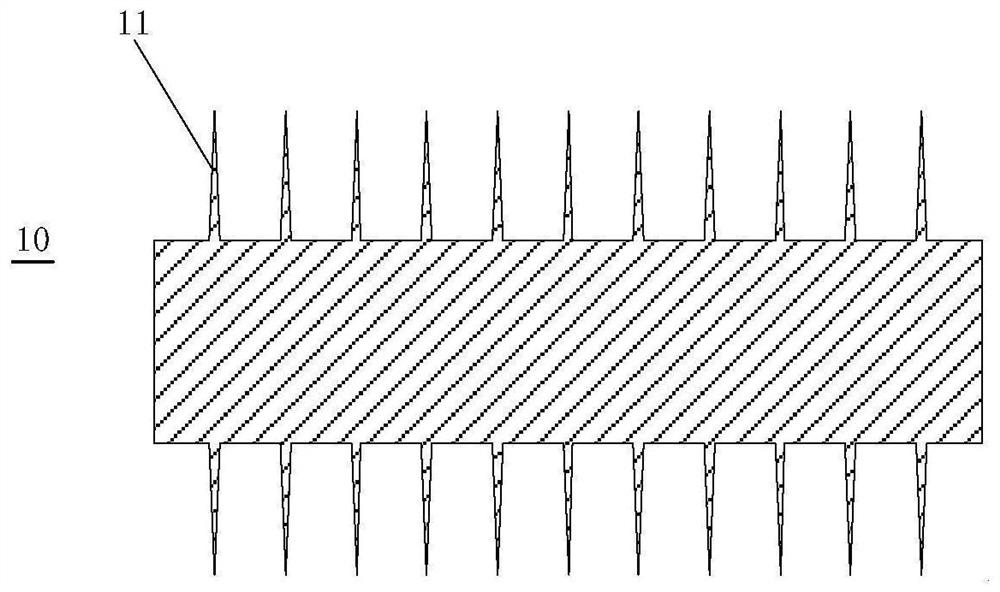

Medical non-woven material free of bag breaking and high bacterium blocking performance and preparation method thereof

PendingCN114016211AIncrease the strength of vertical and horizontal bondingImprove uniformitySynthetic resin layered productsFilament/thread formingFiberPolymer science

The invention discloses a medical non-woven material free of bag breaking and high in bacterium blocking performance and a preparation method thereof, and relates to the technical field of medical fiber materials, and the preparation method of the medical non-woven material comprises the steps: spunbond cloth is prepared; after a melt-blown raw material melt is placed in a conical annular airflow gap formed by inner ring airflow and outer ring airflow, the melt-blown raw material melt is treated through a texturing treatment space to form melt-blown multi-fluff fibers, the melt-blown multi-fluff fibers are evenly received, and melt-blown cloth is obtained; the spunbond cloth and the melt-blown cloth are placed according to a preset sequence and subjected to hot rolling reinforcement, and the medical non-woven material is obtained; and the medical non-woven material is cut by a cutter and then rolled into a coiled material. The material has the advantages of no bag breakage and high bacteria resistance.

Owner:北京熵图医疗科技合伙企业(有限合伙) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com