Method for preparing finishing agent of modified nano titanium dioxide coating layer of electromagnetic shielding fabric

A nano-titanium dioxide, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, dyeing organosilicon compound treatment, electrical components, etc., can solve the problems that restrict the development of such textiles, and achieve excellent antibacterial and anti-ultraviolet effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, the copper-plated electromagnetic shielding fabric produced by Sanyuan Electronic Technology Co., Ltd. is used as the base material, and the preparation process is as follows:

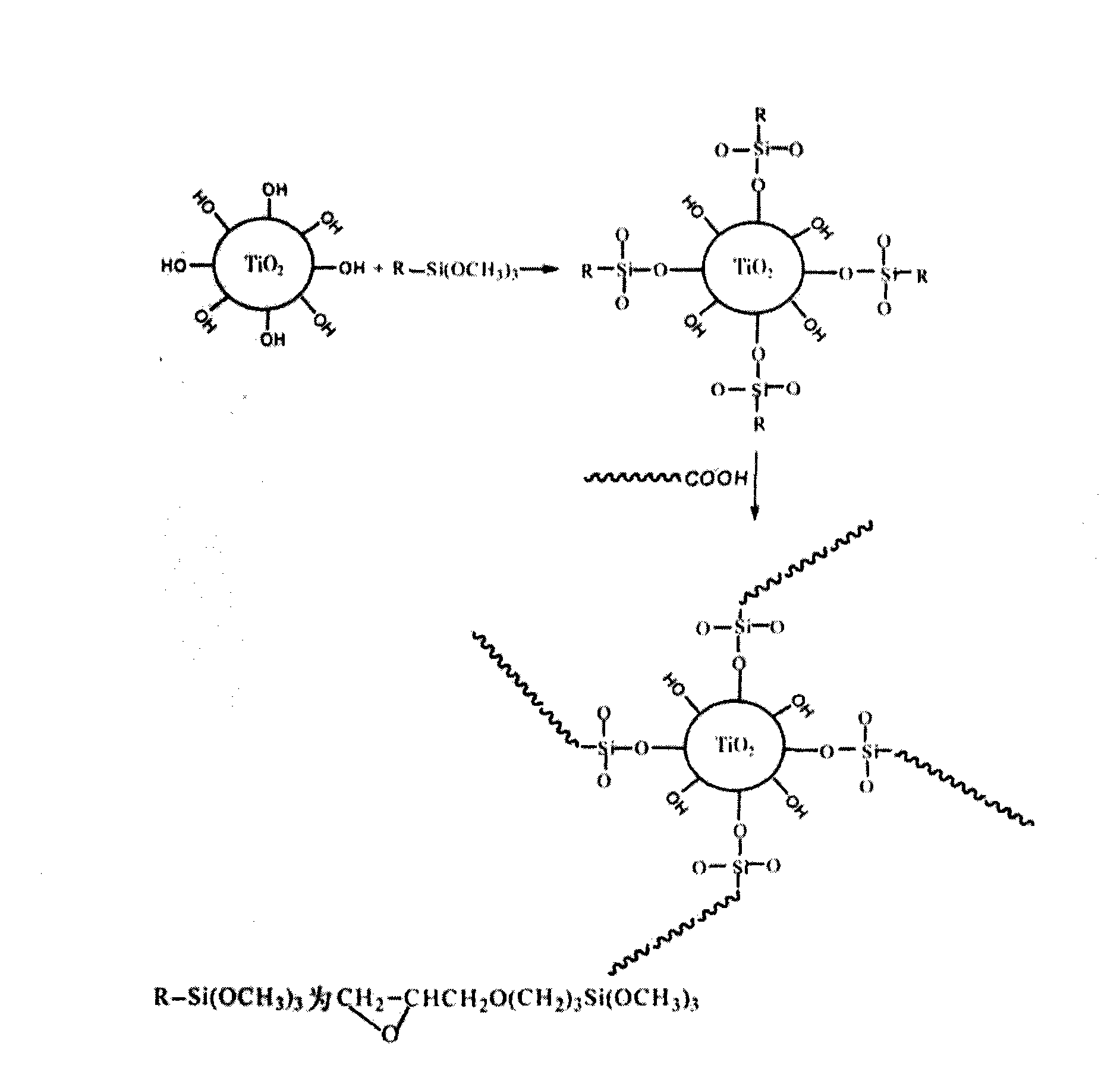

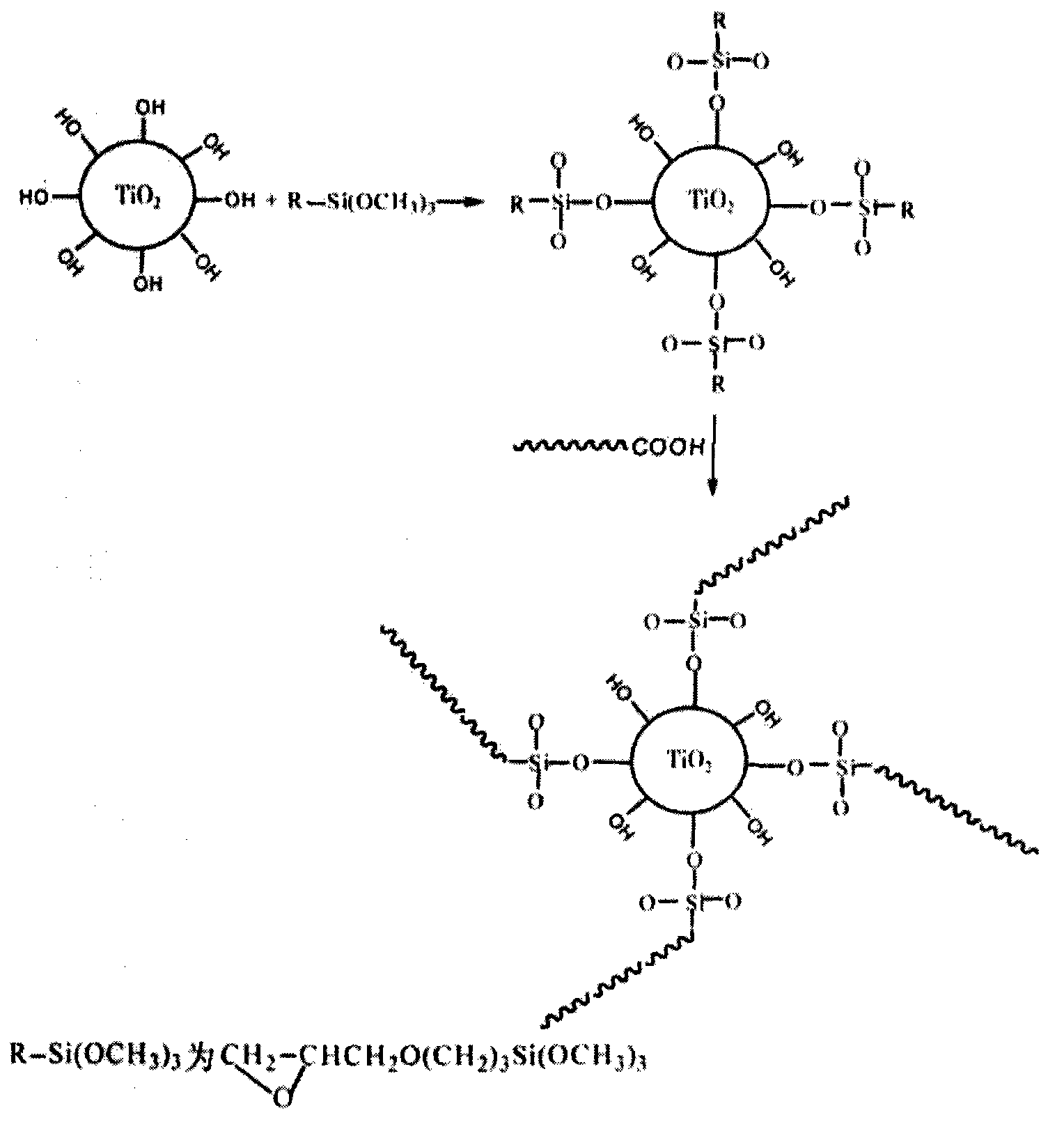

[0021] 1. Add 5 ml of γ-aminopropyltriethoxysilane (silane coupling agent KH-550) to 200 ml of ethanol, adjust the pH of the solution to 4 with acetic acid, stir for 20 minutes, and mix 15 grams of TiO below 20nm 2 Add the powder into it, and carry out strong mechanical stirring at the same time. After 2 hours of reaction, filter the powder out of the solution and dry it. Grind the powder obtained above, add it to ethanol and keep stirring, heat the solution to 80°C in a water bath, then add 0.6 g of stearic acid, react for 2 hours, filter and take out the powder, and dry it, that is A modified nano-titanium dioxide is obtained.

[0022] 2. Proportioning by weight of 98% water-based polyurethane and modified nano-titanium dioxide 2%, mix well to obtain the modified nano-titani...

Embodiment 2

[0027] In this example, the nickel-plated electromagnetic shielding fabric produced by Sanyuan Electronic Technology Co., Ltd. is used as the base material, and the preparation steps are as follows:

[0028] 1. Add 4 ml of γ-glycidyl etheroxypropyl trimethoxysilane (silane coupling agent KH-560) to 150 ml of ethanol, adjust the pH of the solution to 5, stir for 15 minutes, and then mix 10 g TiO with particle size less than 20nm 2 Add the powder into it, and carry out strong mechanical stirring at the same time. After reacting for 1.5 hours, filter the powder out of the solution and dry it. Grind the powder obtained above, add it to ethanol and keep stirring, heat the solution to 60°C through a water bath, then add 0.3 stearic acid, react for 1.5 hours, filter and take out the powder, and dry it to obtain Modified nano titanium dioxide.

[0029] 2. Mix 93% latex resin, 5% modified nano-titanium dioxide, and 2% melamine by weight to obtain the modified nano-titanium dioxide co...

Embodiment 3

[0033] In this example, the silver-plated electromagnetic shielding fabric produced by Sanyuan Electronic Technology Co., Ltd. is used as the base material, and the preparation steps are as follows:

[0034] 1. Add 8 ml of γ-methacryloxypropyl trimethoxysilane (silane coupling agent KH-570) to 200 ml of ethanol, adjust the pH of the solution to 3, stir for 30 minutes, and mix 18 g TiO with particle size less than 20nm 2 Add the powder into it, and carry out strong mechanical stirring at the same time. After 2 hours of reaction, filter the powder out of the solution and dry it. Grind the powder obtained above, add it to ethanol and keep stirring, heat the solution to 70°C in a water bath, then add stearic acid, react for 2 hours, filter and take out the powder, and dry to obtain the modified nano Titanium dioxide.

[0035] 2. Mix 94% polyester resin, 4% modified nano-titanium dioxide, and 2% isocyanate by weight to obtain the modified nano-titanium dioxide coating finishing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com