Antibacterial master batch and antibacterial plastic

An antibacterial masterbatch, antibacterial plastic technology, applied in the direction of single-component polyolefin rayon, single-component polyester rayon, fiber chemical characteristics, etc., can solve the problem of poor chemical stability, poor heat resistance, easy antibacterial ingredients. Decomposition and other problems to achieve the effect of inhibiting activity and killing bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

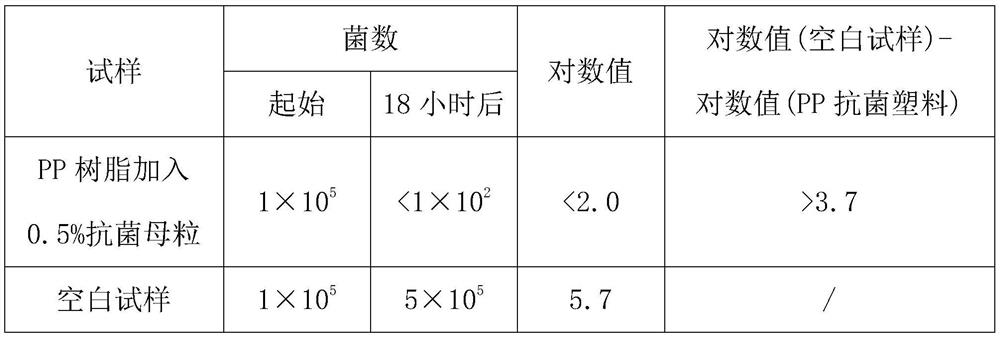

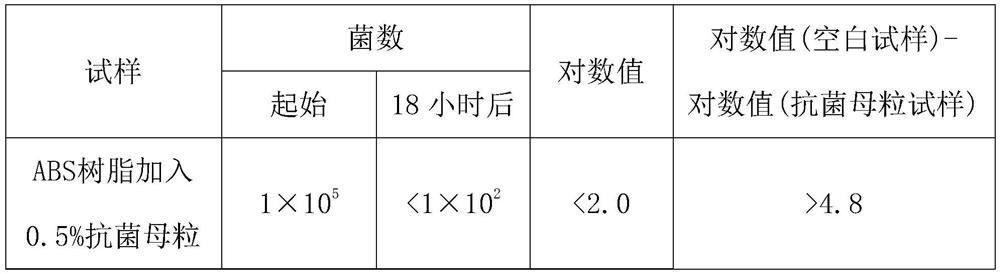

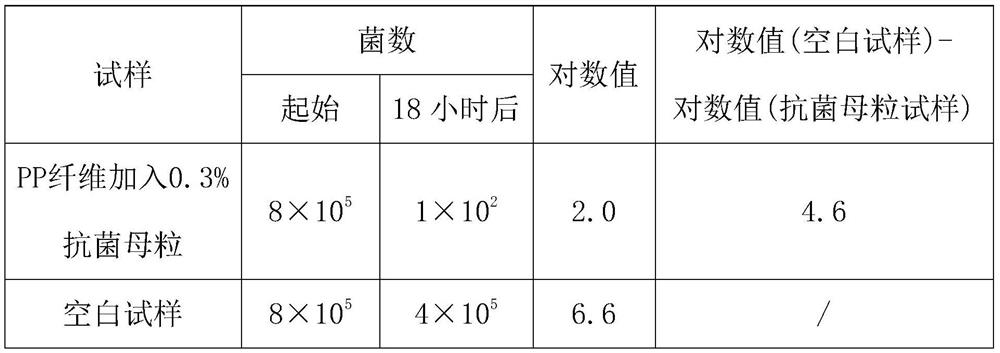

Examples

Embodiment 1

[0025] This embodiment provides an antibacterial masterbatch, which includes the following components in parts by weight: 3 parts of silver-loaded antibacterial agent, 2 parts of dispersant, 1 part of nano-ultraviolet absorber, 3 parts of nano-titanium dioxide, and 35 parts of carrier resin.

[0026] Wherein the nano-titanium dioxide is porous titanium dioxide, the nano-ultraviolet absorber is a benzotriazole-type ultraviolet absorber, and the silver-loaded antibacterial agent is AG300 antibacterial agent of Japan East Asia Synthetic Chemical Company.

[0027] The preparation process of the above antibacterial masterbatch is as follows: Weigh each component by weight, first add porous titanium dioxide and nano-ultraviolet absorber to a high-speed mixer and mix evenly, then add silver-loaded antibacterial agent, dispersant and carrier to the high-speed mixer The resin is evenly stirred, and finally the evenly stirred semi-finished product is extruded, drawn, and pelletized with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com