Patents

Literature

170results about How to "Industrial applicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic transaction verification system

InactiveUS20050097037A1Inhibitory activityIndustrial applicabilityElectric signal transmission systemsDigital data processing detailsBiometric dataSmart card

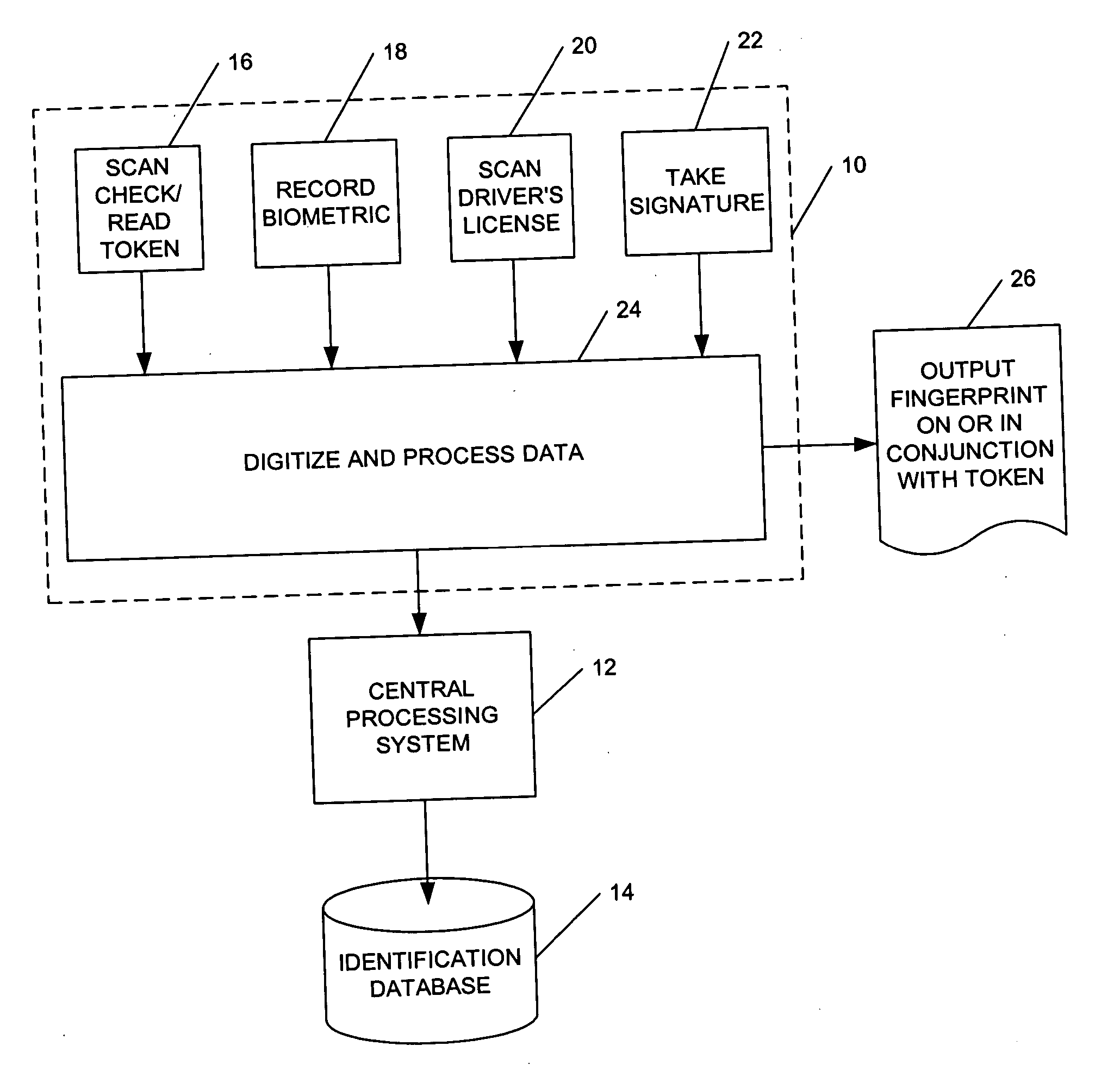

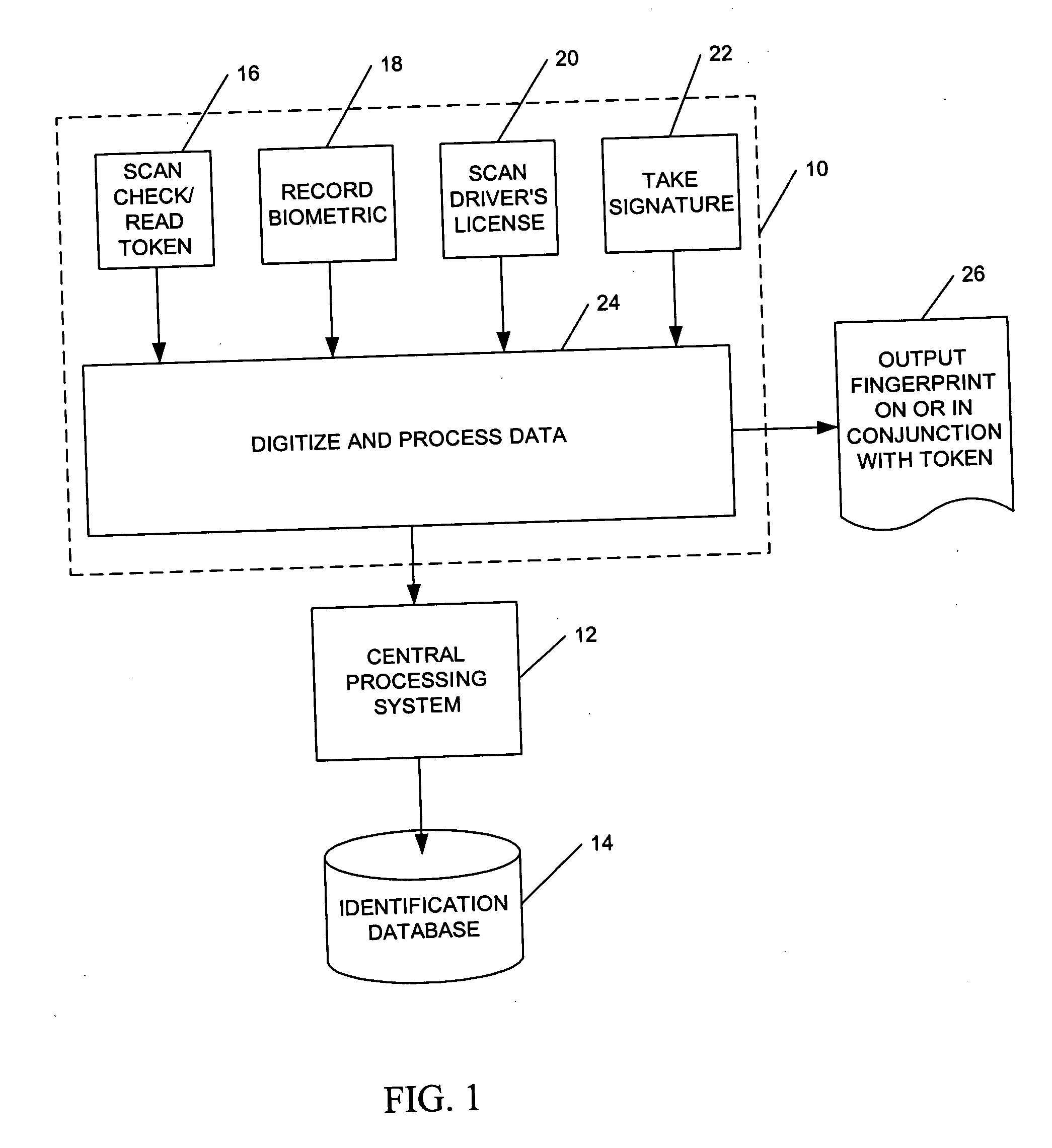

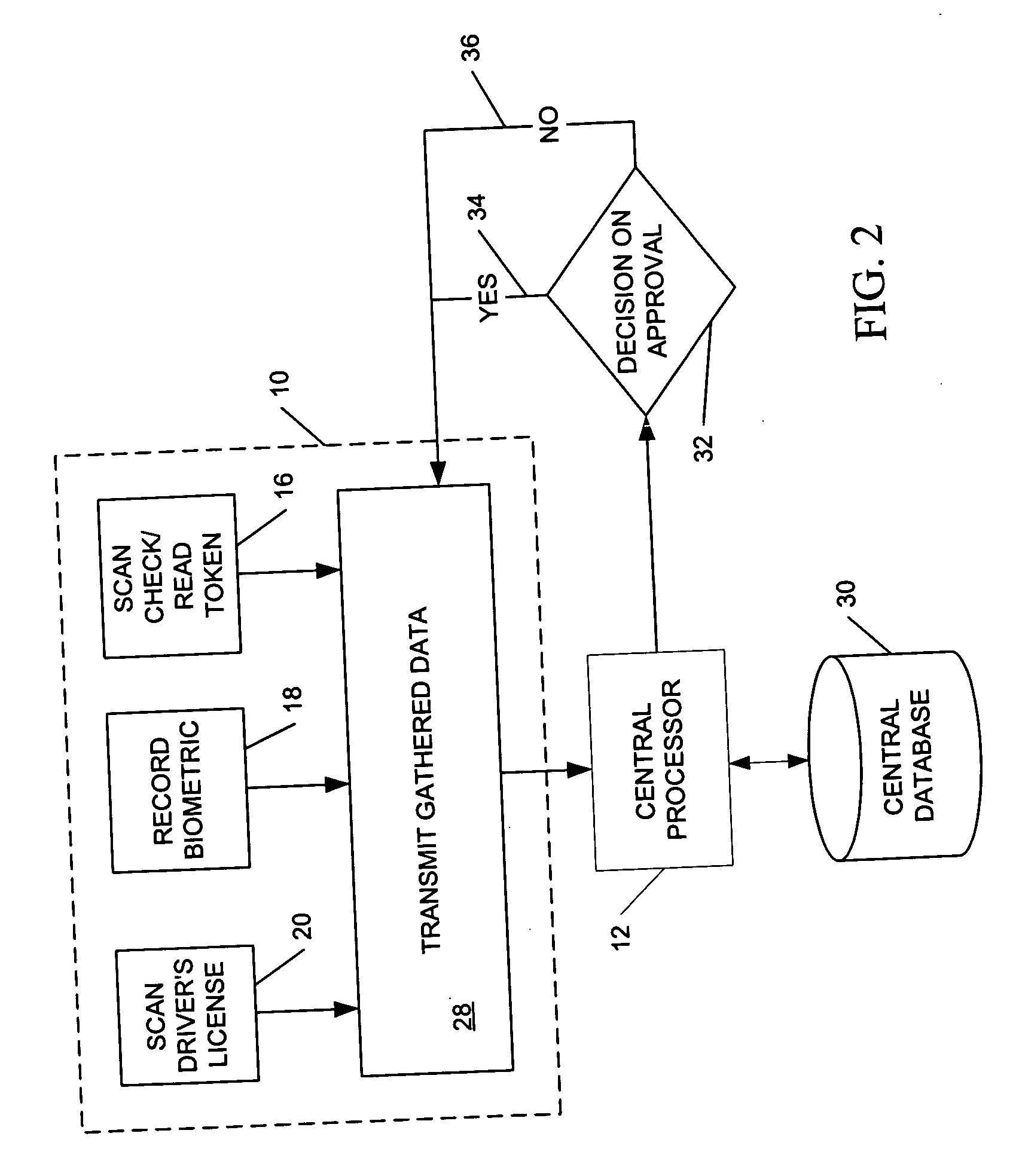

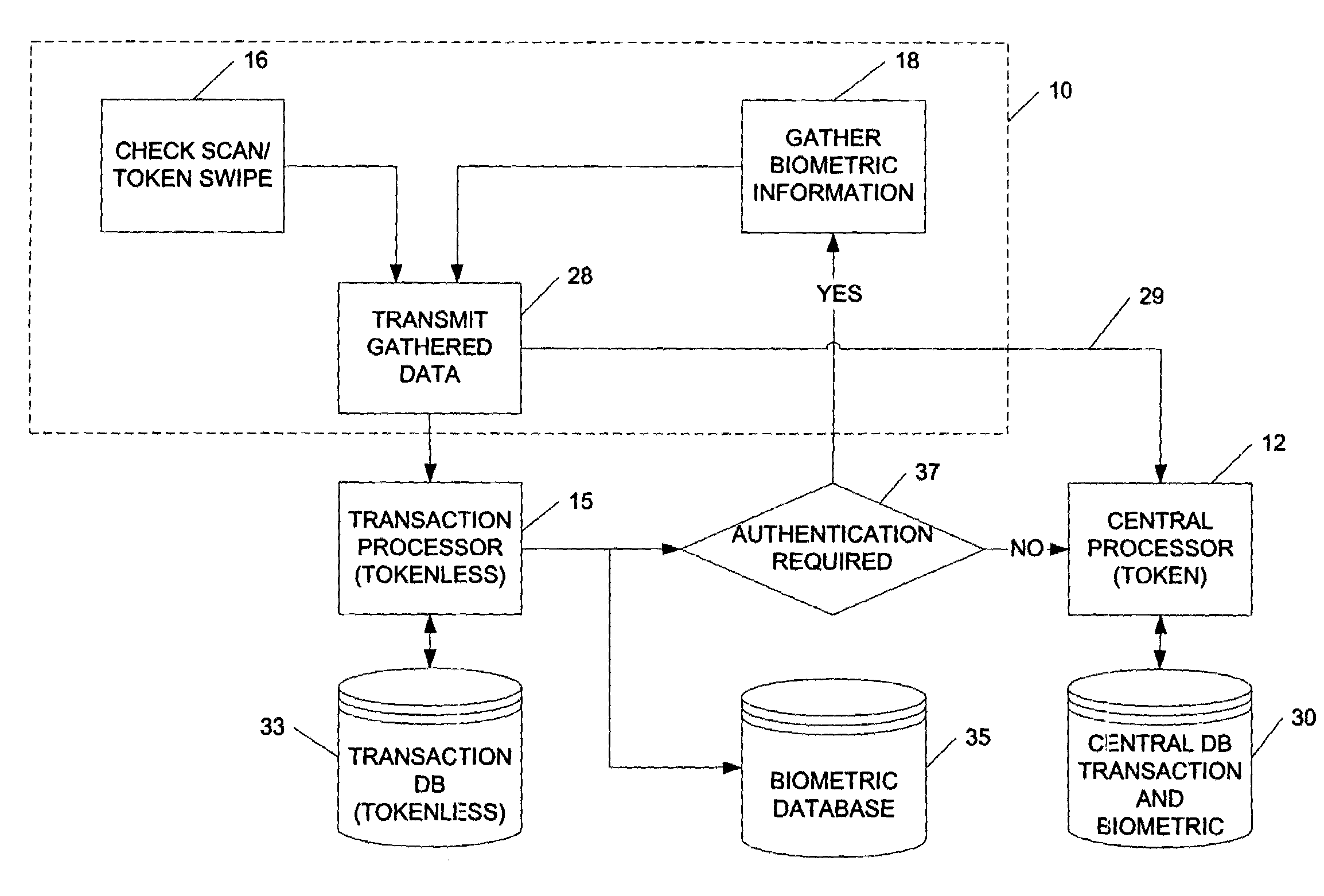

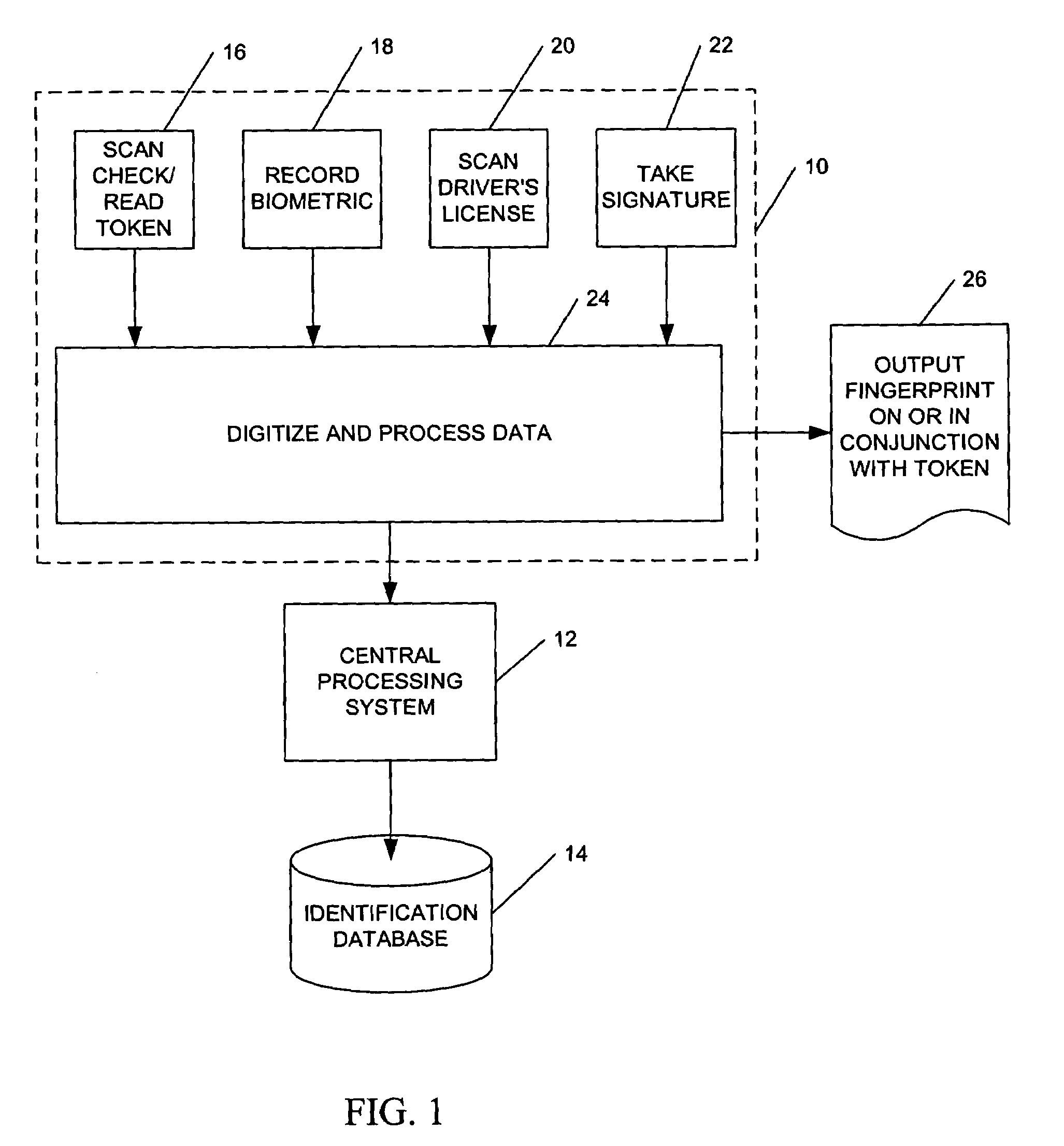

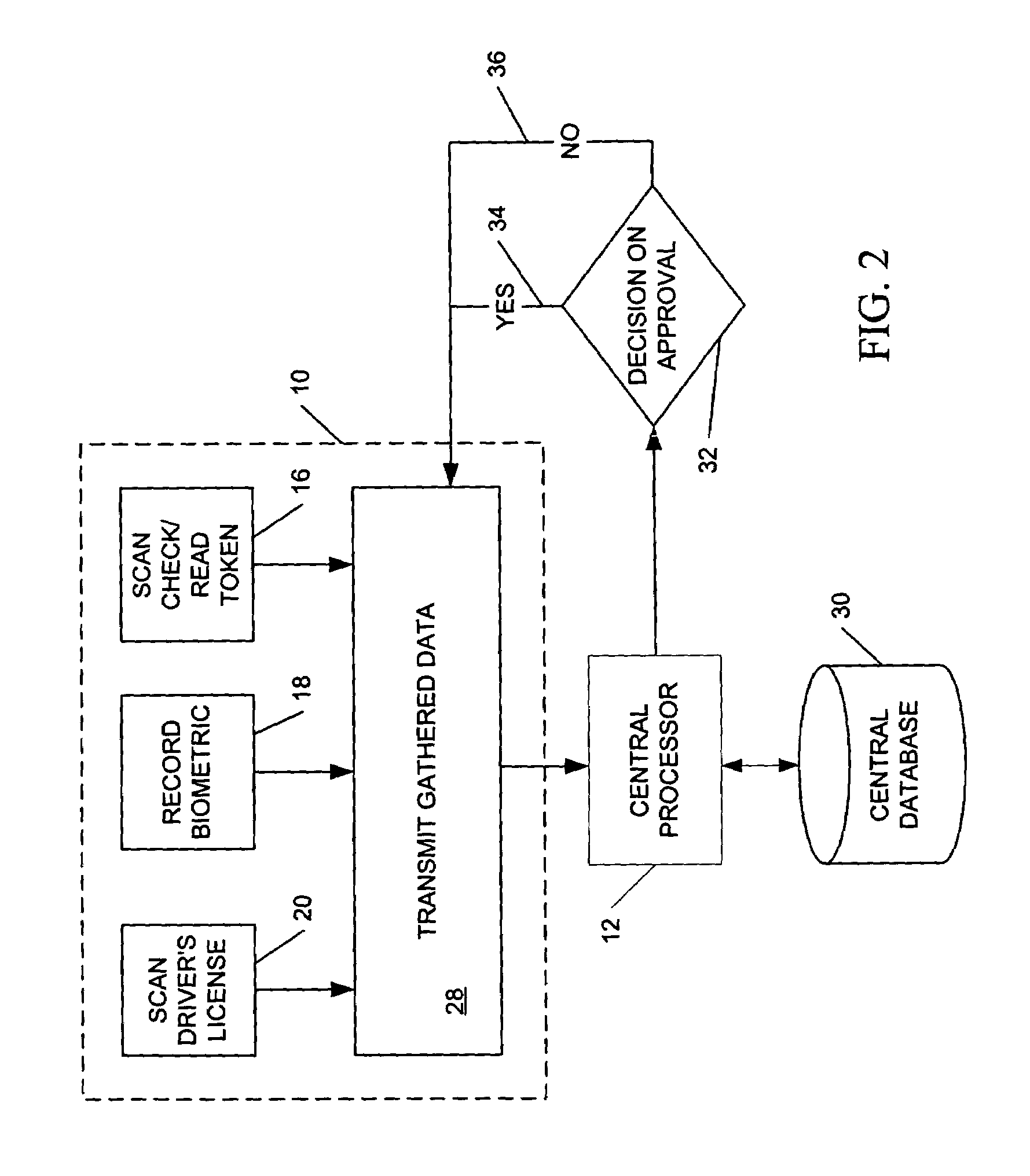

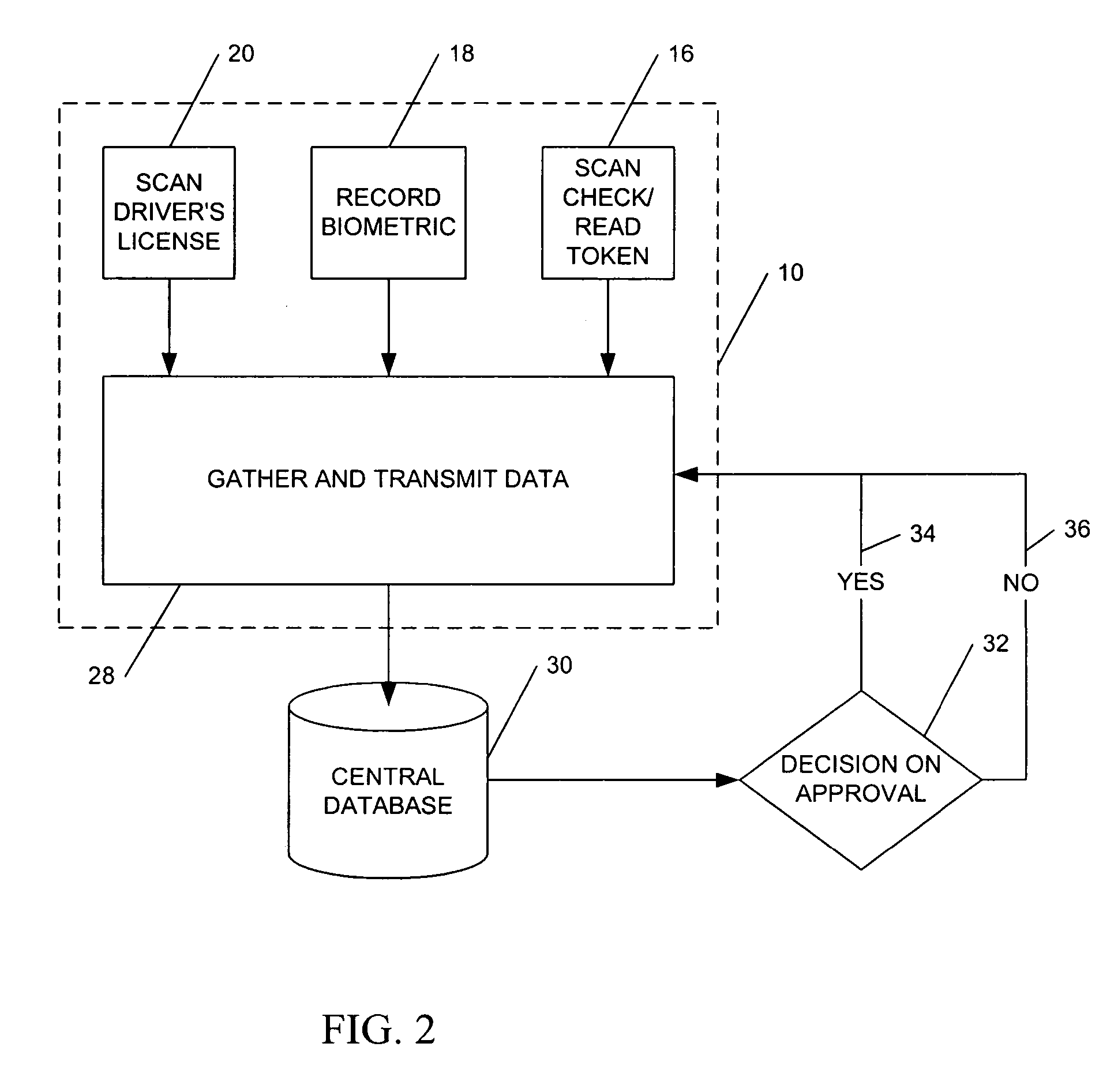

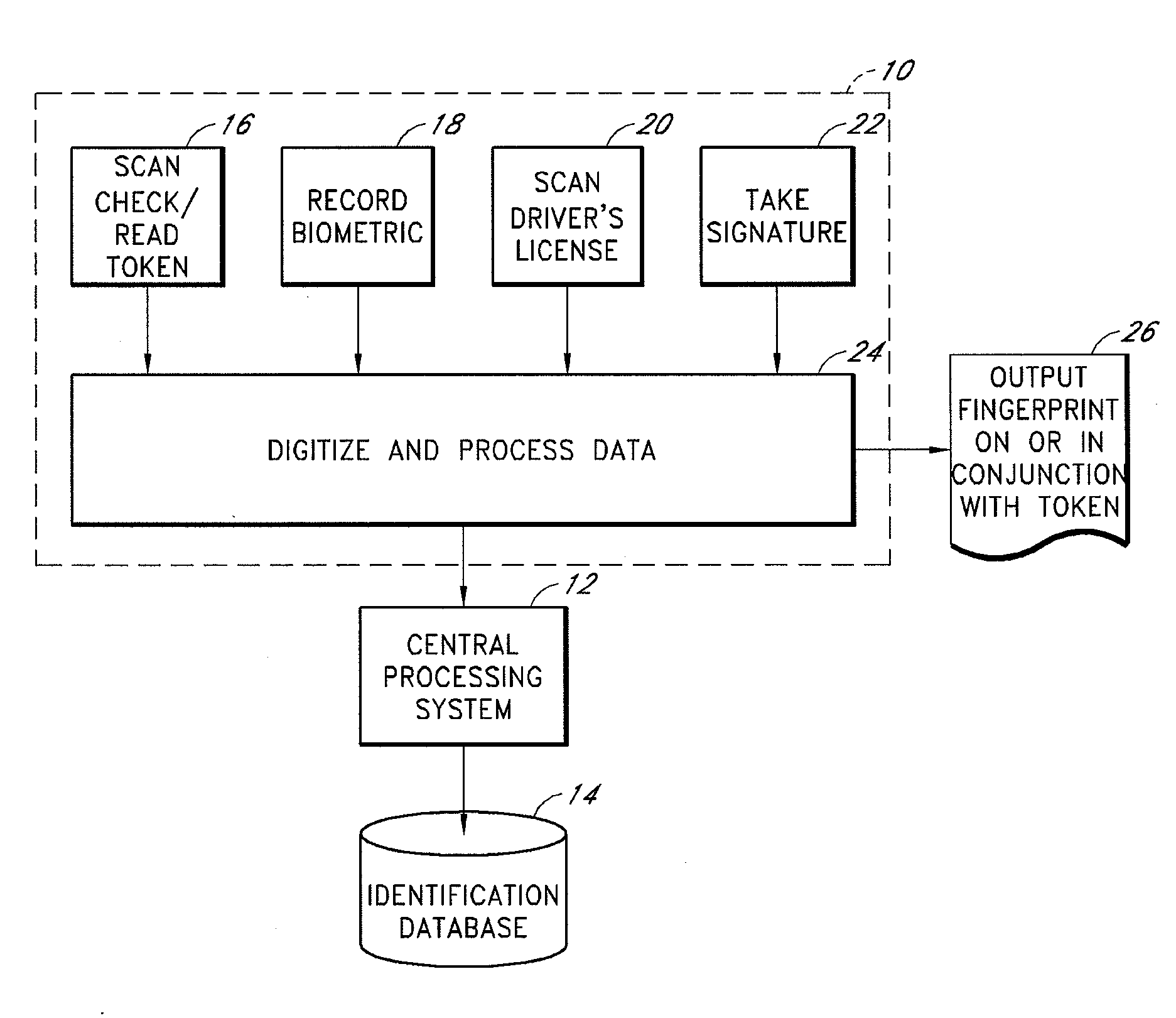

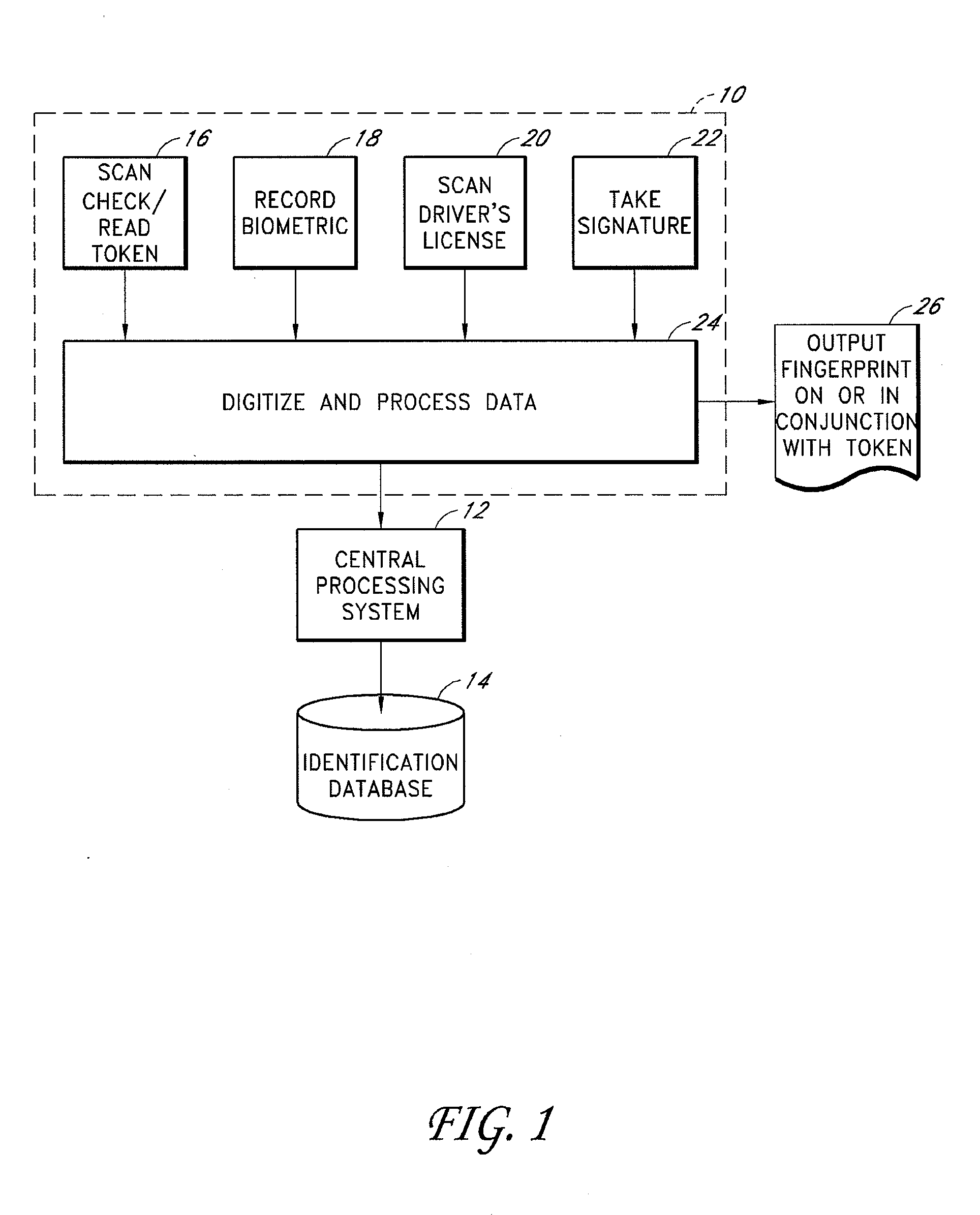

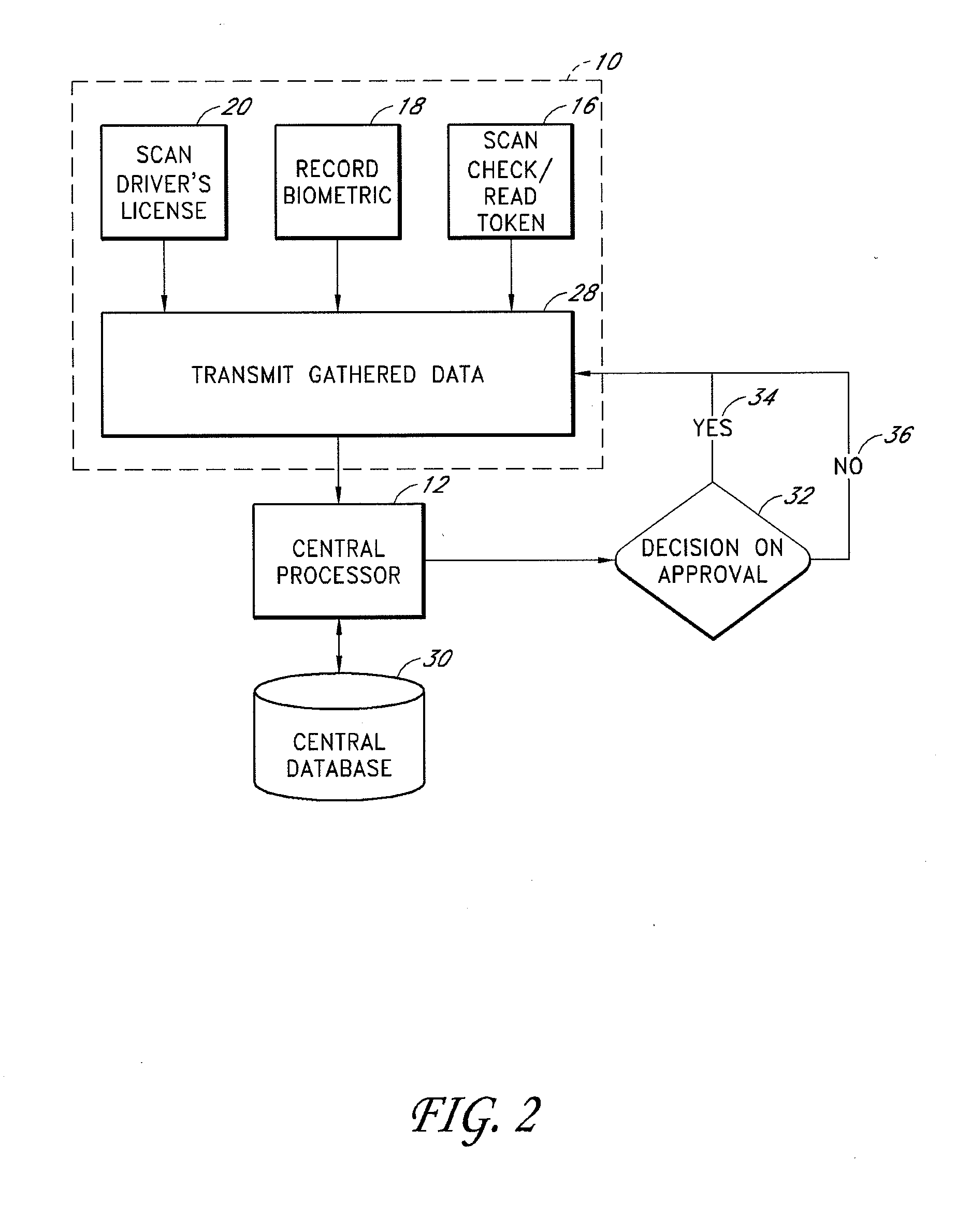

An electronic transaction verification system for use with transaction tokens such as checks, credit cards, debit cards, and smart cards that gathers and transmits information about the transaction token and biometric data. The system preferably has the ability to read or scan transaction and account information printed or encoded on the transaction token, digitally encode biometric data, scan drivers' licenses or other identification cards, and take a signature of a customer, all at a transaction location for purposes of account verification. The electronic transaction verification system preferably digitizes various indicia of the token, such as the magnetic ink (MICR) line on a presented check or the magnetic strip on a credit card or debit card, and transmits the transaction information data to a central processing system, at which the central processing system compares the inputted data with an existing database of information to determine if the customer at the point of the transaction is in fact authorized to use the account, and if the account is in satisfactory condition for approval of the transaction. The electronic verification system includes a biometric data device for recording and / or transmitting biometric data taken at the transaction location. The electronic transaction verification system can be used in conjunction with a tokenless transaction processing system to determine if the token presented for payment is associated with an account established for an authorized user that has registered with the tokenless transaction processing system.

Owner:BIOMETRIC PAYMENT SOLUTIONS

Electronic transaction verification system

InactiveUS7349557B2Inhibitory activityIndustrial applicabilityElectric signal transmission systemsDigital data processing detailsPaymentBiometric data

An electronic transaction verification system for use at a location where a transaction token is presented for payment. The electronic transaction verification system digitizes various indicia of the token, and transmits the transaction information data to a central processing system. The central processing system compares the transaction data with an existing database of information to determine if the customer at the point of the transaction is authorized to use the account. The electronic verification system includes a biometric data device for recording and / or transmitting biometric data taken at the transaction location. The electronic transaction verification system can be used in conjunction with a tokenless transaction processing system to determine if the token presented for payment is associated with an account established for an authorized user that has registered with the tokenless transaction processing system.

Owner:BIOMETRIC PAYMENT SOLUTIONS

Electronic transaction verification system

InactiveUS7231068B2Great riskReduce riskElectric signal transmission systemsDigital data processing detailsBiometric dataTransaction data

An electronic transaction verification system for use with transaction tokens that gathers and transmits information about the transaction token and biometric data. The electronic transaction verification system preferably digitizes various indicia of the token and transmits the transaction information data to a central system. The central system compares the transaction data with an existing database of information to determine if the customer at the point of the transaction is in fact authorized to use the account, and if the account is in satisfactory condition for approval of the transaction. The electronic verification system includes a biometric data device for recording and transmitting biometric data at the point of the transaction to a biometric database for comparison and identity verification in real time.

Owner:BIOMETRIC PAYMENT SOLUTIONS

Electronic Transaction Verification System

InactiveUS20080156866A1Industrial applicabilityGreat riskComplete banking machinesFinanceBiometric dataCheque

An electronic transaction verification system for use with transaction tokens such as checks, credit cards, debit cards, and smart cards that gathers and transmits information about the transaction token and biometric data. The system preferably has the ability to read or scan transaction and account information printed or encoded on the transaction token, digitally encode biometric data, scan drivers' licenses or other identification cards, and take a signature of a customer, all at a transaction location for purposes of account verification. The electronic transaction verification system preferably digitizes various indicia of the token, such as the magnetic ink (MICR) line on a presented check or the magnetic strip on a credit card or debit card, and transmits the transaction information data to a central processing system, at which the central processing system compares the inputted data with an existing database of information to determine if the customer at the point of the transaction is in fact authorized to use the account, and if the account is in satisfactory condition for approval of the transaction. The electronic verification system includes a biometric data device for recording and / or transmitting biometric data taken at the transaction location. The electronic transaction verification system can be used in conjunction with a tokenless transaction processing system to determine if the token presented for payment is associated with an account established for an authorized user that has registered with the tokenless transaction processing system.

Owner:BIOMETRIC PAYMENT SOLUTIONS

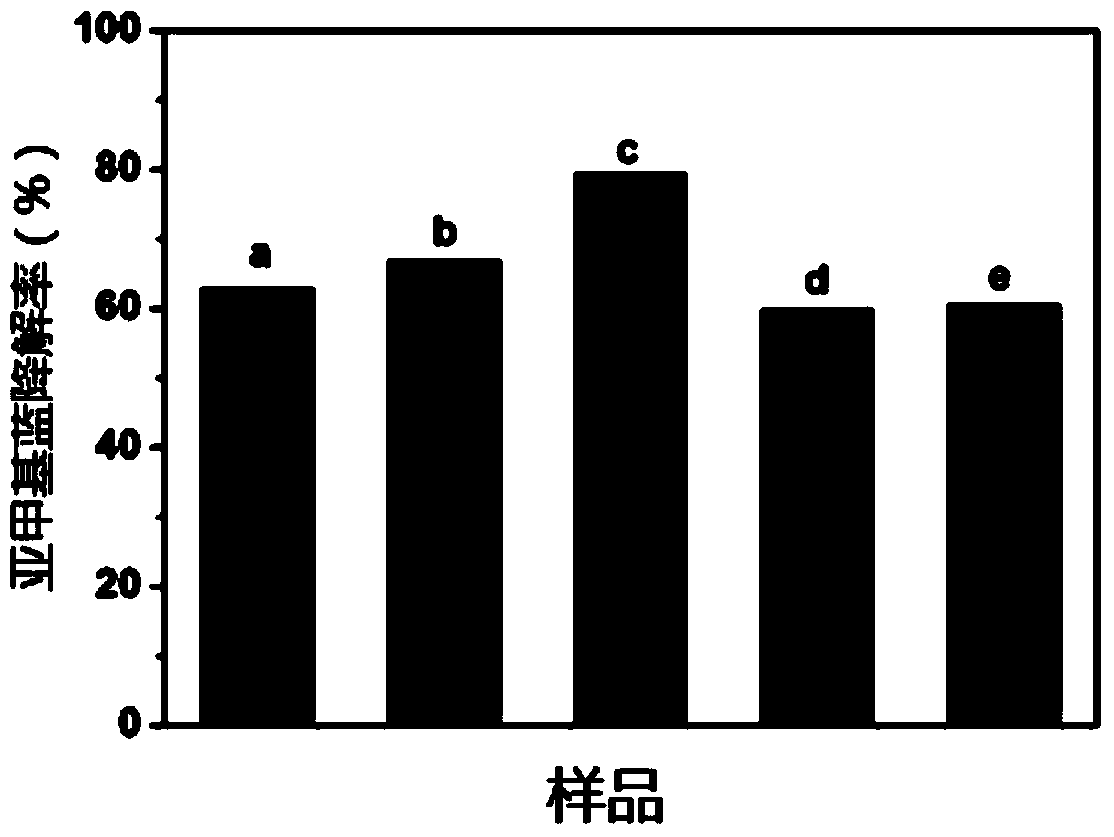

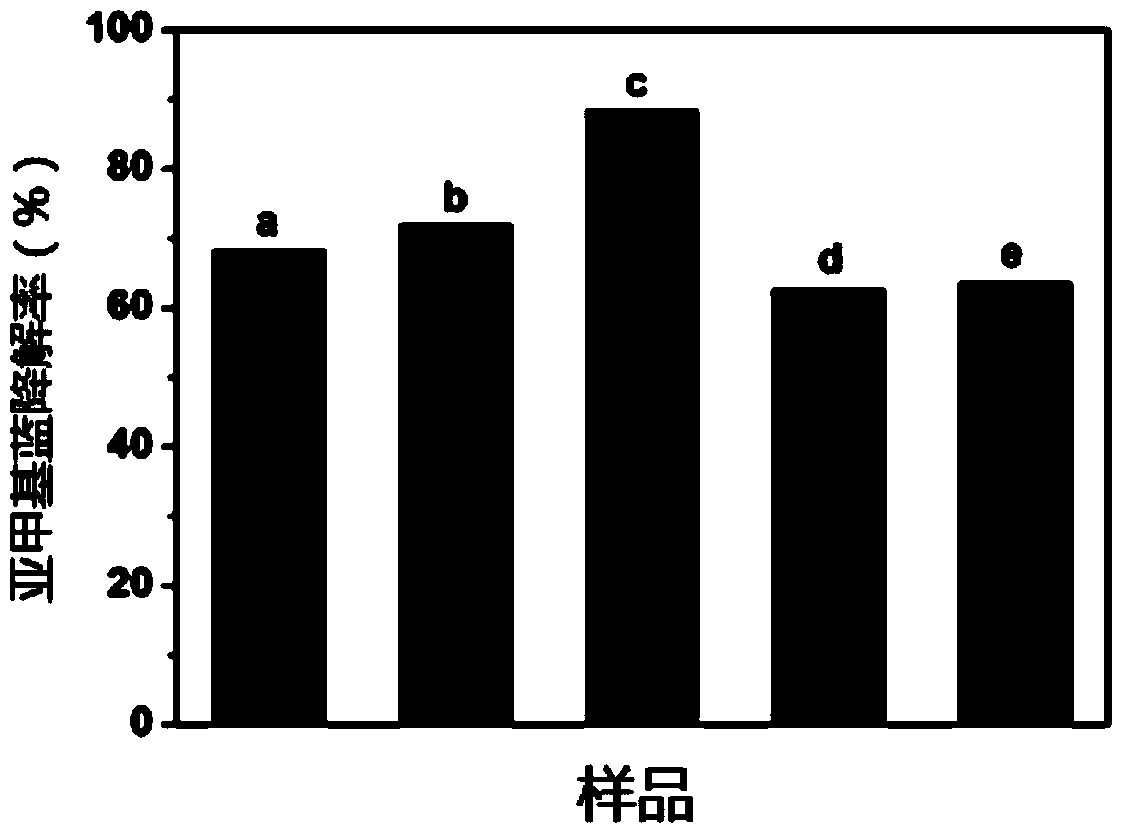

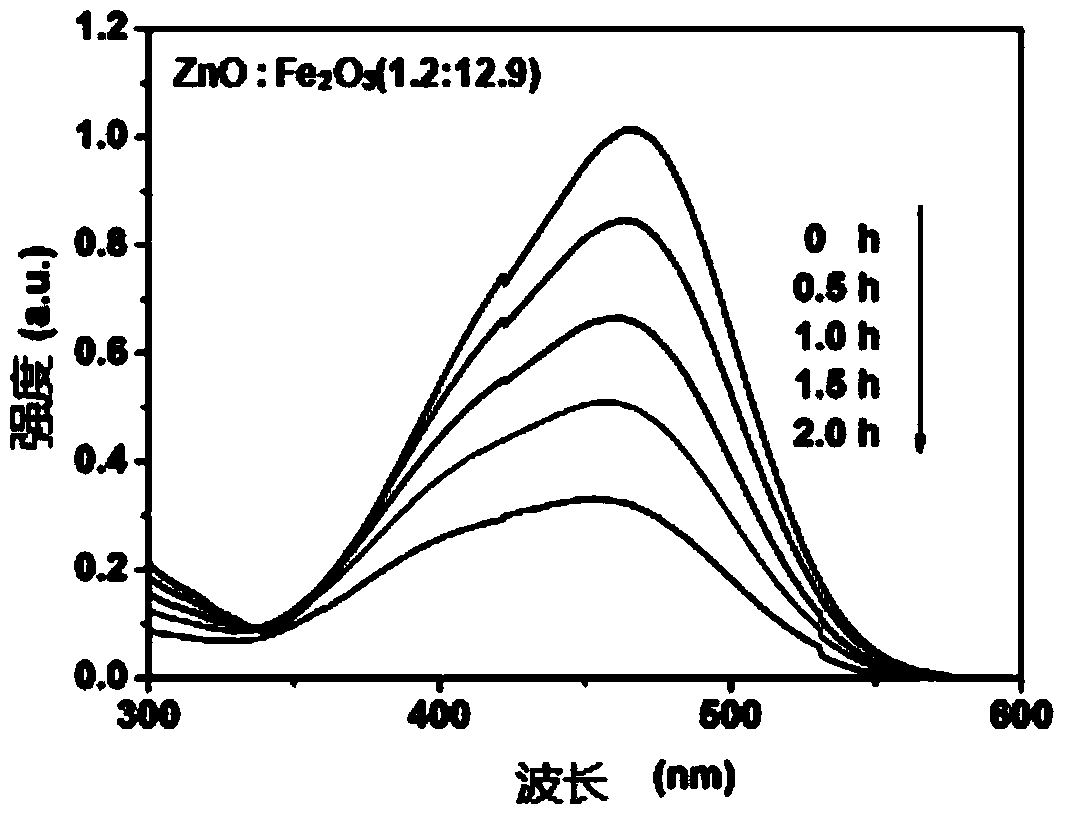

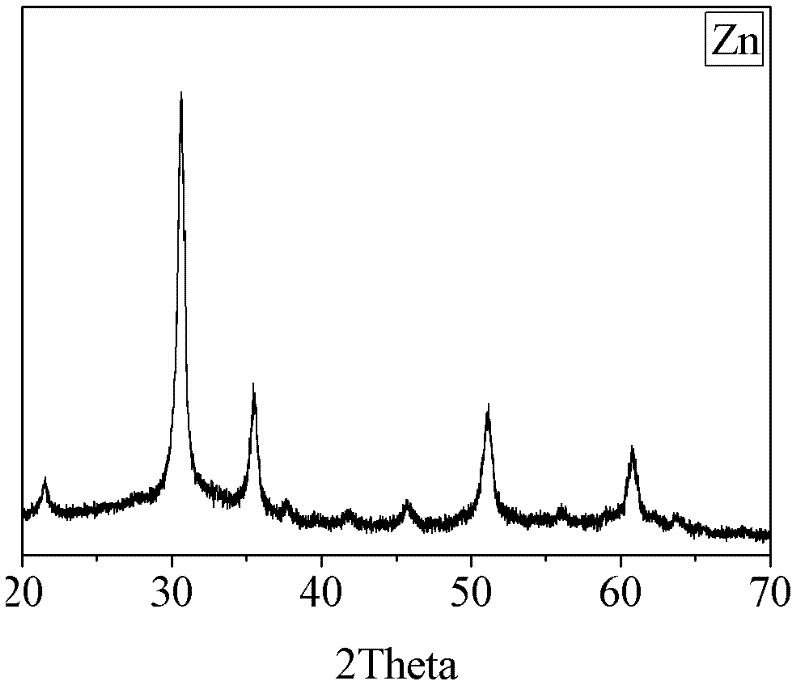

Novel C3N4/ZnO/Fe2O3 composite photocatalyst and preparation method as well as application thereof

ActiveCN103736514AWide absorption wavelength rangeIncrease profitPhysical/chemical process catalystsWater/sewage treatment by irradiationHazardous substanceCarbon nitride

The invention discloses a novel C3N4 / ZnO / Fe2O3 composite photocatalyst and a preparation method thereof. The method comprises the following steps: preparing a carbon nitride (C3N4) catalyst and a ZnO / Fe2O3 catalyst, then mixing according to the proportion, grinding and preparing the C3N4 / ZnO / Fe2O3 composite photocatalyst. The novel C3N4 / ZnO / Fe2O3 composite photocatalyst has the advantages that the photocatalytic efficiency is high, photocatalysis can be carried out in the range of ultraviolet band and visible light wavelength, the application range is wider, high-efficiency degradation can be carried out on wastewater, especially pollutants in the dye wastewater, the degradation is thorough and the used time is short; the method is simple in operation, mild in reaction condition, does not use toxic and harmful substances as materials, and is green and environment-friendly, thus avoiding secondary pollution.

Owner:安徽丰华医药包装有限公司

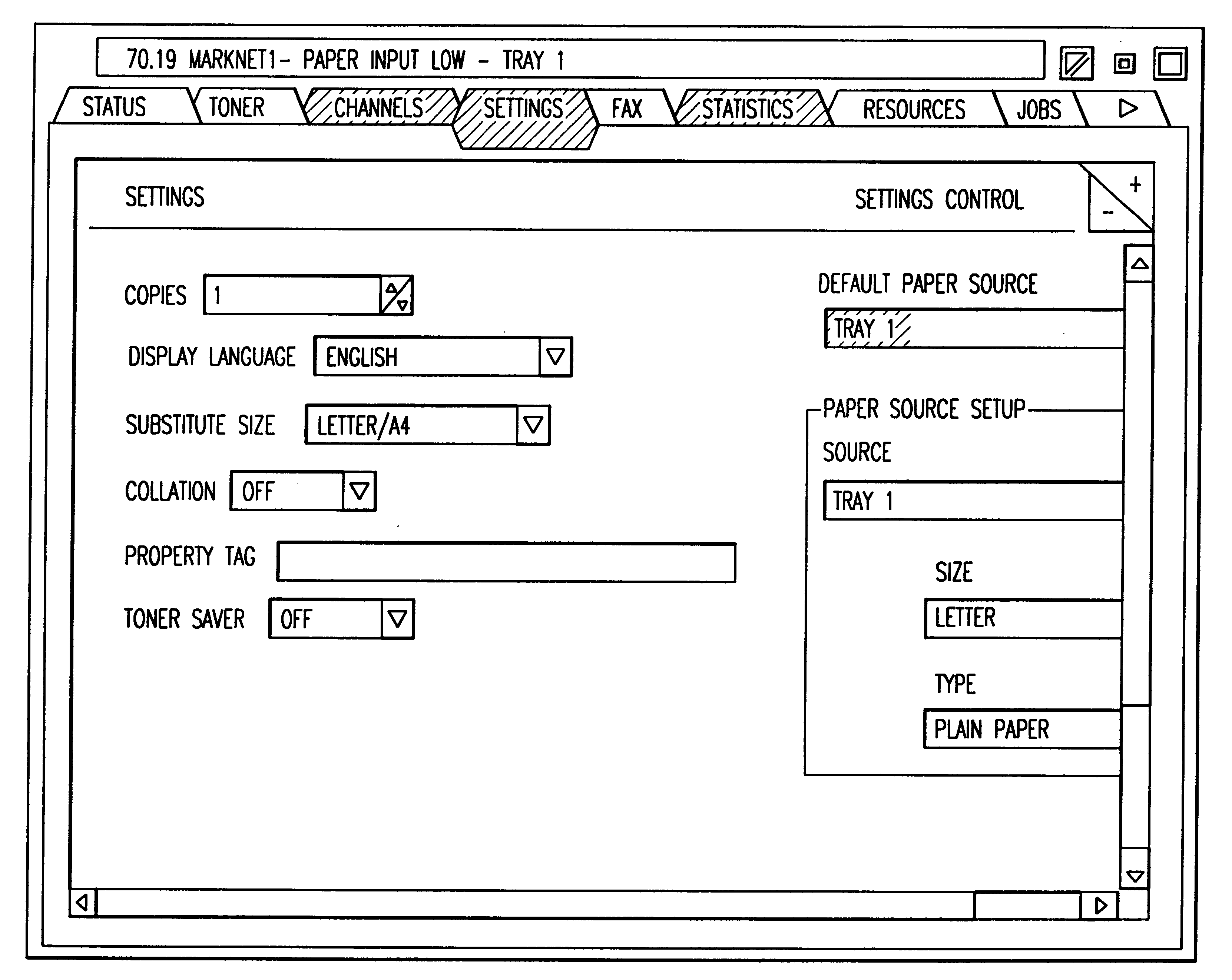

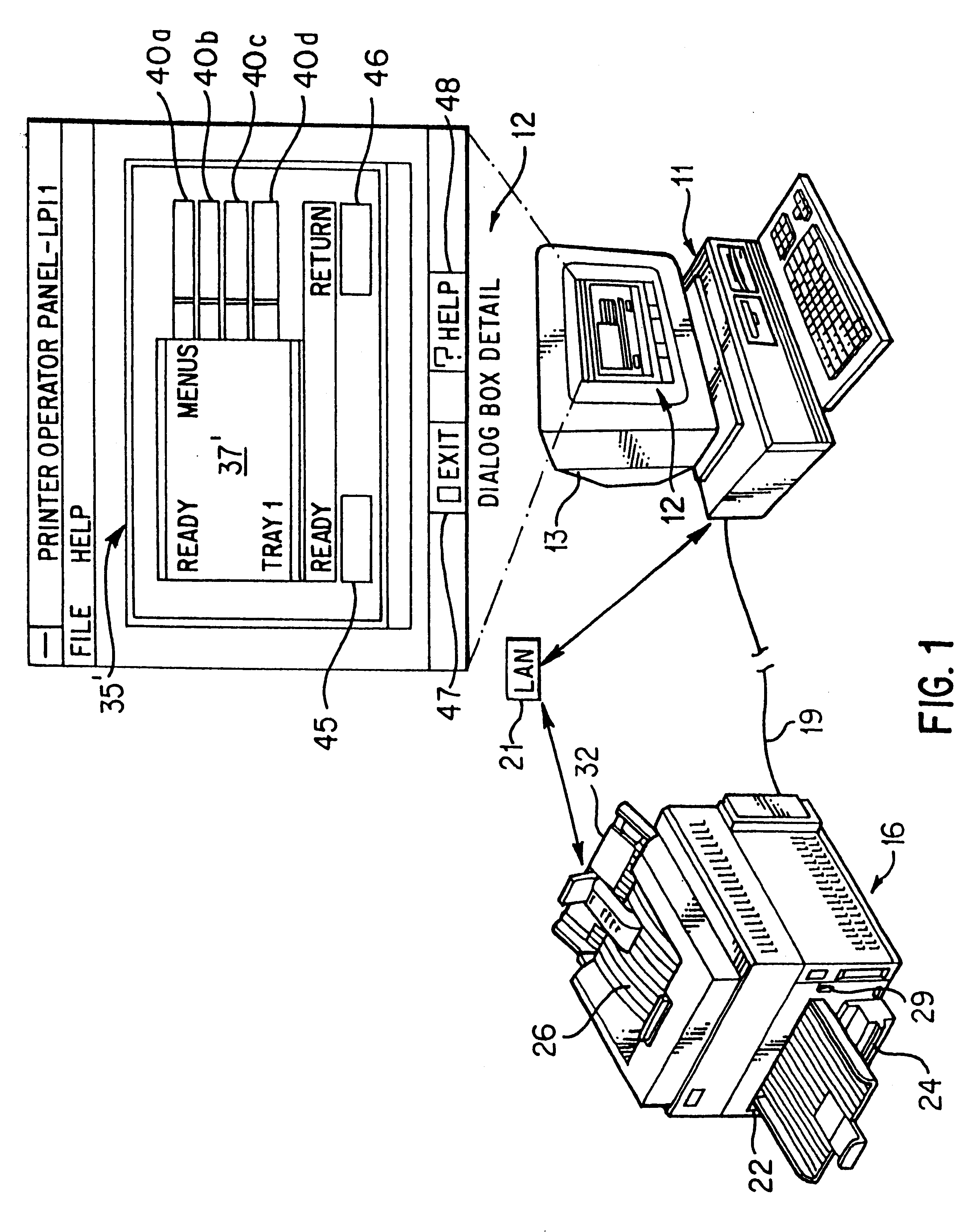

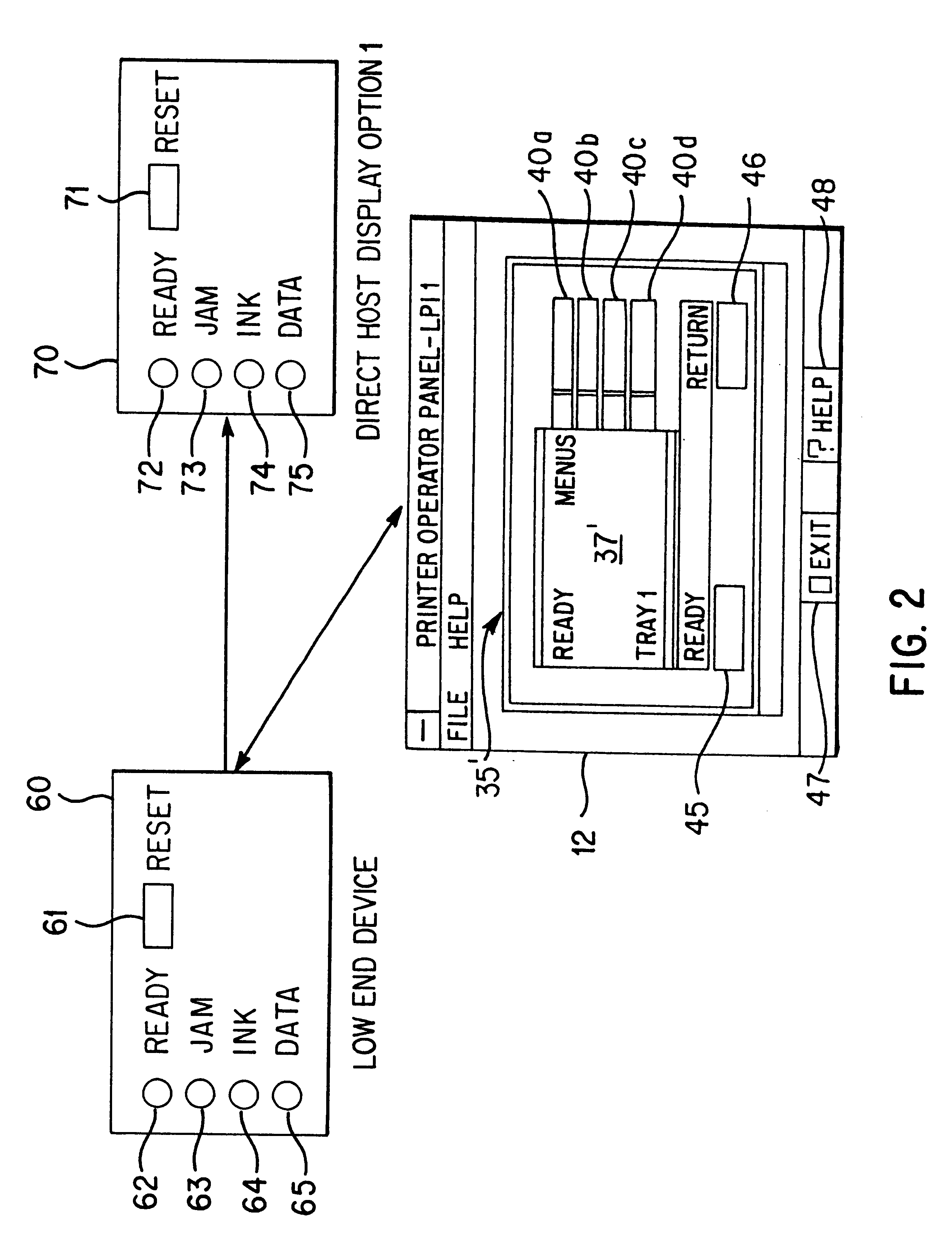

System and method for providing a virtual operator panel for a peripheral device

InactiveUS6498611B1Industrial applicabilityAvoid spreadingProgram controlMemory systemsLocal variableData memory

A system and method for providing a virtual operator panel for a peripheral device where the system includes a peripheral device including a processor and a data store that stores public settings corresponding to private settings of the peripheral device, each public setting indicative of at least one private setting of the peripheral device. The peripheral device has a device process and a host process, or alternately, is in bidirectional communication with at least one host computer including a data store, a display and a processor. The host computer or host process selectively transmits a request to the peripheral device or device process requesting public settings of the peripheral device for the generation of a virtual operator panel for the peripheral device. The peripheral device or device process receives the request for peripheral device settings from the host computer or host process, and transmits a response including at least one public setting from the data store of the peripheral device, and the host computer or host process receives the response from the peripheral device and generates a virtual operator panel based upon the response. In one embodiment, the public setting is a metavariable that implicates one or more local variables of the peripheral device. There is also provided a method for generating a virtual operator panel for a peripheral device including the steps of transmitting a request for peripheral device public settings from a host computer or host process to a peripheral device or device process, receiving the request at the peripheral device or device process, generating a response in the peripheral device or device process that includes at least one public setting of the peripheral device, transmitting the response from the peripheral device or device process to the host computer or host process, receiving the response at the host computer or host process, and generating a functional virtual operator panel based upon the public setting included in the received response.

Owner:LEXMARK INT INC

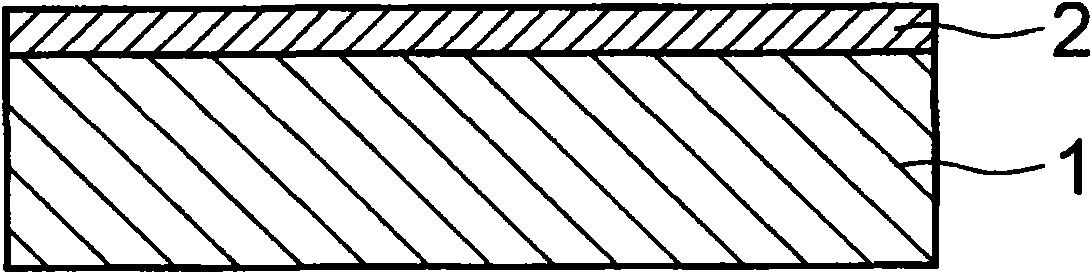

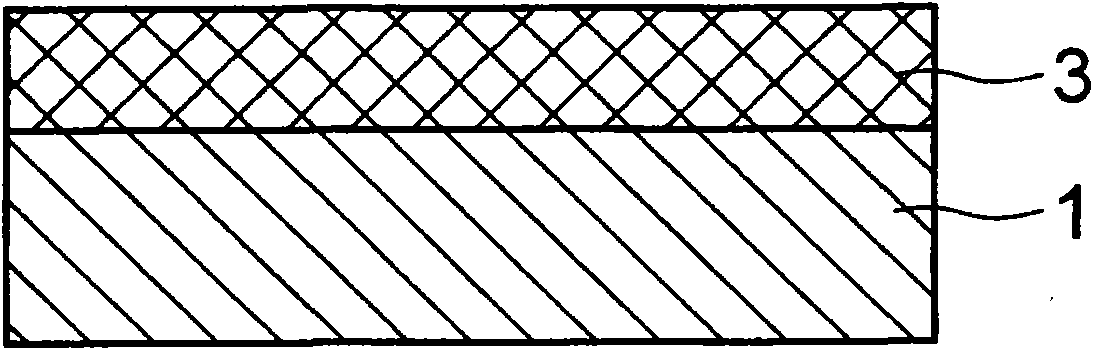

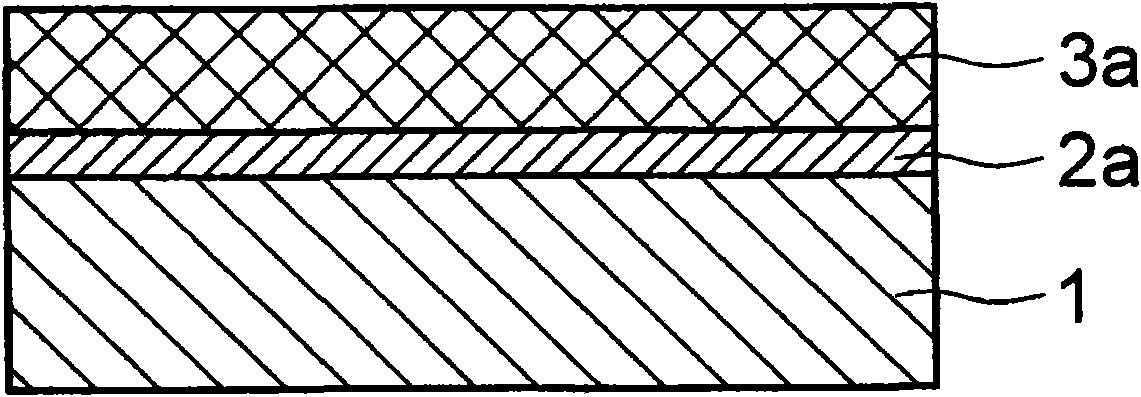

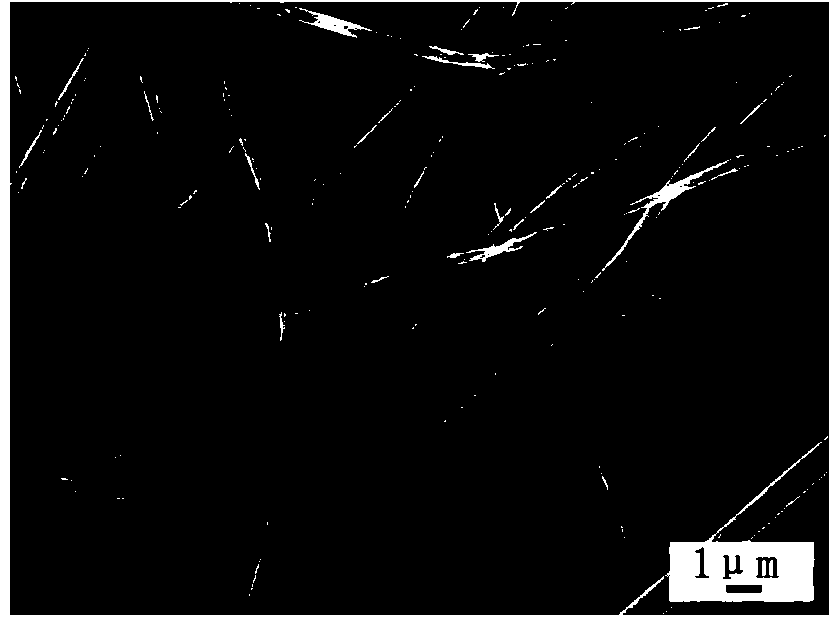

Flexible transparent conductive film and flexible functional element using the same

InactiveCN101842854AImprove flexibilityCheap manufacturingConductive layers on insulating-supportsLayered productsSputteringReverse order

A flexible transparent conductive film on which a first transparent conductive layer (2a) formed by chemical vapor deposition and a second transparent conductive layer (3a) formed by coating are provided on a base film (1) in order of mention or in the reverse order. The major component of the first transparent conductive layer (2a)is a conductive oxide, and the major components of the second transparent conductive layer (3a) are conductive oxide particles and a binder matrix. The first transparent conductive layer (2a) and the second transparent conductive layer (3a) are in close contact with each other, thereby hardly causing cracks in the first transparent conductive layer (2a), and minimizing the deterioration of conductivity even if a crack occurs. With this, the flexible transparent conductive film and a flexible functional device using this having transparency, conductivity, and conductivity stability equivalent to conventional sputtering ITO films and excellent in flexibility are provided.

Owner:SUMITOMO METAL MINING CO LTD

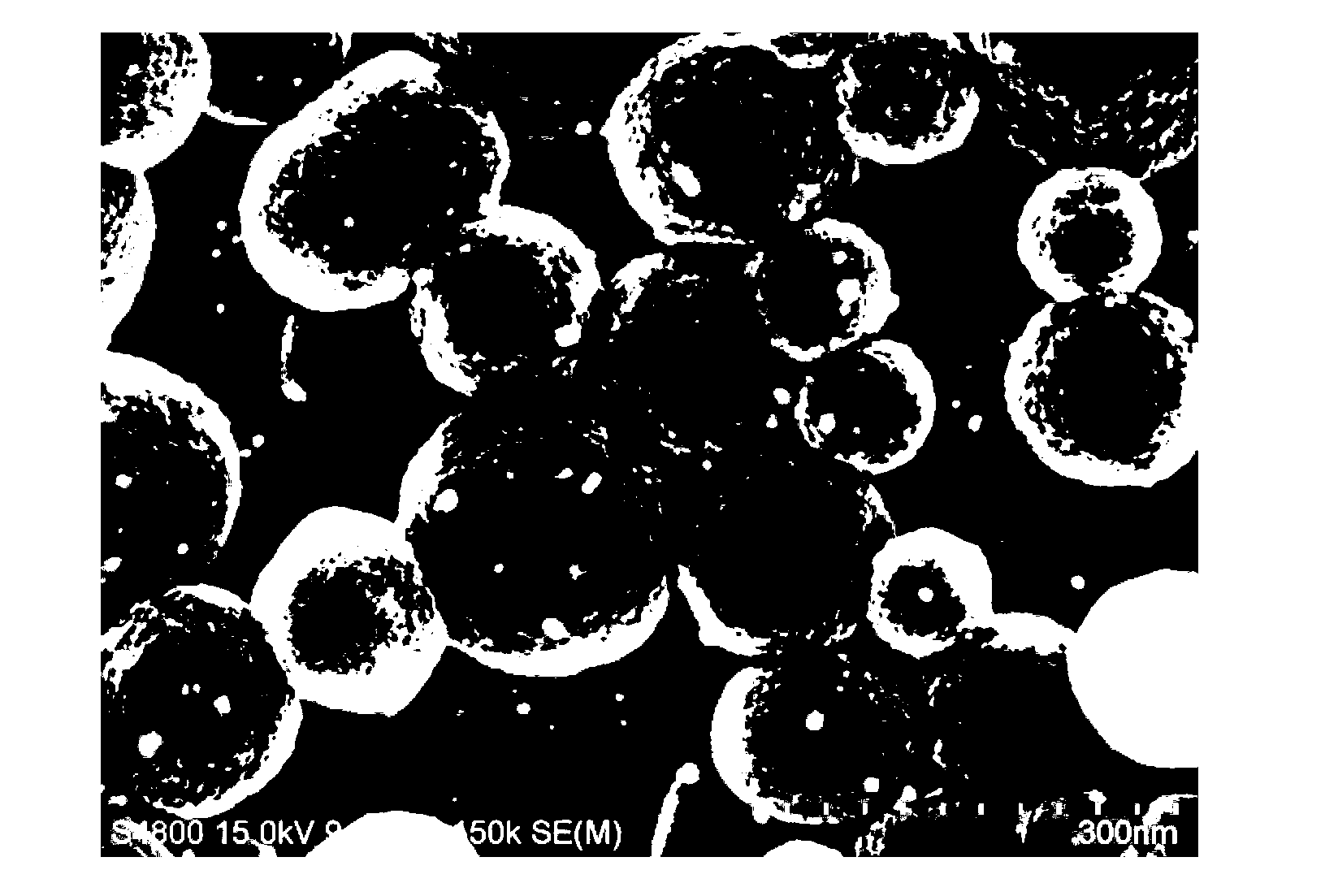

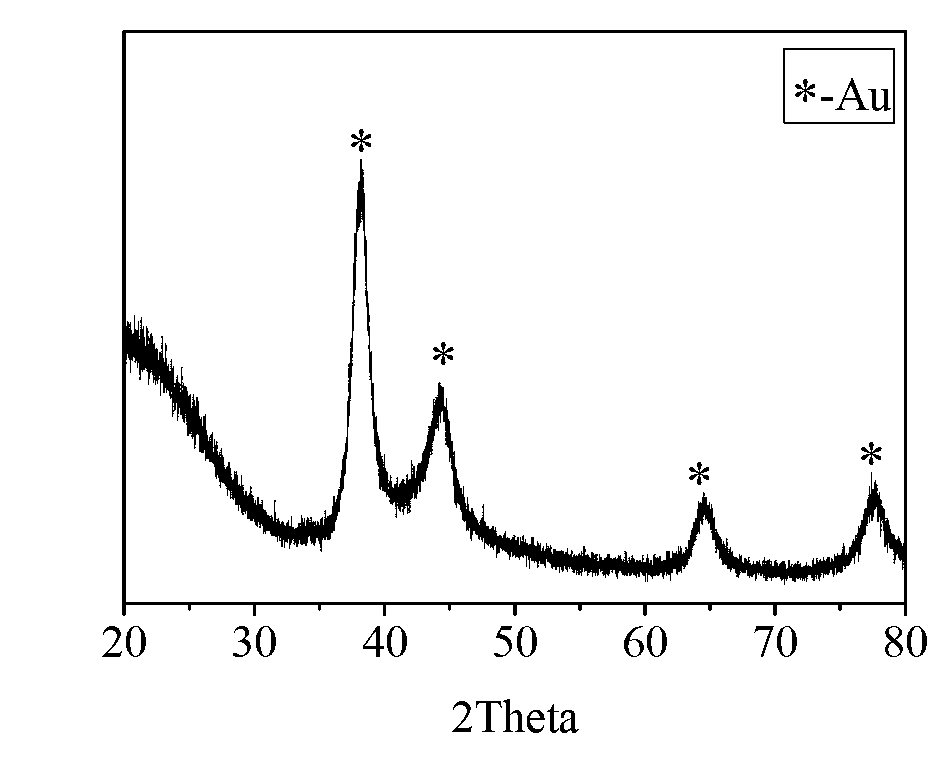

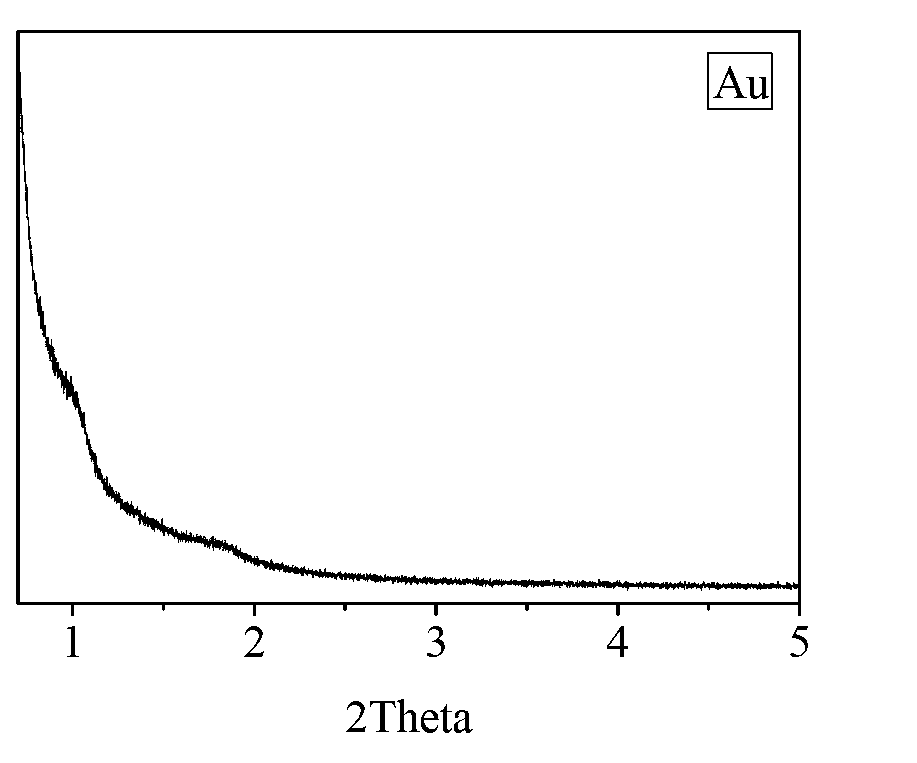

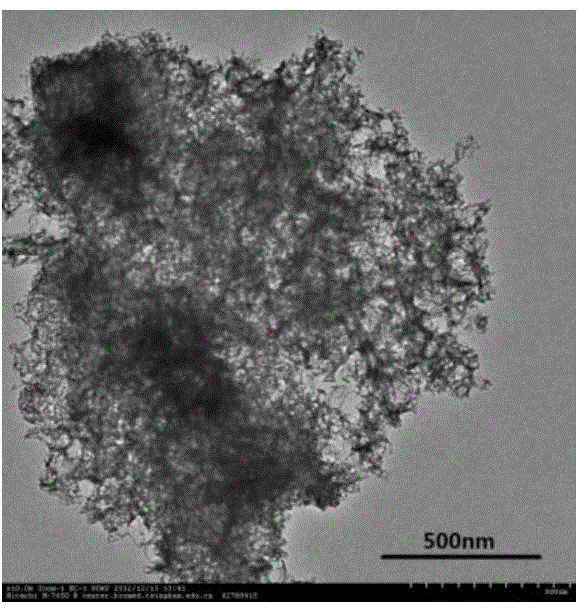

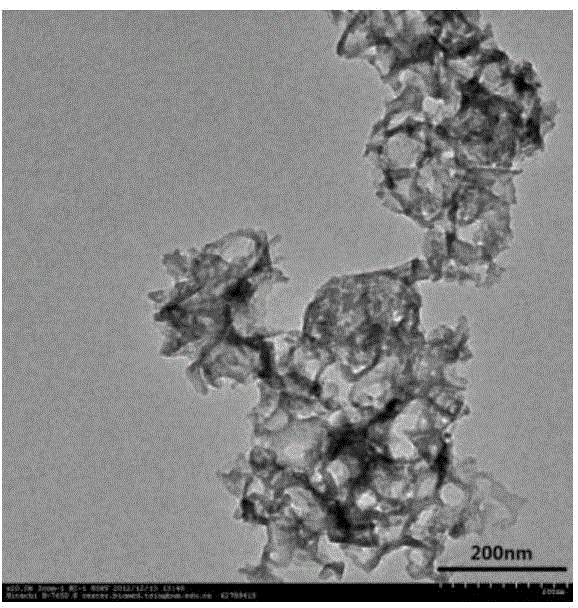

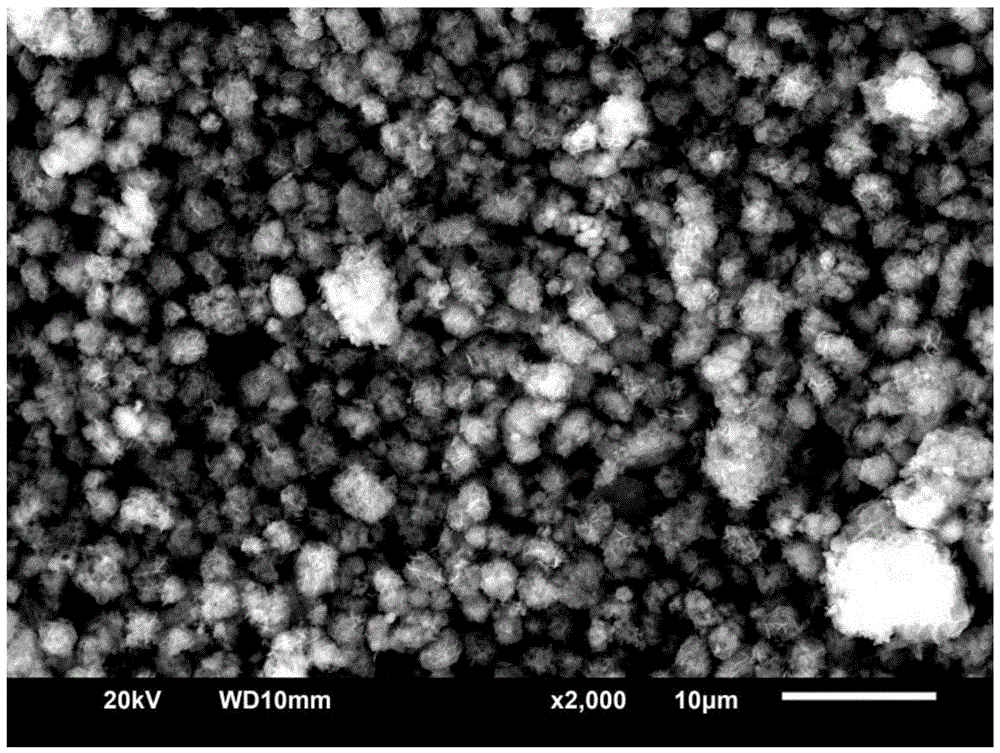

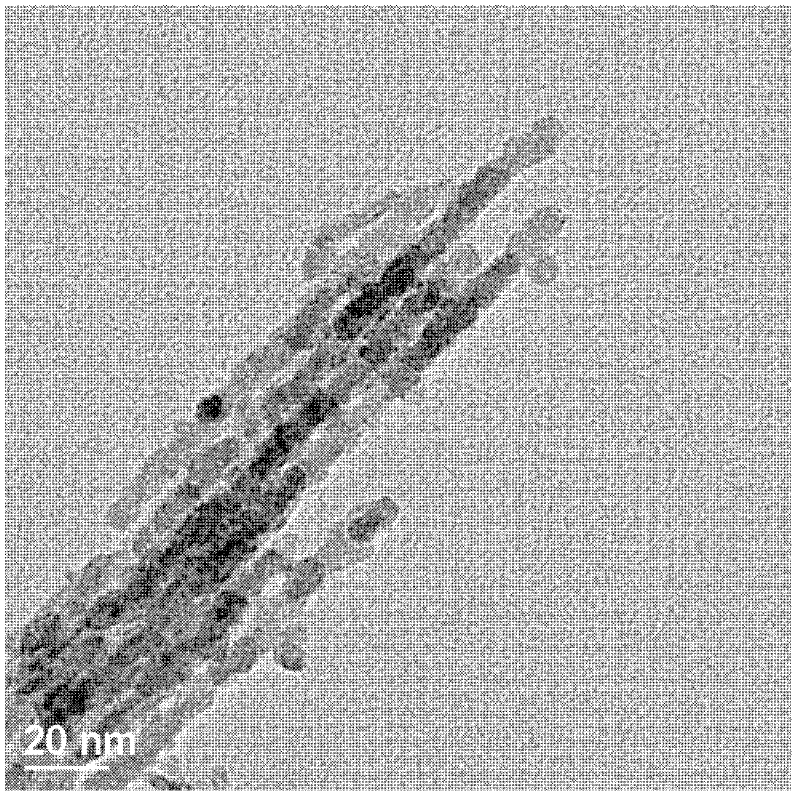

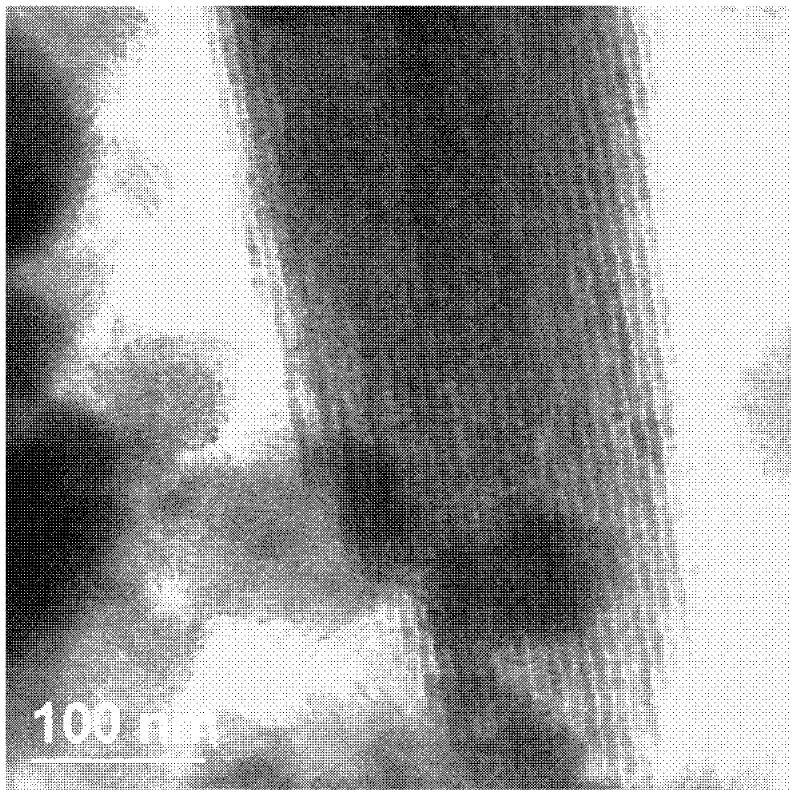

Metal or metal oxide loaded mesoporous carbon material and preparation method thereof

InactiveCN103303903AEvenly distributedSmall granularityMaterial nanotechnologyNano-carbonPore diameterSurface-active agents

The invention provides a metal or metal oxide loaded nano ordered mesoporous carbon material. The nano ordered mesoporous carbon material has the spherical appearance with the diameter of 100-300nm, the specific surface area is 500-600m<2> / g, and the pore diameter is 15-20nm. The invention also provides the preparation method of the material. A soft template method is used, firstly, a carbon precursor with a surface active agent is synthesized, then, by virtue of hydrothermal reaction and roasting, the surface active agent of the carbon precursor is removed, and the metal or metal oxide loaded spherical nano ordered mesoporous material is obtained. The method can realize loading of various different metal components, can be used for effectively regulating the material performance, and is expected to expand the use of the nano ordered mesoporous carbon material. The nano ordered mesoporous carbon material synthesized by the invention is consistent in shape and controllable in size, the metal nano constituents are distributed uniformly, operations are simple in preparation process, and the requirement on equipment is low, so that the nano ordered mesoporous carbon material has industrial practicability.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

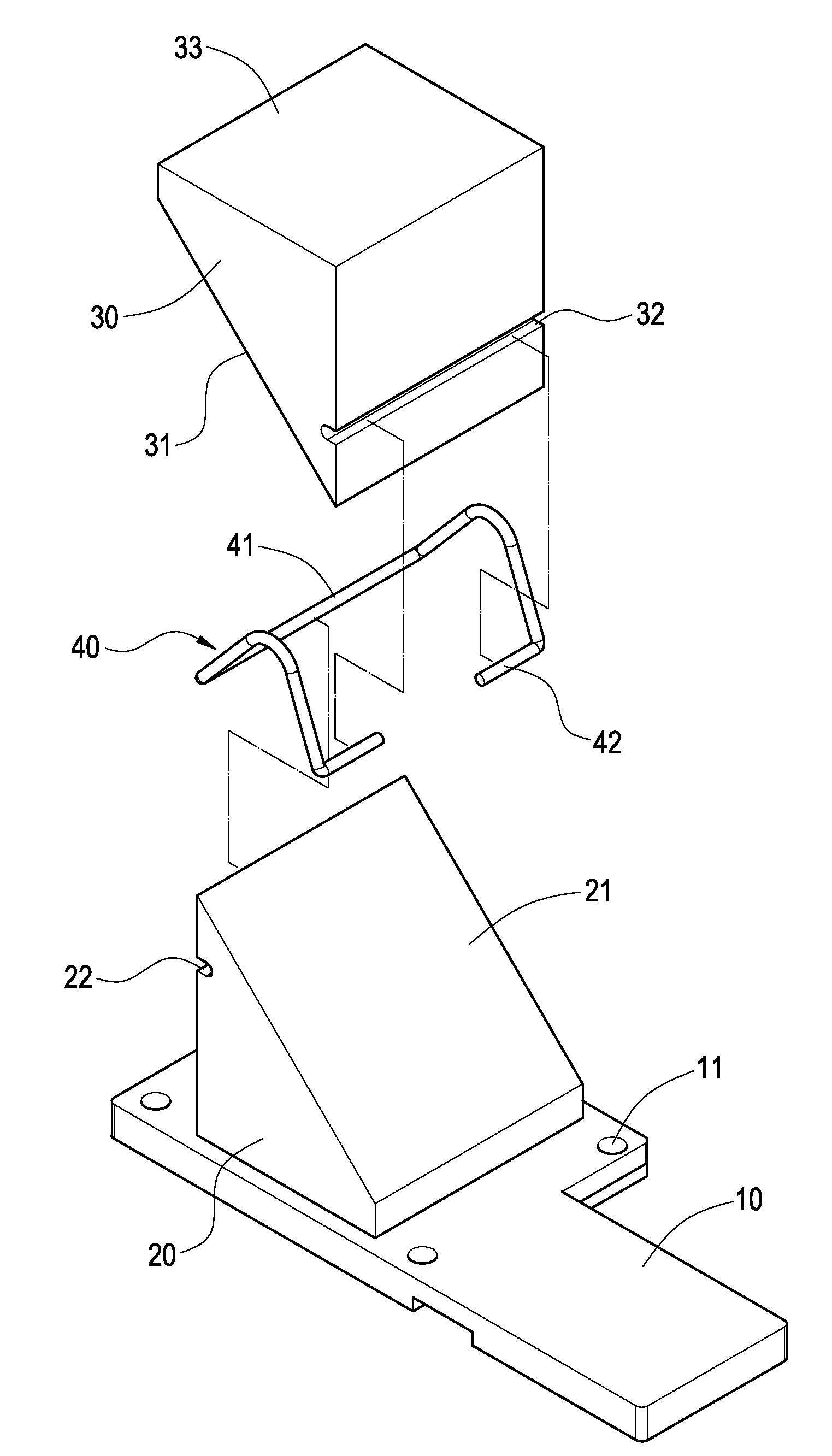

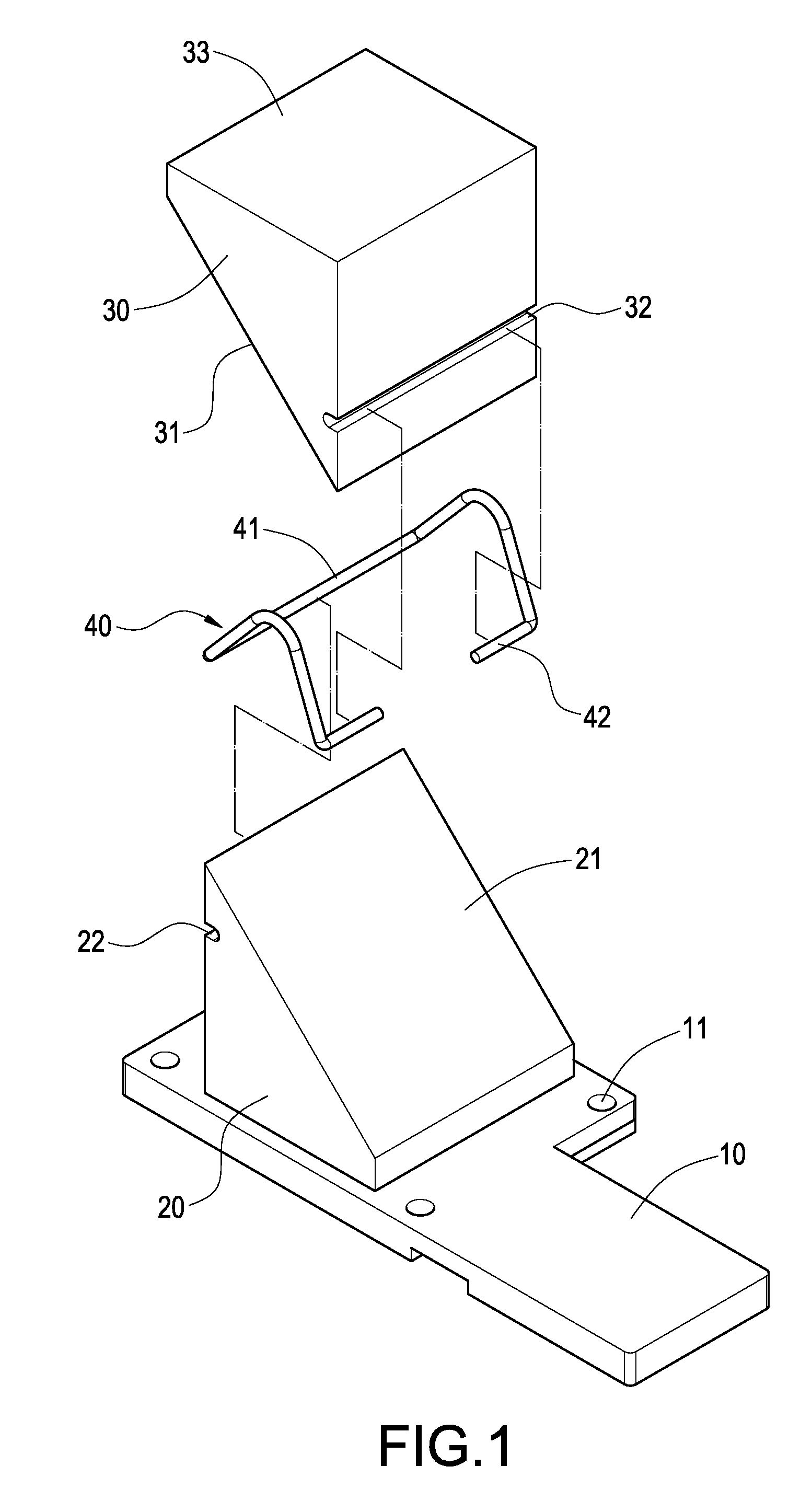

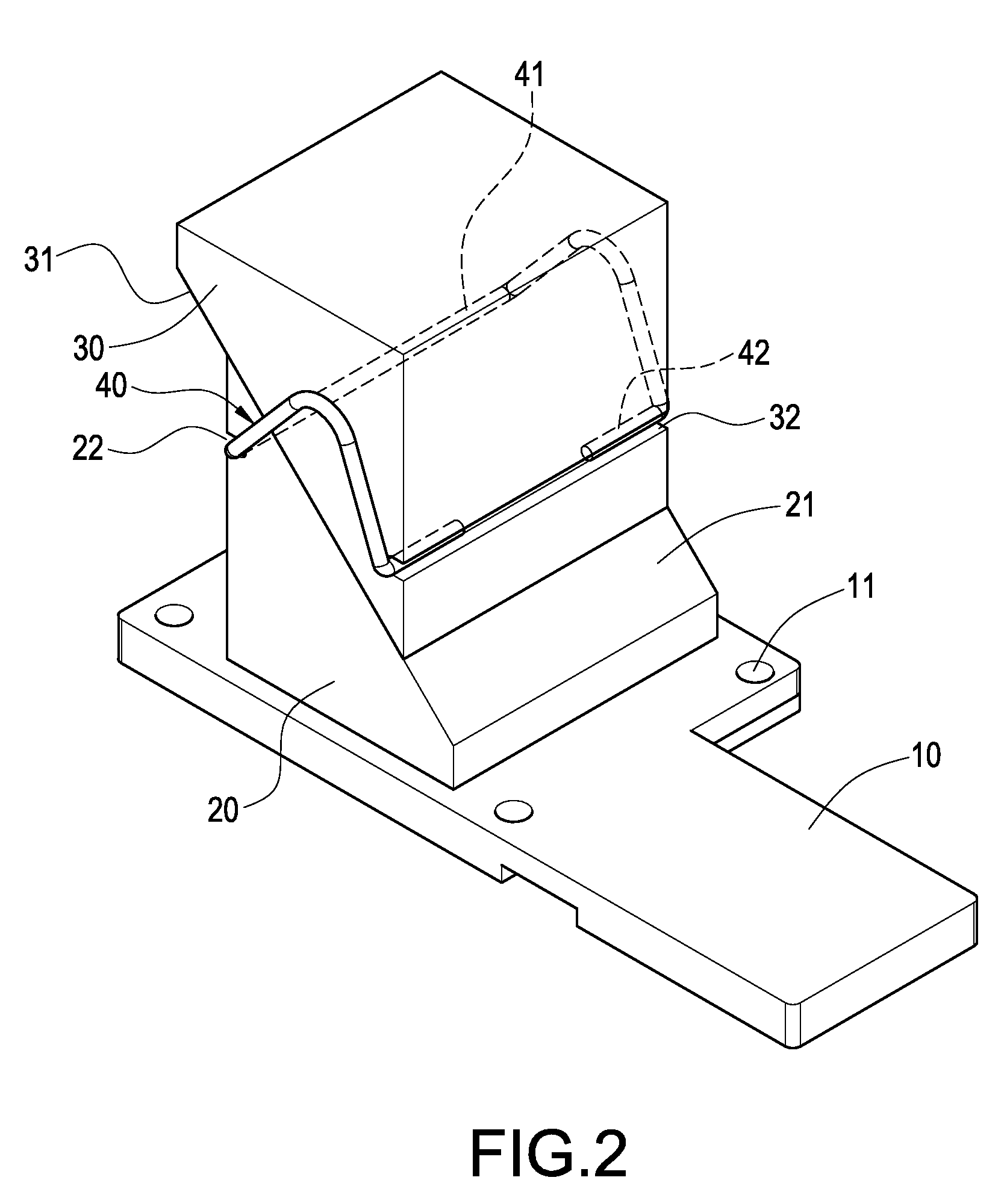

Heat-conducting assembly

InactiveUS20090229808A1Improve thermal efficiencyAvoid efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

A heat-conducting assembly is mounted between a heat-generating element and a heat-dissipating plate. The heat-conducting assembly includes a base, a first heat-conducting block, a second heat-conducting block and an elastic element. The base is attached on the heat-generating element. The first heat-conducting block is provided on the base. The first heat-conducting block has a first slope and a fixing groove. The second heat-conducting block abuts on the heat-dissipating plate. The second heat-conducting block has a second slope and a locking groove. The second slope is slidingly disposed on the first slope. The elastic element has a fixed end and a buckling end formed on one side of the fixed end. The fixed end is fixed in the fixing groove, and the buckling end is buckled into the locking groove. Via this arrangement, the heat-conducting efficiency of the heat-conducting assembly of the present invention can be improved.

Owner:CHEMTRON RES

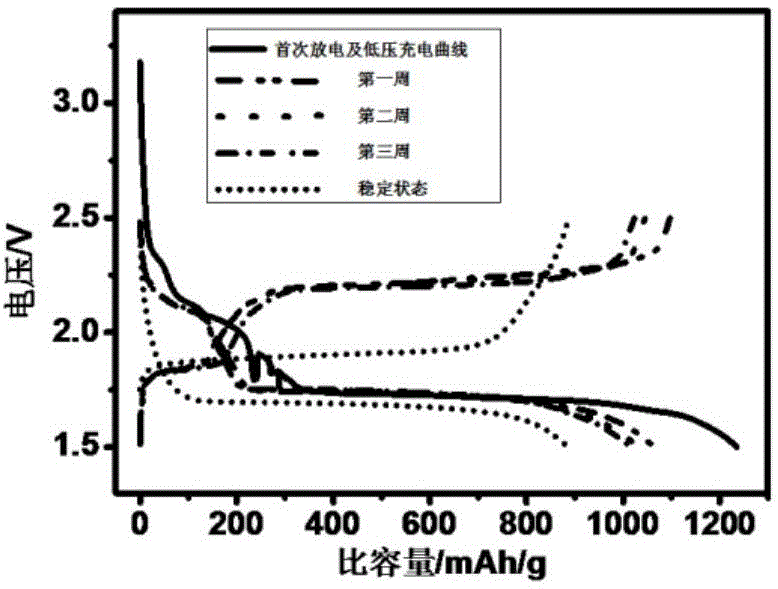

Manufacturing method for long-life lithium sulfur battery positive electrode

InactiveCN105304958ANo pollutionEasy to operateCell electrodesSecondary cells charging/dischargingLithium sulfideSulfide ions

The invention discloses a new method for on-site synthesis of a lithium ion conductive protection film for preventing poly-sulfide-ions diffusion on a surface of a lithium sulfur battery positive electrode, and an application therefor. The method is carried out by the steps of reducing the initial discharge voltage lower limit of a lithium sulfur battery taking a carbon sulfur composite as the positive electrode material to be lower than the normal working voltage 1.5V to generate the lithium ion conductive protection film; the film is quite high in the lithium ion conductivity and capable of preventing the poly-sulfide-ions from being dissolved in an electrolyte to enable the lithium sulfur battery to realize and maintain higher cycle performance, rate capability, coulombic efficiency and lower self discharge performance, so that the service life of the lithium sulfur battery is prolonged, and the use cost of the lithium sulfur battery is reduced; meanwhile, porous carbon with hierarchical pores used as the supporting material can accommodate the poly-sulfide-ions and lithium sulfide generated in charging and discharging processes of sulphur and the lithium sulfur battery; and the sulphur content in the carbon-sulfur composite material made from the porous carbon with the hierarchical pores is high, so that the comprehensive specific capacity of the carbon-sulfur composite product can be improved so as to further increase the overall energy density of the battery.

Owner:TSINGHUA UNIV

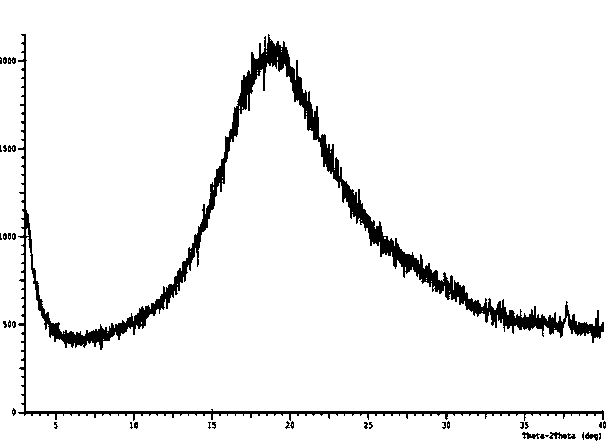

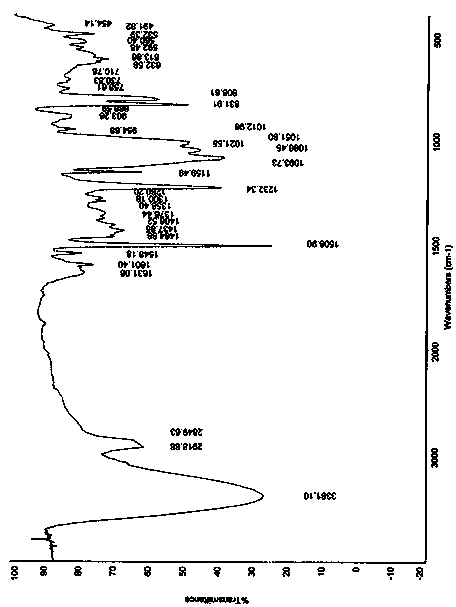

Amorphous substance of canagliflozin and preparation method of amorphous substance

The invention discloses an amorphous substance of canagliflozin and a preparation method of the amorphous substance. Through DSC (Differential Scanning Calorimetry) scanning, the amorphous substance is found to have an endothermic peak within the temperature range of 53-63 DEG C and has characteristic absorption peaks at the wavelengths of about 832cm<-1> and 809cm<-1> in an infrared spectrogram. The invention also discloses an application of the amorphous substance to preparation of drugs for treating type-2 diabetes.

Owner:CHONGQING PHARMA RES INST

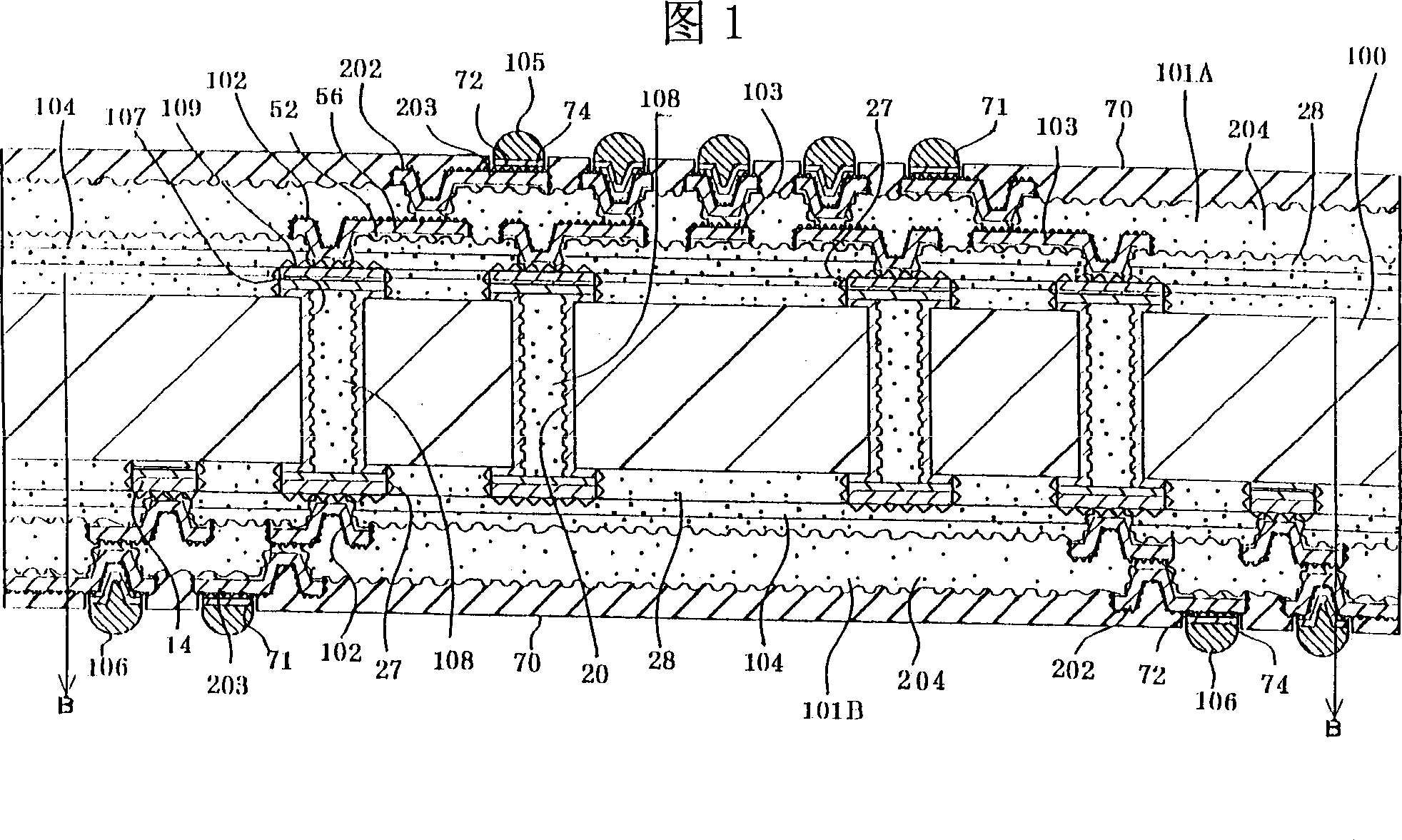

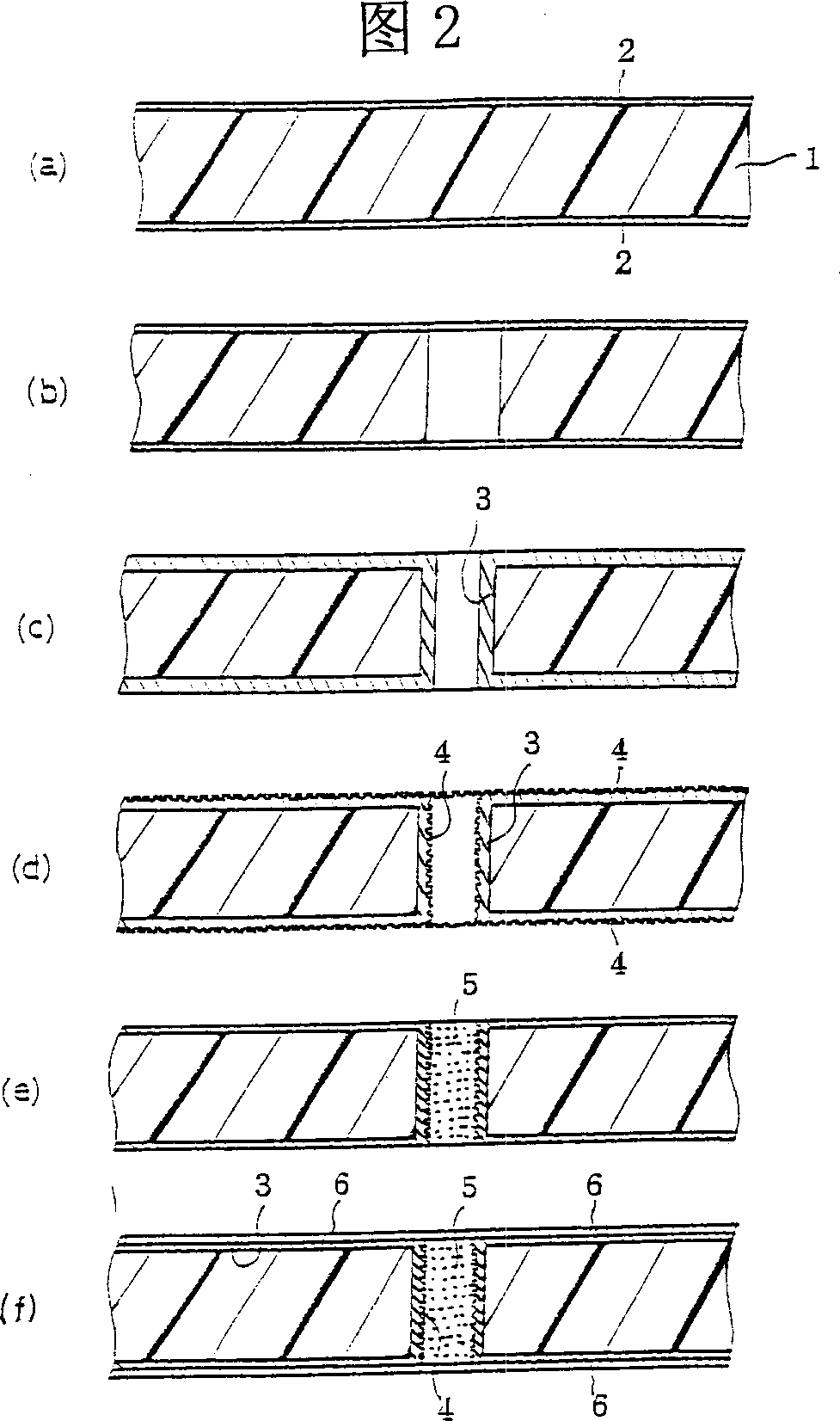

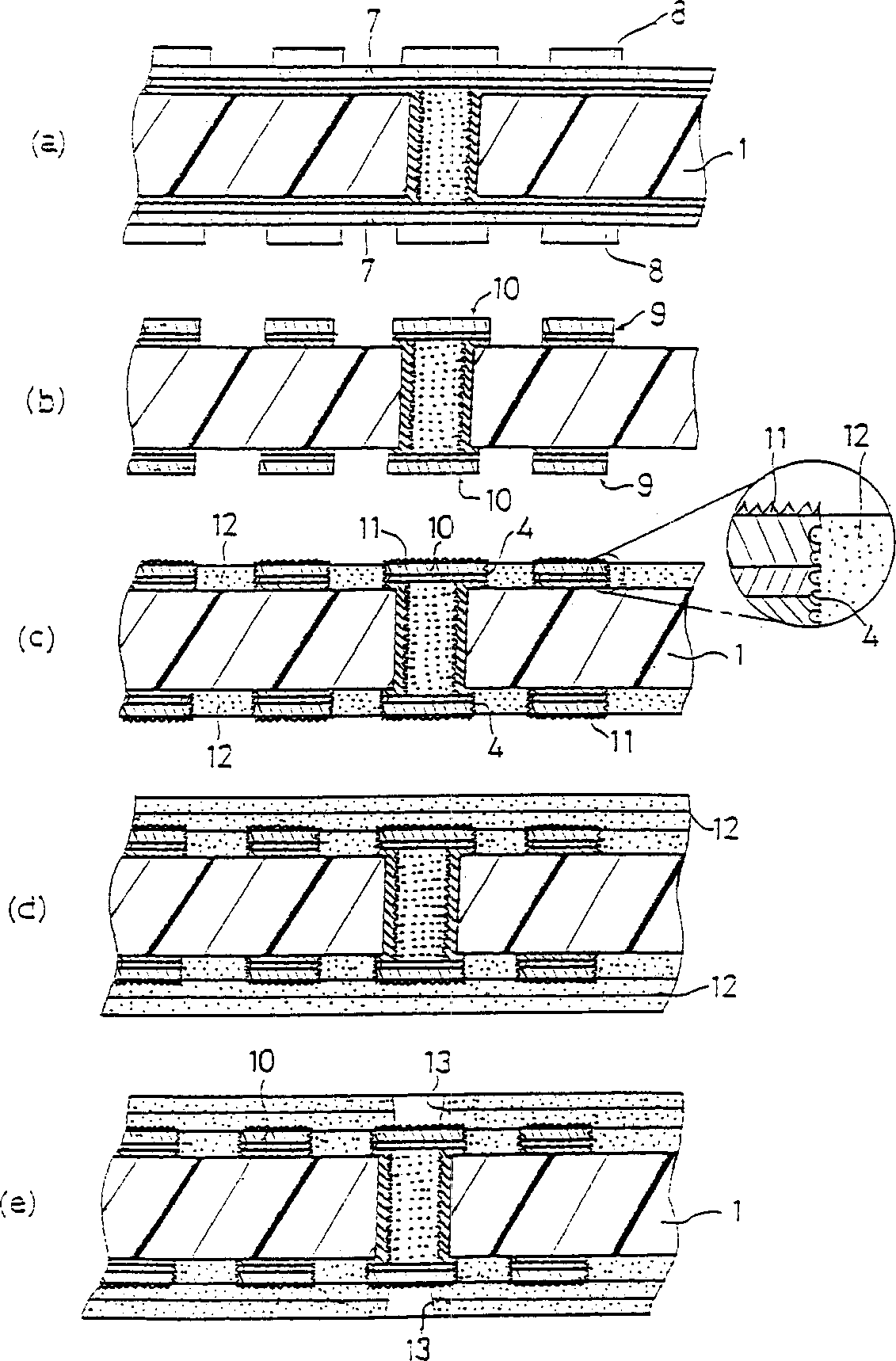

Multilayer printed wiring board and its manufacturing method, and resin composition for filling through-hole

InactiveCN1272298AIndustrial applicabilityInsulating substrate metal adhesion improvementLayered productsHigh densityElectrical conductor

A multilayer printed wiring board is composed of a substrate (100) provided with through-holes (107), and a wiring board (101) formed on the substrate (100) through the interposition of an interlaminar insulating resin layer (104), the through-holes (107) having a roughened internal surface and being filled with a filler (108), an exposed part of the filler (108) in the through-holes (107) being covered with a through-hole-covering conductor layer (109), and a viahole (102) formed just thereabove being connected to the through-hole-covering conductor layer (109). Without peeling between the through-holes (107) and the filler (108), this wiring board has a satisfactory connection reliability between the through-holes (107) and the internal layer circuit (103) and provides a high density wiring.

Owner:IBIDEN CO LTD

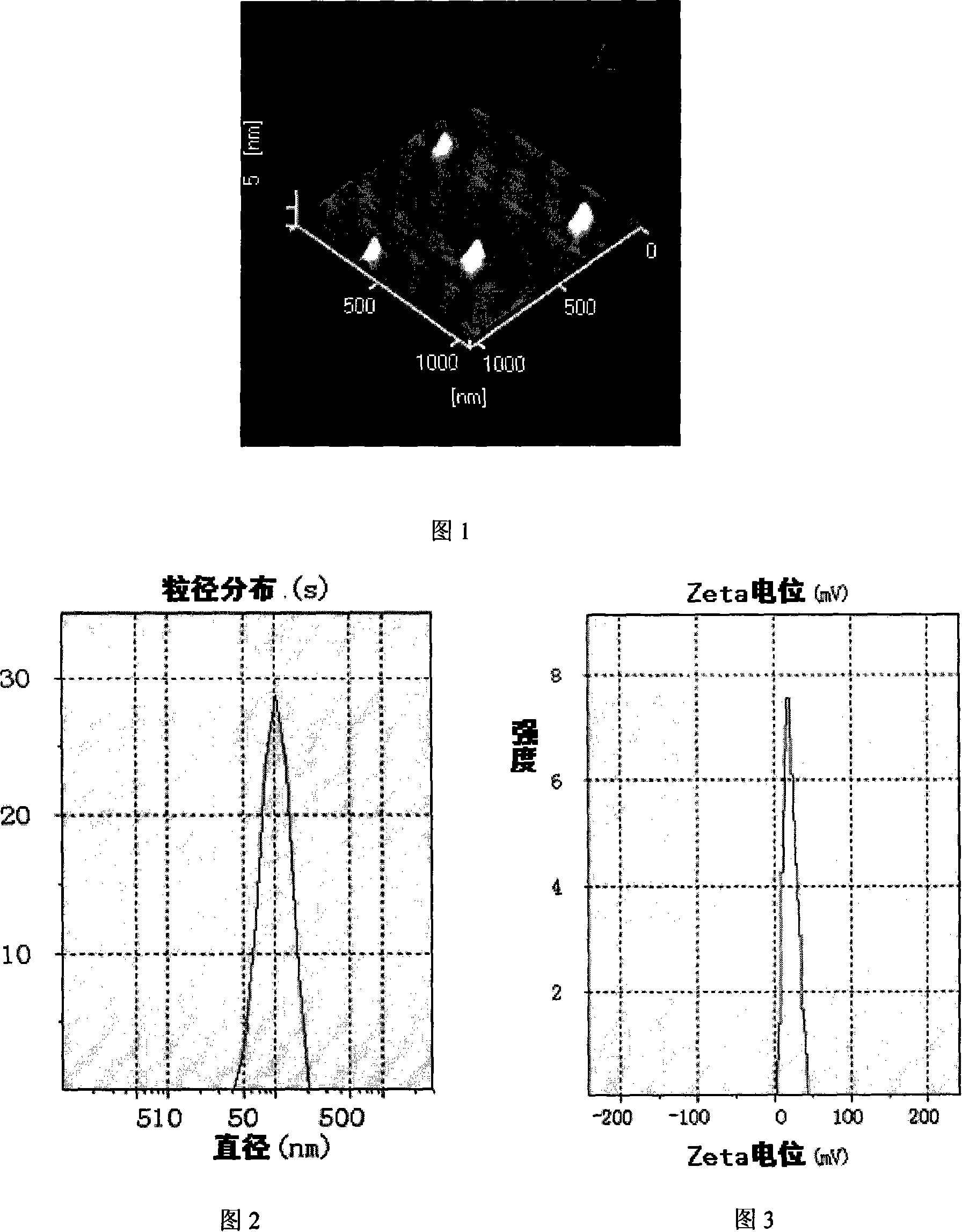

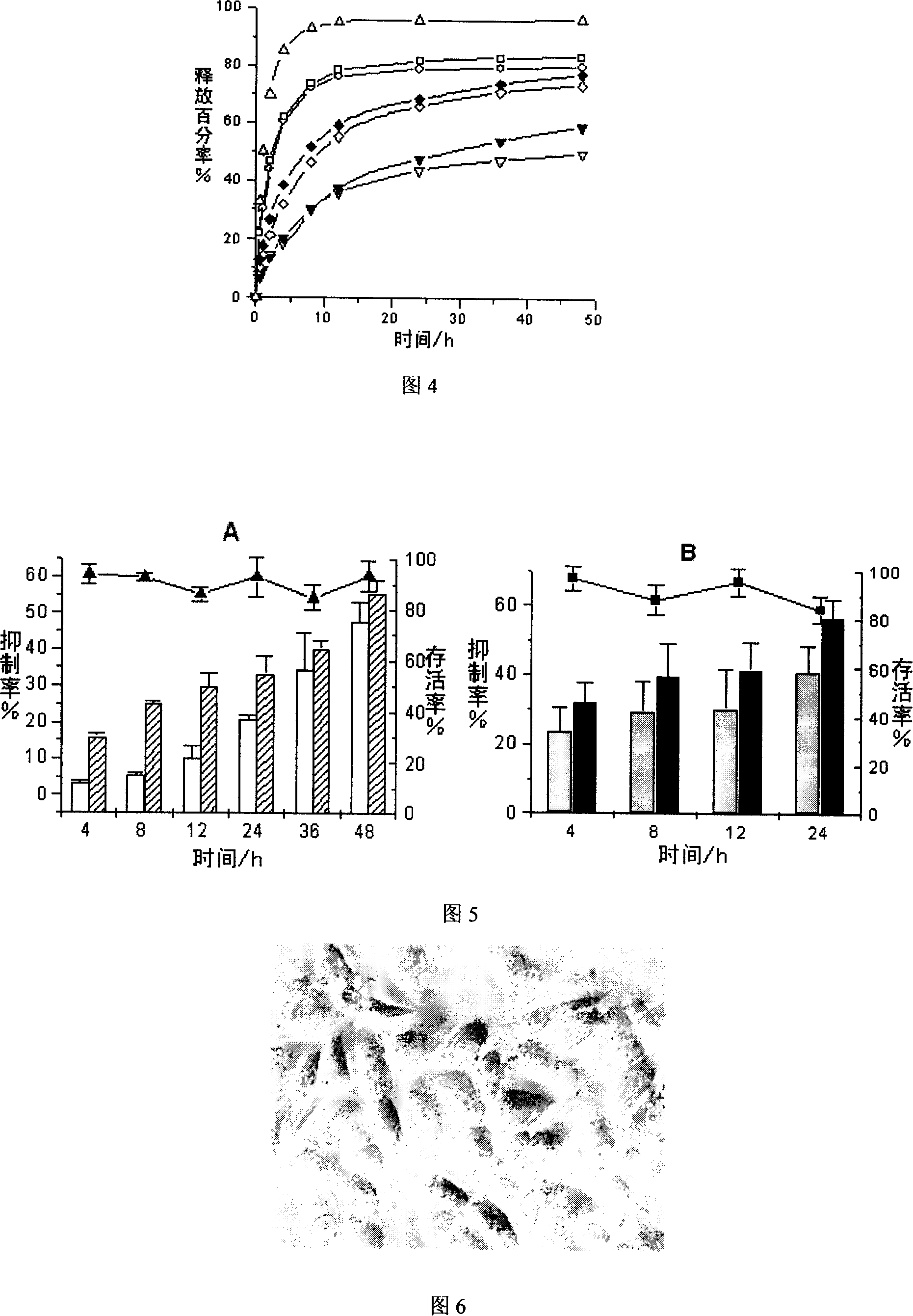

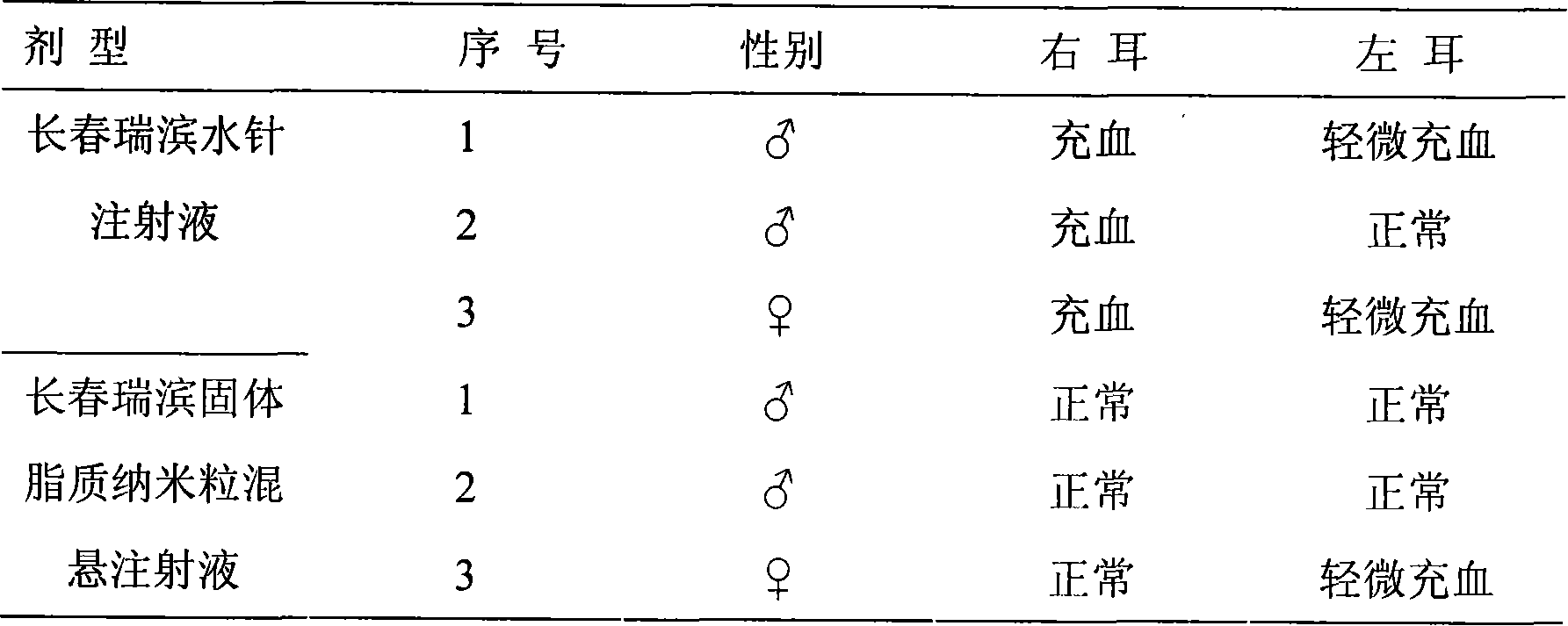

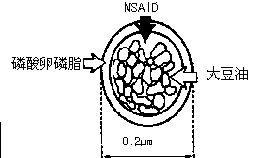

Vinorelbine solid lipid nano granule, freeze drying formulated product and method of preparing the same

InactiveCN101129375AAvoid degradationPrevent proliferationOrganic active ingredientsPowder deliveryWater bathsLipid formation

Disclosed is kind of Vinorelbine solid lipid nanoparticles which comprise (by weight percent) vinorelbine 1-25%, grease material 30-90%, phospholipids 5-50% oleinic acid 0-20%. The preparing process consists of melting liposome material through water-bath, dissolving phosphatides, oleic acid and Vnorelbine with ethanol, dropping into the liposome material, removing ethanol under decompression condition, cooling down and freezing, placing into pH 2-5 aqueous phase, triturating and homogenizing the turbid liquor to obtain the freeze-dried preparation with improved anticancer reactivity of Vinorelbine.

Owner:ZHEJIANG UNIV

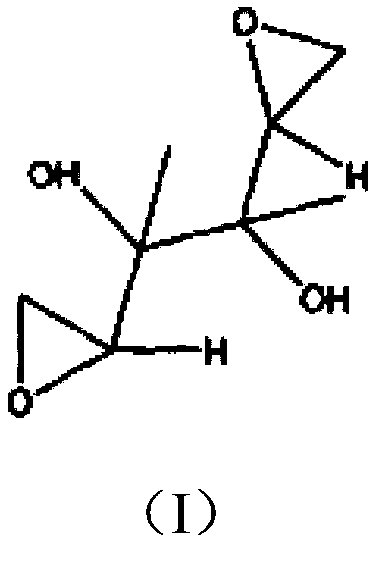

Compositions and methods to improve the therapeutic benefit of suboptimally administered chemical compounds including substituted hexitols such as dianhydrogalactitol and diacetyldianhydrogalactitol

InactiveCN103476250AUse effectively and efficientlySide effect preventionBiocideHydroxy compound active ingredientsDianhydrogalactitolSide effect

The present invention describes methods and compositions for improving the therapeutic efficacy of therapeutic agents previously limited by suboptimal therapeutic performance by either improving efficacy as monotherapy or reducing side effects. Such methods and compositions are particularly applicable to substituted hexitols such as dianhydrogalactitol and diacetyldianhydrogalactitol.

Owner:DEL MAR PHARMA

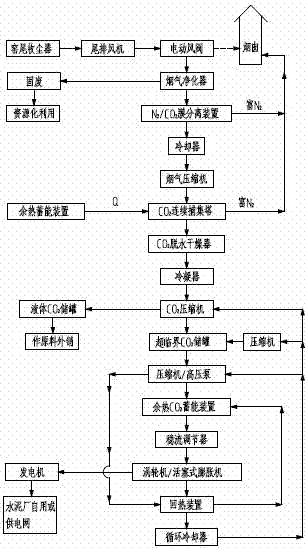

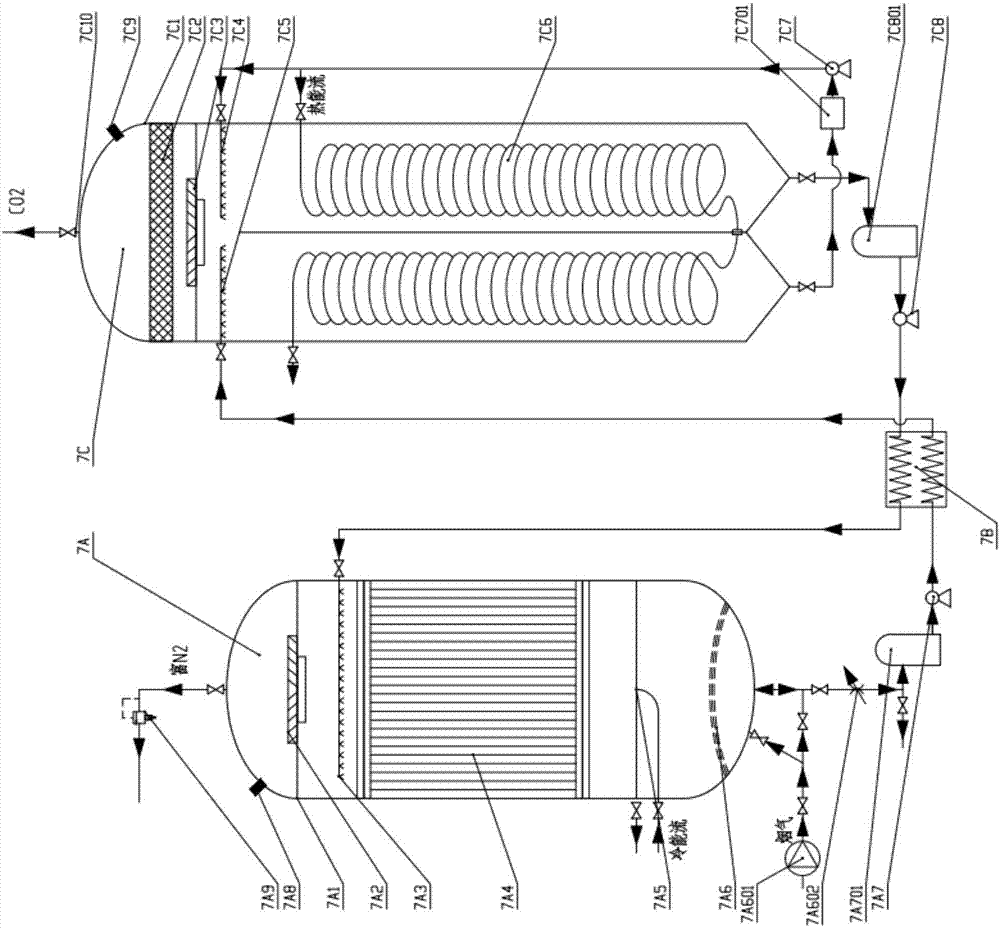

Method for trapping carbon dioxide in cement kiln flue gas and generating by carbon dioxide

ActiveCN106914116ASimple processLess investmentGas treatmentUsing liquid separation agentProduction lineTrapping

The invention relates to a method for trapping carbon dioxide in cement kiln flue gas and generating by carbon dioxide. The method comprises the following steps: 1) purification of flue gas; 2) membrane separation for enriching CO2; 3) continuous trapping of CO2; 4) liquefaction storage of CO2; 5) energy storage of supercritical CO2 fluid; 6) tempering and generating by supercritical CO2; and 7) circulation of supercritical CO2 and back heating utilization. The method aims at the technical equipment characteristic of a cement production line and flue gas composition characteristic, waste heat energy produced during a cement production process and / or high temperature heat energy which can generate unfavorable influence are taken as main energy for realizing carbon dioxide trapping and supercritical CO2 generating, and the method has the advantages of low self-energy consumption, low investment, and low operation cost.

Owner:长沙紫宸科技开发有限公司

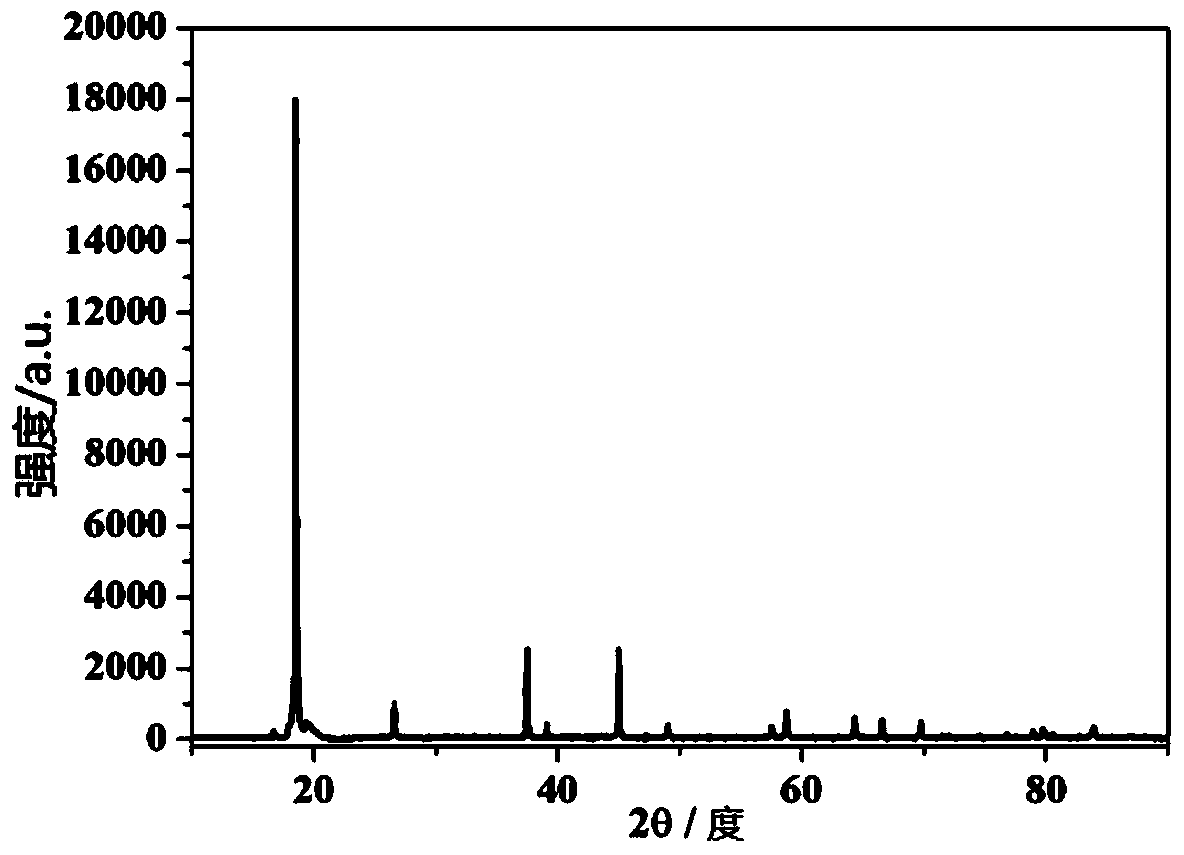

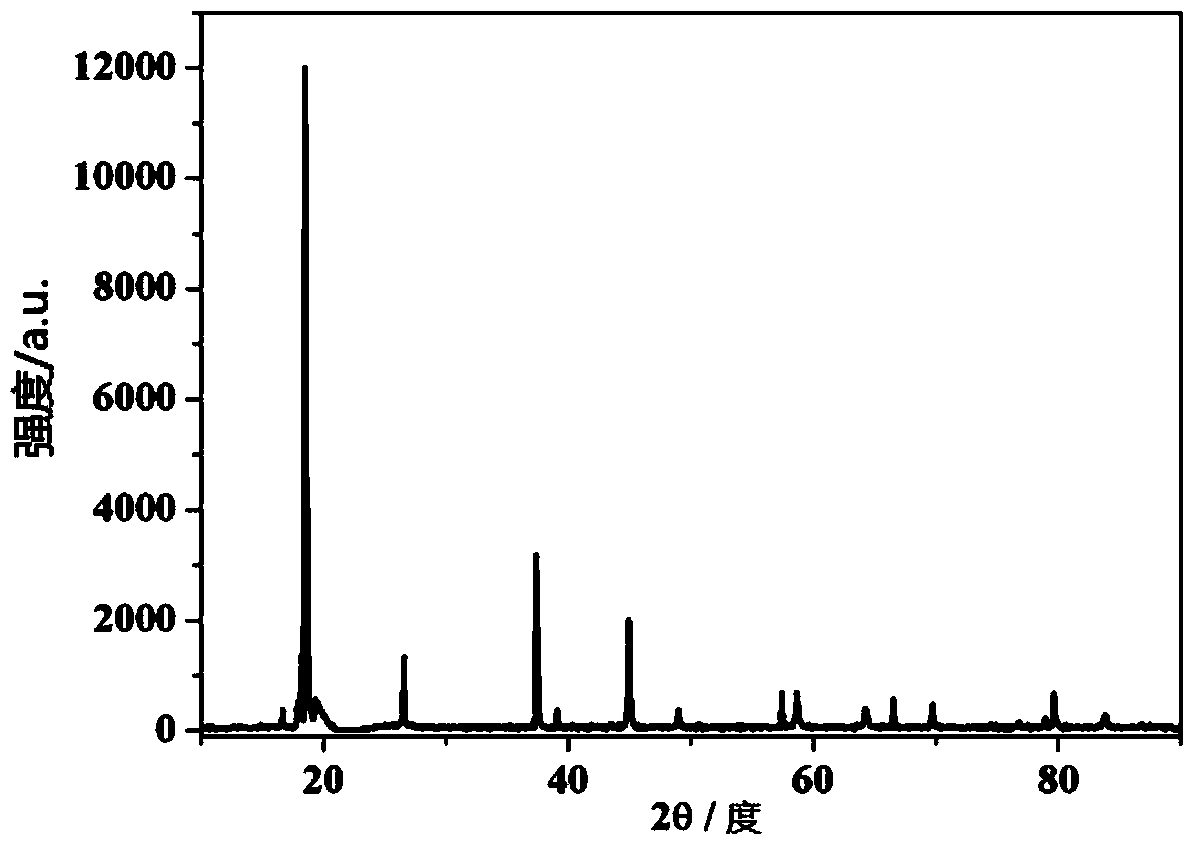

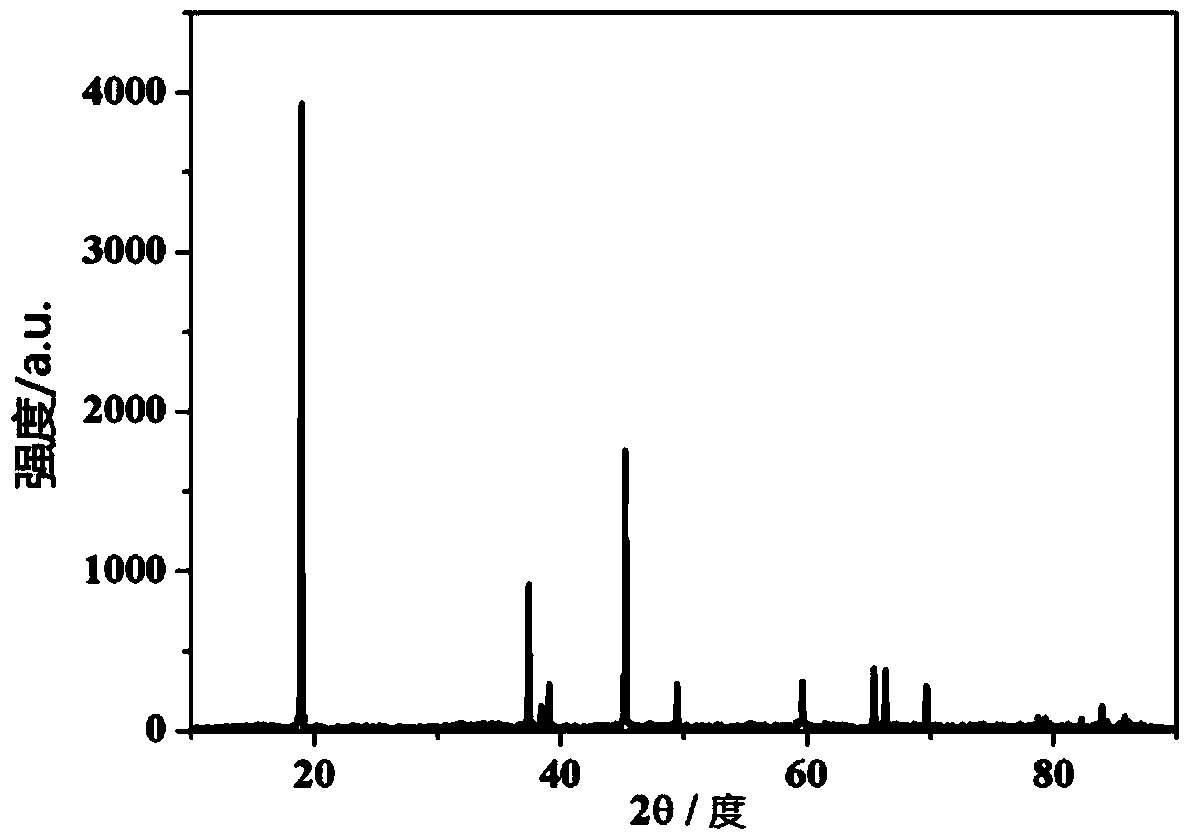

Modified lead nickel niobate-lead zirconate titanate piezoelectric ceramics and preparing method thereof

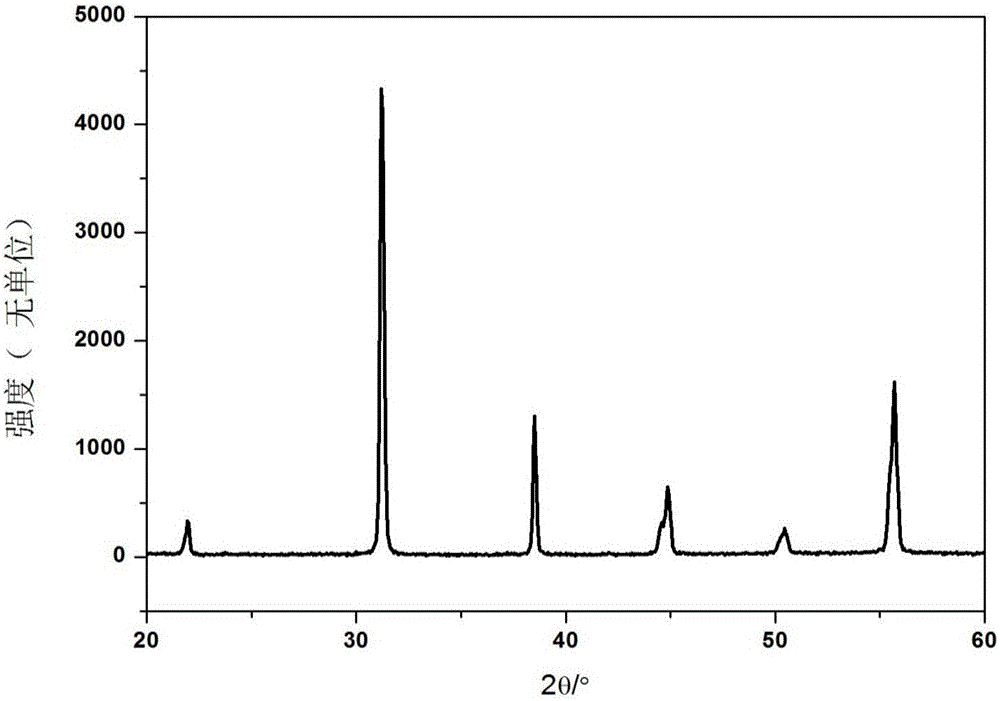

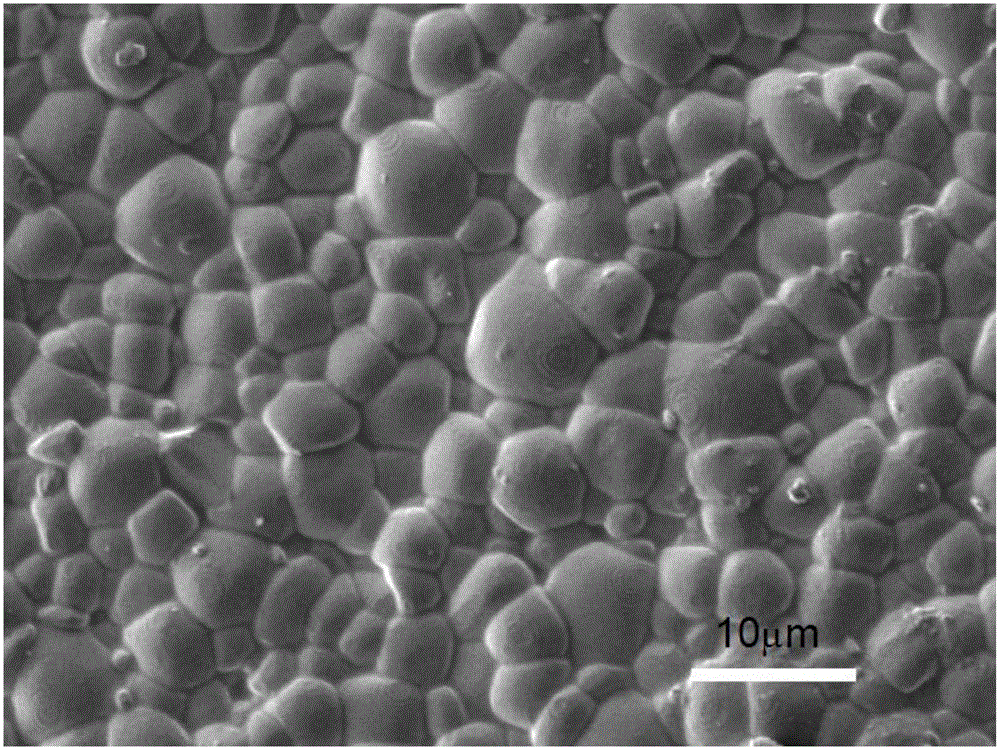

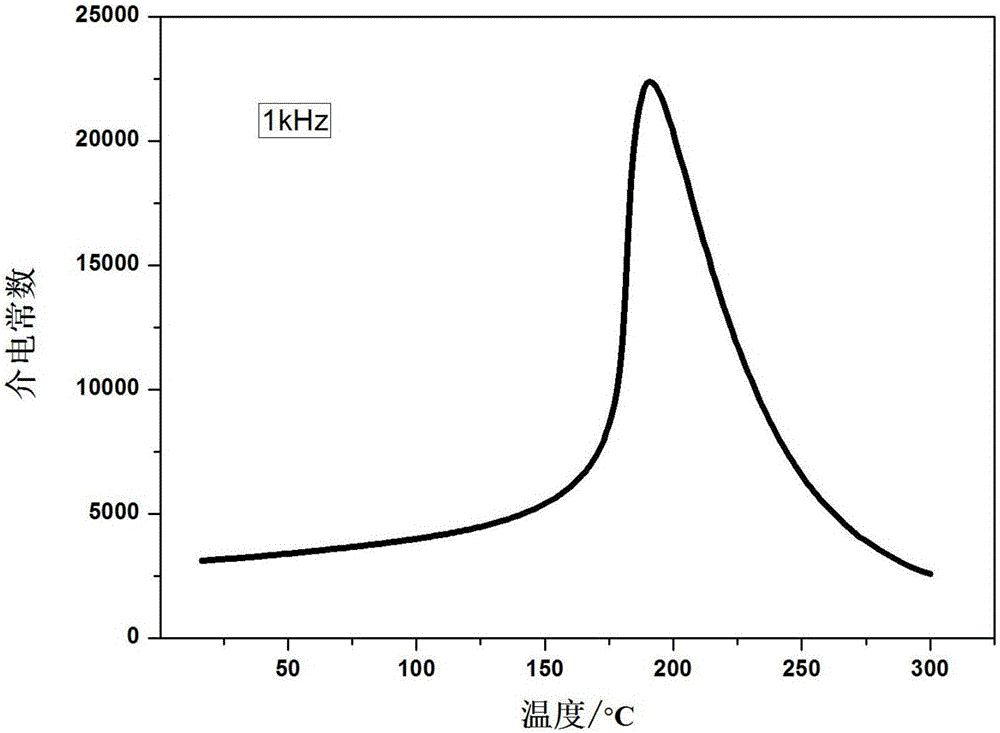

InactiveCN106220169AHigh curie temperatureTurn simplePiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateElectromechanical coupling coefficient

The invention discloses modified lead nickel niobate-lead zirconate titanate piezoelectric ceramics. The chemical components are as follow: Pb1-xMex(Ni1 / 3Nb2 / 3)0.326(ZryTi1-y)0.674O3+3%PbO+3% NiO+zwt%A; wherein Me represents any one or two of strontium and neodymium, and A represents any one of antimony oxide and yttrium oxide. As strontium or neodymium and antimony or yttrium are doped into the piezoelectric ceramics, a substitution solid solution is formed, and the piezoelectric ceramics with good comprehensive performance of 0.326 PNN-0.647 PZT are obtained. The piezoelectric ceramics have excellent piezoelectric and dielectric properties, the high Curie temperature and a high electromechanical coupling coefficient. The preparing method is simple, raw materials are easy to obtain, and the preparing method has industrial applicability.

Owner:重庆胜普昂凯科技有限公司

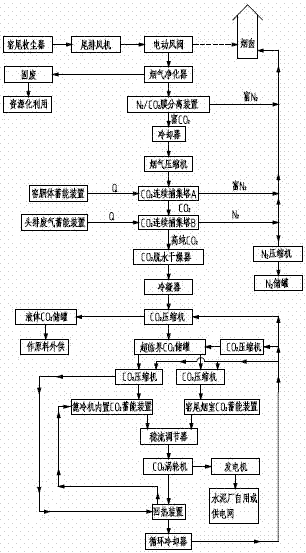

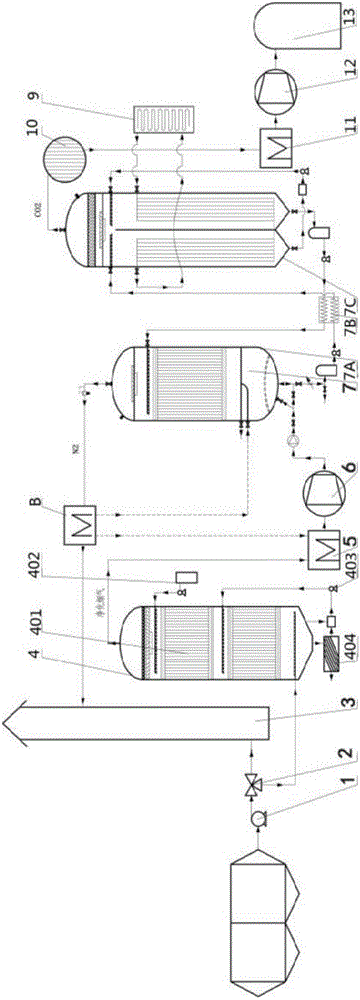

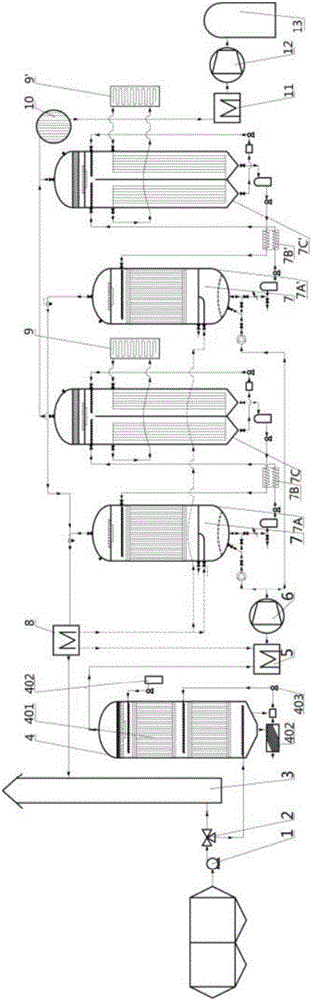

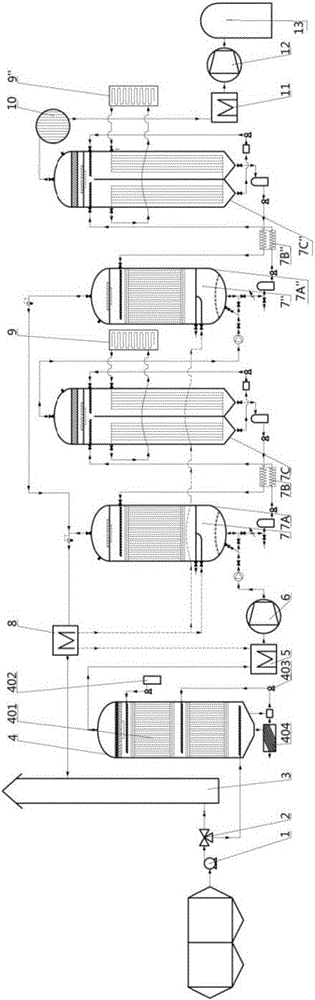

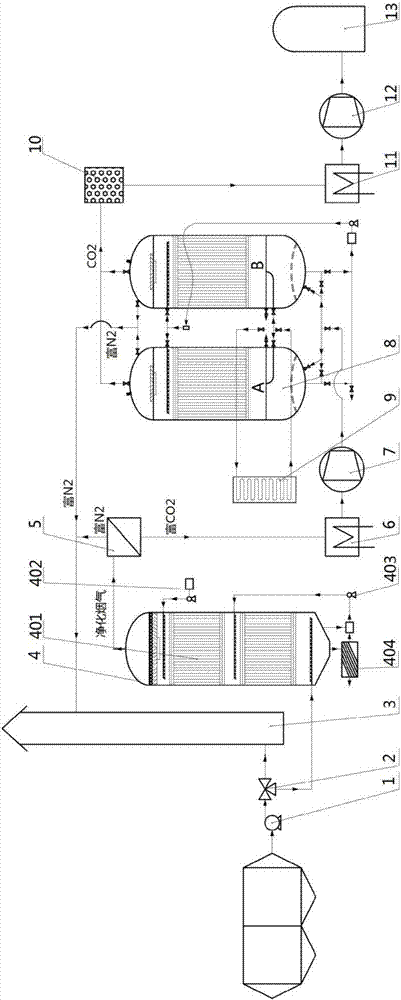

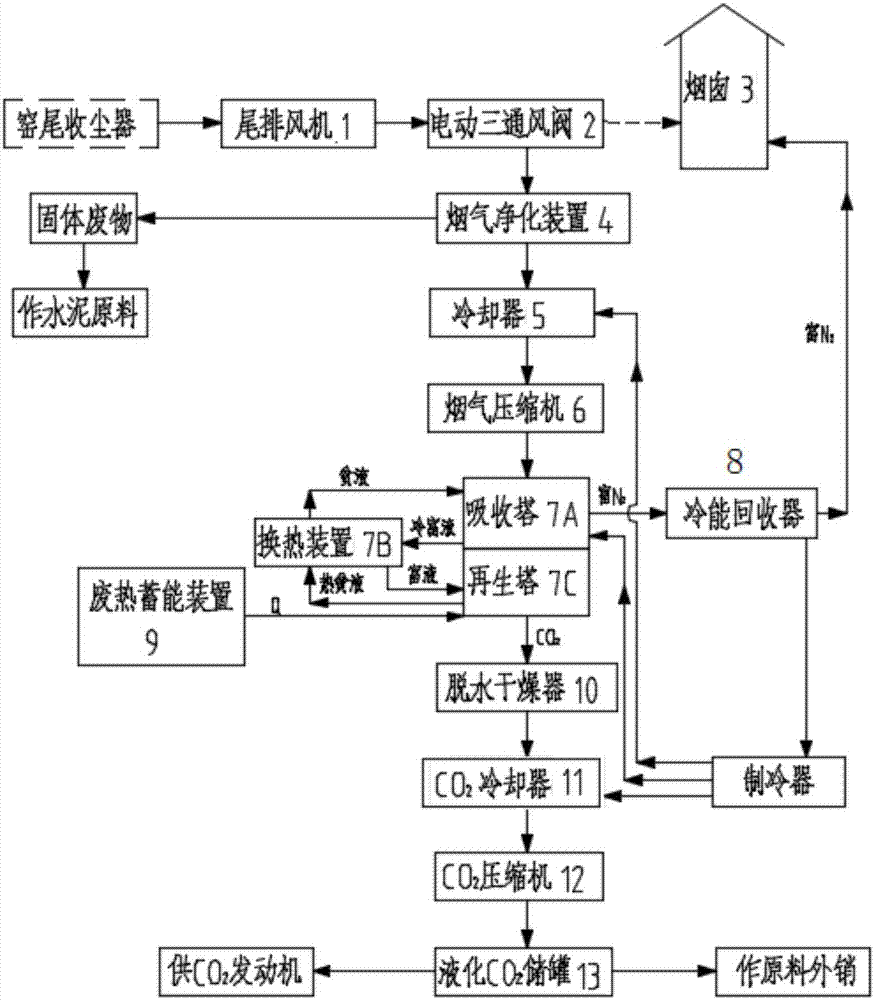

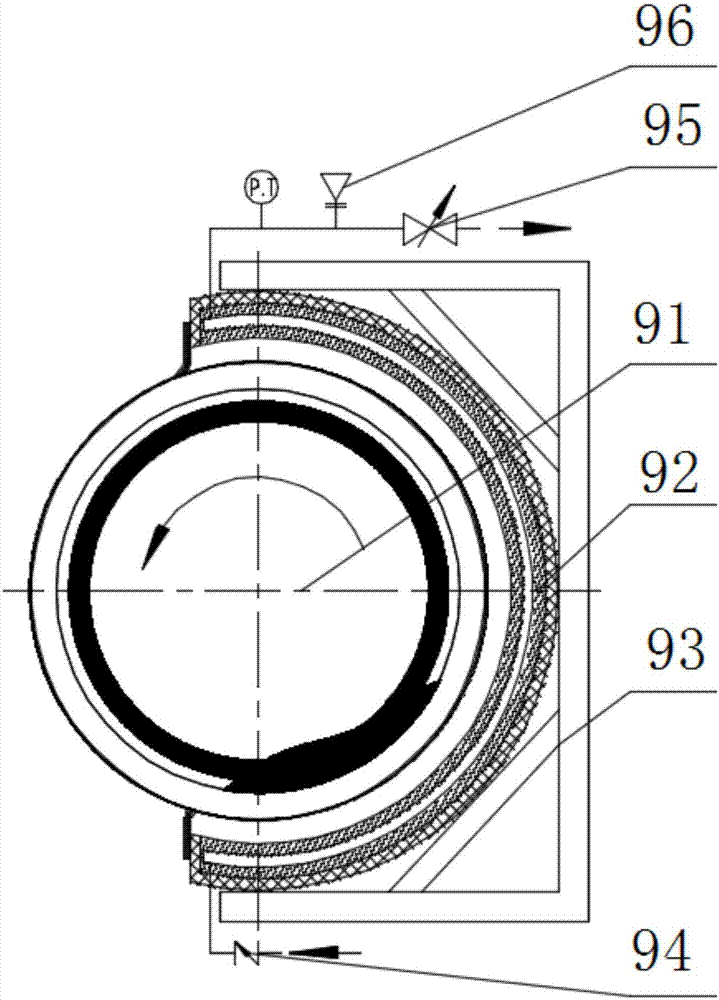

Device system for continuously trapping CO2 in flue gas of cement kiln through hydrate method

ActiveCN106823754ACapture completelyCapture thoroughlyProductsGas treatmentSelf consumptionProcess equipment

The invention provides a device system for continuously trapping CO2 in flue gas of a cement kiln through a hydrate method. The device system comprises a tail exhaust fan, an electric three-way air valve, a chimney, a flue gas purifying device, a cooler, a flue gas compressor, a CO2 absorbing tower-regeneration tower unit, a cold energy recovery device, a waste heat energy storage device, a dehydration dryer, a CO2 cooler, a CO2 compressor and a liquefied CO2 storage tank. The CO2 absorbing tower-regeneration tower unit comprises a CO2 absorption tower, a poor / rich fluid heat exchanger device and a CO2 regeneration tower, and the above parts are orderly connected. The device system is based on a cement production line process and process equipment, utilizes cement production waste heat as heat exchange energy, utilizes a hydrate accelerator to continuously capture the CO2 in flue gas of the cement kiln, can purify the flue gas, and realizes high efficiency, low self-consumption, low investment and low operating cost.

Owner:长沙紫宸科技开发有限公司

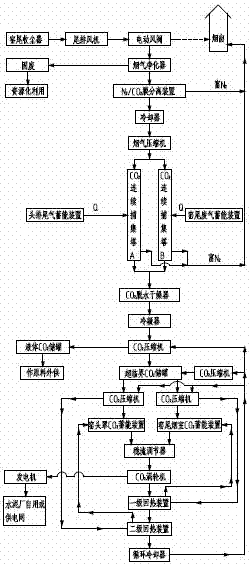

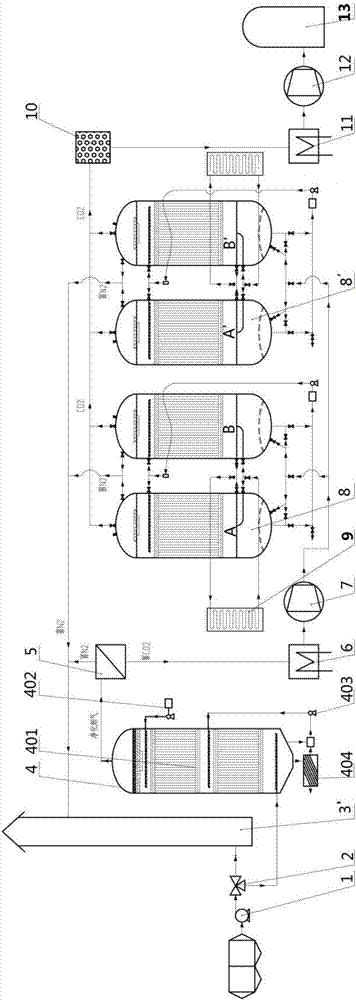

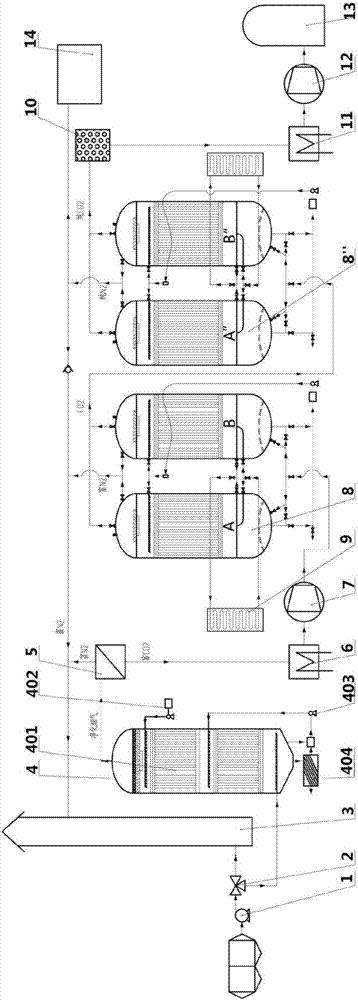

Equipment system applicable to continuous capture of CO2 in flue gas of cement kiln

PendingCN107115776AEffective emission reductionEffective productivityProductsReagentsProduction lineFlue gas

The invention discloses an equipment system applicable to continuous capture of CO2 in flue gas of a cement kiln. The equipment system comprises a kiln end exhaust fan, a chimney, a flue gas oxidization purifier, a N2 / CO2 membrane separation device, a cooler, a flue gas compressor, a CO2 cycle capture tower, a dehydration dryer, a CO2 cooler, a CO2 compressor and a liquefied CO2 storage tank, wherein the kiln end exhaust fan is communicated with a gas inlet of the flue gas oxidization purifier; a purified flue gas outlet of the flue gas oxidization purifier is communicated with a gas inlet of the N2 / CO2 membrane separation device; a N2-rich discharge port of the N2 / CO2 membrane separation device is communicated with the chimney; a CO2-rich discharge port of the N2 / CO2 membrane separation device is sequentially communicated with the CO2 cycle capture tower by the cooler and the flue gas compressor; the CO2 cycle capture tower comprises a CO2 cycle capture releaser A and a CO2 cycle capture releaser B which alternately and continuously perform CO2 capture and CO2 release. The equipment system is simple in structure and low in construction cost, has industrial applicability, realizes clean discharge of the flue gas on a cement production line, realizes effective discharge reduction and low-carbon production of a cement enterprise, and also realizes high-efficiency and continuous CO2 capture and separation.

Owner:长沙紫宸科技开发有限公司

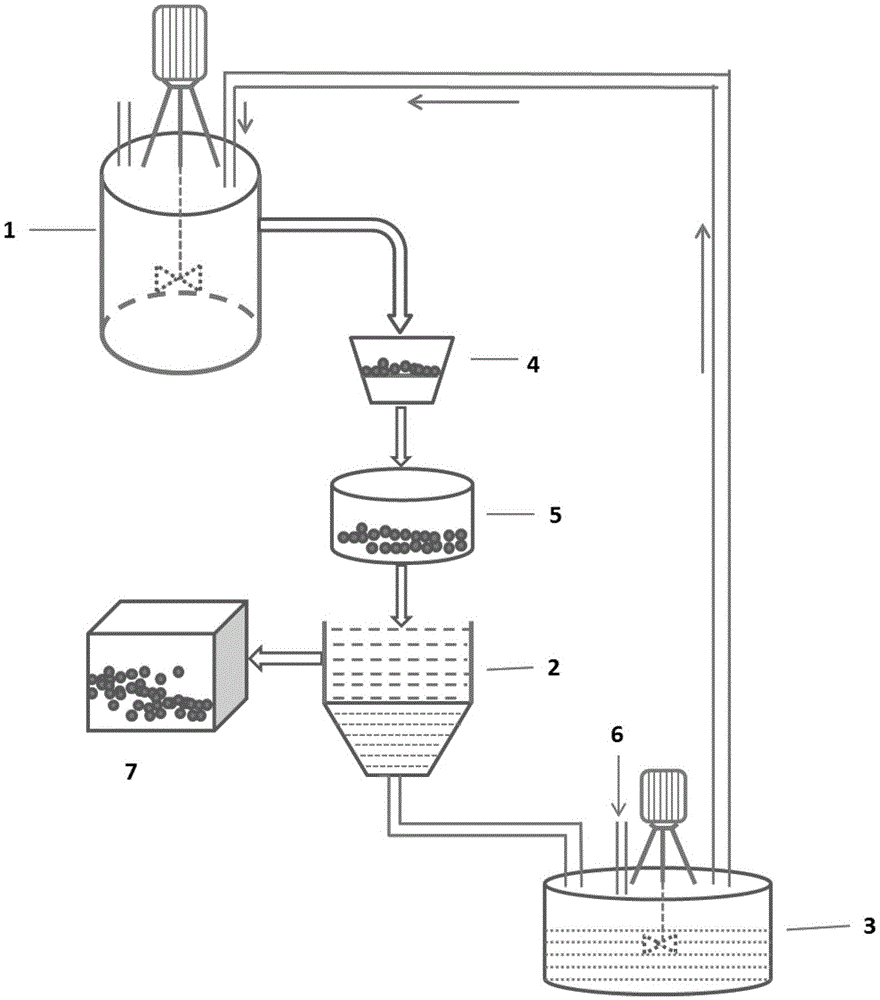

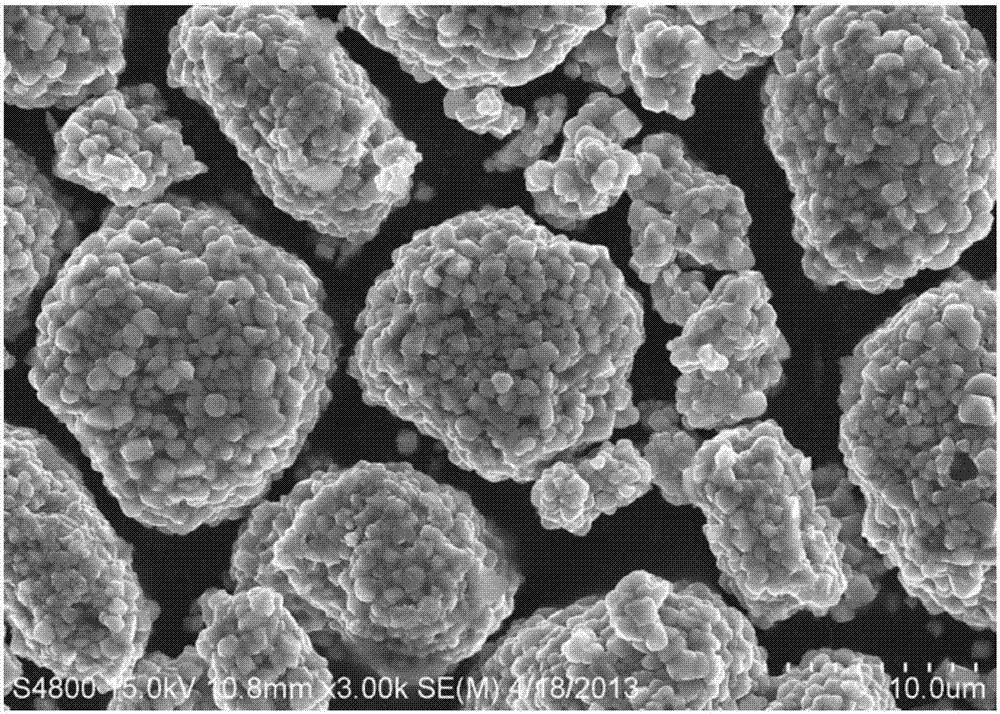

A method for preparing nickel-cobalt-manganese ternary material precursor

ActiveCN103943847BRealize comprehensive utilizationIncrease profitCell electrodesSecondary cellsManganeseCobalt

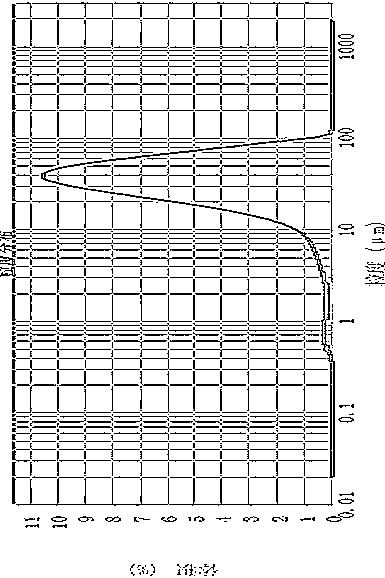

The invention discloses a method for preparing a nickel-cobalt-manganese ternary material precursor. By virtue of the method, waste small-particle-size nickel-cobalt-manganese ternary material precursors in a product are separated out and recycled into a reaction kettle, so that the ternary material precursors with the particle size of 7-15 micro meters account for over 95% in the product.

Owner:北京盟固利新材料科技有限公司

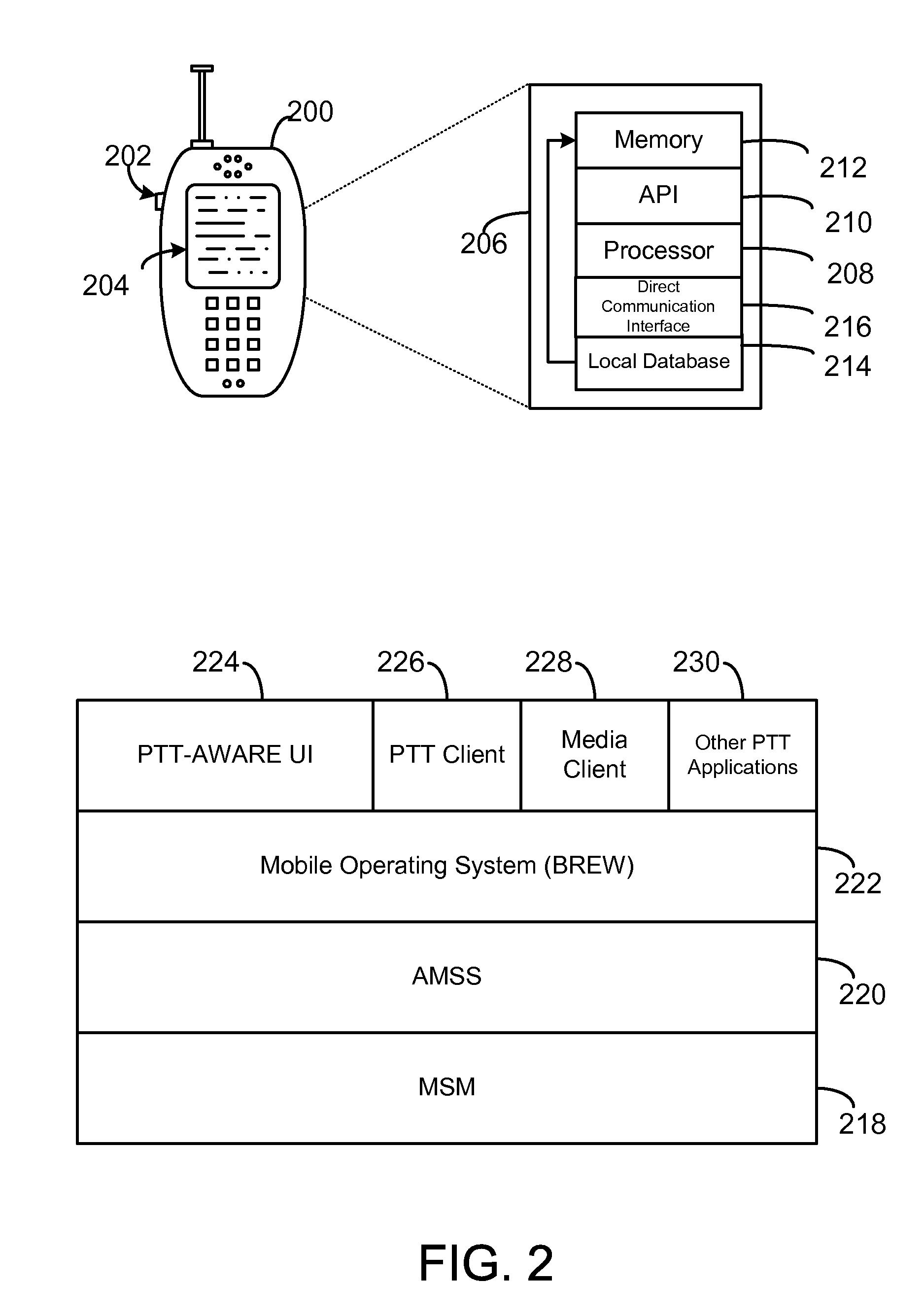

Session-triggered pushing of group communication data

ActiveUS20110177804A1Industrial applicabilityConnection managementBroadcast service distributionCommunications serverPush-to-talk

Exemplary techniques for sending data packages, such as media objects, during group communication sessions between wireless telecommunication devices, such as push-to-talk communication sessions, are disclosed. In one embodiment, the data packages, such as discrete data packages, are queued at the transmitting wireless communication device and then sent to other group members upon establishment of channels for group communications to the group members. The data packages can also be queued at the group communication server prior to being sent to a target device.

Owner:QUALCOMM INC

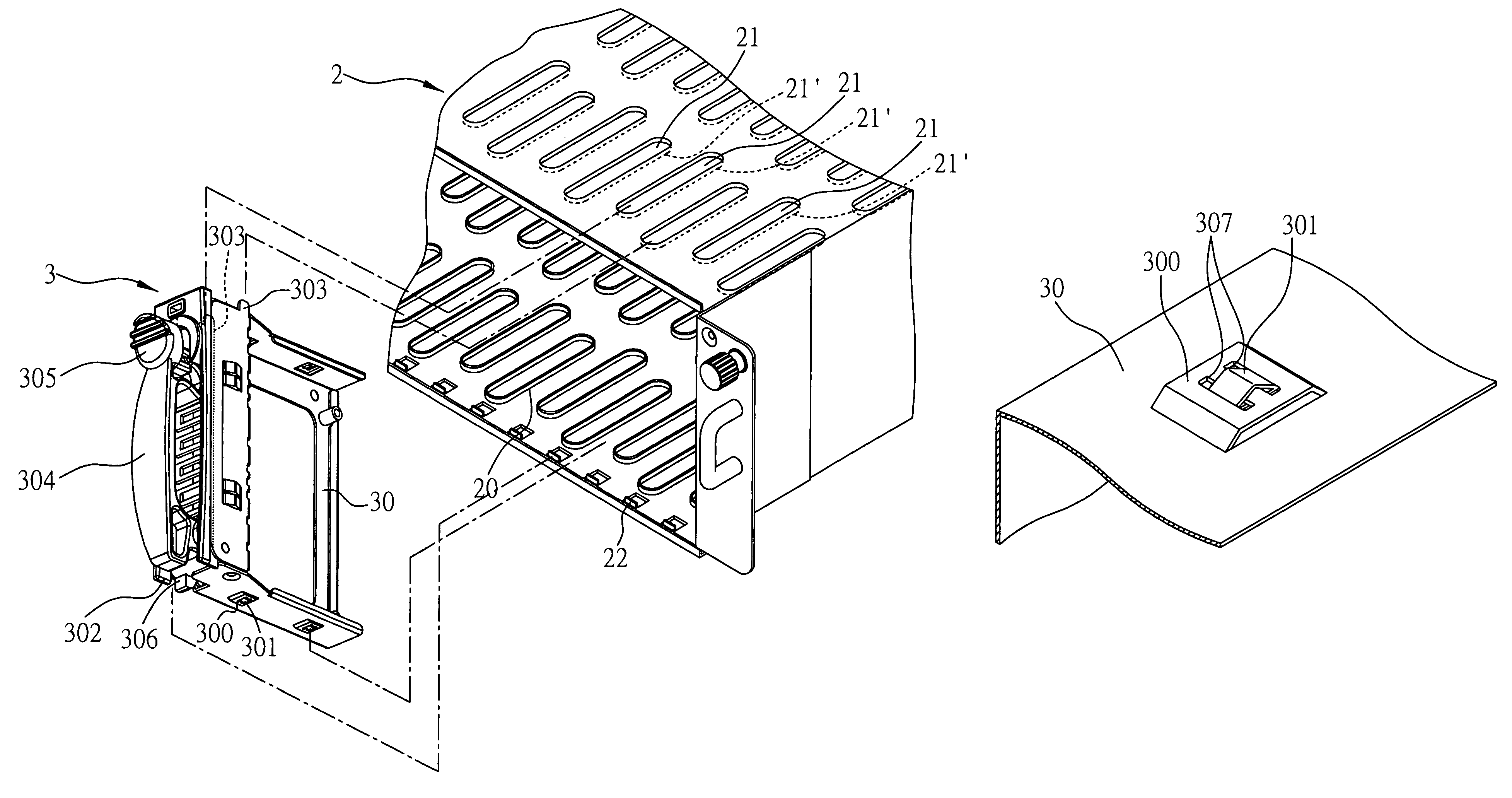

Shield member

InactiveUS7326078B1Smoothly and tightly inserted in slotShorten the lengthCarrier constructional parts dispositionIncorrect coupling preventionEngineeringMechanical engineering

Owner:INVENTEC CORP

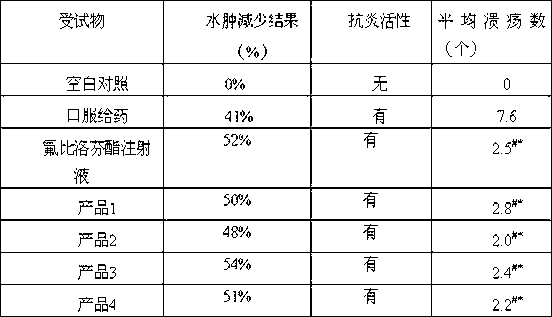

Novel 2-(2-fluorine-4biphenyl)-propionic acid pharmaceutical composition

ActiveCN103301101AReduce gastrointestinal adverse reactionsIndustrial applicabilityOrganic active ingredientsNervous disorderArgininePropionine

The invention provides a novel 2-(2-fluorine-4biphenyl)-propionic acid pharmaceutical composition. Flurbiprofen and basic amino acid arginine or lysine form a pharmaceutical composition solution. The composition can be administrated in an injection or oral administration manner and can also be further administrated in a freeze-drying manner. Compared with a flurbiprofen axetil injection, a flurbiprofen composition not only does not influence the antipyretic, anti-inflammation and analgestic effects of the flurbiprofen, but also has the advantages of simple technology, low cost, high quality, stable long shelf life and convenience in quality control, storage and transportation; moreover, compared with a conventional oral preparation, the flurbiprofen composition has the same low gastrointestinal tract adverse reaction as the flurbiprofen axetil injection.

Owner:南京星福星医药科技有限公司

Preparation method of easy cleaning ceramic tile

ActiveCN107382377AGood pollution resistanceEasy to cleanDecorative surface effectsNanotechnologyCeramic tiles

Belonging to the technical field of ceramics, the invention relates to a preparation method of an easy cleaning ceramic tile. The preparation method of the easy cleaning ceramic tile comprises the steps of: (a) preparing a blank layer; (b) applying overglaze on the blank layer to form an overglaze layer; (c) conducting printing on the overglaze layer to form a printing layer; and (d) applying easy cleaning protective glaze on the printing layer to form an easy cleaning protective dry granular layer. The easy cleaning protective glaze comprises the following components by mass: 90-110 parts of easy cleaning protective glaze, 230-270 parts of stamp-pad ink, and 20-40 parts of transparent glaze. The preparation method provided by the invention has the advantages of simple operation, easy implementation and low cost. The ceramic tile prepared by the method has excellent antifouling and easy cleaning properties, i.e. good antifouling performance and easy cleaning.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

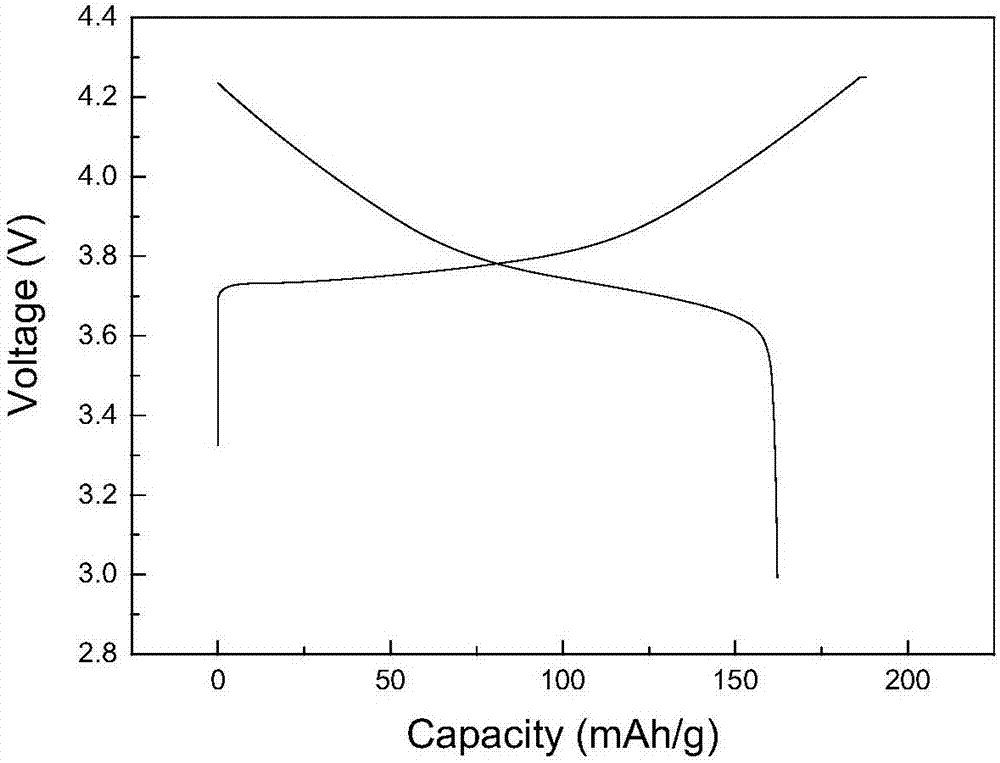

Preparation method of lithium ion battery positive electrode material

ActiveCN104051727AReduce manufacturing costLow priceCell electrodesSecondary cellsLithium hydroxidePhysical chemistry

The invention discloses a preparation method of a lithium ion battery positive electrode material. The method is characterized in that a mixture of lithium nitrate and lithium hydroxide acts as a lithium source and also acts as a solvent, so that a lithium source and a cobalt source are subjected to solid-liquid mixing and react nearby a lithium source eutectic point, so that the diffusion path of an ion is shortened, the thermal treatment temperature is lowered and the forging time is shortened, and finally the lithium ion battery positive electrode material with excellent electrochemical performance is obtained.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Method for continuously catching CO2 in cement kiln flue gas with hydrate method

ActiveCN106955569AFlexible adjustment and utilizationSolve expensive problemsGas treatmentDispersed particle separationProduction lineProcess equipment

The invention provides a method for continuously catching CO2 in cement kiln flue gas with a hydrate method. The method comprises the following steps: continuously catching, curing, separating CO2 in continuously-flowing flue gas stream by taking a hydrate promoter solution as a catching agent and taking a large amount of waste residual heat generated in a cement production process as an energy source through a CO2 absorbing tower-regeneration tower unit comprising a silk screen catching bed device, and enriching a CO2 hydrate and continuously separating and discharging N2-enriched gas flow to realize continuous catching; continuously enriching caught CO2 hydrate rich liquor, transferring the enriched CO2 hydrate rich liquor into a regeneration tower for performing continuous separating and releasing to obtain continuous CO2 gas flow, and recycling hydrate poor liquor obtained by continuous separating and releasing; drying, cooling, compressing and storing the CO2 being subjected to continuous separating and releasing. By adopting the method, the CO2 in the cement kiln flue gas is continuously caught efficiently at low cost by using a part of process equipment on a cement production line and waste residual heat generated in the cement production process, so that the technical problem that only intermittent high-pressure air-tight catching is available and continuous catching is unavailable in a process of catching CO2 with a hydrate is solved.

Owner:长沙紫宸科技开发有限公司

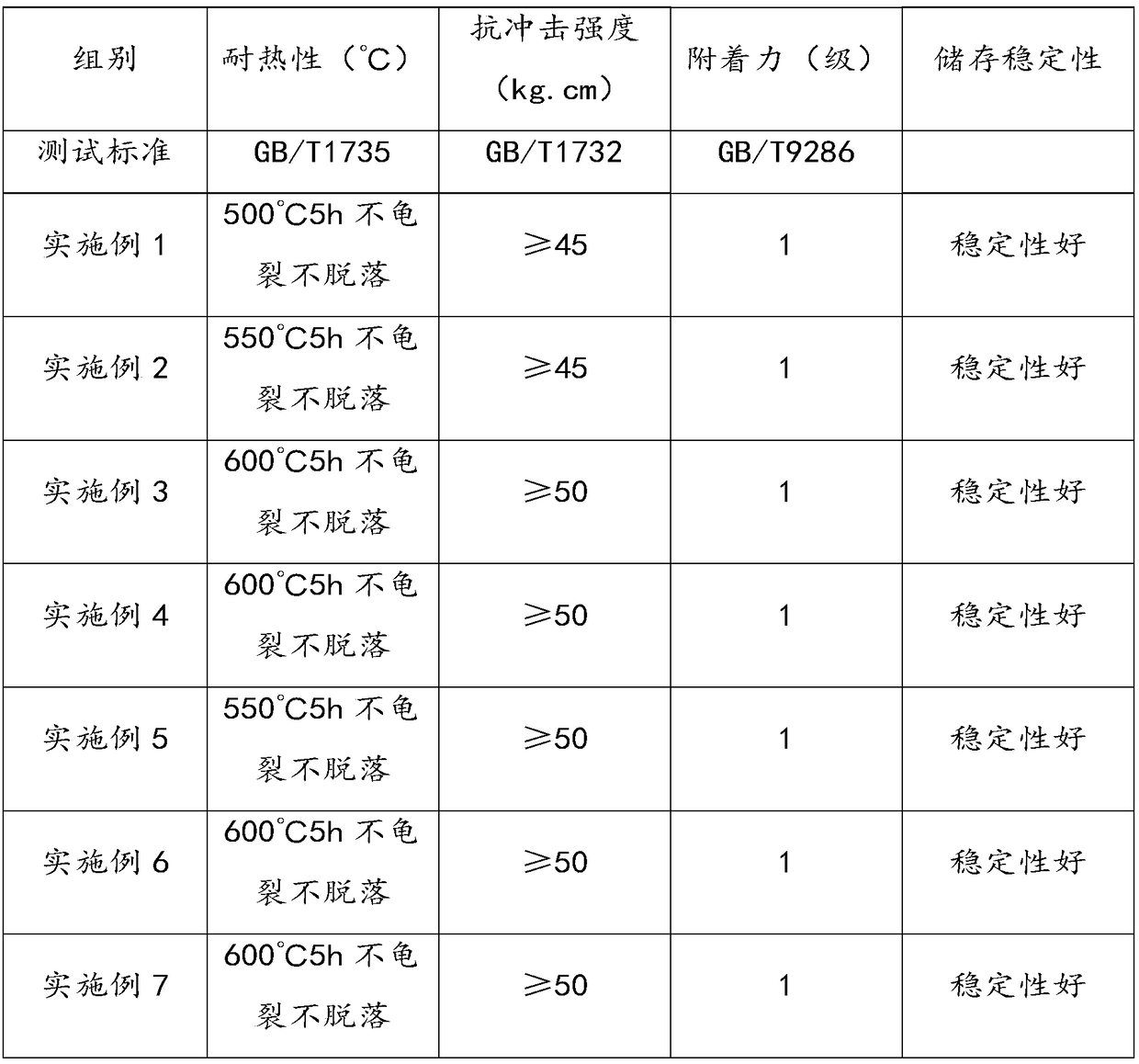

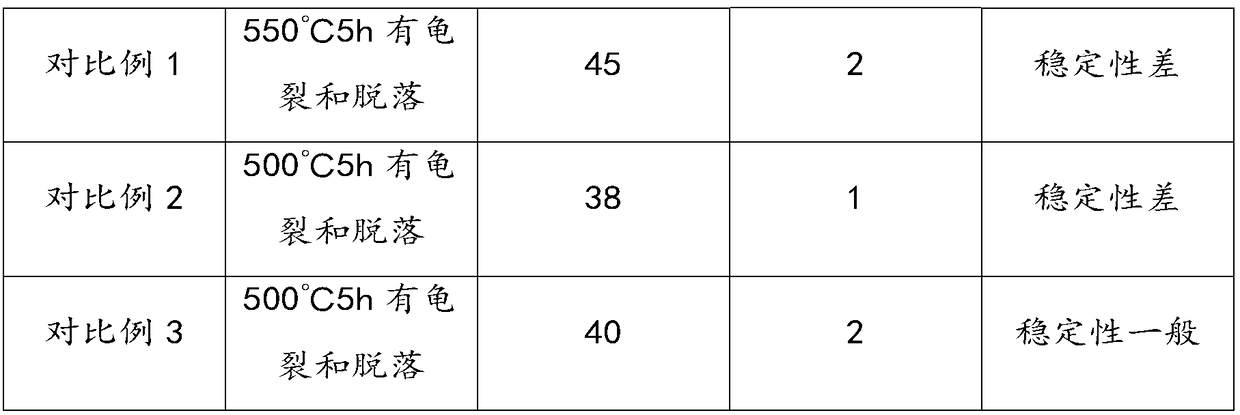

Waterborne high temperature resistant paint and preparation method thereof

InactiveCN108949017AGood high temperature resistanceLow VOCFireproof paintsAnti-corrosive paintsSilicone resinAluminium

The invention belongs to the technical field of coatings, and relates to a waterborne high temperature resistant paint and a preparation method thereof. The waterborne high temperature resistant paintcomprises the following components in parts by mass: 55-65 parts of waterborne modified silicone resin, 15-30 parts of waterborne aluminium silver paste, 1-8 parts of a drier, 2-7 parts of a levelingagent, 2-7 parts of a dispersant and 8-15 parts of water. The waterborne high temperature resistant paint has excellent high temperature resistance and excellent corrosion resistance, adhesive forceand impact-resistant strength.

Owner:HEBEI BIERNIKE CO LTD

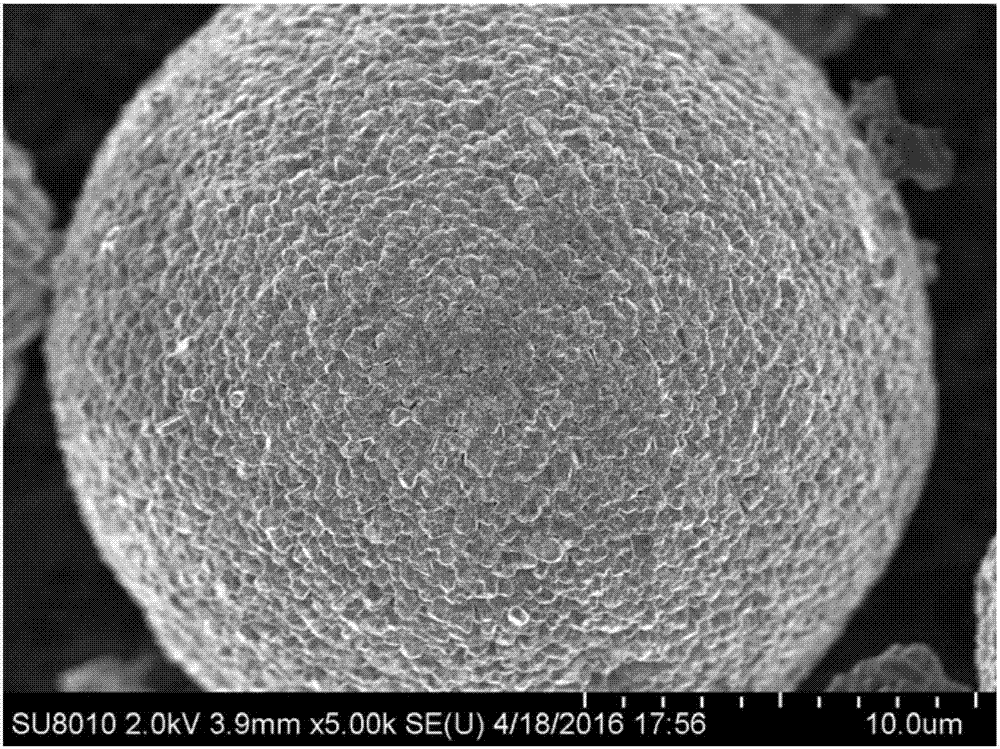

Preparation method for indium oxide sequential nano mesoporous materials doping with metal

InactiveCN102642863AIncrease useConsistent shapeMaterial nanotechnologyGallium/indium/thallium compoundsSolventIndium(III) oxide

The invention provides a preparation method for indium oxide sequential nano mesoporous materials doping with metal, which comprises the following steps of: 1) the mass ratio of surfactants, nitrate of indium, ethanol, template tetraethoxysilane and hydrochloric acid in raw materials is (5-20):(1-6):50:(10-40):(0.07-0.15), the mass ratio of doping metal and indium is (0.02-0.15):1, and the doping metal is in the form of metal salt; mixing up salt with doping metal, surfactants, nitrate of indium and ethanol, stirring the mixture until the solid is totally dissolved; 2) adding tetraethoxysilane and hydrochloric acid and evenly mixing up; 3) removing dissolvent through standing and heating; 4) removing surfactants via roasting; and 5) removing the template via dissolving by aqueous alkali. According to the method provided by the invention, various different metal elements can be doped, the shape of synthesized In2O3 sequential nano mesoporous material is uniform, the operation is simple, the requirement on equipment is low, and the industrial practicality is realized.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

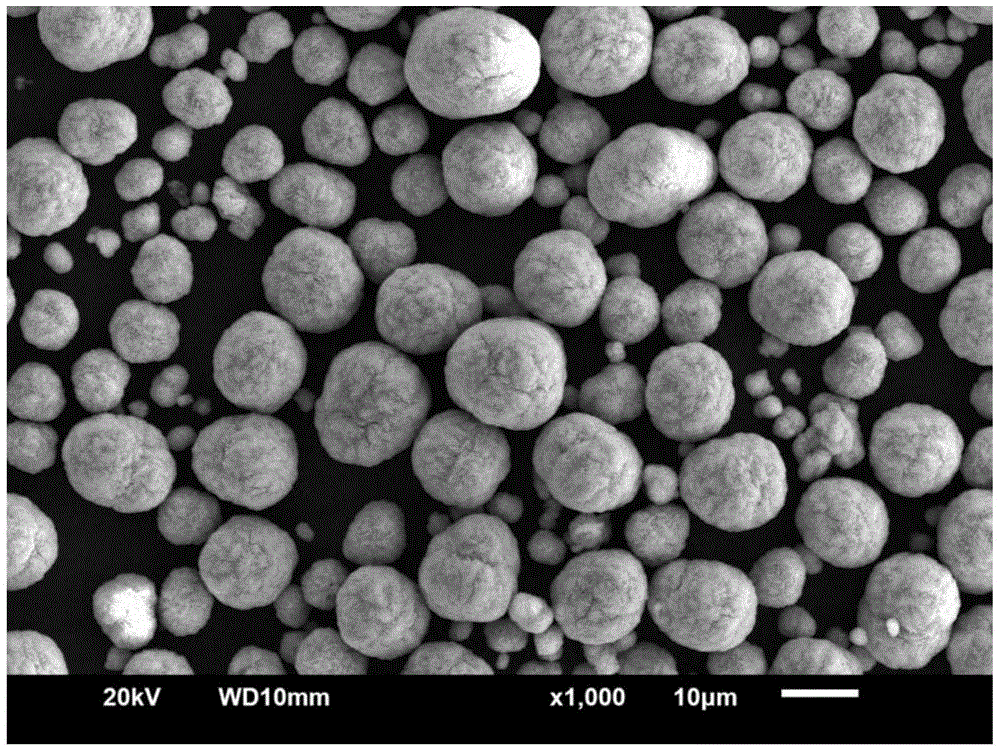

Preparation method of nickel-cobalt-manganese ternary material, cathode material for lithium-ion battery, and lithium-ion battery

InactiveCN107204429AUniform particle sizeEasy to processElectrode thermal treatmentImpregnation manufacturingManganesePhysical chemistry

The invention belongs to the technical field of lithium-ion batteries, and relates to a preparation method of a nickel-cobalt-manganese ternary material, a cathode material for a lithium-ion battery, and the lithium-ion battery. The preparation method of the nickel-cobalt-manganese ternary material comprises the following steps: (a) mixing a ternary material precursor, a lithium compound and a solvent to obtain a mixture; (b) carrying out ball-milling on the mixture to obtain mixed particles A; (c) carrying out spray drying on the mixed particles A to obtain a mixture B; (d) sintering the mixture B to obtain the nickel-cobalt-manganese ternary material. The nickel-cobalt-manganese ternary material prepared by the method is high in tap density, good in consistency, controllable in particle size and stable in performance, and has excellent physical and electrochemical properties; therefore, the nickel-cobalt-manganese ternary material can be used as cathode material for the lithium-ion battery.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

Polyphenylene sulfide superfine fiber and preparation method thereof

ActiveCN103774277AIncrease productivityEasy to operateMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolyolefinPolymer science

The invention provides a polyphenylene sulfide superfine fiber and a preparation method thereof. The preparation method comprises the steps of blending polyphenylene sulfide and polyolefin, preparing blended sea-island fiber by adopting a melt-blending method, thus obtaining the polyphenylene sulfide superfine fiber by taking an organic solvent as a stripping base phase. The method is simple to operate, the solvent can be recycled, polyphenylene sulfide in the blended sea-island fiber prepared by using the method is high proportion, the production efficiency is improved, and the prepared polyphenylene sulfide superfine fiber is high in degree of crystallinity.

Owner:BEIJING INST OF CLOTHING TECH

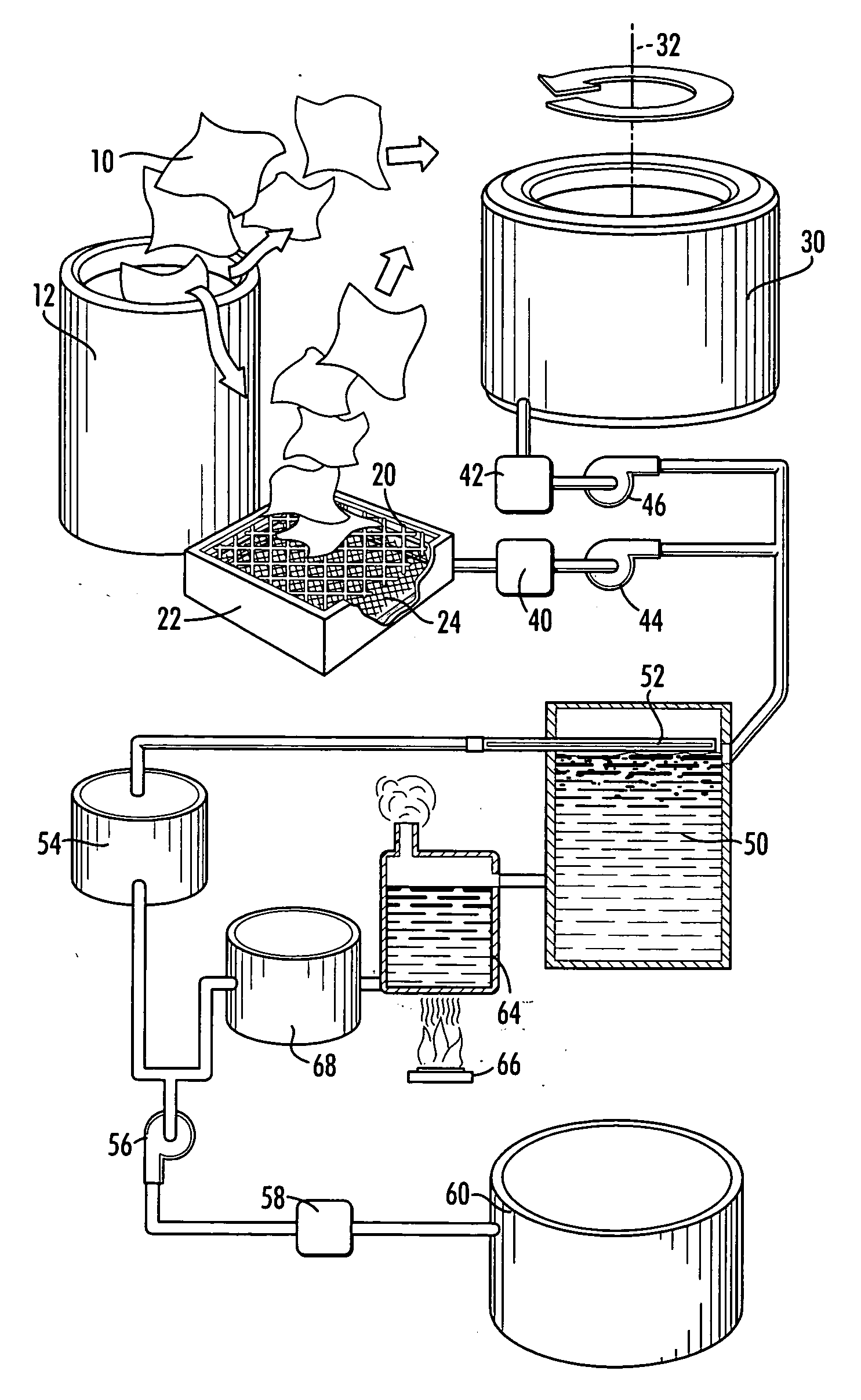

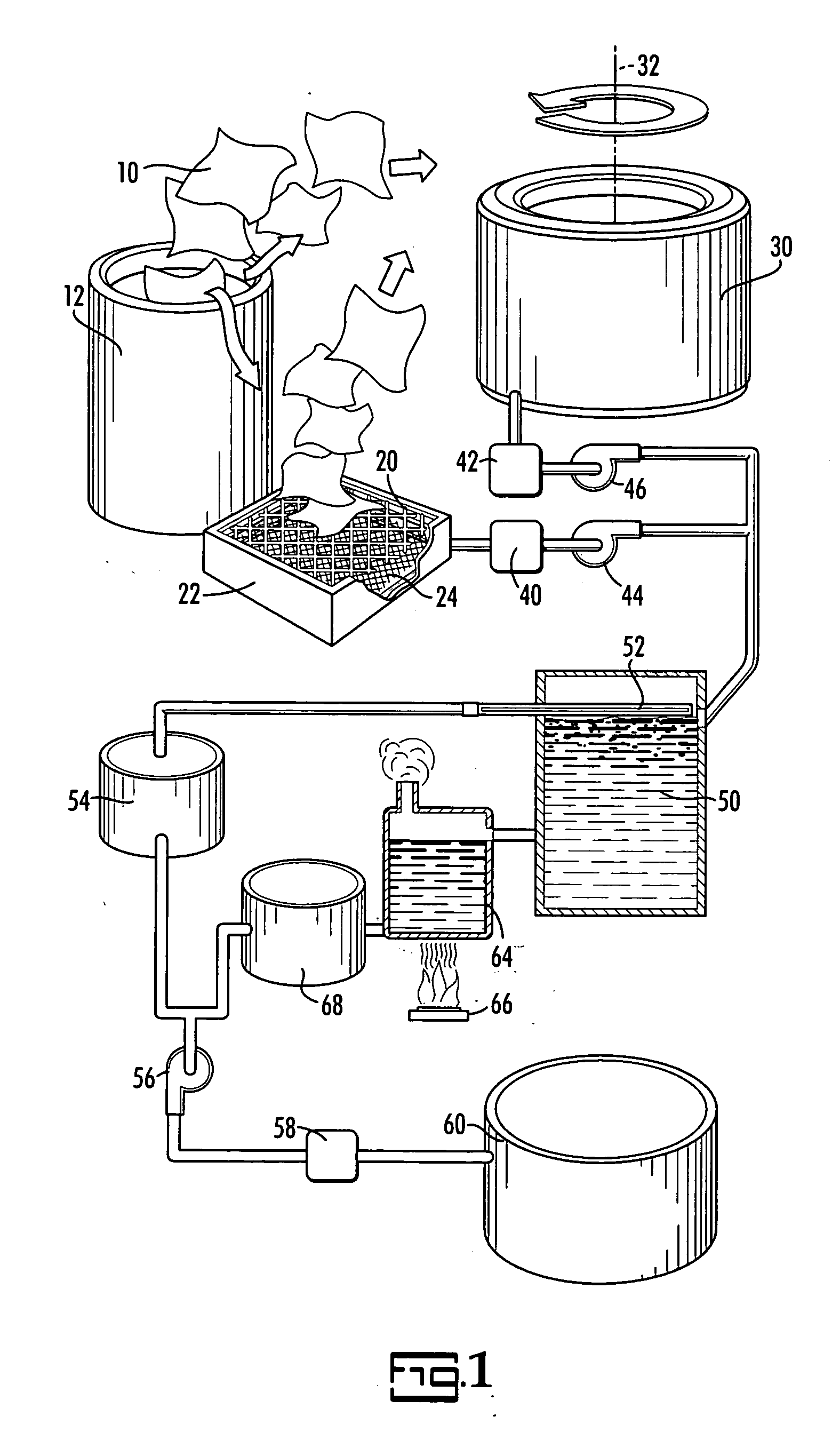

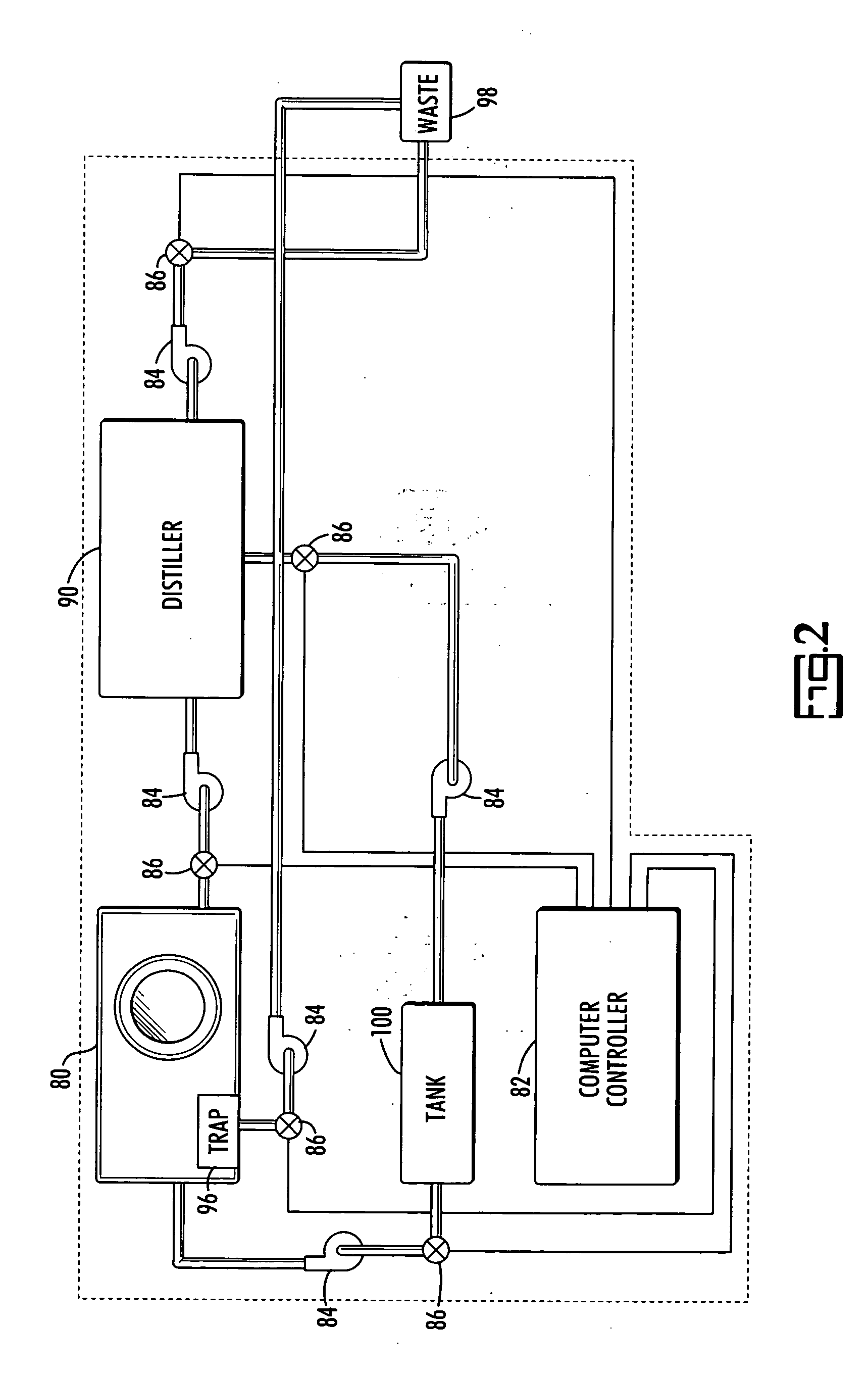

Method for cleaning textile absorbers

InactiveUS20050204478A1Fresher scentSoft feelDry-cleaning apparatusWashing receptaclesPropyl bromideEngineering

A method and system for cleaning textile absorbers that can be recycled. The system includes the use of a particular cleaning fluid, n-propyl bromide, to clean the textile absorbers for reuse. The system may also include a removal component in which excess extraneous substances are removed from the textile absorbers prior to cleaning the textile absorbers.

Owner:MIDDLETON RICHARD G

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com