Preparation method of nickel-cobalt-manganese ternary material, cathode material for lithium-ion battery, and lithium-ion battery

A technology of lithium-ion batteries and ternary materials, which is applied in battery electrodes, electrode heat treatment, circuits, etc., can solve the problems affecting the positive electrode materials of lithium-ion batteries, such as tap density, cycle performance, high unqualified rate of particle size distribution of precursors, and final products. Stability is difficult to control and other issues, to achieve excellent physical and electrochemical properties, good dispersion of secondary particles, and easy control of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In the first aspect, this embodiment provides a method for preparing a nickel-cobalt-manganese ternary material, including the following steps:

[0043] (a) mixing a ternary material precursor, a lithium compound and a solvent to obtain a mixture;

[0044] (b) ball milling the mixture to obtain mixed particles A;

[0045] (c) spray drying the mixed particles A to obtain the mixed material B;

[0046] (d) Sintering the mixed material B to obtain a nickel-cobalt-manganese ternary material.

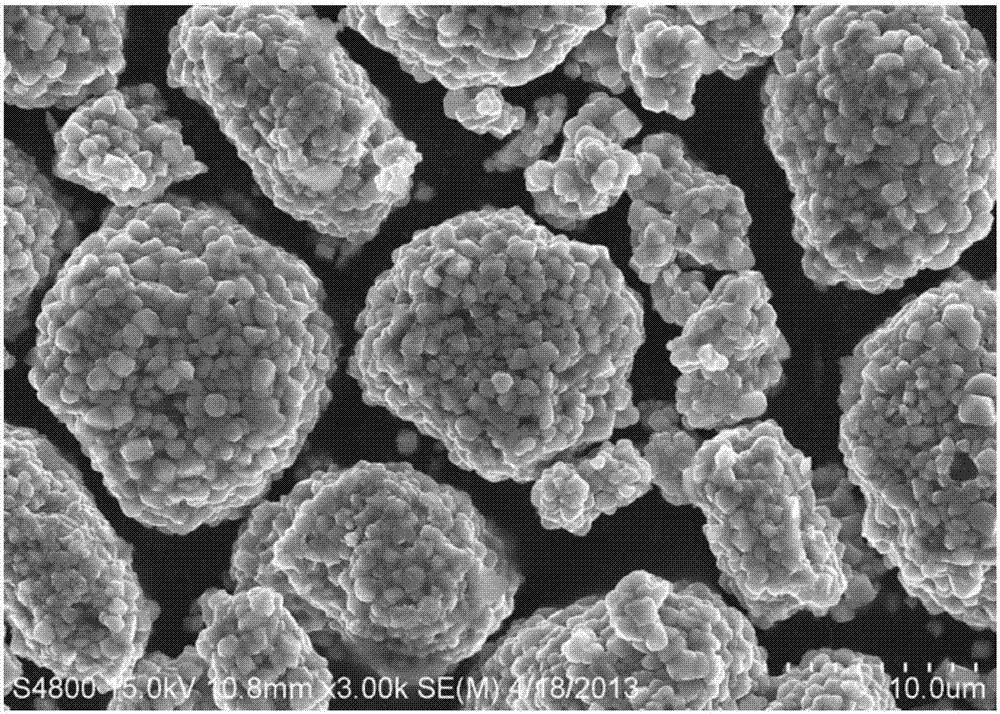

[0047] In the prior art, the particle size distribution of the precursor is mostly controlled by controlling the stirring speed, reaction temperature, lye concentration and other process parameters in the process of preparing the ternary material precursor, thereby affecting the particle size distribution of the ternary material. Uniformity, tap density, etc.; while this method needs to control many parameters, it is easy to lead to a high failure rate of particle size distribution,...

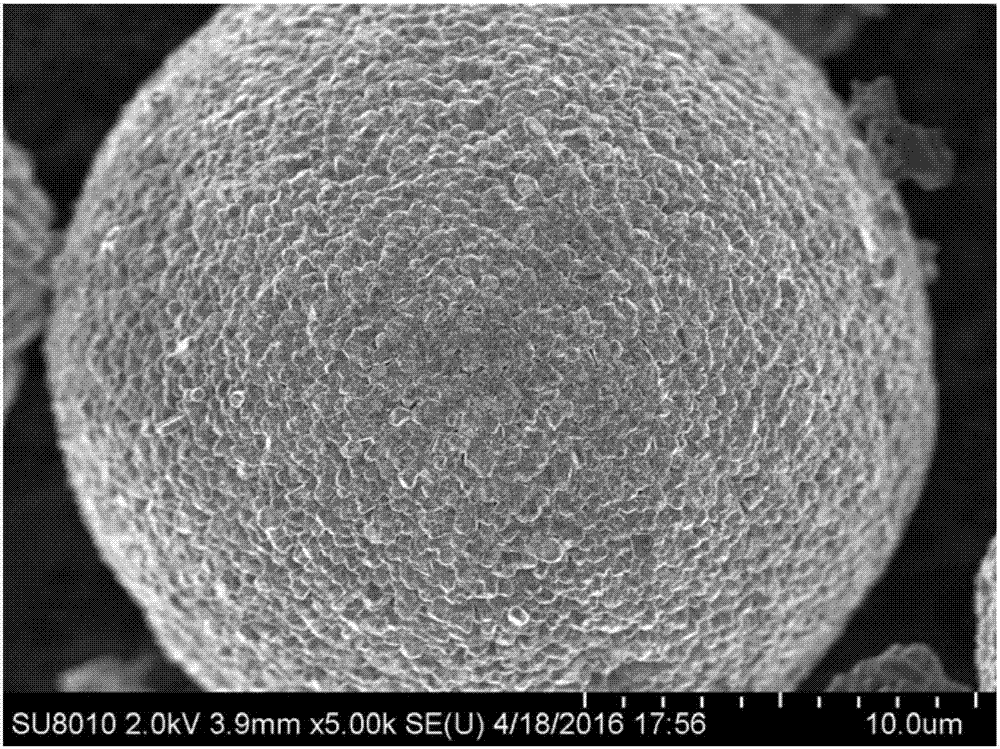

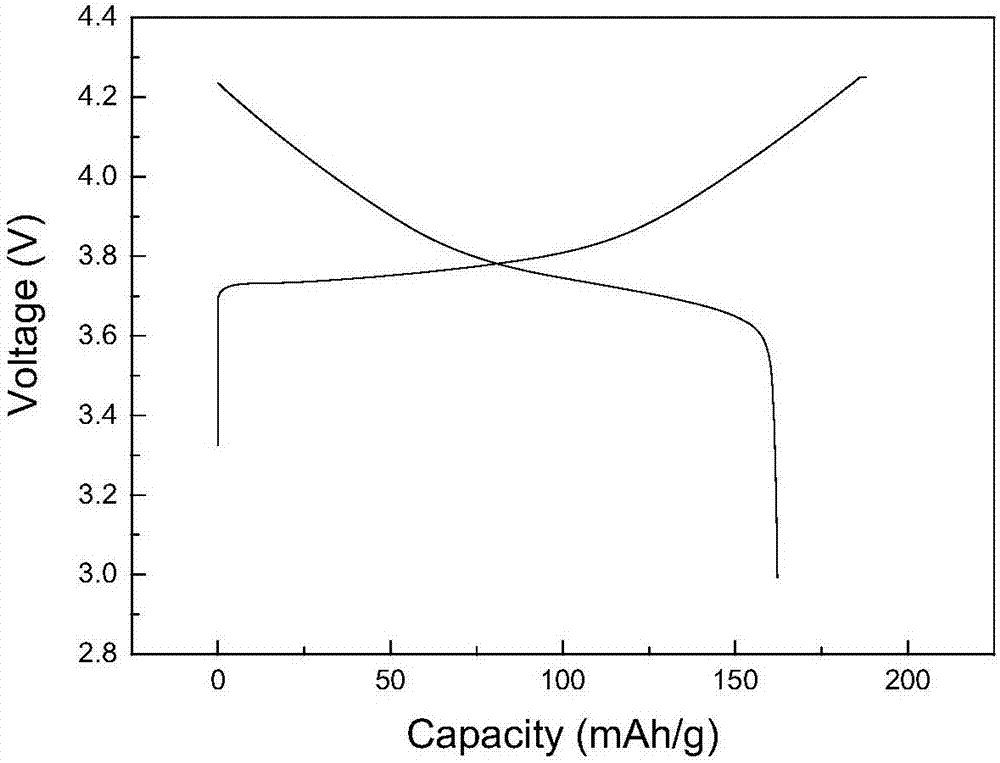

Embodiment 1

[0093] A preparation method of nickel-cobalt-manganese ternary material, comprising the following steps:

[0094] (a) Weigh the ternary material precursor Ni respectively 0.5 co 0.3 mn 0.2 (OH) 2 , lithium compound lithium carbonate and deionized water, the Ni 0.5 co 0.3 mn 0.2 (OH) 2 and lithium carbonate according to Ni 0.5 co 0.3 mn 0.2 (OH) 2 The molar ratio of Li and Li is 1:1 and added to the stirring container, and at the same time, deionized water is added for mixing to obtain a mixture, and the solid content of the mixture is controlled at 20%;

[0095] (b) Pre-grinding the above mixture with a stirring mill for 1 hour, and then finely grinding it with a sand mill for 2 hours to obtain mixed particles A;

[0096] (c) Spray-dry the above-mentioned mixed particles A with a centrifugal spray dryer, the rotation speed of the atomizer is 20000 rpm, the inlet air temperature is 100°C, and the outlet air temperature is 60°C, to obtain the mixed material B;

[009...

Embodiment 2

[0101] A preparation method of nickel-cobalt-manganese ternary material, comprising the following steps:

[0102] (a) Weigh the ternary material precursor Ni respectively 0.5 co 0.3 mn 0.2 (OH) 2 , lithium compound lithium carbonate and deionized water, the Ni 0.5 co 0.3 mn 0.2 (OH) 2 and lithium carbonate according to Ni 0.5 co 0.3 mn 0.2 (OH) 2 Add Li into the stirring container at a molar ratio of 1:1, and add deionized water for mixing at the same time to obtain a mixture, and the solid content of the mixture is controlled at 10%;

[0103] (b) Pre-grinding the above-mentioned mixture with a stirring mill for 10 hours, and then finely grinding it with a sand mill for 20 hours to obtain mixed particles A;

[0104] (c) Spray-dry the above-mentioned mixed particles A with a centrifugal spray dryer, the rotation speed of the atomizer is 10000 rpm, the inlet air temperature is 350°C, and the outlet air temperature is 160°C, to obtain the mixed material B;

[0105] (d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com