Heat-conducting assembly

a technology of heat-conducting blocks and heat-conducting components, which is applied in the direction of lighting and heating apparatus, semiconductor devices, solid-state devices, etc., can solve the problems of deterioration of heat-conducting efficiency of heat-conducting blocks, affecting the operation of electronic products or electronic elements, and affecting the life of electronic components. , to achieve the effect of improving heat-conducting efficiency, avoiding deterioration of heat-conducting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

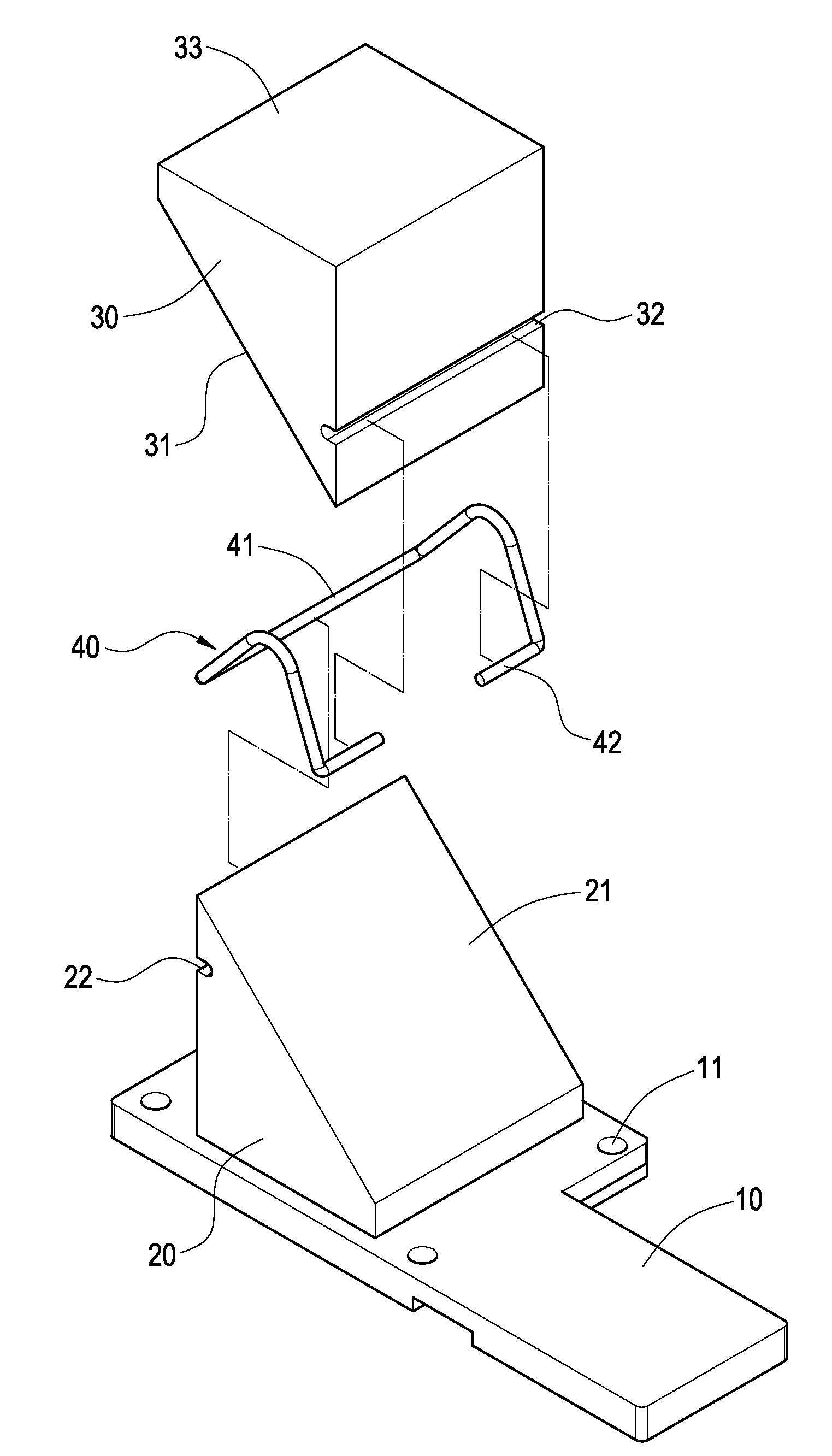

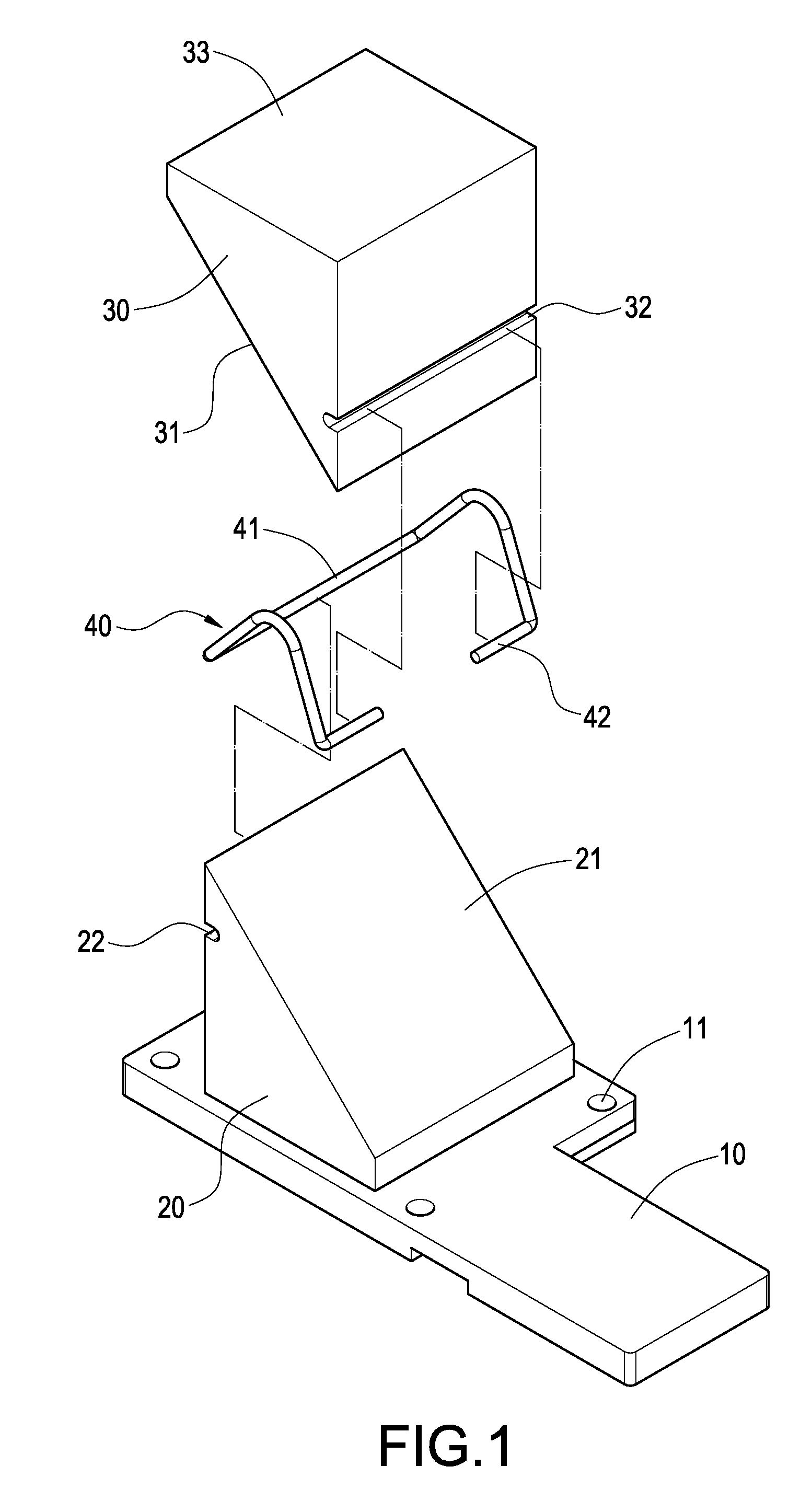

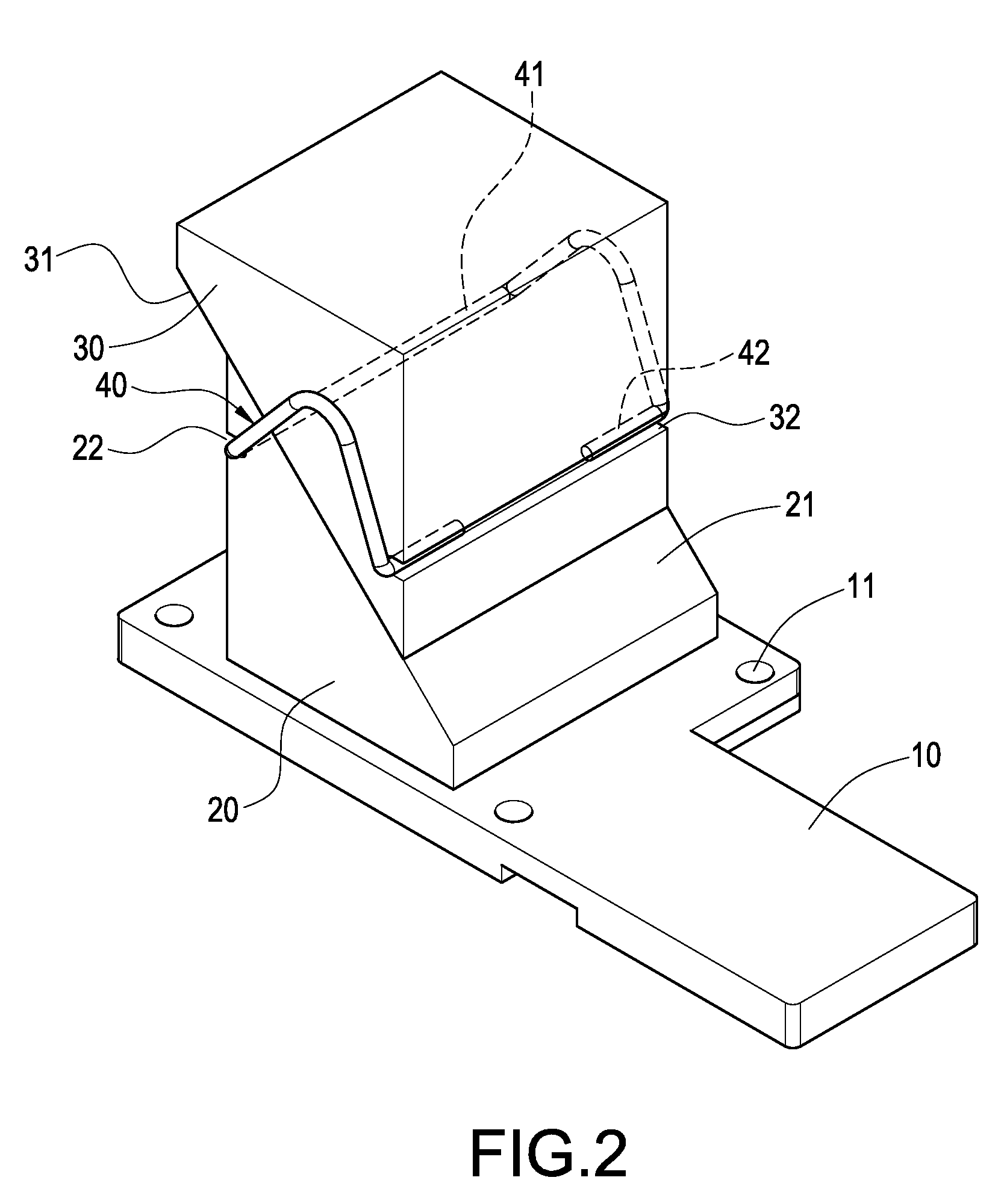

[0022]Please refer to FIGS. 1, 2 and 5. The heat-conducting assembly of the present invention is mounted in an electronic product 70. The electronic product 70 comprises a frame 71, a heat-conducting plate 72 located above the frame 71, a motherboard 73 provided on the frame 71, and a heat-generating element 74 located on the motherboard 73. The heat-conducting assembly is constituted of a base 10, a first heat-conducting block 20, a second heat-conducting block 30, and an elastic element 40.

[0023]The base 10 is attached on the heat-generating element 74. The base 10 comprises a plurality of through-holes 11 for allowing a plurality of positioning pieces 12 to pass through respectively. The positioning piece 12 may be a pin or bolt. The base 10 can be formed into an L shape. The base 10 can be formed differently based on the number and positions of the heat-generating elements 74, so that the base 10 can be applied to conduct the heat of a plurality of heat-generating elements 74. I...

second embodiment

[0030]Please refer to FIG. 6. The difference between the present embodiment and the first embodiment lies in that the elastic element 40 is a torsion spring 43 for providing a larger elastic force. Via this arrangement, the heat-conducting assembly of the present invention can abut tightly between the heat-generating element 74 and the heat-dissipating plate 72 to conduct the heat generated by the heat-generating element 74 to the heat-dissipating plate 72.

third embodiment

[0031]Please refer to FIG. 7. The heat-conducting assembly of the present invention is mounted between a heat-generating element 74 and a heat-dissipating plate 72. The heat-conducting assembly is constituted of a base 10, a first heat-conducting block 20, a second heat-conducting block 30, a fixing element 50 and an elastic body 60.

[0032]The base 10 is attached on the heat-generating element 74. The base 10 comprises a plurality of through-holes 11 for allowing a plurality of positioning pieces 12 to pass through respectively.

[0033]The first heat-conducting block 20 is disposed on the base 10. The first heat-conducting block 20 can be formed integrally with the base 10. Alternatively, the first heat-conducting block 20 and the base 10 can be formed separately and then both members are assembled together. The first heat-conducting block 20 has a first slope 21 and a fixing hole 24 penetrating the first slope 21. The fixing hole 24 is a screw hole.

[0034]The second heat-conducting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com