A method for preparing nickel-cobalt-manganese ternary material precursor

A technology of ternary materials and precursors, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of increased production costs, waste of resources, etc., and achieve improved tap density, low requirements for production equipment, and improved raw materials. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

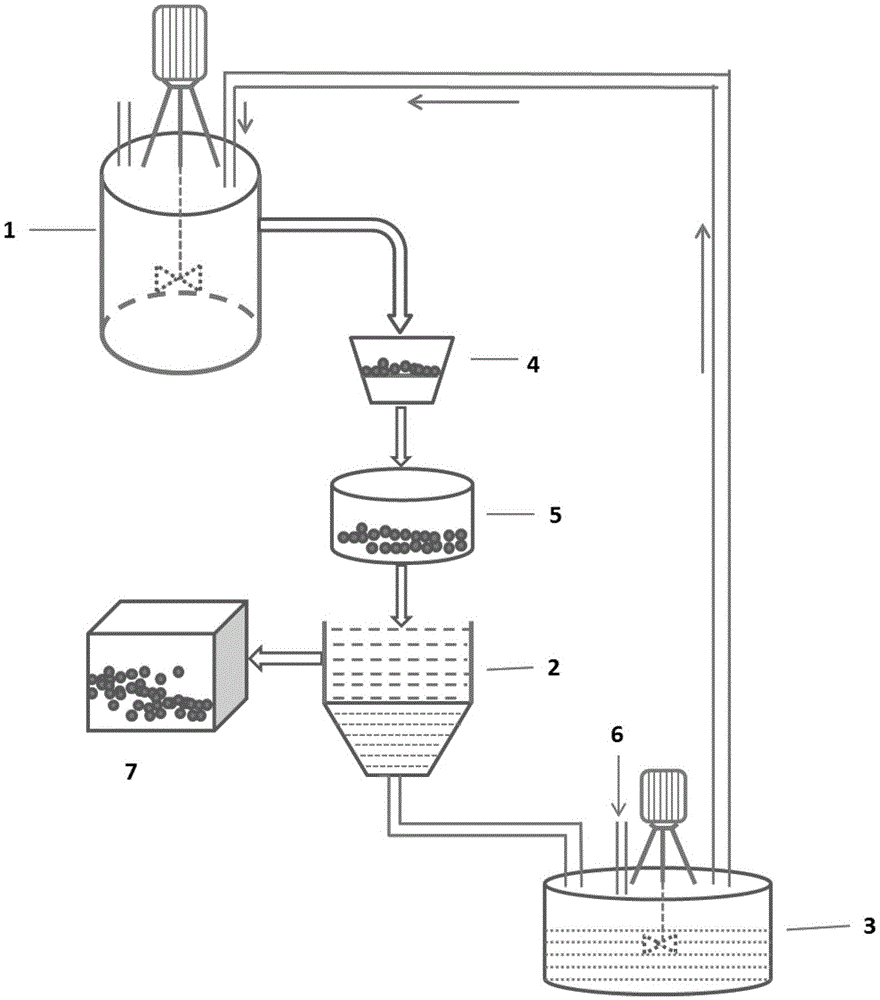

Method used

Image

Examples

preparation example Construction

[0054] According to the method for preparing nickel-cobalt-manganese ternary material precursor provided by the present invention, it has the following advantages:

[0055] (1) The method provided by the present invention can comprehensively utilize the small particle waste of the precursor of the ternary material produced in the production process, improve the raw material utilization rate of the ternary material in the production process, realize the full utilization of raw materials, and avoid the waste from being Waste of resources and cost increase due to waste;

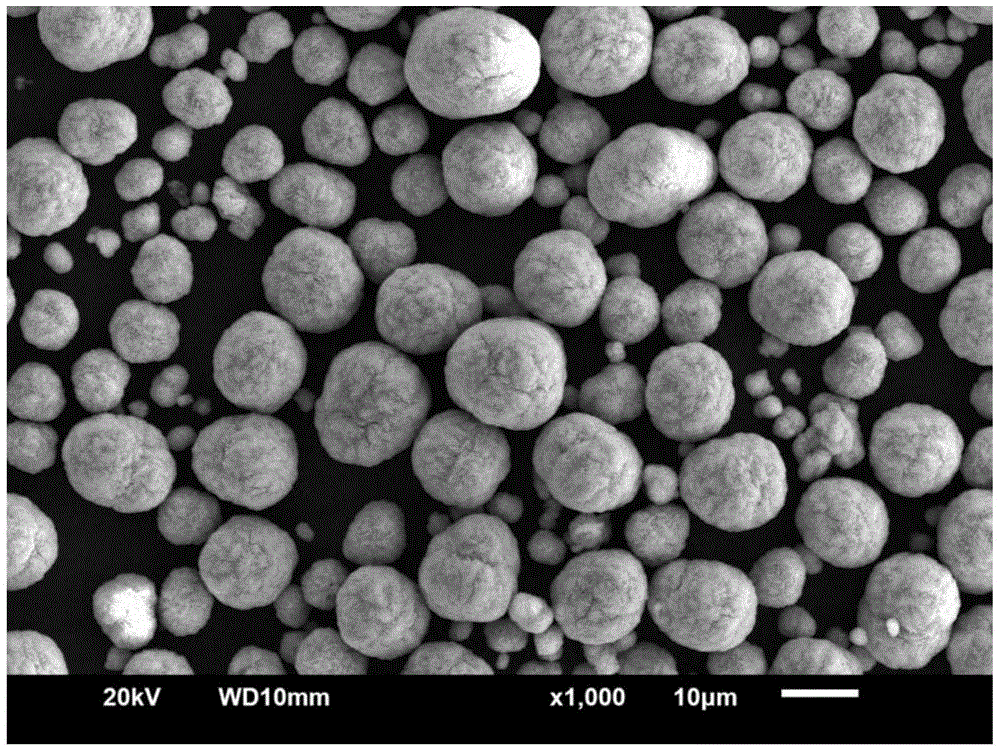

[0056] (2) The content of the nickel-cobalt-manganese ternary material precursor with a particle size of 7 to 15 microns in the product is more than 95%, and the tap density of the precursor is more than 2.3g / cm3, which can improve the ternary cathode material. Tap density and cycle performance of follow-up lithium batteries;

[0057] (3) The method provided by the present invention is simple to operate, has lo...

Embodiment 1

[0060] Steps:

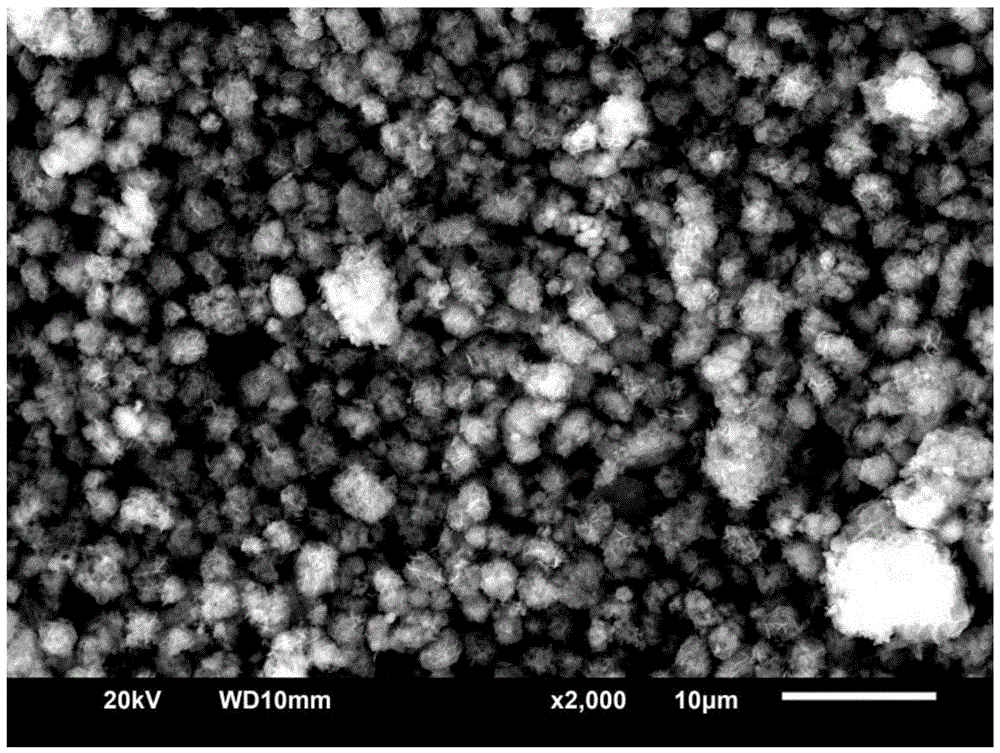

[0061] (1) A mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate (the total concentration of the mixed solution is 2mol / L, of which Ni 2+ , Mn 2+ and Co 2+ The concentration ratio is 1:1:1), the NaOH solution with a concentration of 3mol / L and the ammonia solution with a concentration of 3mol / L are added to the reactor in parallel, the reaction temperature of the reactor is 60°C, and the stirring speed is 1300r / min. The pH of the system is 11, and Ni with a D50 particle size of 4 microns 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Ternary material precursor particles (electron micrographs such as figure 2 shown) into the reaction kettle at a rate of 2ml / min, and the liquid overflows naturally;

[0062] (2) Input the material liquid overflowed and discharged in step (1) into the filter device for filtration and washing until no by-product salt sodium sulfate remains, then transfer to the drying device, dry at 110°C for 3 hours, and then pulverize to obta...

Embodiment 2

[0065] Steps:

[0066] (1) A mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate (the total concentration of the mixed solution is 2mol / L, of which Ni 2+ , Mn 2+ and Co 2+ The concentration ratio is 5:3:2), the NaOH solution with a concentration of 4mol / L and the ammonia solution with a concentration of 3mol / L are added to the reactor in parallel, the reaction temperature of the reactor is 60°C, and the stirring speed is 1300r / min. Control the reaction The pH of the system is 11, and Ni with a D50 particle size of 5 microns 0.5 co 0.2 mn 0.3 (OH) 2 The ternary material precursor particles are added to the reaction kettle at a rate of 3ml / min, and the liquid overflows naturally;

[0067] (2) Input the material liquid overflowed and discharged in step (1) to the filter device for filtration and washing until no by-product salt sodium sulfate remains, then transfer to the drying device, dry at 120°C for 4 hours, and then pulverize to obtain Ternary mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com