Multilayer printed wiring board and its manufacturing method, and resin composition for filling through-hole

A technology for printed circuit boards, conductive compositions, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuits, etc., can solve gaps or voids, lack of adhesion of conductive materials, and insufficient use of high-density wiring functions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

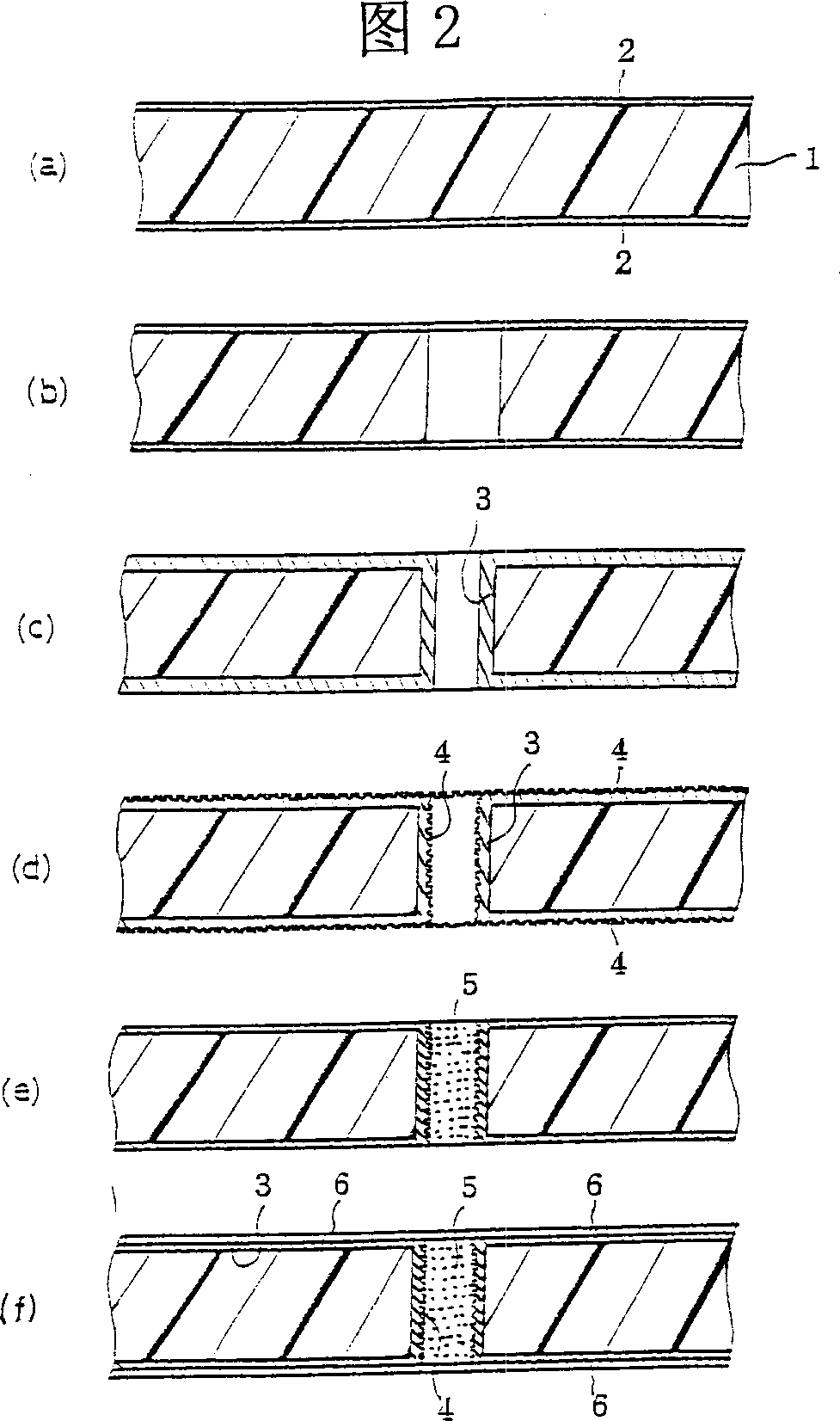

[0177] (1), a copper-clad laminate made of 0.8 mm thick polytetrafluoroethylene resin (hereinafter referred to as trade name: Teflon) substrate 1 and 18 microns thick, copper foil 2 laminated on the substrate 1 ( Matsushita Electric Works, Ltd., manufactured, trade name: R4737) as a raw material, the surface of the copper foil 2 is roughened (see FIG. 2(a)). Drill holes on the copper-clad laminate first, and then treat the inner surface of the hole with a modifier containing organic metal sodium (manufactured by Junkosha Co. Ltd., product name Tetraetch) to improve the wettability of the hole surface (see Figure 2 ( b)).

[0178] Then coat palladium-tin colloid on the substrate, then immerse the substrate in the electroless plating solution comprising the following composition to form a 2 micron thick electroless plating film on the entire substrate surface:

[0179] [Chemical Plating Solution]

[0180] EDTA 150 g / l

[0181] Copper Sulfate 20 g / L

[0182] Forma...

Embodiment 2

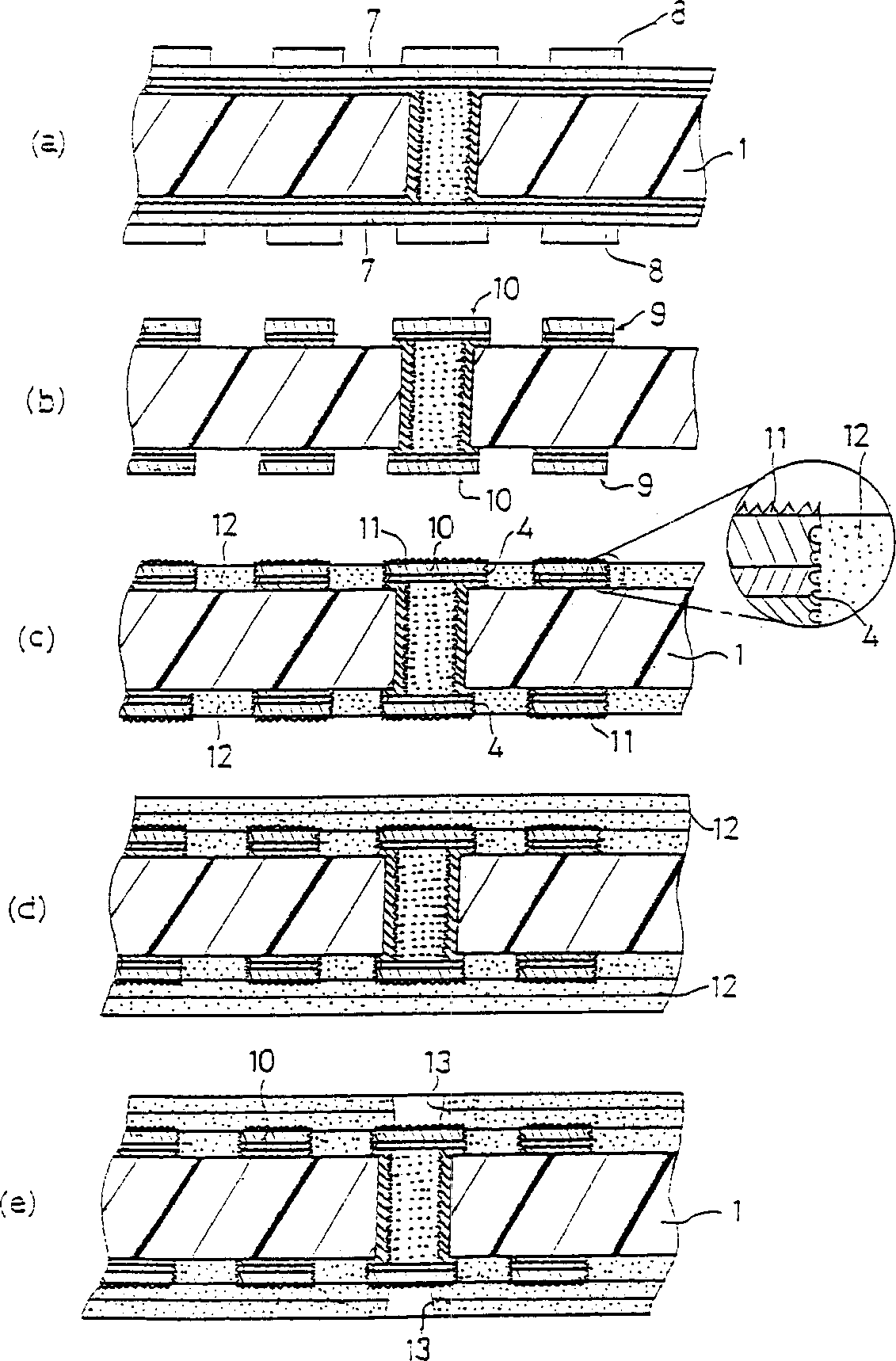

[0221] (Example 2) Multilayer core substrate

[0222] (1) Form an etch-resistant layer on both surfaces of a double-sided copper-clad laminate 1' with a thickness of 0.5 mm, then etch with an aqueous solution of sulfuric acid and hydrogen peroxide to obtain a substrate with a conductor circuit, and then place the Glass fiber-epoxy resin prepreg and copper foil 2 at a temperature of 165-170°C and a pressure of 20 kg / cm 2 Laminated successively on both surfaces of the substrate under the conditions to form a multilayer core substrate 1' (see Figure 5 (a)).

[0223] (2), drilling a diameter on the multilayer core substrate 1 ' is a through hole with a diameter of 300 microns (see Figure 5 (b)), then coated with palladium-tin colloid, then the substrate is immersed in the composition of the same chemical plating solution as in Example 1 to form a 2 micron thick chemical plating film on the entire substrate surface. Then make this substrate carry out electroplating copper plat...

Embodiment 3

[0252] A multilayer printed wiring board was fabricated in the same manner as in Example 1, except that when the through hole was filled with copper paste, the conductor layer 10 covering the through hole was not formed to cover the exposed copper paste. According to the present method, since the surface of the copper paste can be easily removed when the hole is formed in the insulating resin layer by the laser beam irradiation method, pits may be formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com