Polyphenylene sulfide superfine fiber and preparation method thereof

A technology of polyphenylene sulfide and ultrafine fiber, which is applied in the field of spinning, can solve problems such as environmental pollution, accelerated equipment aging, and low recycling rate, and achieve the effects of reducing production costs, improving production efficiency, and uniform distribution of island phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Dry the fiber-grade polyphenylene sulfide slices with a melt index of 110g / 10min in a vacuum drying oven at 120°C for 12 hours; dry the dried polyphenylene sulfide and polypropylene with a melt index of 36g / 10min at a ratio of 40 / 60 After the mass ratio is uniformly blended, it is placed in a screw spinning machine for blending and spinning. The spinning temperature is 290°C. The primary polyphenylene sulfide / polyolefin blend fiber is drawn and heat-set at 120°C. The draw ratio 1.5 times to obtain structurally stable polyphenylene sulfide / polyolefin blended sea-island fibers.

[0067] The polyphenylene sulfide / polyolefin blended sea-island fibers were dissolved and stripped in xylene at 120°C for 1 hour to obtain polyphenylene sulfide ultrafine fibers with a diameter distribution of 210-1100 nm and an average diameter of about 590 nm. The scanning Electron microscope such as figure 1 As shown, the crystallinity is 57.8%, the content of the prepared polyphenylene sulfid...

Embodiment 2

[0069] Dry the fiber-grade polyphenylene sulfide slices with a melt index of 110g / 10min in a vacuum drying oven at 120°C for 12 hours; dry the dried polyphenylene sulfide and polypropylene with a melt index of 36g / 10min at a ratio of 50 / 50 After the mass ratio is uniformly blended, it is placed in a screw spinning machine for blending and spinning. The spinning temperature is 290°C. The primary polyphenylene sulfide / polyolefin blend fiber is drawn and heat-set at 120°C. The draw ratio 1.5 times to obtain structurally stable polyphenylene sulfide / polyolefin blended sea-island fibers.

[0070] The polyphenylene sulfide / polyolefin blended sea-island fibers were dissolved and stripped in xylene at 120°C for 3 hours to obtain polyphenylene sulfide ultrafine fibers with a diameter distribution of 290-1200nm and an average diameter of about 620nm. Electron microscope such as figure 2 As shown, the crystallinity is 59.4%, the content of the prepared polyphenylene sulfide ultrafine f...

Embodiment 3

[0072] Dry the fiber-grade polyphenylene sulfide chips with a melt index of 110g / 10min in a vacuum drying oven at 120°C for 12 hours; dry the dried polyphenylene sulfide and polypropylene with a melt index of 25g / 10min at a ratio of 50 / 50 After the mass ratio is uniformly blended, it is placed in a screw spinning machine for blending and spinning. The spinning temperature is 290°C. The primary polyphenylene sulfide / polyolefin blend fiber is drawn and heat-set at 120°C. The draw ratio 2 times, to obtain structurally stable polyphenylene sulfide / polyolefin blended sea-island fibers.

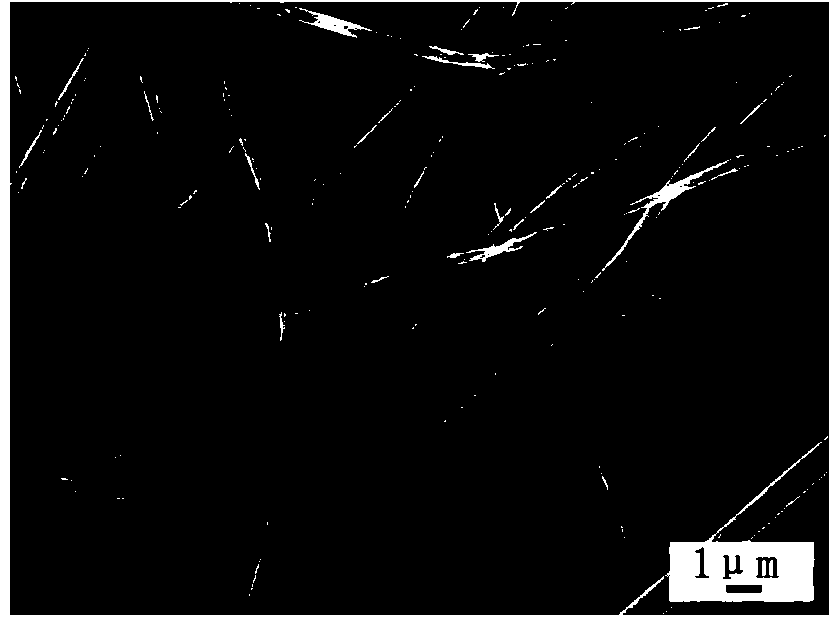

[0073] The polyphenylene sulfide / polyolefin blended sea-island fibers were dissolved and stripped in xylene at 120°C for 2 hours to obtain polyphenylene sulfide ultrafine fibers with a diameter distribution of 120-900 nm and an average diameter of about 340 nm. The scanning Electron microscope such as image 3 As shown, the crystallinity is 55.7%, the content of the prepared polyphenylene sulfide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com