Preparation method for indium oxide sequential nano mesoporous materials doping with metal

A nano-mesoporous material, indium oxide technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as inappropriate doping of various metals, and achieve broadened uses and shapes Consistent, low-equipment-required results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

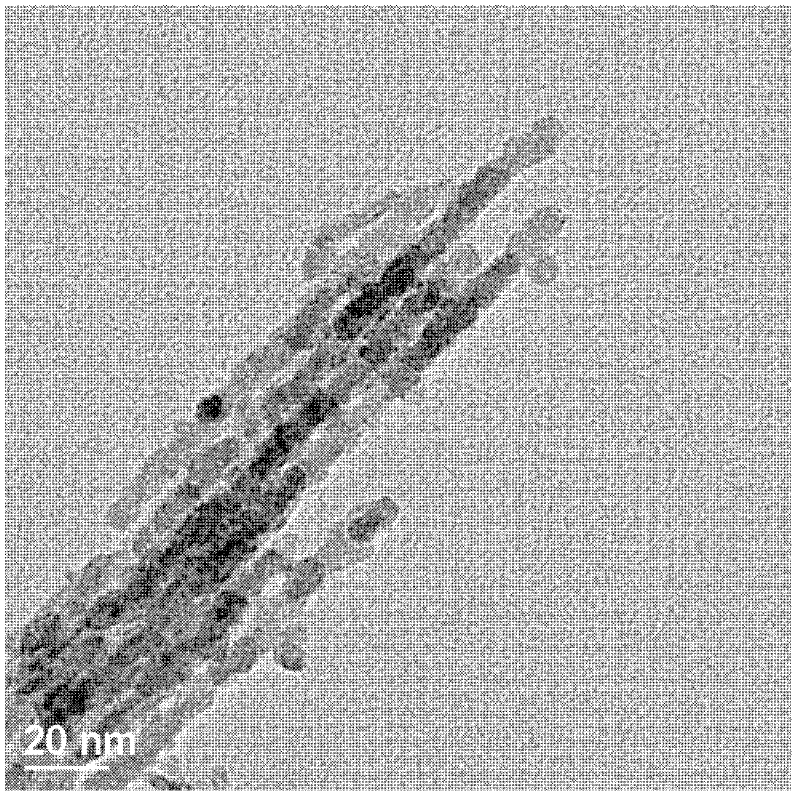

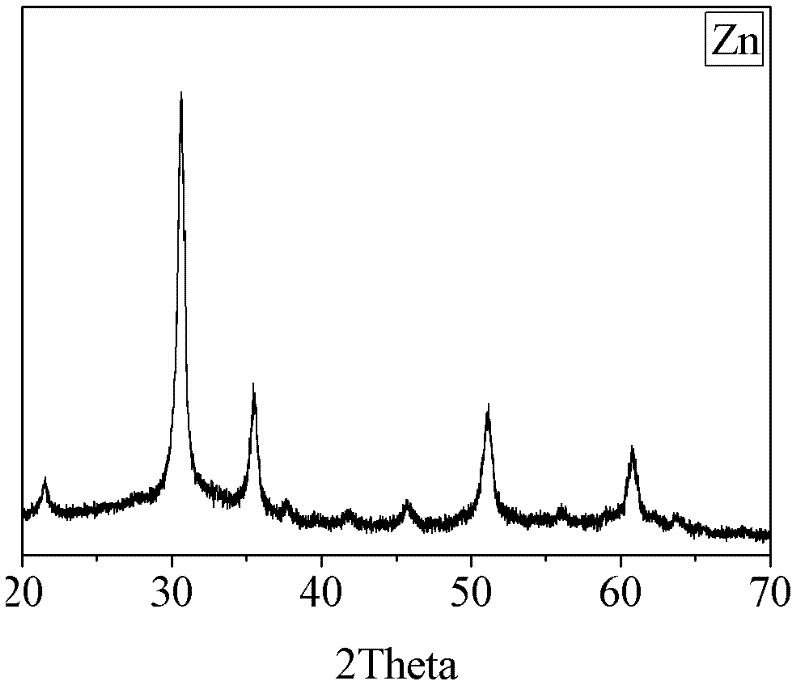

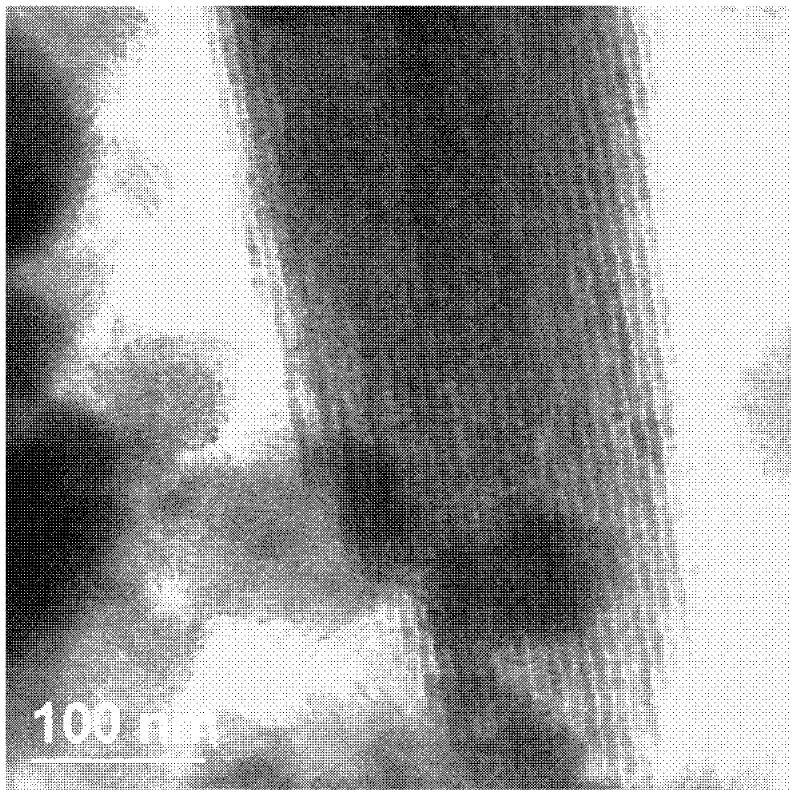

[0034] Embodiment 1: Preparation of Zn-doped In 2 o 3 Ordered nano-mesoporous materials

[0035] 10g surfactant P123, 3g In(NO 3 ) 3 4.5H 2 O, 0.291g Zn(NO 3 ) 2 ·6H 2 O, stir 50g of ethanol until completely dissolved, then add 25g of TEOS, stir for 10min, add 3g of 1mol / L HCl and stir for 10min, transfer to a porcelain boat and place in air for 72h; spread 3mm thick paraffin on the surface of the sample, oil bath Heat at 60°C for 24h, wipe off the paraffin wax on the surface of the sample, and then bake at 500°C for 8h in a muffle furnace (heating rate 3°C / min); add 40ml of 2mol / L NaOH solution to the sample and stir for 2h, then centrifuge and remove the upper layer Clear liquid, repeat the operation 3 times, then wash twice with water and ethanol respectively, and dry in air to obtain In 2 o 3 Ordered Nanomesoporous Materials.

[0036] After structural characterization, the obtained Zn-doped In 2 o 3 The ordered nano-mesoporous material has a pore diameter of 2....

Embodiment 2

[0037] Embodiment 2, preparation Cu-doped In 2 o 3 Ordered nano-mesoporous materials

[0038] 10g surfactant P123, 3g In(NO 3 ) 3 4.5H 2 O, 0.236gCu(NO 3 ) 2 ·3H 2 O, 50g of ethanol was stirred until completely dissolved, then 25g of TEOS was added, after stirring for 10min, 3g of 1mol / L hydrochloric acid was added and stirred for 10min, then transferred to a porcelain boat and placed in air for 72h; spread 3mm thick paraffin on the surface of the sample, oil bath Heat at 50°C for 30h, wipe off the paraffin wax on the surface of the sample, and then bake at 500°C for 8h in a muffle furnace (heating rate 1°C / min); add 30ml of 3mol / L NaOH solution to the sample and stir for 2h, then centrifuge and remove the upper layer Clear liquid, repeat the operation 3 times, then wash twice with water and ethanol respectively, and dry in air to obtain In 2 o 3 Ordered Nanomesoporous Materials.

[0039] After structural characterization, the obtained Cu-doped In 2 o 3 The ordered...

Embodiment 3

[0040] Embodiment 3: Preparation of Mg-doped In 2 o 3 meso-ordered nano-mesoporous materials

[0041] 10g surfactant P123, 3g In(NO 3 ) 3 4.5H 2 O, 0.25g Mg(NO 3 ) 2 ·6H 2 O, stir 50g of ethanol until completely dissolved, then add 25g of TEOS, stir for 10min, add 3g of 1mol / L HCl and stir for 10min, transfer to a porcelain boat and place in air for 72h; spread 3mm thick paraffin on the surface of the sample, oil bath Heat at 60°C for 24h, wipe off the paraffin wax on the surface of the sample, and then bake at 500°C for 7h in a muffle furnace (heating rate 5°C / min); add 60ml of 1mol / L NaOH solution to the sample and stir for 2h, then centrifuge and remove the upper layer Clear liquid, repeat the operation 5 times, then wash twice with water and ethanol respectively, and dry in air to obtain In 2 o 3 Ordered Nanomesoporous Materials.

[0042] After structural characterization, the obtained Mg-doped In 2 o 3 The ordered nano-mesoporous material has a pore diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com