Patents

Literature

117results about How to "Soft feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

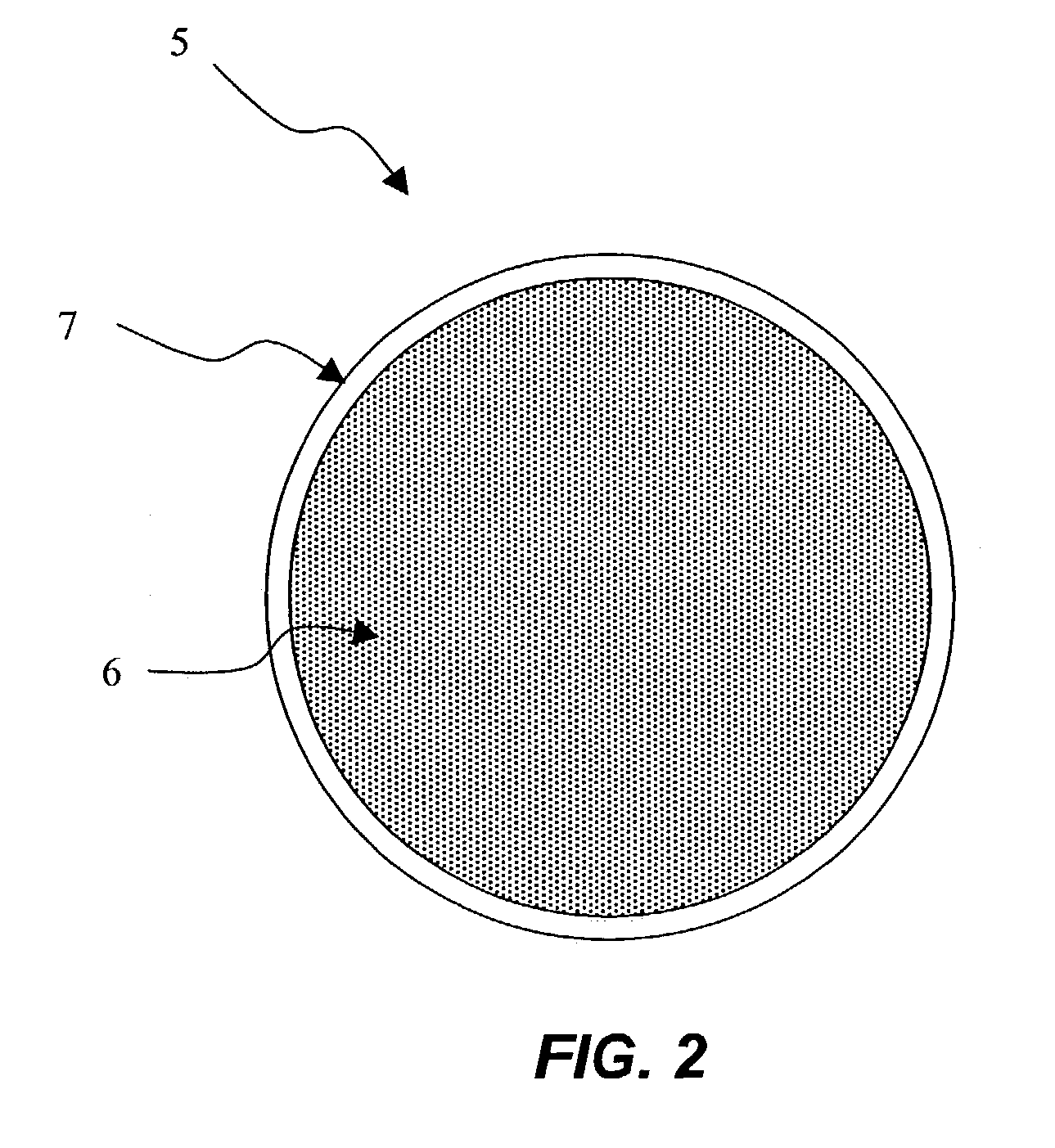

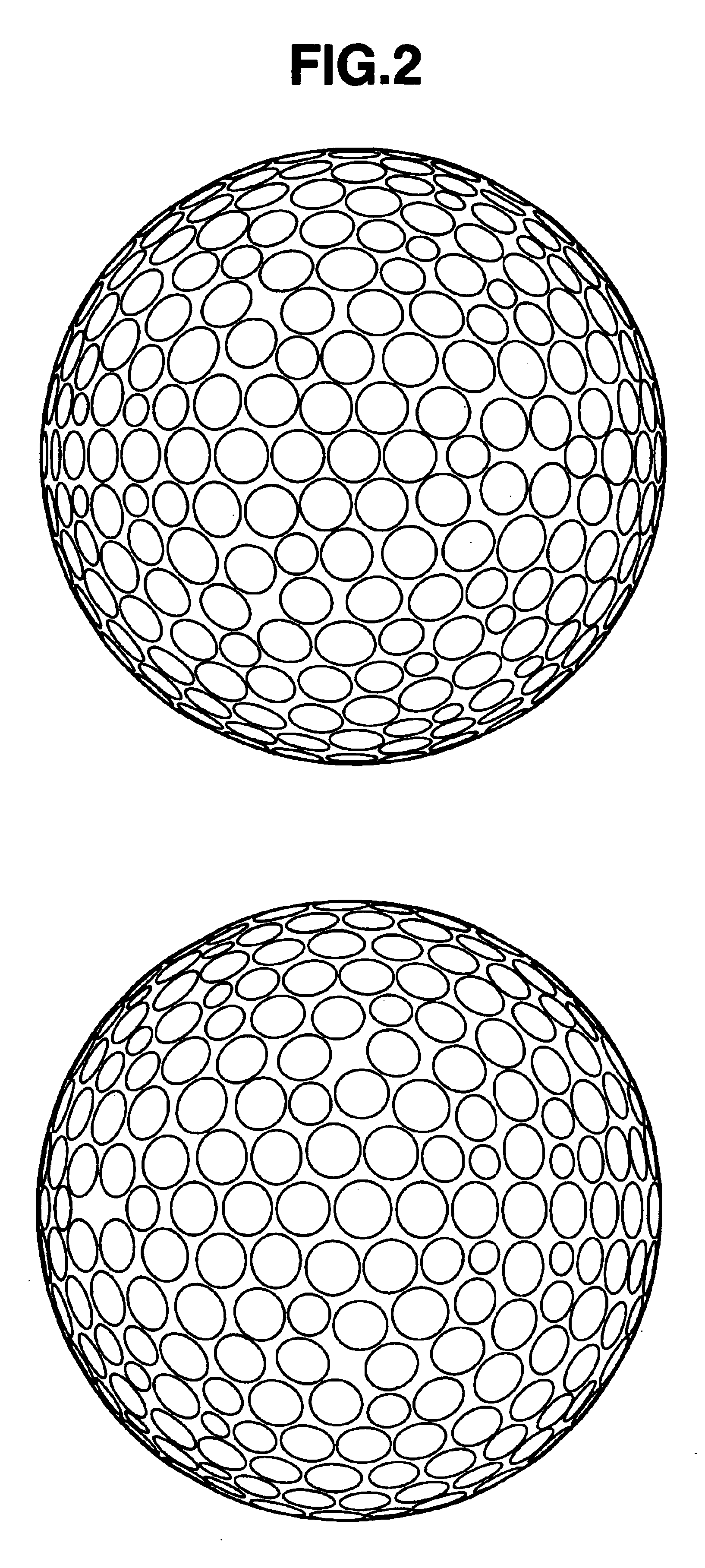

Solid golf ball

ActiveUS20060128900A1Soft touchGood rebound characteristicsGolf ballsSolid ballsRare earthCarboxylic acid

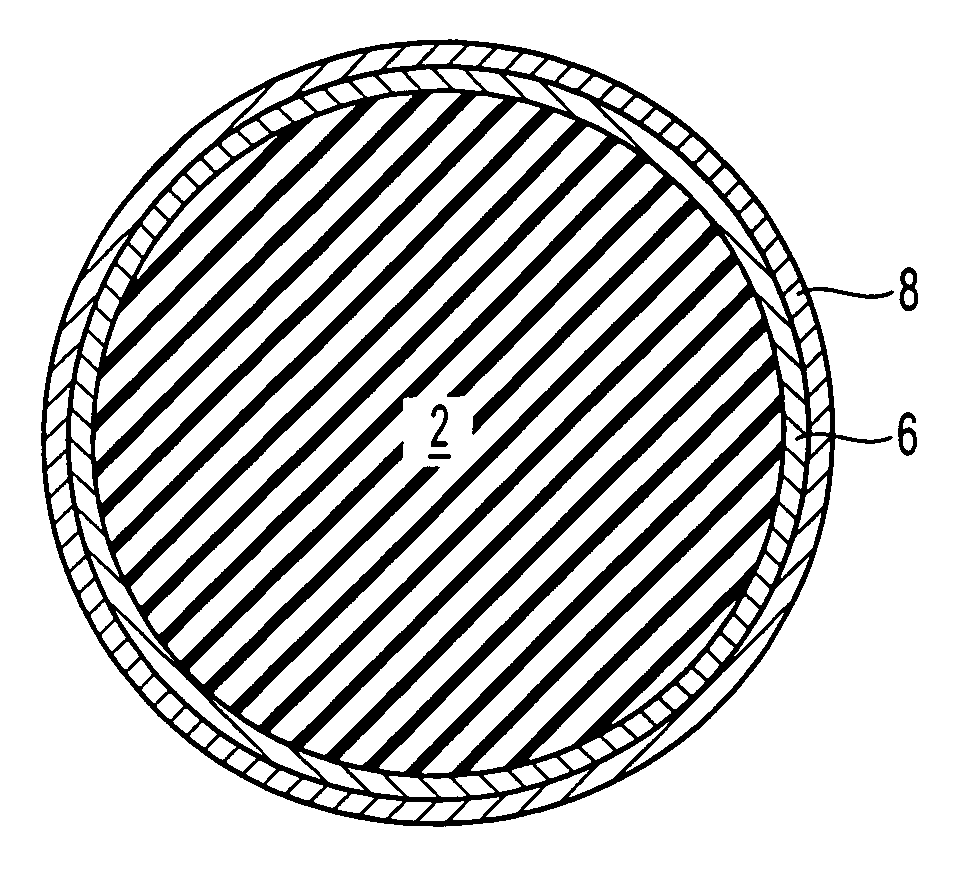

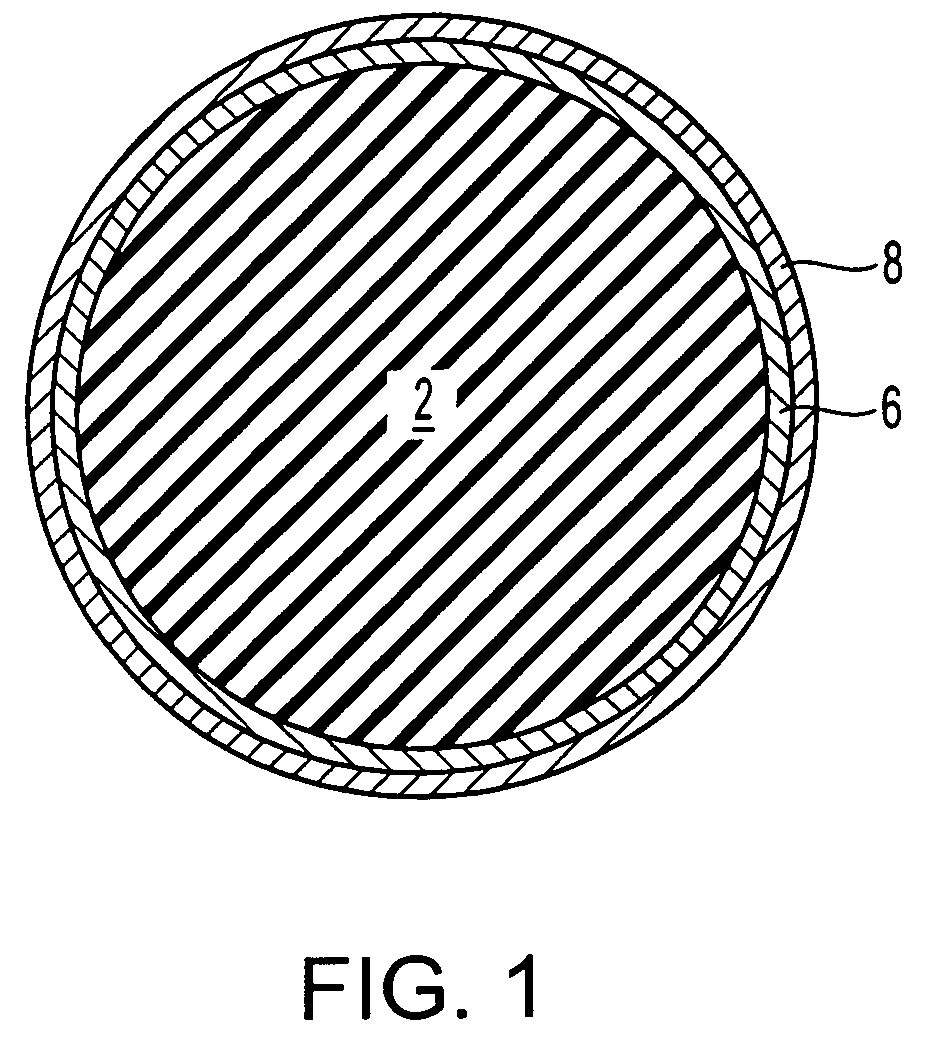

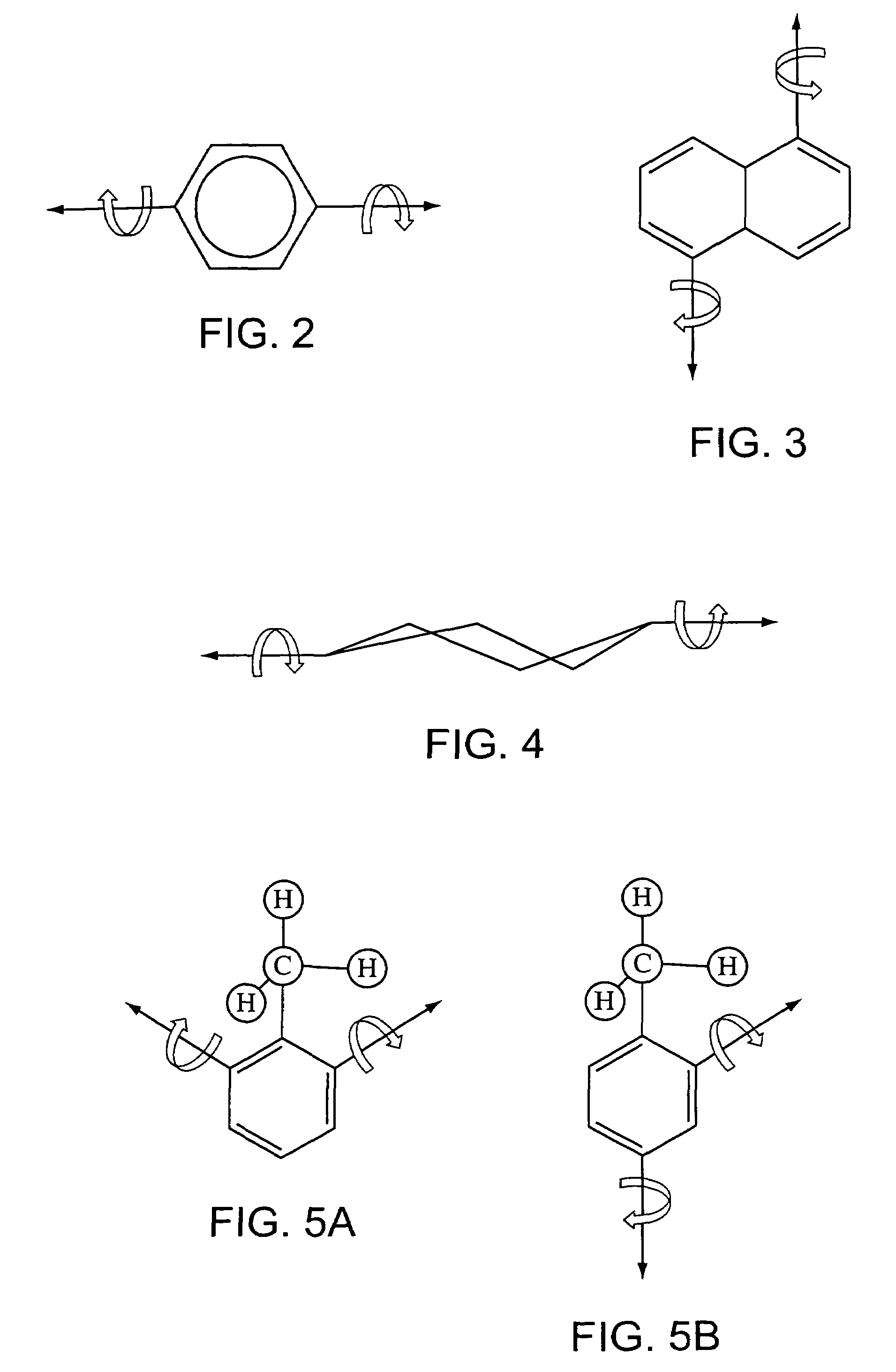

The present invention provides a solid golf ball comprising a hot-molded product of a rubber composition comprising (a) 100 parts by weight of a polybutadiene synthesized using a rare-earth catalyst and having a cis-1,4 content of at least 60% and a 1,2 vinyl content of at most 2%, having a viscosity η at 25° C. as a 5 wt % solution in toluene of up to 600 mPa·s, and having Mooney viscosity (ML1+4 (100° C.)) of more than 30, (b) 0.01 to 0.5 parts by weight of a sulfur, (c) 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, (d) 0.1 to 5 parts by weight of an organosulfur compound, (e) 5 to 80 parts by weight of an inorganic filler, and (f) 0.1 to 5 parts by weight of an organic peroxide, wherein the hot-molded product has a difference in JIS-C hardness between the center and surface thereof of more than 20 and up to 40. The solid golf balls of the invention have a soft feel upon impact and excellent rebound characteristics. Moreover, the solid golf balls are improved in flight performance by making its spin rate reduced when shot with a driver.

Owner:BRIDGESTONE SPORTS

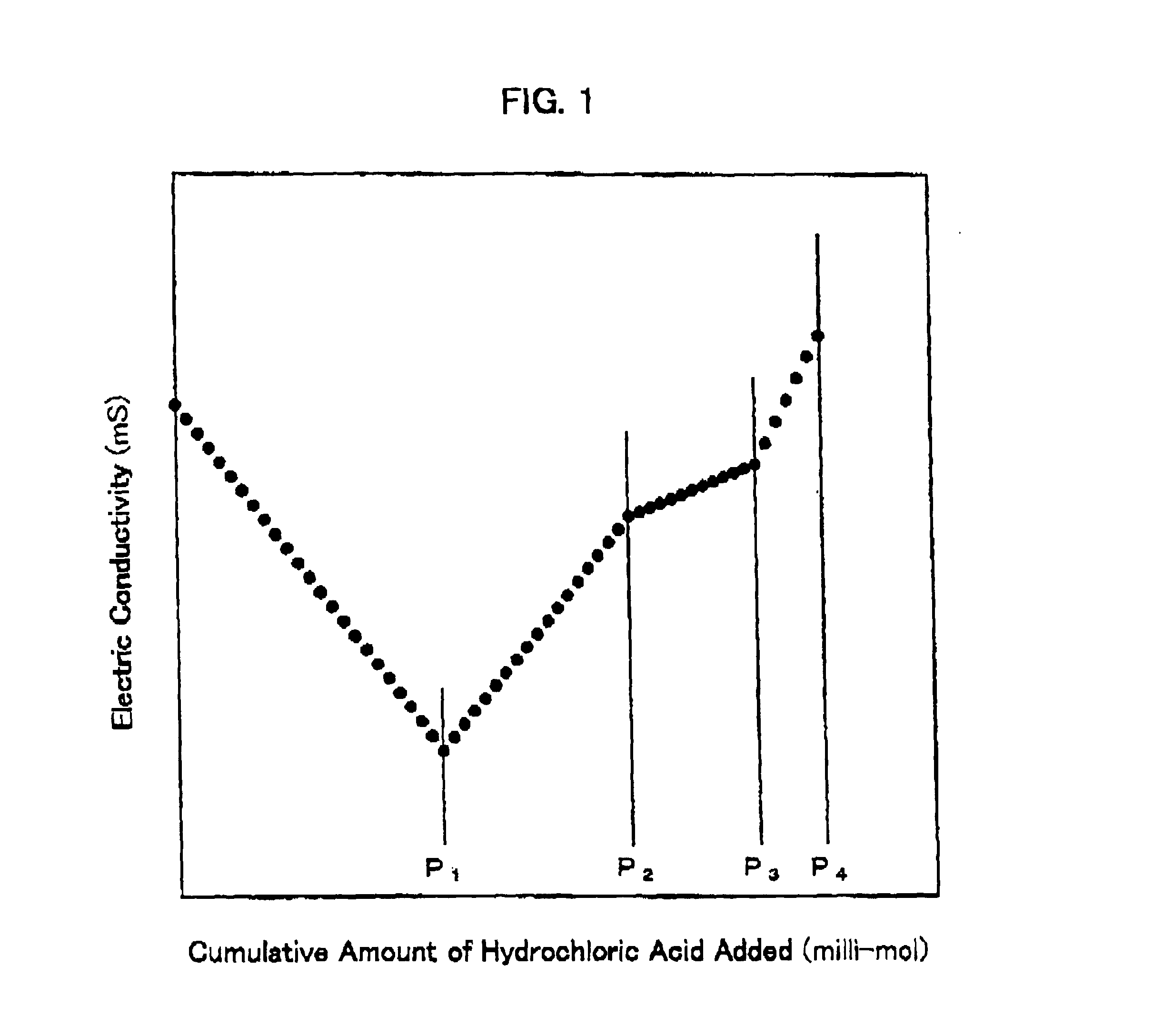

Latex for dip forming and molded object obtained by dip forming

A latex for dip forming which comprises a copolymer prepared by polymerizing 10 to 90% by weight of a conjugated diene monomer, 0.1 to 20% by weight of an ethylenically unsaturated acid monomer and 10 to 89.9% by weight of other ethylenically unsaturated monomer or monomers copolymerizable therewith, wherein the sum of the amount of acid groups bonded to or adsorbed on the surface of the copolymer constituting the latex and the amount of acid groups present in the aqueous phase of the copolymer latex is in the range of 0.1 to 2 meq. in terms of hydrochloric acid, per gram of the copolymer. This latex is dip-formed to give a dip-formed article having no fear of development of a protein allergy, and exhibiting a soft feeling and a high mechanical strength.

Owner:ZEON CORP

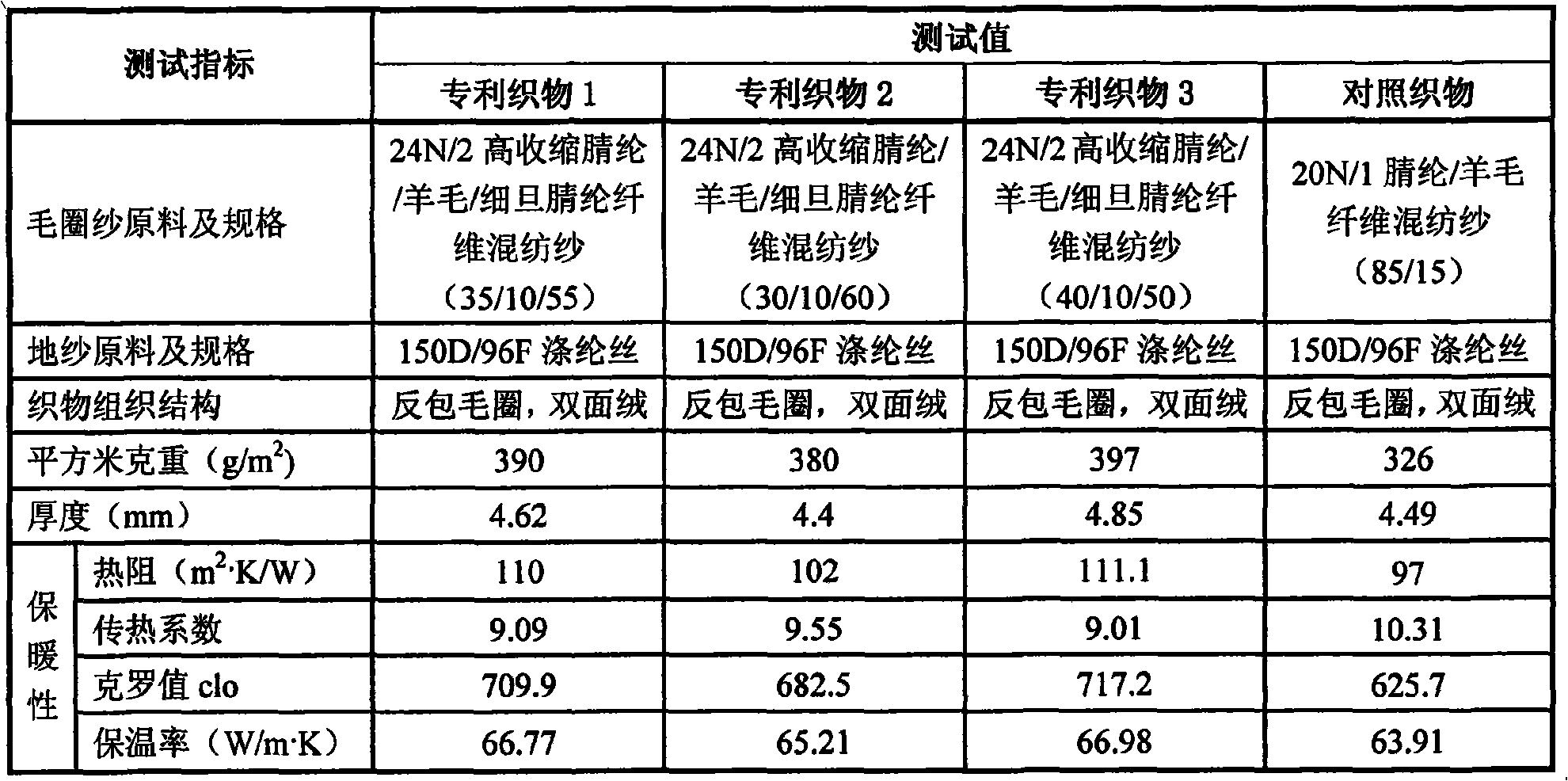

Acrylic and fleece coarse gauge weft knitting double-napped shell fabric and production method thereof

The invention discloses an acrylic and fleece coarse gauge weft knitting double-napped shell fabric and a production method thereof. By taking terylene stretch yarns as ground yarns and high-shrinkage acrylon / fleece / fine denier acrylic fiber blending yarns as terry yarns, the weft knitting double-napped shell fabric is produced by finishing after conducting napping on a single-side terry fabric which is knitted by a coarse gauge single-side circular terry weft knitting machine, wherein the count of the terylene stretch yarns is 150D / 96F; the blending ratio range of the high-shrinkage acrylon / fleece / fine denier acrylic fiber blending yarns is 30-40 / 10 / 50-60; and the count of the blending yarns is 20-30 / 2. The acrylic and fleece coarse gauge weft knitting double-napped shell fabric integrates softness, fluffiness, massiness, plumpness, elasticity, air permeability and warmth retention property into one body, thus being suitable for making knitted jackets as well as sport or leisure coats in autumn and winter.

Owner:上海嘉麟杰纺织科技有限公司

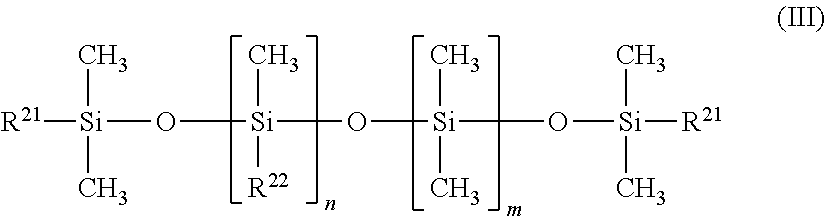

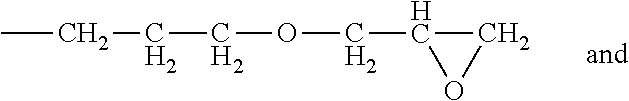

Preparation method of quaternary ammonium type positive ion polyurethane base polyether block hydrophilic silicone softener ultra-micro emulsion and product thereof

ActiveCN103497307AImprove soft feelGood application performanceGrip property fibresVegetal fibresPrepolymerIon

The invention relates to a preparation method of quaternary ammonium type positive ion polyurethane base polyether block hydrophilic silicone softener ultra-micro emulsion and a product thereof. The preparation method comprises the steps that raw materials comprising polymerization monomers, a modifier, an adjuvant and distilled water are prepared; dehydration pre-treatment is conducted on polyether ether glycol; the pre-polymerized reaction is conducted on the dehydrated polyether ether glycol, an end hydroxyl polysiloxane linear body and diisocyanate under the catalyst function of a polymerization catalyst, and a prepolymer is prepared; the chain extension reaction is conducted on the prepolymer, a tertiary amine chain extender agent and an aminosilane coupling agent and an intermediate is prepared; a polymerization stropping agent is added and the reaction is stopped, and a quaternization reagent is added for conducting a quanternization reaction; a product is prepared through emulsification. The preparation method of quaternary ammonium type positive ion polyurethane base polyether block hydrophilic silicone softener ultra-micro emulsion can give unique soft waxy style for various fabric weaving products, is used for improving the soft feel of various kinds of fabric products, does not affect the hydrophilia of natural fiber fabrics, and has good application performance and wide application prospects.

Owner:中山市天信助剂实业有限公司

High density ultra-fine fabrics

InactiveUS20110111666A1Soft silky feelEfficiently applyLayered productsBed linenPolyesterWater soluble

Provided is a high-density micro fabric, and more particularly, a high-density micro fabric which eliminates the necessity of a cire processing as a post-processing. The high-density micro fabric is woven using warp and weft yarns, wherein a single strand fineness of either of a warp or weft yarn or both of the warp and weft yarns is in the range of 5 denier to 100 denier, a fineness of a monofilament constituting one strand of either of a warp or weft yarn or both of the warp and weft yarns is in the range of 0.1 denier to 1.5 denier, the warp yarn is nylon, polyester, or a composite yarn including nylon and polyester, and the weft yarn is nylon, polyester, or a composite yarn including nylon and polyester, and a high shrinkage nylon yarn, a nylon partially oriented yarn, a nylon spin draw yarn having an elongation at break of 25% or higher, or a water soluble PVA-based yarn that is removed by water during a scouring process or a dyeing process is mixed or arranged with either of a warp or weft yarn, and k value of a shrunken fabric is 22 or greater.

Owner:KIM EE

Golf ball

Owner:BRIDGESTONE SPORTS

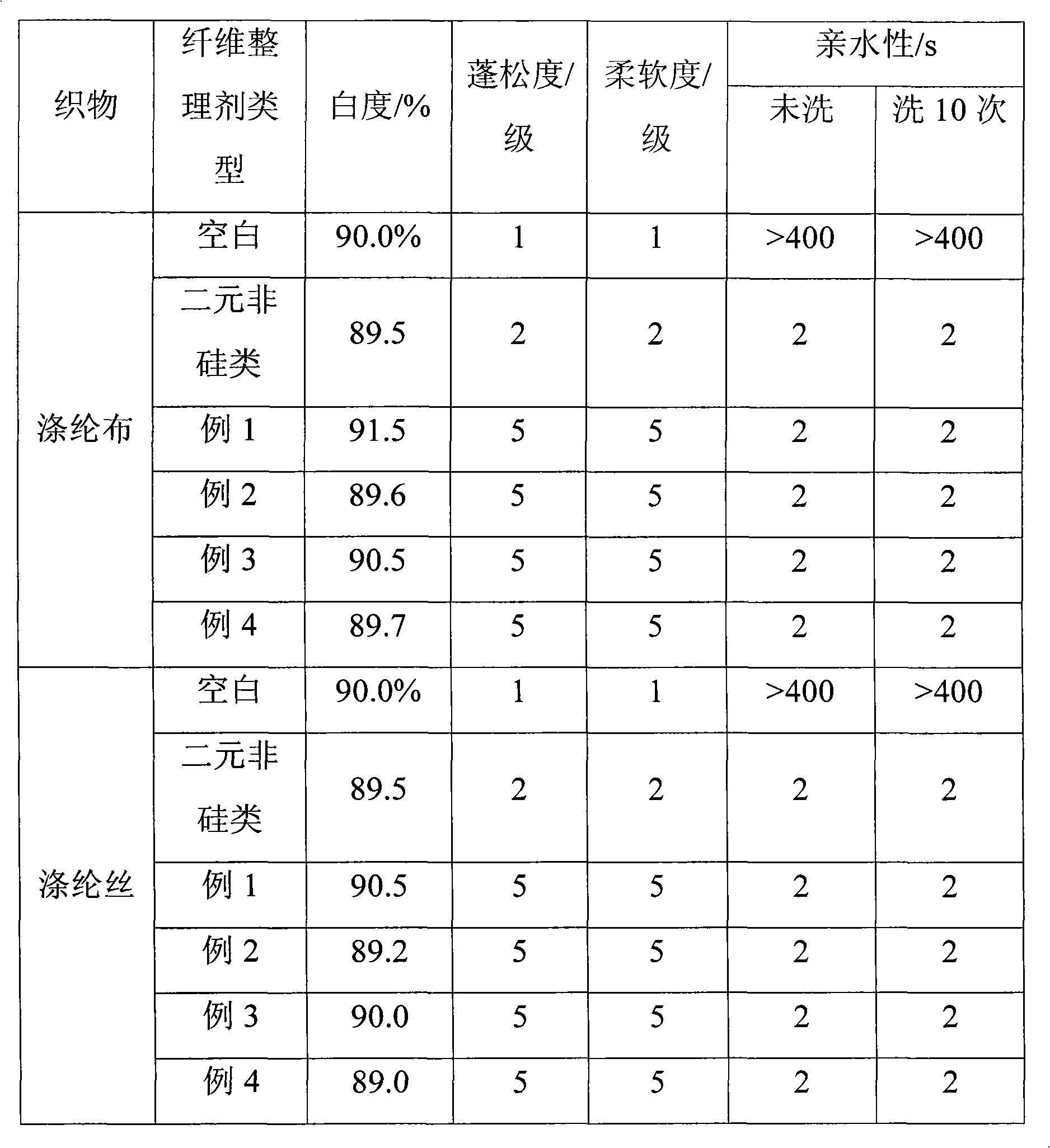

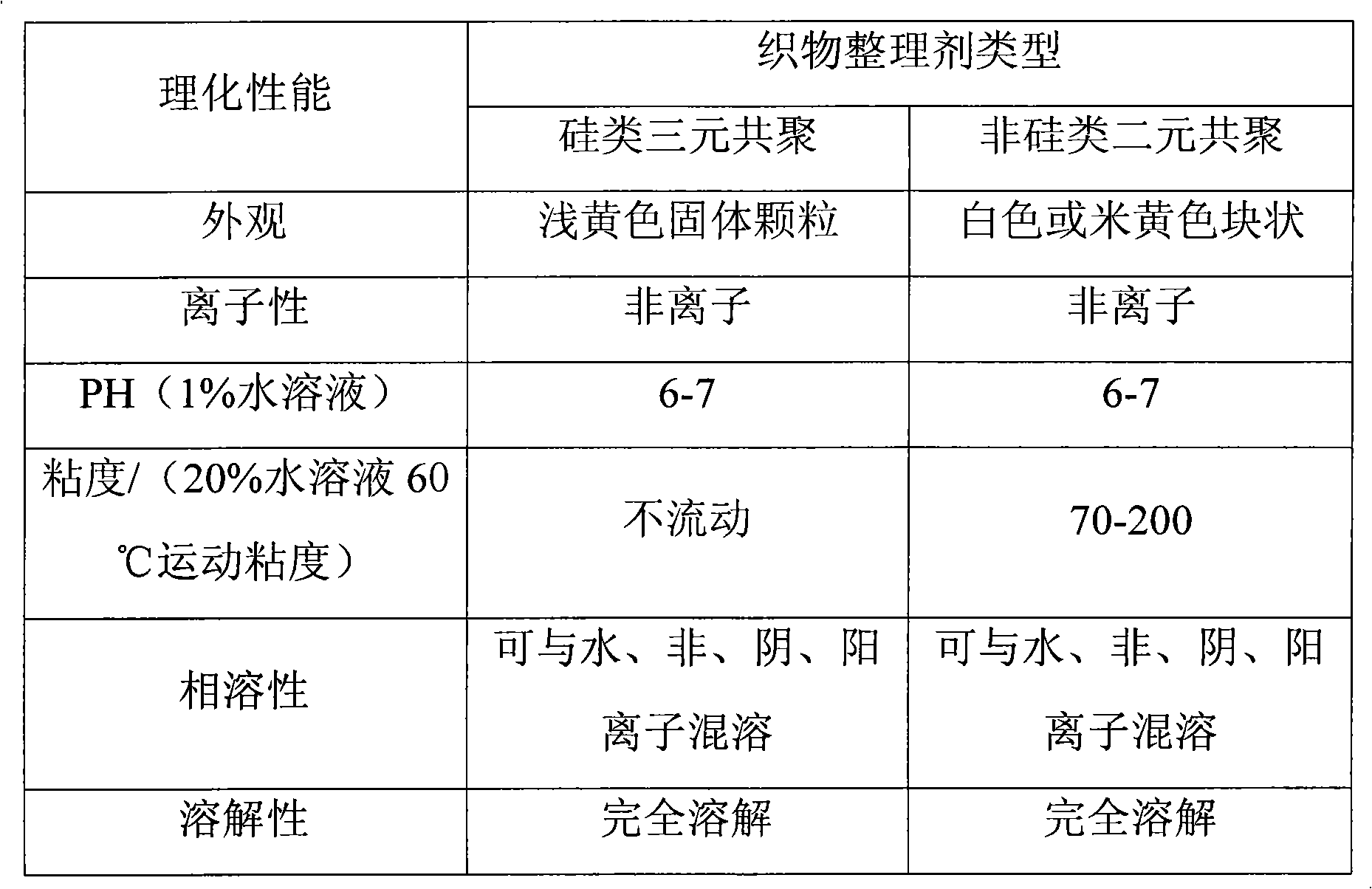

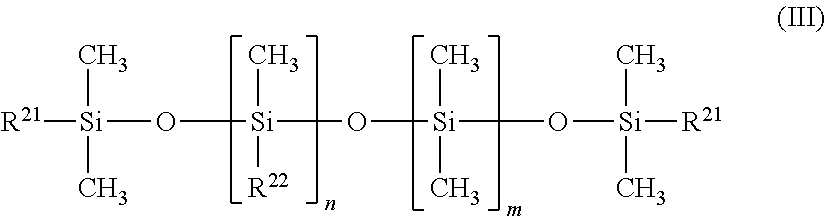

Method for preparing polyester and polyether modified silicone oil ternary copolymer textile finishing agent

The invention relates to a method for preparing a polyester and polyether modified silicone oil ternary copolymer textile finishing agent, and belongs to the field of the synthesis of ternary copolymer synthetic fiber finishing agents. The method comprises the following steps of: performing a hydrosilylation reaction of allyl polyether and hydrogen-containing silicone oil under the action of a chloroplatinic acid catalyst to form polyether modified silicone oil; and performing a polycondensation reaction of the polyether modified silicone oil and dimethyl terephthalate, glycol and polyethylene glycol under the action of antimonous oxide, manganese acetate, n-tetrabutyl titanate and triphenyl phosphate to obtain the polyester and polyether modified silicone oil ternary copolymer multifunctional textile finishing agent. The textile finishing agent can make textiles very absorbent, antistatic and washable and touch very soft.

Owner:LIAONING KELONG FINE CHEM

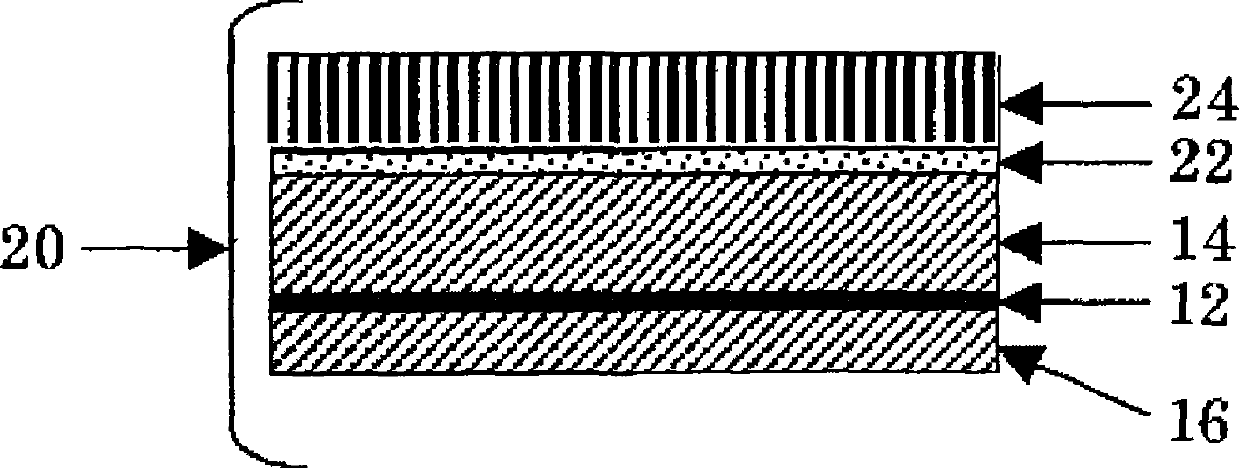

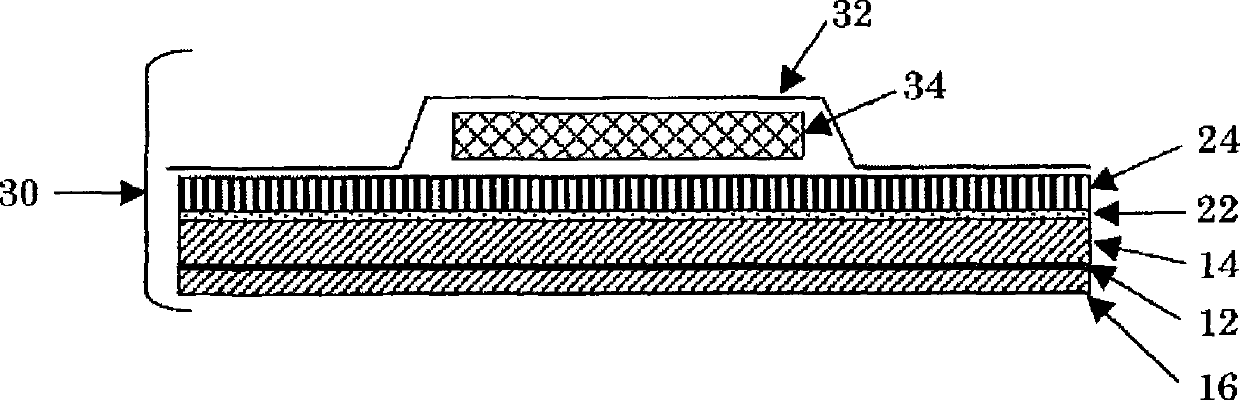

Flame-retardant metal-coated cloth

InactiveUS20050159061A1Improve flame retardant performanceSoft touchChemical protectionHeat protectionPhosphoric Acid EstersMetal coating

A flame-retardant metal-coated cloth having a high degree of flame retardancy and a soft feeling without the use of any halogen compound or antimony compound is provided. In the flame-retardant metal-coated cloth, a flame-retardant film comprising a mixture (E) of a phosphorus compound (A), a metal hydroxide (B), a phosphoric ester (C), and a thermoplastic resin (D), is formed on at least one surface of a metal-coated cloth, and the ratio of (A):(B):(C):(D) is 20 to 200:100 to 950:10 to 250:100 in terms of a weight ratio.

Owner:DAIKYO CHEM +1

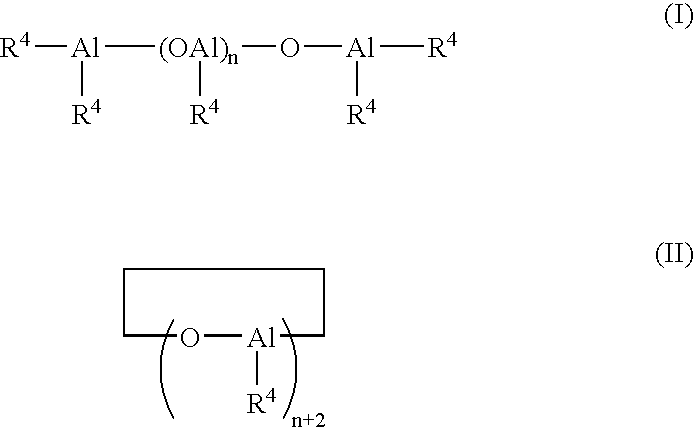

Process for producing polysiloxanes with nitrogen-containing groups

ActiveUS8796198B2Good effectSoft feelGroup 4/14 element organic compoundsOrganic detergent compounding agentsOrganic groupNitrogen

A process for producing amino-functional polysiloxanes by reacting the components A) identical or different terminally hydroxy-functional, linear or branched polysiloxanes, B) identical or different alkoxysilanes of the formulaR1xR23-xSiR3 (I)where R1 is identical or different alkyl radicals having 1 to 4 carbon atoms, R2 is identical or different alkoxy radicals having 1 to 4 carbon atoms, R3 is an organic radical having at least one nitrogen atom, x=0 to 2, and C) water, in the presence of D) one or more phosphorus-containing, Brønsted-acidic compounds, to the correspondingly obtainable polysiloxanes containing nitrogen-containing groups, and to the use thereof are provided.

Owner:EVONIK DEGUSSA GMBH

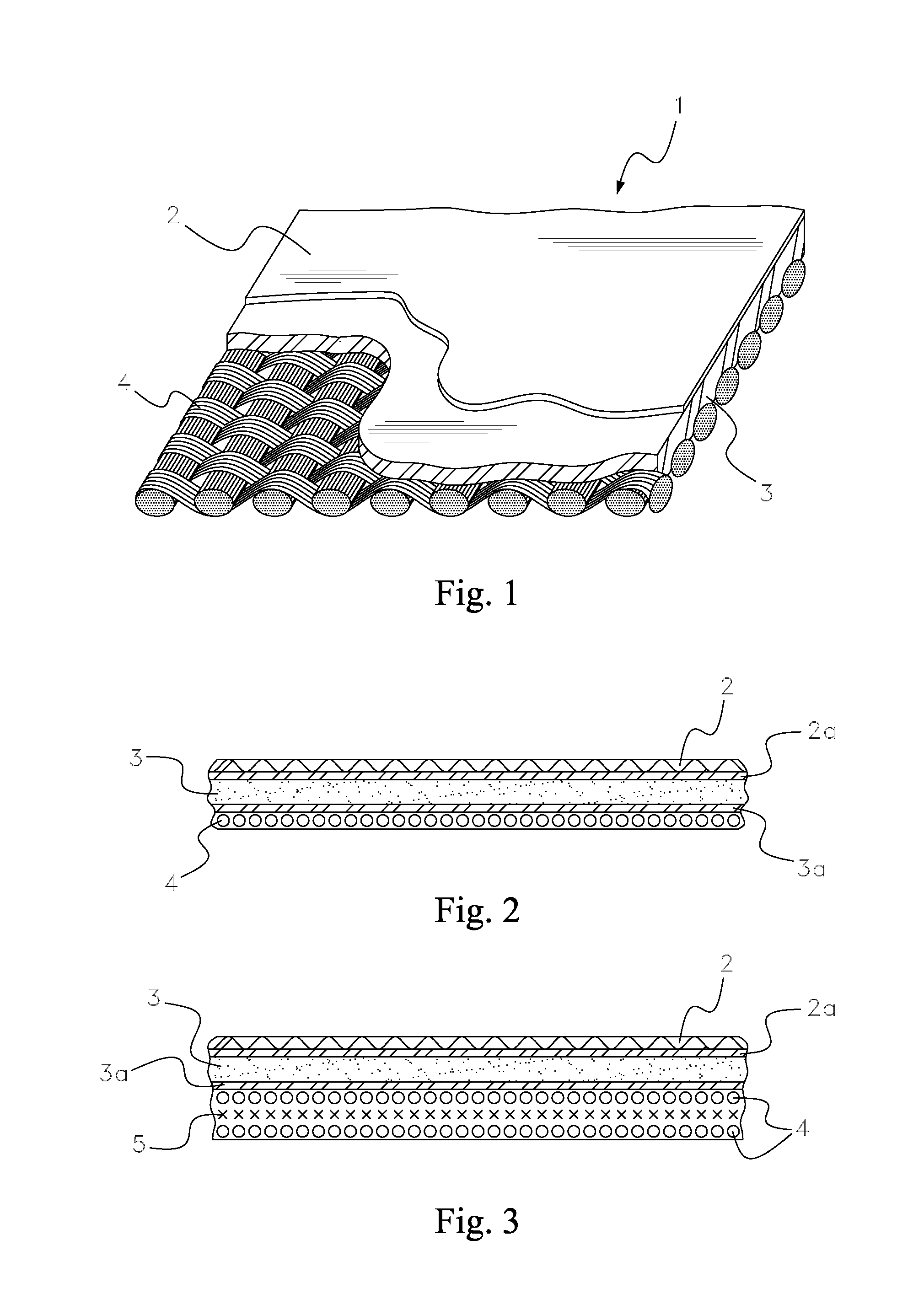

Soft tactile coating for multi-filament woven fabric

A polyolefin woven fabric extrusion coating with superior soft tactile characteristic is disclosed comprising ethylenic elastomer and thermoplastic vulcanizate. The combination performs in a synergistic fashion to obtain more pleasing soft tactile characteristic than is available with either elastomer or thermoplastic vulcanizate alone. The inclusion of additives may enhance properties and include plastomer, UV stabilizers, flame retardant, antiblock, colorant, printable additives and polar additives.

Owner:IRIS WOVEN U S LLC

Nonwoven-fabric laminate, moisture-permeable nonwoven-fabric laminated sheet comprising nonwoven-fabric laminate, and sanitary supply employing these

ActiveCN101374652AReduce the ratioLess amountSynthetic resin layered productsSanitary towelsPolymer sciencePropylene Polymers

A nonwoven-fabric laminate which comprises a first spun-bonded nonwoven fabric comprising a propylene polymer (first SB nonwoven fabric), a melt-blown nonwoven fabric comprising a propylene polymer and superposed on the first SB nonwoven fabric, and a second spun-bonded nonwoven fabric comprising a propylene polymer (second SB nonwoven fabric) and superposed on the melt-blown nonwoven fabric and which has an overall basis weight of 30 g / m<2> or less. The nonwoven-fabric laminate is characterized in that the first SB nonwoven fabric has a basis weight of 3-25 g / m<2>, the second SB nonwoven fabric has a basis weight of 1-11 g / m<2>, the ratio of the basis weight of the first SB nonwoven fabric to the basis weight of the second SB nonwoven fabric is 1.6 or higher, the ratio of the thickness of the first SB nonwoven fabric to the thickness of the second SB nonwoven fabric is 1.4 or higher, the melt-blown nonwoven fabric has a basis weight less than 3 g / m<2>, and the areal proportion of press-bonded parts is 6-25%.

Owner:MITSUI CHEM INC

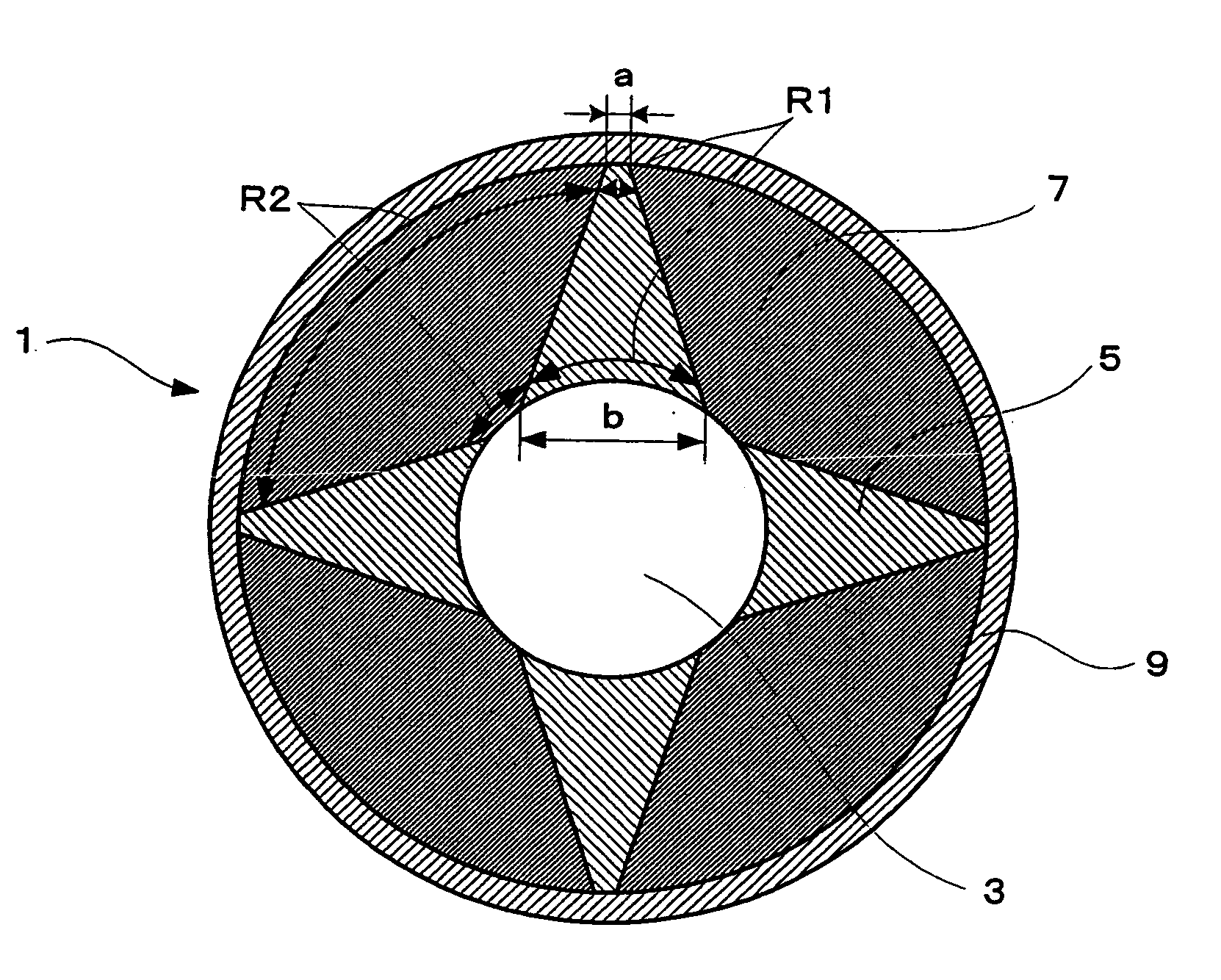

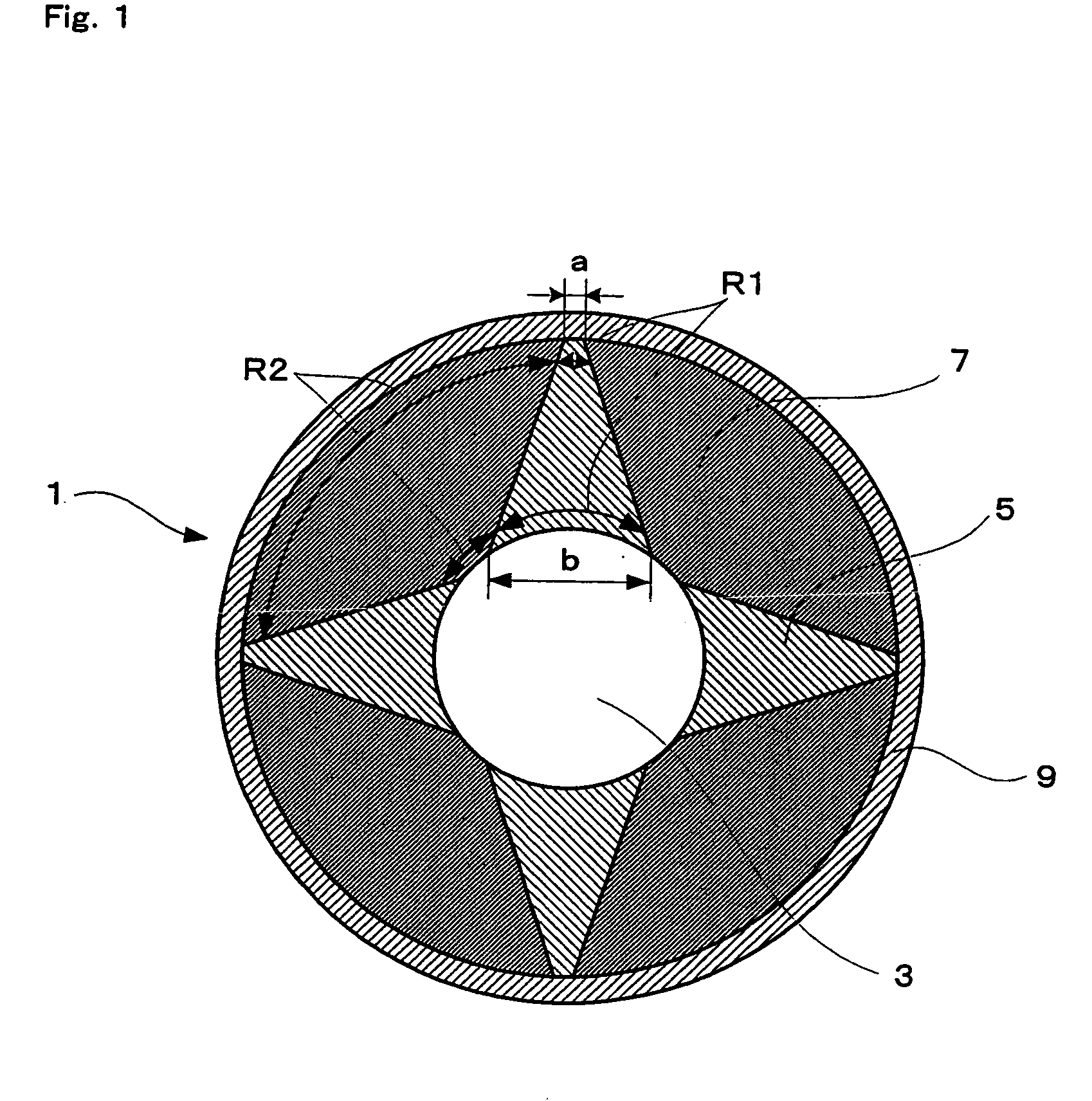

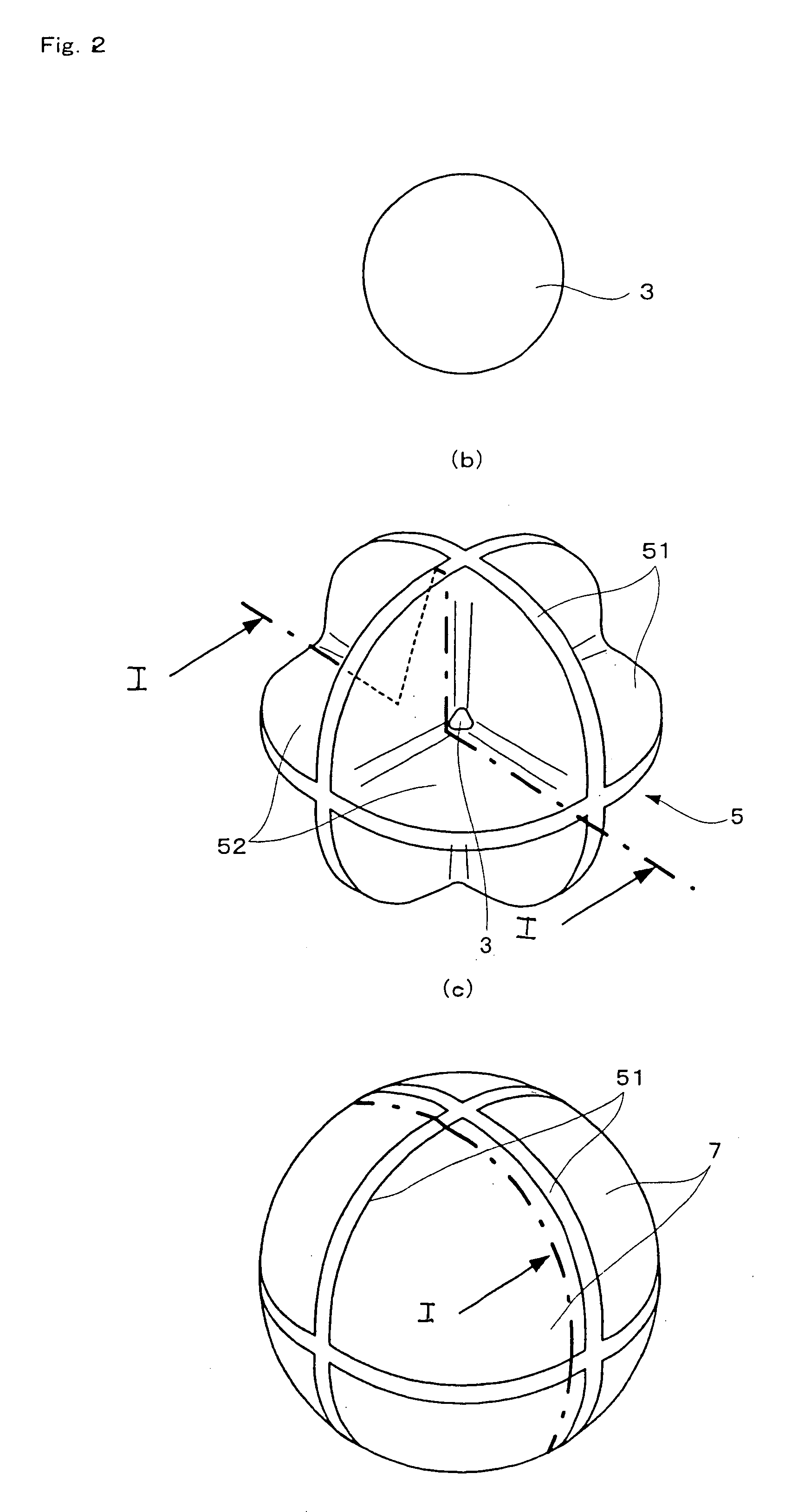

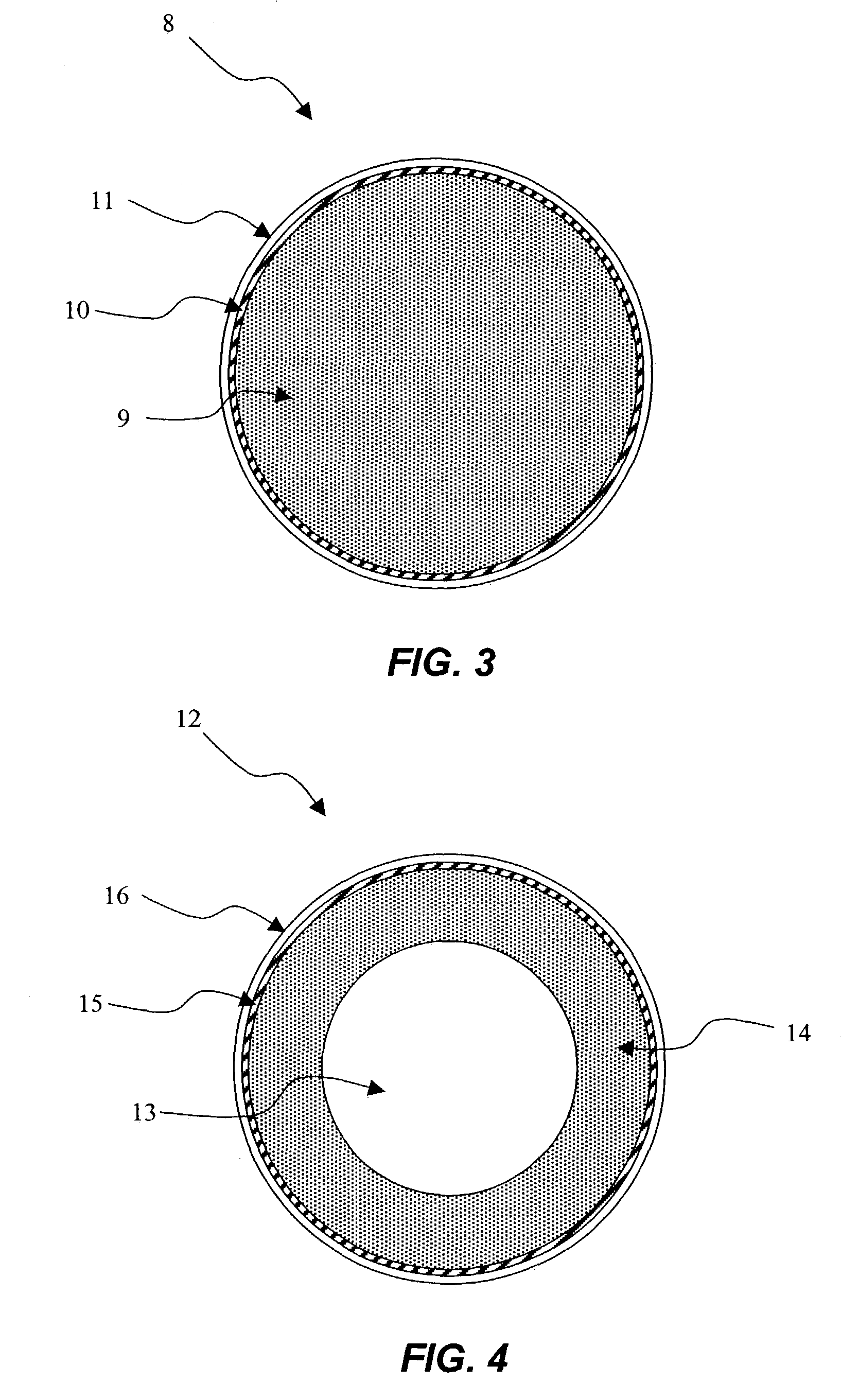

Multi-piece golf ball, manufacturing method thereof and mold for manufacturing the same

The present invention provides a multi-piece golf ball comprising a core 3, a first intermediate layer 5, a second intermediate layer 7, and a cover 9, wherein the first intermediate layer 5 comprises a plurality of ribs 51 formed on the core 3; the second intermediate layer 7 is placed in concave portions surrounded by the ribs 51; and the cover 9 forms an outermost layer; with each of the ribs extending so that its width increases from the cover side to the core side; the concave portions being shaped into a funnel-like form by the side surfaces of the ribs; the hardness of the core 3, the first intermediate layer 5 and the second intermediate layer 7 being different from each other; and the hardness of the first intermediate layer 5 being greater than that of the second intermediate layer 9.

Owner:MIZUNO CORPORATION

Multilayer golf ball

A multilayer golf ball with a solid center diameter in the range of about 1.40 to 1.52 inches, a ionomeric polymer mantle with a thickness of about 0.050 inches, and a hardness in the range of 50 to 55 Shore D and a polyurethane having a cover hardness in the range of 50 to 60 Shore D with a thickness of about 0.050 inches. The compression may be 50–60 PGA. The compression of the core may be 70–80 PGA. The compression of the above exemplary embodiment of the ball may be 80–90 PGA. A ball having such characteristics exhibits superior distance performance without compromising shot-making feel.

Owner:TAYLOR MADE GOLF

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

Process for producing polysiloxanes with nitrogen-containing groups

ActiveUS20130040875A1Minimize oxidation potentialGood storage stabilitySilicon organic compoundsDetergent compounding agentsOrganic groupCompound (substance)

A process for producing amino-functional polysiloxanes by reacting the components A) identical or different terminally hydroxy-functional, linear or branched polysiloxanes, B) identical or different alkoxysilanes of the formulaR1xR23-xSiR3 (I)where R1 is identical or different alkyl radicals having 1 to 4 carbon atoms, R2 is identical or different alkoxy radicals having 1 to 4 carbon atoms, R3 is an organic radical having at least one nitrogen atom, x=0 to 2, and C) water, in the presence of D) one or more phosphorus-containing, Brønsted-acidic compounds, to the correspondingly obtainable polysiloxanes containing nitrogen-containing groups, and to the use thereof are provided.

Owner:EVONIK DEGUSSA GMBH

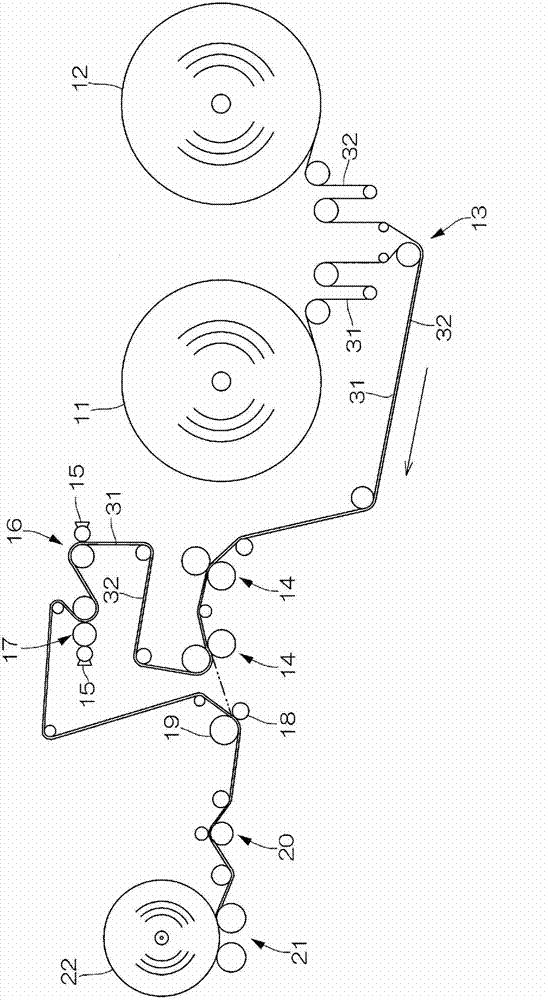

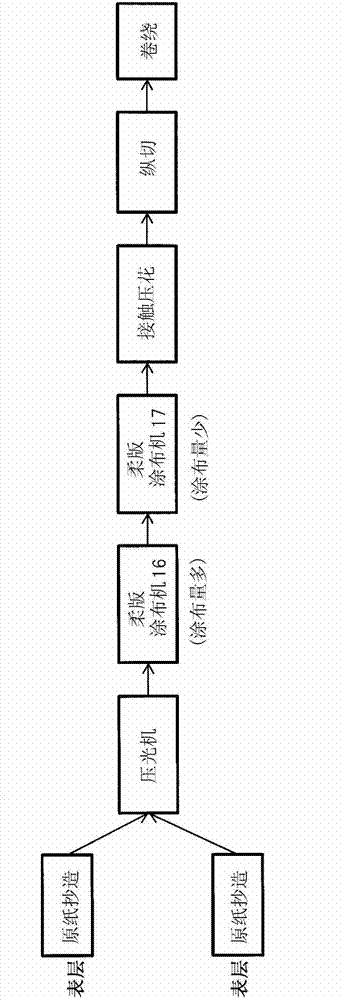

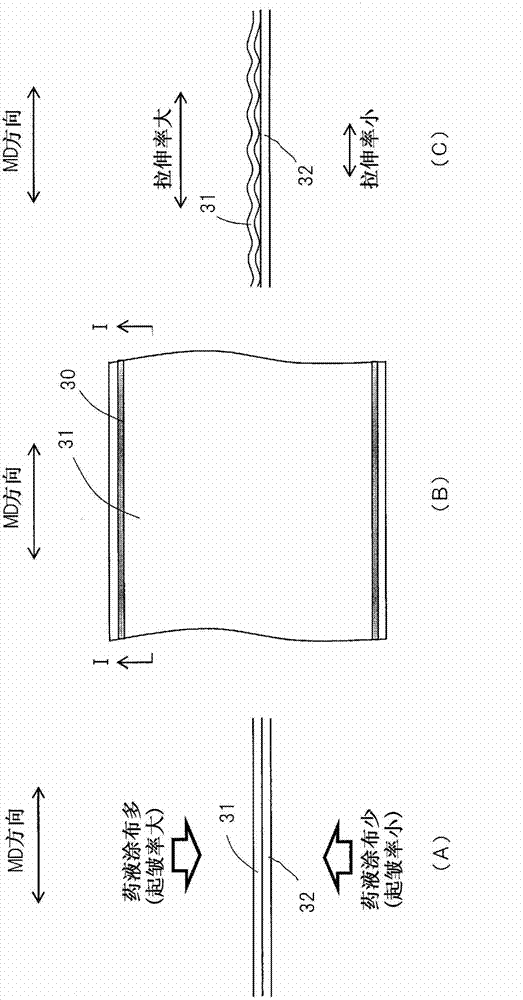

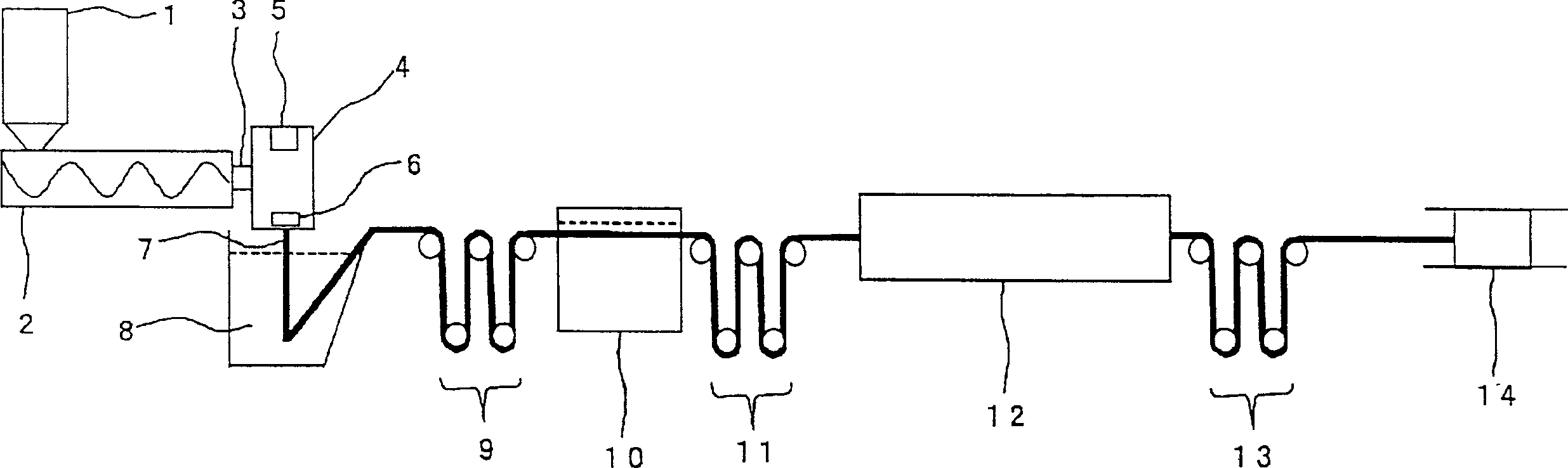

Method of manufacturing secondary whole roll for tissue paper product

ActiveCN102711571ASoft feelImprove wiping effectSpecial paperBathroom accessoriesChemical solutionBiomedical engineering

Disclosed is a tissue paper manufactured so as to be bulky without using bulking agents and the like and without increasing the number of manufacturing processes. Also disclosed is a method of manufacturing secondary whole rolls for a tissue paper product, which comprises (1) a laminating step of forming a laminated continuous sheet by laminating primary whole rolls fed from a plurality of primary whole rolls in a direction along which the rolls continue; (2) a chemical-solution applying step of applying chemical solution only to one of the top layers of the laminated continuous sheet or applying more chemical solution to one of the top layers than to the other top layer; (3) a joining step of forming linear joint portions that prevent layer separation on the laminated continuous sheet by nipping the laminated continuous sheet between a receiving roller and a driven roller. (4) a slitting step of slitting the laminated continuous sheet into sheets having a width or a several-fold width of a tissue paper product; and (5) a coiling step of forming a plurality of secondary whole rolls having the width or the several-fold width of the tissue paper product by coaxially coiling the slit laminated continuous sheets.

Owner:DAIO PAPER CORP

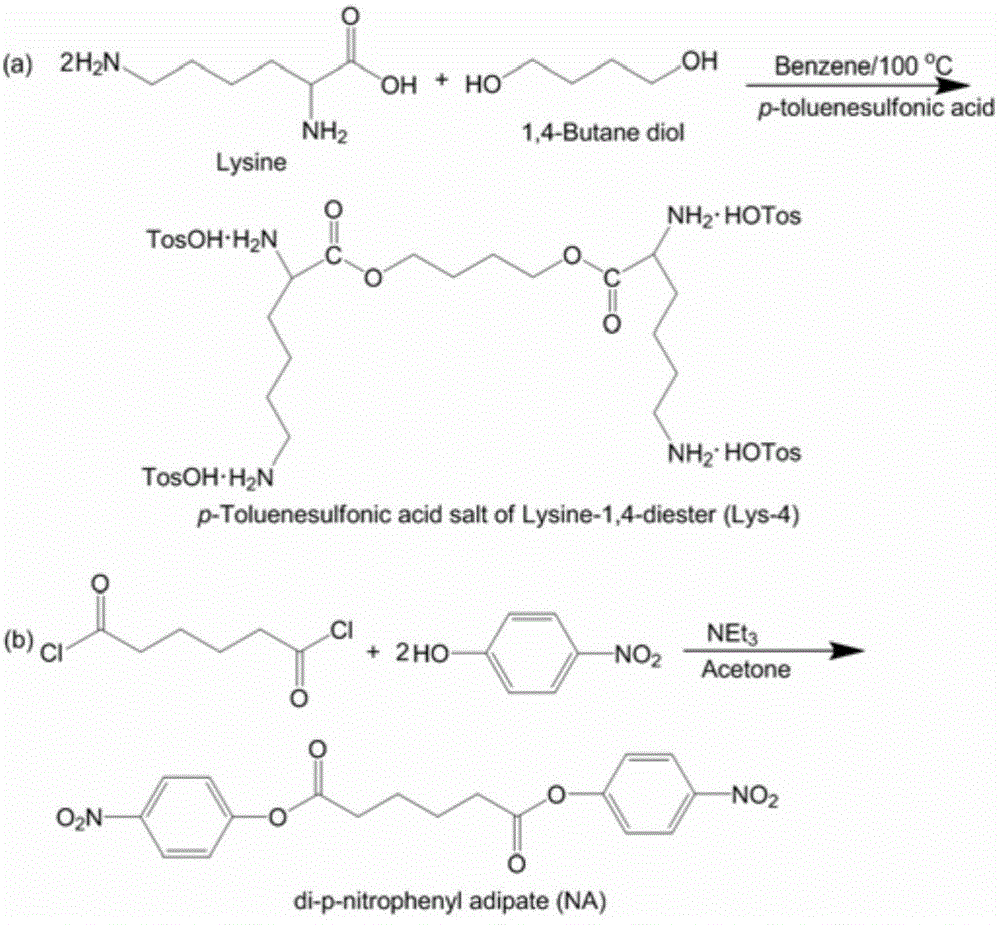

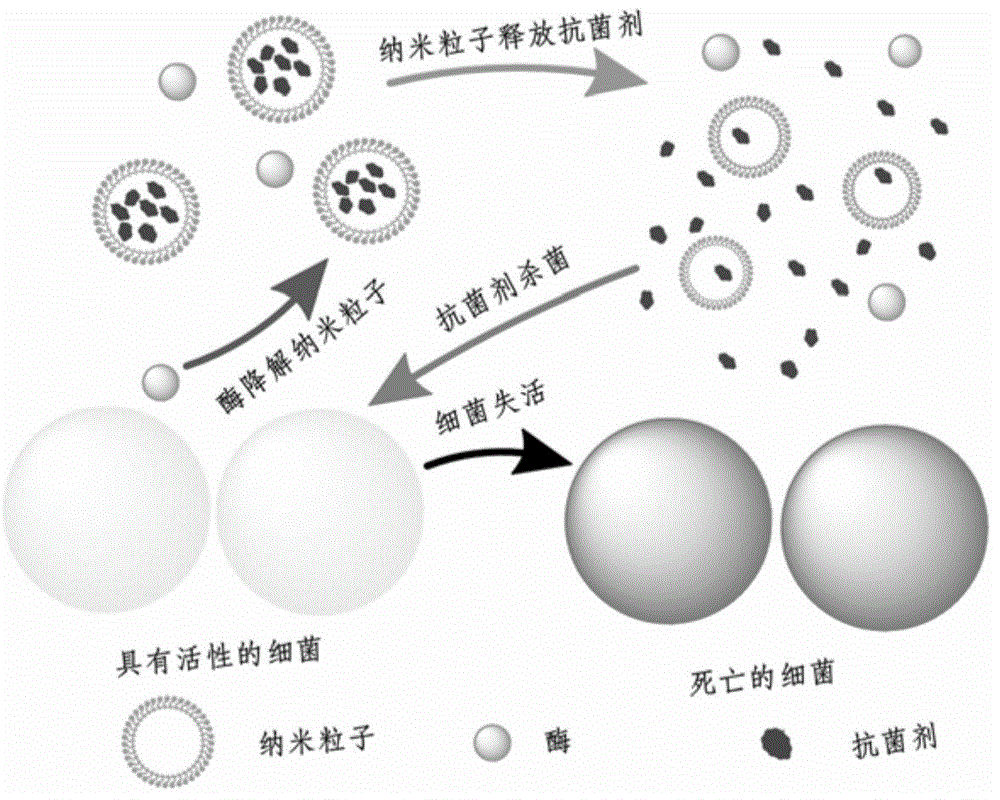

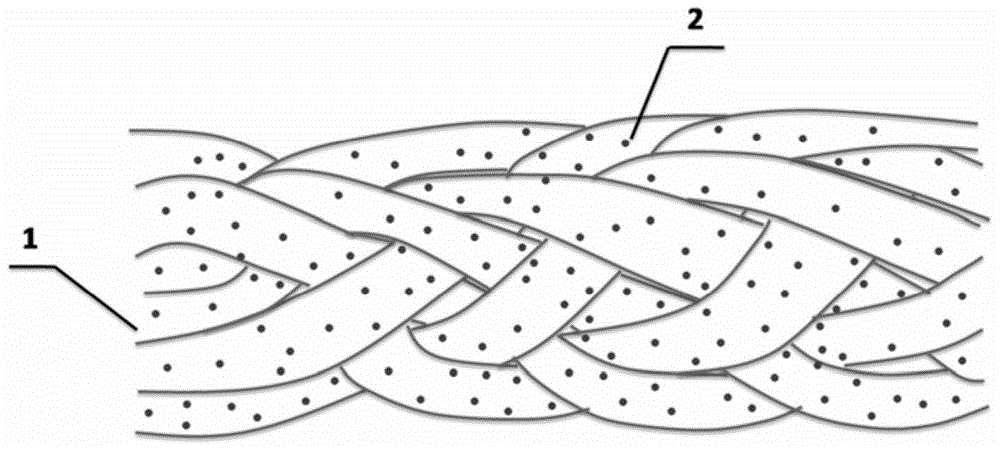

Chemical grafted type long-acting sustained-release silk suture with antibacterial function and preparation method of silk suture

The invention relates to a chemical grafted type long-acting sustained-release silk suture with an antibacterial function and a preparation method of the silk suture. The chemical grafted type long-acting sustained-release silk suture comprises braiding yarn and nanoparticles with the antibacterial function. The silk suture is activated in a buffer solution containing EDC and NHS, the nanoparticles with the antibacterial function are added for grafting, and the chemical grafted type long-acting sustained-release silk suture is obtained. The silk suture contains an antibacterial agent on the surface, thus having sterilizing and bacterial inhibition functions; the antibacterial agent is uniformly dispersed in the nanoparticles and antibacterial drugs are continuously and slowly released with the continuous biodegradation of nanoparticles, so that the silk suture has long-acting and stable sustained release and antibacterial functions.

Owner:DONGHUA UNIV

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

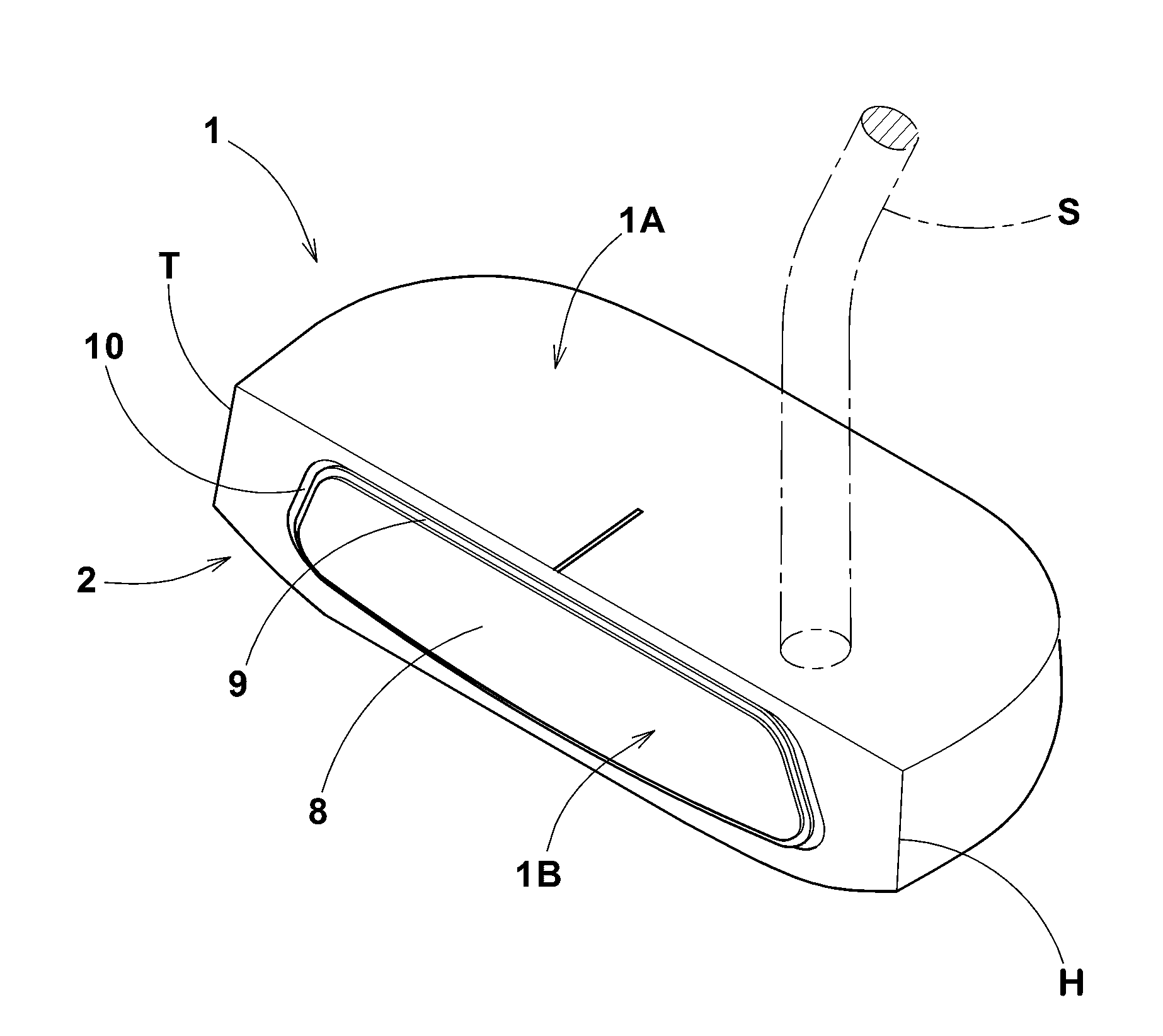

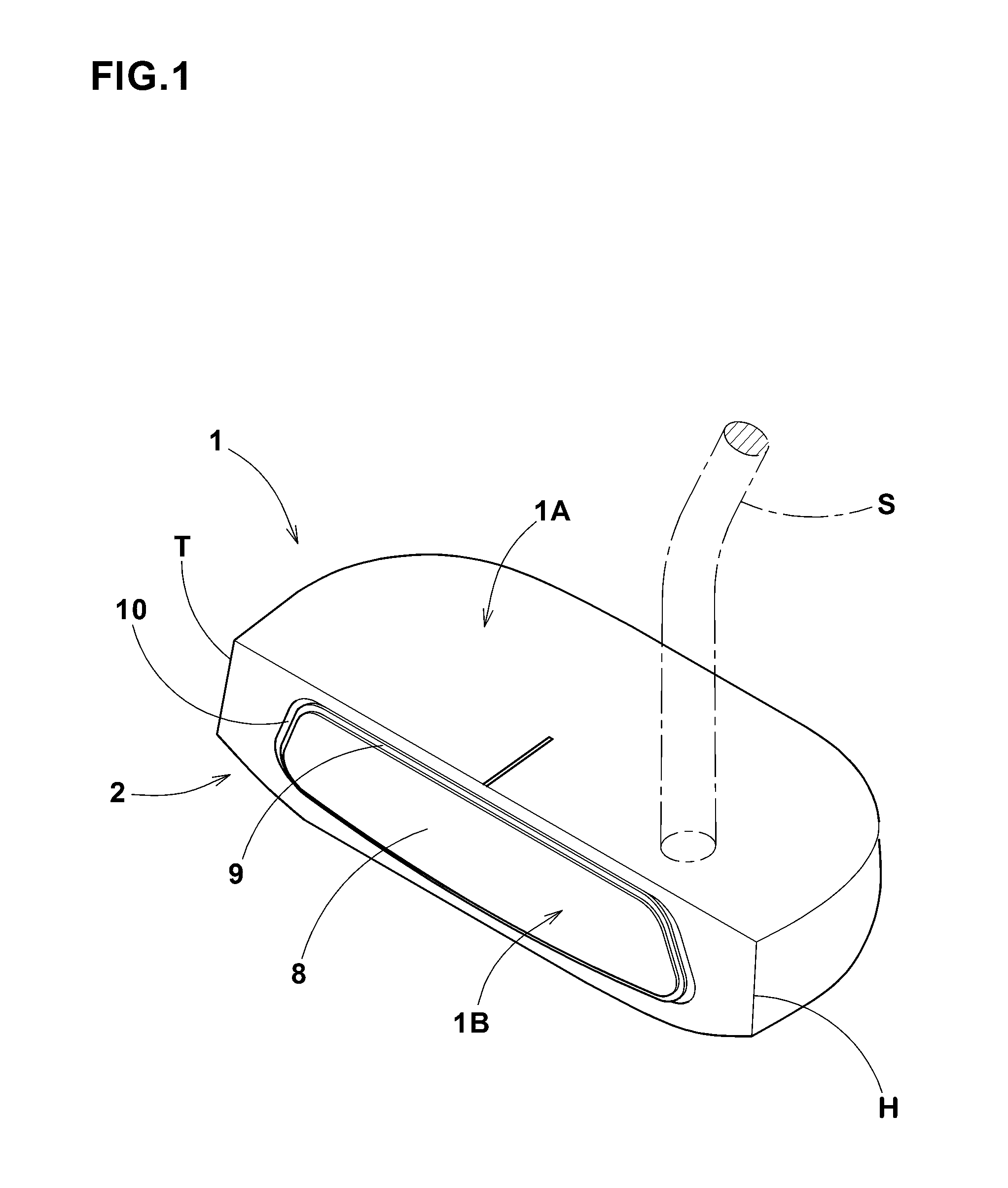

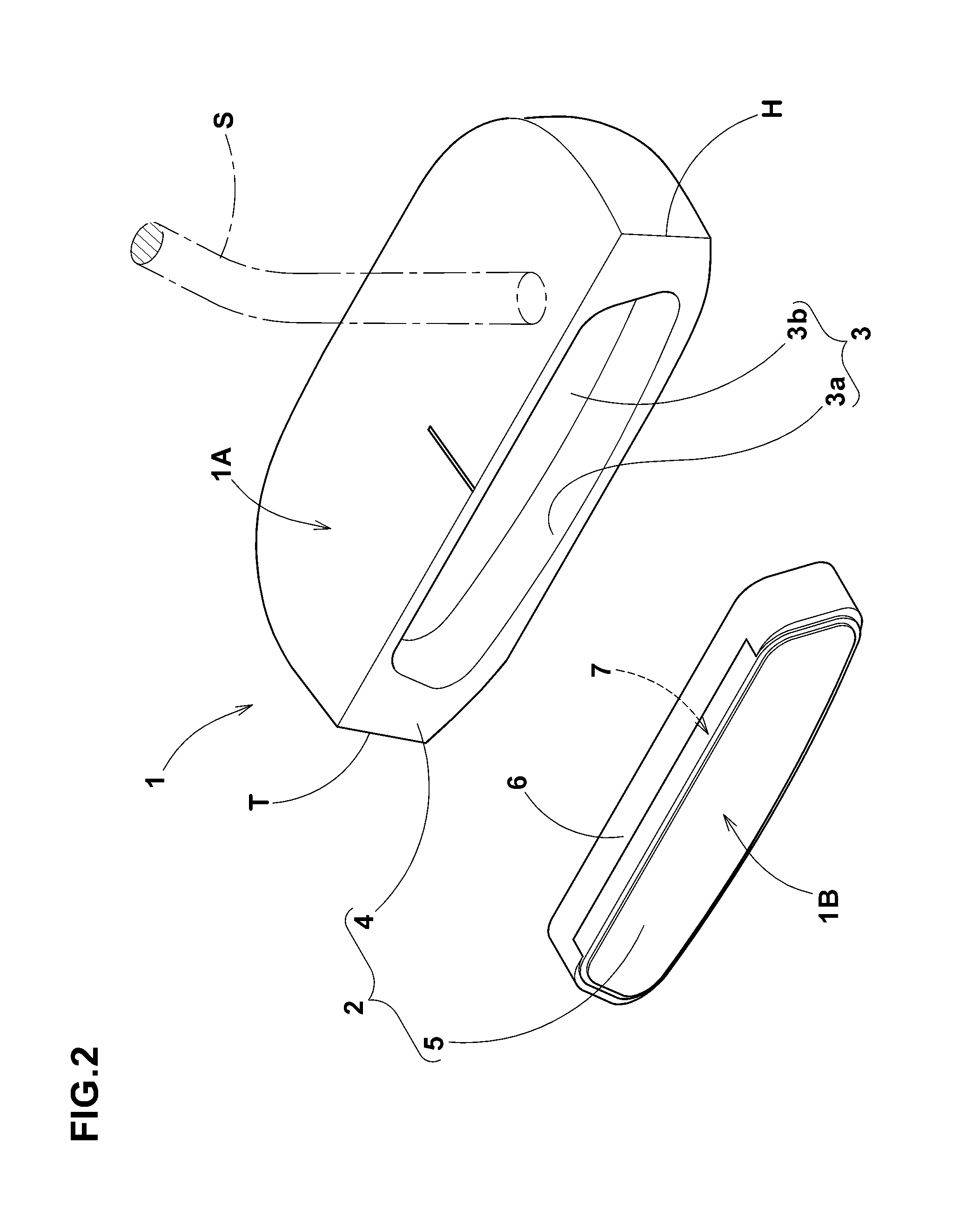

Putter type golf club head and putter type golf club

InactiveUS20130005503A1Stable ball rolling distanceSteady directionGolf clubsRacket sportsBiomedical engineeringGolf club

Owner:SUMITOMO RUBBER IND LTD

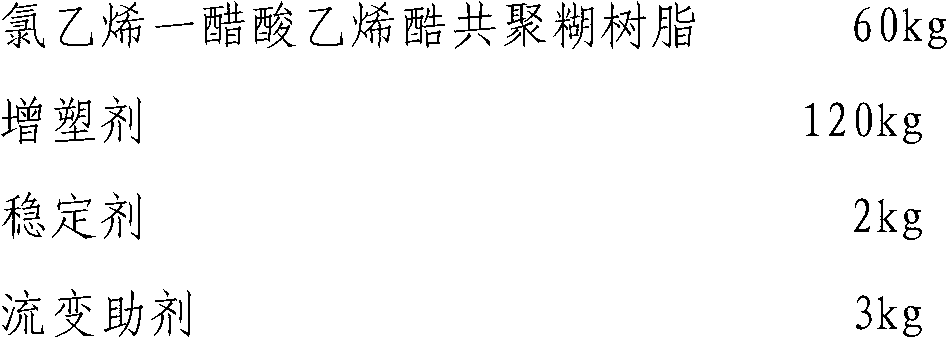

Heat-set ink used for textile printing and preparation method thereof

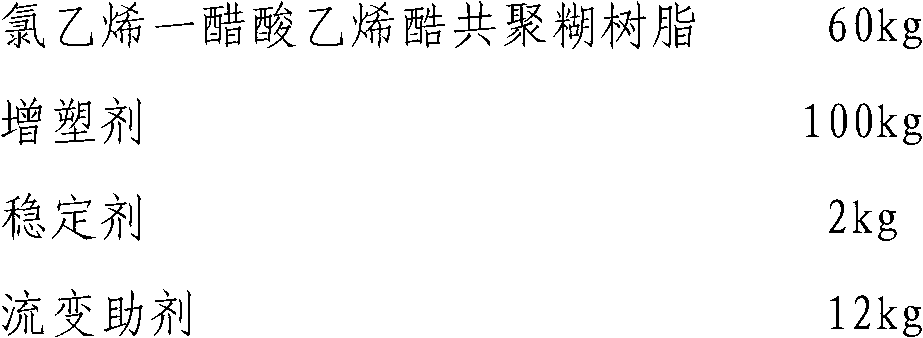

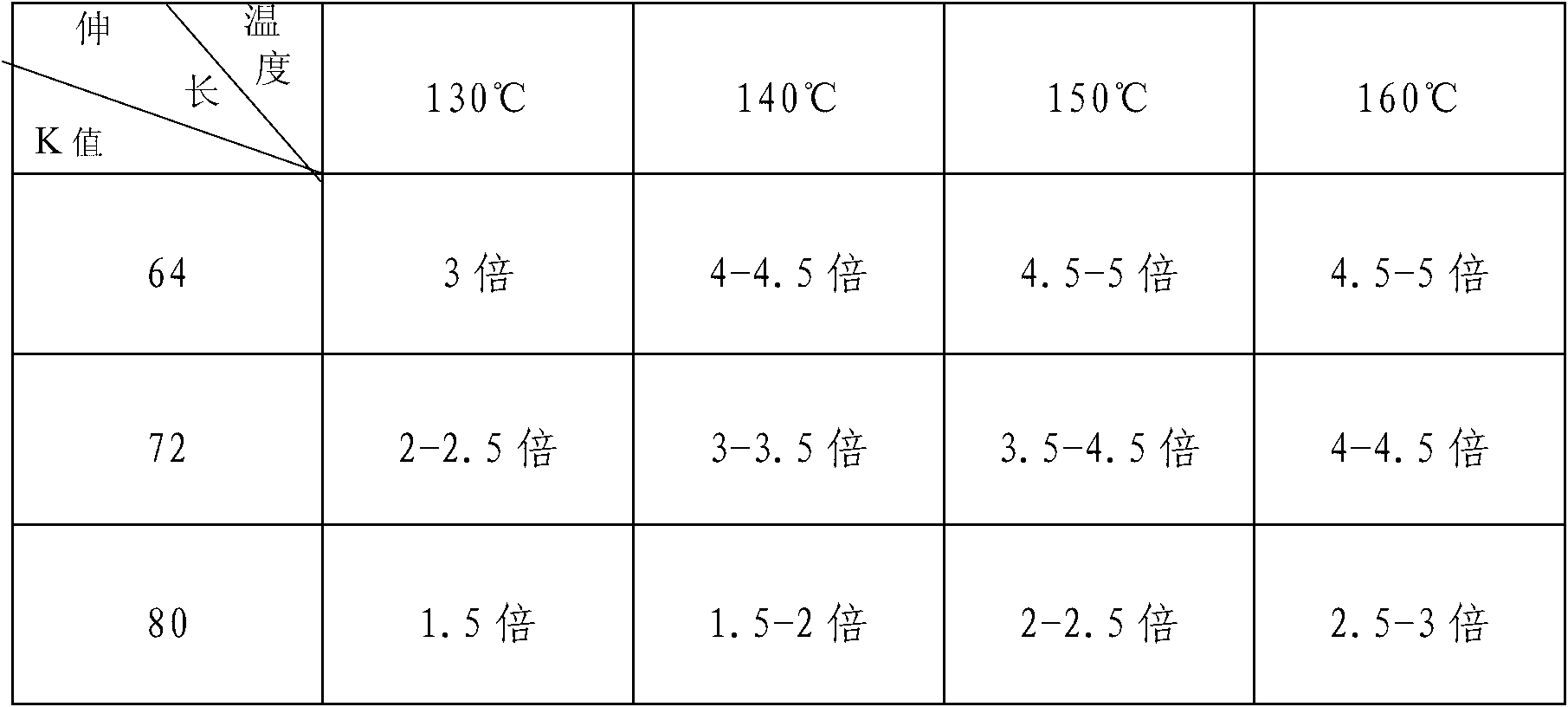

The invention relates to heat-set ink used for textile printing and a preparation method of the heat-set ink. The heat-set ink used for textile printing is characterized by comprising the following components in parts by weight: 10-40 parts of chloroethylene-vinyl acetate copolymerization paste resin, 20-60 parts of plasticizer, 1-3 parts of stabilizing and 2-7 parts of rheological additive, wherein the polymerization degree of the chloroethylene-vinyl acetate copolymerization paste resin is 1,000, the K value is 62-69, and the weight percentage of the vinyl acetate component is 3-8%. Phthalic acid ester plasticizers are not contained in the heat-set ink used for textile printing, and the curing temperature of the heat-set ink used for textile printing is between 120 DEG C and 140 DEG C.

Owner:中山市中益油墨涂料有限公司

Monofilament yarn and process for producing same

InactiveCN1420950ASoft feelNo damageThin material handlingMonocomponent polyesters artificial filamentYarnPolyethylene terephthalate

A polytrimethylene terephthalate monofilament yarn which is excellent in flexibility, flex recovery, and durability in long-term use. It is characterized by being made of a polytrimethylene terephthalate comprising 90 mol% or more trimethylene terephthalate repeating units and 10 mol% or less repeating units of another ester and by having a single yarn fineness of 50 dtex or higher, an intrinsic viscosity of 0.8 to 1.3 dl / g, and a shrinkage in boiling water of 2% or lower.

Owner:ASAHI KASEI KK

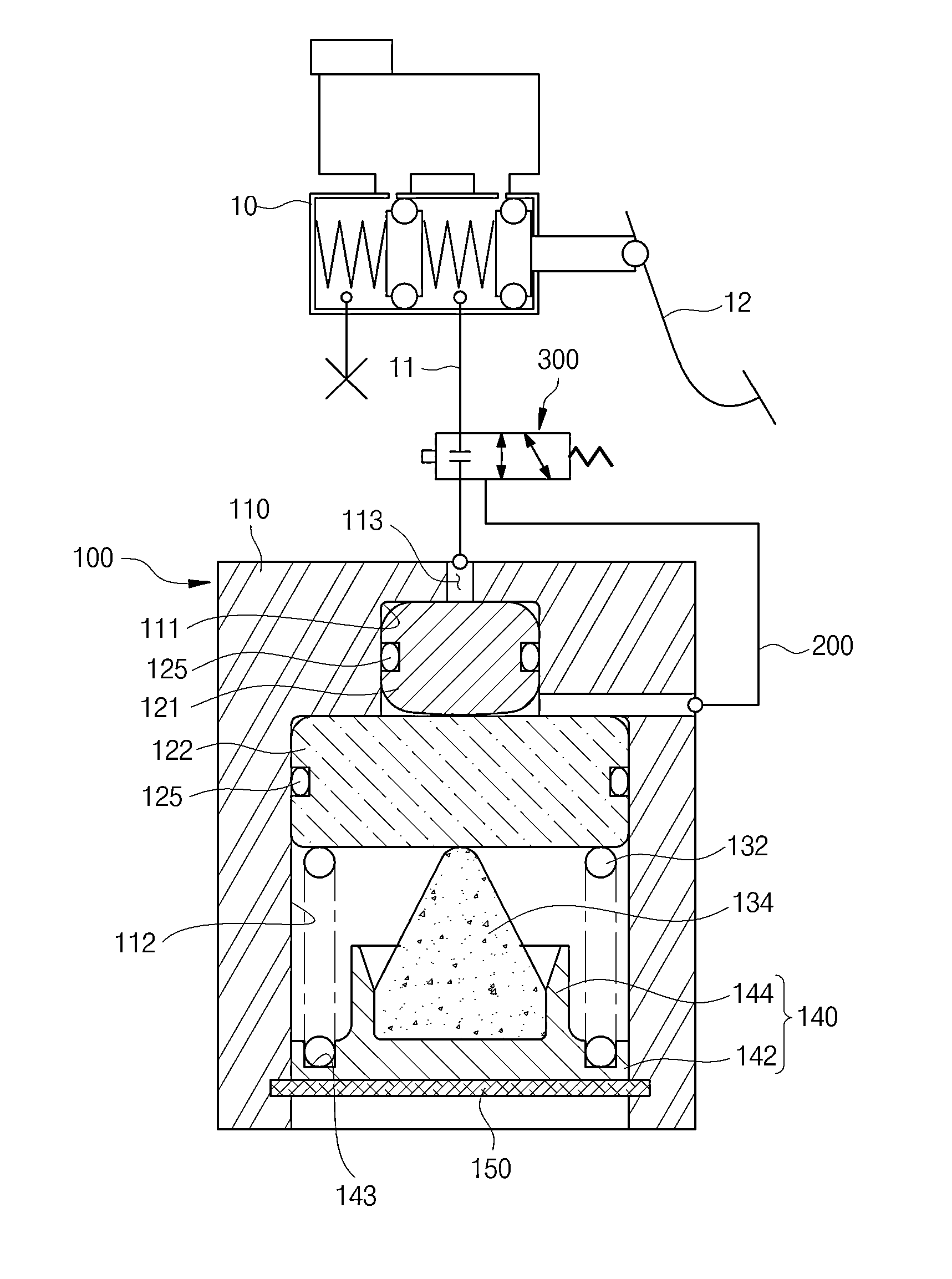

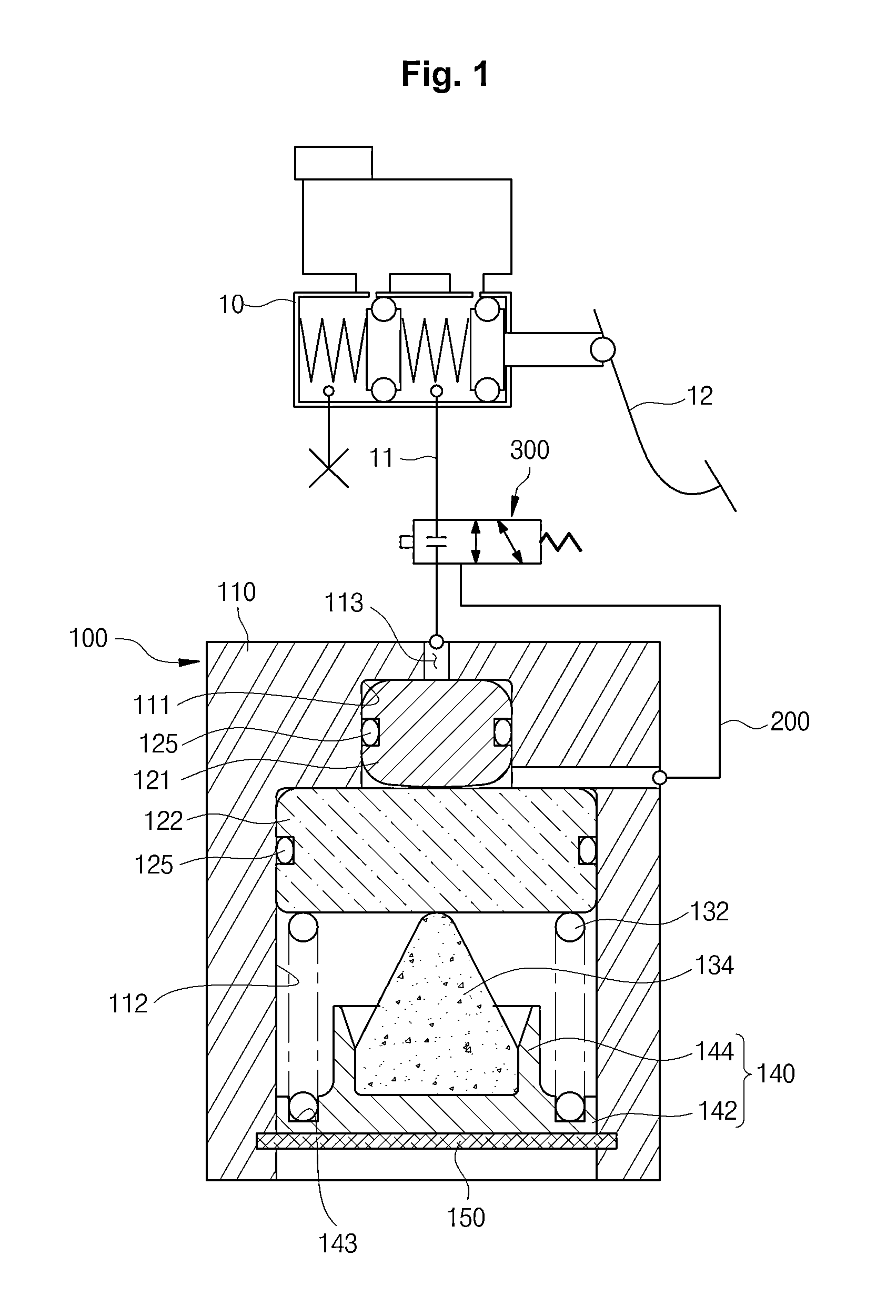

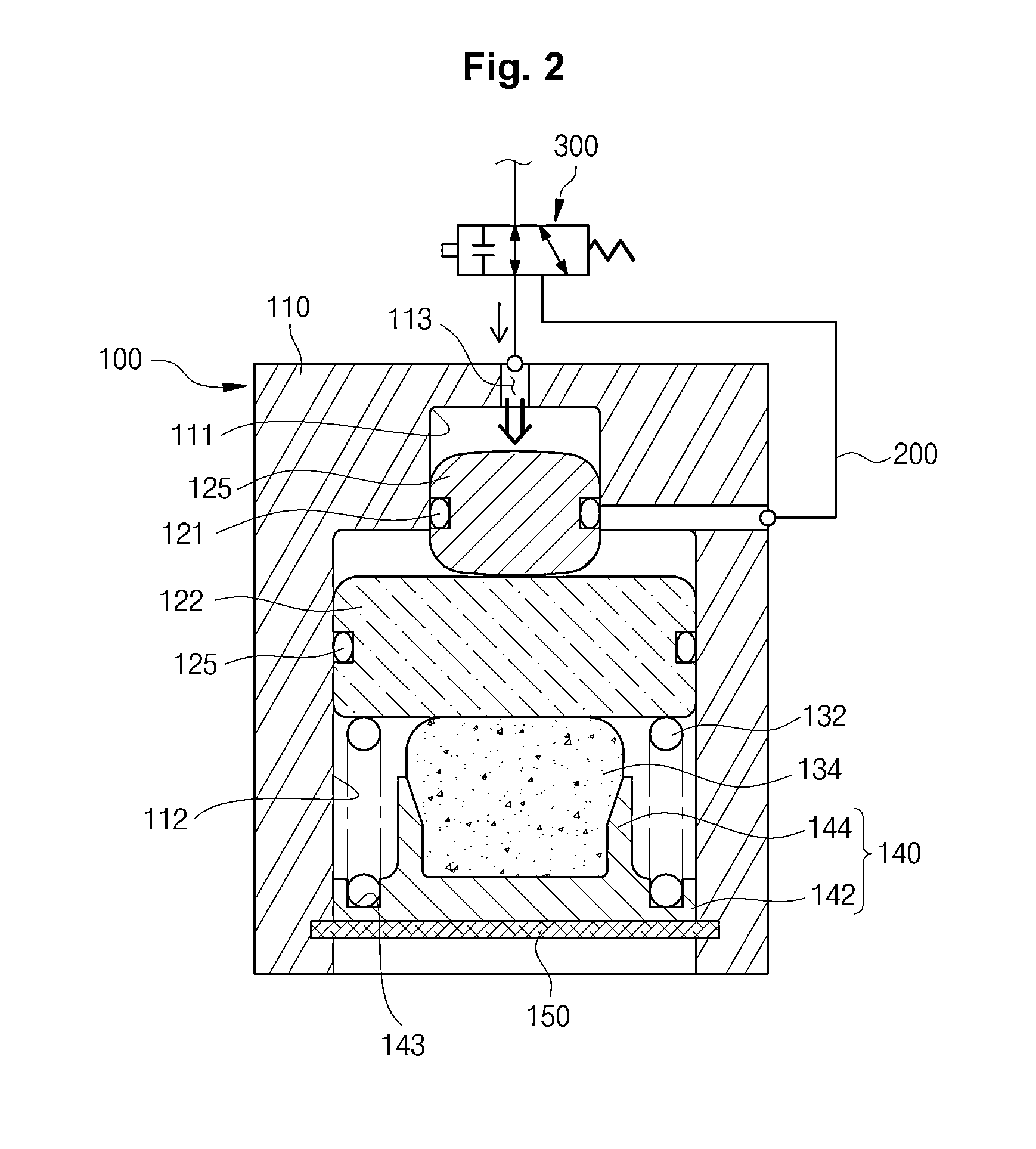

Pedal feeling adjusting device

ActiveUS20150166023A1Hard pedal feelingSoft feelControlling membersBraking action transmissionDriver/operatorDamp housing

Disclosed herein is a pedal feeling adjusting device. According to an embodiment of the present invention, the pedal feeling adjusting device that adjusts pedal feeling provided to a driver by an oil pressure generated in accordance with pedal effort of the driver, includes a pedal simulator that includes a simulator block in which an oil hole connected to a master cylinder through a flow path is formed on an upper portion thereof to receive the oil pressure in accordance with the pedal effort of the driver and bores are formed therein to contact the oil hole, a damping housing coupled to seal the bores, first and second pistons provided in series in the bores to be compressed by oil and slidably moved, and an elastic member supported by the damping housing and compressed in accordance with movement of the first and second pistons to provide a reaction force, a hydraulic flow path that is connected to the flow path to provide the oil pressure between the first and second pistons, and a control valve that is provided in the flow path to control the oil pressure to be selectively provided to the oil hole or the hydraulic flow path. Here, the first and second pistons are formed to have mutually different diameters.

Owner:HL MANDO CORP

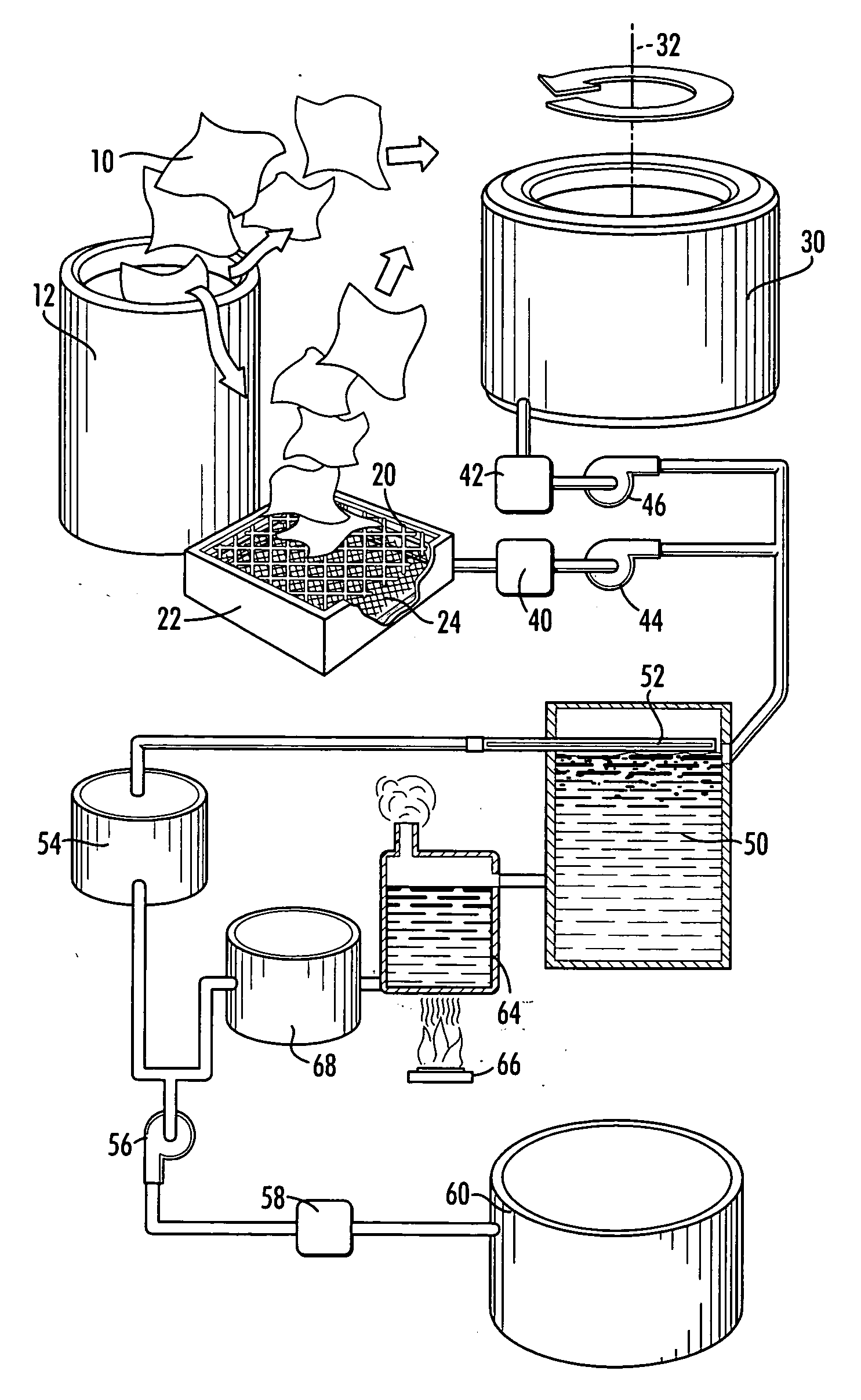

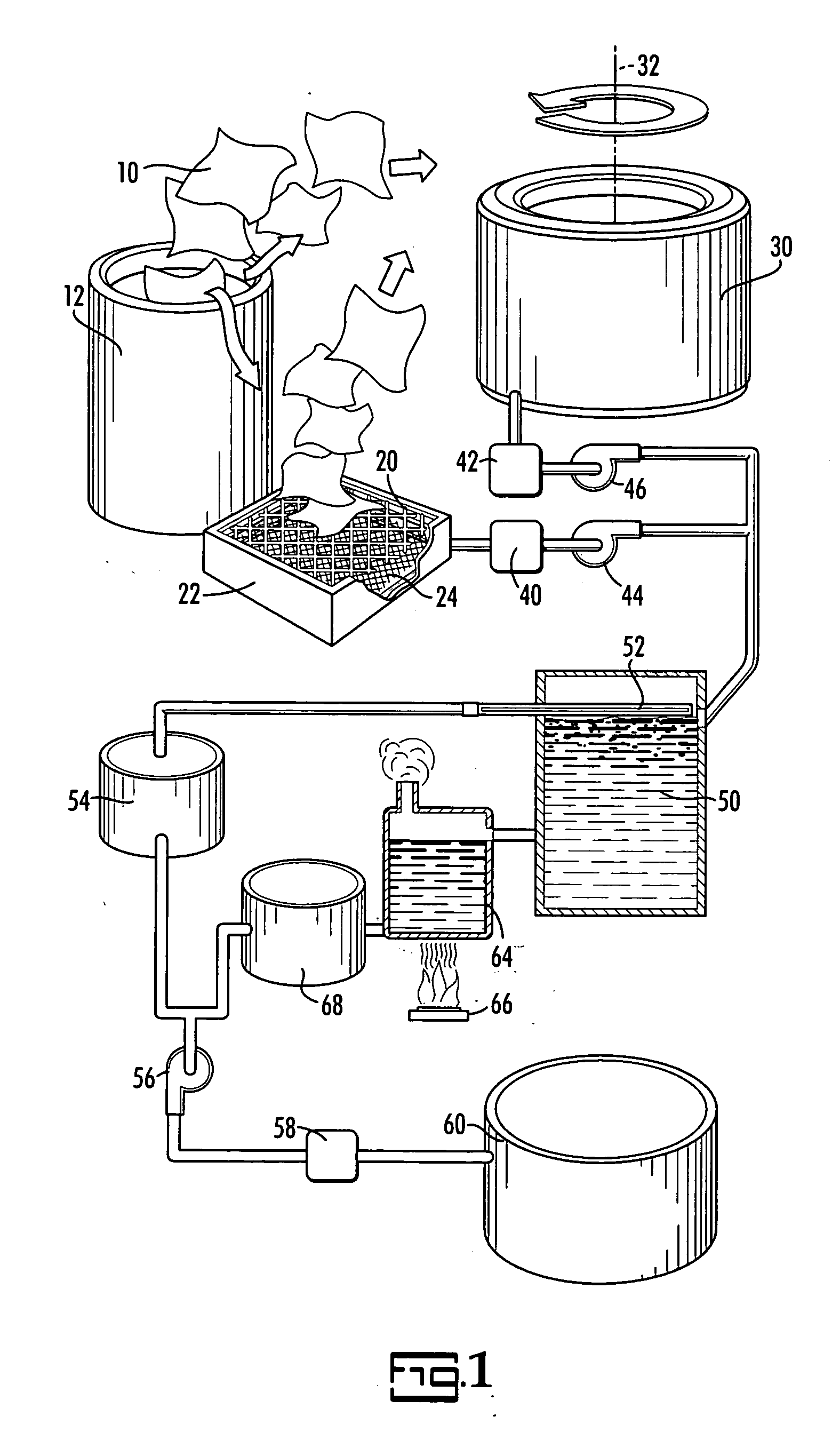

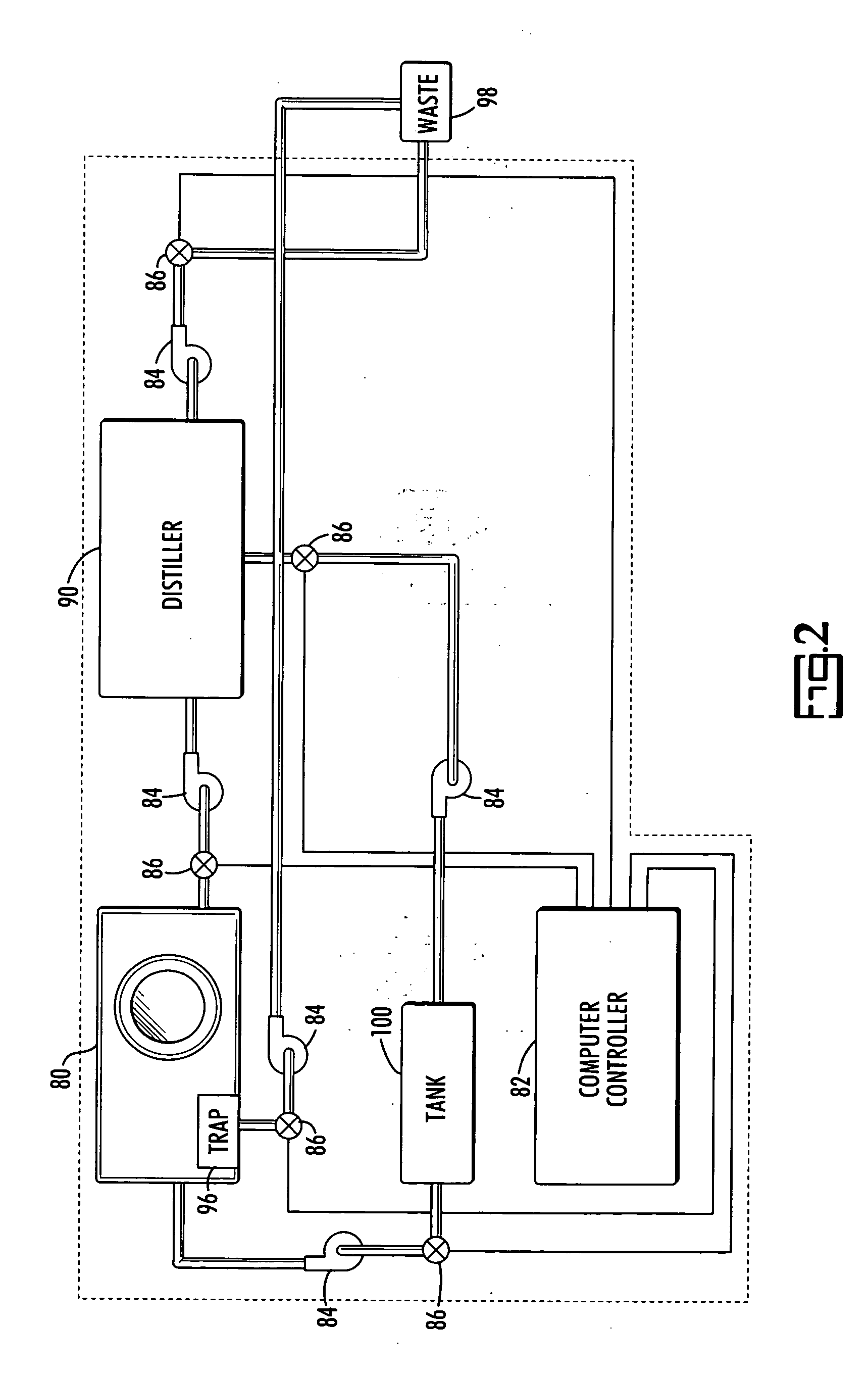

Method for cleaning textile absorbers

InactiveUS20050204478A1Fresher scentSoft feelDry-cleaning apparatusWashing receptaclesPropyl bromideEngineering

A method and system for cleaning textile absorbers that can be recycled. The system includes the use of a particular cleaning fluid, n-propyl bromide, to clean the textile absorbers for reuse. The system may also include a removal component in which excess extraneous substances are removed from the textile absorbers prior to cleaning the textile absorbers.

Owner:MIDDLETON RICHARD G

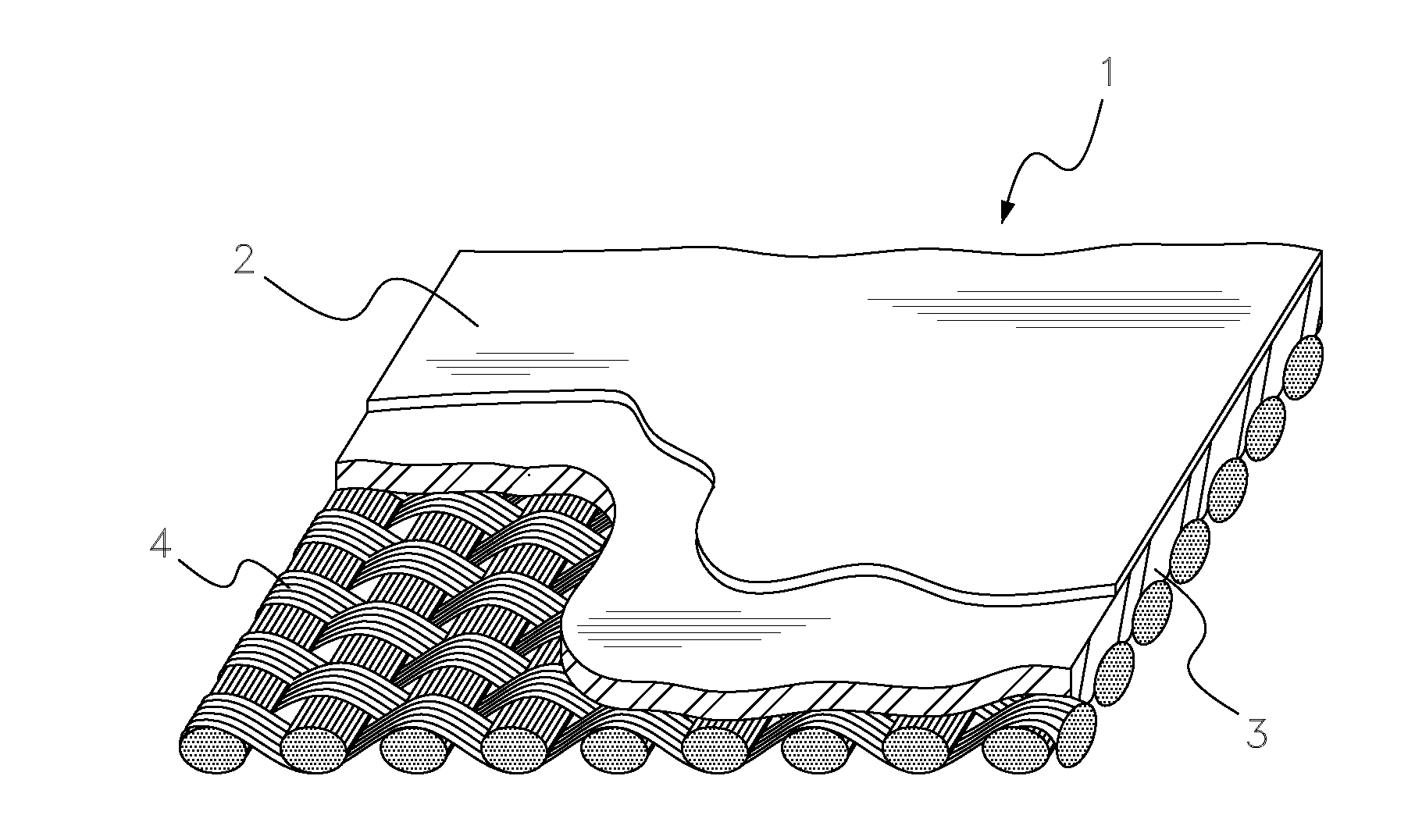

Synthetic leather-like Composite with smoke and flame resistant properties

InactiveUS20150247282A1Low and no ignition propagationSoft touchSynthetic resin layered productsCoatingsPolymer chemistrySmoke

A synthetic leather-like composite product comprising a polysiloxane top surface having the appearance and surface characteristics of leather, a polysiloxane solid or cellular core, and a textile fabric barrier layer.

Owner:BRADFORD COATINGS LLC

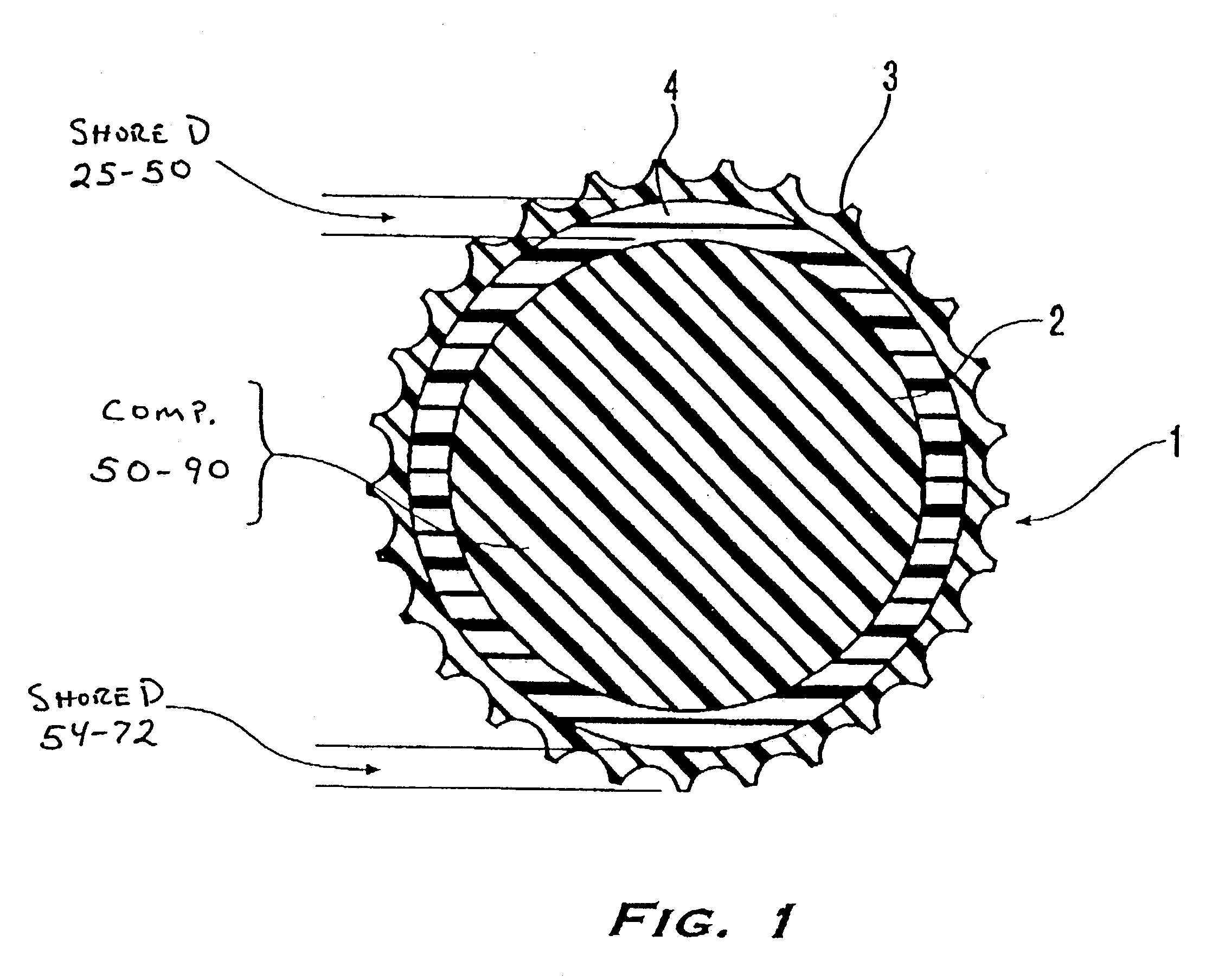

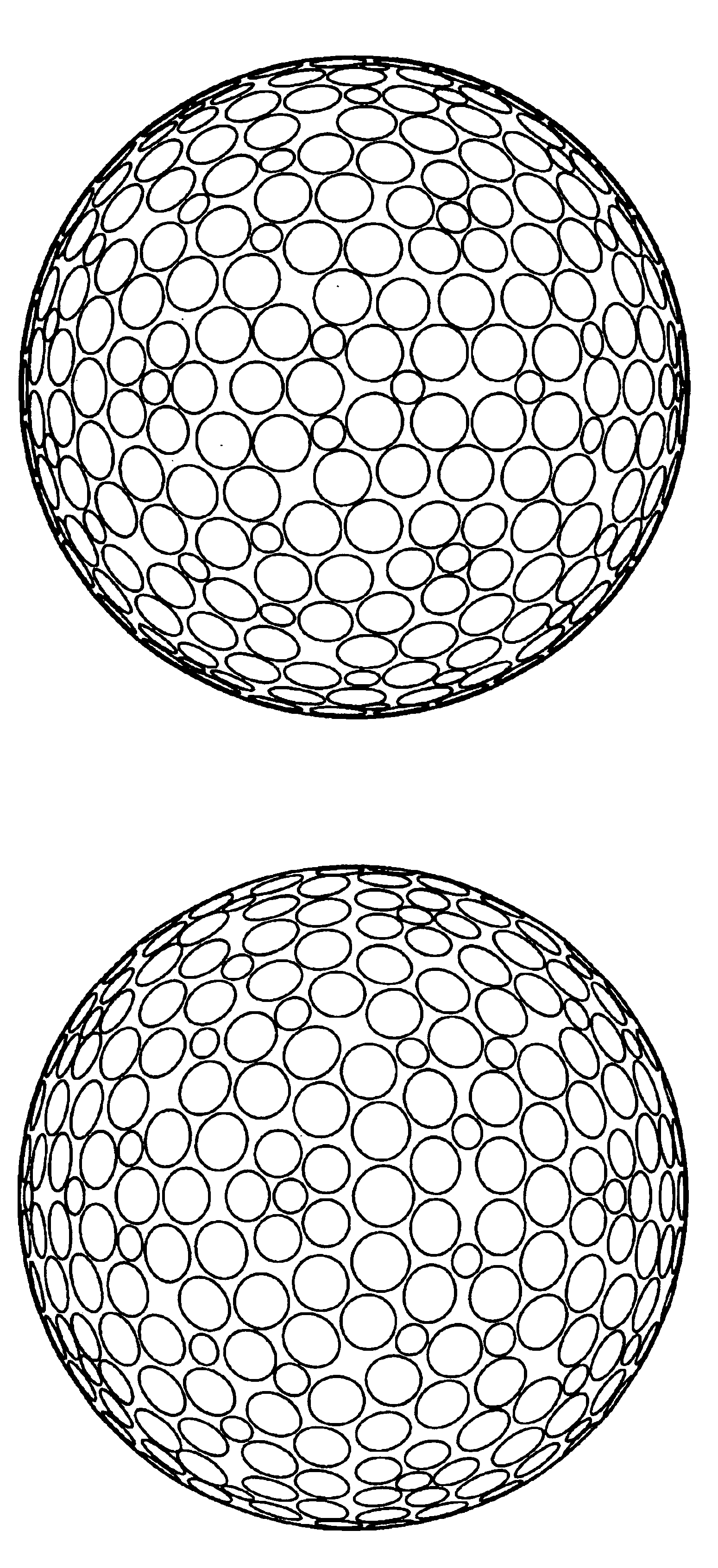

Multilayered golf ball and composition

InactiveUS7015300B2Low driver spinSoft feelPolyurea/polyurethane coatingsGolf ballsIsocyanateDiamine

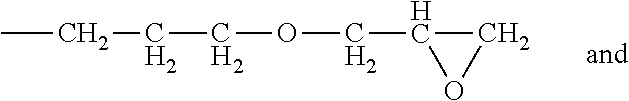

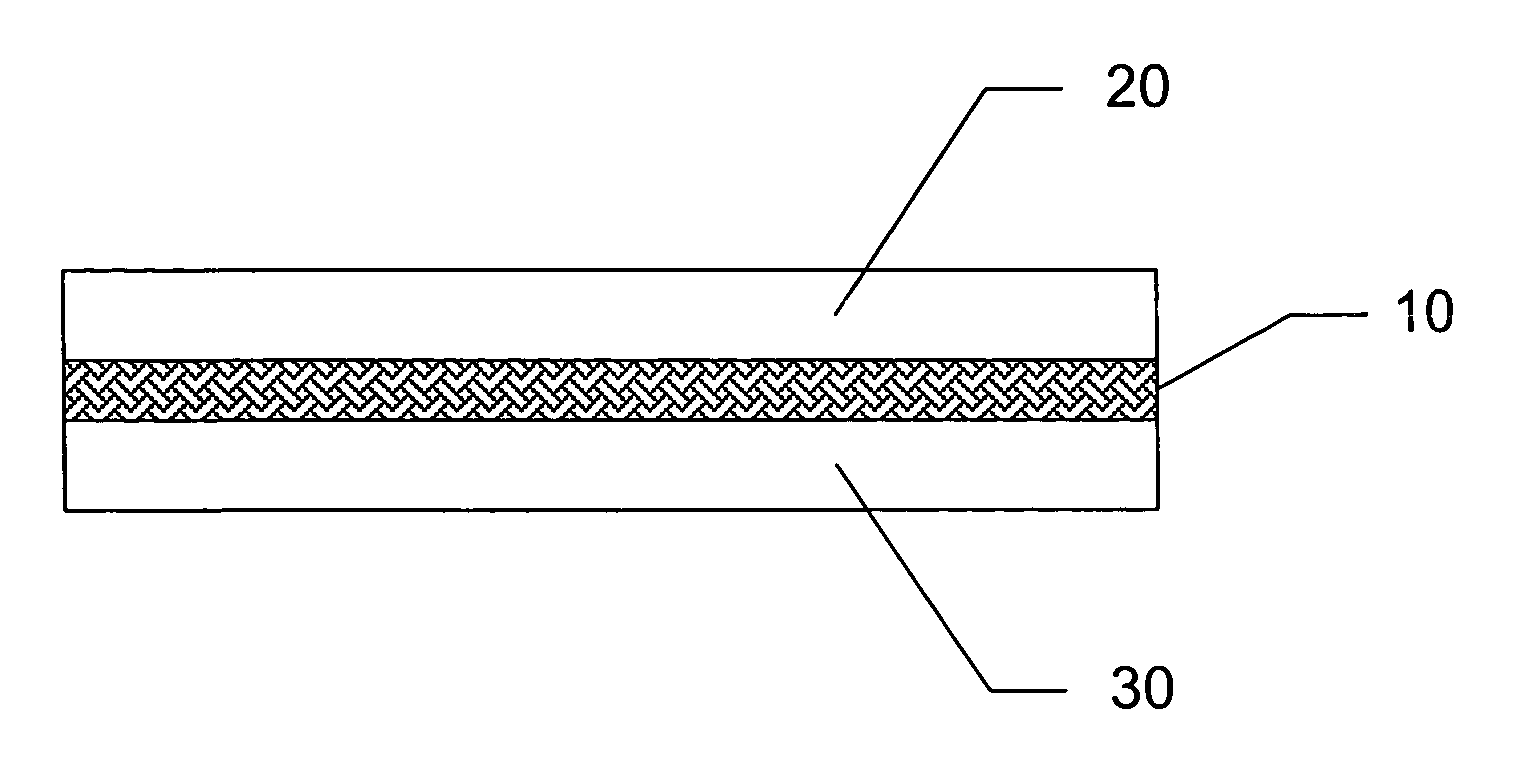

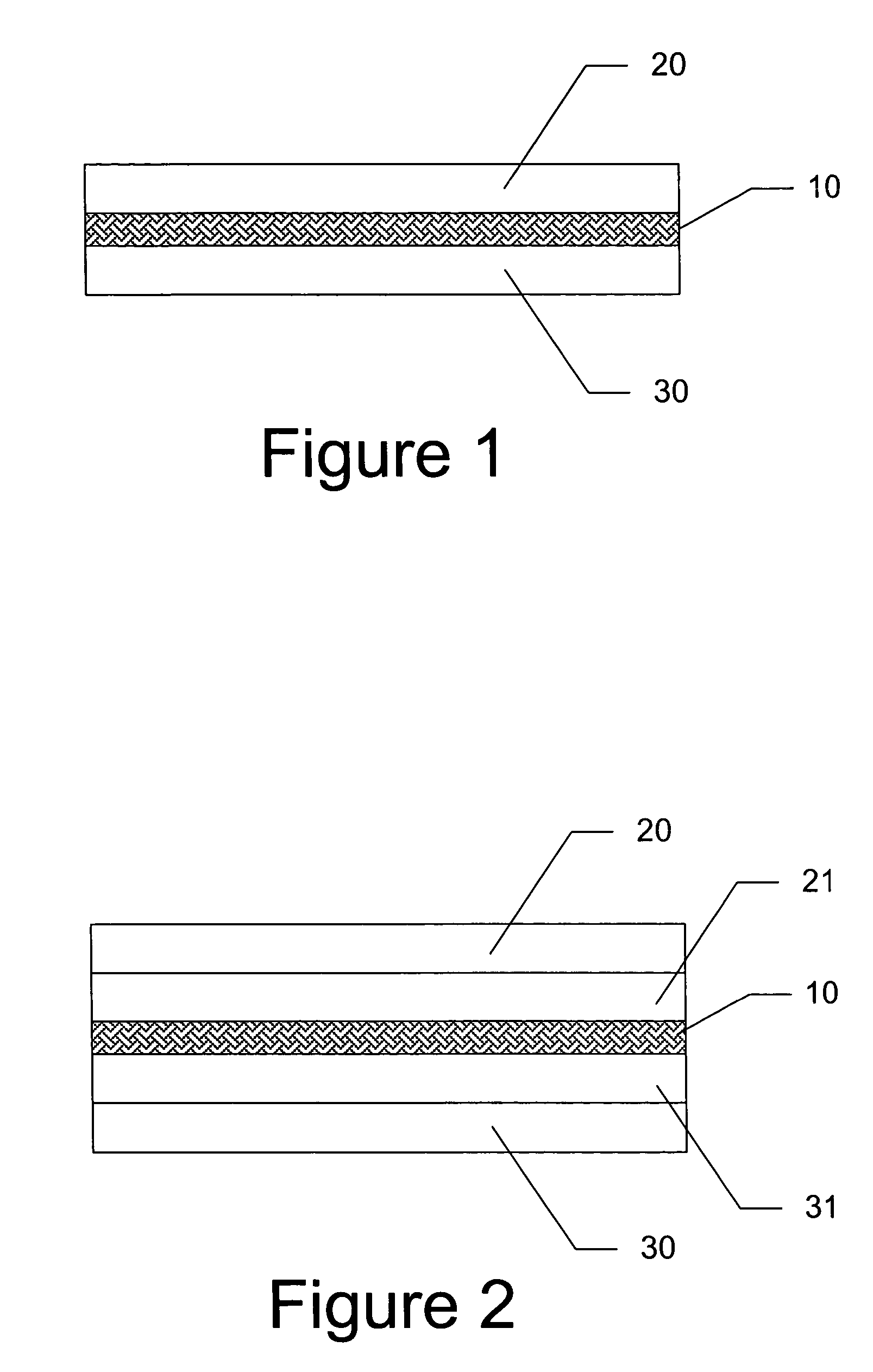

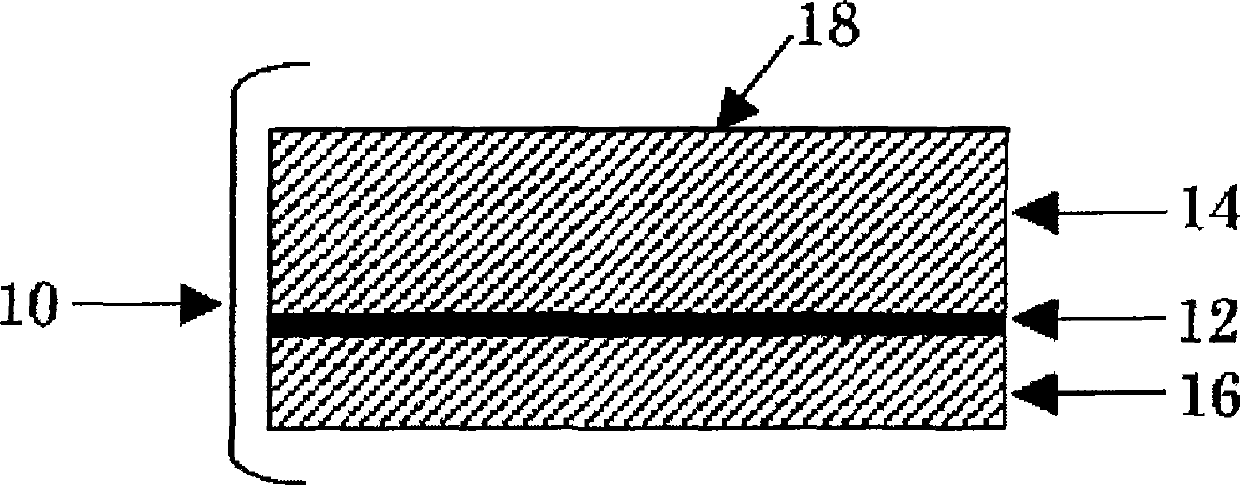

A multilayer golf ball formed of a core, a cover layer and an optional intermediate layer disposed between the core and cover, wherein at least one layer includes a composition including a diisocyanate, a polyol or amine-terminated compound, and a curing agent, wherein the curing agent includes a diol or secondary diamine.

Owner:ACUSHNET CO

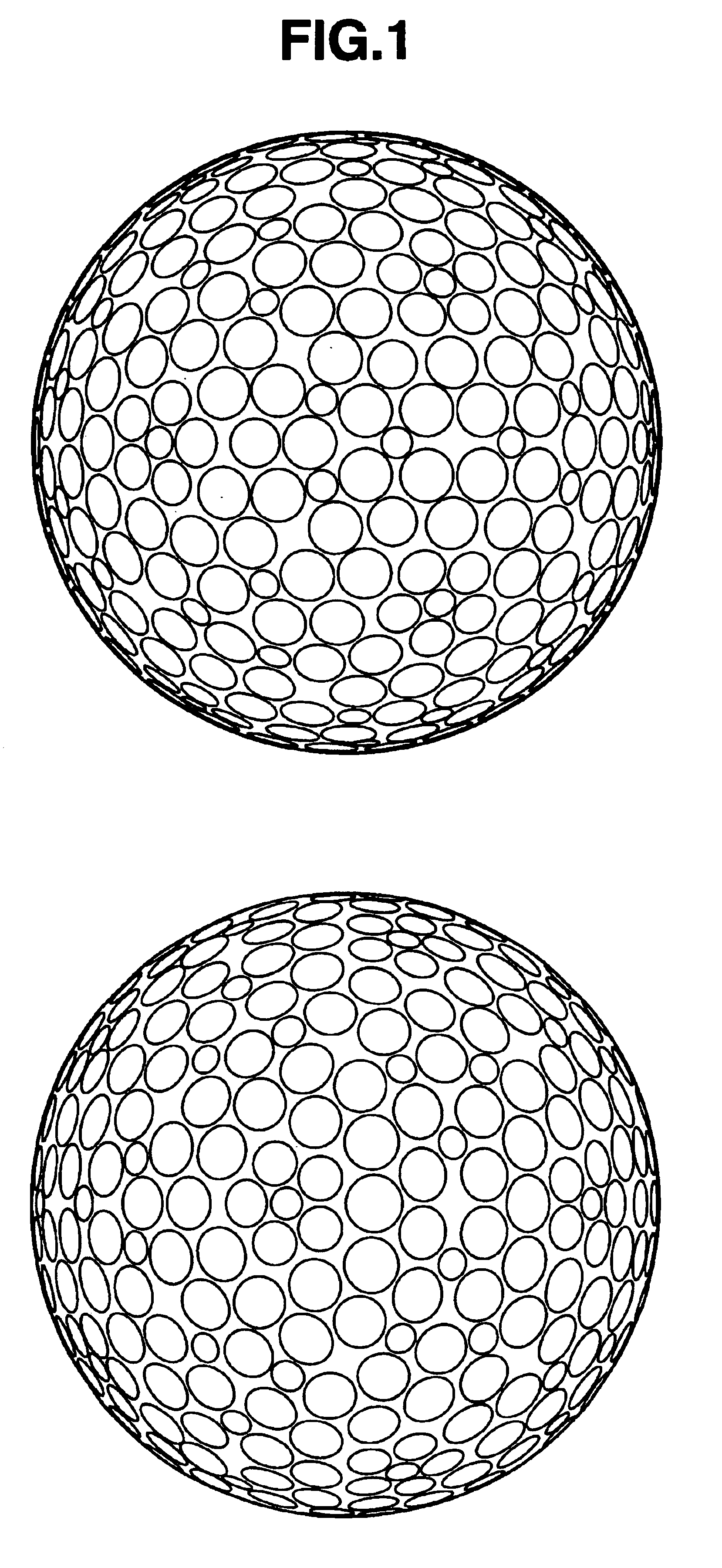

Two-piece solid golf ball

ActiveUS6921346B2Improve flight performanceSoft feelGolf ballsSolid ballsRare-earth elementSaturated carboxylic acid

Disclosed herein is a two-piece solid golf ball consisting of a solid core and a cover, the solid core being formed from a rubber composition composed of a rubber base material of polybutadiene synthesized by using a catalyst of rare earth element, a small amount of organic peroxide, an unsaturated carboxylic acid and / or a metal salt thereof, an organic sulfur compound, and an inorganic filler, and the cover being formed mainly from a mixture of an ionomer-containing resin composition and an inorganic filler. The two-piece solid golf ball is by far superior to conventional ones in flying performance, cover durability, scuff resistance, and shot feeling.

Owner:BRIDGESTONE SPORTS

Afterfinish process of stiff, moisture-absorption and quick-drying shirt collar lining

InactiveCN102505483AIncreasing concentration gradientImprove antistatic performanceFibre treatmentFiberResist

The invention discloses an afterfinish process of stiff, moisture-absorption and quick-drying shirt collar lining. A certain amount of modifier of polyethylene siloxane is selected to serve as quick-drying moisture absorber of finishing agent and is mixed with resin and Cat / M catalyst prepare a padding liquor, of which the PH value is 4.5; then fabric to be finished is put into the padding liquor; and when the padding rate reaches 80 percent, the only thing to do is to perform two steps (namely predrying and baking). The substance mainly having moisture-absorption and quick-drying effects in the padding finishing liquor is the modifier of the polyethylene siloxane, which is applicable to the moisture-absorption and quick-drying finishing of cotton, terylen and the blending intertexture thereof, and gives the fabric magnificent soft feel. The modifier of the polyethylene siloxane adopts a padding method and can be used independently, can also be used with first minification bodies, such as shrink-resist and crease-resist finishing agent, stiff resin and the like, reduces the swelling ratio of fiber hole canals, and obtains better moisture-absorption and quick-drying effects.

Owner:如皋市五山漂染有限责任公司

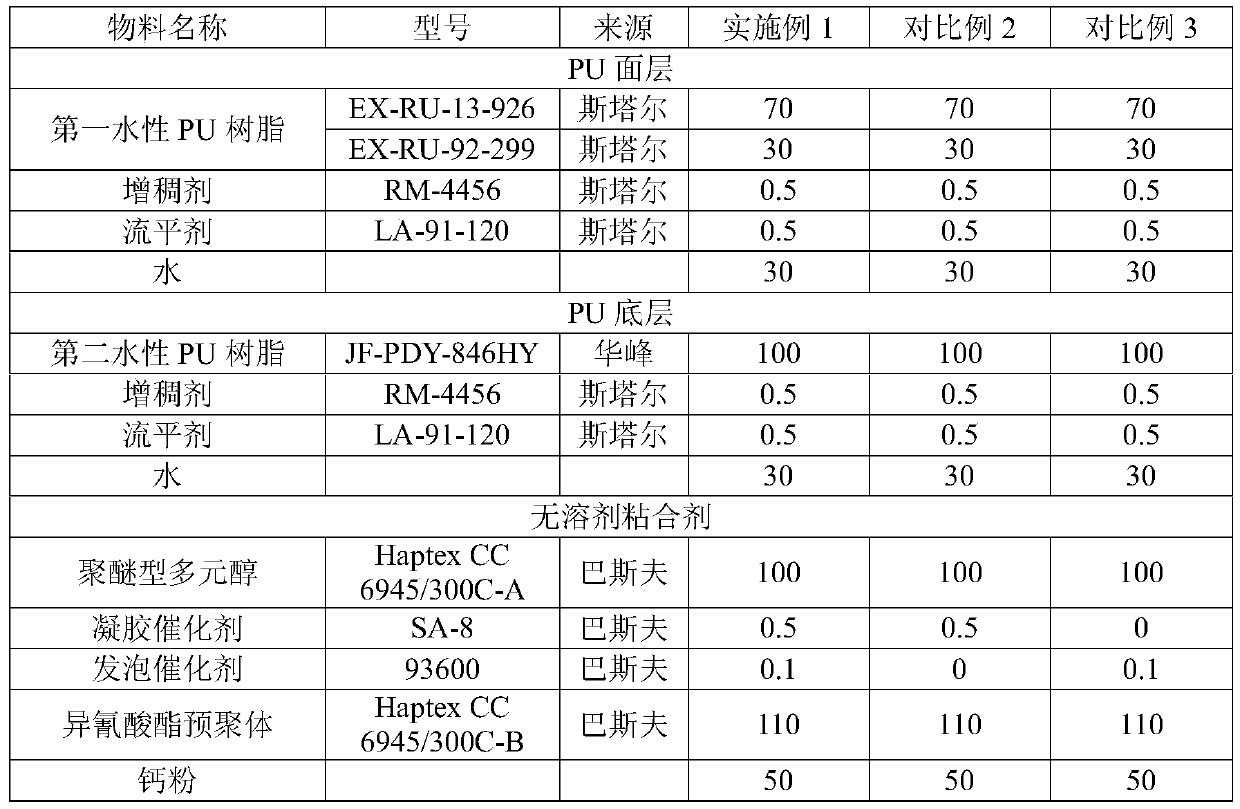

Preparation method of shoe lining leather

ActiveCN111169123AHigh peel strengthImprove folding resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceFolding endurance

The invention relates to a preparation method of shoe lining leather. The preparation method comprises the following steps: (1) uniformly mixing and stirring PU resin, a thickener, a leveling agent and water to prepare mixed slurry; (2) coating the surface of release paper with the mixed slurry, carrying out drying to obtain a PU surface layer, coating the surface layer with the mixed slurry, carrying out drying, and forming a PU bottom layer on the PU surface layer to obtain a PU dry film; (3) impregnating base cloth with water-based wet resin, and carrying out drying to obtain a base; and (4) coating the PU bottom layer of the PU dry film with a solvent-free adhesive, carrying out pre-drying, laminating the PU dry film with the base, and conducting drying and curing to obtain the shoe lining leather. According to the invention, the PU dry film and the base are compounded by adopting the specific solvent-free adhesive, a formula of the solvent-free adhesive is optimized, and proper raw materials are selected to prepare the PU bottom layer and the PU surface layer, so the peel strength of the shoe lining leather is greatly improved, and the folding resistance and the wear resistance of the shoe lining leather are improved; and the DMF content of the shoe lining leather meets requirements prescribed by the ZDHC organization according to detection results.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

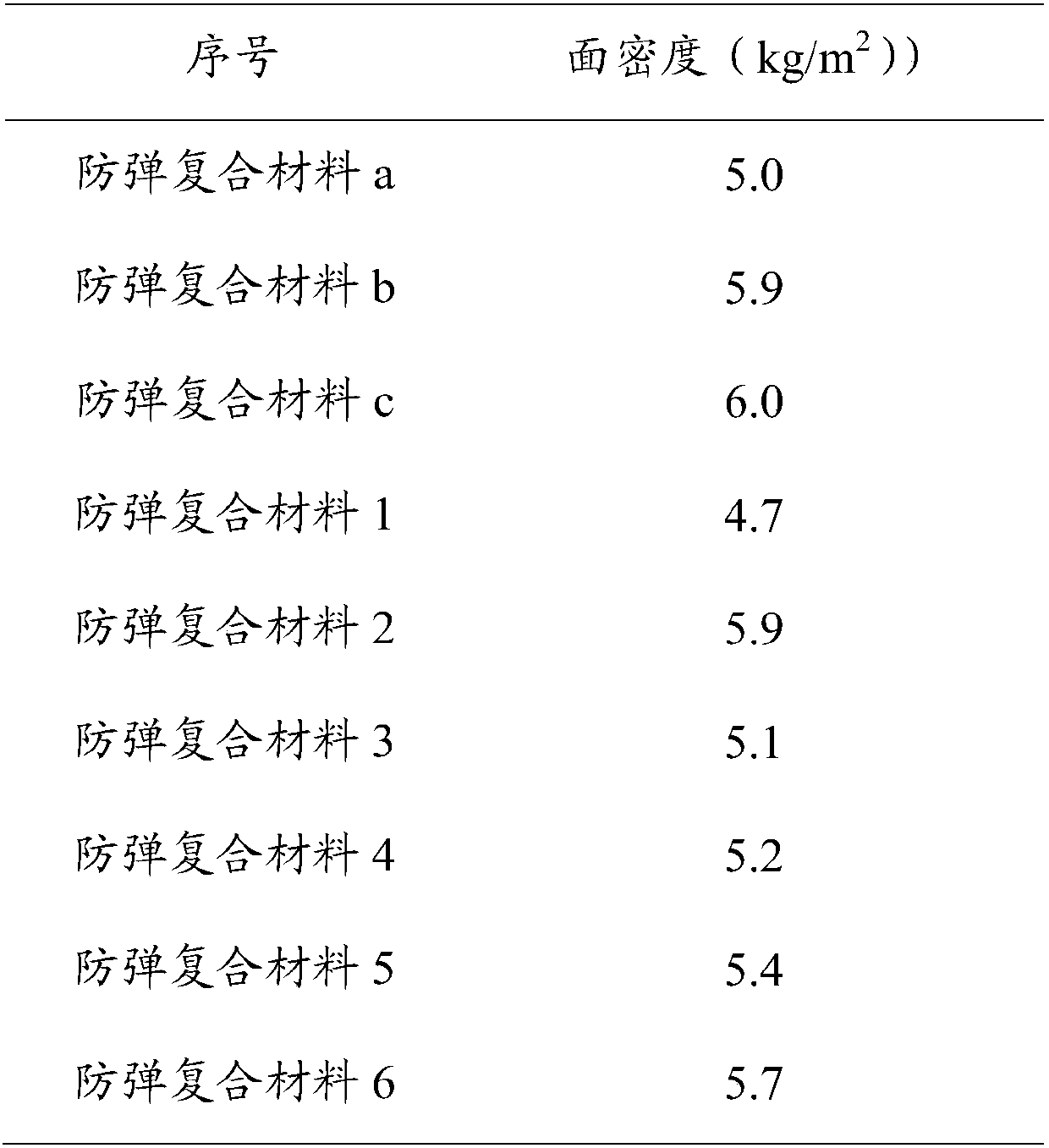

Bulletproof composite material and preparation method and application thereof

ActiveCN108673984AHigh tensile strengthHigh tensile modulusProtective equipmentFibre typesPolyolefinThermoplastic polyurethane

The invention discloses a bulletproof composite material, the bulletproof composite material is a resin-based composite material comprising polyimide fiber as a reinforcing body, wherein the mass ratio of the polyimide fiber is 60% to 90% by mass percentage, and the mass ratio of a resin matrix is 10% to 40%. The polyimide fiber is modified fiber which is subjected to interfacial treatment using an inert modifier, and the inert modifier is obtained by mixing aqueous thermoplastic polyurethane and aqueous polyolefin resin in a certain ratio. The invention also discloses a preparation method andapplication of the bulletproof composite material. The polyimide fiber is used as the reinforcing body, and the reinforcing body is subjected to the special interfacial treatment, infiltrated into the matrix resin according to a certain arrangement manner, and compounded with the resin matrix by a specific composite process, the prepared bulletproof composite material has the characteristics of good tensile strength and tensile modulus, good resistance to high and low temperature, light weight, and good flame retardancy and spinnability, and is suitable for preparation of soft and highly-comfortable-to-wear bulletproof clothing and bulletproof armor materials.

Owner:BEIJING PROTECH NEW MATERIAL SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com