Synthetic leather-like Composite with smoke and flame resistant properties

a synthetic leather and composite technology, applied in the direction of synthetic resin layered products, transportation and packaging, upholstery, etc., can solve the problems of product appearance and ease of care that are not leather-like,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

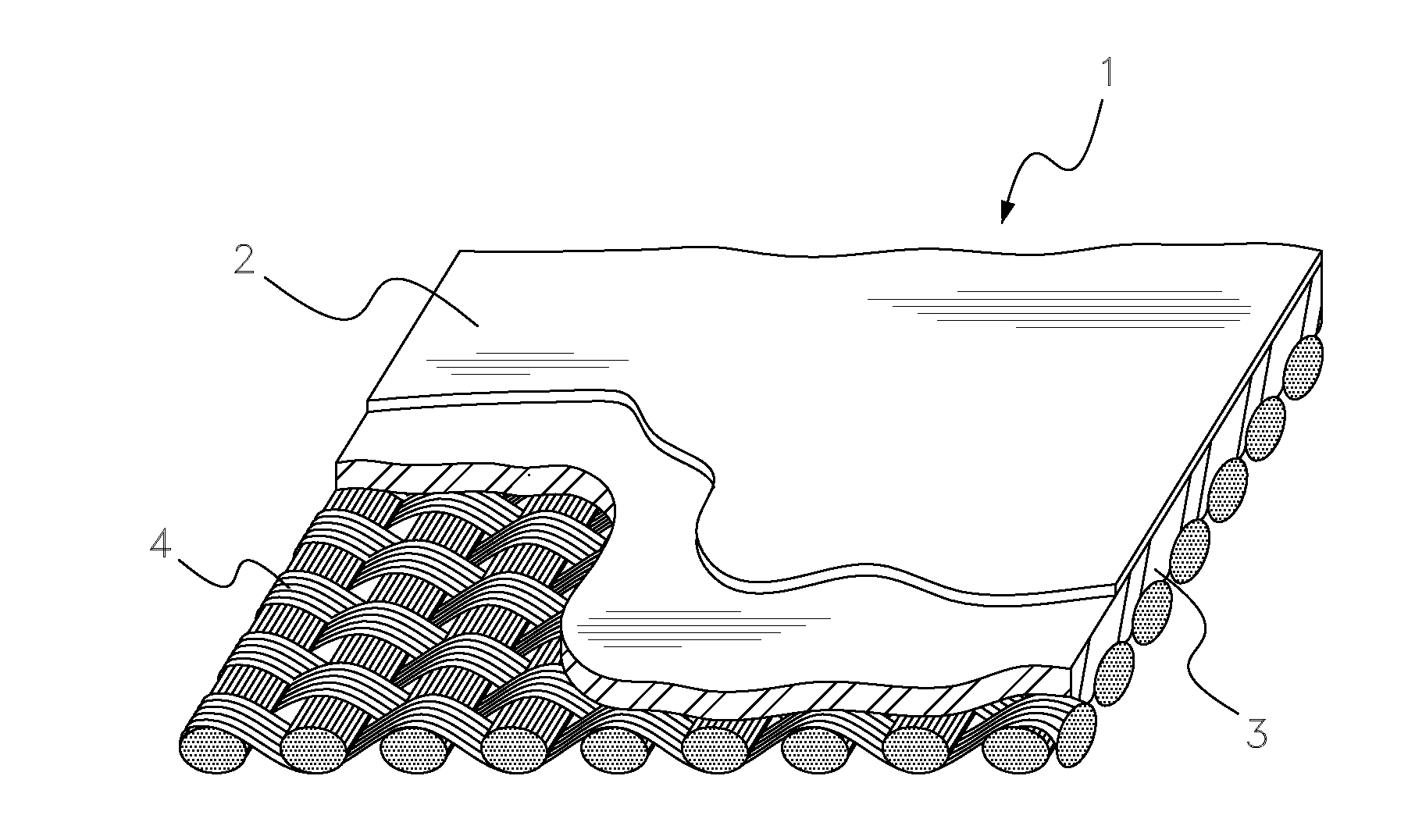

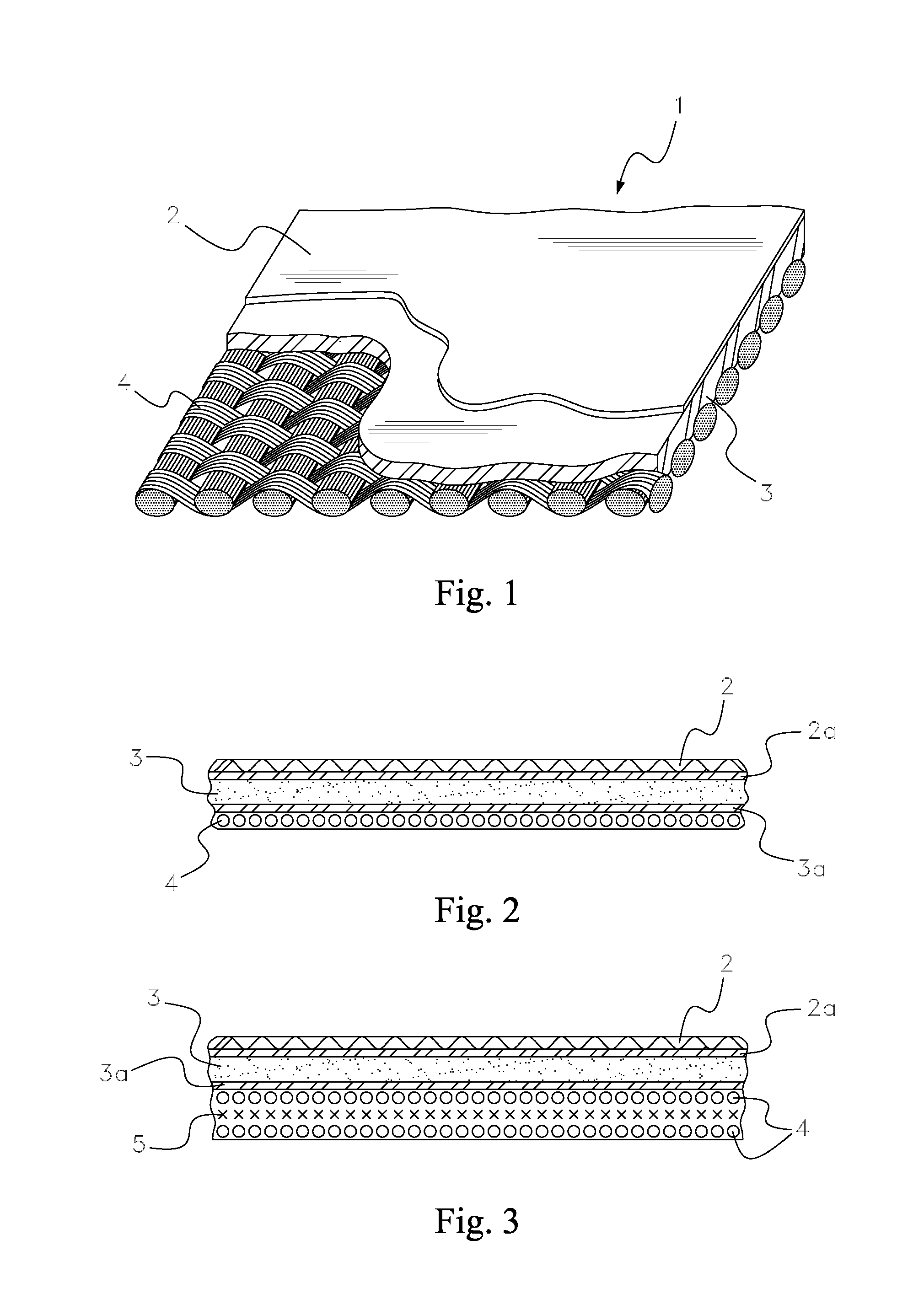

[0011]The composite product is transfer or direct coated to a release paper to achieve the synthetic leather look and surface characteristics. The product is produced in multiple layers with a top surface having the leather-like appearance, and adhesive intermediate layers (from 2 to 8 layers) which consist of polysiloxary chemistry. These layers are transferred / direct coated to a textile. In the case of a transfer coated product, they are chemically coated. There is no lamination in the direct coating method of making the product. The top surface layer is from about 2 to 10 mils in thickness, while the core itself is from about 6 to about 30 mils in thickness. The barrier layer is typically about 200 mils in thickness, although layers of greater or lesser thicknesses may also be used effectively. Polysiloxane adhesives of varying viscosities, such as between about 6-10,000 cps are useful, although more typically from 40-80,000 cps. Viscosities of from about 120-200,000 cps can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com