Patents

Literature

41 results about "Glycol dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycol dehydration is a liquid desiccant system for the removal of water from natural gas and natural gas liquids (NGL). It is the most common and economical means of water removal from these streams. Glycols typically seen in industry include triethylene glycol (TEG), diethylene glycol (DEG), ethylene glycol (MEG), and tetraethylene glycol (TREG). TEG is the most commonly used glycol in industry.

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Method for inhibiting corrosion of butyl rubber chloromethane glycol dehydration system

The invention discloses a method for inhibiting corrosion of a butyl rubber chloromethane glycol dehydration system. The method is characterized by comprising the following steps of: adding alkylol amine into a chloromethane glycol dehydration and regeneration system; and removing chloride ions and iron ions produced in the system by using an anion exchange resin, wherein both steps cannot be saved. By using the technical scheme, a small amount of the alkylol amine is added, so the corrosion speed of carbon steel can be controlled, so that a small amount of the chloromethane is consumed and the loss of chloromethane solvent is reduced; meanwhile, the concentration of the chloride ions in the system is low and the corrosion to the carbon steel is also low; and the chloride ions and the iron ions can be removed by adopting the anion exchange resin, so the concentrations of the chloride ions and the iron ions are further reduced. Because the amount of hydrochloric acid produced by hydrolyzing the chloromethane is reduced, and the hydroxyl ions produced after the anion exchange resin exchanges the chloride ions neutralize the hydrogen ions of the system, the corrosion of the glycol dehydration and regeneration system can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP

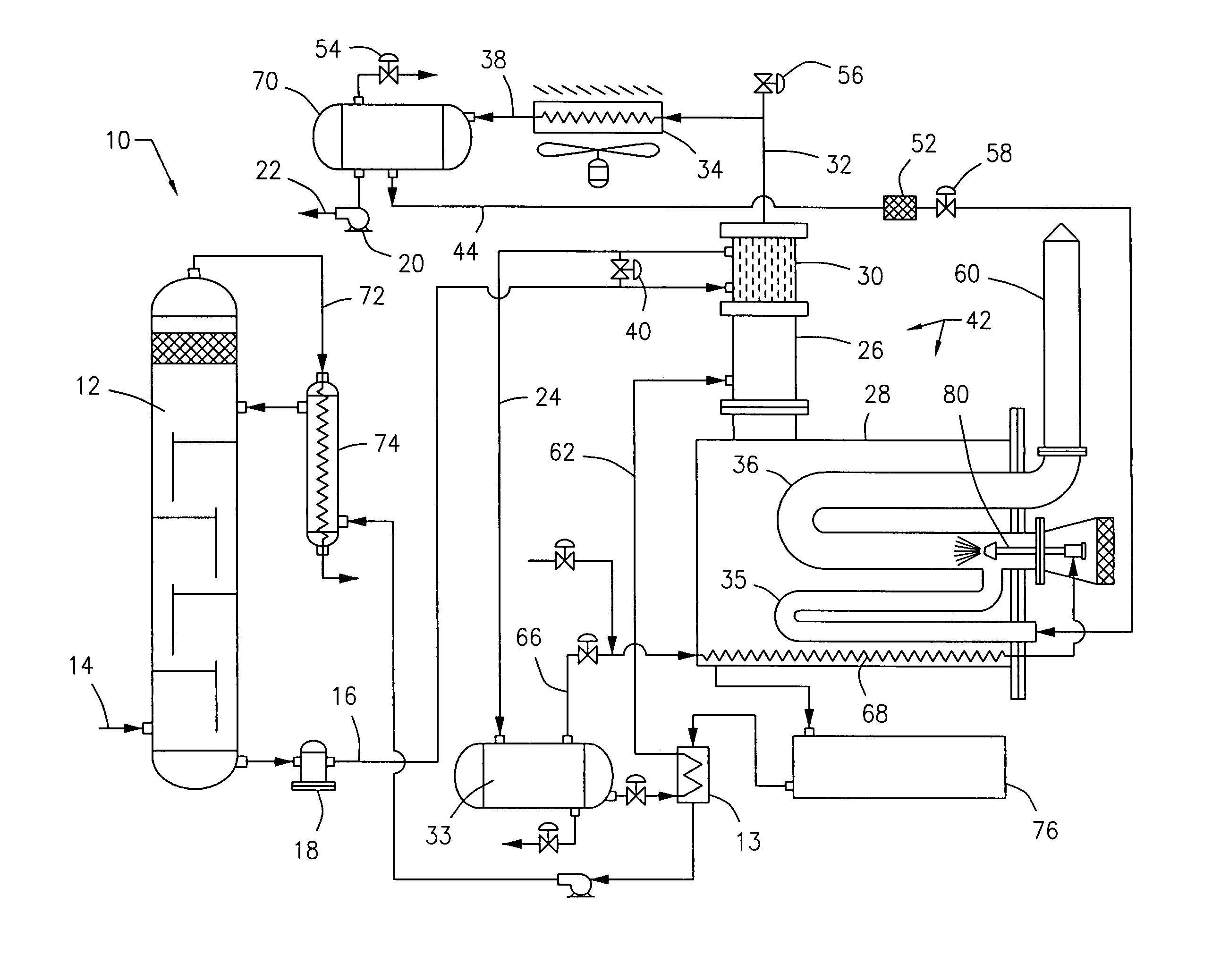

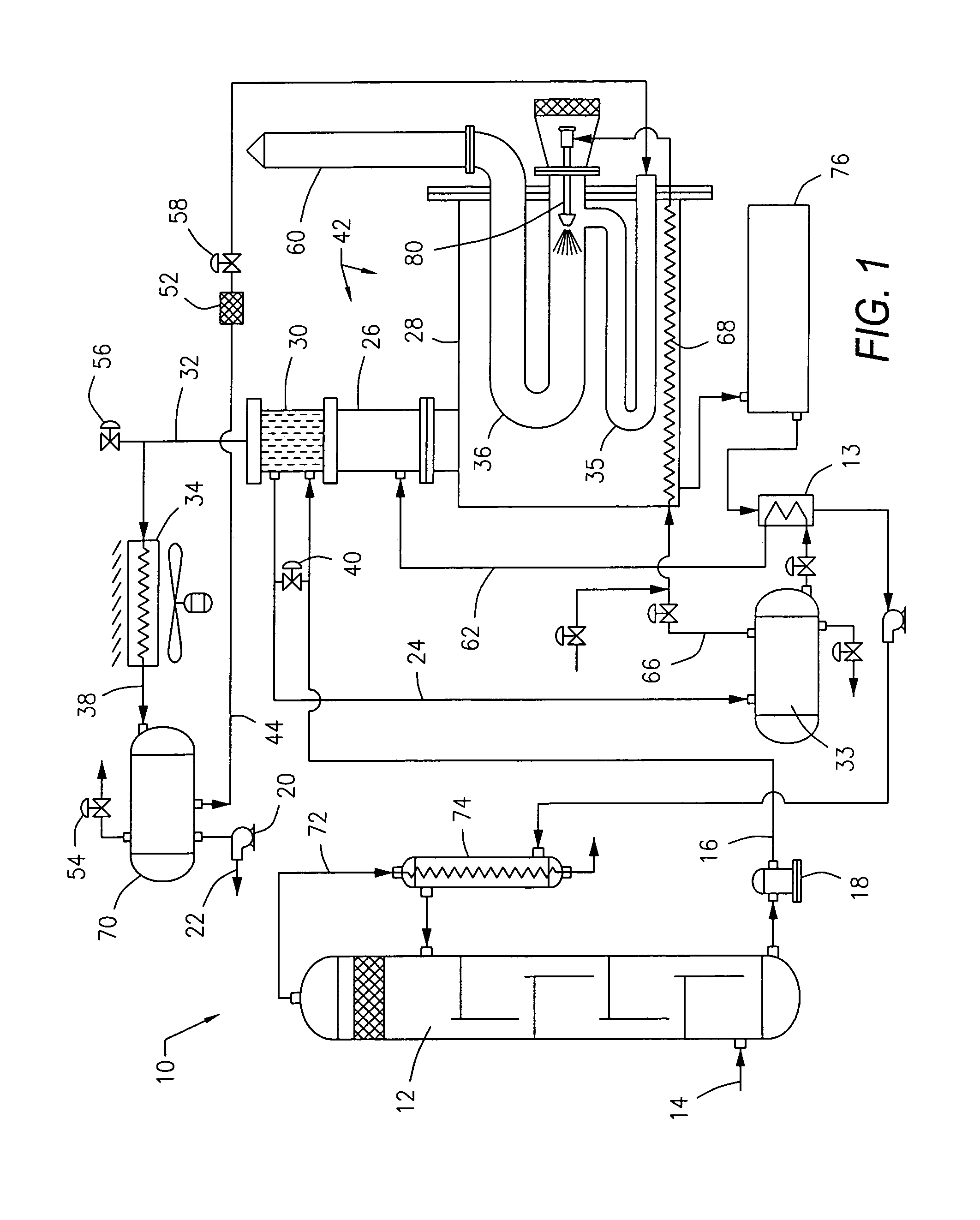

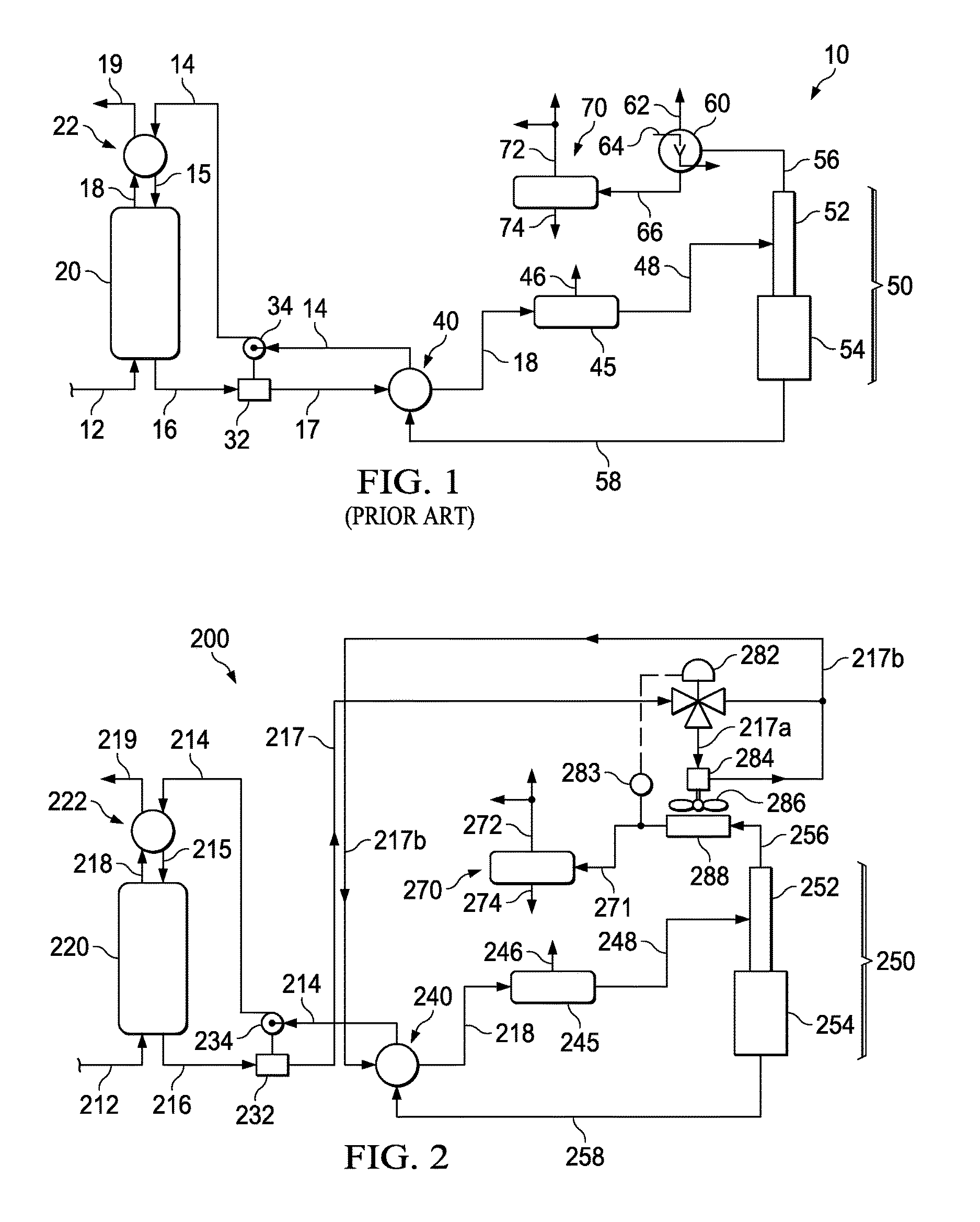

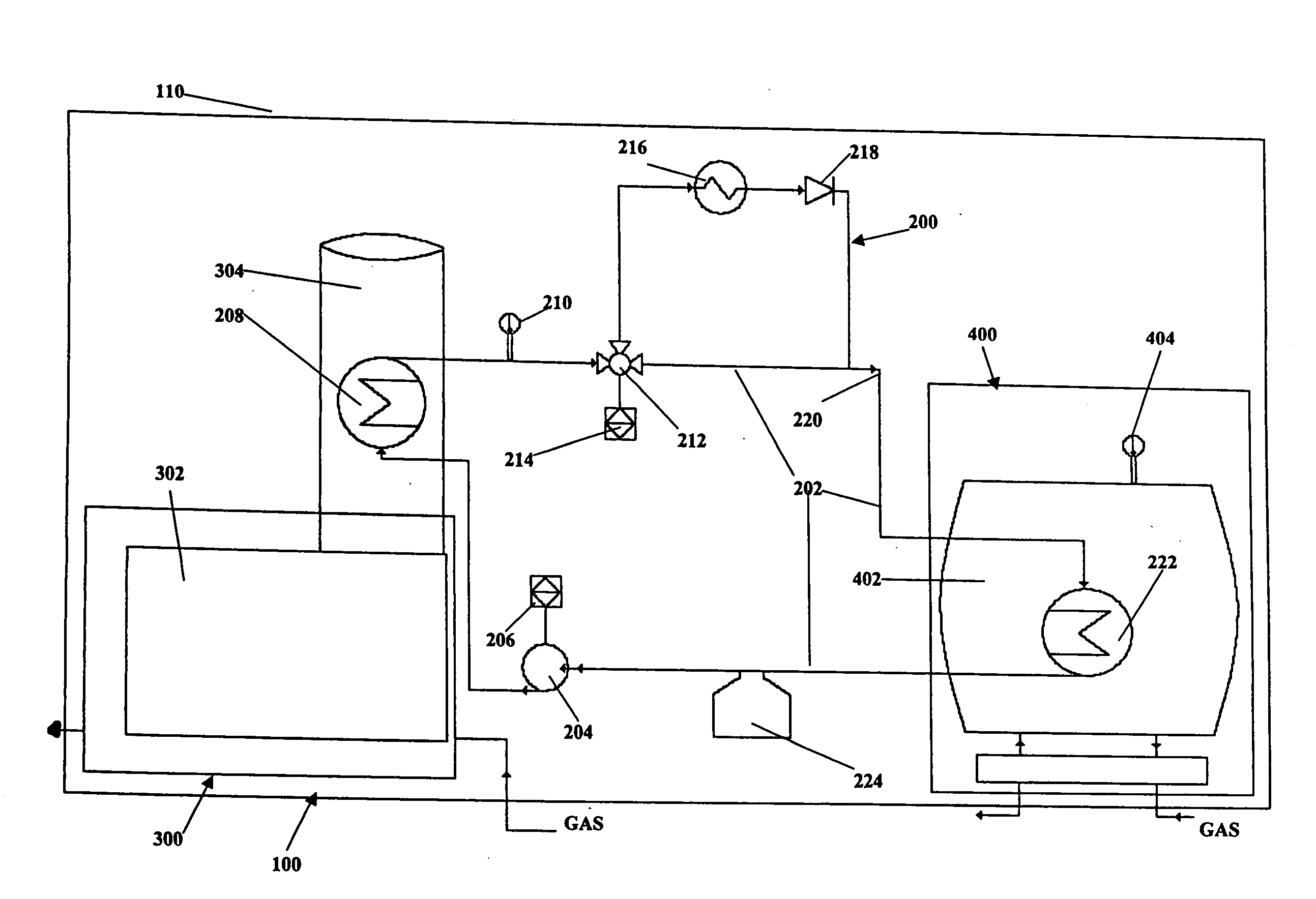

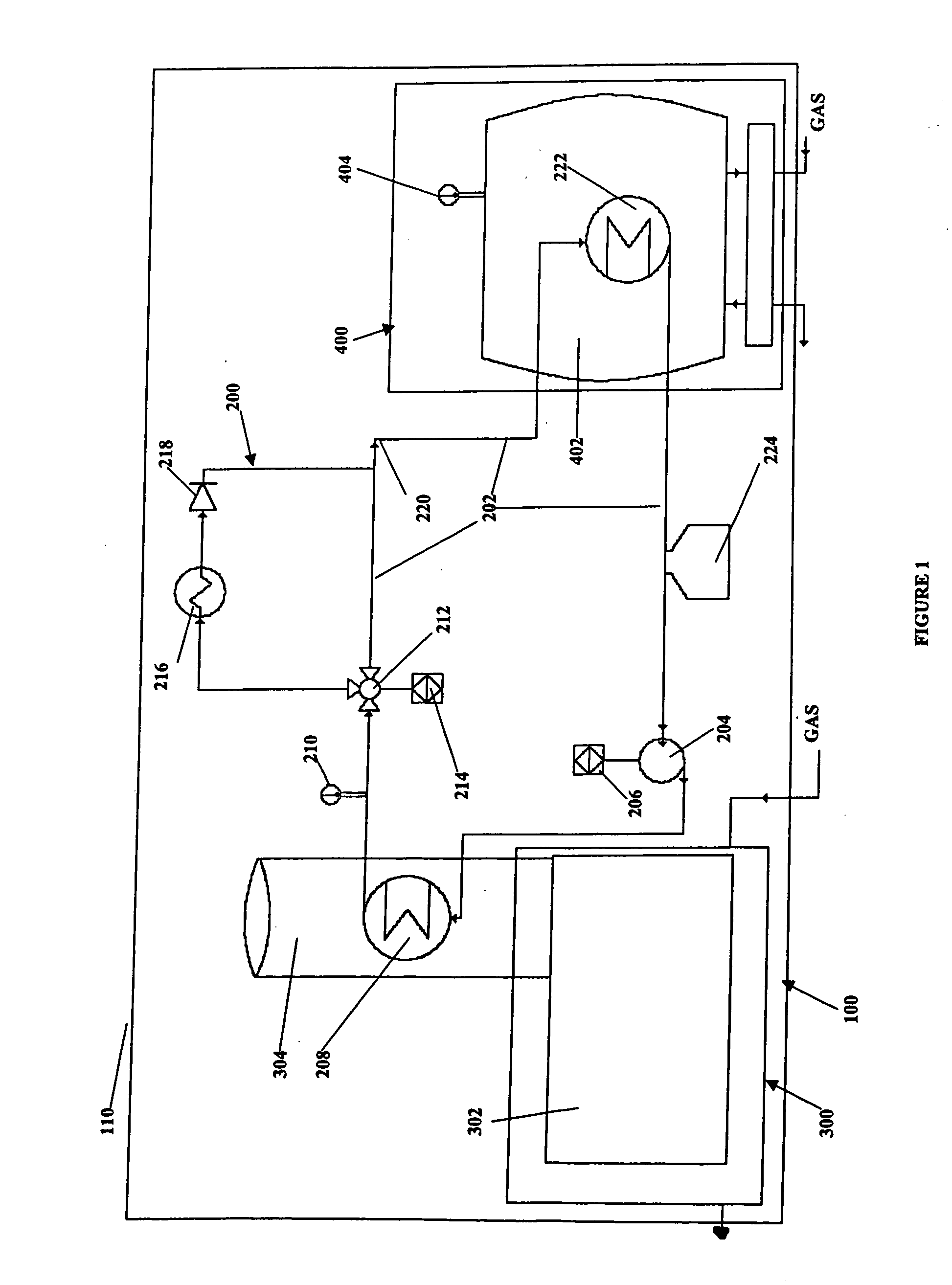

Low emission natural gas processing dehydration system

ActiveUS7935228B1Reduction of fuel gas requiredResist formationSolidificationLiquefactionReboilerFractionating column

A process to reduce emissions discharged from a natural gas processing system wherein the processing system includes a glycol dehydrator for absorbing water, moisture and absorbable hydrocarbons, a reboiler for heating water rich glycol, a still column in communication with the reboiler and a reflux condenser. The process includes the steps of directing vapors and gases from the still column and reflux condenser to a condenser in order to condense vapors to liquid. The gases and liquids from the condenser are directed to a condensate separator in order to separate by gravity. Non-condensible vapors and water from the condensate separator are delivered to a vaporization chamber immersed in the reboiler. Water is re-vaporized into steam and permitted to mix with non-condensible vapors in the vaporization chamber. The steam and non-condensible vapors are inducted into a combustion zone in a firetube in the reboiler. The hydrocarbons in the vapors are combusted in the firetube.

Owner:PROCESS EQUIP & SERVICE

Method for preparing acetaldehyde by ethylene glycol through dehydration

InactiveCN108047010ANo pollution in the processHigh activityOrganic compound preparationCatalyst activation/preparationChemical industryFixed bed

The invention discloses a method for preparing acetaldehyde by ethylene glycol through dehydration, and belongs to the technical field of chemical industries. The method includes the steps: taking active carbon as a carrier, taking phosphoric acid, sulfuric acid or sulfate and sulfate as active components, soaking the active carbon by the aid of the active component, and drying and roasting the soaked active carbon to obtain a supported catalyst; performing activating treatment on the supported catalyst to obtain an activated supported catalyst; performing dehydration reaction on ethylene glycol by aid of a fixed bed reactor filled with the supported catalyst under a certain condition to obtain the acetaldehyde. According to the method, the catalyst is simple and convenient to prepare, high in activity and good in stability and can still keep good activity after repeatedly being used, the conversion rate of the ethylene glycol ranges from 70% to 99%, and the selectivity of the acetaldehyde ranges from 50% to 98%.

Owner:YANGZHOU UNIV

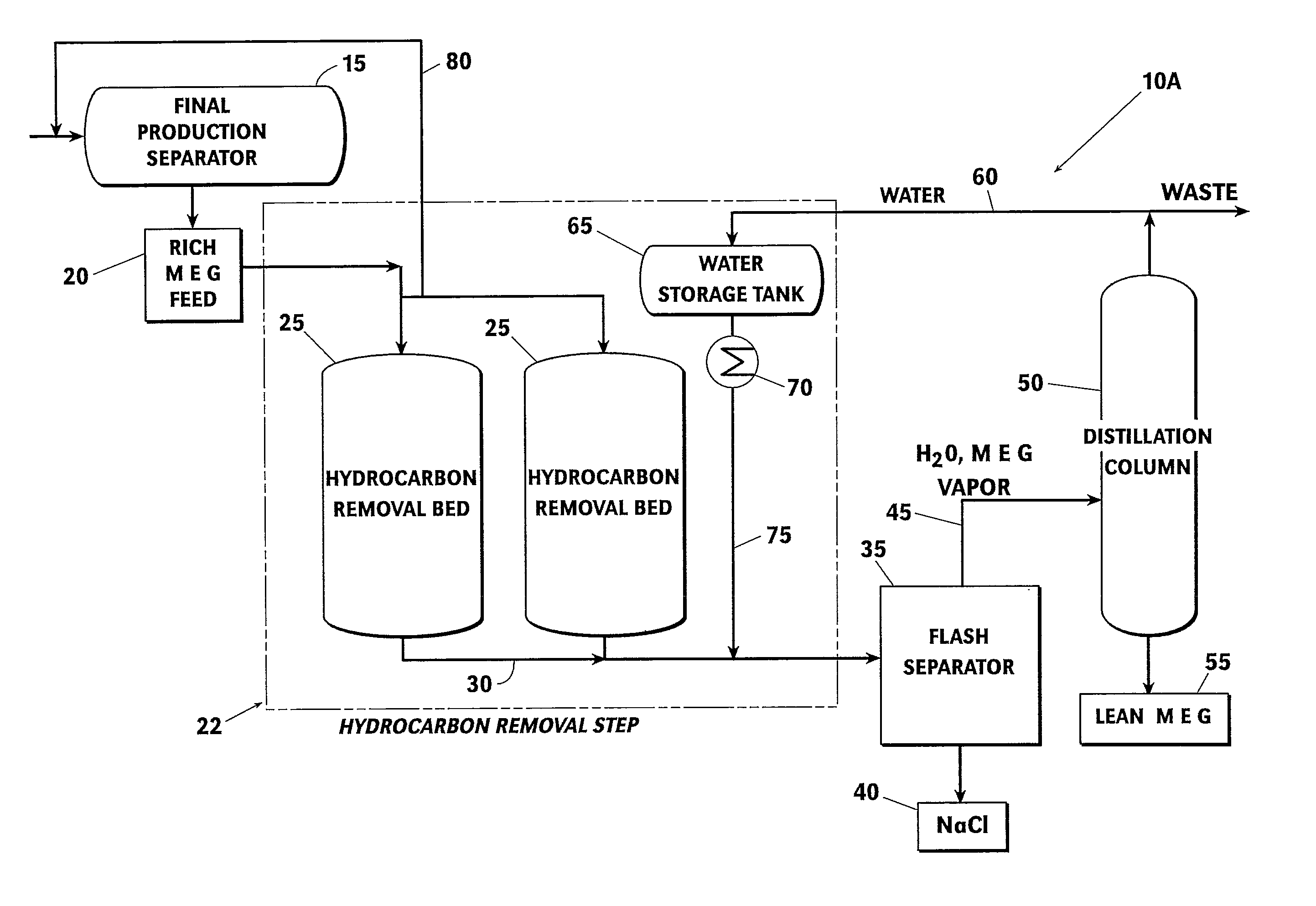

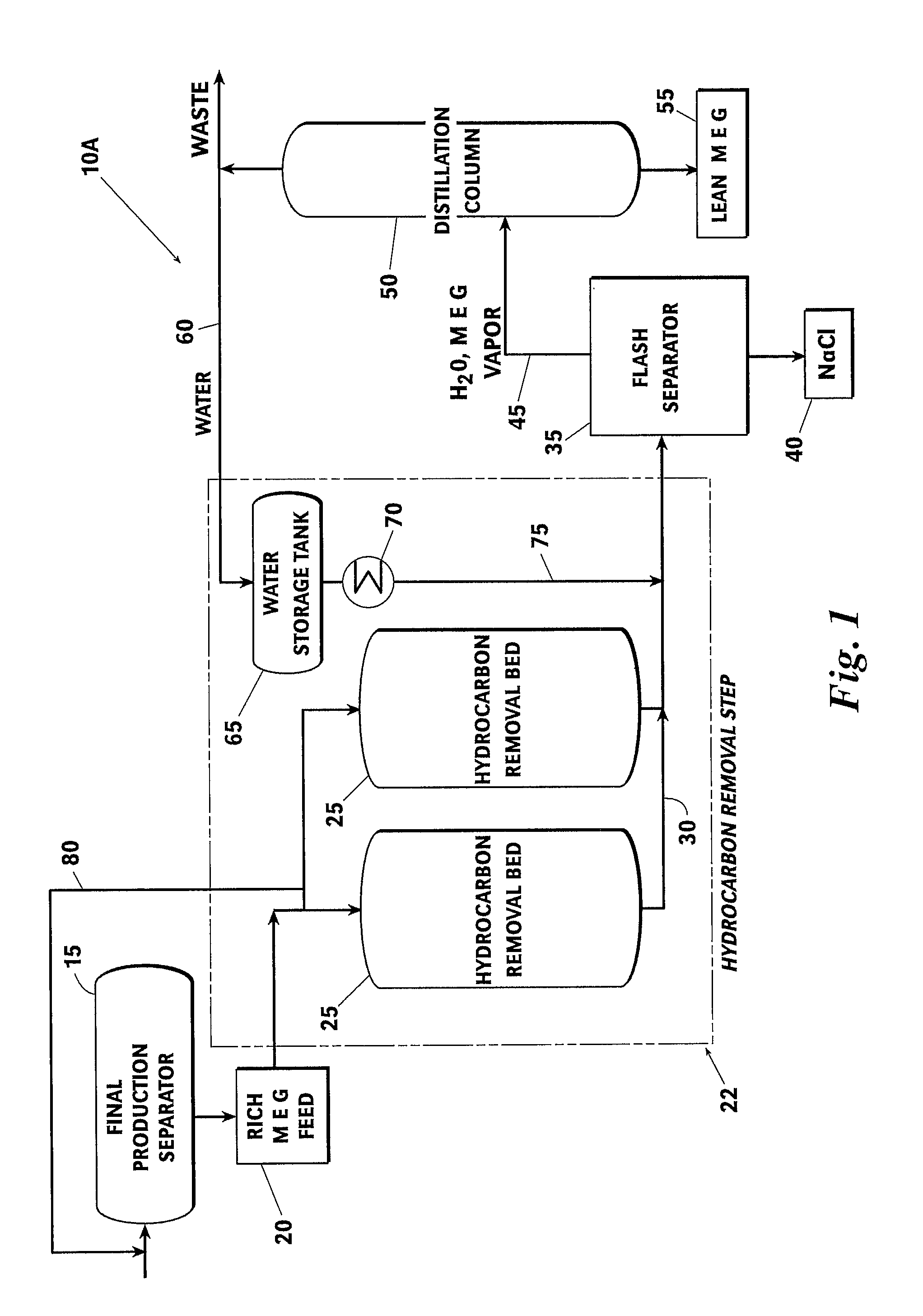

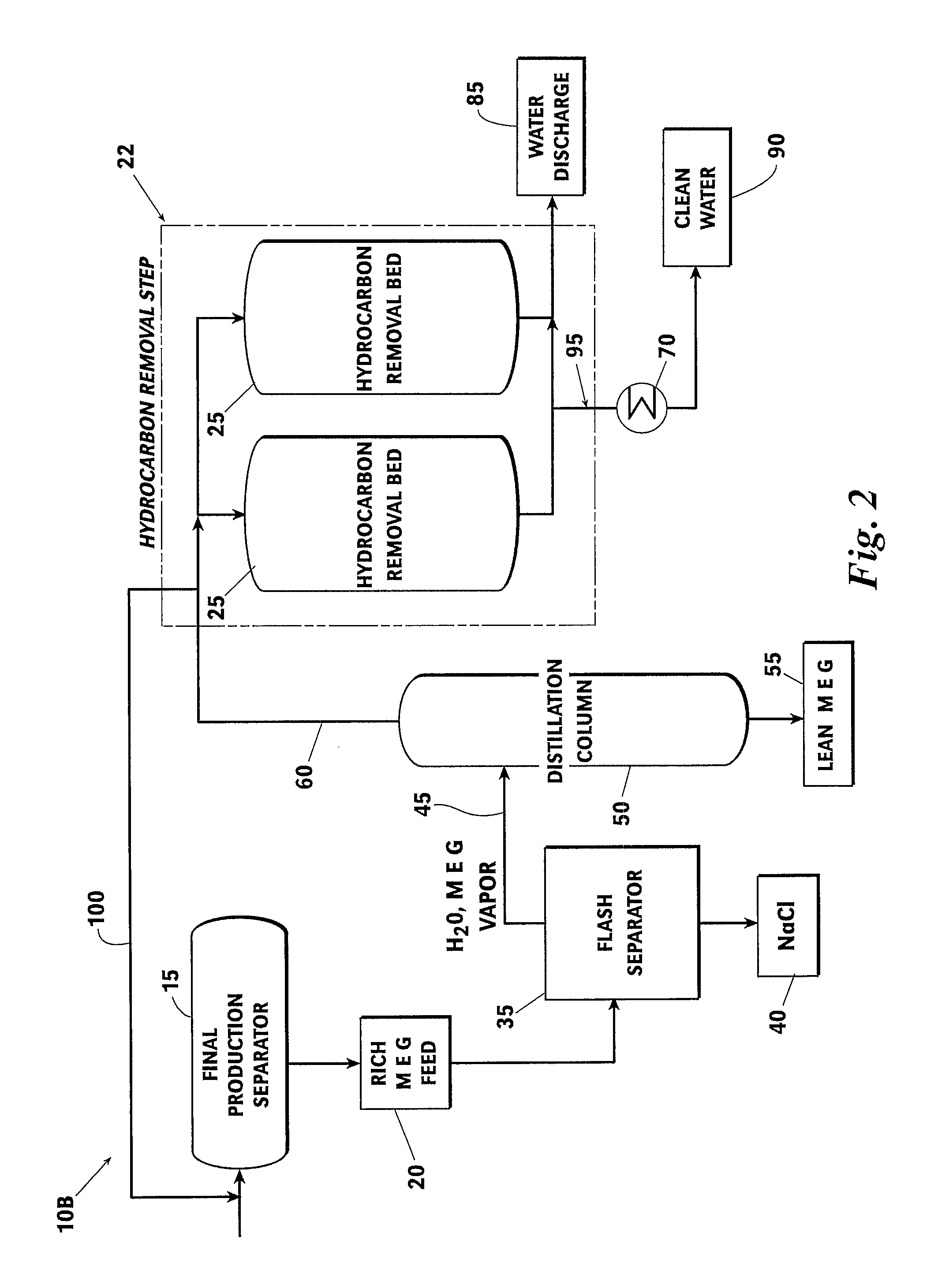

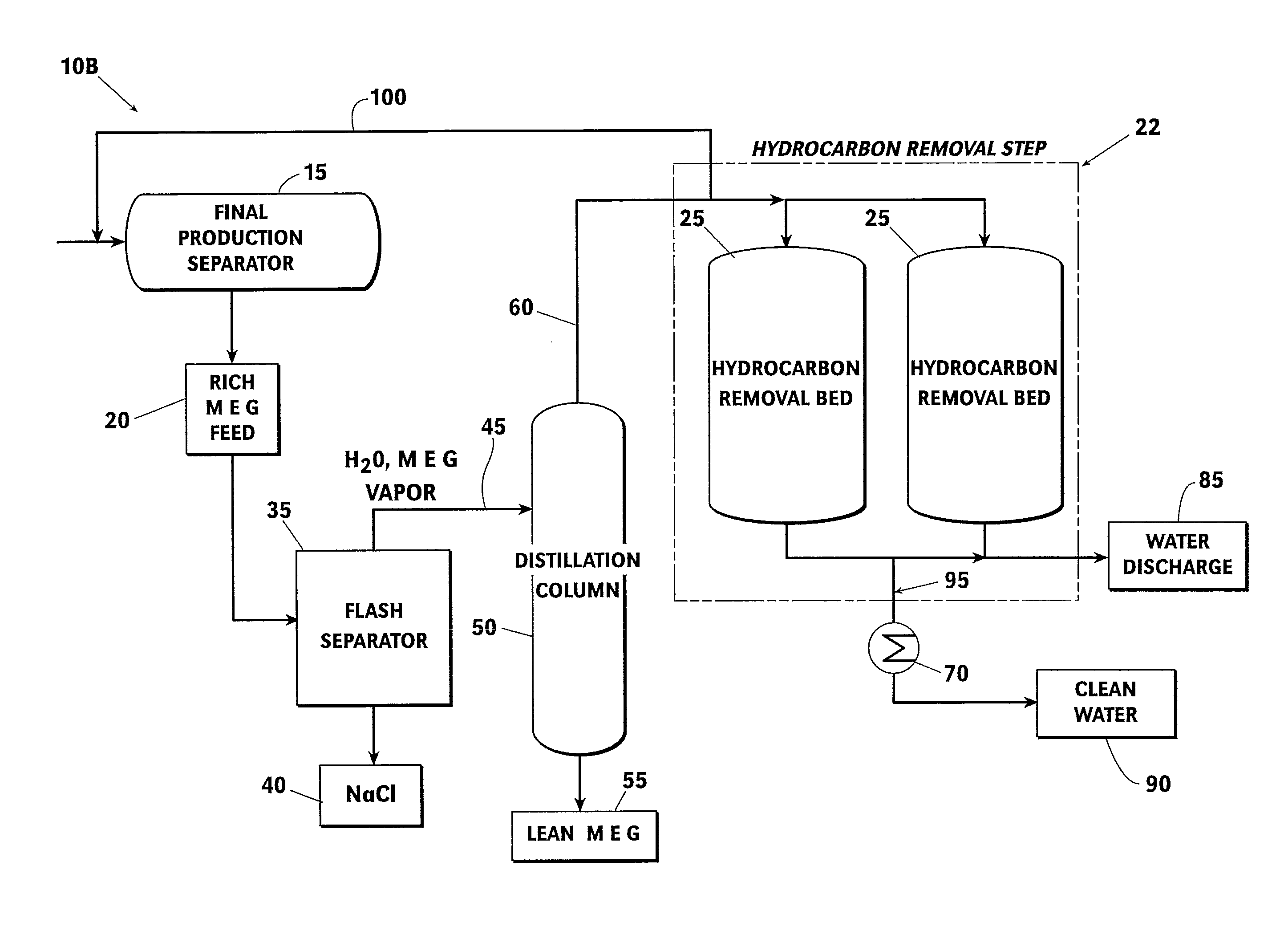

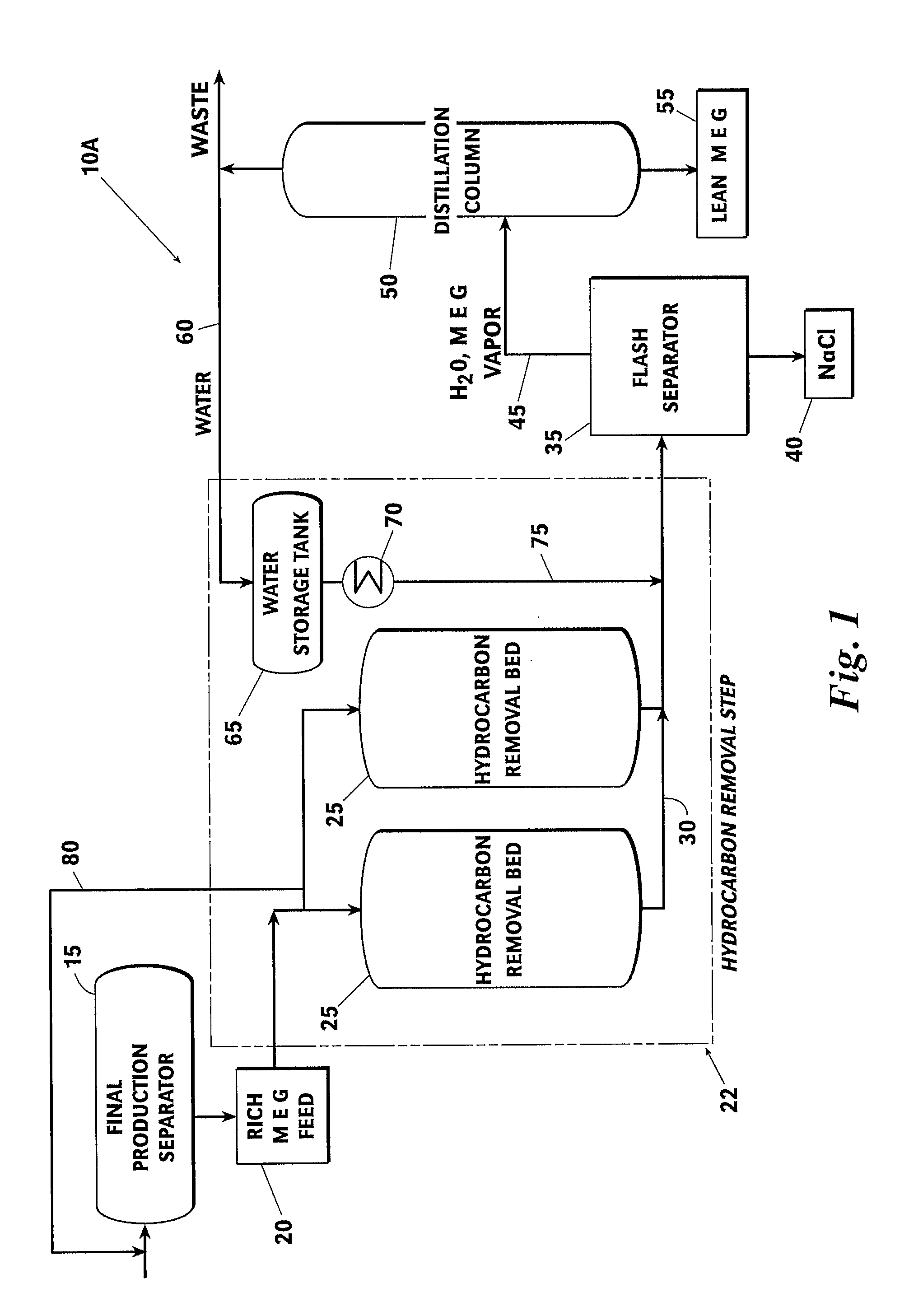

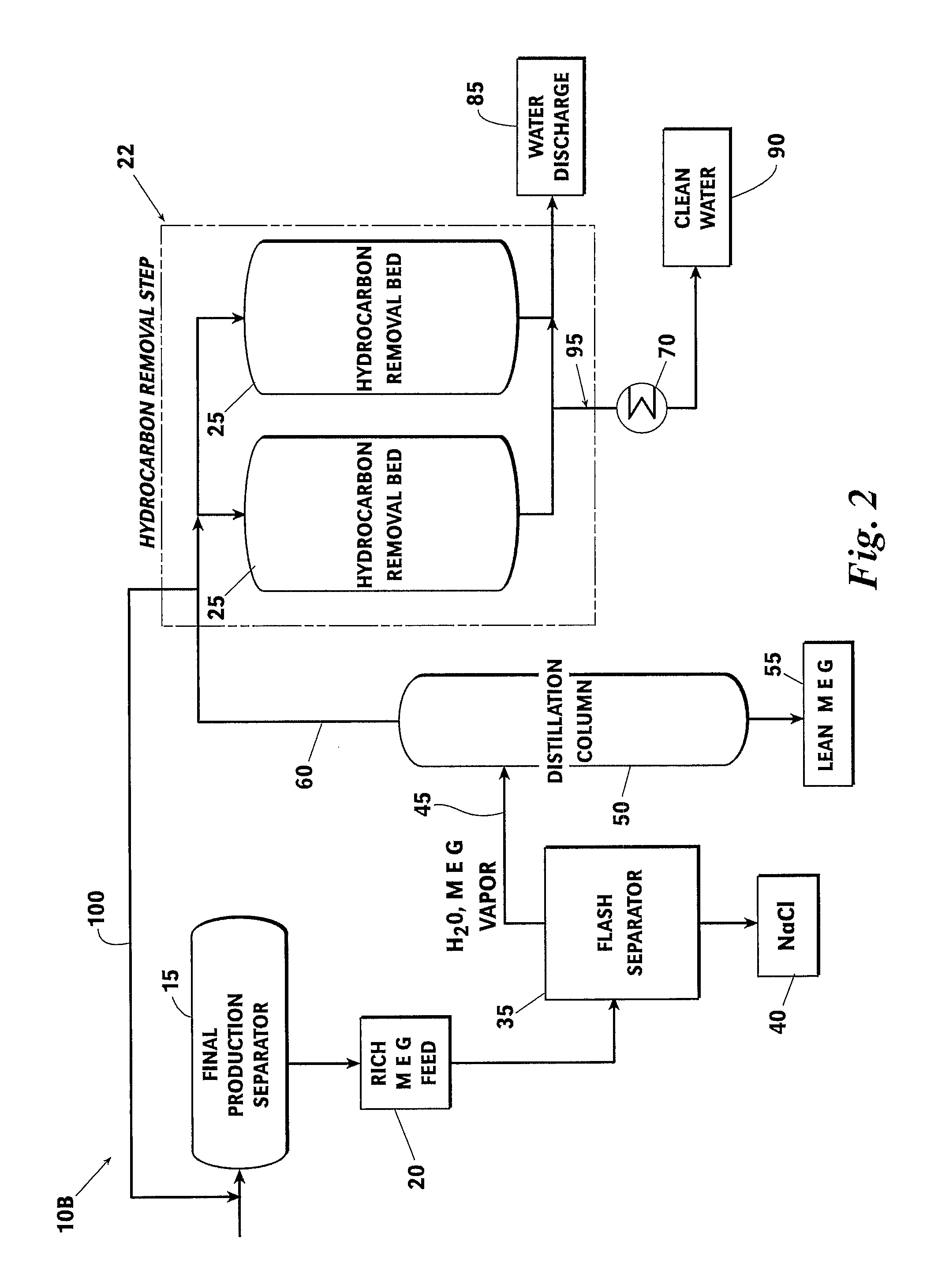

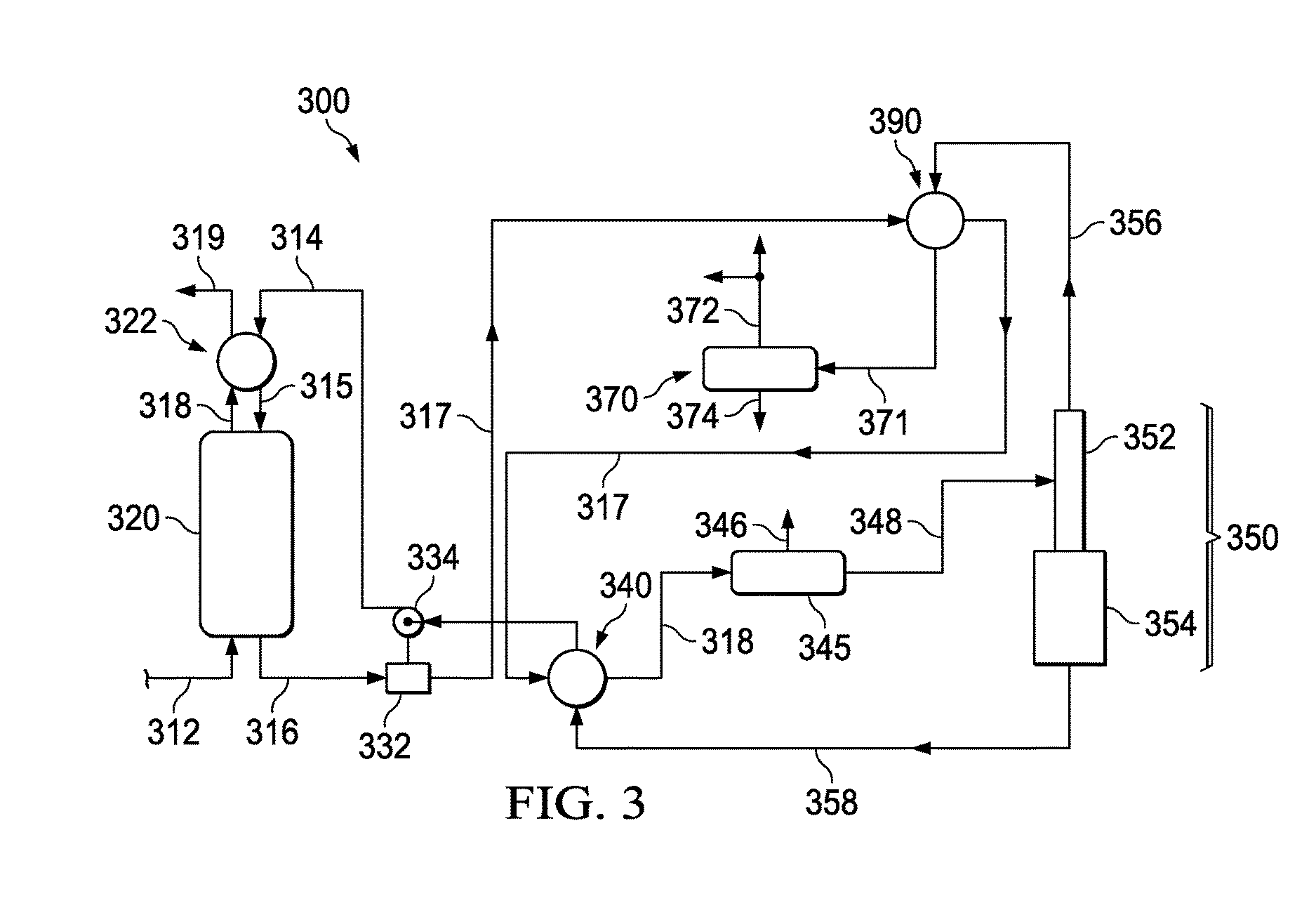

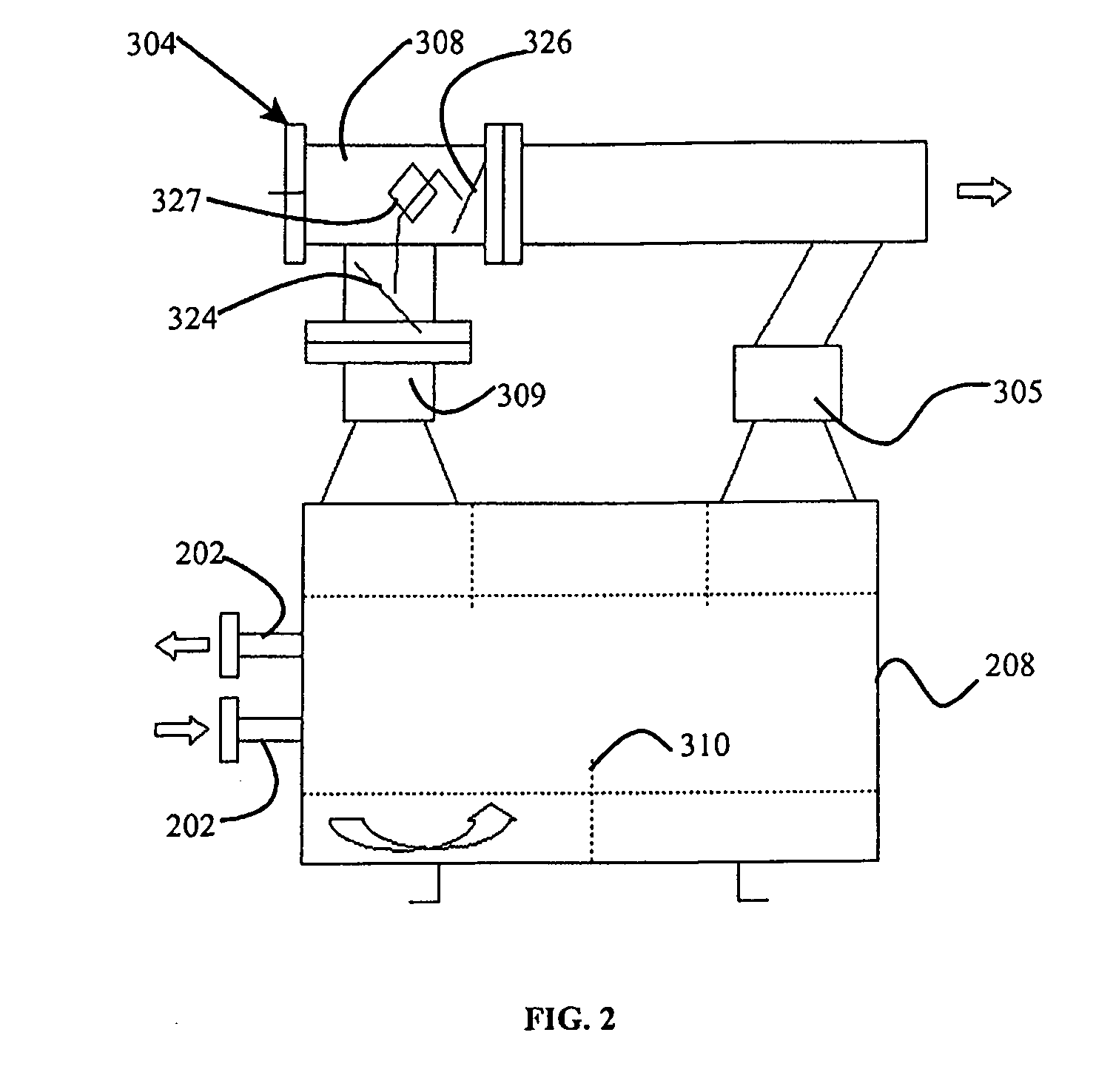

Hydrocarbon removal from gas process feed streams by regenerable filters

ActiveUS8808546B2Reduce hydrocarbon contentReduced footprintGas treatmentIon-exchanger regenerationStream flowFractionating column

A system and process for removing hydrocarbons from a gas process feed stream is presented. The treatment process may be, but is not limited to, glycol dehydration, amine sweetening, and MEG reclamation. As an example, a hydrocarbon removal bed containing a solid adsorbent material adsorbs the hydrocarbons in a rich MEG feed stream as it passes through the hydrocarbon removal bed. After the hydrocarbons have been removed, the feed stream flows through a flash separator and a distillation column to reclaim MEG. Alternatively, the hydrocarbon removal bed may be used after the MEG reclamation process to remove hydrocarbons in the distilled water from the distillation column. Spent solid adsorbent material may be regenerated in place.

Owner:CAMERSON INT CORP

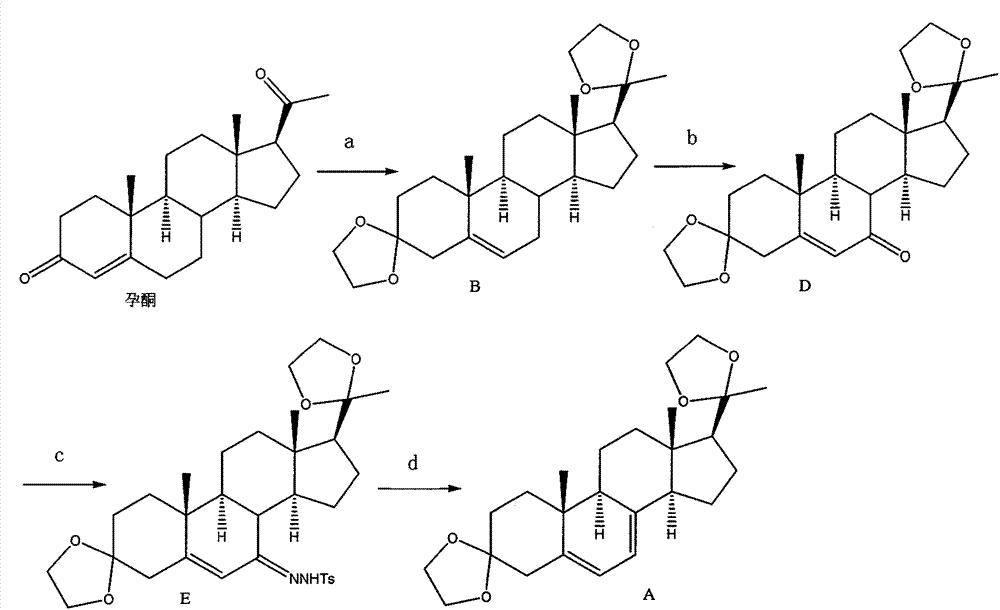

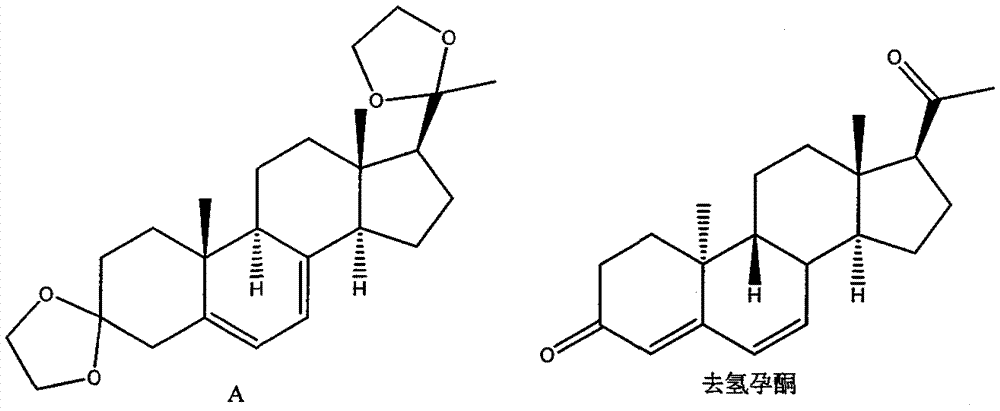

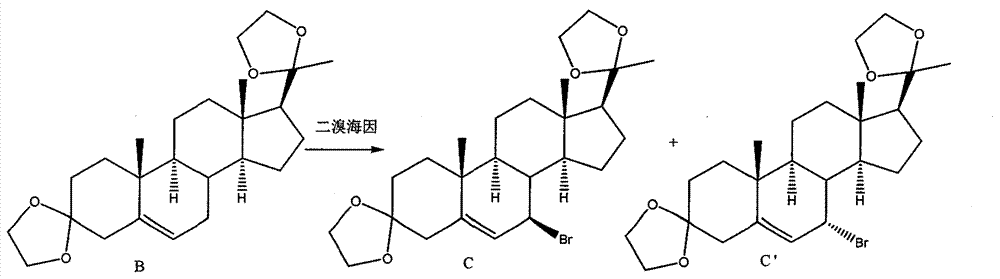

New preparation method of 5,7-pregnadiene-3,20-dione-diethyl ketal

Disclosed is a preparation method of 5,7-pregnadiene-3,20-dione-diethyl ketal. The preparation method comprises: performing dehydration condensation on progesterone by using glycol to protect two carbonyls, so as to obtain a compound B; performing allylic selective oxidization on the compound B to obtain a compound D; performing condensation on the compound D and p-toluenesulfonhydrazide, so as to obtain a compound E; and performing a Shapiro reaction to remove hydrazone from the compound E, so as to obtain 5,7-pregnadiene-3,20-dione-diethyl ketal (a compound A).

Owner:TAIZHOU HISOUND PHARMA CO LTD

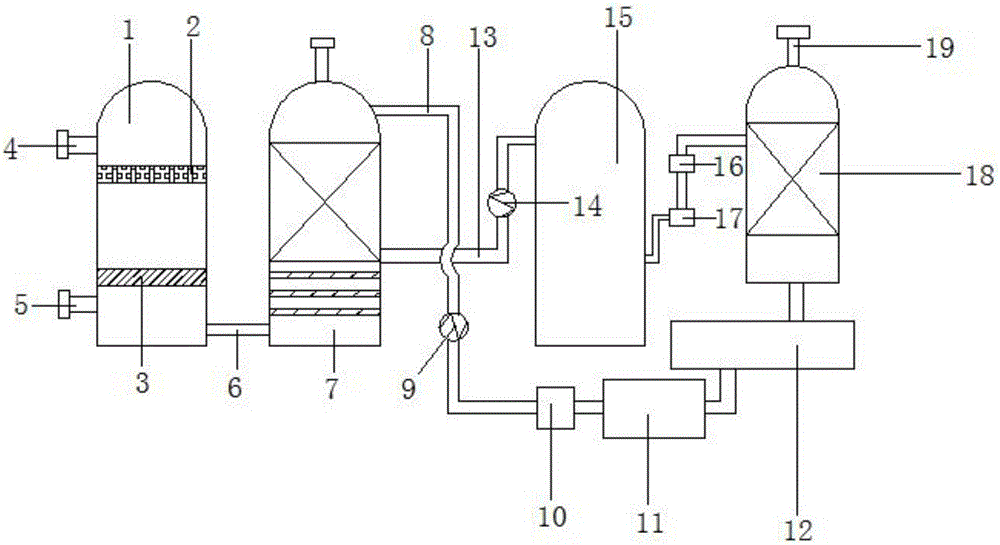

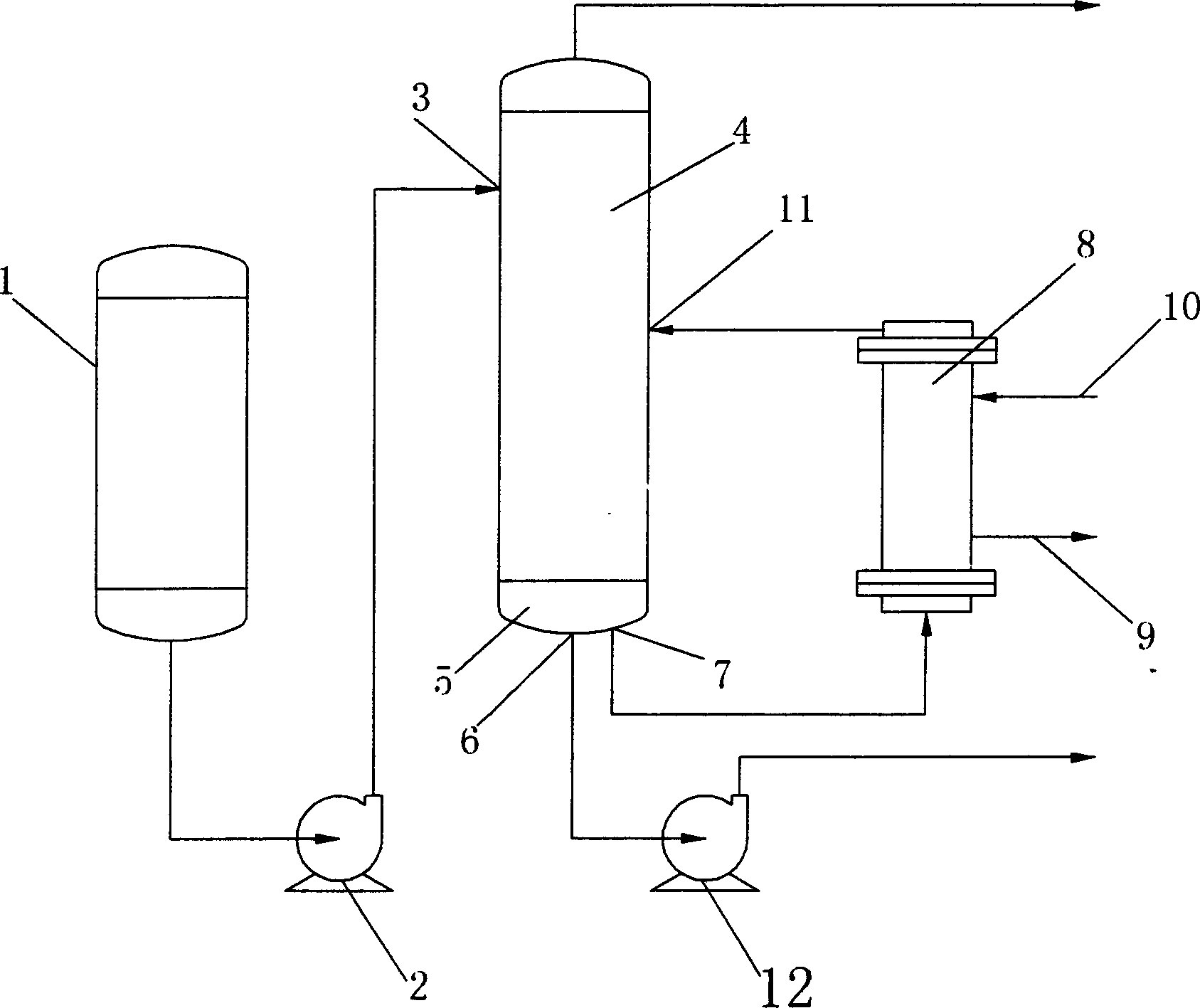

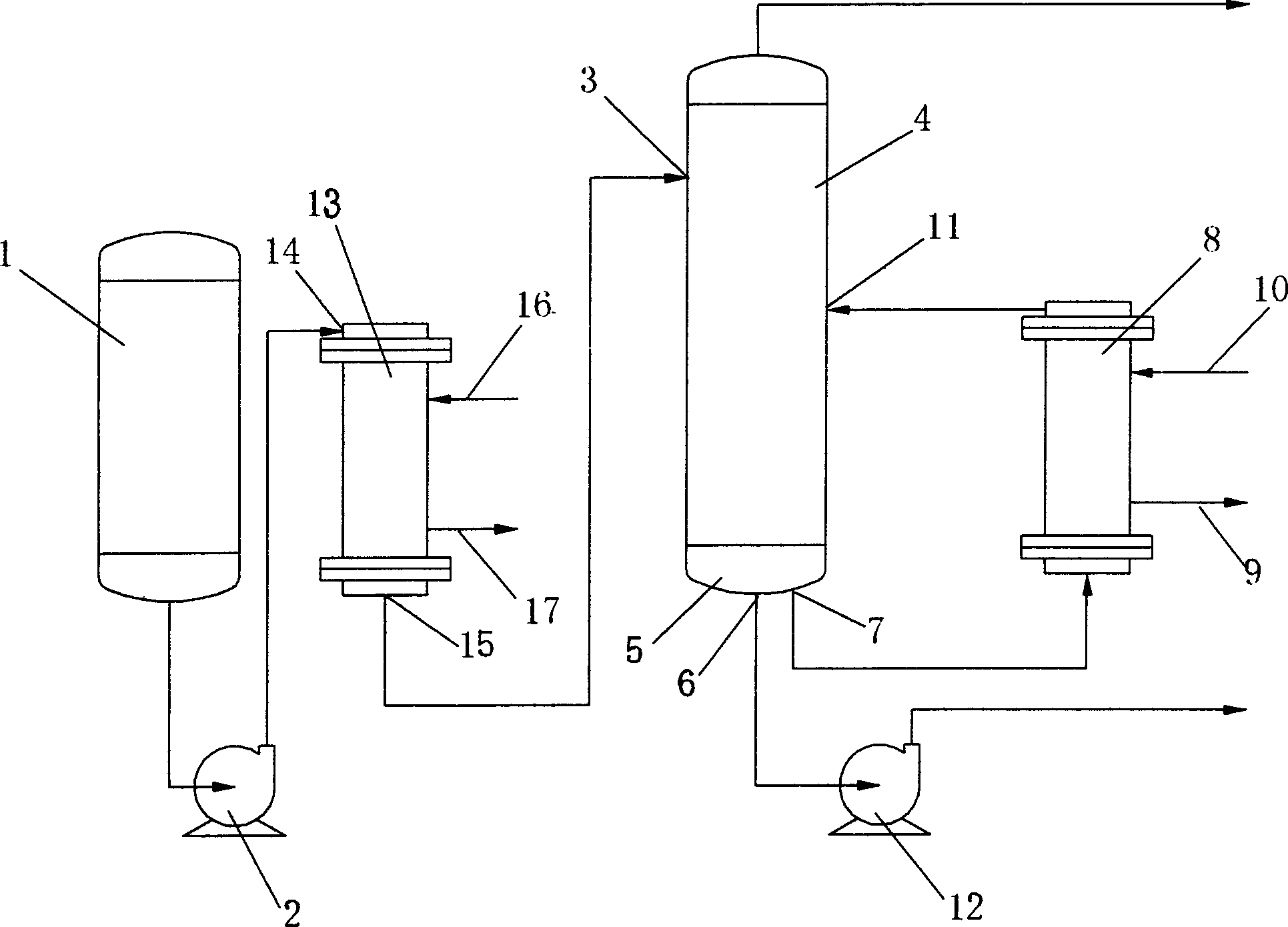

Natural gas dehydration device

InactiveCN106753633AAchieve the purpose of reuseImprove heat transfer efficiencyGaseous fuelsNatural gas dehydrationProcess engineering

The invention discloses a natural gas dehydration device in the technical field of natural gas dehydration. The device comprises a separator, wherein a coalescence filter element and a separation filter element are arranged at the top and bottom of an inner cavity of the separator respectively, a gas inlet pipe is arranged at the top of the left side of the separator, the top of the right side of a dehydration absorption tower is connected with a concentrated glycol pipeline, a lean and rich liquid heat exchanger is mounted on the concentrated glycol pipeline, the other end of the concentrated glycol pipeline is connected with a glycol circulation pump, the center of the right side of the dehydration absorption tower is connected with a flash tank through a diluted glycol pipeline, a heat exchanger is mounted on the diluted glycol pipeline, and a filter device is connected with the right side of the flash tank through a connecting pipe. Glycol is used to dehydrate natural gas, the glycol dehydration temperature is strictly controlled, the dehydration efficiency is improved, the device is convenient to use and adopts a simple process, energy consumption is reduced, the dehydration efficiency is improved, and the cost is saved.

Owner:JILIN JIANZHU UNIVERSITY

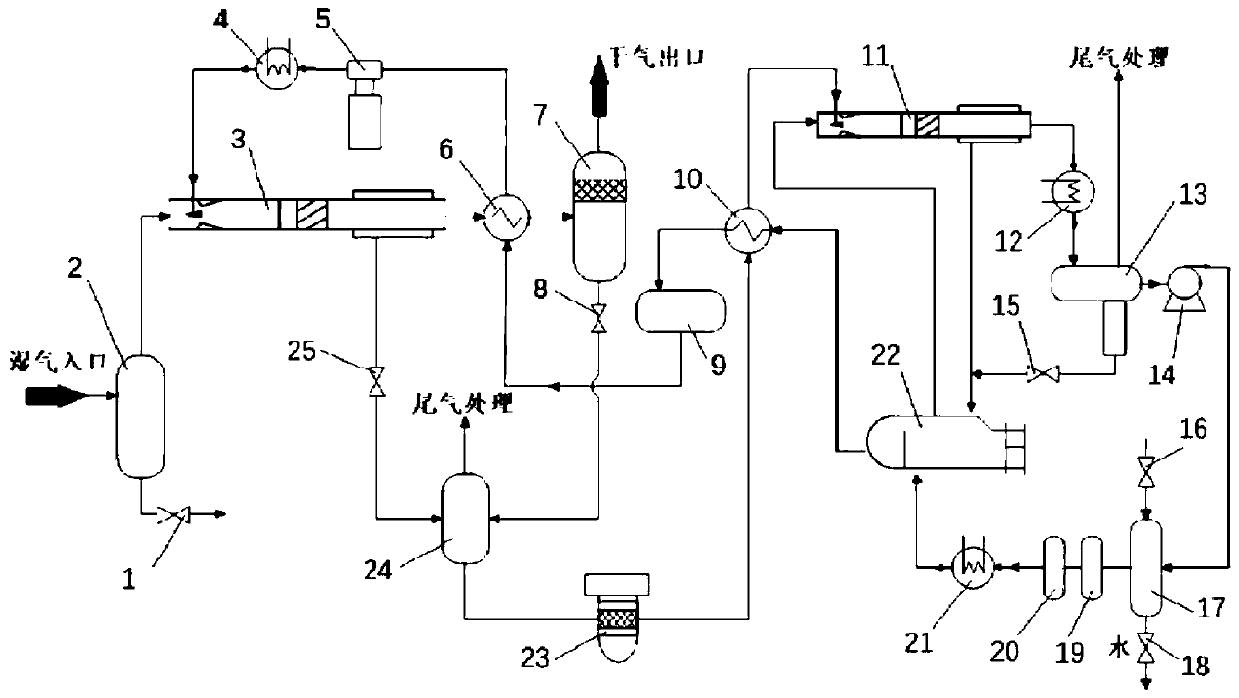

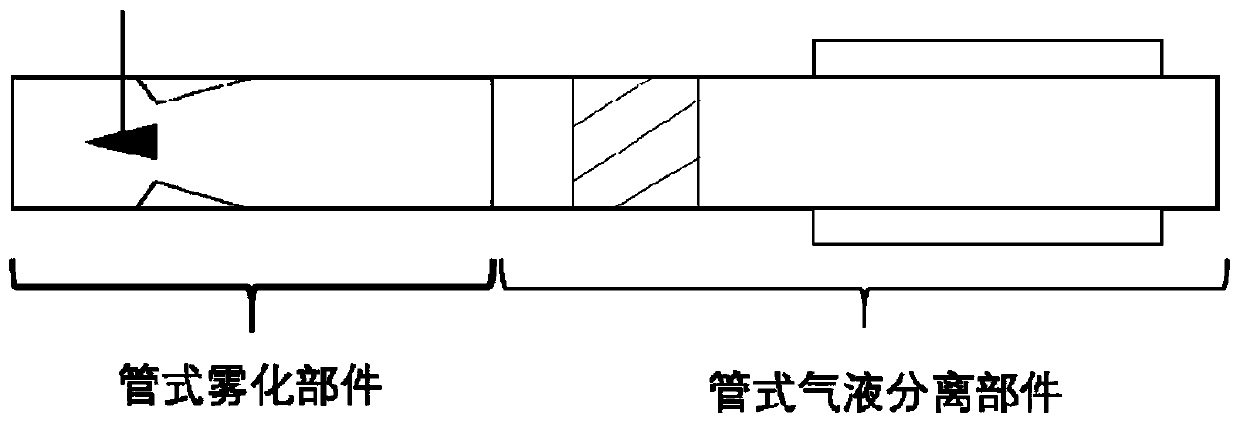

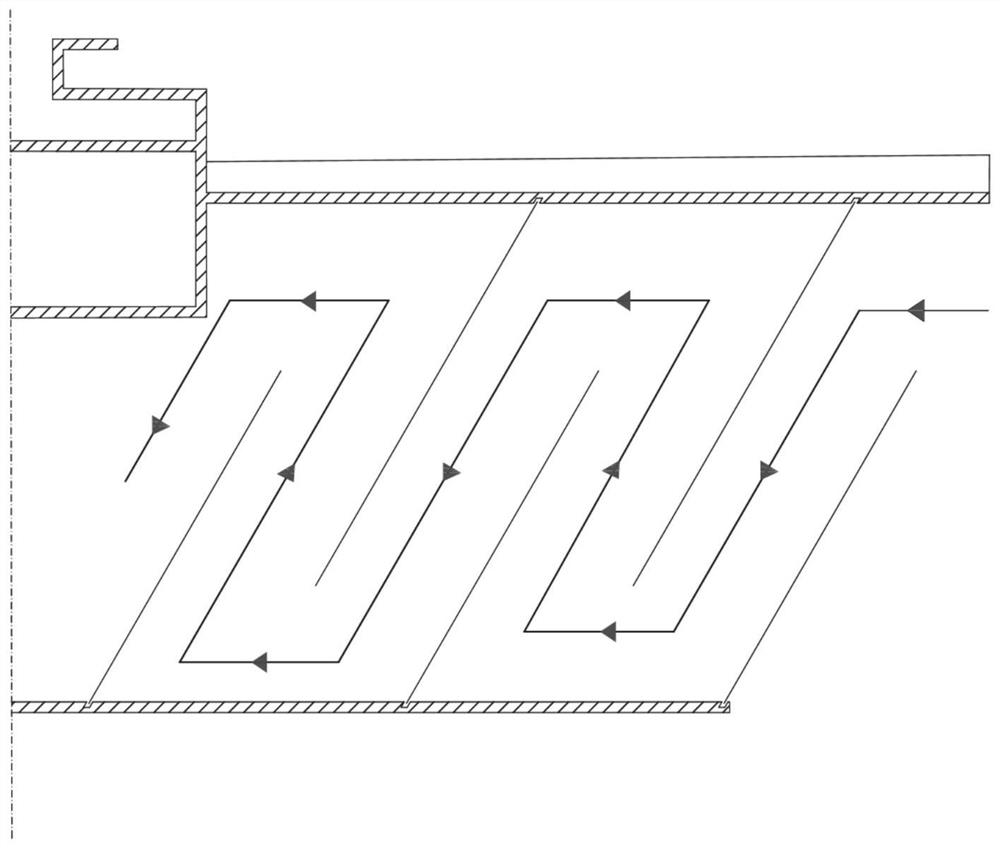

Efficient compact glycol dehydration system and method for natural gas

ActiveCN111454758AImprove compactnessSatisfy productivityDispersed particle separationGaseous fuelsReboilerGlycol synthesis

The invention discloses an efficient compact tubular glycol dehydration system and method for natural gas. The dehydration system and method are applicable to an offshore platform. The system comprises an underflow valve of a filter separator, the filter separator, a tubular gas-liquid contact absorber, a triethylene glycol condenser, a glycol pump, a natural gas / lean glycol heat exchanger, a demister, an underflow valve of a demister, a lean glycol storage tank, a lean / rich glycol heat exchanger, a tubular gas-liquid contact desorber, a condenser, a three-phase separator, a stripping agent pump, a coalescer, a drain valve of the coalescer, a stripping agent dryer, a stripping agent heater, a reboiler, a glycol filter and a flash tank. According to the invention, a triethylene glycol contact absorption dehydration part for natural gas adopts the tubular gas-liquid contact absorber, and a triethylene glycol regeneration part adopts a tubular rich ethylene glycol desorber, so the height,the volume and the weight of equipment can be reduced; a triethylene glycol barren solution is used as an absorbent, so the dew point of water at an outlet of natural gas having undergone water absorption treatment in an absorption system can be reduced to -60 DEG C or below; the circulation volume and loss of triethylene glycol are reduced, operation and running cost is greatly saved, the spaceoccupation of an offshore platform is effectively reduced, and the treatment requirements of long-distance transportation and liquefied natural gas on space-limited occasions such as an offshore platform can be met.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Hydrocarbon Removal from Gas Process Feed Streams by Regenerable Filters

ActiveUS20140053730A1Reduce hydrocarbon contentReduced footprintGas treatmentIsotope separationSorbentStream flow

A system and process for removing hydrocarbons from a gas process feed stream is presented. The treatment process may be, but is not limited to, glycol dehydration, amine sweetening, and MEG reclamation. As an example, a hydrocarbon removal bed containing a solid adsorbent material adsorbs the hydrocarbons in a rich MEG feed stream as it passes through the hydrocarbon removal bed. After the hydrocarbons have been removed, the feed stream flows through a flash separator and a distillation column to reclaim MEG. Alternatively, the hydrocarbon removal bed may be used after the MEG reclamation process to remove hydrocarbons in the distilled water from the distillation column. Spent solid adsorbent material may be regenerated in place.

Owner:CAMERSON INT CORP

Natural Gas Processing for Reduction in BTX Emissions and Energy Efficiency

InactiveUS20170021303A1Reduce releaseReduce moistureGas treatmentGaseous fuelsHydraulic motorNatural-gas processing

An energy-efficient continuous process (and apparatus) that eliminates or reduces the emission of BTX into the environment during a process of dewatering natural gas using glycol. The apparatus includes an absorption tower to dewater the natural gas, and a glycol dewatering unit that includes a reboiler and a distillation column. Overhead vapor, including steam and BTX vapor, from the distillation column is condensed in an air-cooled heat exchanger. The liquefied BTX may be separated for fuel, sale or other disposal. A fan is positioned to force or induce air to flow through the air-cooled heat exchanger. The fan may be driven by a hydraulic motor by pressure of a glycol process stream. In another embodiment, the overhead vapors from the distillation column are cooled against a stream of water-containing glycol being charged to the glycol dewatering unit thereby preheating this stream and reducing energy input to the reboiler.

Owner:OLIVIER GENE RANDAL

Method and device for dehydration of glycol by extending coking period of tower-drier reboiler

InactiveCN1557795AExtend the coking cycleIncrease heat loadHydroxy compound separation/purificationPreparation by hydrolysisReboilerPulp and paper industry

The glycol dewatering method for delaying the scaling period of reboiler in drying tower includes the control on the material temperature of drying tower, and features that the glycol solution temperature is 95-130 deg.c. The present invention also provides a glycol dewatering apparatus related to the method for delaying the scaling period of reboiler in drying tower. The method of the present invention can decrease the scaling speed of the reboiler obviously to reduce stop loss, lower cost in descaling, reduce drained sewage and protect environment.

Owner:北京东方石油化工有限公司

Preparation method of 1,4-dioxane produced by dehydrating ethylene glycol

InactiveCN108101882ALarge specific surface areaMild catalytic performancePhysical/chemical process catalystsOrganic chemistryActivated carbonAlkaline earth metal

The invention relates to a preparation method of 1,4-dioxane produced by dehydrating ethylene glycol. According to the preparation method, activated carbon is used as a carrier, alkali metal salts oralkaline earth metal salts are taken as active components, a catalyst loaded with the active components is prepared after impregnation, and the 1,4-dioxane is prepared by carrying out a dehydration reaction on the ethylene glycol which is used as the raw material. The catalyst used in the method is simple and convenient to prepare, high in activity and good in stability, and still maintains betteractivity after being used for a plurality of times; furthermore, the conversion rate of the ethylene glycol is within a range of 50-99%, and the selectivity of the 1,4-dioxane is within a range of 30-98%.

Owner:YANGZHOU UNIV

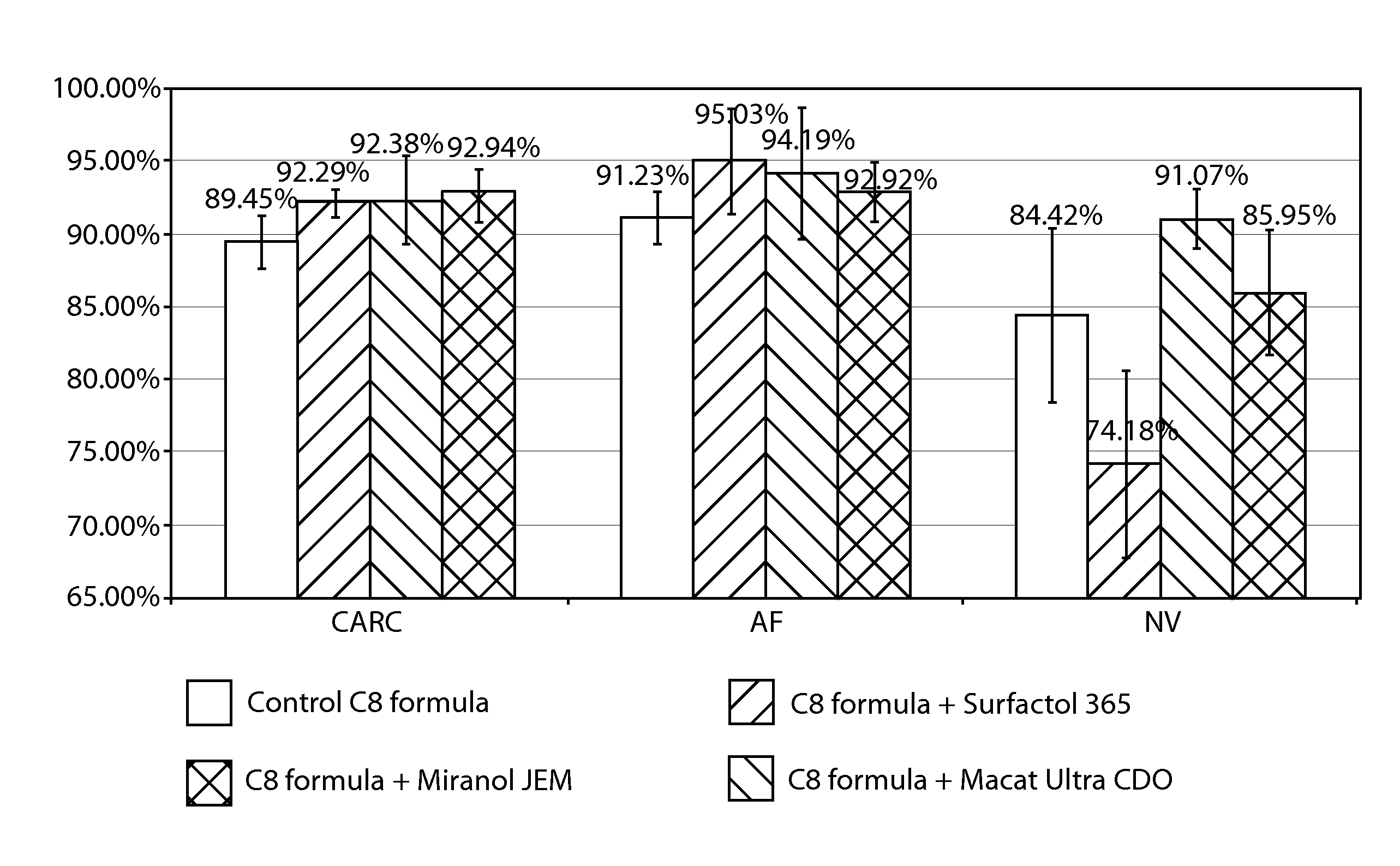

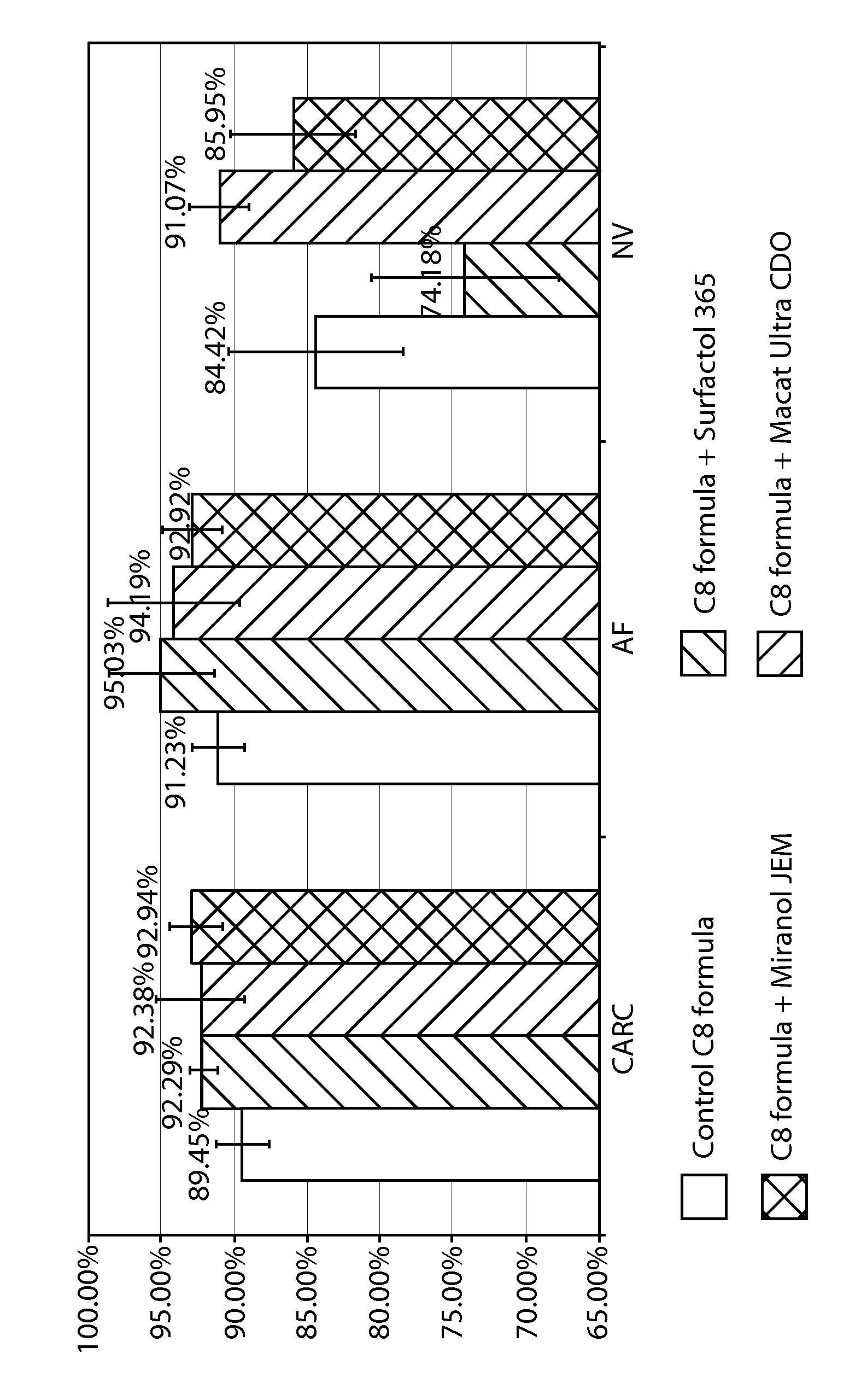

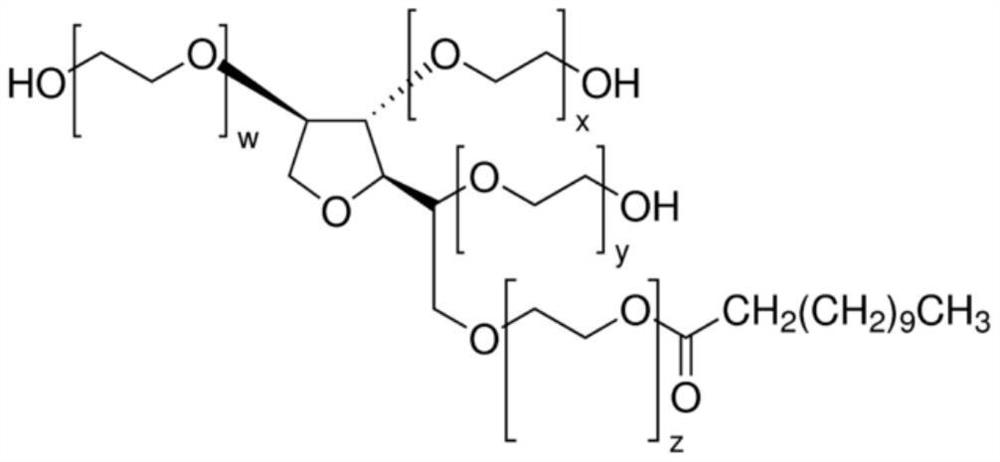

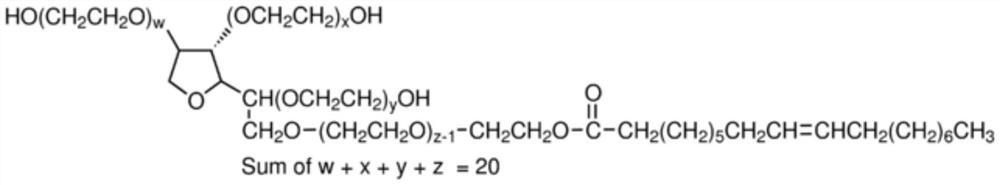

Surfactant composition and method for decontamination

ActiveUS9295865B2Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemical structureSodium metasilicate

Non-corroding cleaning compositions for cleaning exterior surfaces of a vehicle are disclosed. The cleaning compositions include an alkyl dimethylamine oxide surfactant with a first chemical structure, an alkyl dimethylamine oxide surfactant with a second chemical structure, a C8-18 alkyl polyethylene glycol sorbitan fatty ester surfactant, a C12-14 secondary alcohol ethoxylate surfactant, a sodium nitrite corrosion inhibitor, and sodium metasilicate are disclosed.

Owner:TDA RES

Apparatus for dehydrator and compressor combination skid and method of operation

InactiveUS20080115665A1Easy to manufactureLiquid degasificationDispersed particle filtrationReboilerGas compressor

A method and apparatus for the dehydration of glycol, comprising a gas compressor unit including an engine which produces a flow of hot exhaust gas; a glycol dehydrator unit including a reboiler for heating and dehydrating the glycol; transferring heat from the exhaust gas to the reboiler to heat the glycol; and a support platform, wherein the gas compressor unit, the glycol dehydrator unit and the circuit for transferring heat are all supported on the support platform.

Owner:LEADER ENERGY SERVICES +1

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

Owner:CHINA PETROLEUM & CHEM CORP

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

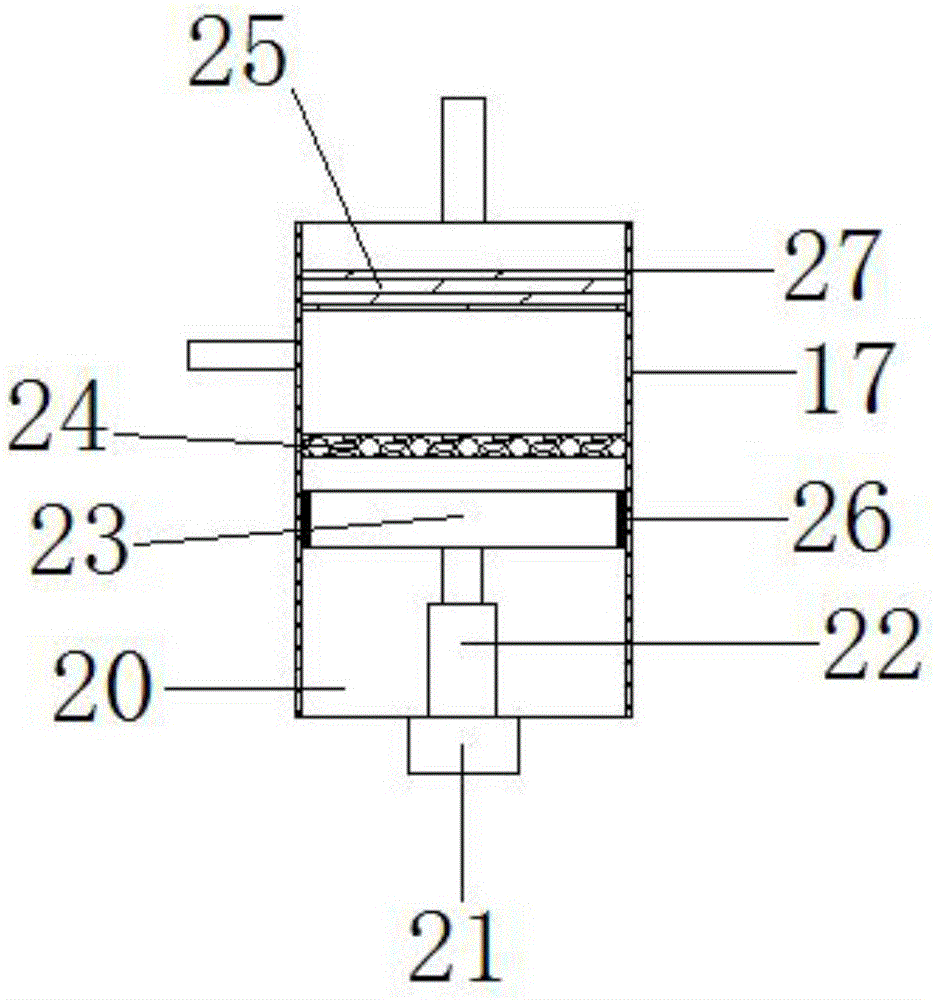

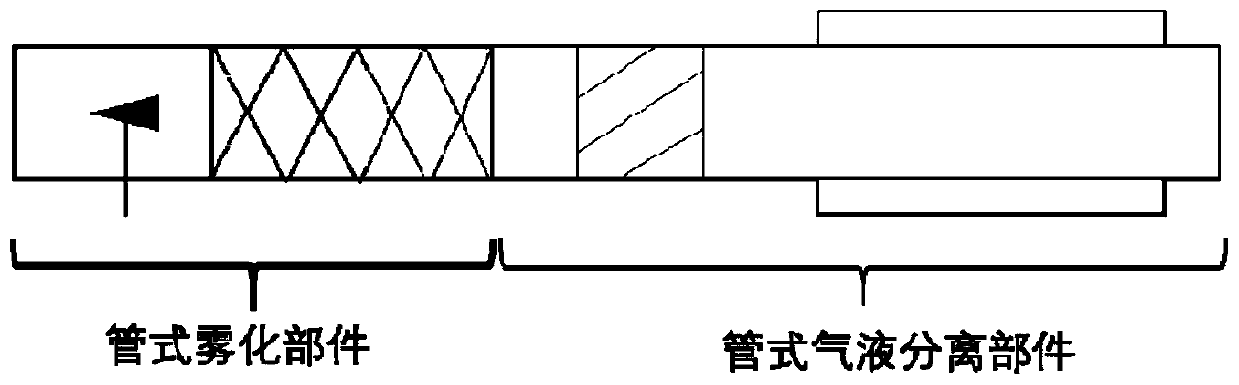

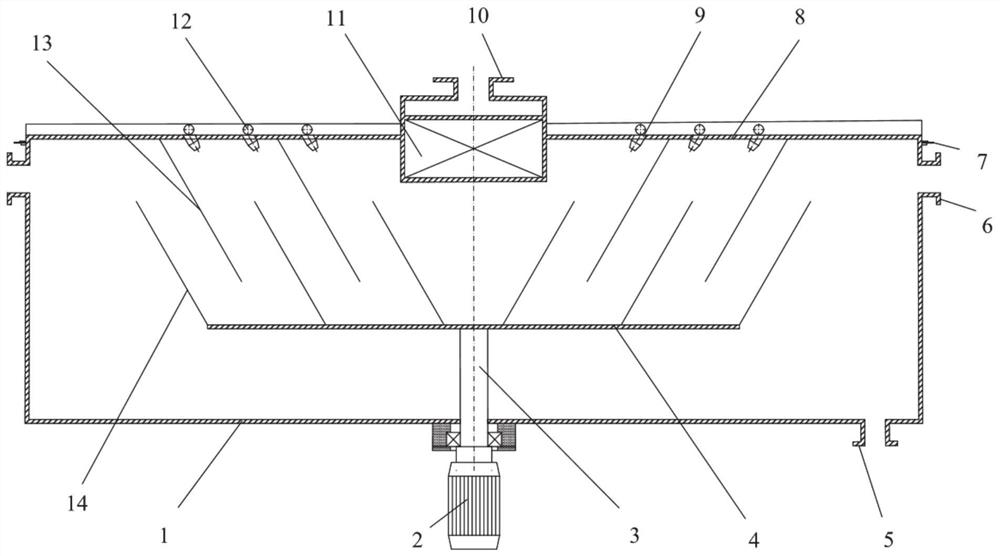

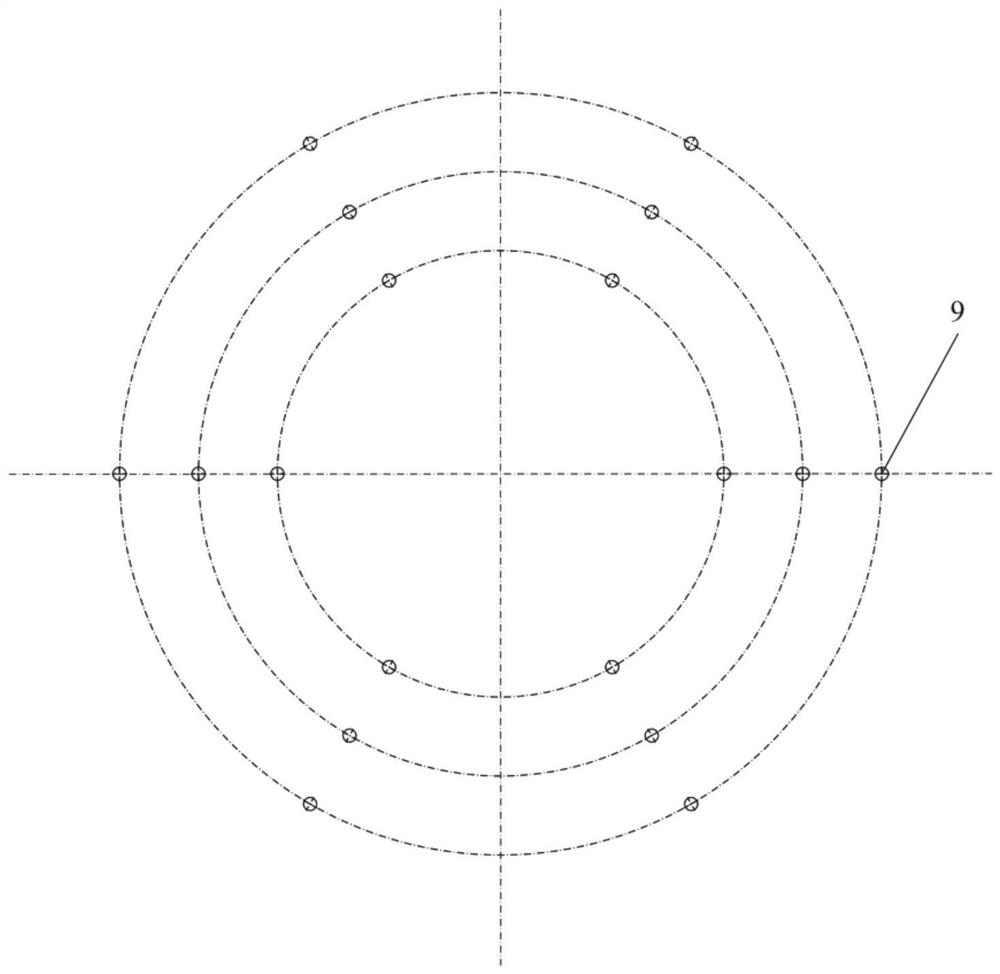

A kind of high-efficiency atomized glycol dehydration device and its using method and application

ActiveCN111676077BFully contactedImprove dehydration efficiencyGaseous fuelsDispersed particle separationPhysical chemistryNatural gas dehydration

The invention provides a high-efficiency atomized glycol dehydration device and its use method and application, belonging to the technical field of natural gas dehydration technology. The high-efficiency atomized glycol dehydration device is mainly composed of two parts: a glycol atomization unit, a gas-liquid contact and a separation unit. The device designed by the invention can make the contact between the raw material gas and the glycol more fully through the organic combination of the supergravity technology and the traditional triethylene glycol dehydration tower, improve the mass transfer effect, and better solve the problem that the original glycol dehydration equipment is bulky. Compared with the original dehydration equipment, it has the characteristics of low equipment height, small footprint, convenient maintenance and low production cost, and is more suitable for the treatment of offshore natural gas, so it has good practical application value. .

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

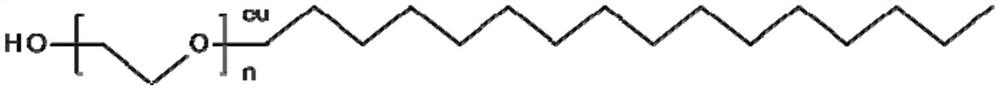

Germ-repellent plastic, a gas pathway of a respiratory device containing, and a manufacturing method therefor

PendingCN112262176AReduce adhesionReduce leachingRespiratory masksMedical devicesLow-density polyethyleneElastomer

A germ-repellent plastic for use in a gas pathway of a respiratory device contains an anti-biofouling compound, and a basic plastic. The anti-biofouling compound is optionally selected from the groupof a polyol, a polyether polyol, a polyol derivative, and a combination thereof; or the anti-biofouling compound is selected from the group consisting of a polyether, a poly (ethylene glycol) ether, apolysorbate, and a combination thereof; or the anti-biofouling compound is selected from the group consisting of poly (ethylene glycol) sorbitan monolaurate, poly (ethylene glycol) sorbitan monooleate, poly (ethylene glycol) sorbitol hexaoleate, ceteareth, and a combination thereof. The basic plastic is selected from the group of a blend of a low-density polyethylene polymer and an ethyl vinyl acetate copolymer, a blend of a polypropylene polymer and an ethyl vinyl acetate copolymer, a blend of polyolefin elastomer polymers and a polyvinyl chloride polymer. A method for manufacturing such a germ-repellent plastic, a gas pathway component of a respiratory device containing the germ-repellent plastic, and a respiratory device are also described.

Owner:VINCENT MEDICAL MFG

A modified molecular sieve catalyst and its application in treating 3-methyl-3-buten-1-ol high-concentration wastewater

ActiveCN112495430BReduce adsorptionImprove performanceWater treatment parameter controlMolecular sieve catalystsCalcium silicateMolecular sieve

The invention provides a preparation method of a hydrophobically modified molecular sieve catalyst. Firstly, metal oxide and silicon source compound hydrolyzate are uniformly mixed, and a mixture of calcium silicate and modifier bentonite is added at the same time, so that the metal oxide can be firmly attached to the catalyst surface. , so that the surface has a large number of coordinatively unsaturated metal sites as Lewis acid sites. In addition, the addition of hydrophobic additives is beneficial to reduce the adsorption of water on the catalyst surface, improve the efficiency of glycol dehydration, and further improve the performance of the catalyst. Utilizing the catalyst to treat the high-concentration wastewater generated in the process of synthesizing 3-methyl-3-butene-1-alcohol by the isobutene method can make the wastewater treatment conditions milder, the treatment efficiency is higher, and the wastewater treatment cost and energy consumption can be greatly reduced.

Owner:WANHUA CHEM GRP CO LTD

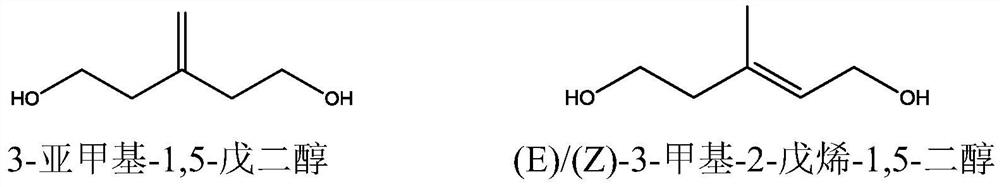

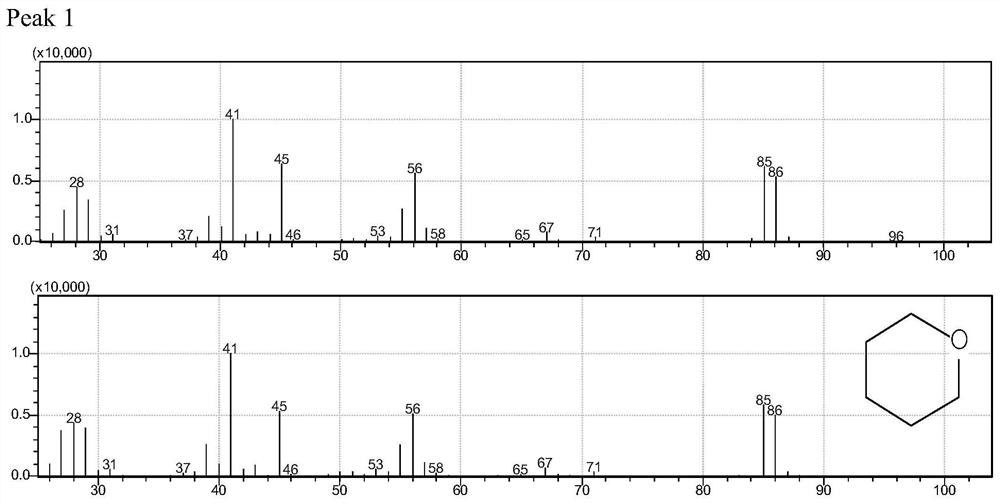

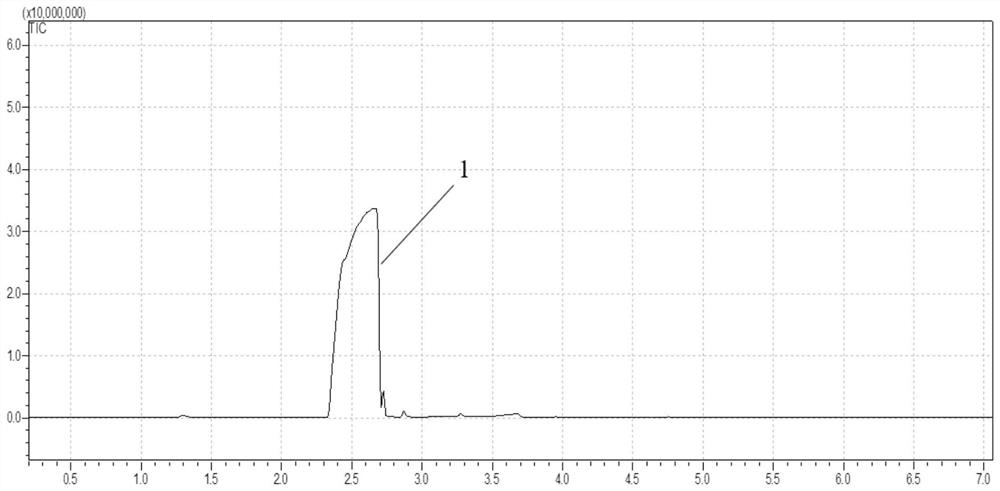

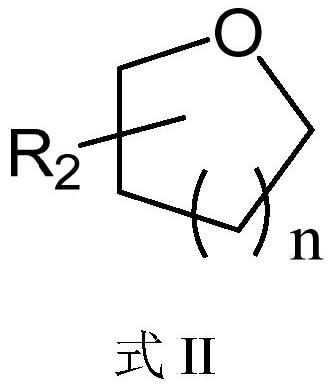

Method for preparing cyclic ether through dehydration cyclization of diol

PendingCN114437000AHigh yieldEfficient reaction conditionsOrganic chemistryPtru catalystCyclic ether

The invention discloses a method for preparing cyclic ether through diol dehydration cyclization. The method comprises the following steps: carrying out a diol dehydration reaction in a temperature range of 50-200 DEG C by using an ionic liquid as a solvent and a catalyst to prepare cyclic ether. The ionic liquid catalytic system provided by the invention has the advantages of high efficiency, simplicity, mildness (120 DEG C), no metal participation and the like, can efficiently catalyze glycol dehydration to prepare cyclic ether, and has a relatively high industrial application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method and product of modified cationic water-based polyurethane emulsion containing hydrophilic and hydrophobic side long chains

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

Fuel for low-carbon environmentally friendly boiler as well as preparation method thereof

InactiveCN108219891AImprove ignition performanceIncrease cetane numberBiofuelsSolid fuelsLow noise3-Hydroxypropionic acid

The invention discloses fuel for a low-carbon environmentally friendly boiler as well as a preparation method thereof. The fuel consists of the following raw materials in parts by weight: 68 to 76 parts of illegal cooking oil, 37 to 45 parts of hydrogen peroxide, 11 to 19 parts of 3-hydroxypropionic acid, 15 to 25 parts of peroxidase, 9 to 17 parts of diethylene glycol and 1 to 5 parts of nickel nitrate. The fuel is prepared by treating the illegal cooking oil serving as a main raw material by the hydrogen peroxide, performing treating by the peroxidase, the 3-hydroxypropionic acid and the nickel nitrate, adding the diethylene glycol and dehydrating, so that the ignition property of low-carbon oil is improved, the cetane number of the fuel is greatly increased, the lubricating property ishigh, and the product does not have side effect on any system parts, has strong power and low noise, has high dry resistance and stability, is clean, environmentally friendly and energy-saving, and avoids carbon deposition, corrosivity and mechanical wear after long-time use. The fuel is sufficient in raw material, low in cost and simple in production process, reduces production cost and can be widely used in the fields of boilers, diesel vehicles, ships, catering and the like.

Owner:郝德厚

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

Composite corrosion inhibitor for butyl rubber chloromethane glycol dehydration and regeneration system

The invention relates to a composite corrosion inhibitor for a butyl rubber chloromethane glycol dehydration and regeneration system. The composite corrosion inhibitor comprises at least two compounds, wherein the compounds are selected from heterocyclic compounds; the heterocyclic compounds are selected from nitrogen heterocyclic compounds and sulfur heterocyclic compounds, preferably the compounds are all selected from the nitrogen heterocyclic compounds, or the nitrogen heterocyclic compounds and the sulfur heterocyclic compounds; the nitrogen heterocyclic compounds are selected from a pyrrole compound, an imidazole compound, a pyrazol compound, a pyridine compound, a pyrazine compound, a miazine compound, a quinoline compound, an isoquinoline compound and a benzotriazole compound; and the sulfur heterocyclic compounds are thiazole compounds. According to the composite corrosion inhibitor, the problem of system corrosion due to accumulation of hydrochloric acid in the chloromethane glycol dehydration system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

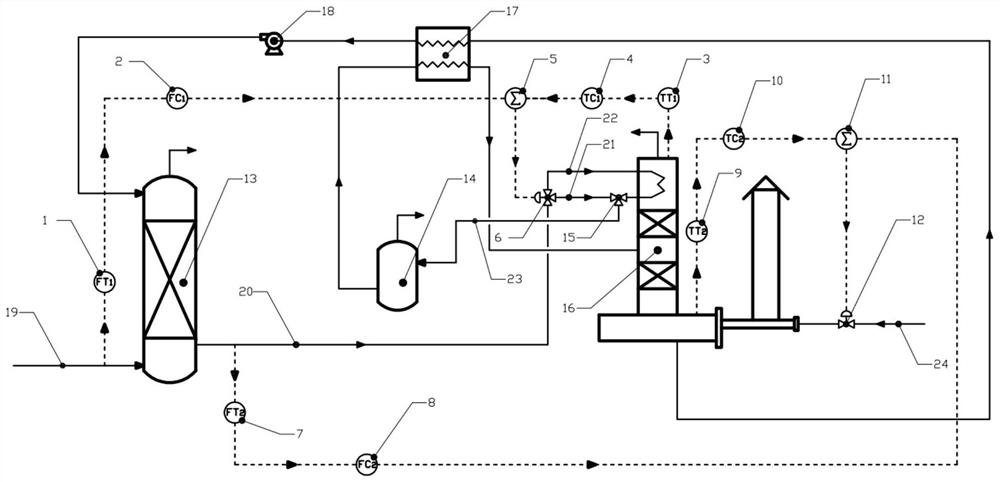

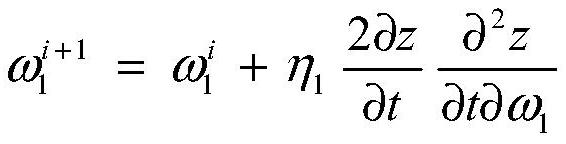

A kind of temperature control system and method for triethylene glycol dehydration process

ActiveCN111399561BControl temperature distributionAccurate control of temperature distributionTemperature control without auxillary powerGaseous fuelsTemperature controlLoop control

The invention discloses a temperature control system and a temperature control method for a triethylene glycol dehydration process. The temperature control system comprises a first temperature controlloop and a second temperature control loop, wherein the first temperature control loop and the second temperature control loop control the top part temperature of a regeneration device by adjusting the flow of a cooling medium entering the top part of the regeneration device, and control the bottom part temperature of the regeneration device by adjusting the flow of a fuel gas entering the bottompart of the regeneration device; and the first temperature control loop and the second temperature control loop each comprise a feedforward control structure and a feedback control structure, feedforward control signals and feedback control signals are subjected to weighted operation through an adder and then act on corresponding valves for adjustment, and the weights of weighted operation are dynamically updated according to real-time temperature deviation. According to the temperature control system and the temperature control method, the accuracy and timeliness of temperature control of atriethylene glycol dehydration device are improved.

Owner:XI AN JIAOTONG UNIV

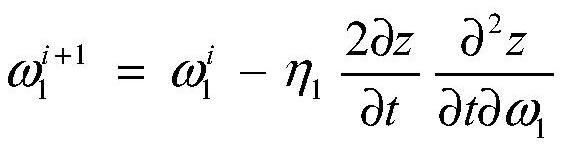

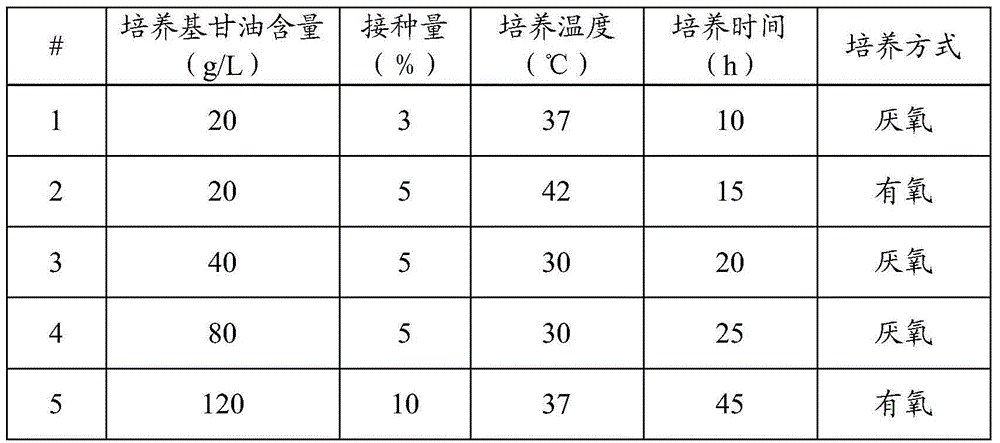

Method for manufacturing 3-hydroxypropionic acid from microbial fermentation glycerol

InactiveCN104830917AEliminate genetic manipulation stepsIncrease concentrationFermentation3-Hydroxypropionic acid1,3-Propanediol

The invention relates to a method for manufacturing 3-hydroxypropionic acid from microbial fermentation glycerol. The method is implemented by the aid of first microorganisms and second microorganisms. The first microorganisms have glycerol dehydration activity, and the glycerol can be converted into 3-hydroxy-propionaldehyde or 1, 3-propylene glycol by the first microorganisms. The second microorganisms have glycol dehydration activity, and the 3-hydroxy-propionaldehyde or the 1, 3-propylene glycol glycerol can be converted into the 3-hydroxypropionic acid by the second microorganisms. The first microorganisms can be selected from Klebsiella pneumoniae and the like and genetically engineered bacteria of the Klebsiella pneumoniae and the like; the second microorganisms are Gluconobacter oxydans and genetically engineered bacteria of the Gluconobacter oxydans. The method has the advantages that the glycerol is used as a substrate, the two types of microorganisms are subjected to sectioned mixed fermentation to manufacture the 3-hydroxypropionic acid, the concentration of final products can be improved as compared with an existing single-bacterium fermentation method mainly on the basis of genetically engineered bacteria, the rate of converting the glycerol into the 3-hydroxypropionic acid can be increased as compared with the existing single-bacterium fermentation method, lactic acid in fermentation liquor can be converted into acetic acid, accordingly, the concentration of the lactic acid of byproducts can be reduced, and separation and purification stress can be relieved; the concentration of the 3-hydroxypropionic acid can reach 75gL<-1> at least, and accordingly the method has an excellent industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com