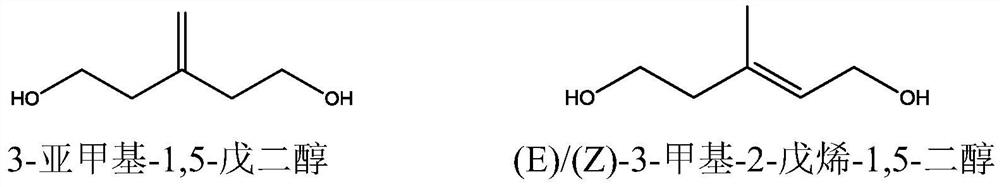

A modified molecular sieve catalyst and its application in treating 3-methyl-3-buten-1-ol high-concentration wastewater

A high-concentration wastewater and molecular sieve technology, which is applied in the direction of molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of difficult to realize the reuse of useful substances in wastewater, long treatment process, poor applicability, etc., and achieve reduction Wastewater Treatment Costs and Energy Consumption, Efficiency Improvement, Performance Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix 50g of methyltriethoxysilane and 600g of water, and stir at 50°C for 6 hours to hydrolyze the organosilicon to form Emulsion A; at room temperature, add 20g of zirconium dioxide to 140g of trifluoroacetic acid, and stir Until all the solids are dissolved, solution B is formed; 16.6 g of calcium silicate and 3.4 g of bentonite are fully stirred and mixed for later use; at room temperature, solution B is slowly added to emulsion A, and 10 g of isoleucine is added dropwise at the same time, stirring 35min, add the mixture of calcium silicate and bentonite and stir well for 4h to form a uniform gel; put the gel in an oven, evaporate the water and organic solvent to dryness, grind it into powder and put it in a muffle furnace at 220°C After calcination and crystallization for 6 hours, the catalyst was washed with 4% hydrochloric acid aqueous solution and then washed with ethanol, and finally placed in an oven for drying at 80 °C to obtain a hydrophobically modified molecu...

Embodiment 2

[0046] Mix 32g of hexamethyldisilazane and 650g of water, and stir at 55°C for 5h to hydrolyze the organosilicon to form Emulsion A; at room temperature, add 15g of titanium dioxide to 175g of tetramethylethylenediamine, Stir until all the solids are dissolved to form solution B; fully stir and mix 14g calcium silicate and 2.55g bentonite for later use; at room temperature, slowly add solution B to emulsion A, add 9.6g leucine dropwise, and stir 45min, add the mixture of calcium silicate and bentonite and stir well for 3.5h to form a uniform gel; put the gel in an oven, evaporate the water and organic solvent to dryness, grind it into powder and put it in a muffle furnace at 230°C After calcination and crystallization for 4.5 h, the catalyst was washed with 5% phosphoric acid aqueous solution and then with methanol, and finally put into an oven for drying at 90 °C to obtain a hydrophobically modified molecular sieve catalyst, which is designated as CAT-2.

Embodiment 3

[0048] Mix 26g of tert-butyldimethylsilyl chloride and 700g of water, and stir at 58°C for 4.5h to hydrolyze the organosilicon to form Emulsion A; at room temperature, add 16g of tungsten trioxide to 195g of dimethyl carbonate , stir until all the solids are dissolved to form solution B; fully stir and mix 10.5g calcium silicate and 1.5g bentonite for later use; at room temperature, slowly add solution B to emulsion A, and add 8.5g stearin dropwise at the same time acid, stir for 65 minutes, add calcium silicate and bentonite mixture and stir well for 3 hours to form a uniform gel; put the gel in an oven, evaporate the water and organic solvent to dryness, grind it into powder and put it in a muffle furnace After calcination and crystallization at 235°C for 5h, the catalyst was washed with 3.2% phosphoric acid aqueous solution and then washed with acetonitrile. Finally, it was put into an oven for drying at 95°C to obtain a hydrophobically modified molecular sieve catalyst, den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com