A kind of temperature control system and method for triethylene glycol dehydration process

A temperature control system and temperature control loop technology, applied in the field of natural gas chemical industry, can solve the problems of control system response delay, low control accuracy, temperature control system unable to control the temperature distribution of the whole tower, etc., and achieve the effect of precise control and timely temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

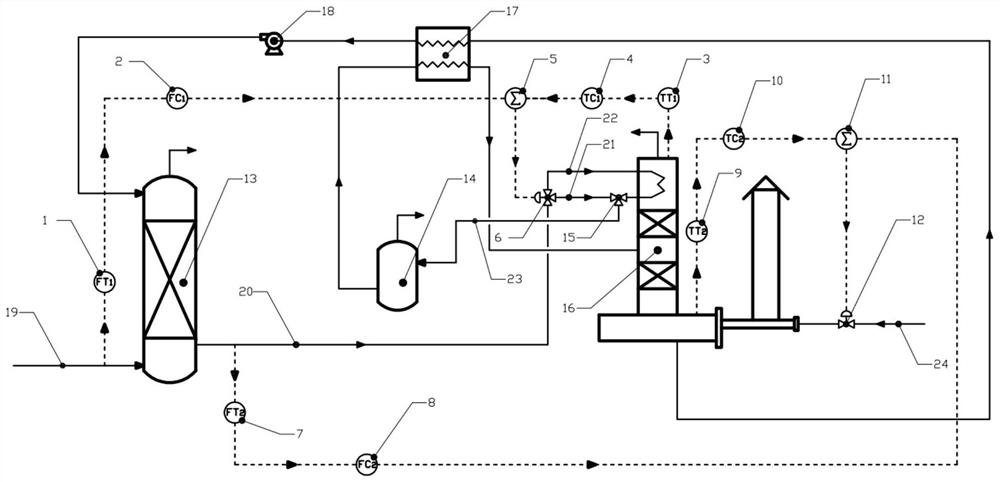

[0078] In this embodiment, the first temperature control loop and the second temperature control loop are arranged on the basis of the existing triethylene glycol dehydration process, wherein:

[0079] The first temperature control loop includes a first flow sensor 1, a first flow controller 2, a first temperature sensor 3, a first temperature controller 4, a first adder 5, a first solenoid valve 6 and a manual valve required for matching 15 and bypass line 21. The first flow sensor 1 is arranged on the natural gas inlet pipeline 19, the first flow controller 2 is connected with the first flow sensor 1, the first temperature sensor 3 is arranged on the top of the regeneration device 16, the first temperature controller 4 is connected with the first temperature sensor 3 is connected, the first adder 5 is connected with the first flow controller 2 and the first temperature controller 4 to perform the addition operation of the control signal, the first solenoid valve 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com