A controllable electrolytic aluminum tank heat dissipation window waste heat recovery device

A technology of waste heat recovery device and heat dissipation window, which is applied in waste heat treatment, charging treatment types, lighting and heating equipment, etc., can solve the problems of harsh working environment in the production workshop, uncontrollable temperature of the electrolytic aluminum tank, high temperature of the wall surface of the electrolytic aluminum tank, etc. To achieve the effect of improving the working environment of the workshop, improving the work efficiency of workers, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

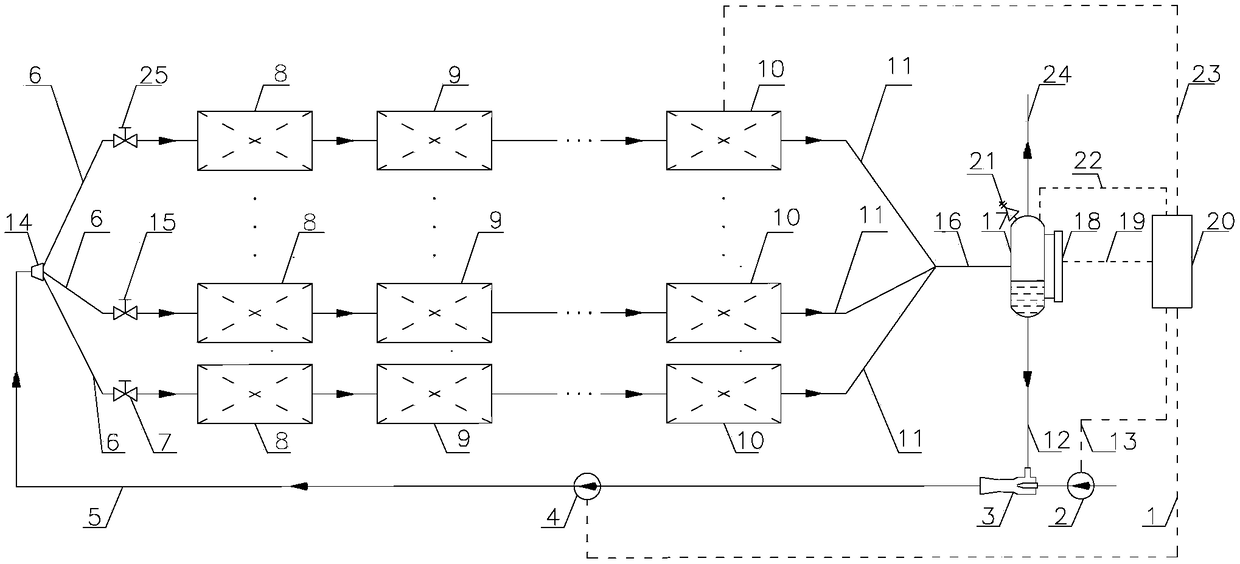

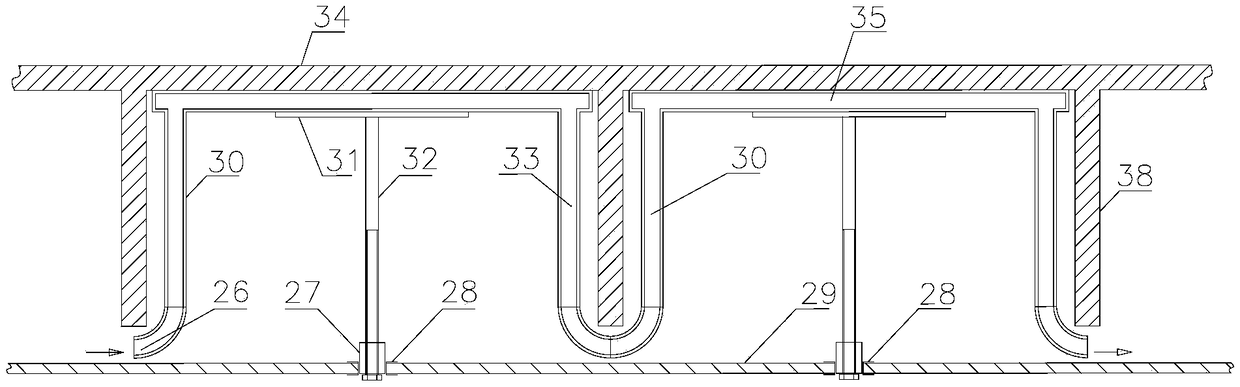

[0018]The main structure of the controllable electrolytic aluminum tank heat dissipation window waste heat recovery device involved in this embodiment includes: circulating water pump adjustment control line 1, supplementary water booster pump 2, ejector 3, circulating water pump 4, liquid supply main pipe 5 , the liquid branch pipe 6, the first branch flow regulating valve 7, the first heat extraction unit 8, the second heat extraction unit 9, the nth heat extraction unit 10, the two-phase flow branch pipe 11, the circulating water pipe 12, Pressure pump adjustment control line 13, liquid separator 14, second branch flow control valve 15, two-phase flow main pipe 16, gas-liquid separator 17, liquid level gauge 18, water level signal line 19, central controller 20, safety Valve 21, steam temperature and pressure signal line 22, heat extraction unit temperature signal line 23, steam supply pipe 24, mth branch flow regulating valve 25, connecting elbow 26, fixed frame 27, guide r...

Embodiment 2

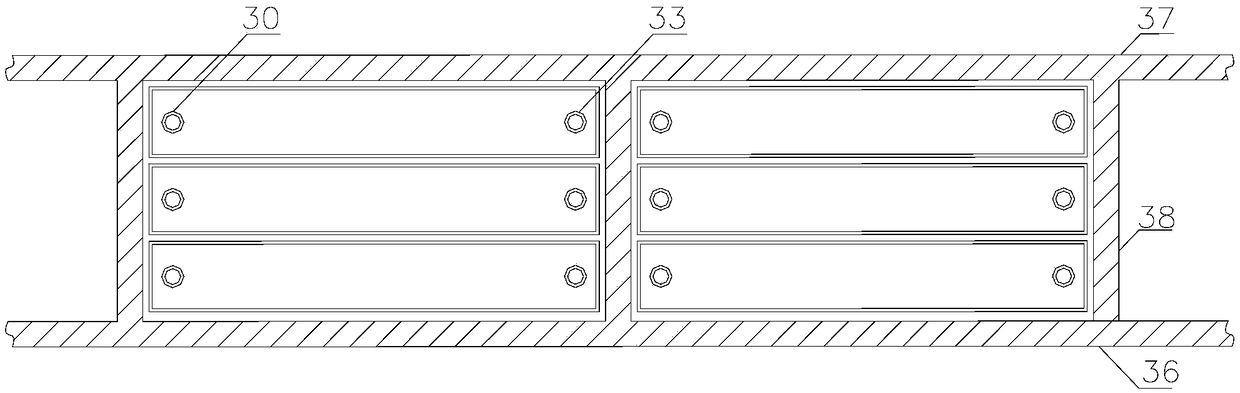

[0026] The heat extraction unit subsystem of this embodiment is realized in the heat dissipation window of the electrolytic aluminum tank. The upper steel plate 37, the lower steel plate 36 and two vertical plates 38 of the heat dissipation window form a heat dissipation window. In this embodiment, each heat dissipation window is arranged 3 heat extraction units, each heat extraction unit is welded with an input pipe 30 and an output pipe 33 on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com