Efficient compact glycol dehydration system and method for natural gas

A natural gas, compact technology, applied in the field of high-efficiency and compact natural gas glycol dehydration system, can solve the problems of high installation requirements, poor system reliability, and high maintenance costs, and achieve flexible installation and layout, small footprint and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

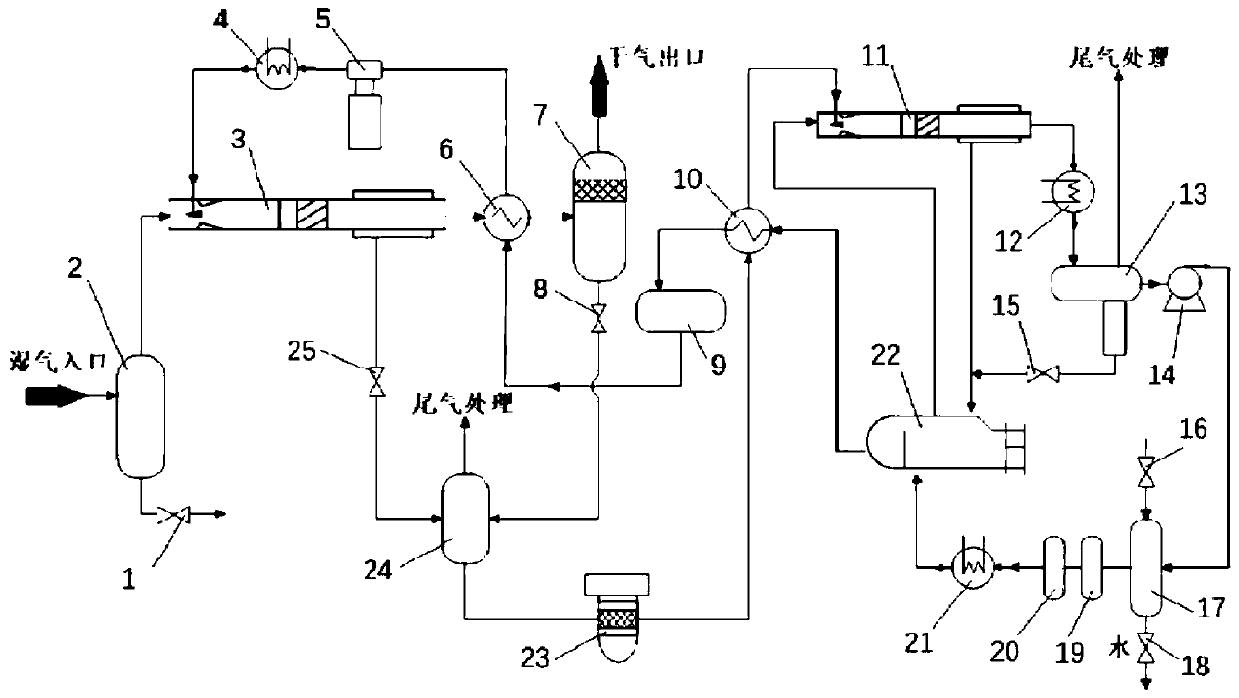

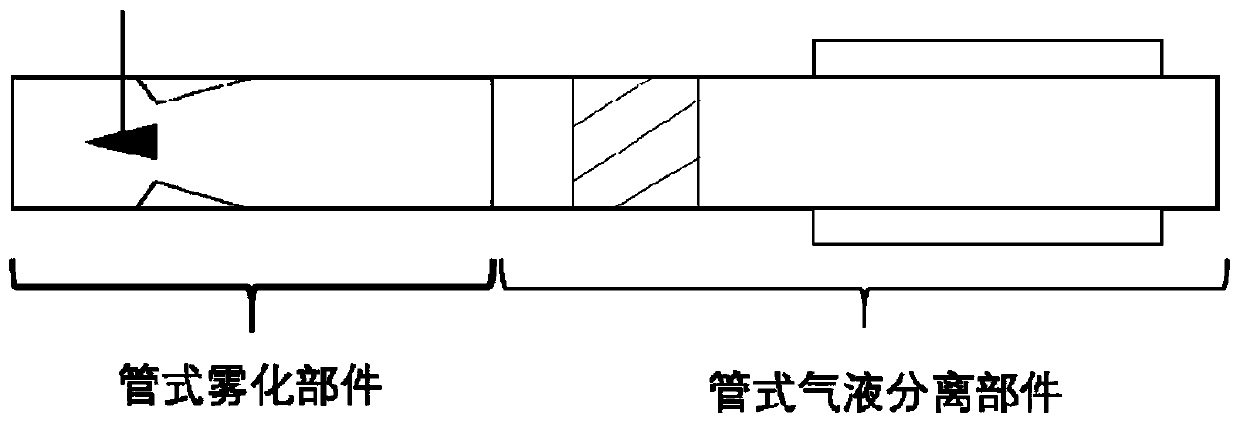

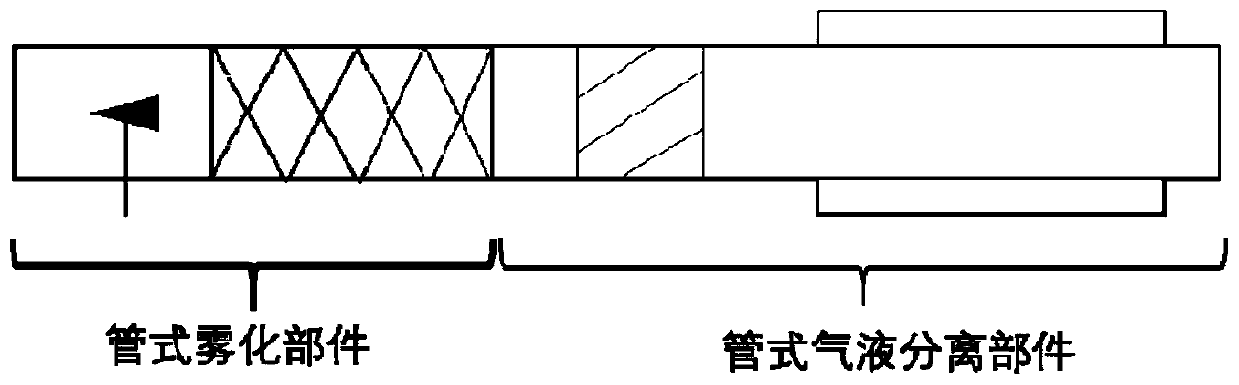

[0074] see figure 1 As shown, the present invention proposes a high-efficiency and compact natural gas glycol dehydration process, including a filter separator bottom flow valve 1, a filter separator 2, a tubular gas-liquid contact absorber 3, a triethylene glycol condenser 4, and a glycol pump 5. Natural gas / lean glycol heat exchanger 6, demister 7, demister underflow valve 8, lean glycol storage tank 9, lean / rich glycol heat exchanger 10, tubular gas-liquid contact desorber 11, Condenser 12, three-phase separator 13, stripping agent pump 14, first stop valve 15, stripping agent injection stop valve 16, coalescer 17, coalescer drain valve 18, first stripping agent dryer 19 , The second stripping agent dryer 20, the stripping agent heater 21, the reboiler 22, the glycol filter 23, the flash tank 24, the second stop valve 25.

[0075] The bottom outlet of the filter separator 2 is connected to the filter separator underflow valve 1, the outlet of the filter separator underflow...

Embodiment 1

[0103] Use the above-mentioned device and process to remove gaseous water in natural gas with triethylene glycol:

[0104] The pressure of the natural gas entering the system is 7MPa, the volume ratio of the triethylene glycol lean liquid to the natural gas to be treated is 1:10000, the volume ratio of the amount of stripping agent to the amount of triethylene glycol rich liquid is 0.15:1, and the stripping agent is positive Heptane, TEG condenser temperature is 35°C, natural gas flow rate in the tubular gas-liquid contact absorber is 12m / s, triethylene glycol lean liquid atomized droplet D32 particle size is 100μm, tube gas-liquid contact desorption The gas phase velocity in the vessel is 12m / s, the particle size of the atomized droplet D32 rich in triethylene glycol rich liquid is 100μm, and the temperature of the reboiler is 204°C; under these process conditions, the purity of the regenerated triethylene glycol poor liquid reaches 99.99% wt%, the water dew point of natural ...

Embodiment 2

[0106] As shown in Example 1, other conditions remain unchanged, the natural gas flow rate in the tubular gas-liquid contact absorber is 20m / s, the particle size of the triethylene glycol lean liquid atomized droplet D32 is 60 μm, and the gas-liquid contact desorber in the tubular gas-liquid contact desorber The gas phase velocity is 20m / s, and the particle size of the atomized droplet D32 of the triethylene glycol rich liquid is 60μm. Using this process condition, the purity of the regenerated triethylene glycol lean liquid reaches 99.99wt%, and the dew point of natural gas water after dehydration reaches - 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com