Patents

Literature

38results about How to "Reduce hydrocarbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

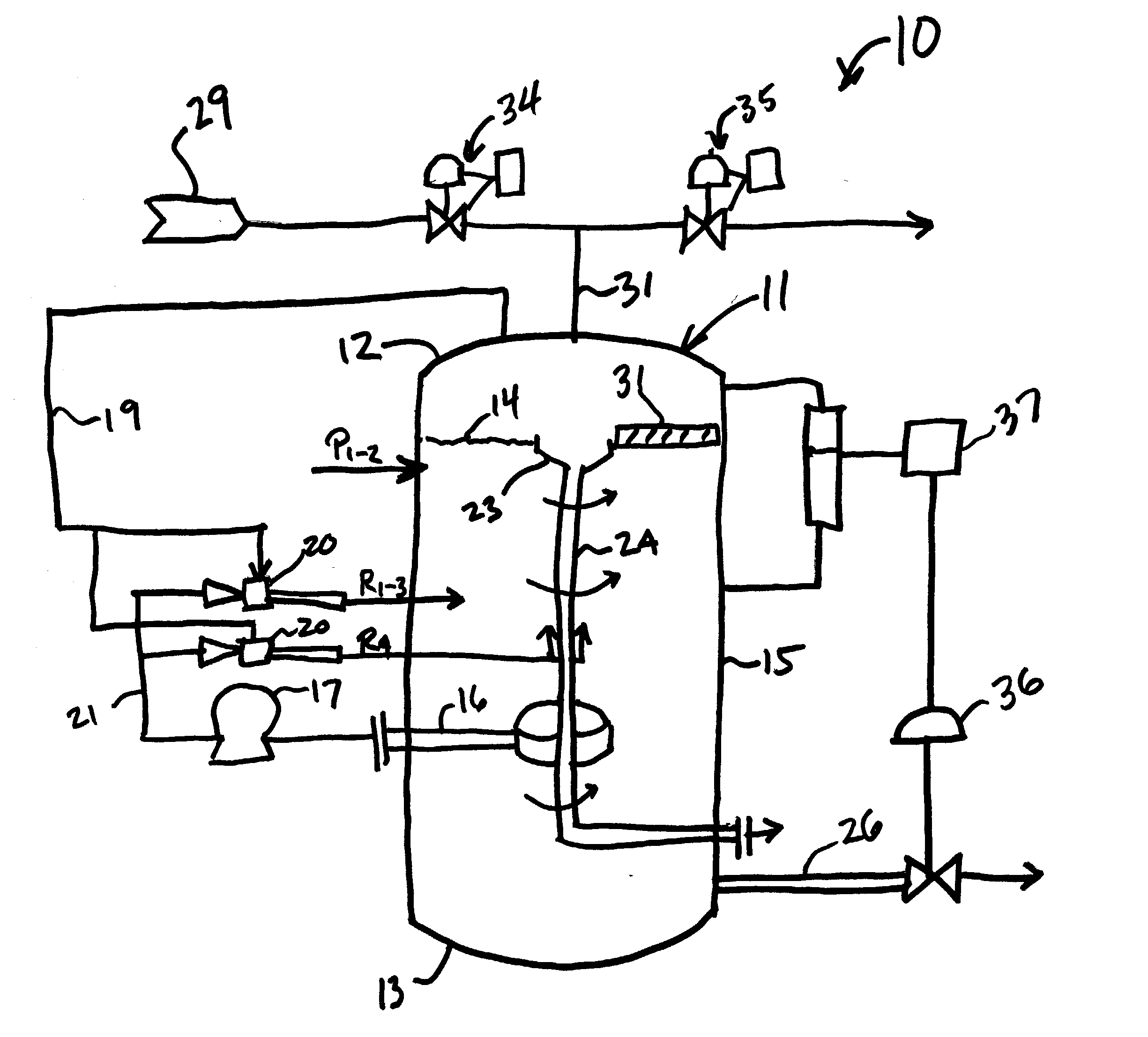

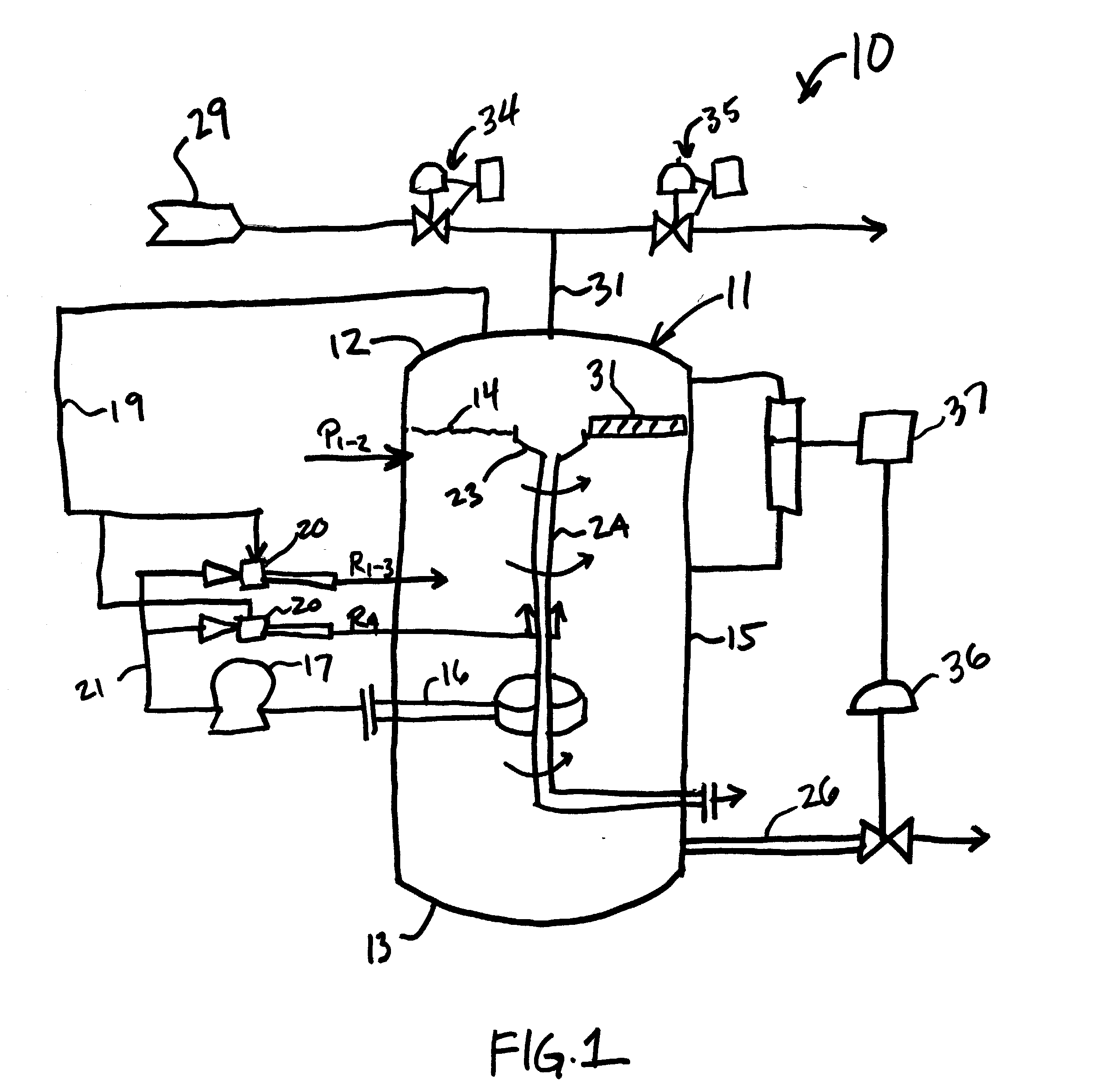

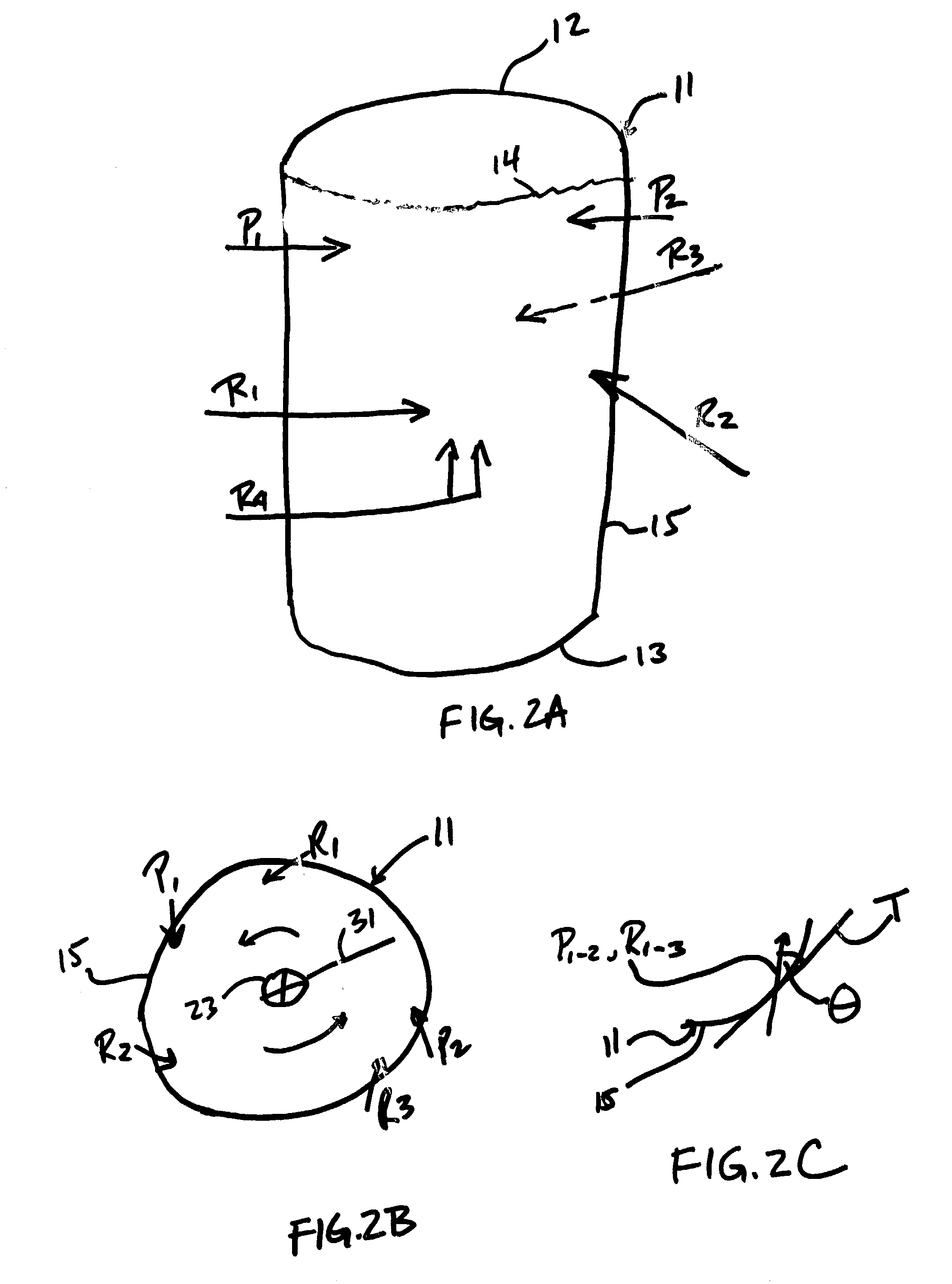

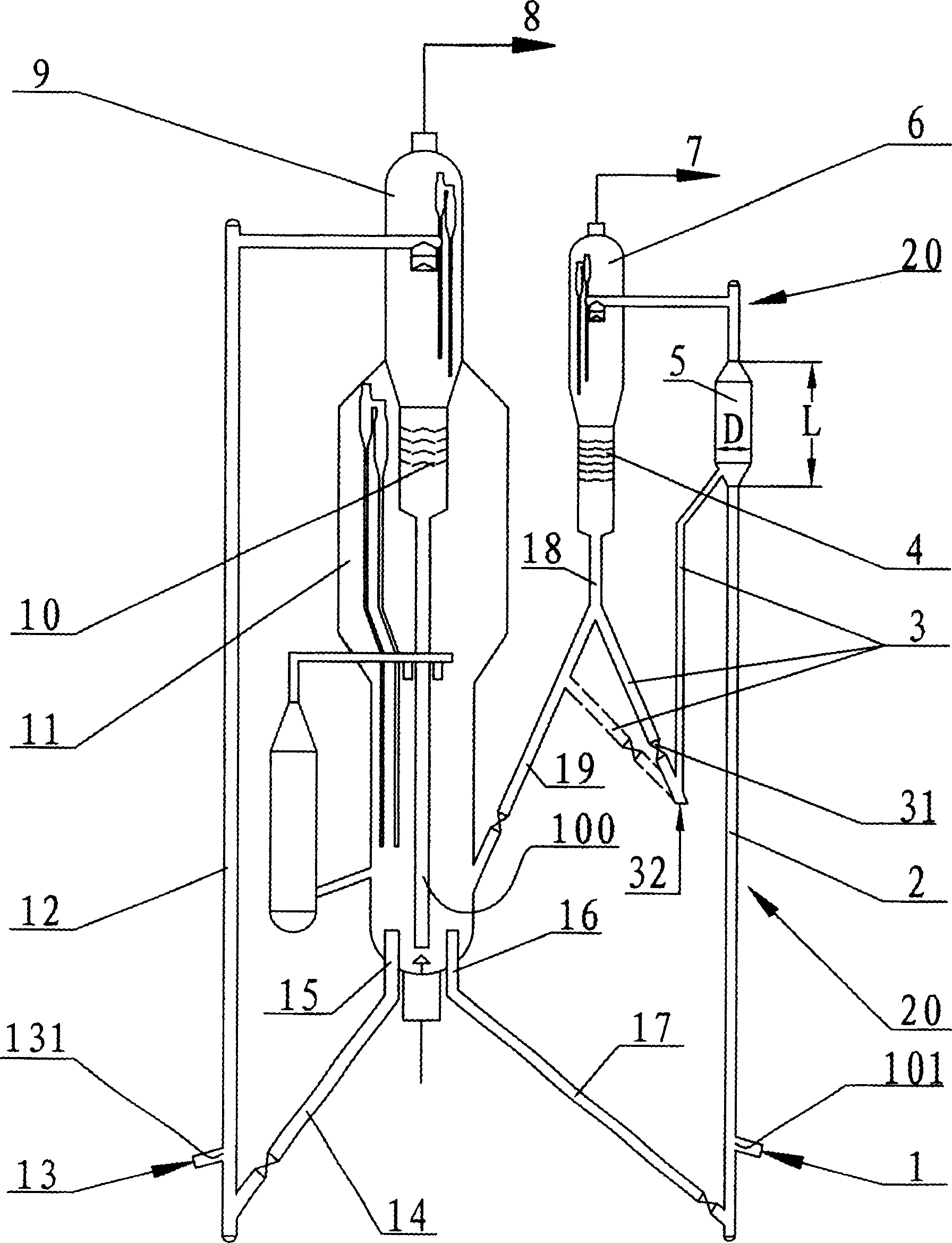

Method and apparatus for removing hydrocarbons from water

InactiveUS20040035799A1Reduce hydrocarbon contentEncourage cyclonic flowReversed direction vortexFlotationWater treatment systemMarine engineering

An improved production water treatment system and method are disclosed. The treatment apparatus includes a vertically oriented vessel with tangentially disposed injection nozzles including one or more injection nozzles for the introduction of production water and one or more injection nozzles for the introduction of recycled water from the vessel and a sparge gas. The tangential orientation of the injection nozzles creates a cyclonic flow within the vessel for improved sparge gas bubble / hydrocarbon contact. A hydrocarbon-rich layer migrates to the top surface of the liquid in the vessel where it is removed about a center axis of the vessel. The resulting hydrocarbon-lean production water has a sufficiently low hydrocarbon content that it is eligible for more intensive processing, such as with organophillic clay cartridges.

Owner:AMCOL INTERNATIONAL CORPORATION

Desulfurization method and novel sorbents for same

InactiveCN1382201AOctane dropReduce hydrocarbon contentSolid sorbent liquid separationAlkali metal oxides/hydroxidesParticulatesSorbent

Provided is a particulate sorbent composition comprising a zinc titanate support loaded with a promoter metal in a substantially reduced valence state selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium, or mixtures thereof , for desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by contacting said feed stream in a desulfurization zone with a particulate adsorbent composition and then subjecting the resulting low sulfur content The stream is separated from the sulfided sorbent, which is then regenerated and activated before being recycled back to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Desulfurization and novel sorbents for same

InactiveCN1331591COctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesParticulatesPorosity

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

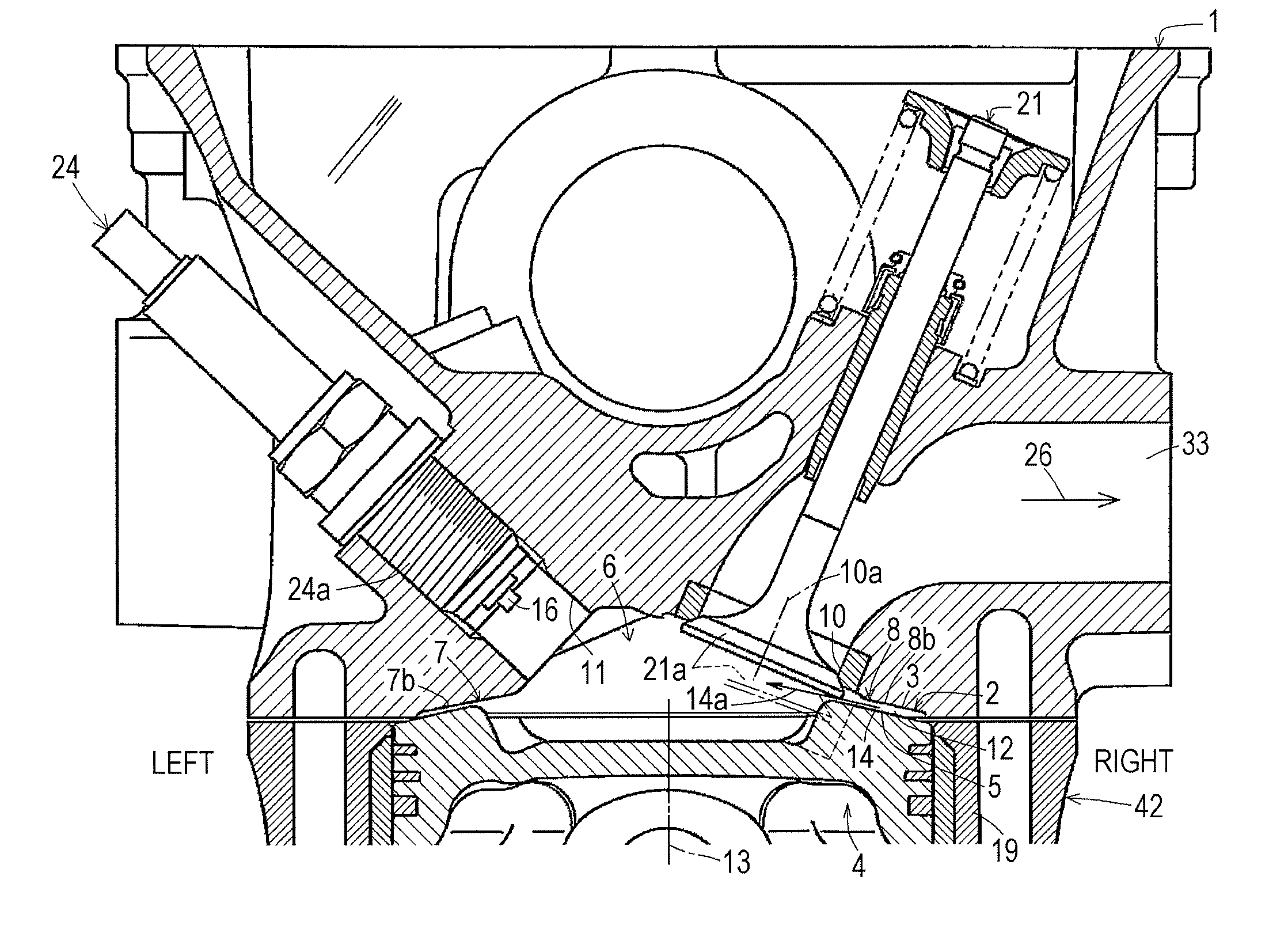

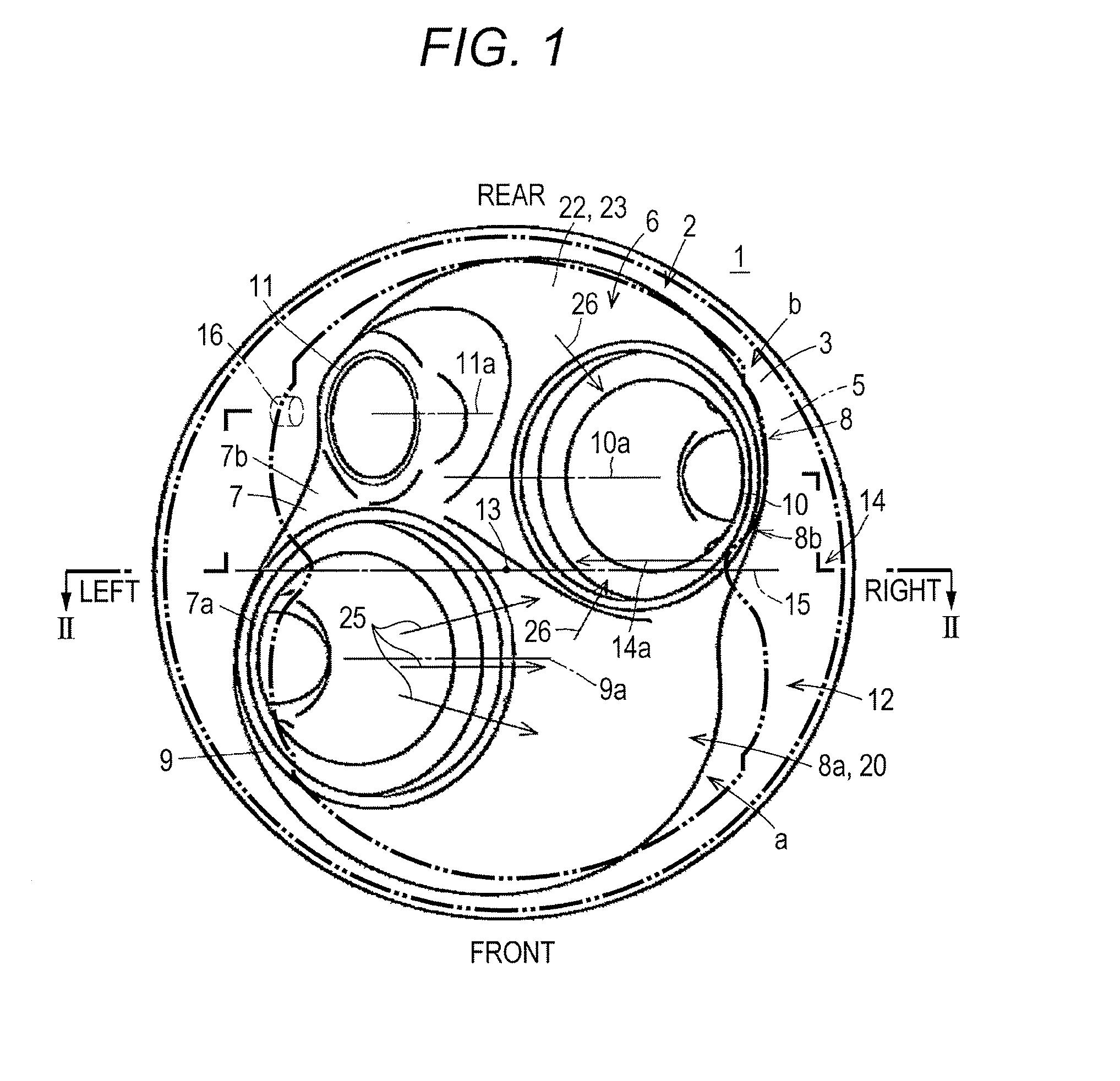

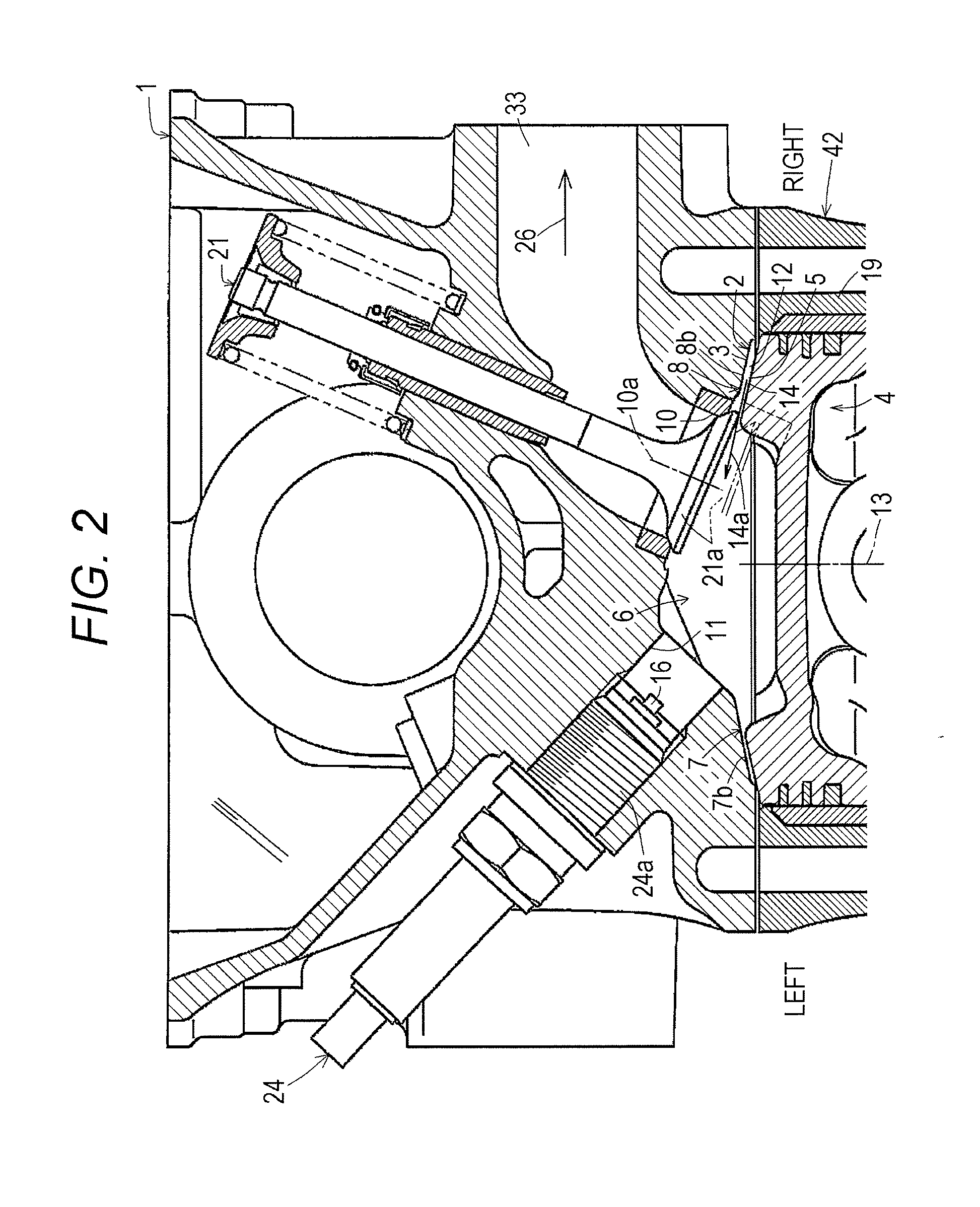

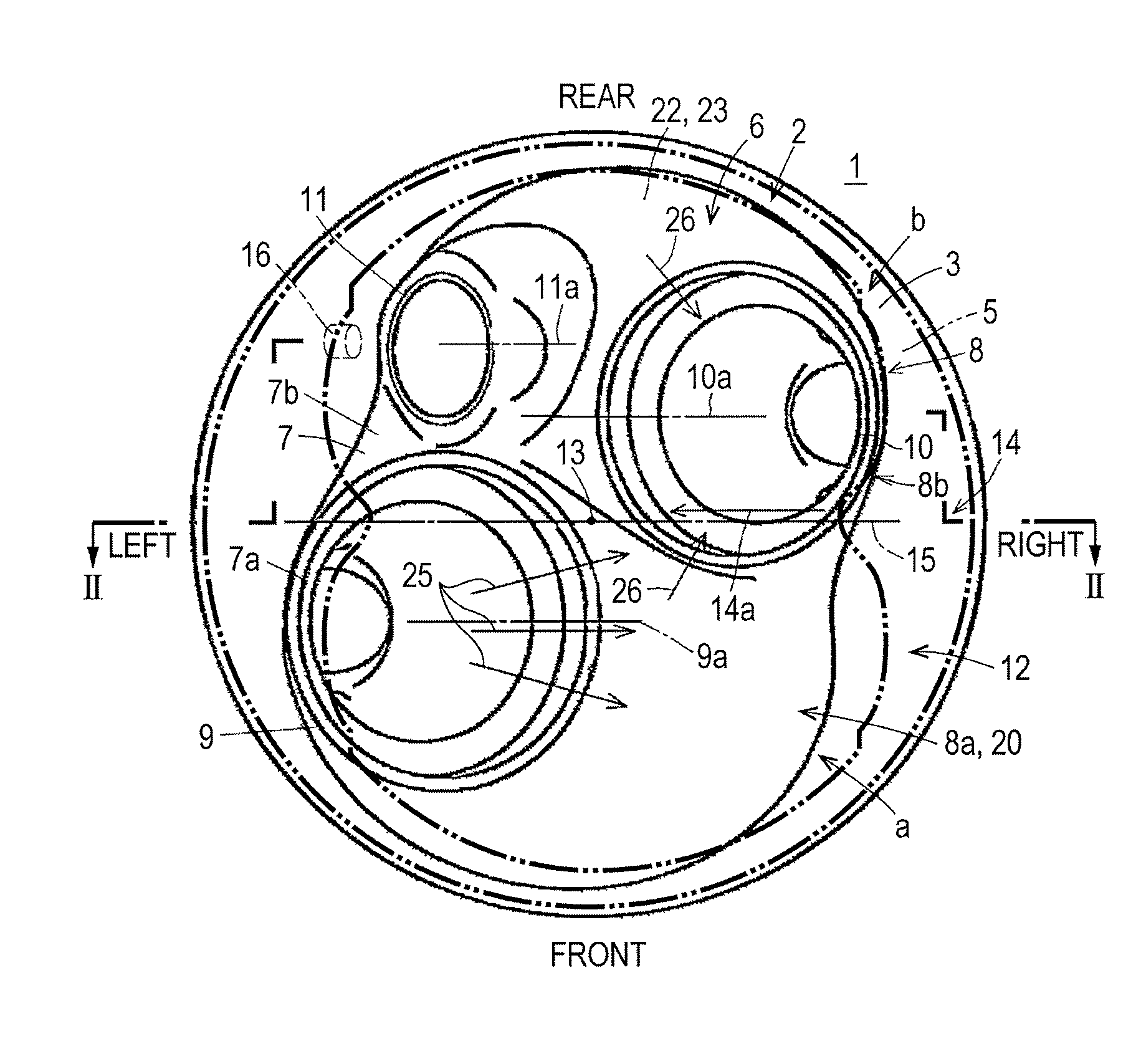

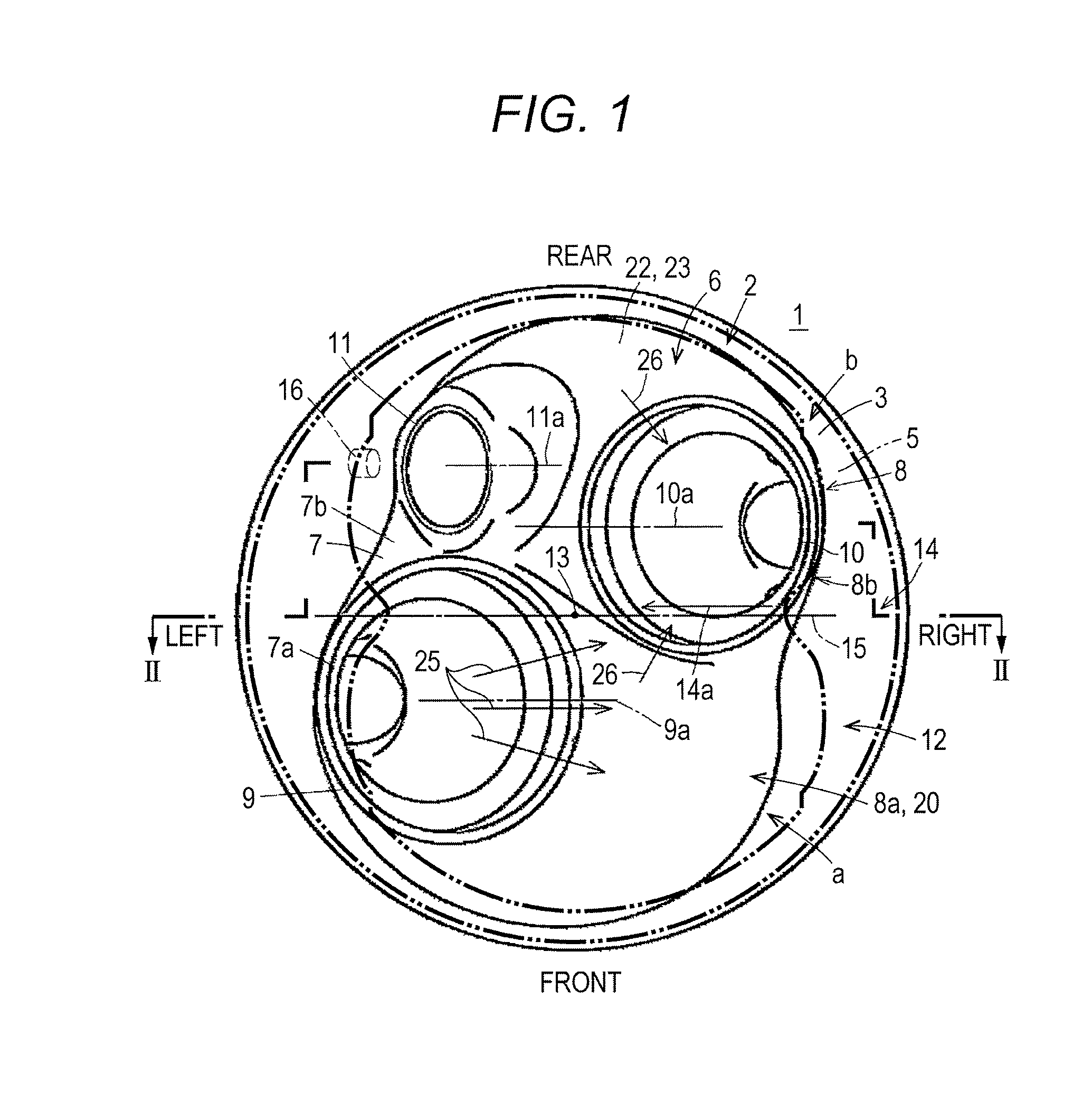

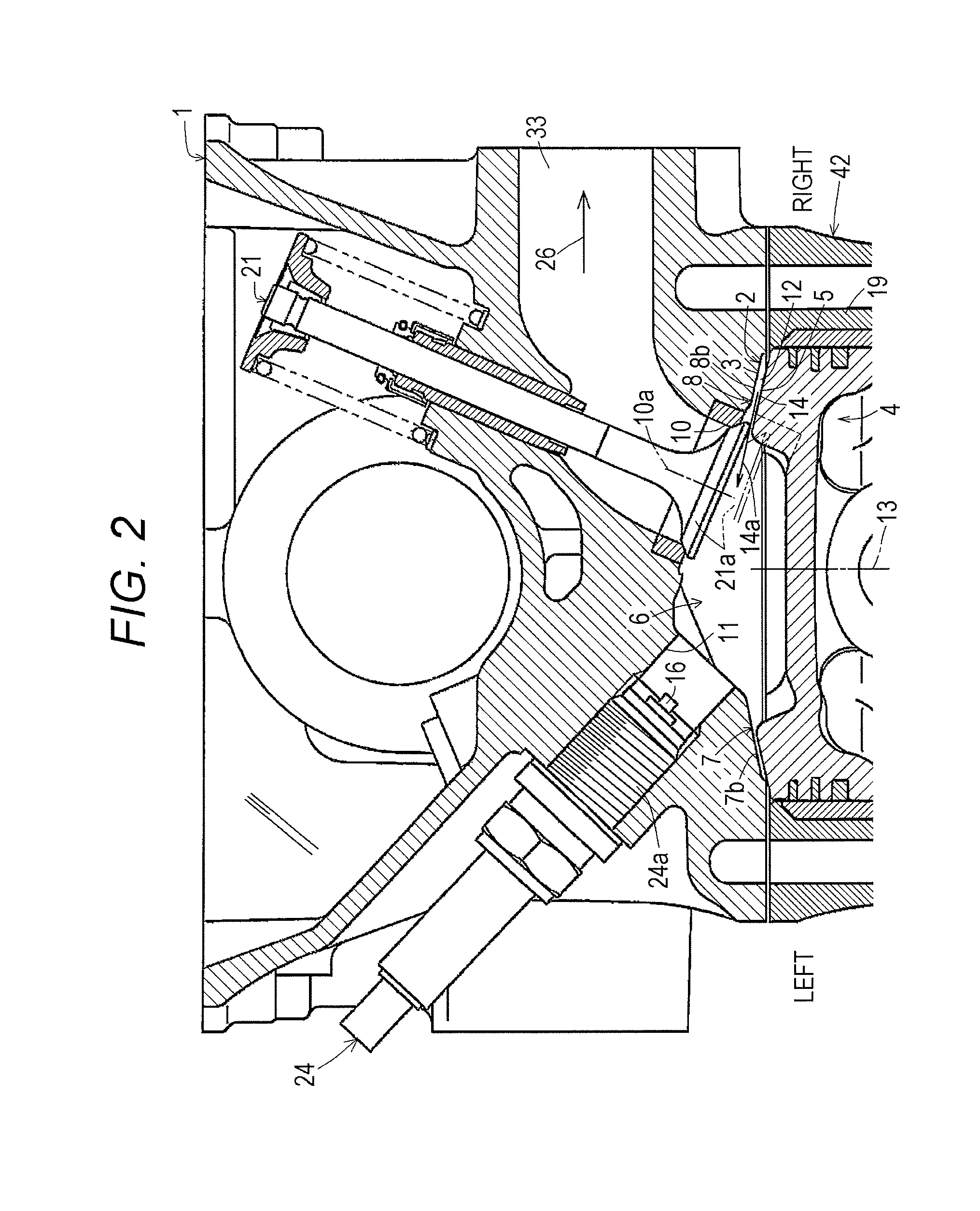

Spark-ignition engine

ActiveUS20140238367A1Reduce hydrocarbon contentInternal combustion piston enginesCombustion chamberExhaust valve

A spark-ignition engine capable of reducing the content of hydrocarbon in exhaust gas is provided. When viewed from a direction parallel to a cylinder center axis, given a central virtual line passing a squish area maximum-width section and the center of a combustion chamber recessed section, and one area a and the other area b divided by the central virtual line, an intake valve port or an exhaust valve port is opened in one area of any opposed section of opposed sections of the combustion chamber recessed section. A spark-plug attachment hole is formed in the other area of the opposed section, such that, when viewed from the direction parallel to the cylinder center axis, a spark discharge section at a tip of a spark plug does not overlap the central virtual line.

Owner:KUBOTA LTD

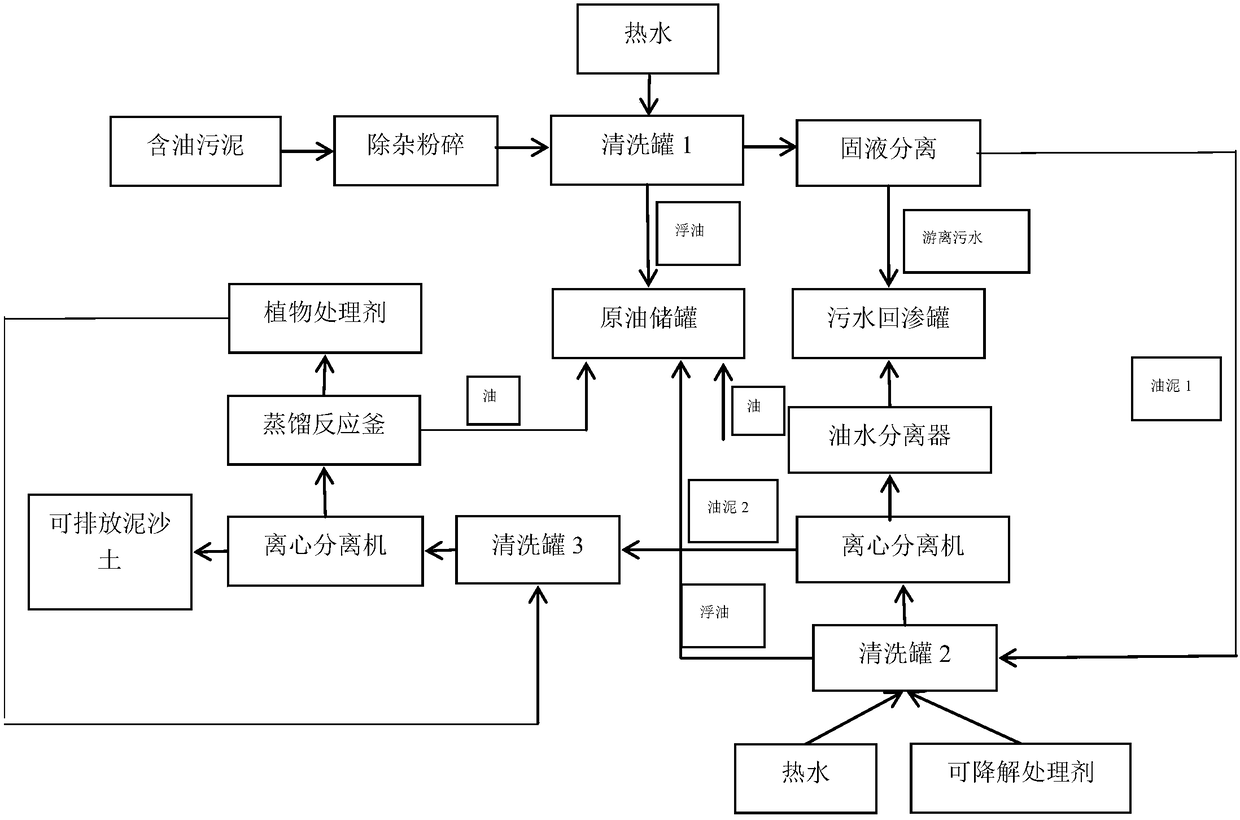

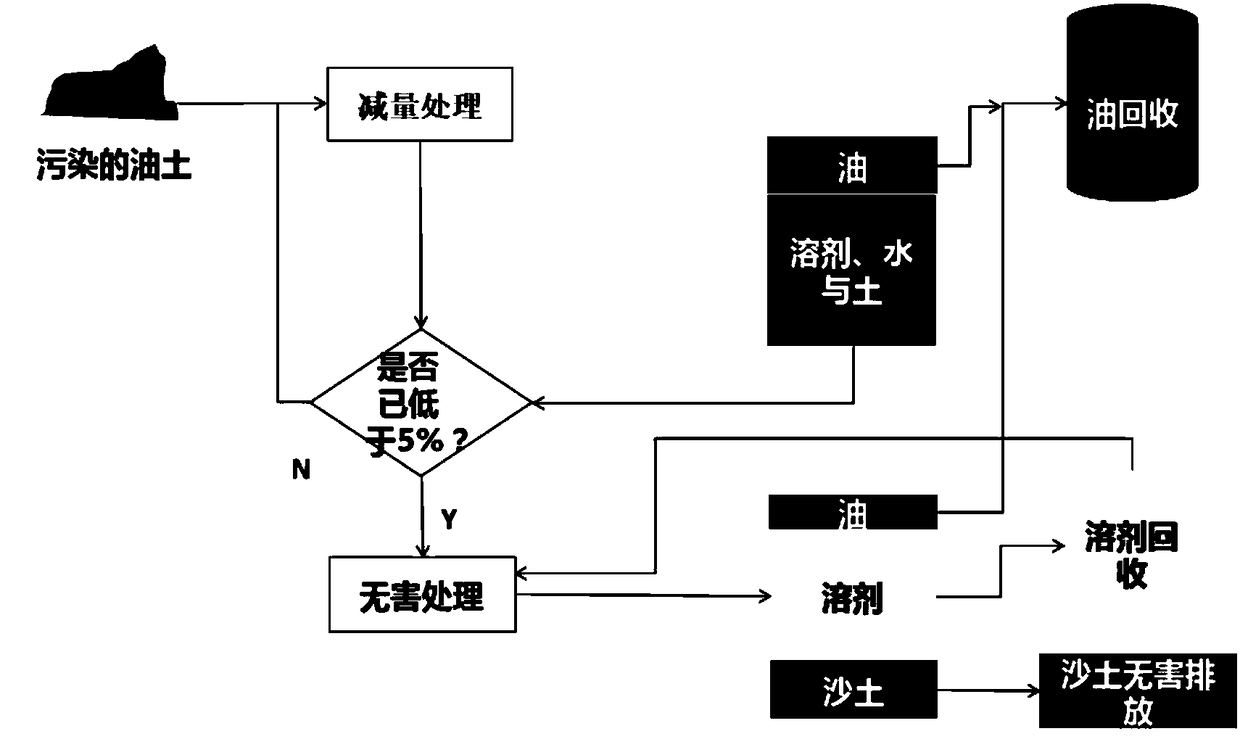

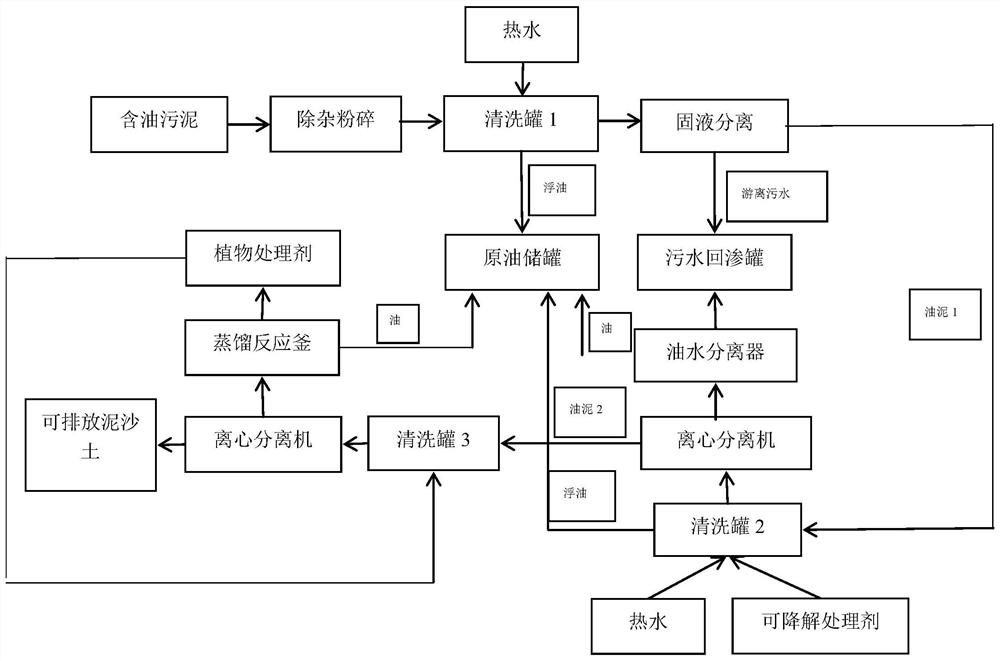

Harmless recycling treatment method for oily sludge

ActiveCN108558155AEasy to operateHigh oil removal rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeWastewater

The invention provides a harmless recycling treatment method for oily sludge. The harmless recycling treatment method comprises the following steps: carrying out crushing treatment on the oily sludge;uniformly blending the oily sludge with water and stirring; after standing and layering, overflowing and separating out upper-layer floating oil to a petroleum recycling tank; treating a residual solid-liquid phase and carrying out centrifugal solid-liquid separation to obtain free water and infiltrating the free water to use; carrying out second-time decrement treatment on a residual solid phase; adding water and a degradable treatment agent and stirring; after standing and layering a system, overflowing the upper-layer floating oil into the petroleum recycling tank; centrifuging and separating a mixture obtained by the decrement treatment and carrying out oil-water separation on an obtained liquid phase; conveying an oil phase into the petroleum recycling tank and conveying the water phase into a sewage infiltration tank for circular utilization; carrying out harmful treatment on the residual solid phase; centrifuging and separating; distilling the liquid phase to recycle a plant treatment agent; conveying residual oil into the petroleum recycling tank and drying residual sludge. The harmless recycling treatment method for the oily sludge is simple to operate and has a wide application range and an extremely high oil removal rate; wastewater is recycled and the treated sewage can be directly used for farmland planting.

Owner:任航

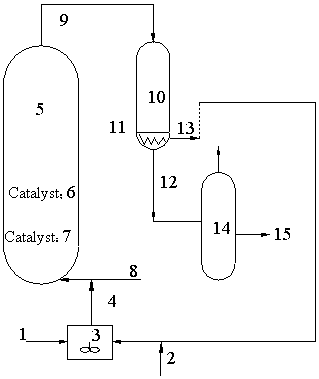

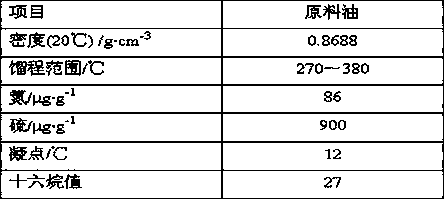

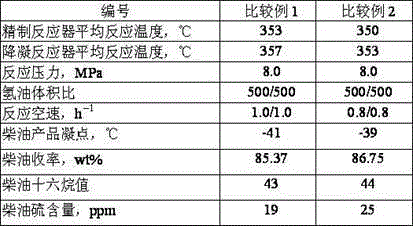

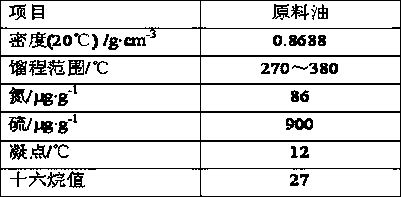

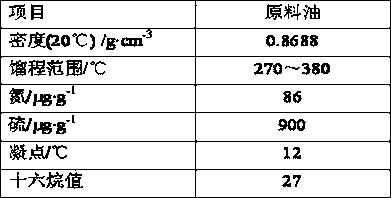

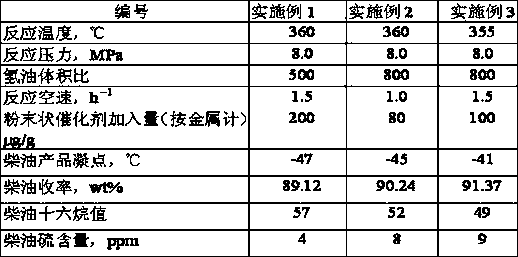

Inferior diesel pour-point depressing modification method

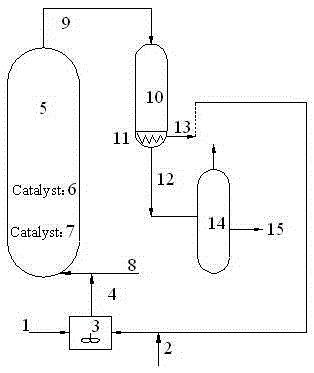

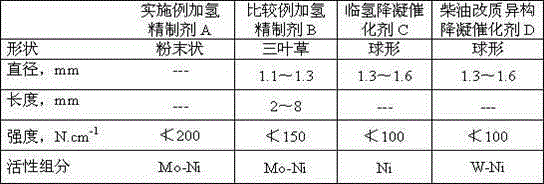

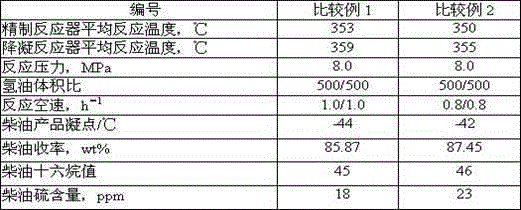

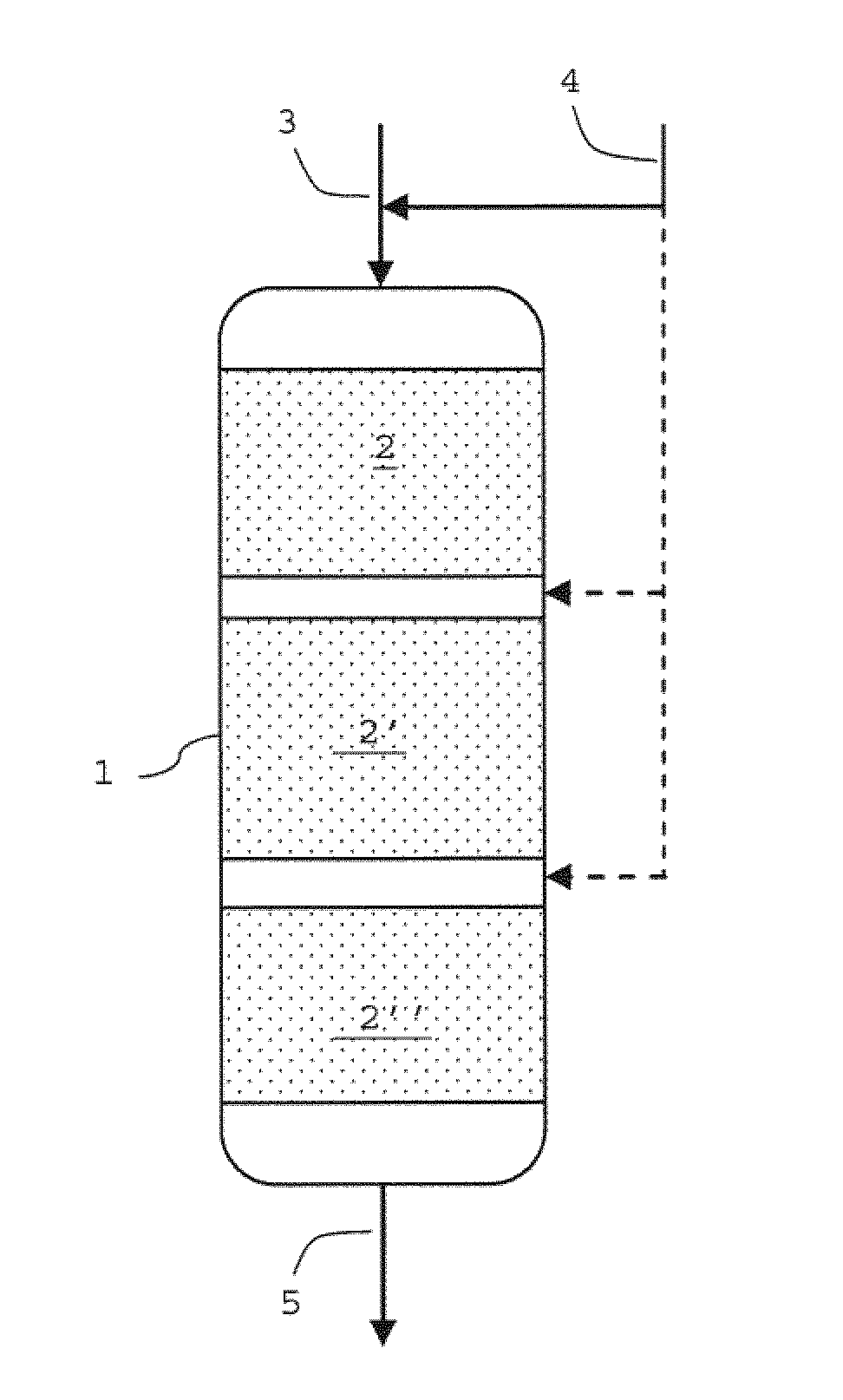

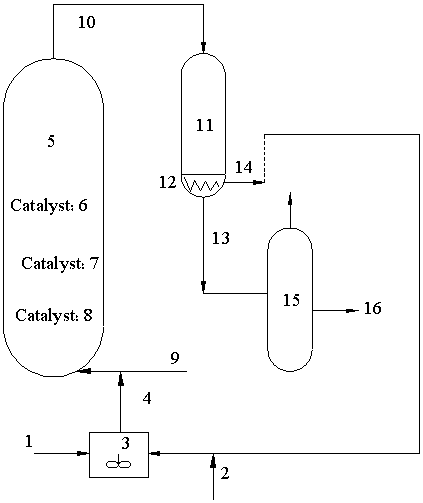

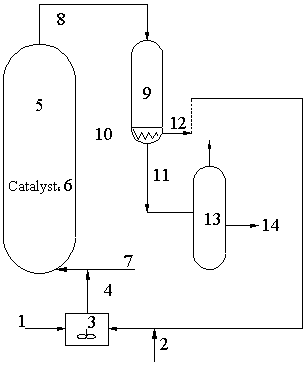

ActiveCN106675643ARealize comprehensive utilizationQuality assuranceTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionPour point

The invention discloses an inferior diesel pour-point depressing modification method, which comprises the following contents: (1) an inferior diesel material and a powdery hydrofining catalyst are fully mixed in a mixer to obtain a mixed feed of the catalyst and the raw oil; (2) the mixed feed and hydrogen enter a boiling-bed reactor from the bottom of a reactor filled with a mixture of a hydrodewaxing catalyst and a hydro-upgrading catalyst to undergo a hydrogenation reaction; (3) the reaction product is charged out of the top of the boiling-bed reactor and then enters a stable reactor to supplement hydrofining; and (4) the material undergoes solid-liquid separation, and a liquid phase enters a fractionating system so as to obtain a diesel product with high quality, low pour point, low sulfur content and high cetane number. According to the method, the backmixing characteristic of the boiling-bed reactor is fully utilized, and cooling and hydrofining of the hydrodewaxing process and temperature rising of the hydro-upgrading process are reasonably utilized. Therefore, the diesel with low pour point and ultra-low sulfur content is produced, cetane number is raised, hot-spot temperature of the device is reduced, running period is prolonged, and operation expenses are saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

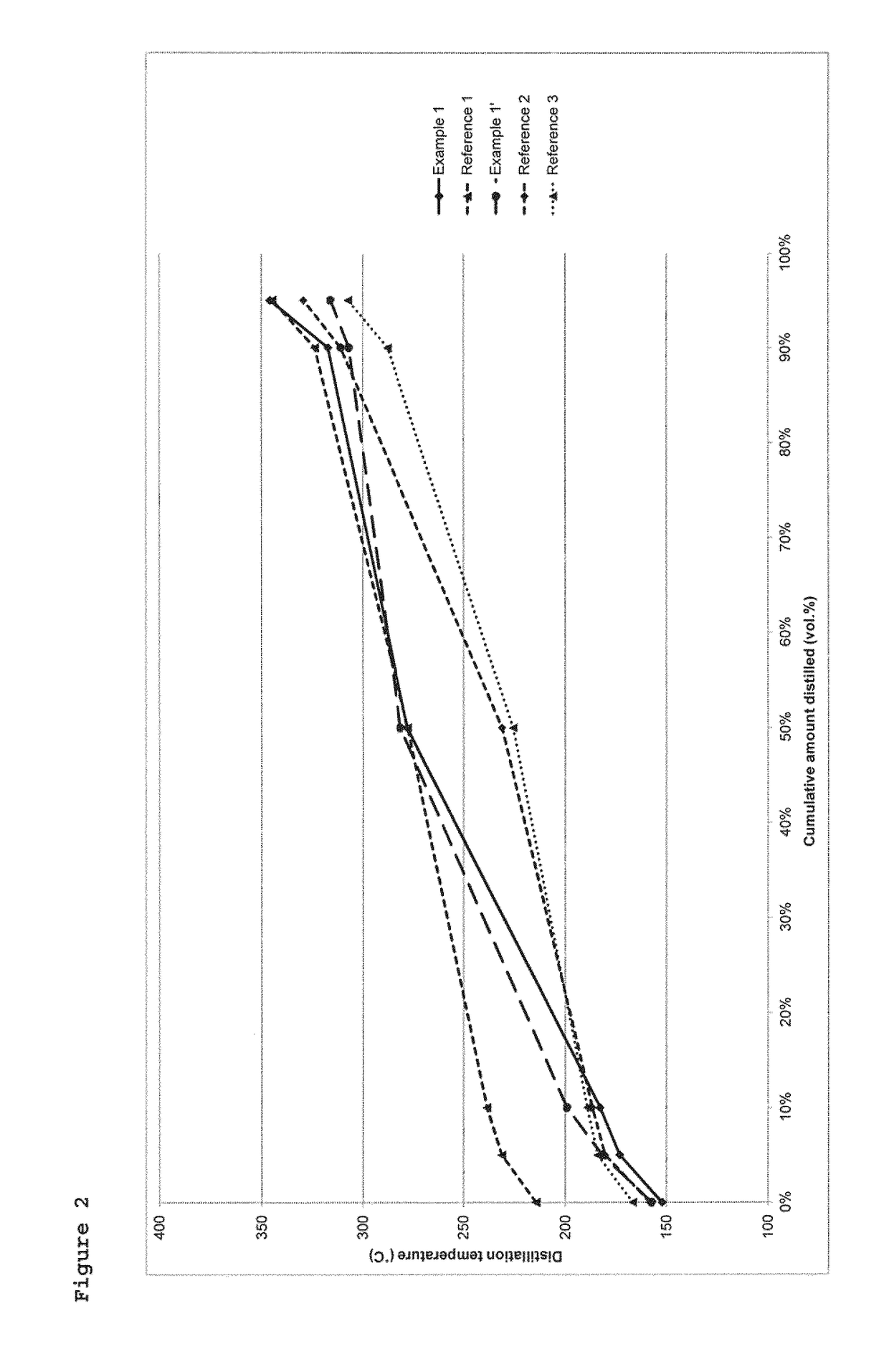

Renewable hydrocarbon composition

ActiveUS20160046872A1High normal hydrocarbon contentLow oxygenFatty acid hydrogenationHydrocarbon by hydrogenationAlkaneOxygen

The present invention provides a composition comprising 10-40 mass! of C8-30 linear alkanes, up to 20 mass % of C7-20 aromatic hydrocarbons, at least 90 mass % of which are monoaromatic, and no more than 1 massl in total of oxygen containing compounds; wherein the total amount of C8-30 alkanes in the composition is 50-95 mass % (and the total amount of C8-30 alkanes, C7-20 aromatic hydrocarbons and C8-30 cycloalkanes is at least 95 massl; and wherein the amounts are based on the mass of the composition. Also provided is a method for producing the composition comprising the step of hydroprocessing a biological feedstock using a catalyst and the step of fractionating the product of the hydroprocessing step.

Owner:UPM-KYMMENE OYJ

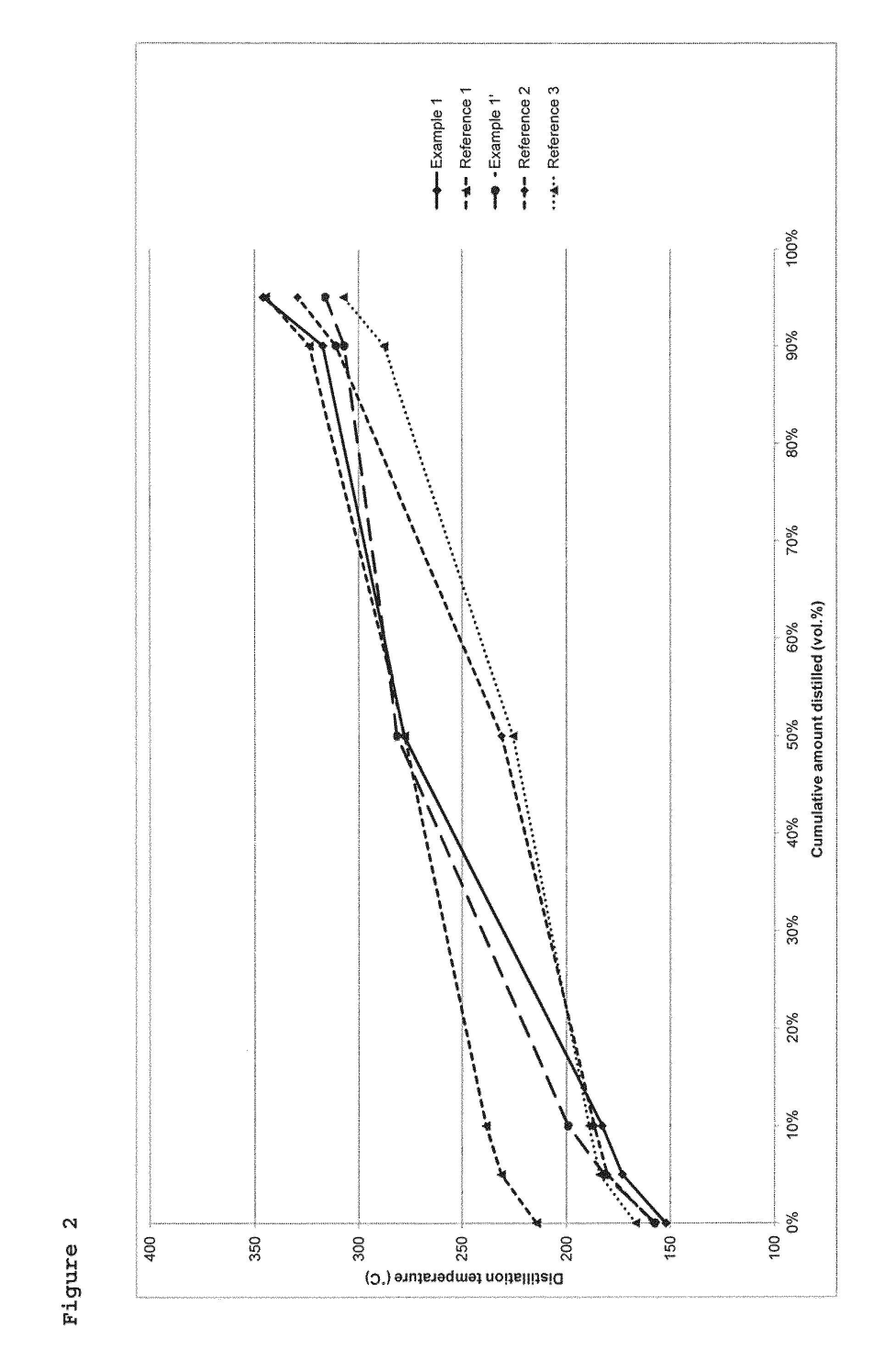

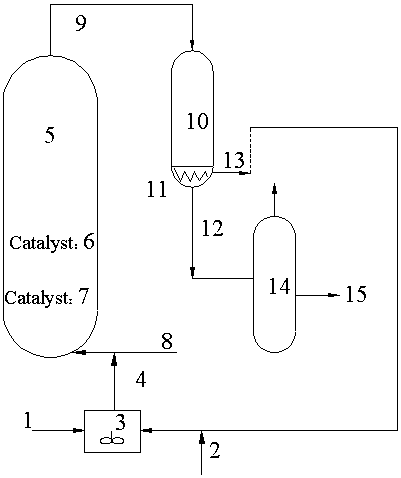

Coal tar full-fraction fluidized bed-fixed bed combined treatment process

ActiveCN111378490AIncrease temperatureLow viscosityTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a coal tar full-fraction fluidized bed-fixed bed combined treatment process. The combined treatment process comprises the following steps: feeding a full-fraction coal tar rawmaterial and an auxiliary agent into a pretreatment tank for mixing; carrying out liquid-solid separation after mixing treatment; a liquid-phase material obtained after separation enters a fluidized bed hydrogenation reaction unit for a hydrogenation reaction; feeding the obtained reaction outflow into a separation tank to be subjected to gas-liquid separation, thus forming a gas-phase material and a liquid-phase material after separation, and then separating the liquid-phase material into a first liquid-phase material and a second liquid-phase material, returning the first liquid-phase material to the pretreatment tank; feeding the second liquid-phase material to a fixed bed hydrogenation reaction unit for hydrogenation reaction; and fractionating the reaction outflow to prepare naphtha,diesel oil and hydrogenated tail oil. The process provided by the invention can realize efficient utilization and long-period operation of coal tar resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

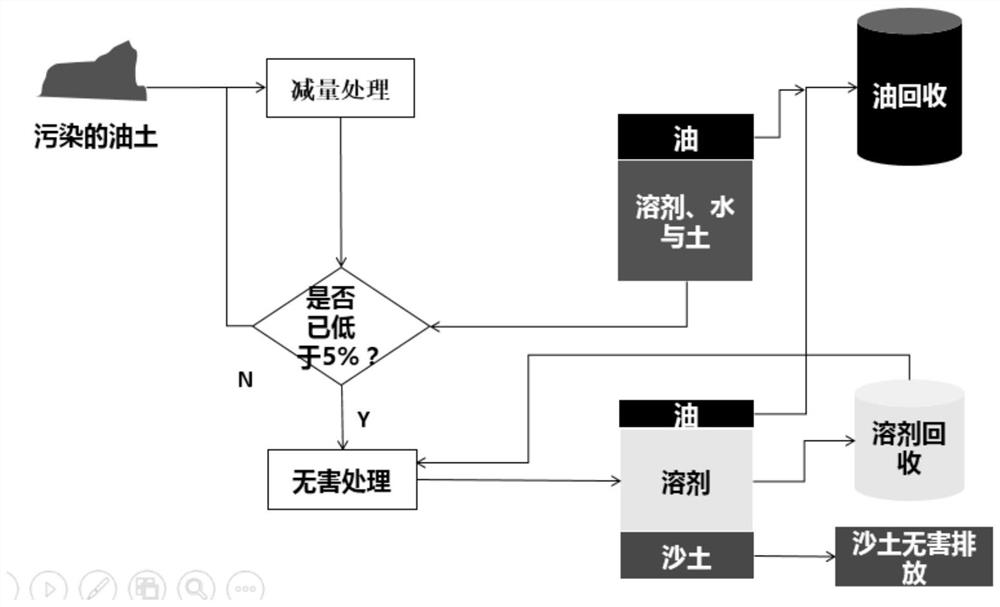

Separation of hydrocarbons from inorganic material

InactiveCN105670678AReduce hydrocarbon contentReduce or eliminate the needRefining by heating/coolingRefining by water treatmentCavitationRinse water

The invention relates to an apparatus for separating hydrocarbons from solid particles, wherein the apparatus comprises a slurry inlet for receiving a slurry comprising water, hydrocarbons and solid particles, a water supply for rinsing water, and a slurry outlet. The apparatus further comprises a plurality of nozzles configured to provide rinsing water as droplets with sufficient speed to induce cavitation in the slurry, and separating means for extracting a liquid containing water and hydrocarbons from the slurry and a separate liquid outlet for the extracted liquid.

Owner:ENNOX TECH

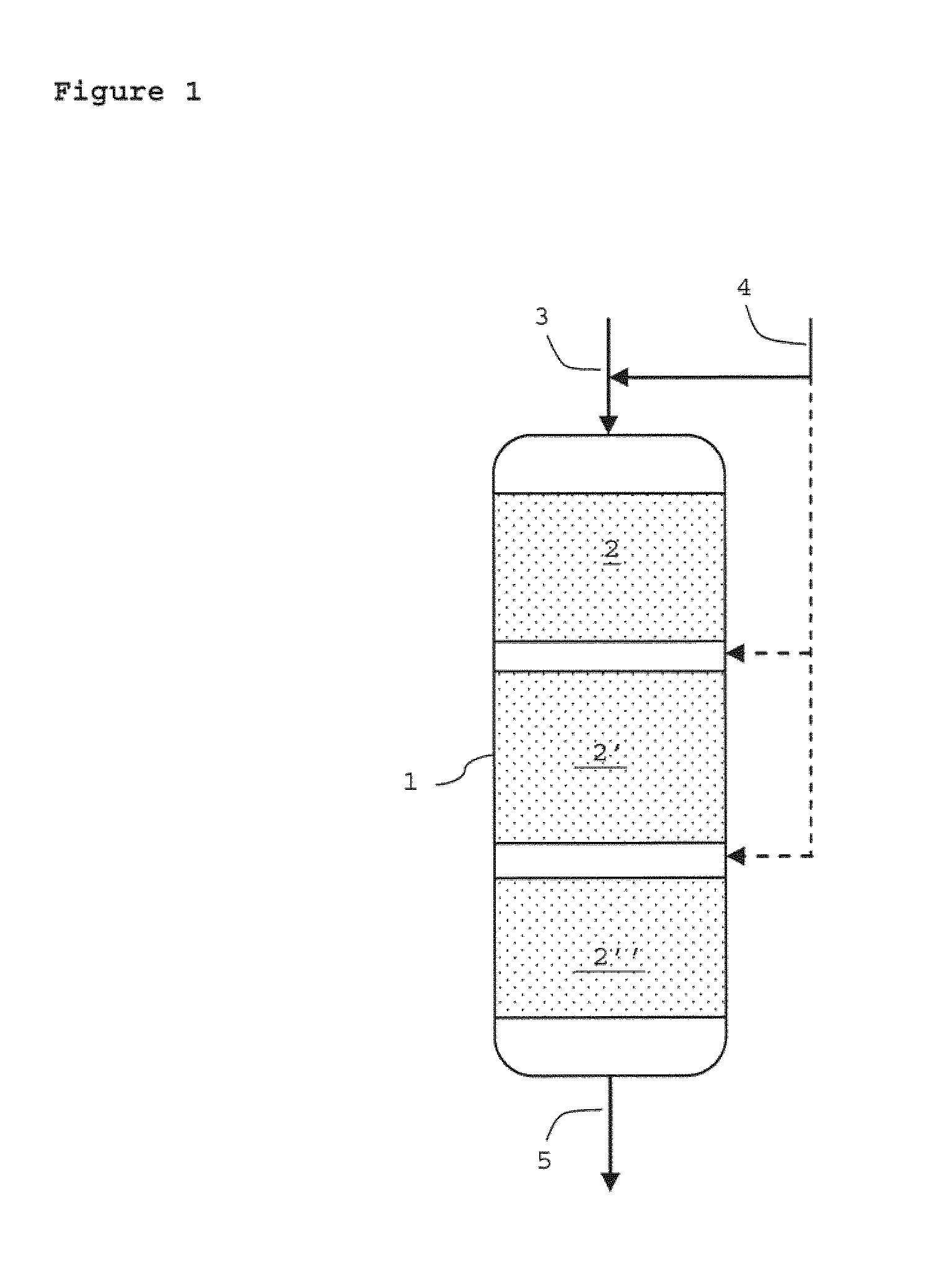

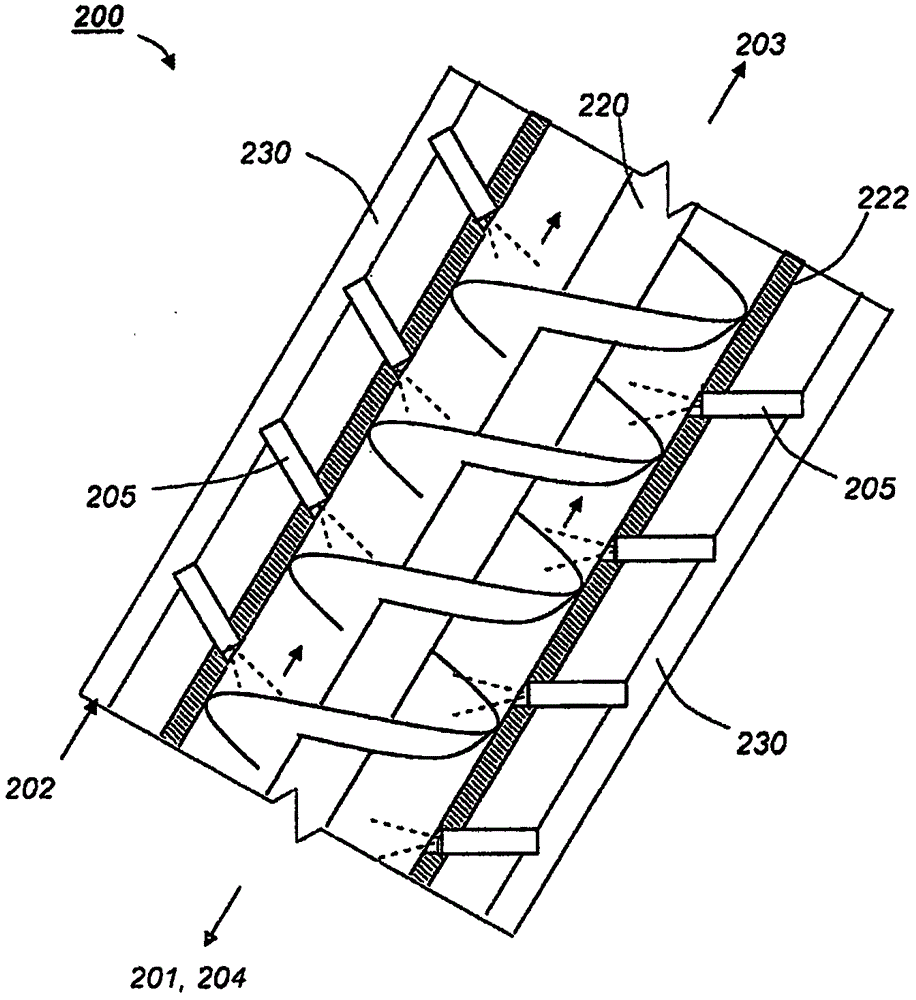

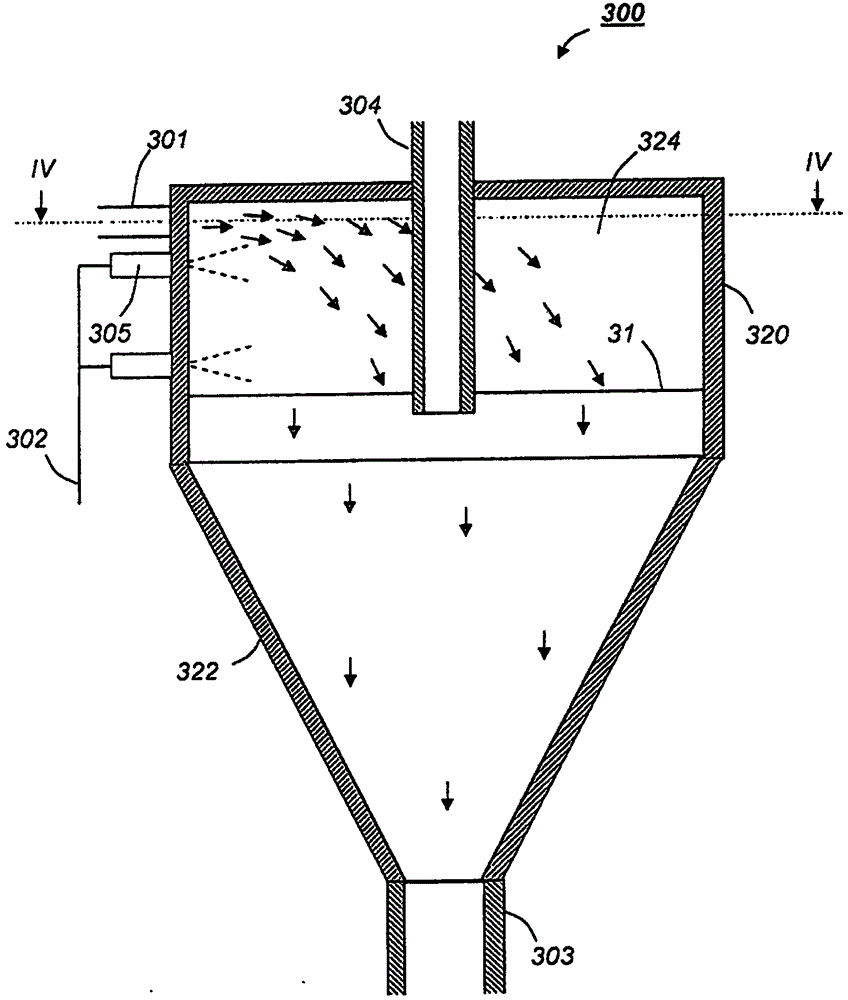

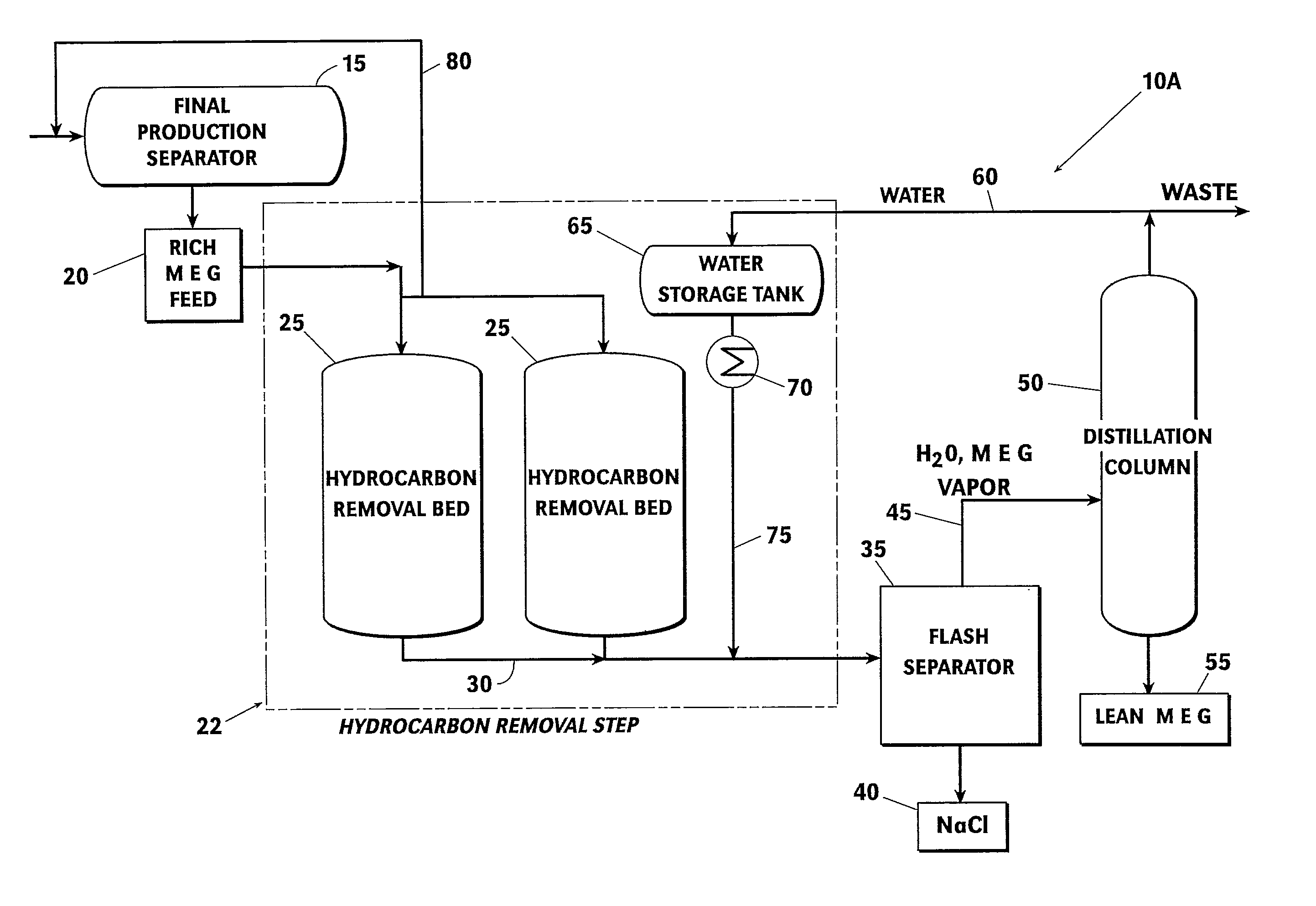

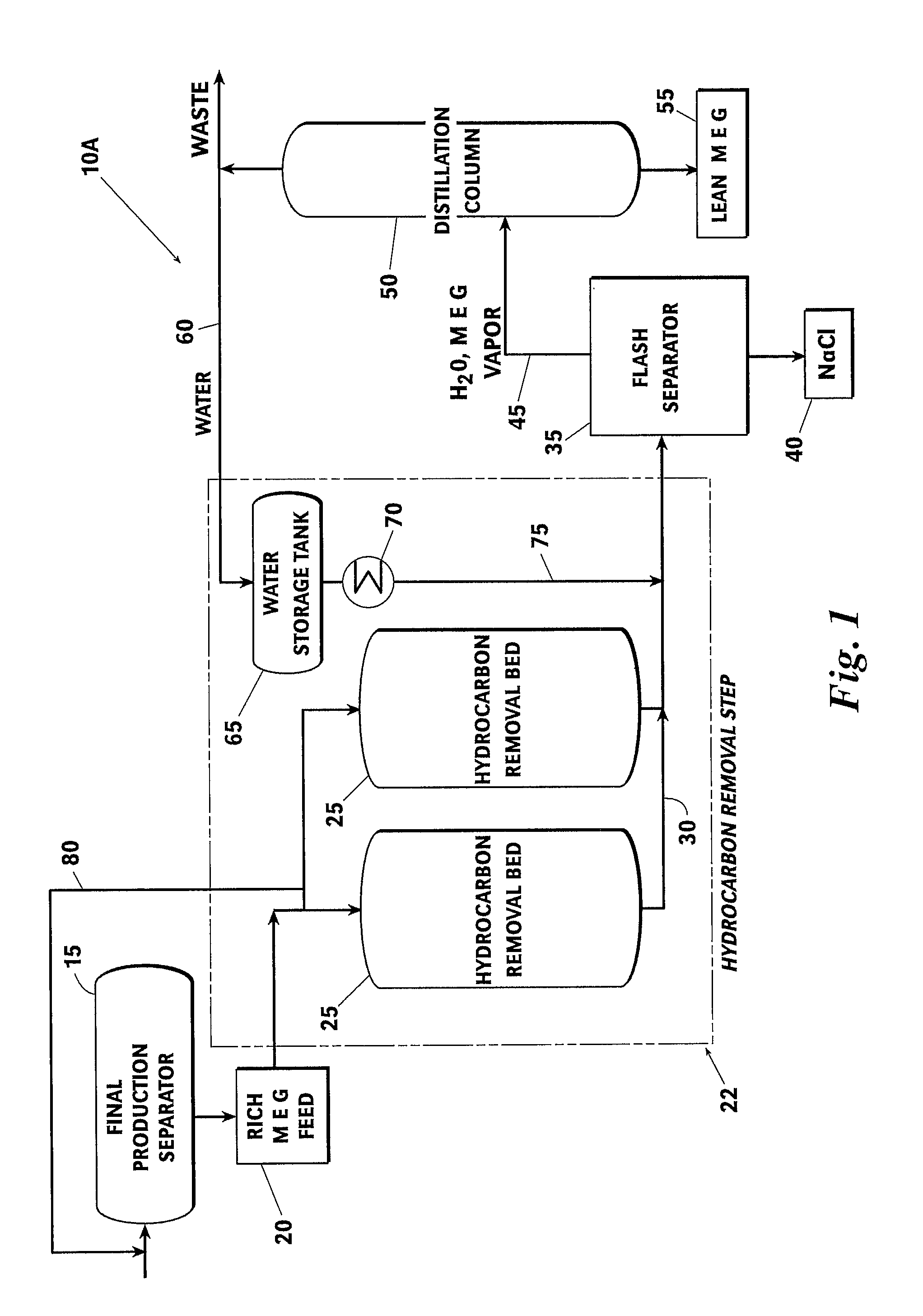

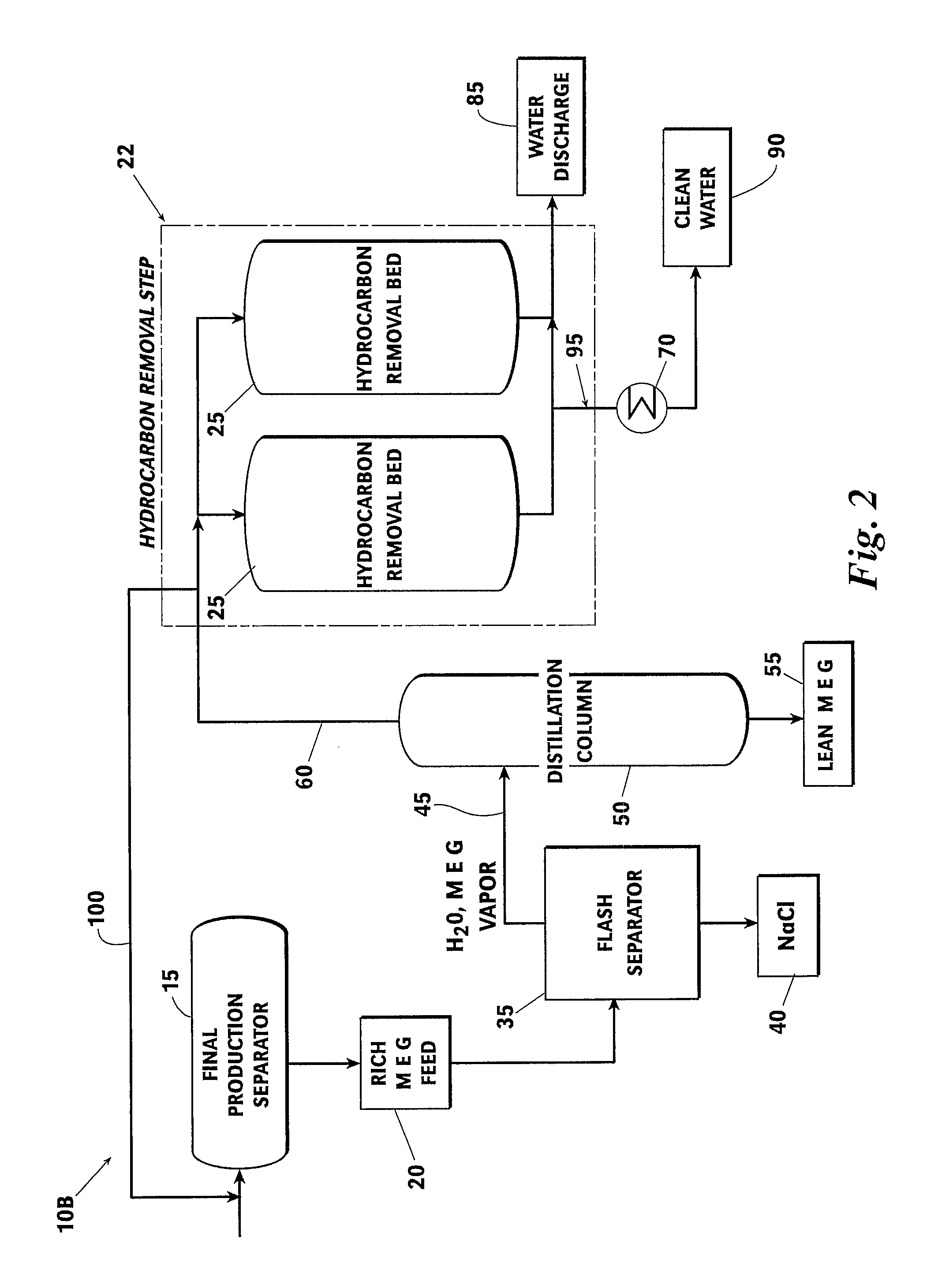

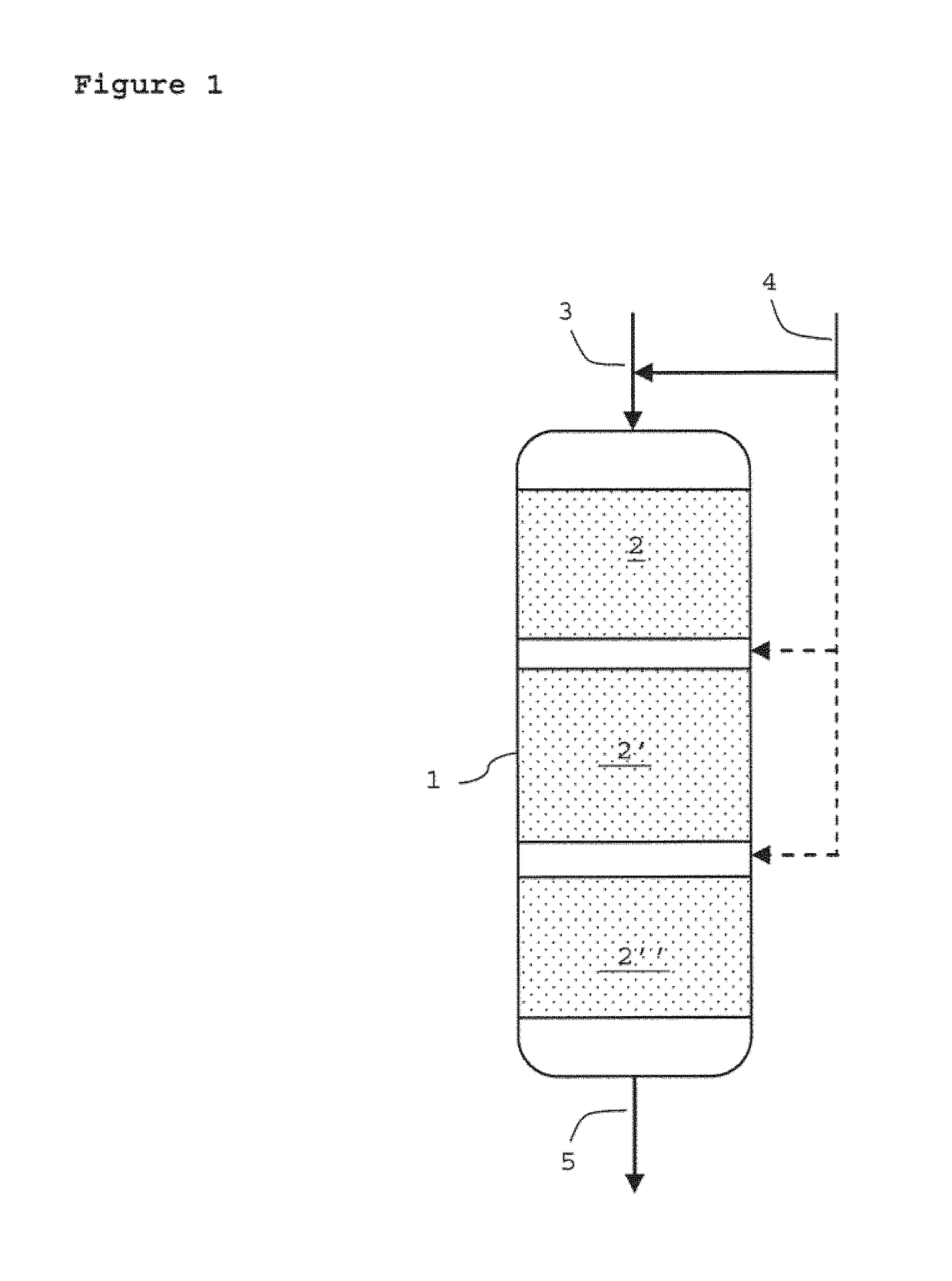

Hydrocarbon removal from gas process feed streams by regenerable filters

ActiveUS8808546B2Reduce hydrocarbon contentReduced footprintGas treatmentIon-exchanger regenerationStream flowFractionating column

A system and process for removing hydrocarbons from a gas process feed stream is presented. The treatment process may be, but is not limited to, glycol dehydration, amine sweetening, and MEG reclamation. As an example, a hydrocarbon removal bed containing a solid adsorbent material adsorbs the hydrocarbons in a rich MEG feed stream as it passes through the hydrocarbon removal bed. After the hydrocarbons have been removed, the feed stream flows through a flash separator and a distillation column to reclaim MEG. Alternatively, the hydrocarbon removal bed may be used after the MEG reclamation process to remove hydrocarbons in the distilled water from the distillation column. Spent solid adsorbent material may be regenerated in place.

Owner:CAMERSON INT CORP

Double lift pipe catalytic cracking method and device for modifying inferior patrol

ActiveCN1298812CReduce olefin contentReduce hydrocarbon contentCatalytic crackingOil processingGasoline

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

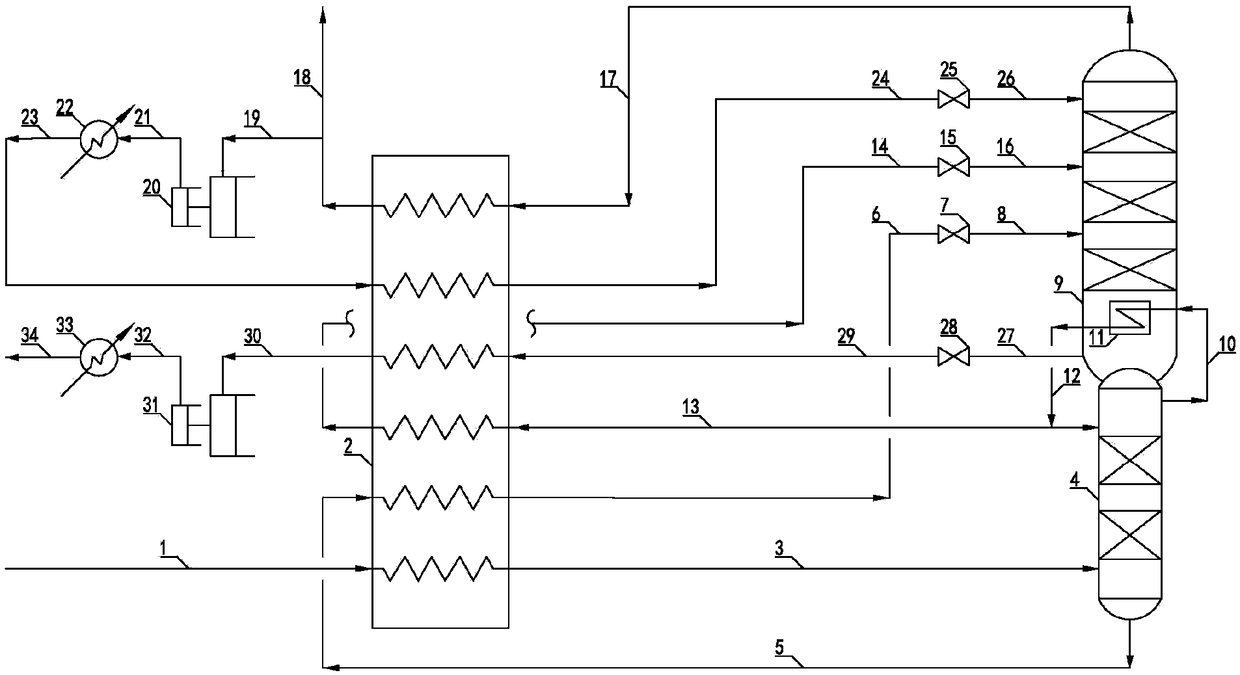

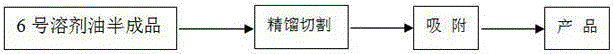

Process apparatus and method of nitrogen-containing natural gas dual-column cryogenic denitrification

PendingCN108384593AReduce hydrocarbon contentReduce energy consumptionSolidificationLiquefactionLiquid hydrocarbonsProduct gas

The invention discloses a process apparatus and method of nitrogen-containing natural gas dual-column cryogenic denitrification. The process apparatus comprises a denitrification cold box and a high-pressure denitrification column connected through a pipeline; a bottom outlet of the high-pressure denitrification column, the denitrification cold box and the high-pressure denitrification column areconnected in sequence; an upper outlet of the high-pressure denitrification column, a heat exchanger, the denitrification cold box and a low-pressure denitrification column are connected in sequence;a top outlet of the low-pressure denitrification column, the denitrification cold box, an ammonia compressor, a cooler, the denitrification cold box and a top feed port of the low-pressure denitrification column are connected in sequence; a bottom outlet of the low-pressure denitrification column, a fourth throttle valve, the denitrification cold box, a product gas compressor and the cooler are connected in sequence. Compared with the prior art, the process apparatus and method have the advantages the hydrocarbon content in nitrogen is greatly decreased, the purity of removed nitrogen is > / =99% by mol; cold is provided for the system after throttling of denitrified liquid hydrocarbon, external coolant circulation is canceled, and energy consumption of the apparatus is decreased.

Owner:CHINA PETROLEUM ENG & CONSTR +1

Method for modifying the fluorine distribution in a hydrocarbon compound

PendingUS20200140357A1Increase contentHigh fluorine contentPreparation by dehalogenationChemical/physical/physico-chemical processesPtru catalystHydrocotyle bowlesioides

The present invention relates to a process for modifying the fluorine distribution in a hydrocarbon compound, comprising a step of placing in contact between a hydrocarbon compound and a catalytic composition comprising a chromium-based catalyst, said process being performed in a reactor made of a material comprising a base layer made of a material M1 and an inner layer made of a material M2, said base layer and said inner layer being laid against each other, characterized in that the material M2 comprises at least 80% by weight of nickel on the basis of the total weight of the material M2, advantageously at least 90% by weight, preferably at least 95% by weight, in particular at least 99% by weight of nickel on the basis of the total weight of the material M2.

Owner:ARKEMA FRANCE SA

Spark-ignition engine

ActiveUS8997724B2Reduce hydrocarbon contentSparking plugsInternal combustion piston enginesExhaust valveCombustion chamber

A spark-ignition engine capable of reducing the content of hydrocarbon in exhaust gas is provided. When viewed from a direction parallel to a cylinder center axis, given a central virtual line passing a squish area maximum-width section and the center of a combustion chamber recessed section, and one area a and the other area b divided by the central virtual line, an intake valve port or an exhaust valve port is opened in one area of any opposed section of opposed sections of the combustion chamber recessed section. A spark-plug attachment hole is formed in the other area of the opposed section, such that, when viewed from the direction parallel to the cylinder center axis, a spark discharge section at a tip of a spark plug does not overlap the central virtual line.

Owner:KUBOTA CORP

Renewable hydrocarbon composition

ActiveUS10150922B2Highly suitablePoor low temperature propertyFatty acid hydrogenationMolecular sieve catalystAlkaneAromatic hydrocarbon

The present invention provides a composition comprising 10-40 mass! of C8-30 linear alkanes, up to 20 mass % of C7-20 aromatic hydrocarbons, at least 90 mass % of which are monoaromatic, and no more than 1 massl in total of oxygen containing compounds; wherein the total amount of C8-30 alkanes in the composition is 50-95 mass % (and the total amount of C8-30 alkanes, C7-20 aromatic hydrocarbons and C8-30 cycloalkanes is at least 95 massl; and wherein the amounts are based on the mass of the composition. Also provided is a method for producing the composition comprising the step of hydroprocessing a biological feedstock using a catalyst and the step of fractionating the product of the hydroprocessing step.

Owner:UPM-KYMMENE OYJ

A hydrogenation method for increasing the cetane number of inferior diesel oil

ActiveCN106675648BRealize comprehensive utilizationQuality assuranceTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionSulfur

The invention discloses a hydrogenation method for enhancing cetane number of inferior diesel. The method comprises the following steps: (1) sufficiently mixing the inferior diesel raw material and a powdery hydrofining catalyst in a mixer to obtain a catalyst-raw oil feed mixture; (2) adding the feed mixture and hydrogen into an ebullated bed reactor from the reactor bottom filled with a mixture of a hydrodefreezing catalyst and a hydrogenation modification catalyst, and carrying out hydrogenation reaction; (3) discharging the reaction stream containing the powdery hydrofining catalyst out of the top of the ebullated bed reactor into a stable reactor, and carrying out supplementary hydrofining; and (4) carrying out solid-liquid separation on the material obtained in the step (3), and sending the liquid phase into a fractionating system to obtain the high-quality low-pour-point low-sulfur high-cetane-number diesel product. The method reasonably combines the temperature drop in the hydrodefreezing process and the temperature rise in the hydrogenation modification process, thereby lowering the low-pour-point high-cetane-number diesel, lowering the hot-spot temperature of the device and prolonging the operating cycle on the premise of ensuring the high diesel yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

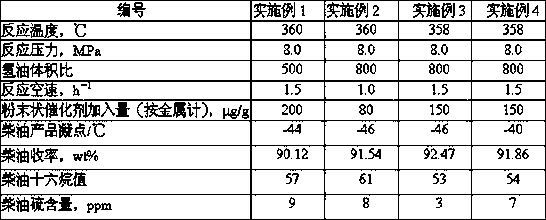

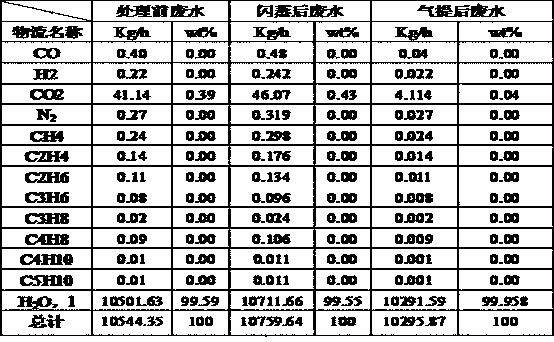

Treatment method of Fischer-Tropsch synthesis recycle gas decarburization wastewater

PendingCN111039479AEasy to operateReduce hydrocarbon contentMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterDecarburization

The invention relates to a treatment method of Fischer-Tropsch synthesis recycle gas decarburization wastewater, which comprises subjecting the wastewater to flash evaporation and striping, and specifically comprises: 1) feeding decarburization wastewater into a flash evaporation tank, carrying out reduced pressure flash evaporation, discharging the gas subjected to flash evaporation from the upper part of a flash evaporation tower, and discharging the wastewater subjected to flash evaporation from the bottom of the tower; 2) feeding the wastewater subjected to flash evaporation into a stripping tower through the upper part of the stripping tower, feeding hydrogen or carbon monoxide or a mixture of the hydrogen and the carbon monoxide into the stripping tower through the lower part of thestripping tower, performing stripping of the wastewater by stripping gas in the stripping tower, discharging water after stripping from the bottom of the tower, and discharging the stripped gas from the top of the tower and returning the discharged stripped gas to a reactor together with flash steam obtained in the step (1). According to the method disclosed by the invention, the comprehensive utilization of wastewater resources is realized while the emission of decarburization wastewater is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

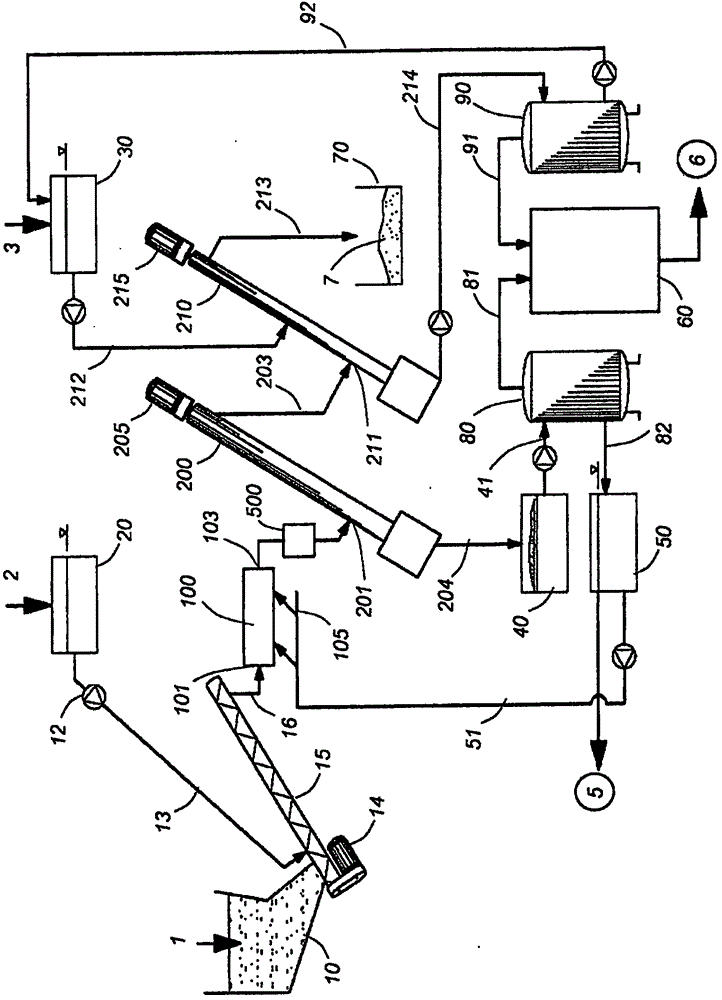

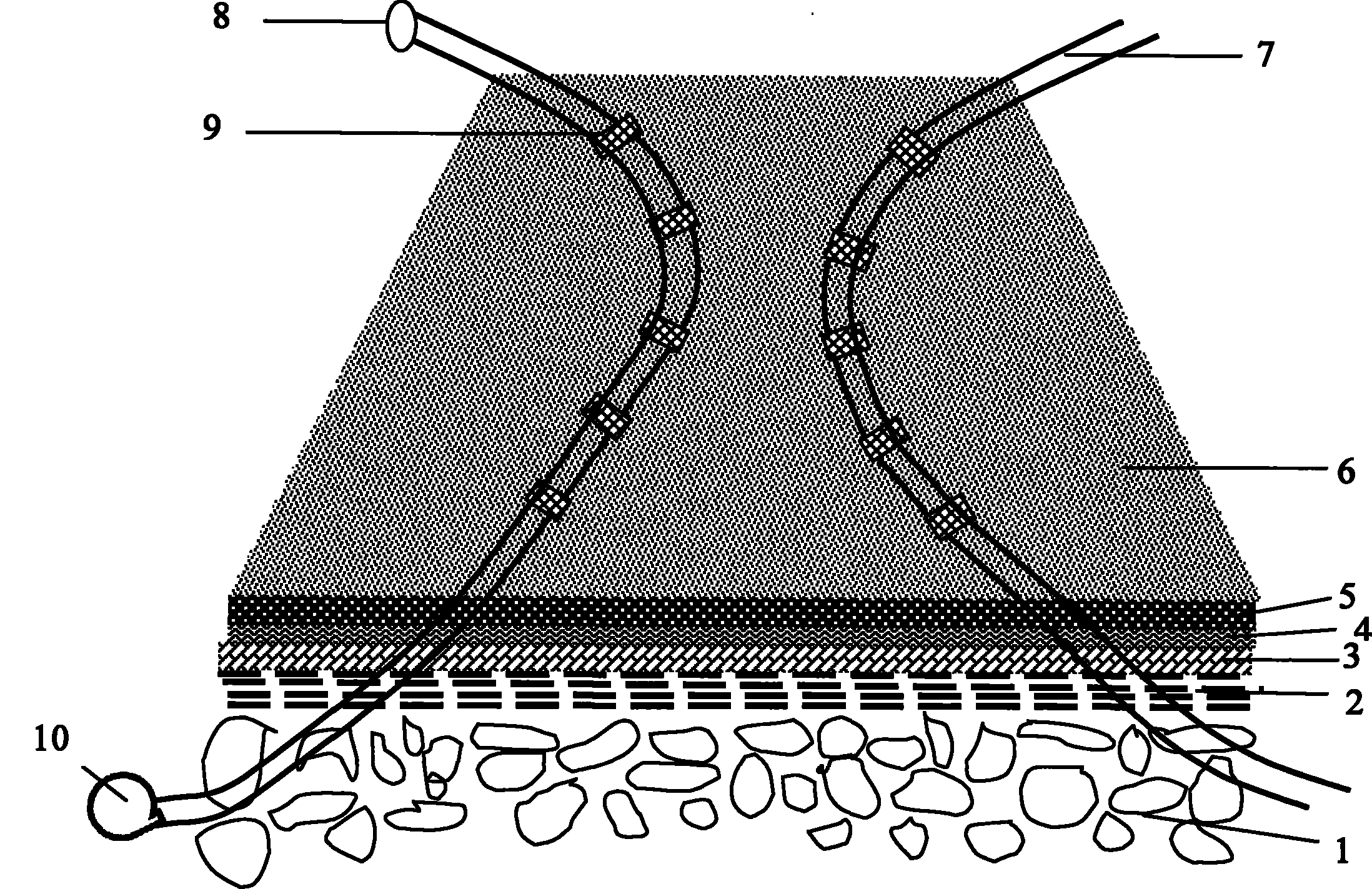

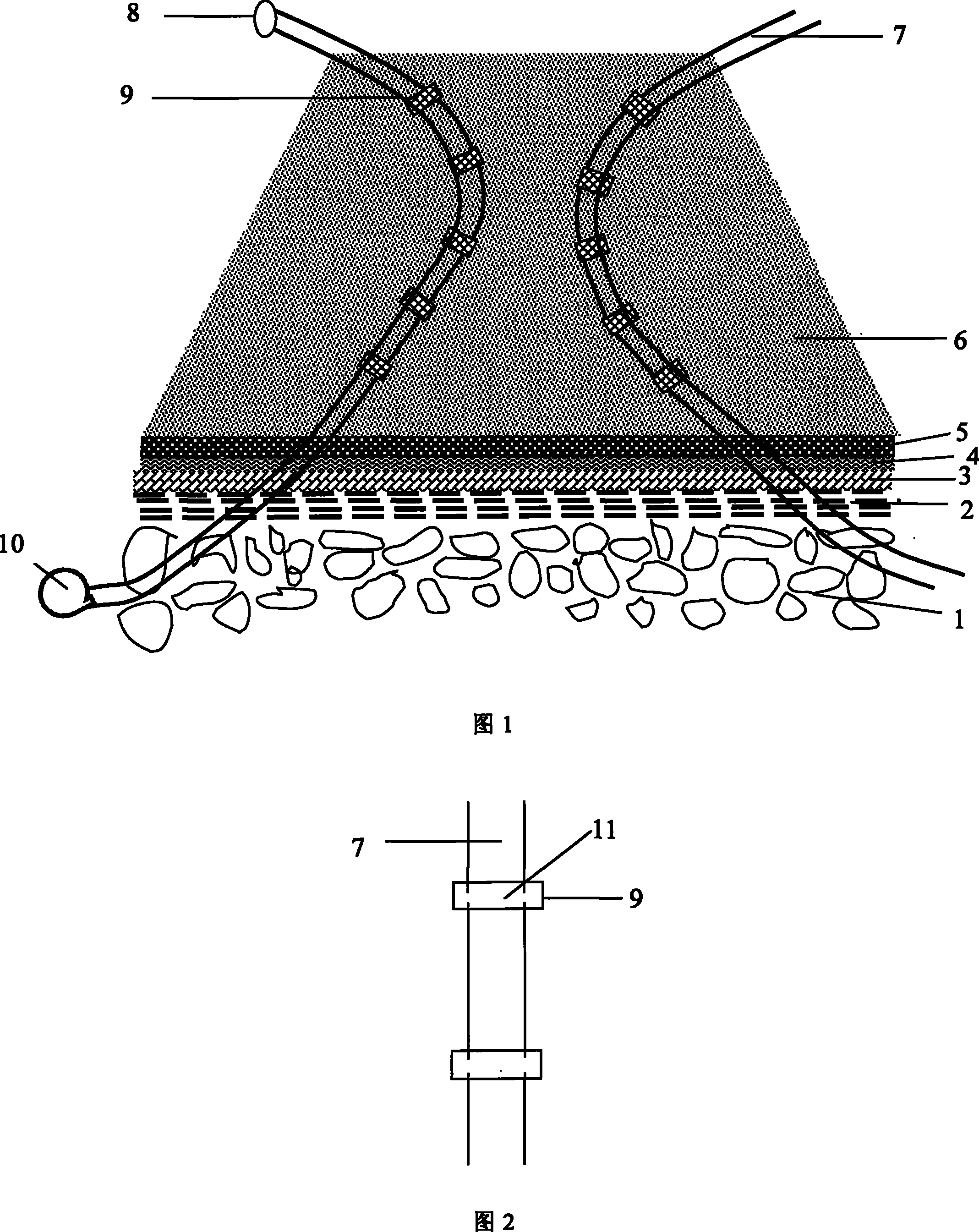

Device and method for biologically repairing high concentration petroleum pollution soil

InactiveCN101234392BReduce hydrocarbon contentReduce disturbanceContaminated soil reclamationHigh concentrationNatural ventilation

The invention relates to a biology repair of soil polluted by the petroleum with high concentration and the method thereof. The method is that gravel layer, corn stalk layer, soybean stalk layer, sawdust layer and cinder layer are laid from bottom in sequence to form the bottom gas ventilation layer, on the bottom gas ventilation layer the stacking is piled formed by mixing the high oil soil withthe supplement. The processing condition of the stacking is regulated and at least one ventilating pipe is arranged through the stacking. Considering the requirement for the forced ventilation, the ventilating pipe mouth extending from the gravel layer is connected with a blower. A sealing cover is arranged in the ventilating pipe mouth which extends from the top of the stacking body. The oxygen supply mode that combines the intermittent forced ventilation and natural ventilation is adopted. With simple process technique, low engineering and operation cost, less process time and high process efficiency, the method as a high efficient, economic and lasting treatment proposal which disturbs a little to the environment, thus finally gets the soil which contains low petroleum hydrocarbon content and is suitable for the seed to germinate and the plant to grow with the obvious economic and social profits.

Owner:OCEAN UNIV OF CHINA

Methanol diesel oil and preparation method thereof

The invention discloses methanol diesel oil and a preparation method thereof. The methanol diesel oil is prepared from, by weight, 23-27 parts of 200 # solvent oil, 28-32 parts of common first-vacuumdiesel oil, 15-17 parts of methyl tertiary butyl ether, 26-32 parts of coal tar, 28-34 parts of aviation kerosene and 15-18 parts of methanol. The preparation method of the methanol diesel oil comprises the following steps that 1, the methyl tertiary butyl ether and the methanol are weighed according to the proportion respectively, the weighed methyl tertiary butyl ether and the methanol are mixedand uniformly stirred, and a methanol-based mixed solution is further prepared; 2, the 200 # solvent oil, the common first-vacuum diesel oil, the coal tar and the aviation kerosene are weighed respectively according to the proportion, the weighed 200 # solvent oil, the common first-vacuum diesel oil, the coal tar and the aviation kerosene are sequentially added into the methanol-based mixed solution obtained in step 1 and stirred evenly, and the methanol diesel oil is obtained. The prepared methanol diesel oil is good in stability, free of layering and good in combustion performance.

Owner:河南妙天新能源研究院有限公司

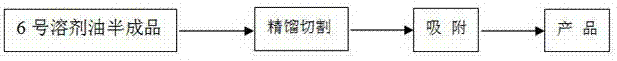

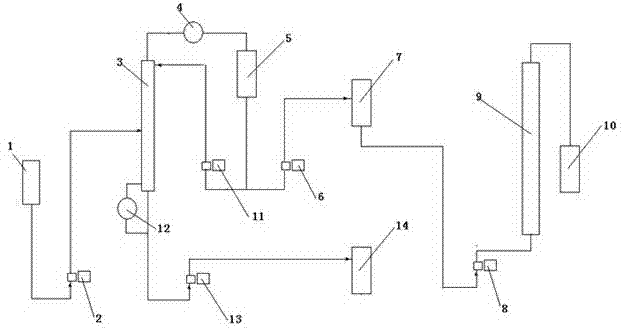

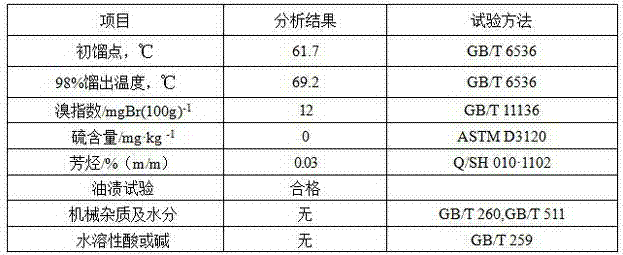

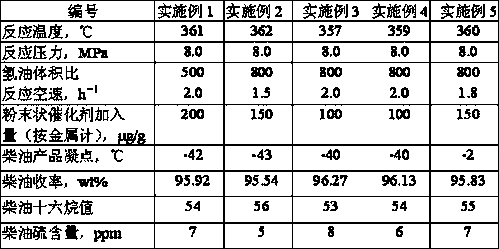

Method and system for preparing plant perfume extraction solvent

ActiveCN103540344ANo pollution in the processSimple processTreatment with plural serial refining stagesEssential-oils/perfumesDistillationUnsaturated hydrocarbon

The invention discloses a method for preparing a plant perfume extraction solvent. The method comprises the following steps: utilizing a semi-finished product of 6# solvent oil as a raw material, rectifying and cutting the raw material in a rectifying tower to obtain a semi-finished product of extraction solvent with a distillation range of 60-70 DEG C, and then, conveying the semi-finished product of extraction solvent into an adsorption tower to be adsorbed to remove the unsaturated hydrocarbons and reduce the bromine index so as to obtain a high-quality plant perfume extraction solvent with low aromatic content, low sulfur content and low bromine index. The technological process of the whole method is simple, the equipment investment is low, and no waste gas or waste water is generated in the production process, thereby generating no environmental pollution.

Owner:CHINA PETROLEUM & CHEM CORP

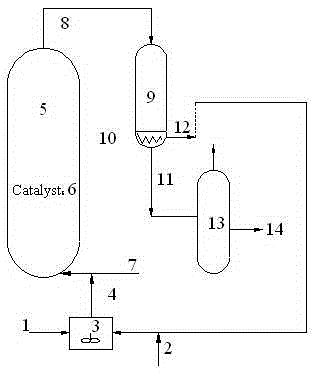

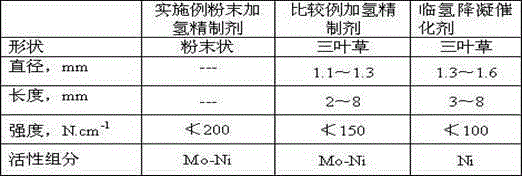

Production method of high-quality low-pour-point diesel

ActiveCN106675641AReduce temperature rise and temperature drop effectsImprove pour point depressing effectTreatment with hydrotreatment processesHydrocarbon oils treatment productsUltra-low-sulfur dieselChemistry

The invention discloses a production method of high-quality low-pour-point diesel. The production method comprises the following steps: (1) adequately mixing a poor-quality diesel raw material with a powdery hydrorefining catalyst in a mixer, so as to obtain a mixed fed material of the catalyst and the raw material diesel; (2) introducing the mixed fed material and hydrogen into a boiling-bed reactor from the bottom of a reactor filled with a hydrodewaxing catalyst, and carrying out hydrogenation reaction; (3) after the reaction of the material containing the powdery hydrorefining catalyst, discharging the material from the top of the boiling-bed reactor, introducing the material into a stable reactor, and carrying out supplementary hydrorefining; and (4) filtering the powdery hydrorefining catalyst from generated diesel, and introducing the diesel into a fractionating system, so as to obtain the high-quality low-pour-point diesel product. By virtue of the method, the yield and cetane number of the diesel are increased when low-pour-point and ultralow-sulfur diesel is produced, the hot-spot temperature of a device is reduced, and the operation cycle is prolonged; and besides, the consumption of cold hydrogen or the fuel gas of a heating furnace is reduced, so that the operation cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for modifying fluorine distribution in a hydrocarbon compound

ActiveUS11459286B2Reduce corrosionIncrease contentPreparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystPhysical chemistry

The present invention relates to a process for modifying the fluorine distribution in a hydrocarbon compound, comprising a step of making contact between said hydrocarbon compound and a catalytic composition comprising a chromium-based catalyst, said process being performed in a reactor made of a material comprising a base layer made of a material M1 and an inner layer made of a material M2, said base layer and said inner layer being laid against each other by bonding.

Owner:ARKEMA FRANCE SA

A treatment method for harmless recycling of oily sludge

InactiveCN108558155BEasy to operateHigh oil removal rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningOil sludgeOil phase

The invention provides a treatment method for harmless resource utilization of oily sludge. The oily sludge is crushed, mixed with water, stirred, and left to separate into layers, and the overflow separates the upper layer of slick oil into the oil recovery tank; the remaining solid-liquid phase is centrifuged for solid-liquid separation, and the obtained free Water re-osmosis is used, the remaining solid phase is subjected to the second reduction treatment, adding water and degradable treatment agent, stirring, after the system is allowed to stand and separate, it overflows the upper layer of oil slick to the oil recovery tank; centrifugal separation reduction After chemical treatment, the obtained liquid phase is subjected to oil-water separation, the oil phase enters the oil recovery tank, and the water phase enters the sewage reinfiltration tank for recycling, and the remaining solid phase is harmlessly treated; centrifuged, the liquid phase is distilled The plant treatment agent is recovered, the remaining oil enters the oil recovery tank, and the remaining sludge is dried. The invention has the advantages of simple operation, wide application range, high oil removal rate, waste water reuse, and treated sludge can be directly used for farmland planting.

Owner:任航

A kind of production method of low condensation diesel oil

ActiveCN106675642BRealize comprehensive utilizationQuality assuranceTreatment with hydrotreatment processesHydrocarbon oils treatment productsMixed feedingHydrogenation reaction

The invention discloses a production method of low-freezing-point diesel. The production method comprises the following steps: (1) completely mixing low-quality diesel raw materials and a powdered Mo-Ni type hydrorefining catalyst in a mixer to obtain mixed feeding materials of the catalyst and the raw material oil; (2) enabling the mixed feeding materials and hydrogen to enter a boiling-bed reactor from the bottom of the reactor to perform hydrogenation reaction, wherein the reactor is filled with a hydrodewaxing catalyst and a Mo-Co type hydrorefining catalyst; (3) discharging material flow containing the powdered Mo-Ni type hydrorefining catalyst after the reaction out of the top of the boiling-bed reactor and entering a stabilized reactor to perform hydrofinishing; and (4) performing solid-liquid separation on the material obtained in the step (3) and enabling liquid phase to enter a fractionating system to obtain the low-freezing-point diesel product. By the method provided by the invention, the temperature reduction in the hydrodewaxing process and the temperature increment in the hydrogenation process are combined and utilized reasonably, so while the low-freezing-point and ultralow-sulfur diesel is produced, the hot-spot temperature of the device is reduced, the operating cycle is prolonged and the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and system for preparing a solvent for extracting plant spices

ActiveCN103540344BSimple processReduce operating costsEssential-oils/perfumesTreatment with plural serial refining stagesFragrance extractionUnsaturated hydrocarbon

The invention discloses a method for preparing a plant fragrance extraction solvent. The No. 6 solvent oil semi-finished product is used as a raw material, which is sent to a rectification tower for rectification and cutting to obtain a semi-finished product of the extraction solvent with a distillation range of 60-70°C, and then The semi-finished product of the extraction solvent is sent to an adsorption tower for adsorption treatment to remove unsaturated hydrocarbons, reduce the bromine index, and obtain a high-quality plant fragrance extraction solvent with low aromatic content, low sulfur content, and low bromine index. The process of the whole method is simple, the equipment investment is low, and there is no waste gas and waste water in the production process, and no environmental pollution is caused.

Owner:CHINA PETROLEUM & CHEM CORP

Process for hydrodesulphurization and olefin reduction of gasoline

ActiveCN100345943CMeet quality requirementsReduce olefin contentRefining by selective hydrogenationHydrogenSulfur

The inventon provides a technical method to HDS for FCC petrol, which comprises: passing remove-dialkene reactor, cutting into light and weight constituents; taking the light constituent to react with gas modification catalyst, then mixing the modified light constituent with weight constituent to contact with selective desulphurization catalyst. Compared with prior art, this invention can process ungraded FCC into high-quality product with low sulfur and olefin content and high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-efficiency hydrogenation and upgrading method for inferior diesel oil

ActiveCN106675640BRealize comprehensive utilizationQuality assuranceTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationHydrogenation reaction

The invention discloses an efficient hydro-upgrading method for poor diesel fuel. The method comprises the following steps of (1) fully mixing the raw material of poor diesel fuel and a powdery hydrorefining catalyst in a mixer to obtain a mixed feeding material; (2) enabling the mixed feeding material and hydrogen to enter a boiling-bed reactor from the bottom part of a reactor filled with a hydrodewaxing catalyst, a hydro-upgrading catalyst and an isomerization-visbreaking catalyst, so as to implement the hydrogenation reaction; (3) discharging the reaction product comprising the powdery hydrorefining catalyst from the top part of the boiling-bed reactor, enabling the reaction product to enter the stable reactor to supplement hydrorefining; and (4) implementing solid liquid separation on the material, and enabling the liquid phase to enter a fractionating system to obtain a high-quality diesel fuel product. The characteristic of backmixing of the boiling-bed reactor is fully utilized, the temperature drop in the process of hydrodewaxing and the temperature rise in the processes of hydrorefining and hydro-conversion are reasonably utilized, the diesel fuel with low condensation point, ultralow sulfur and high cetane number is produced while the high yield of the diesel fuel is guaranteed, the hot-spot temperature of the device is reduced, and the running period is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of high quality low condensation diesel oil

ActiveCN106675641BRealize comprehensive utilizationQuality assuranceTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionHeating furnace

The invention discloses a production method of high-quality low-pour-point diesel. The production method comprises the following steps: (1) adequately mixing a poor-quality diesel raw material with a powdery hydrorefining catalyst in a mixer, so as to obtain a mixed fed material of the catalyst and the raw material diesel; (2) introducing the mixed fed material and hydrogen into a boiling-bed reactor from the bottom of a reactor filled with a hydrodewaxing catalyst, and carrying out hydrogenation reaction; (3) after the reaction of the material containing the powdery hydrorefining catalyst, discharging the material from the top of the boiling-bed reactor, introducing the material into a stable reactor, and carrying out supplementary hydrorefining; and (4) filtering the powdery hydrorefining catalyst from generated diesel, and introducing the diesel into a fractionating system, so as to obtain the high-quality low-pour-point diesel product. By virtue of the method, the yield and cetane number of the diesel are increased when low-pour-point and ultralow-sulfur diesel is produced, the hot-spot temperature of a device is reduced, and the operation cycle is prolonged; and besides, the consumption of cold hydrogen or the fuel gas of a heating furnace is reduced, so that the operation cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

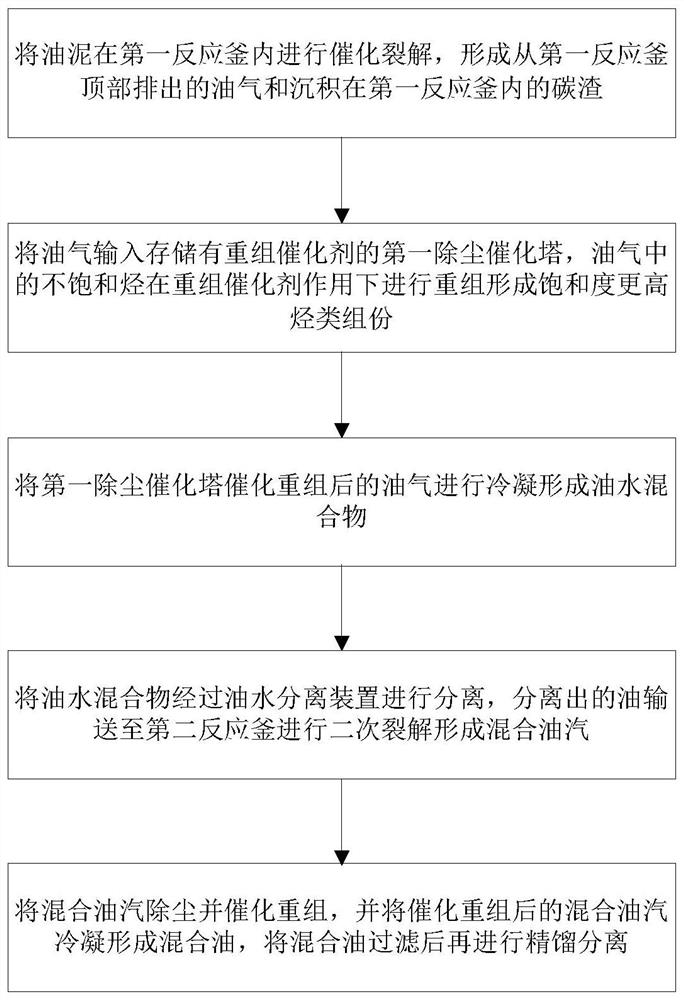

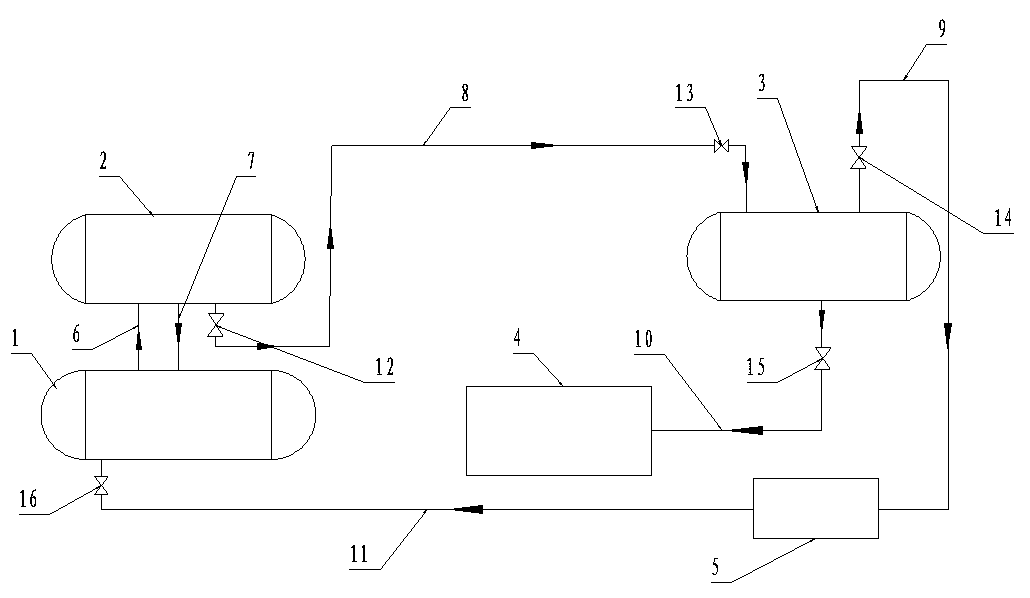

A system and method for synchronous recombination of oil sludge catalytic cracking

ActiveCN109266389BAchieve recyclingAchieve reuseSludge treatmentHydrocarbon oils treatment productsPtru catalystDistillation

The present application provides a system and method for recombination of petroleum sludge through synchronized catalysis and cracking, comprising: performing catalysis and cracking on petroleum sludge in a first reaction still, so as to form petroleum gas discharged from the top of the first reaction still and carbon residues deposited in the first reaction still; inputting the petroleum gas into a first dedusting catalytic tower stored with a recombination catalyst; condensing the petroleum gas after catalytic recombination in the first dedusting catalytic tower to form a petroleum-water mixture; separating the petroleum-water mixture by a petroleum-water separation device, and conveying the separated petroleum to a second reaction still to perform secondary cracking and form mixed petroleum gas; and performing dedusting and catalytic recombination on the mixed petroleum gas, condensing the mixed petroleum gas after catalytic recombination to form mixed oil, filtering the mixed petroleum and then performing distillation separation. The present application realizes the recycle of such resources as water, petroleum and combustible gas in petroleum sludge, thereby achieving resource re-utilization and restoring the use value of the original soil.

Owner:ZHEJIANG KEMAO ENERGY TECH CO LTD

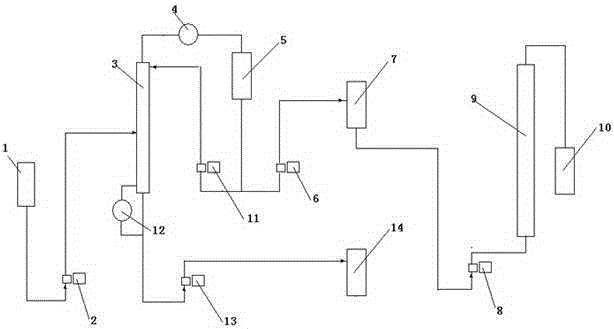

Acid hydrocarbon separation and recycling device of sulfuric acid alkylation system

PendingCN109678638AReduce hydrocarbon contentEnsure safetyHydrocarbon purification/separationSulfur-trioxide/sulfuric-acidAlkyl transferAlkylation

The invention discloses an acid hydrocarbon separation and recycling device of a sulfuric acid alkylation system. The acid hydrocarbon separation and recycling device comprises a reactor, a storage tank, a primary settling tank, a secondary settling tank and a hydrocarbon compressor, wherein the primary settling tank is connected with the reactor through a first pipeline and a second pipeline respectively; the outlet end at the upper end of the primary settling tank is connected with the inlet end at the upper end of the secondary settling tank through a third pipeline; the outlet end at the upper end of the secondary settling tank is connected with the input end of the hydrocarbon compressor through a fourth pipeline; the outlet end at the lower end of the secondary settling tank is connected with the storage tank through a fifth pipeline; the output end of the hydrocarbon compressor is connected with the reactor through a sixth pipeline. By adopting the technical scheme of the invention, acid hydrocarbon can be separated, a good separation effect can be achieved, stability and reliability are achieved, consumption of the device is reduced, the cost is lowered, and the security ofthe storage tank is also ensured.

Owner:安庆市泰发能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com