Separation of hydrocarbons from inorganic material

A liquid separator, the technology of applying hydrocarbons in separation methods, precipitation separation, liquid separation, etc., can solve the problems of consumption recirculation limitation, undescribed use of hot water or steam, limitation of energy consumption, etc., to achieve low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

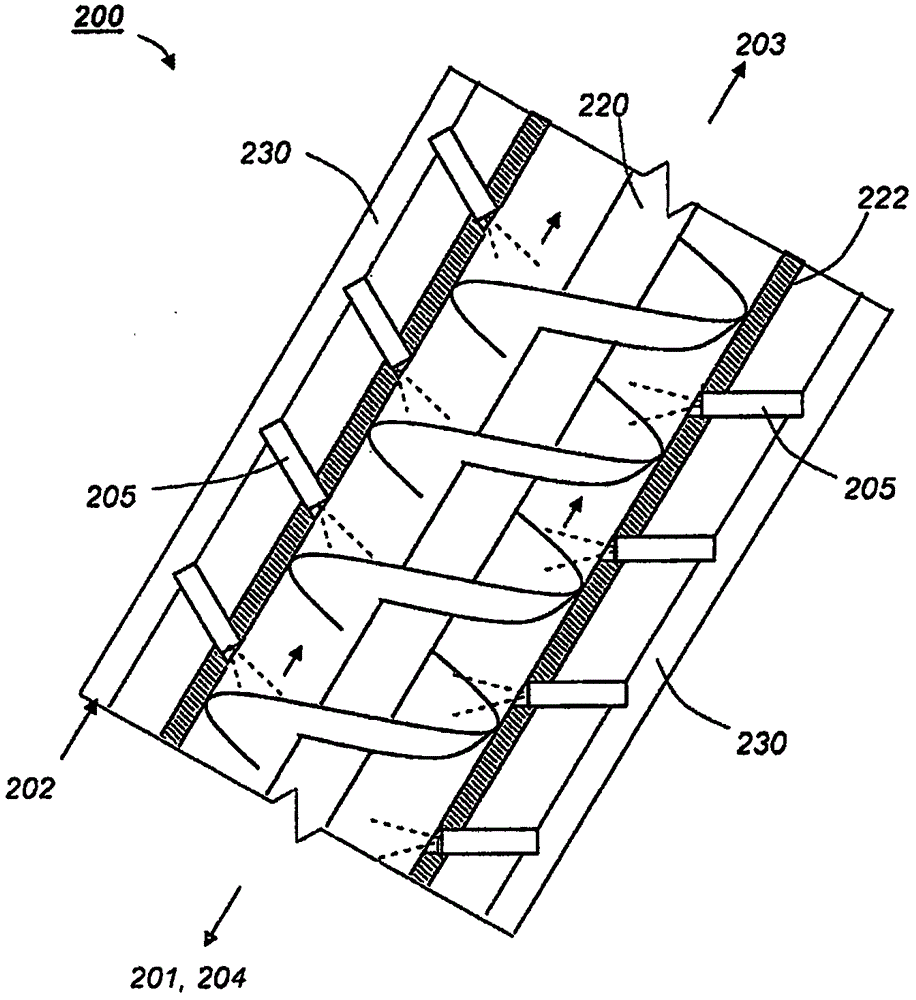

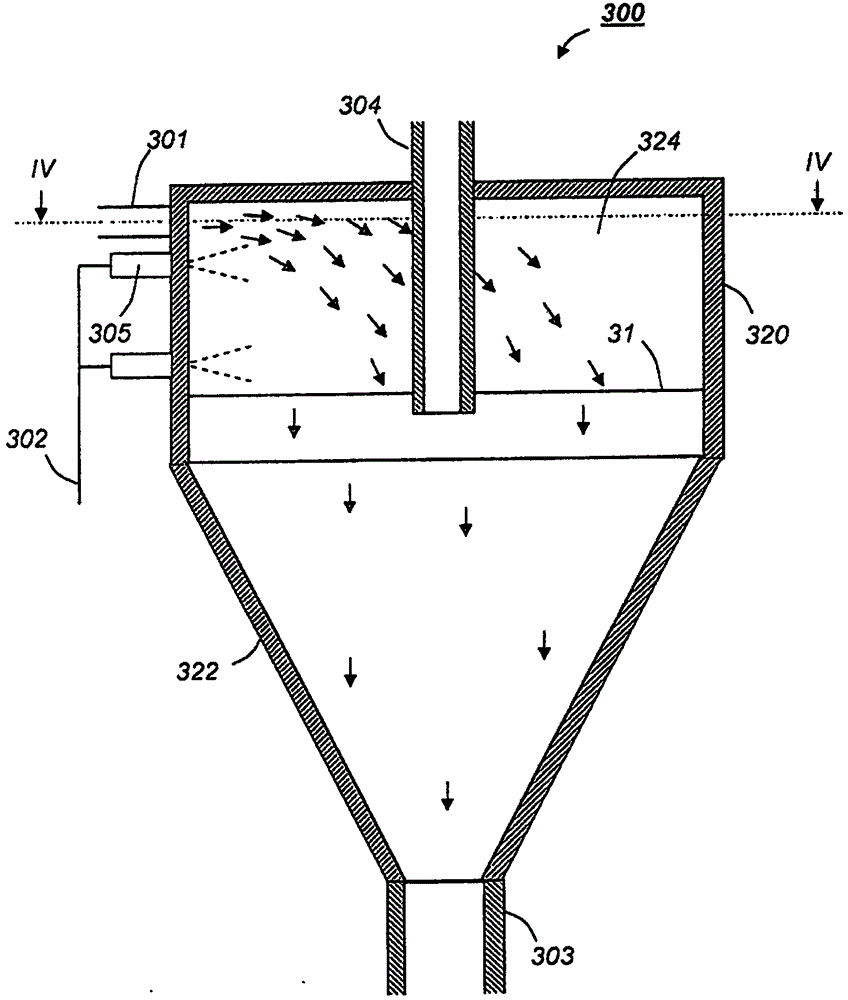

[0045] The drawings are schematic and are intended to illustrate the invention. The drawings are not drawn to scale, and many details that are obvious to those skilled in the art are omitted for clarity. More specifically, some pumps are shown in the drawings without reference numerals. This makes the drawings easier to understand, and the description of the pump represented by, for example, an increase in pressure will only confuse the text with unnecessary details.

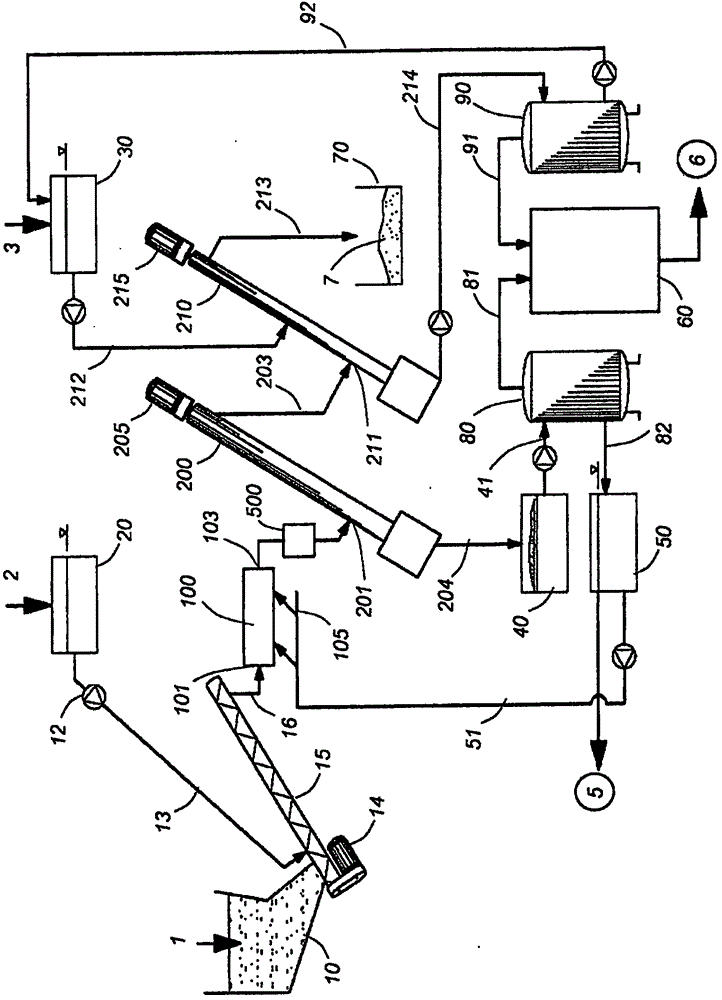

[0046] figure 1 To illustrate the system for separating hydrocarbons from solid matter, the solid matter is an initial mixture 1 of rocks and / or ice chunks of any size, with any content of hydrocarbons, such as oil and / or bitumen. In addition to mixture 1, liquid hydrocarbons 2 and water 3 are provided to the system, especially to the mixing stage of the system. Mixture 1 depends on the application, and the type of liquid hydrocarbon 2 is such that it can be recovered with other hydrocarbons at a later stage, as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com