A high-efficiency hydrogenation and upgrading method for inferior diesel oil

A technology for low-quality diesel oil and hydrotreating, which is applied in hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc. It can solve the contradiction between the depressurization effect and the yield of diesel fractions, and reduce the service life of hydropour depressurization catalyst. , the yield of diesel fractions and the limitation of pour point depressurization, etc., to achieve the effect of strengthening pour point depressurization and hydro-modification effect, improving the utilization efficiency of reaction heat, and improving the effect of pour point depressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

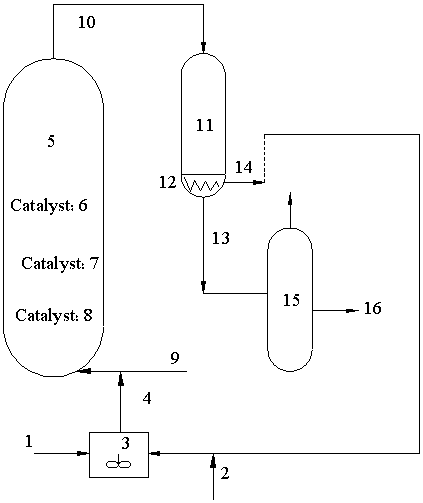

[0041] This example is an ebullating bed hydrogenation test using a hydrodepreciation catalyst, a hydrogenation upgrading catalyst, a hydroisomerization depreciation catalyst and a powdered hydrorefining catalyst. See attached for specific operation procedure figure 1 . In Examples 1-2, the volume ratio of the powdered hydrofining catalyst to the hydrodepreciation catalyst, hydrogenation upgrading catalyst, and isomerization depreciation catalyst is 1:5, among which the hydrodepression catalyst, the hydrogenation upgrading catalyst , The volume ratio of heterogeneous pour point depressant catalyst is 1:1:1. In Example 3, the volume ratio of the powdered hydrofining catalyst to the hydrodepreciation catalyst, hydrogenation upgrading catalyst, and isomerization depreciation catalyst is 3:1, wherein the hydrodepression catalyst, hydrogenation upgrading catalyst, isomerization The volume ratio of the pour point depressing catalyst is 1:2:1. The low-quality diesel oil and the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com