A system and method for synchronous recombination of oil sludge catalytic cracking

A catalytic cracking and oil sludge technology, which is applied in chemical instruments and methods, sludge treatment, hydrocarbon oil treatment, etc., can solve the problems of flammability and explosion, limited treatment, high energy consumption, etc., and achieve the reduction of unsaturated hydrocarbon content, Convenient separation and purification, and the effect of reducing tail gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

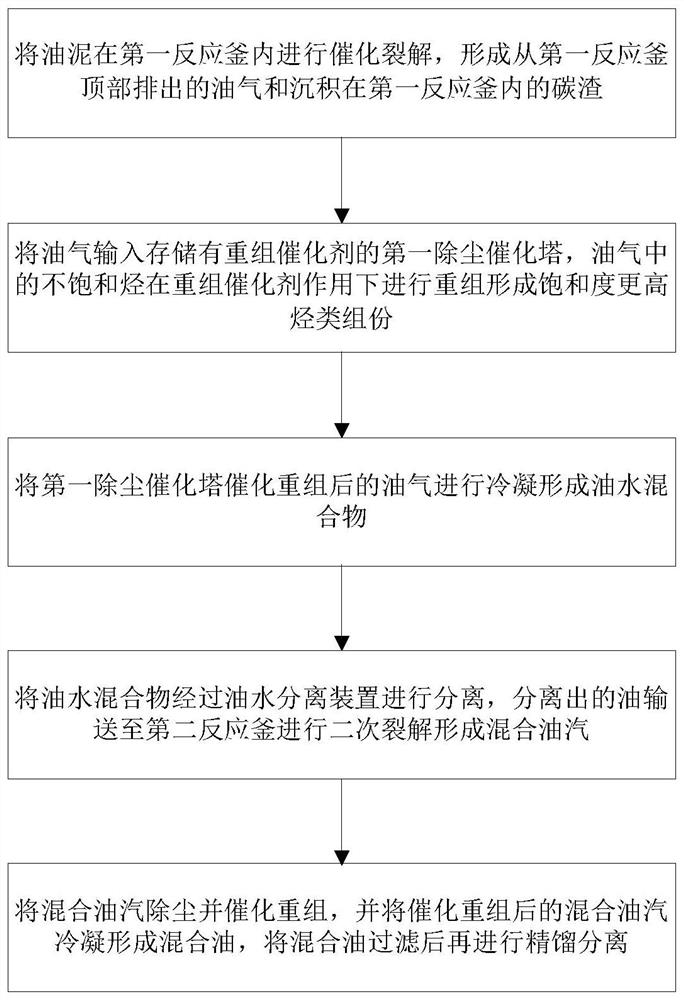

[0025] refer to figure 1 , a method for synchronous recombination of oil sludge catalytic cracking proposed by the present invention, comprising the following steps.

[0026] S1. Catalytic cracking of oil sludge in the first reactor to form oil gas discharged from the top of the first reactor and carbon residue deposited in the first reactor. Specifically, in this step, the bagged oil sludge is first passed through a bag breaking device to separate the oil sludge from the oil sludge bag, and then the oil sludge and the oil sludge bag are respectively added to the first reaction kettle for catalytic cracking. In this way, in this embodiment, the oil sludge bag is decomposed together with the oil sludge, which solves the pollution problem of the oil sludge bag; at the same time, in this step, after the bag is broken, the oil sludge and the oil sludge bag are separated and added to the second feed through different feeding channels. A reactor is beneficial to accurately control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com