Method and system for preparing plant perfume extraction solvent

A technology for extracting solvents and plant spices, applied in the field of preparation of extraction solvents, can solve the problems of high equipment requirements, large equipment investment, and large environmental pollution, and achieve the effects of low operating costs, low investment, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

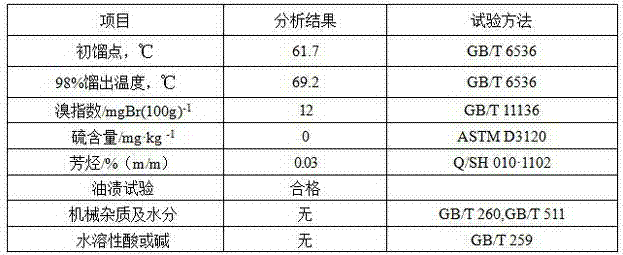

[0020] Raw materials: Low-aromatic low-sulfur No. 6 solvent oil semi-finished product, initial boiling point 62°C, 98% distillation temperature 75°C, aromatics content 0.03%, sulfur content 0 mg·kg -1 , bromine index 78 mgBr (100g) -1 .

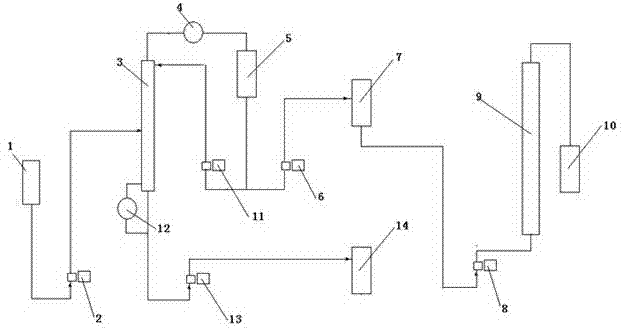

[0021] Start the production system, send the semi-finished product of solvent oil No. 6 to the rectification tower 1 for rectification and cutting, obtain the semi-finished product of the extraction solvent with a distillation range of 60~70°C, and then send the semi-finished product of the extraction solvent to the adsorption tower for adsorption Treatment, removal of unsaturated hydrocarbons, reduction of bromine index, and extraction of plant fragrance solvents.

[0022] The control process parameters are: the number of theoretical plates in the rectification section: 10, the number of theoretical plates in the stripping section: 10, the temperature at the top of the tower: 69°C, the temperature at the bottom of the tower: 82°C, the oper...

Embodiment 2

[0026] Raw materials: Low-aromatic low-sulfur No. 6 solvent oil semi-finished product, initial boiling point 62°C, 98% distillation temperature 75°C, aromatics content 0.03%, sulfur content 0 mg·kg -1 , bromine index 78 mgBr (100g) -1 .

[0027] Start the production system, start the production system, send the semi-finished product of solvent oil No. 6 to the rectification tower 1 for rectification and cutting, obtain the semi-finished product of the extraction solvent with a distillation range of 60~70°C, and then send the semi-finished product of the extraction solvent to the adsorption Adsorption treatment is carried out in the tower to remove unsaturated hydrocarbons, reduce the bromine index, and obtain a plant fragrance extraction solvent.

[0028] The control process parameters are: the number of theoretical plates in the rectification section: 10, the number of theoretical plates in the stripping section: 10, the temperature at the top of the tower: 69°C, the temper...

Embodiment 3

[0032] Raw materials: Low-aromatic low-sulfur No. 6 solvent oil semi-finished product, initial boiling point 62°C, 98% distillation temperature 75°C, aromatics content 0.03%, sulfur content 0 mg·kg -1 , bromine index 78 mgBr (100g) -1 .

[0033] Start the production system, send the semi-finished product of solvent oil No. 6 to the rectification tower 1 for rectification and cutting, obtain the semi-finished product of the extraction solvent with a distillation range of 60~70°C, and then send the semi-finished product of the extraction solvent to the adsorption tower for adsorption Treatment, removal of unsaturated hydrocarbons, reduction of bromine index, and extraction of plant fragrance solvents. The control process parameters are: the number of theoretical plates in the rectification section: 15, the number of theoretical plates in the stripping section: 15, the temperature at the top of the tower: 70°C, the temperature at the bottom of the tower: 84°C, the operating pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com