Device and method for biologically repairing high concentration petroleum pollution soil

A technology for oil pollution and bioremediation, applied in the field of oil pollution treatment, to achieve high treatment efficiency, low petroleum hydrocarbon content, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

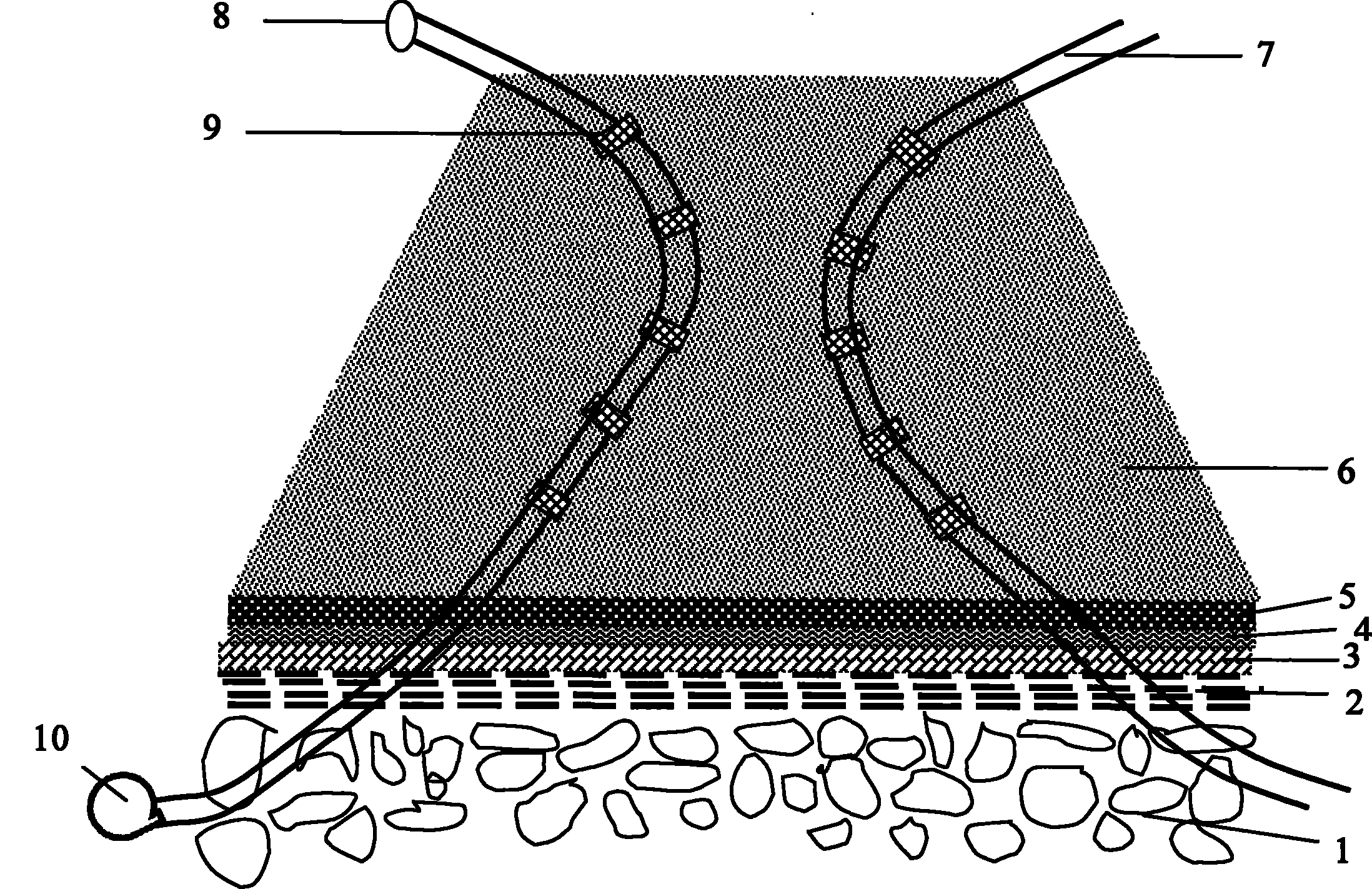

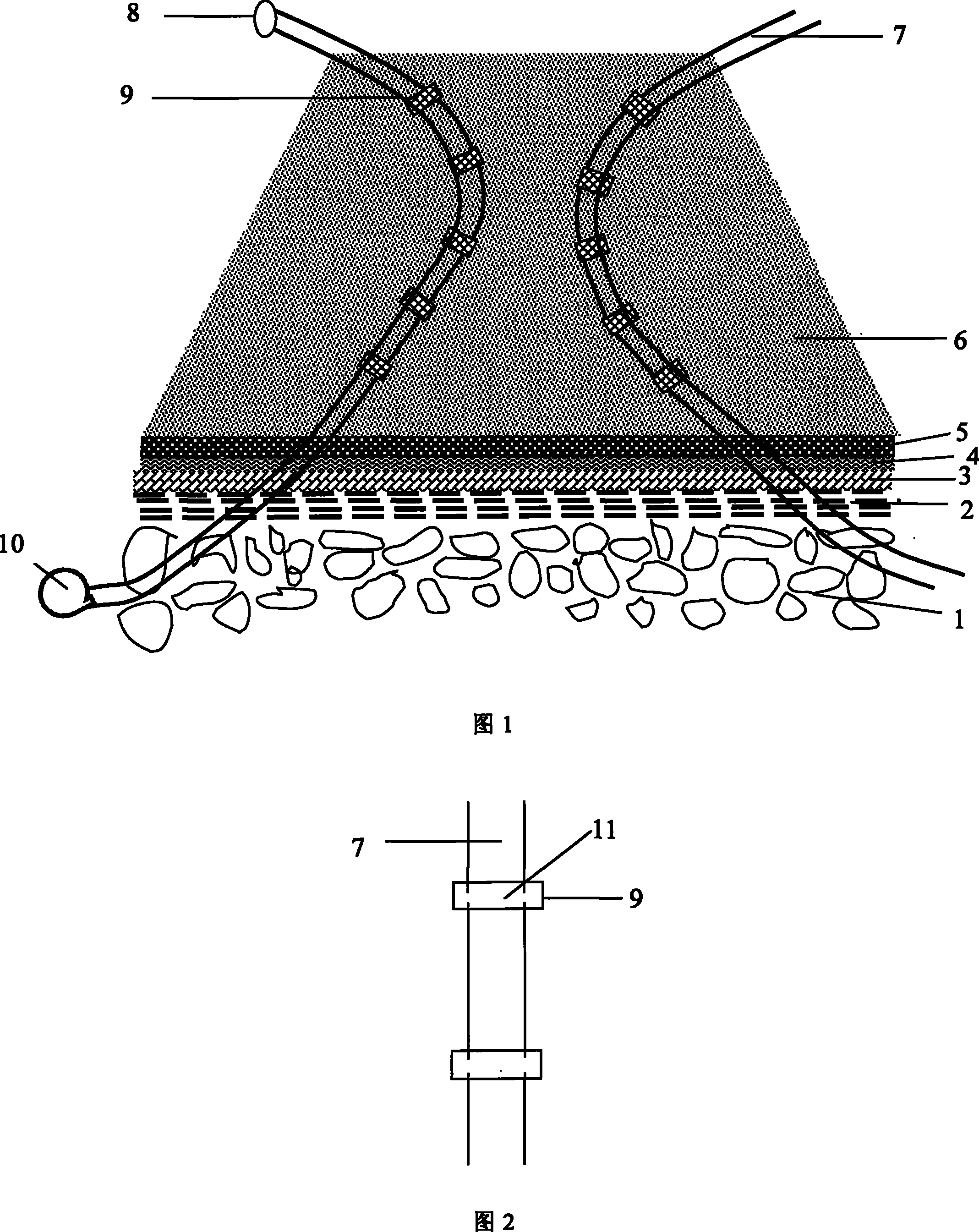

[0019] Collect about 4 cubic meters of high-oil soil (50g / Kg), first disperse the high-oil soil evenly, adjust the carbon-nitrogen ratio to 50 (C:N=50:1), and the pH value to 8.0, and then mix it with 2 times the volume of auxiliary materials As stockpiling material, the auxiliary material composition and its mixing ratio are straw: wood chips: coal ash = 1: 1: 0.5, and the humidity of the stockpiling material is adjusted to be 50%. Then lay the bottom ventilation layer, the gravel layer laying height 15cm, and the corn stalk layer, bean stalk layer, sawdust layer and massive cinder layer laying height are respectively 5cm. Then the uniformly mixed stockpiles are stacked above the bottom ventilation layer, and ventilation pipes are arranged at the same time, and the oxygen supply method combining natural ventilation and forced ventilation is adopted. After 80 days, the petroleum hydrocarbon content in the soil decreased to 9.6g / Kg, that is, the degradation rate was 80.8%. At ...

Embodiment 2

[0021] Collect about 4 cubic meters of high-oil soil (50g / Kg), first disperse the high-oil soil evenly, adjust the carbon-nitrogen ratio to 90 (C:N=90:1), and the pH value to 8.0, and then mix it with 1 volume of auxiliary materials As stockpiling material, the auxiliary material composition and its mixing ratio are straw: sawdust: coal ash = 1: 1: 0.5, and the humidity of the stockpiling material is adjusted to be 60%. Then lay the bottom ventilation layer, the gravel layer laying height 15cm, and the corn stalk layer, bean stalk layer, sawdust layer and massive cinder layer laying height are respectively 5cm. Then the uniformly mixed stockpiles are stacked above the bottom ventilation layer, and ventilation pipes are arranged at the same time, and the oxygen supply method combining natural ventilation and forced ventilation is adopted. After 40 days, the petroleum hydrocarbon content in the soil decreased to 21g / Kg, that is, the degradation rate was 58%. At this time, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com