Process apparatus and method of nitrogen-containing natural gas dual-column cryogenic denitrification

A process device and natural gas technology, which is applied in the fields of nitrogen-containing natural gas double-tower cryogenic removal of nitrogen and nitrogen removal from natural gas, can solve problems such as the reduction of natural gas yield, and achieve the effect of reducing hydrocarbon content and reducing energy consumption of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

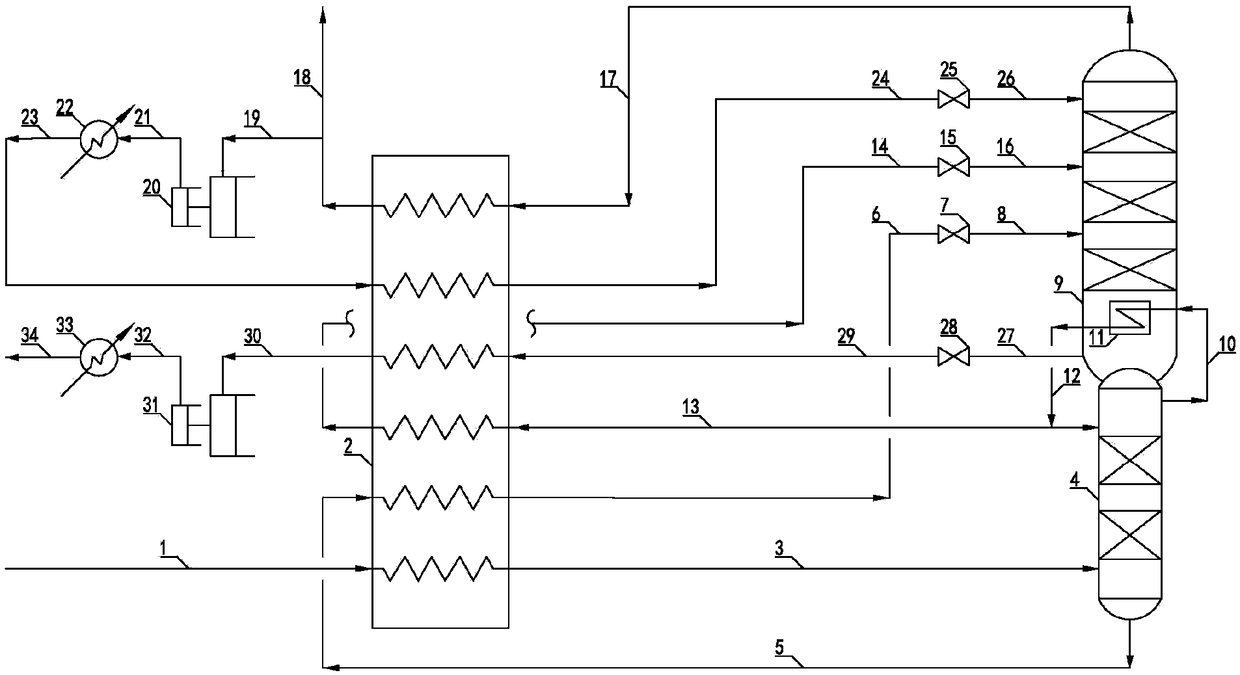

[0014] like figure 1 As shown, a device for nitrogen-containing natural gas double-tower cryogenic denitrification of the present invention includes a denitrification cold box 2, a high-pressure denitrification tower 4, a first throttle valve 7, a low-pressure denitrification tower 9, a heat exchanger 11, Second throttle valve 15, nitrogen compressor 20, cooler 22, third throttle valve 25, fourth throttle valve 28, product gas compressor 31, cooler 33;

[0015] The denitrification cold box 2 and the high-pressure denitrification tower 4 are connected through a pipeline 3;

[0016] The bottom outlet of the high-pressure denitrification tower 4, the denitrification cold box 2, the first throttle valve 7, and the low-pressure denitrification tower 9 are connected through pipelines 5, 6, and 8 in sequence;

[0017] The upper outlet of the high-pressure denitrification tower 4, the heat exchanger 11, the denitrification cold box 2, the second throttle valve 15, and the low-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com