Renewable hydrocarbon composition

a technology of hydrocarbons and compositions, applied in the field of hydrocarbon compositions, can solve the problems of affecting the combustion properties of diesel fuels, and achieve the effect of low oxygen content and high hydrocarbon conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

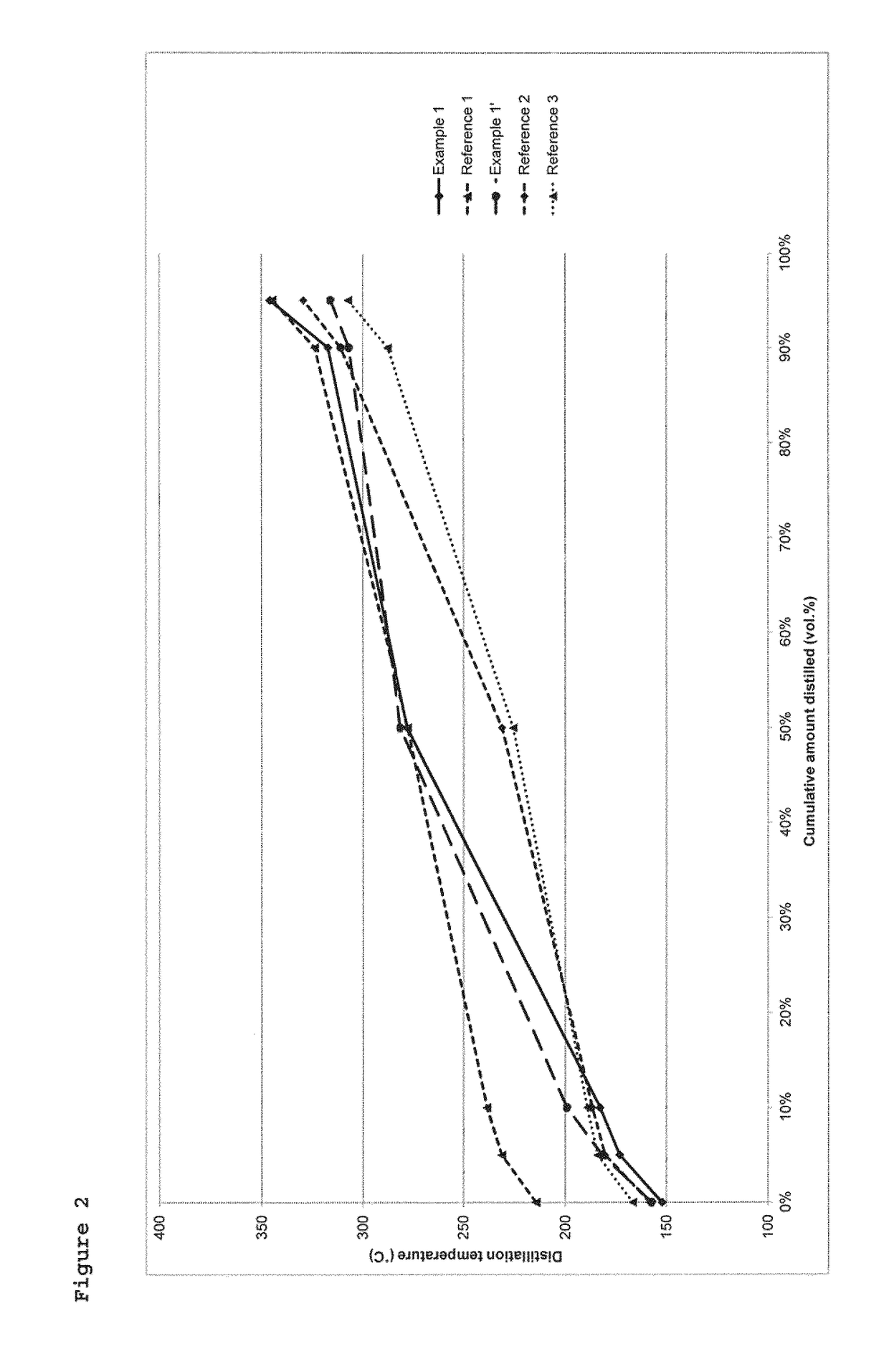

example 1

[0083]A hydrocarbon composition was produced by subjecting crude tall oil to a hydroprocessing treatment. The crude tall oil originated from tall oil soap obtained from chemical digestion of a mixture of northern softwood (pine and spruce) and birch. The crude tall oil contained 51 mass % of fatty acids, 26 mass % of resin acids and 23 mass % of neutral compounds.

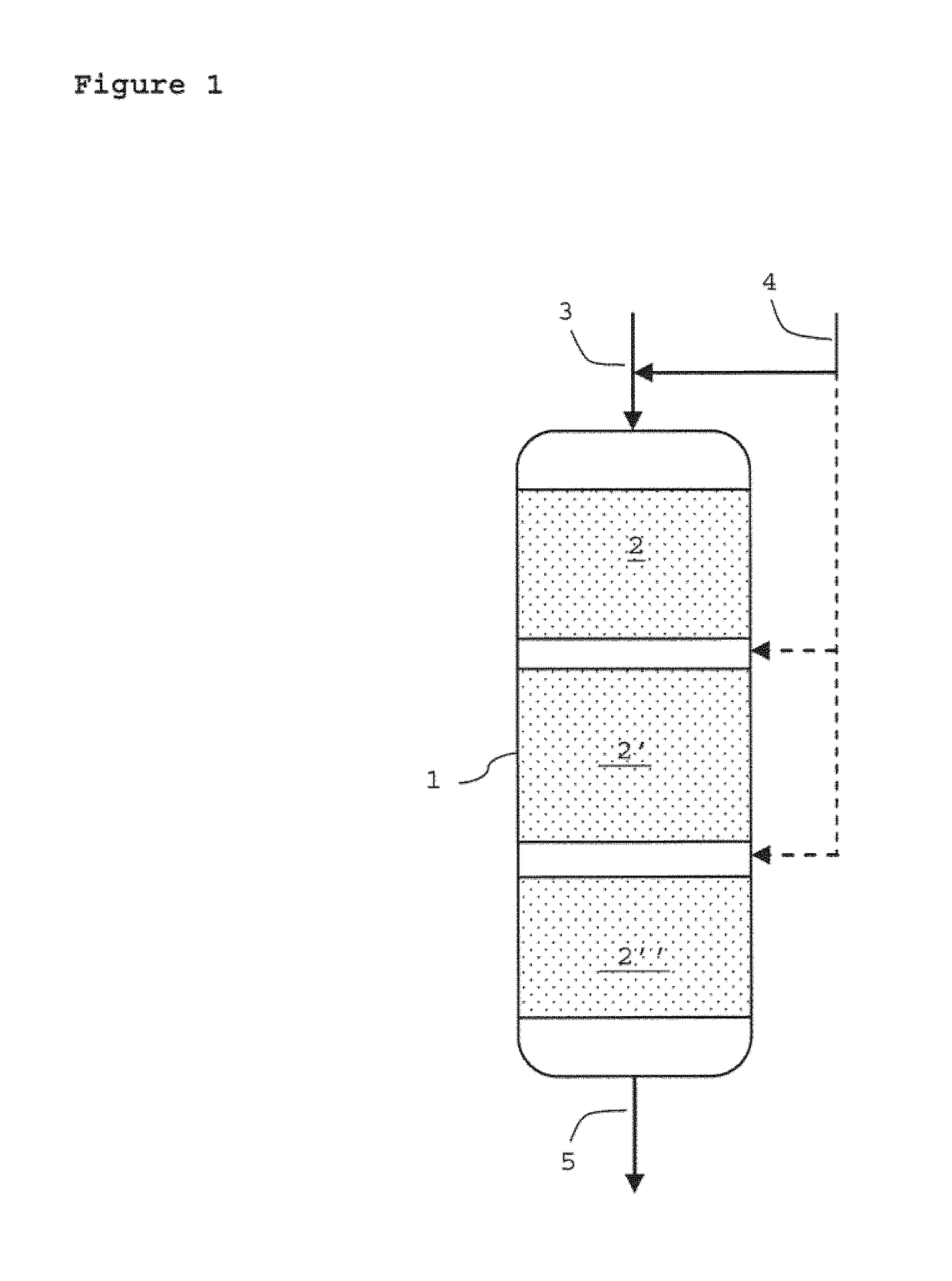

[0084]The crude tall oil was purified by three-step evaporation to remove 4% of the oil as a light fraction and 6% of the oil as a heavy pitch fraction. The purified oil was fed into a pilot reactor system together with hydrogen. The pilot reactor system contained a guard unit having two catalyst beds arranged in series. The catalyst beds each contained Ni, Mo and W as active metals and SiO2 and Al2O3 as support materials and metal scavengers. Hydrogen was mixed with the feed upstream of the guard unit.

[0085]From the guard unit, the composition was passed to a hydroprocessing reactor together with hydrogen. The hydroprocess...

example 2

[0095]A second hydrocarbon composition was isolated from the hydroprocessed composition of Example 1 by subjecting the composition to distillation and collecting the components distilling in the temperature range of 170-300° C. The composition of the collected distillate is detailed in Table 4 below.

[0096]

TABLE 4ComponentAmount (mass %)C8-30 linear alkanes34.3C9-23 linear alkanes33.3C9-20 linear alkanes32.4C15-18 linear alkanes23.9C8-30 branched alkanes39.9C8-30 linear alkanes +74.1C8-30 branches alkanesC8-30 cycloalkanes14.4C8-30 linear alkanes +87.8C8-30 branched alkanes +C8-30 cycloalkanesC7-20 aromatic hydrocarbons11.2C7-20 monoaromatic hydrocarbons10.3C8-30 linear alkanes +99.7C8-30 branched alkanes +C8-30 cycloalkanes +C7-20 aromatic hydrocarbons

[0097]This composition is suitable use as a component of aviation fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass % | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com