Medical valve with positive flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

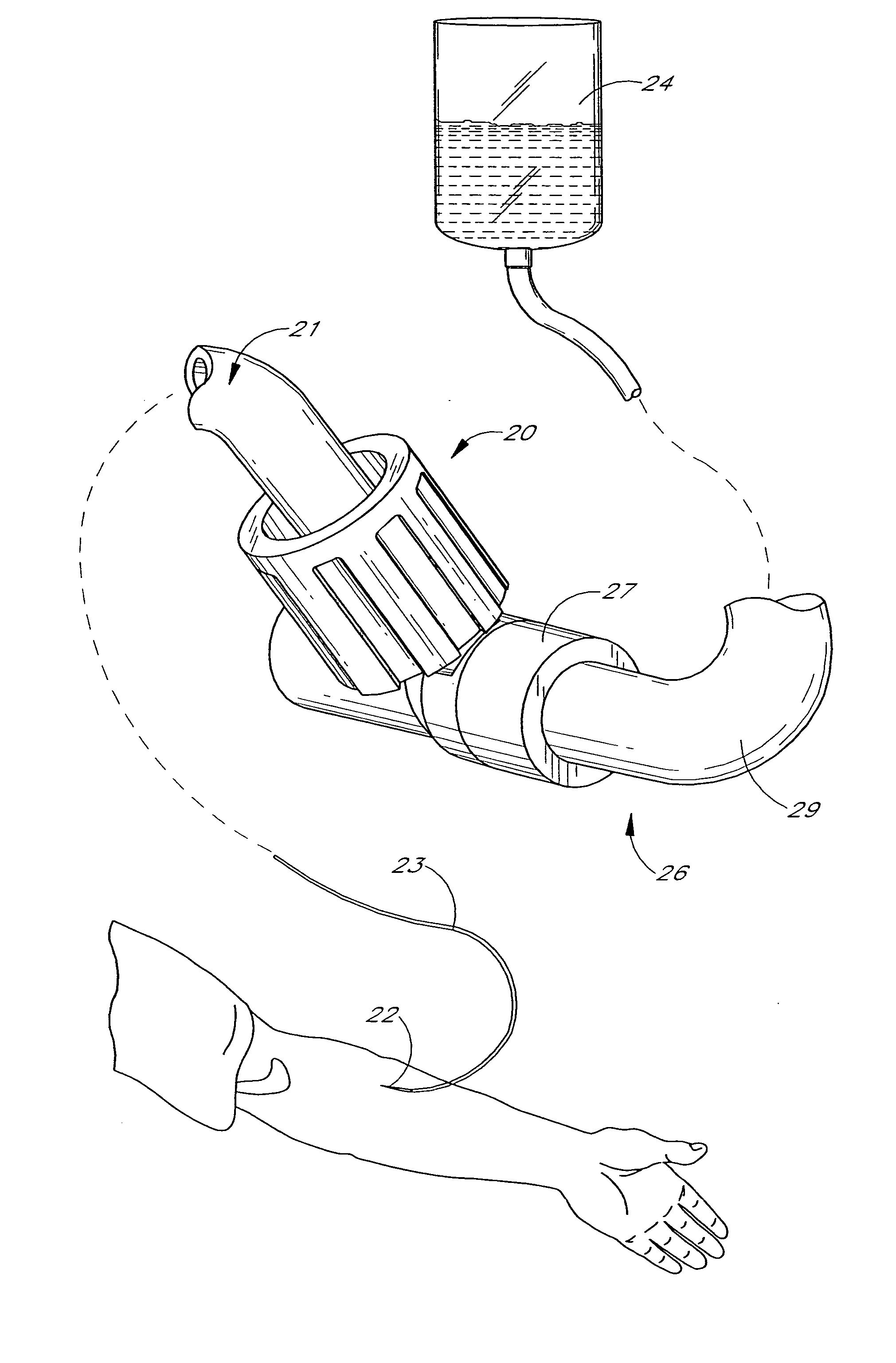

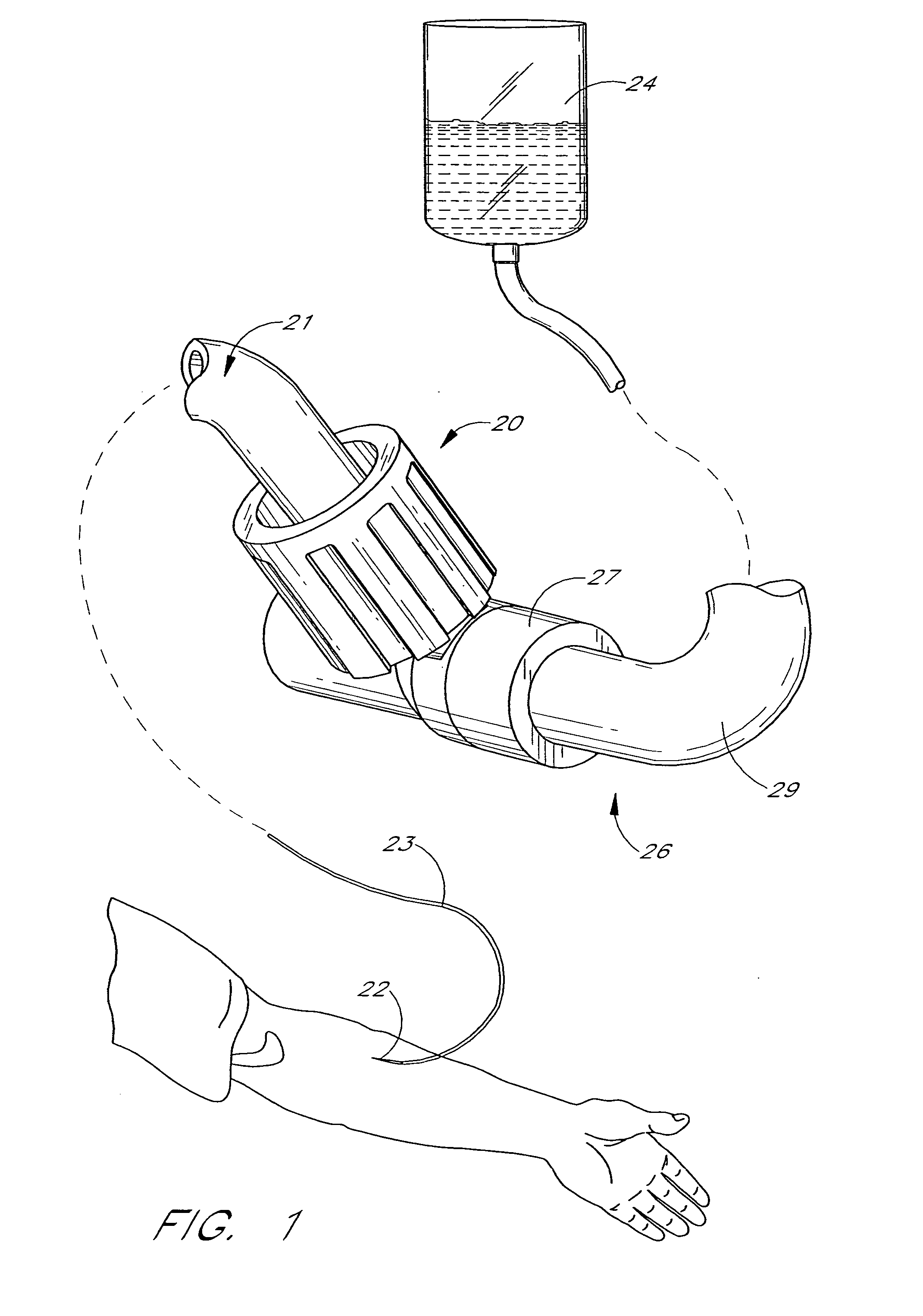

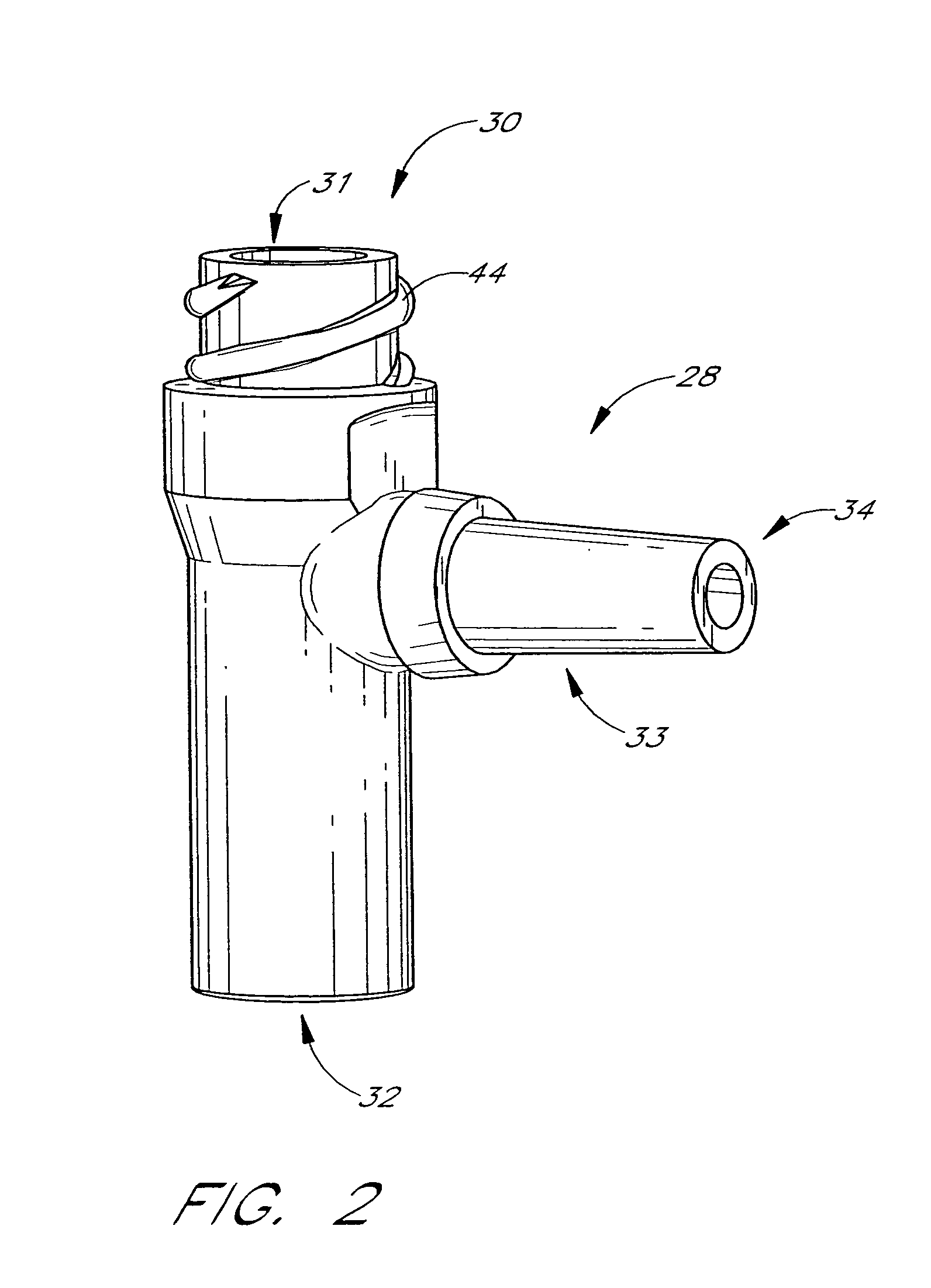

[0073]FIGS. 1-17 illustrate a valve 20 in accordance with the present invention. FIG. 1 illustrates a particular use of the valve 20 to which the valve 20 is well suited. Of course, the valve 20 may be used in a variety of other manners.

[0074] As illustrated in FIG. 1, the valve 20 may advantageously be used to selectively control the flow of fluid to a catheter 22 from a fluid source 24 such as an I.V. bag. In this arrangement, a first medical implement 21 is connected to the valve 20. The first medical implement 21 comprises a tube 23 leading to a catheter 22. One end of the tube 23 is connected to the valve 20, and the catheter 22 has its tip positioned in a patient.

[0075] A second medical implement 26 is also connected to the valve 20. The second medical implement 26 comprises a connecting member 27 positioned at one end of a tube 29 which leads to the I.V. bag 24.

[0076] When so connected, the valve 20 permits fluid to flow from the I.V. bag 24 or other medical fluid source to...

second embodiment

[0110] A second embodiment valve 120 in accordance with the present invention is illustrated in FIGS. 18 and 19. As illustrated, this valve 120 includes a housing 128 which is similar to the housing of the valve 20 described above, except that this housing is shorter in length between a first end 128 and a second end 130, as a piston 142 of the valve 120 is also shorter.

[0111] As illustrated, the first end 130 defines a first port 131, and the opposing second end 132 is closed. A branch 133 extends to a third end 134 defining a branch port 135.

[0112] A main passage 136 extends from the first end 130 towards the second end 132 of the housing. The main passage 136 is defined by an inner surface of a wall of the housing 128. The main passage 136 is generally cylindrical in shape, in this embodiment having no ledges or steps.

[0113] A branch passage 138 extends perpendicularly from the main passage 138 between the first and second ends 130,132 of the housing 128. The branch passage 138...

third embodiment

[0131] A third embodiment valve 220 in accordance with the present invention is illustrated in FIGS. 20 and 21. As illustrated, this valve 220 includes a housing 228. As illustrated, the housing 228 is a generally cylindrical body having a first end 230 defining a first port 231 and having an opposing second end 232.

[0132] A main passage 236 extends from the first end 230 towards the second end 232 of the housing. The main passage 236 is defined by an inner surface of the housing 228. The main passage 236 is generally cylindrical in cross-section. An extension passage 238 of smaller diameter extends from the main passage 238 to the second end 232 of the valve 220, the passage 238 being defined partly by a wall 276. A sleeve 278 is positioned about the outside of the wall 276. The sleeve 278 preferably has threads 279 on an inner surface thereof.

[0133] The piston 242 is movably positioned within the passage 236 of the housing 228. The piston 242 has a body 260 having a generally cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com