Production method of high-quality low-pour-point diesel

A production method and low-quality diesel technology, applied in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve the contradiction between the depressing effect and the diesel fraction yield, the limitation of the diesel fraction yield and the depressing effect, Reduce the service life of hydrogen decondensation catalysts, etc., to prevent polycondensation coke reaction, improve the effect of depreciation, and reduce the effect of temperature rise and temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

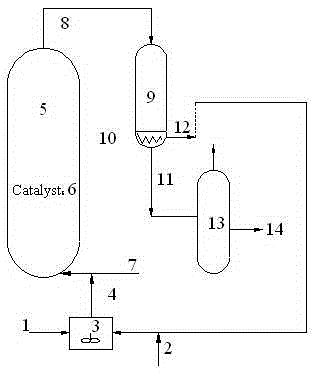

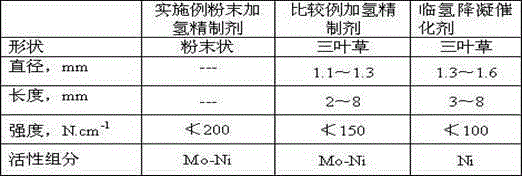

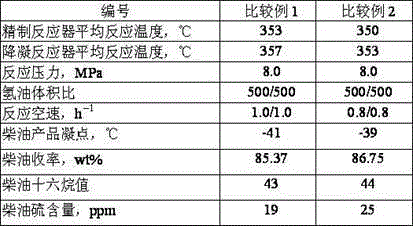

[0038] This example is an ebullating bed hydrogenation test using a hydrodepreciation catalyst and a powdered hydrorefining catalyst. See attached for specific operation procedure figure 1 . The volume ratio of the powdered hydrofinishing catalyst to the hydrodepressing catalyst in Example 1 is 1:3, and the volume ratio of the powdered hydrofining catalyst to the hydrodepressing catalyst in Examples 2-3 is 2:1. The low-quality diesel oil and the powdered hydrorefining catalyst are fully mixed in the mixer to obtain a uniform feed, which enters the ebullating bed reactor through the delivery pump, and the high-pressure hydrogen enters the hydrogenation tank from the bottom of the ebullating bed reactor in the way of feeding. The ebullating bed reactor of the depreciating catalyst keeps the catalyst in a boiling state. Under suitable reaction conditions, it is simultaneously and / or sequentially contacted with the hydrogen depreciating catalyst and the powdered hydrofining catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com