Patents

Literature

61results about How to "Improve quality and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

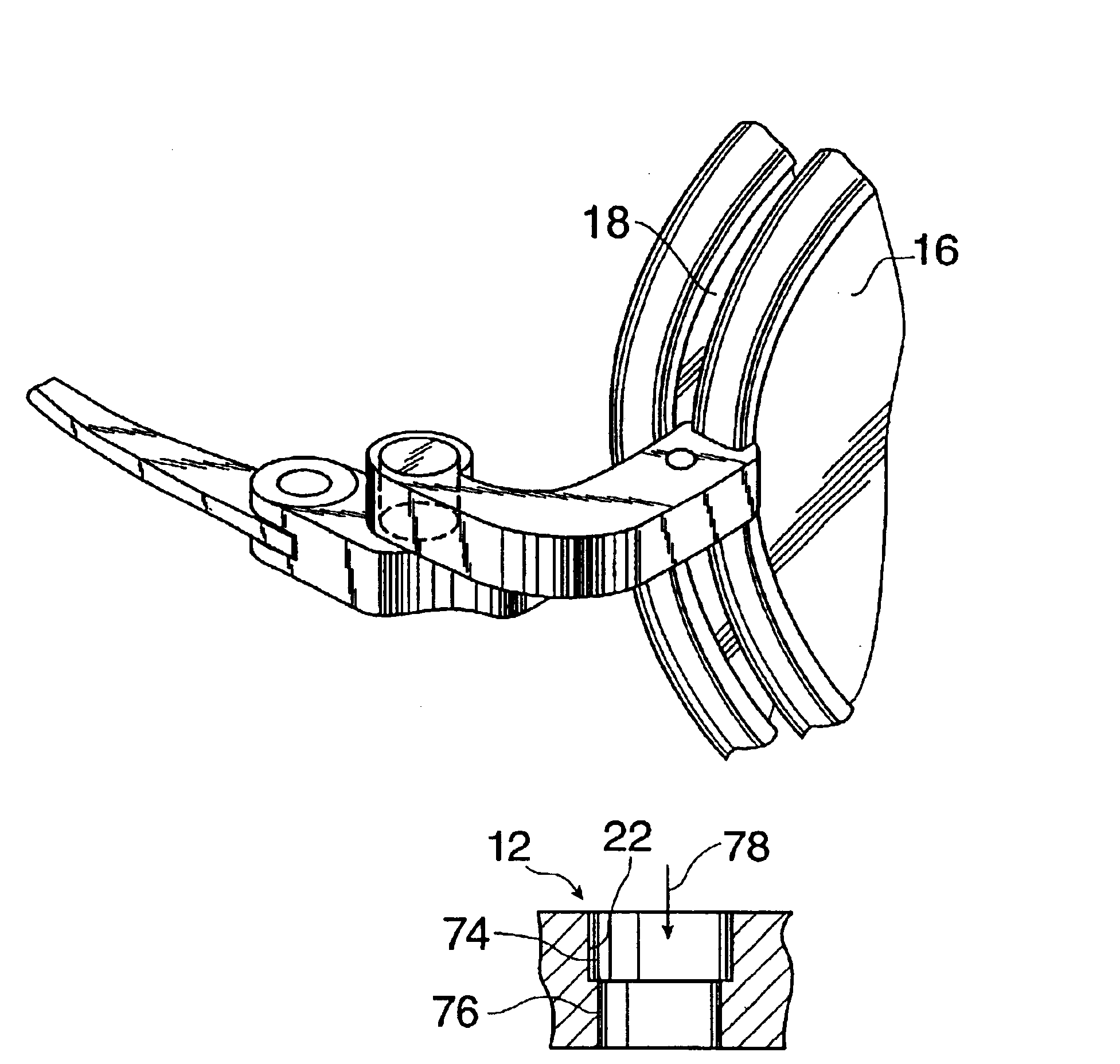

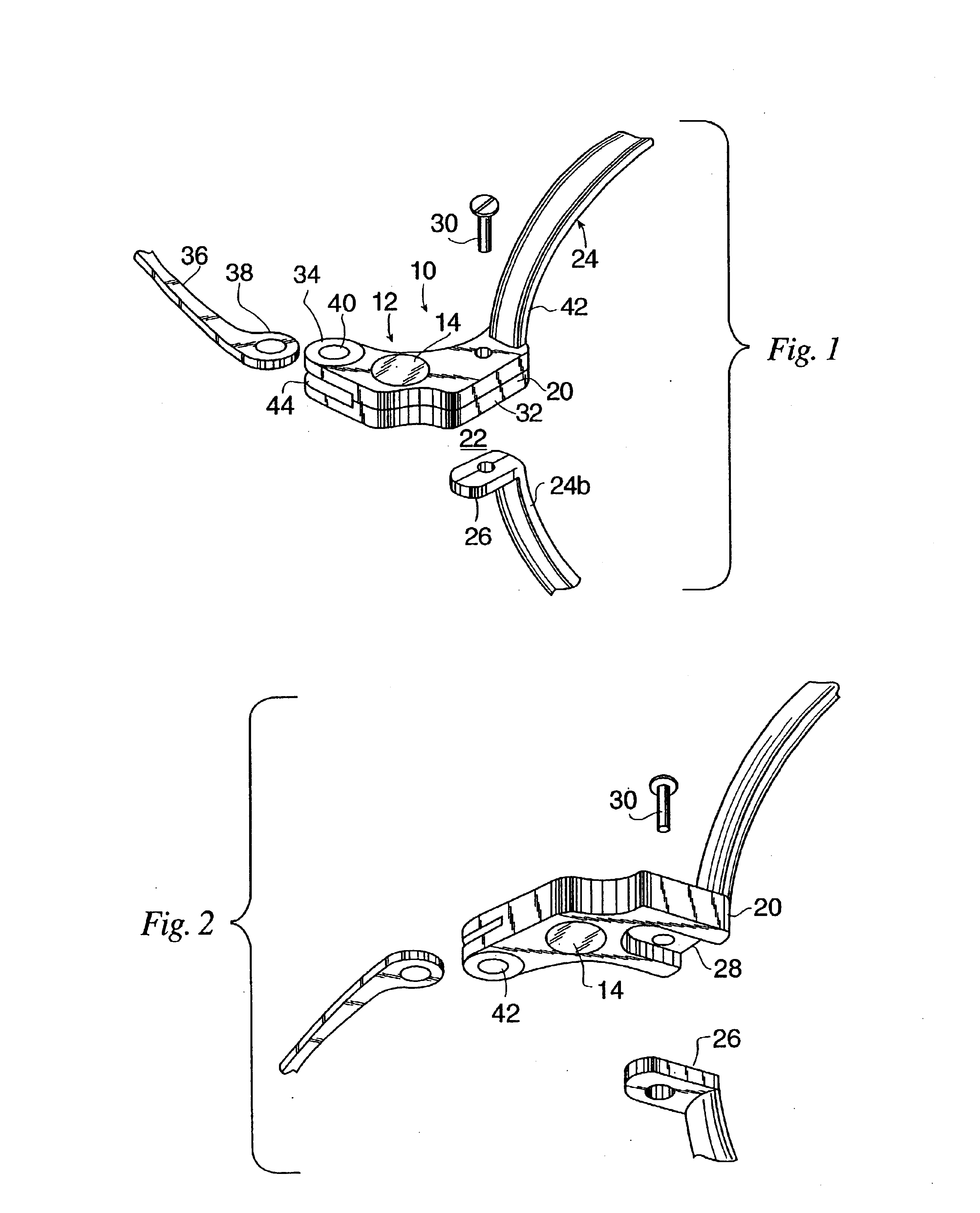

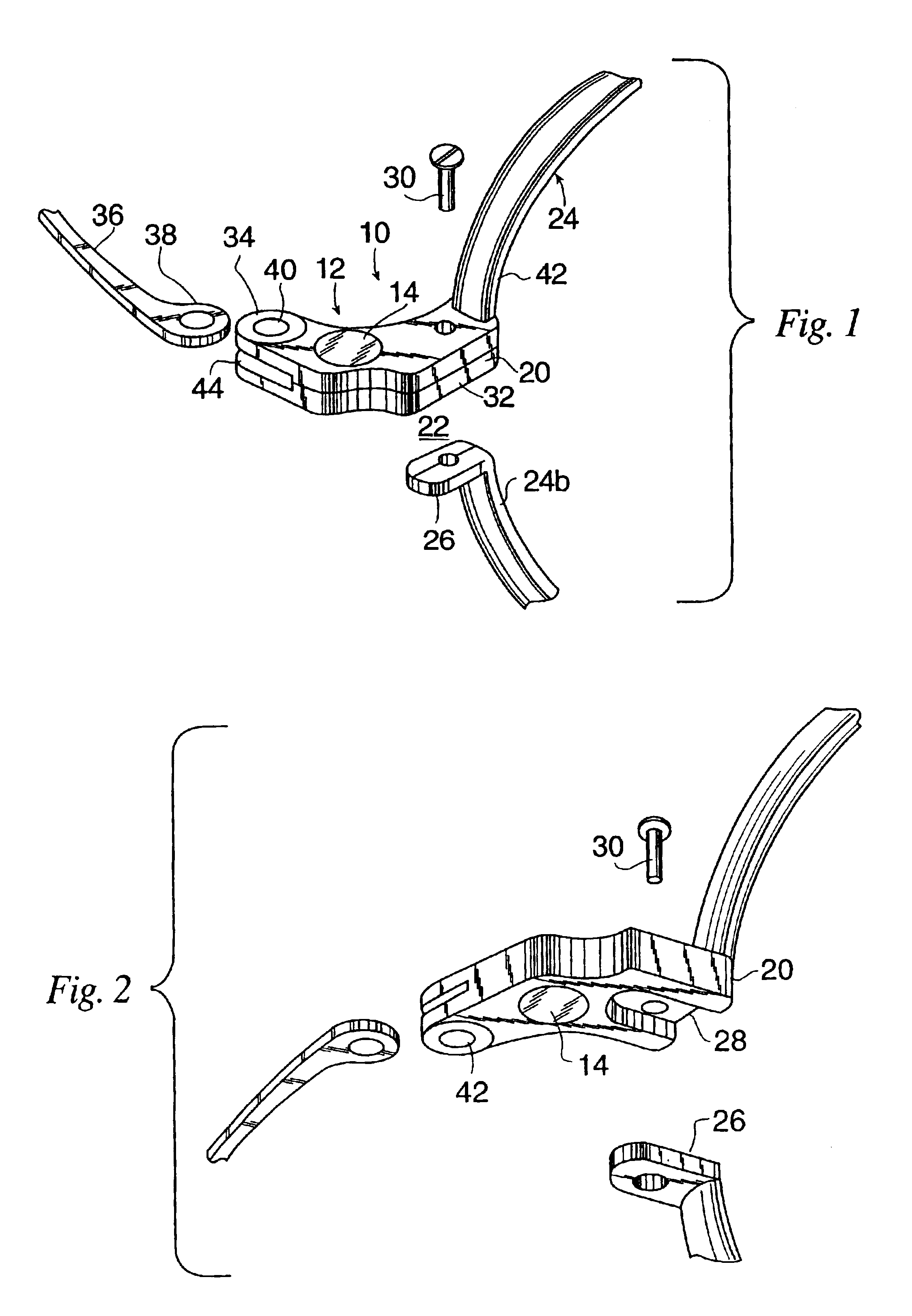

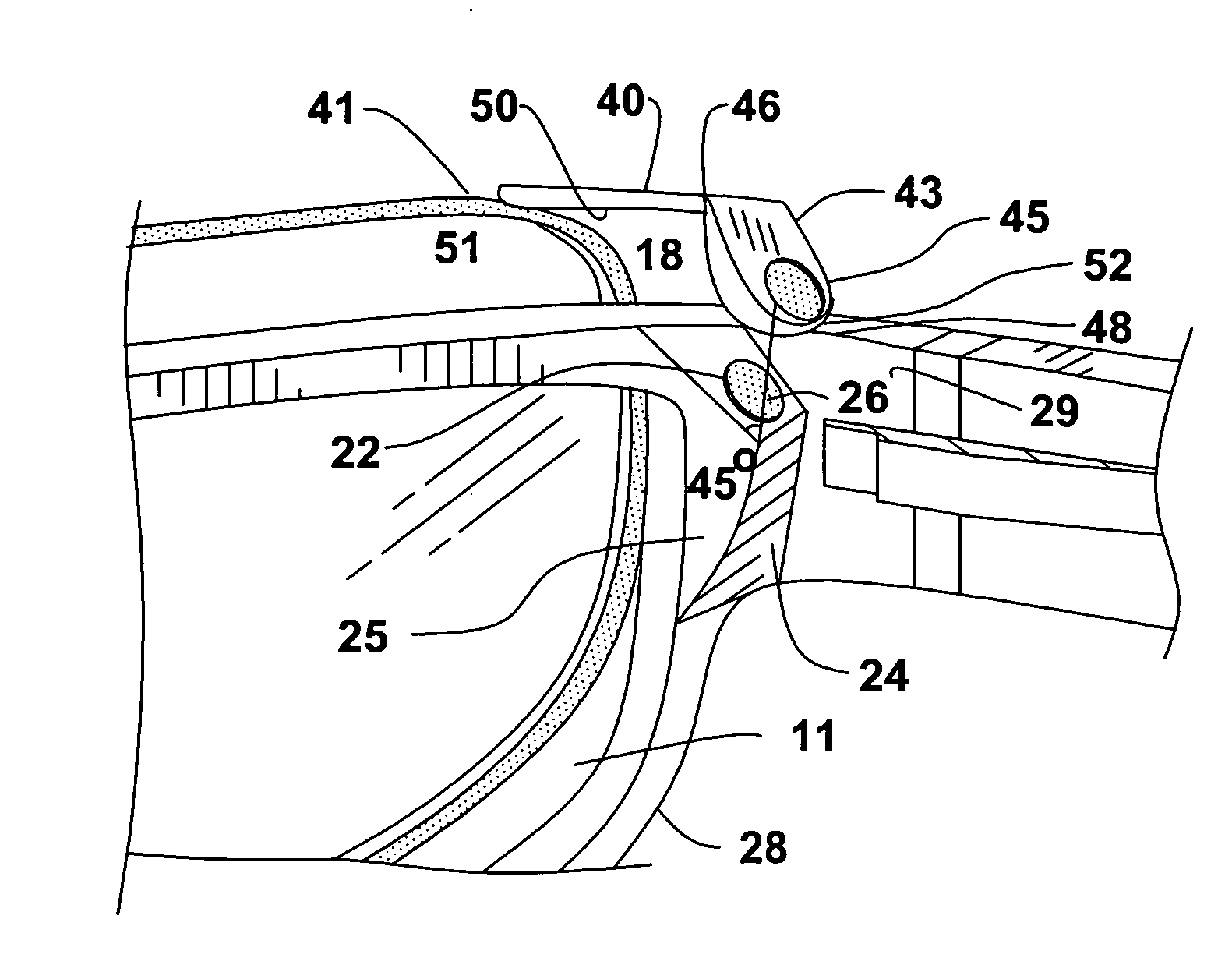

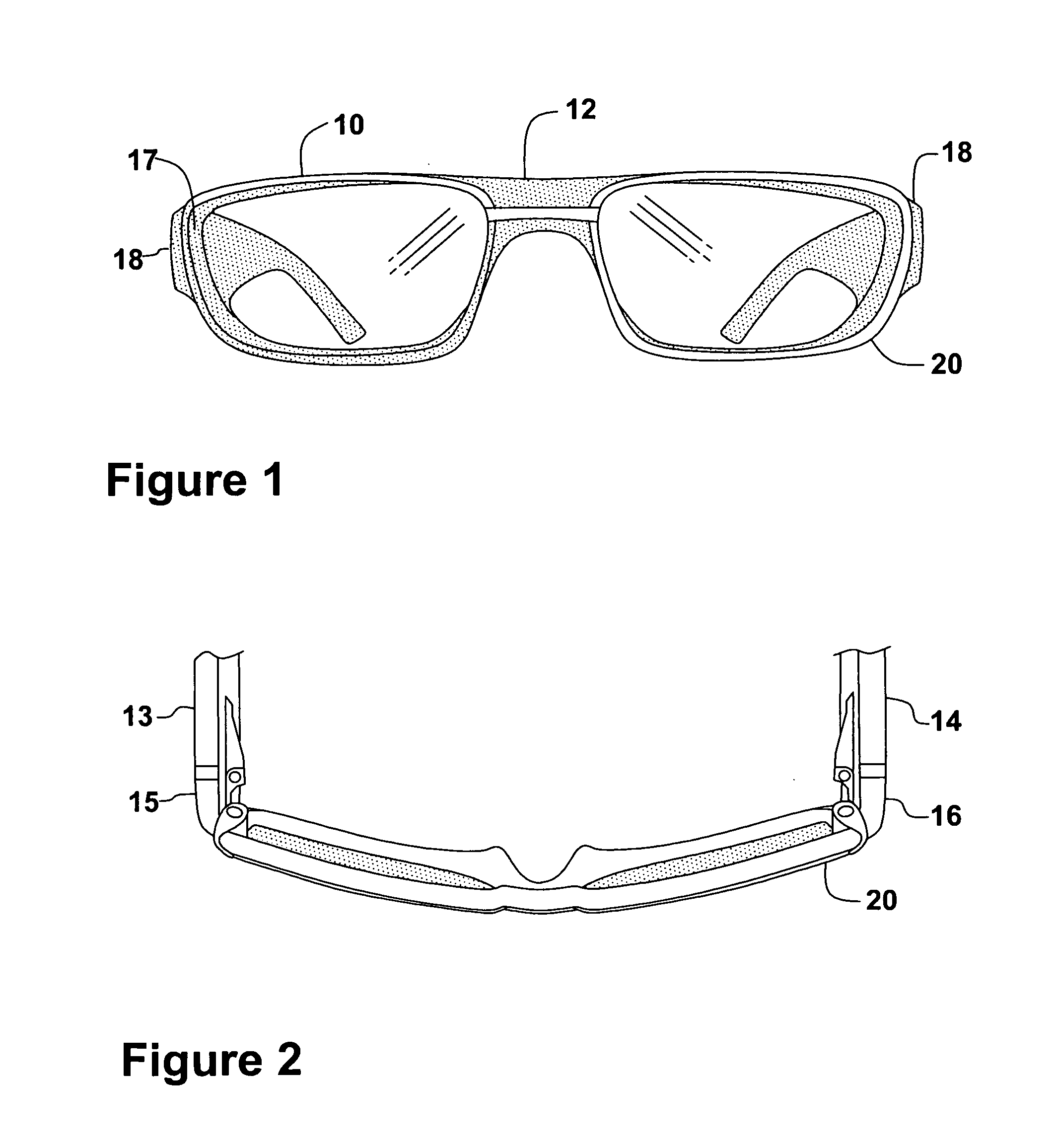

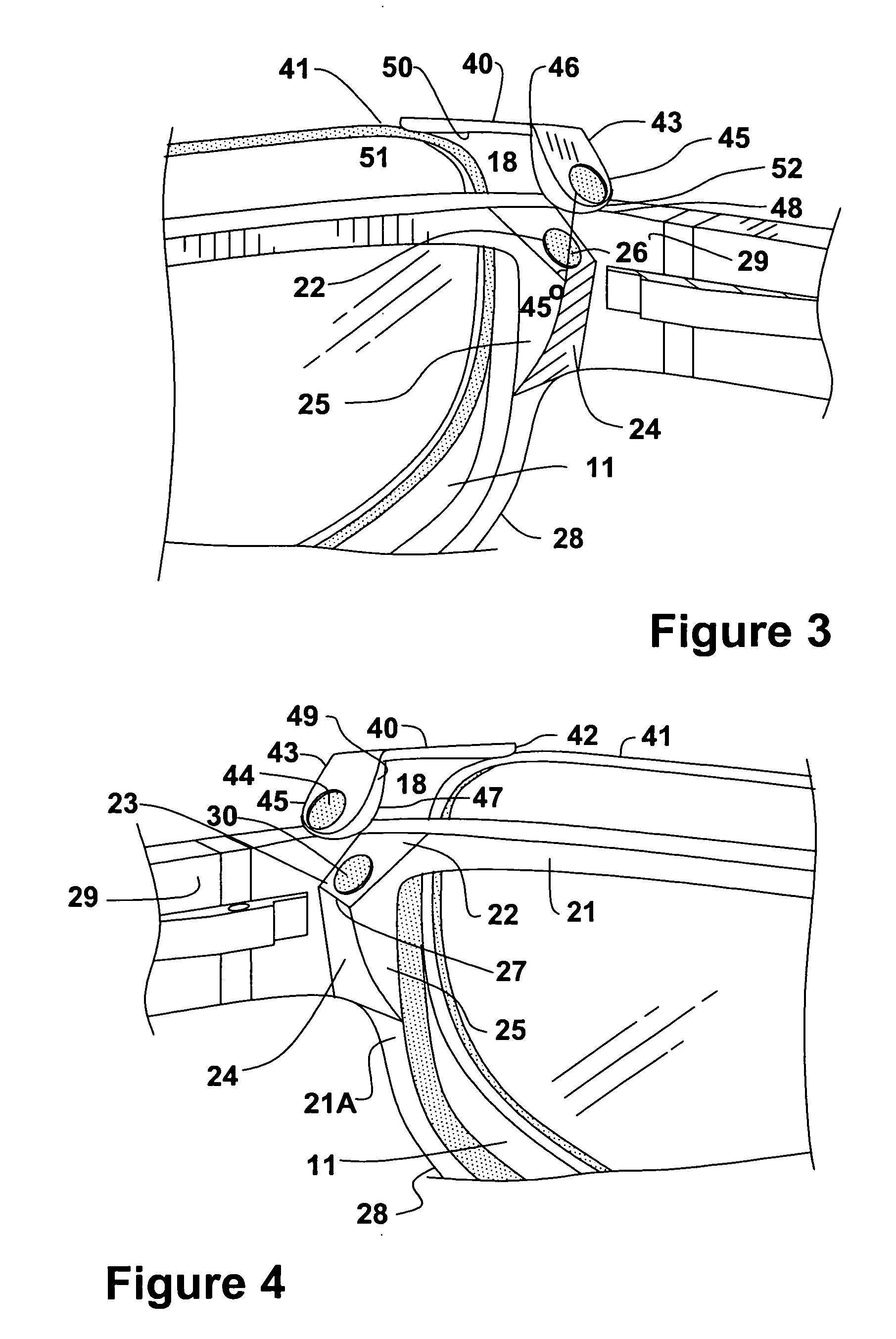

Frame construction for eyewear having removable auxiliary lenses

InactiveUS6866385B2Less expensiveImprove quality and stabilitySpectales/gogglesAuxillary optical partsEyewearEngineering

Owner:ASPEX EYEWEAR

Frame construction for eyewear having removable auxiliary lenses

InactiveUS6883912B1Less expensiveImprove quality and stabilitySpectales/gogglesAuxillary optical partsEyewearEngineering

Owner:WACKER SILTRONIC FUR HALBLETERMATERIALIEN

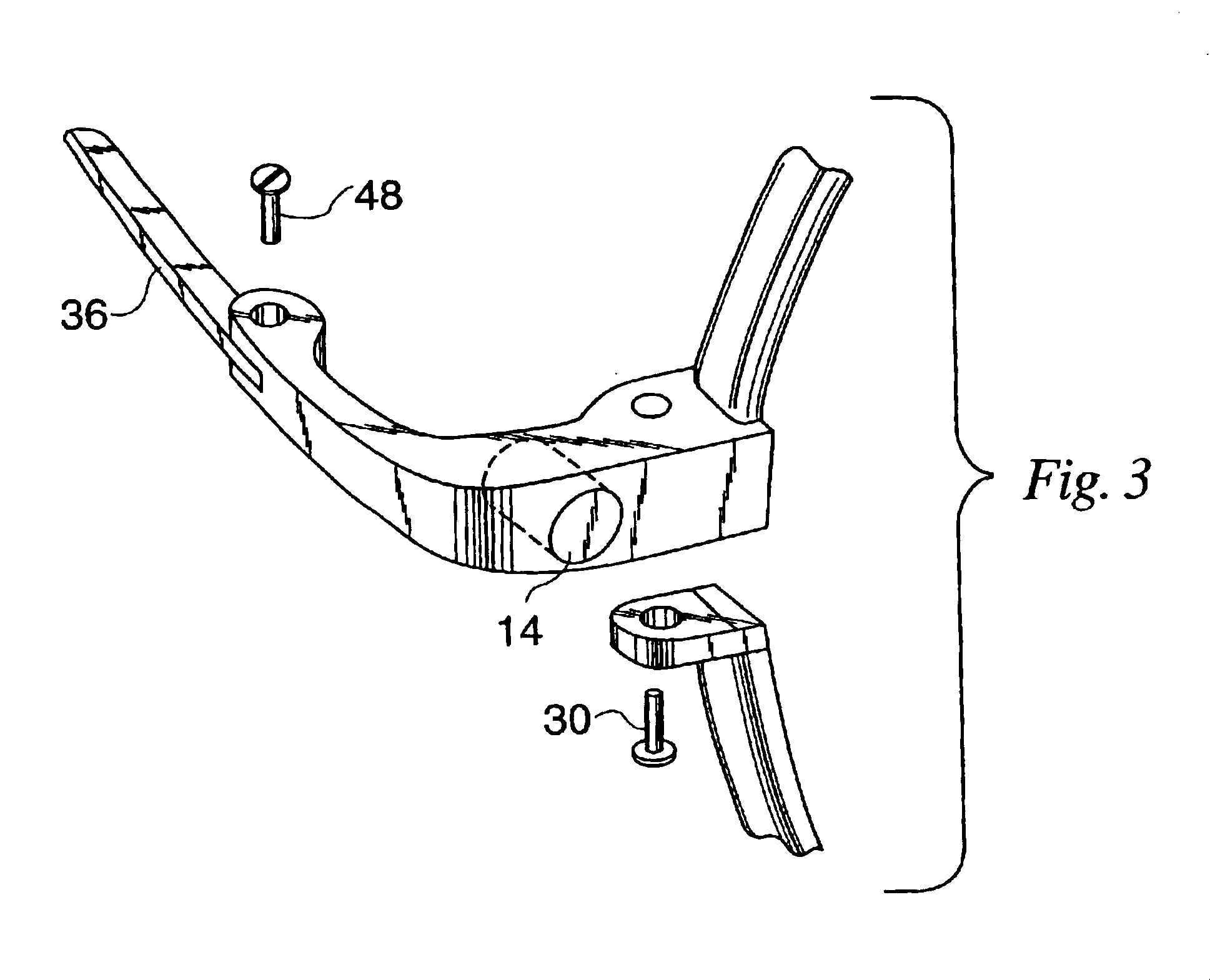

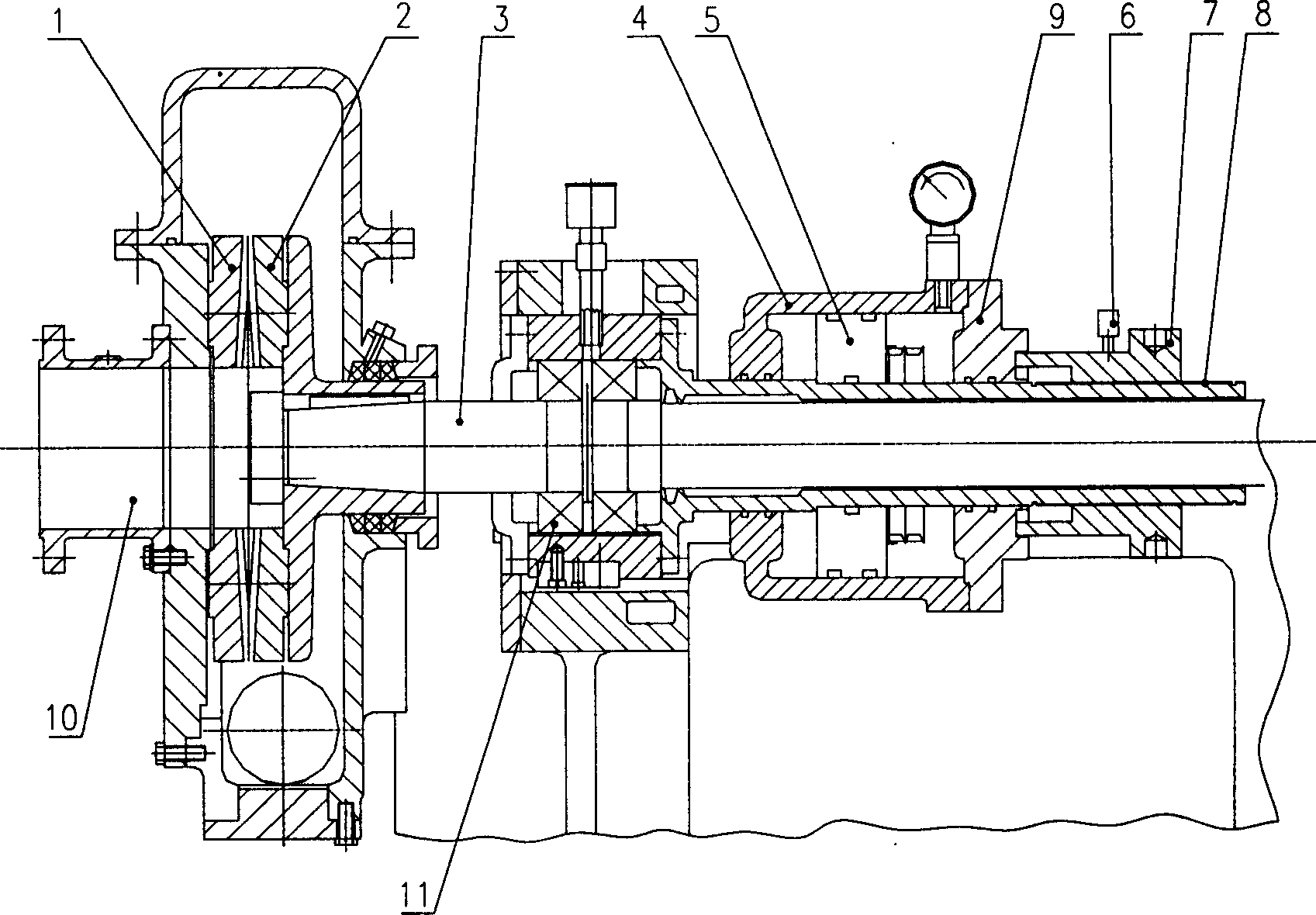

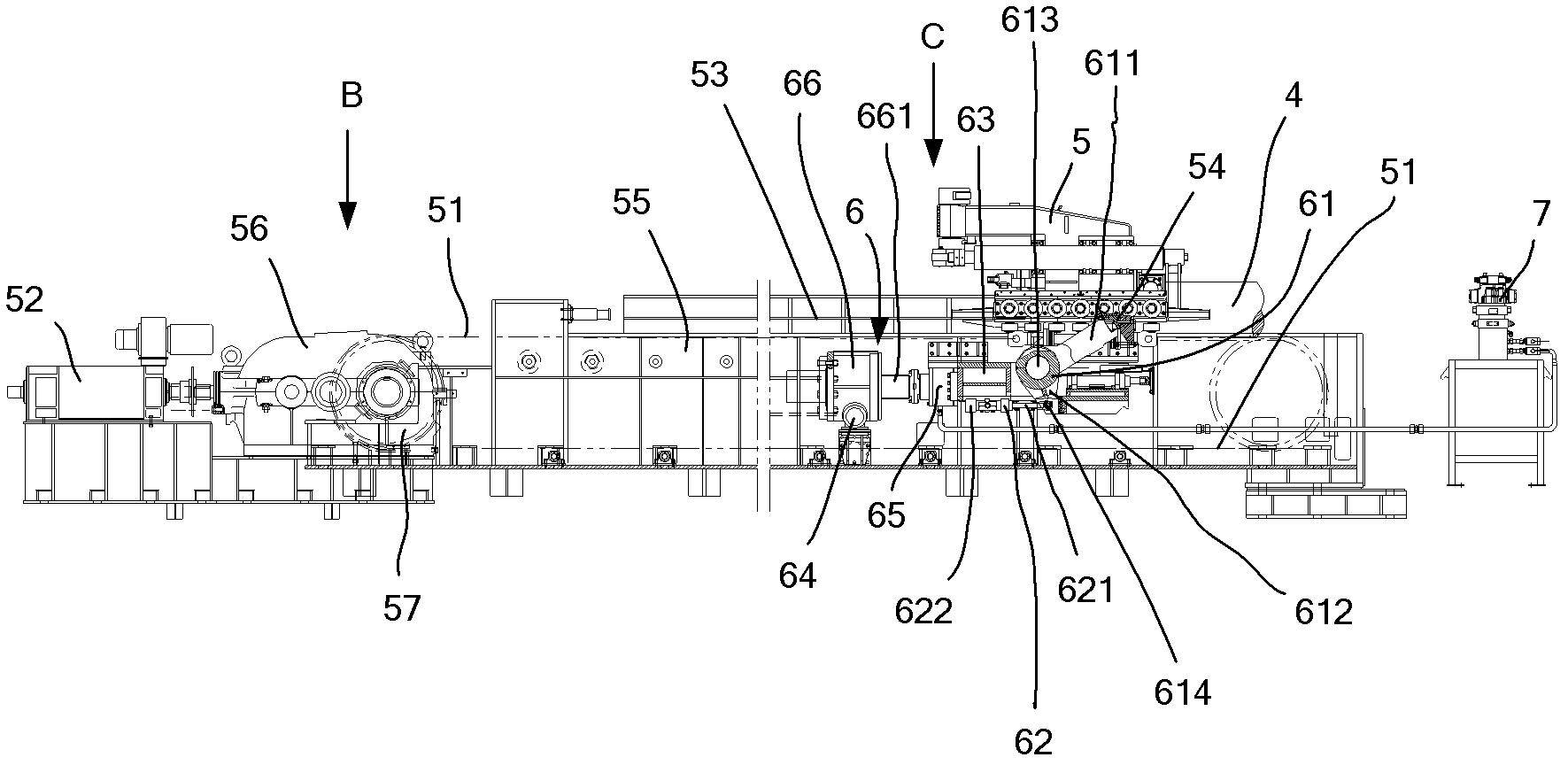

Disc refiner constant pressure pulping method and device

InactiveCN1456747AImprove quality and stabilityAvoid sharp rises in currentPulp beating/refining methodsPistonEngineering

A constant-pressure beating method features that the pressure in grinding area is constant and the beating intensity is controlled by the pressure in grinding area. Its constant-pressure beating apparatus is composed of moving disk, static disk, mainshaft, hydraulic cylinder, piston, push barrel and pressure control module. Its advantages are high pulp quality and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

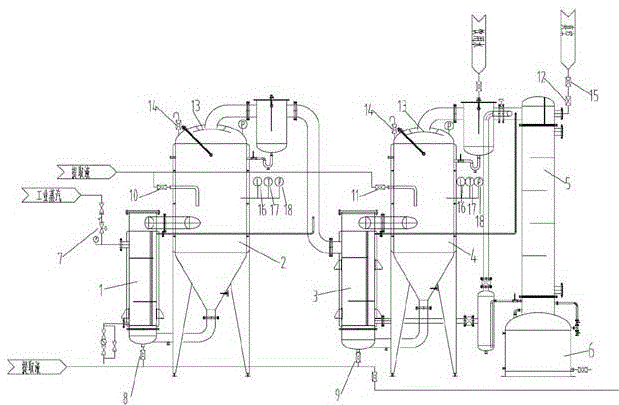

Control method for double-effect concentration process of Chinese traditional medicines

InactiveCN105536274AEasy to controlQuality improvementEvaporator accessoriesEvaporator regulation/controlChinese traditionalEngineering

The invention discloses a control method for the double-effect concentration process of traditional Chinese medicines. The double-effect concentration process of traditional Chinese medicines is carried out in a concentrator. The control method comprises the following steps: starting-up and confirmation; feeding control; control of temperature and pressure in the concentration process; defoaming control; vacuum protection control; control of liquid supplementation in the concentration process; liquid discharging of a liquid receiver; batch turning control; judgment of the terminal point of concentration; and liquid discharging control. Thus, the method provided by the invention realizes precise control of parameters of the double-effect concentration process of traditional Chinese medicines and provides a novel technology to improve traditional Chinese medicine product quality stability and modernization of traditional Chinese medicines.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH

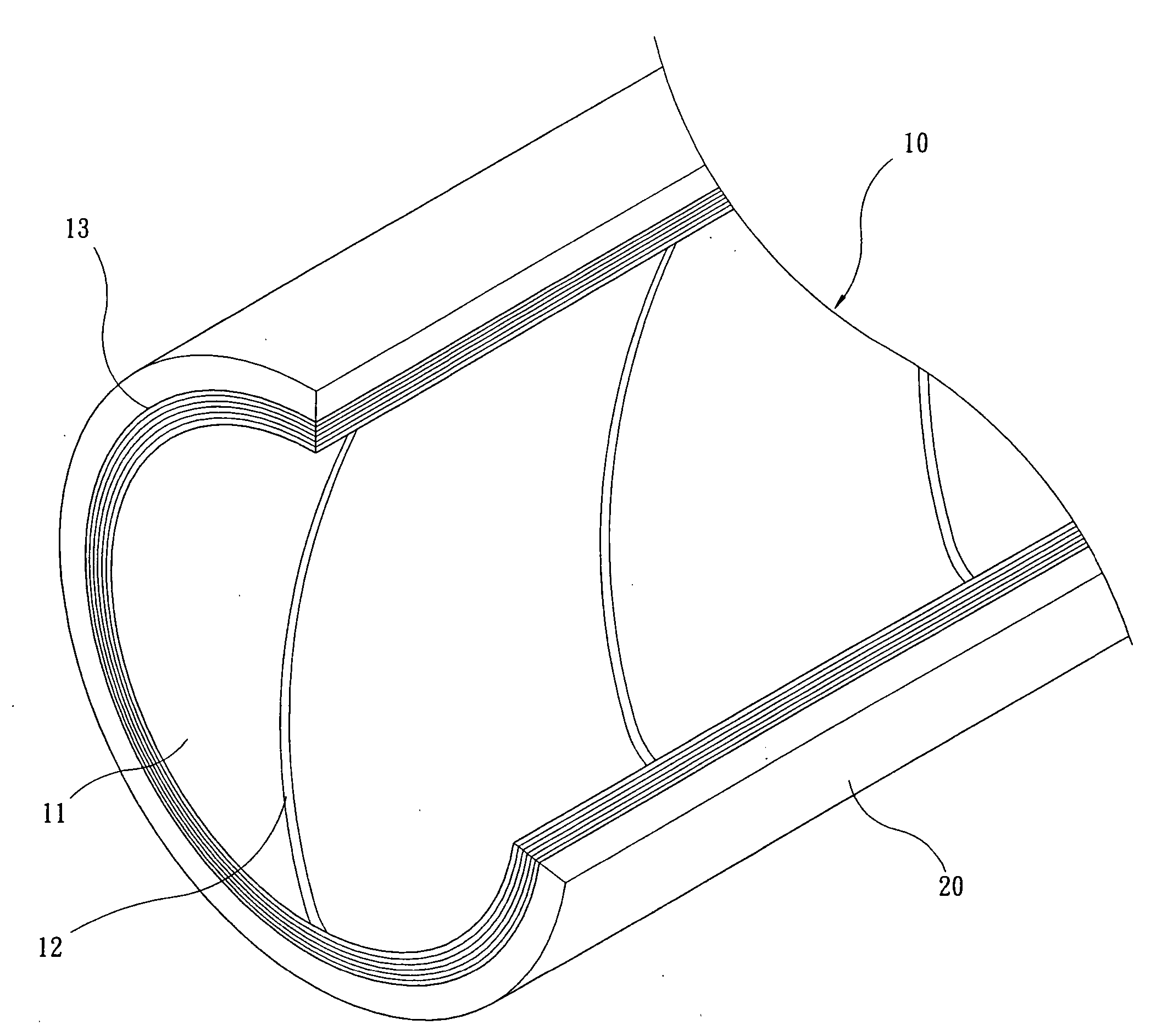

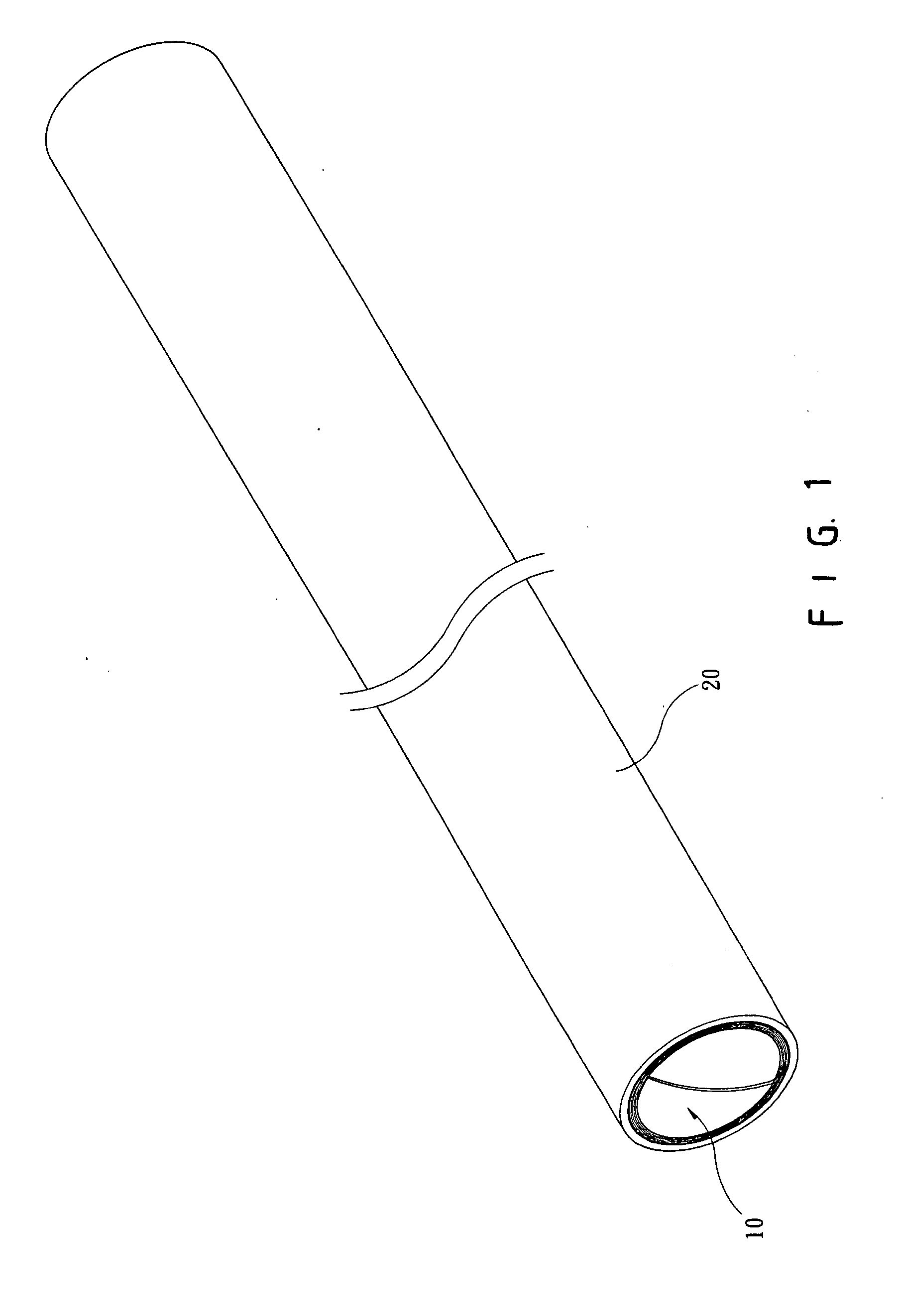

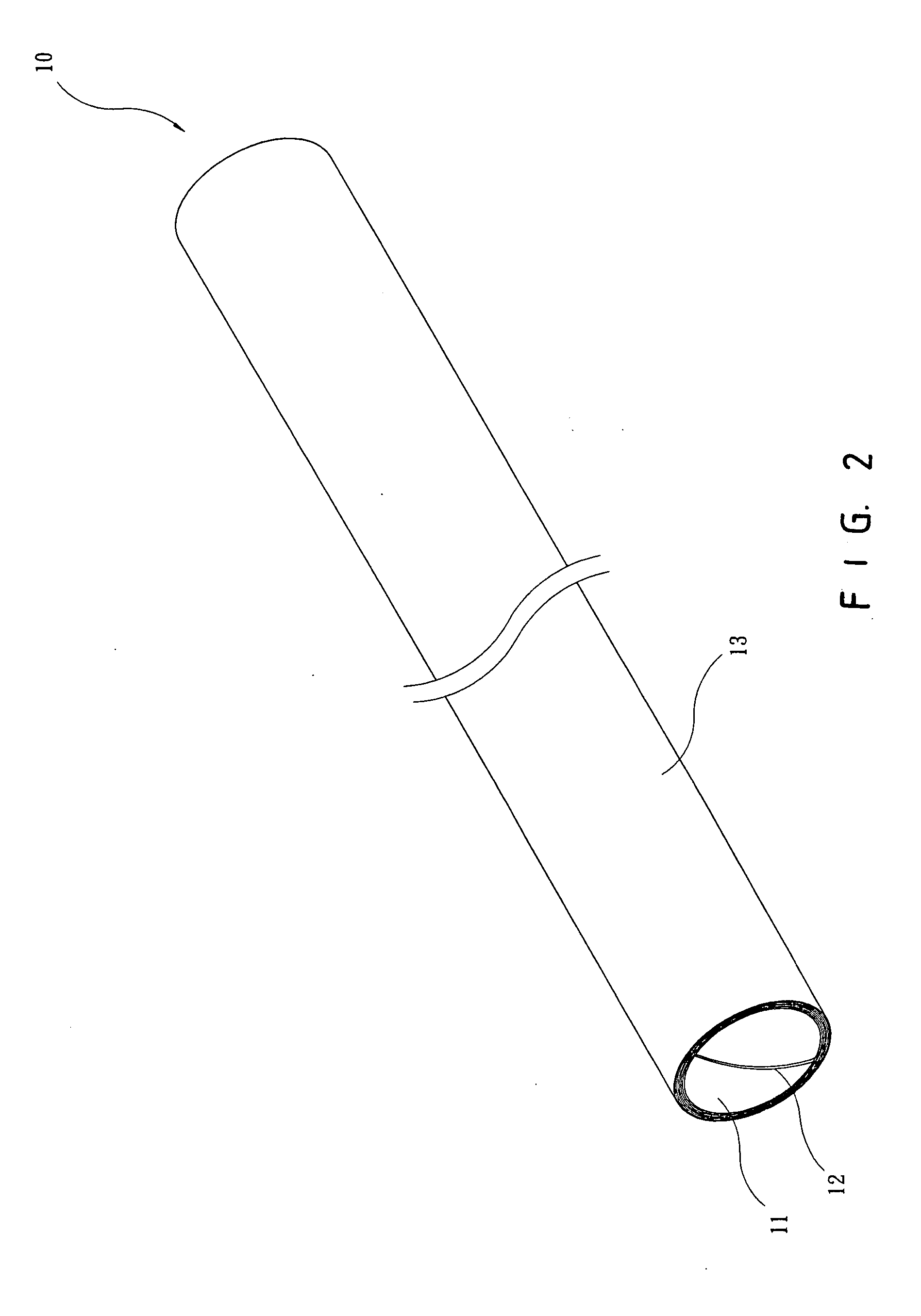

Seamless paper reel

InactiveUS20060043234A1Quality improvementImprove stabilityRigid pipesMetallic foilPulp and paper industry

A paper reel includes a lining, and an enclosure mounted on a periphery of the lining. Thus, the plastic enclosure encompasses a whole length of the paper lining to reinforce the strength of the paper reel, so that when an element, such as a tape, cloth, weaving strap, metallic foil, car insulating paper or the like, is closely wound around the paper reel, the paper reel will not be deformed or distorted due to compression, thereby enhancing the quality and stability of the paper reel.

Owner:CHEN HUI LING

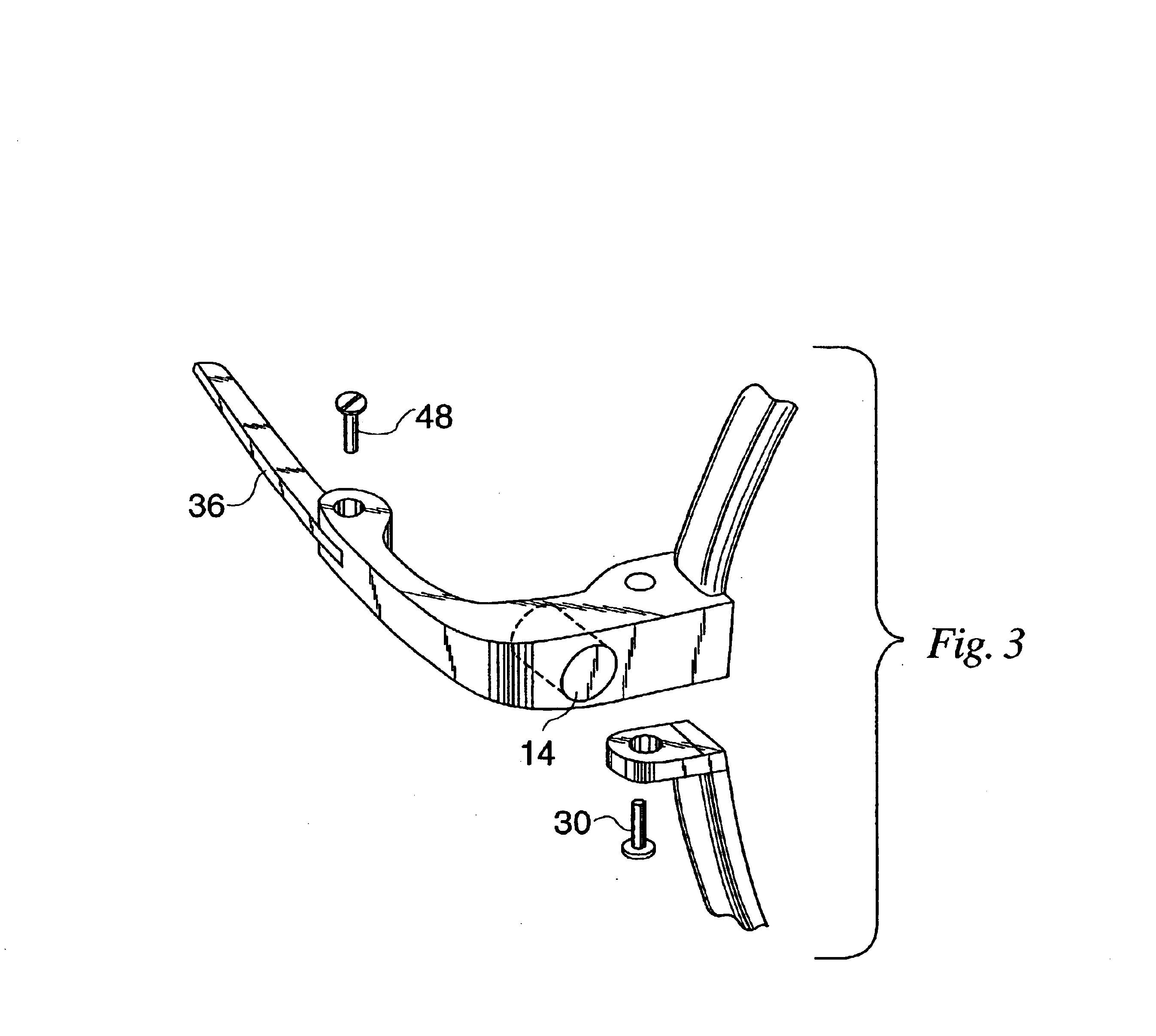

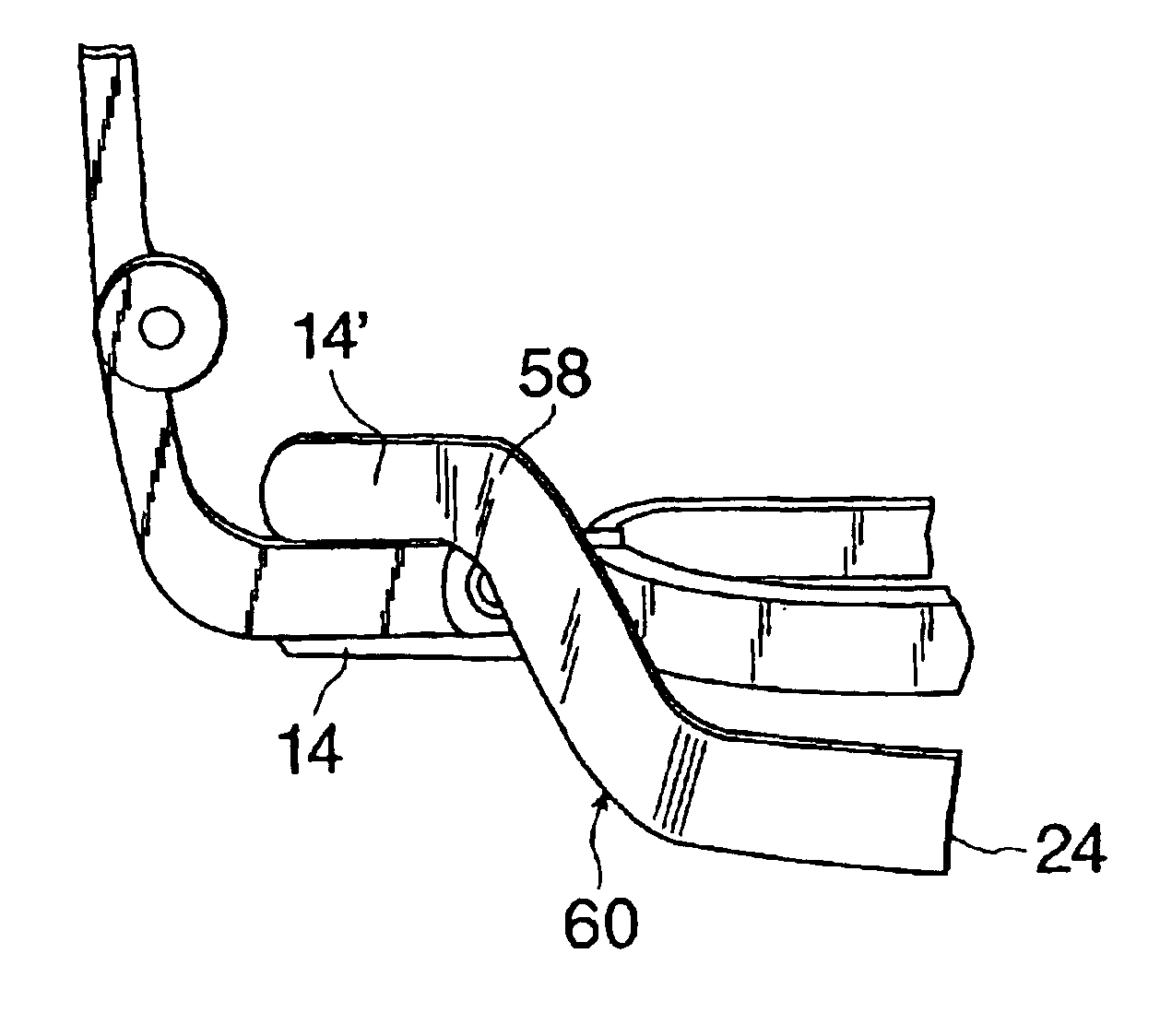

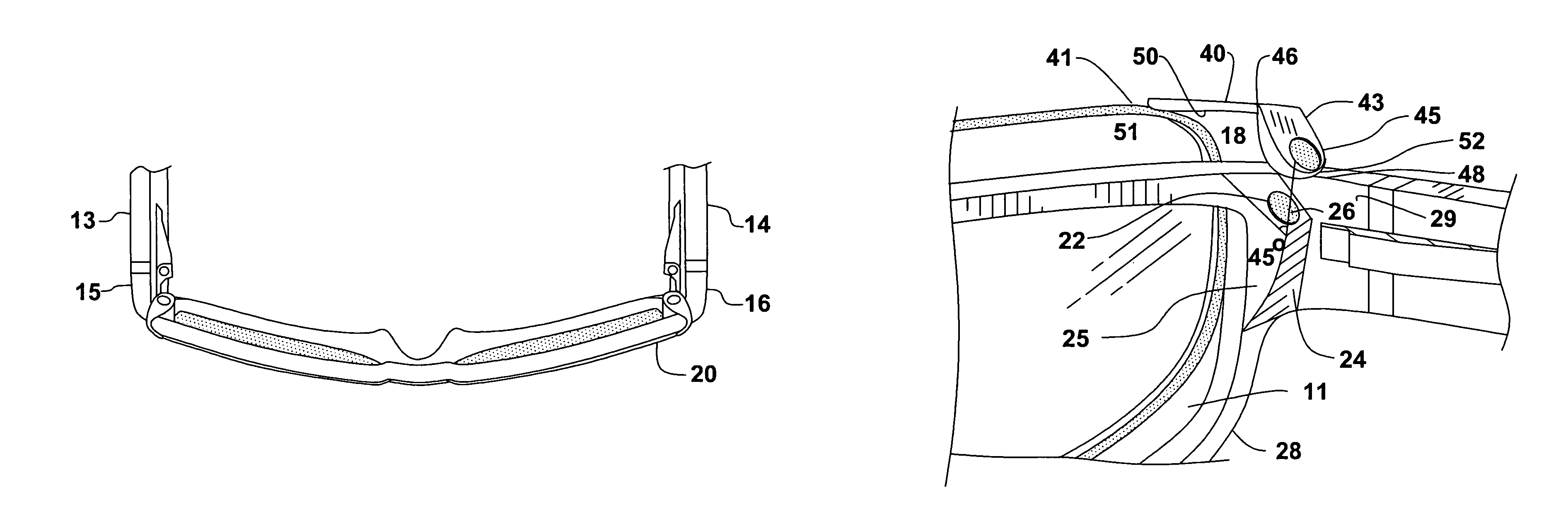

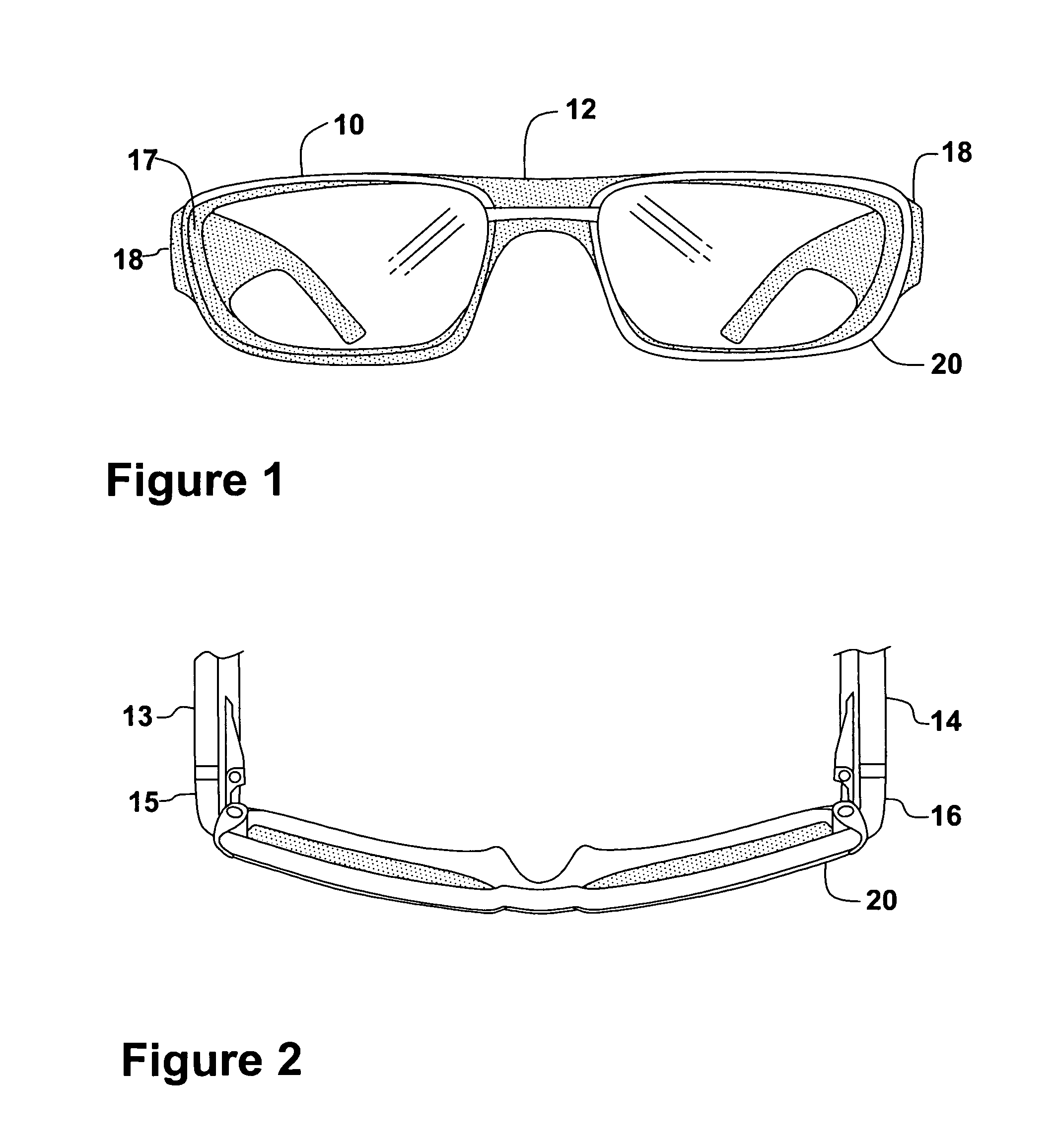

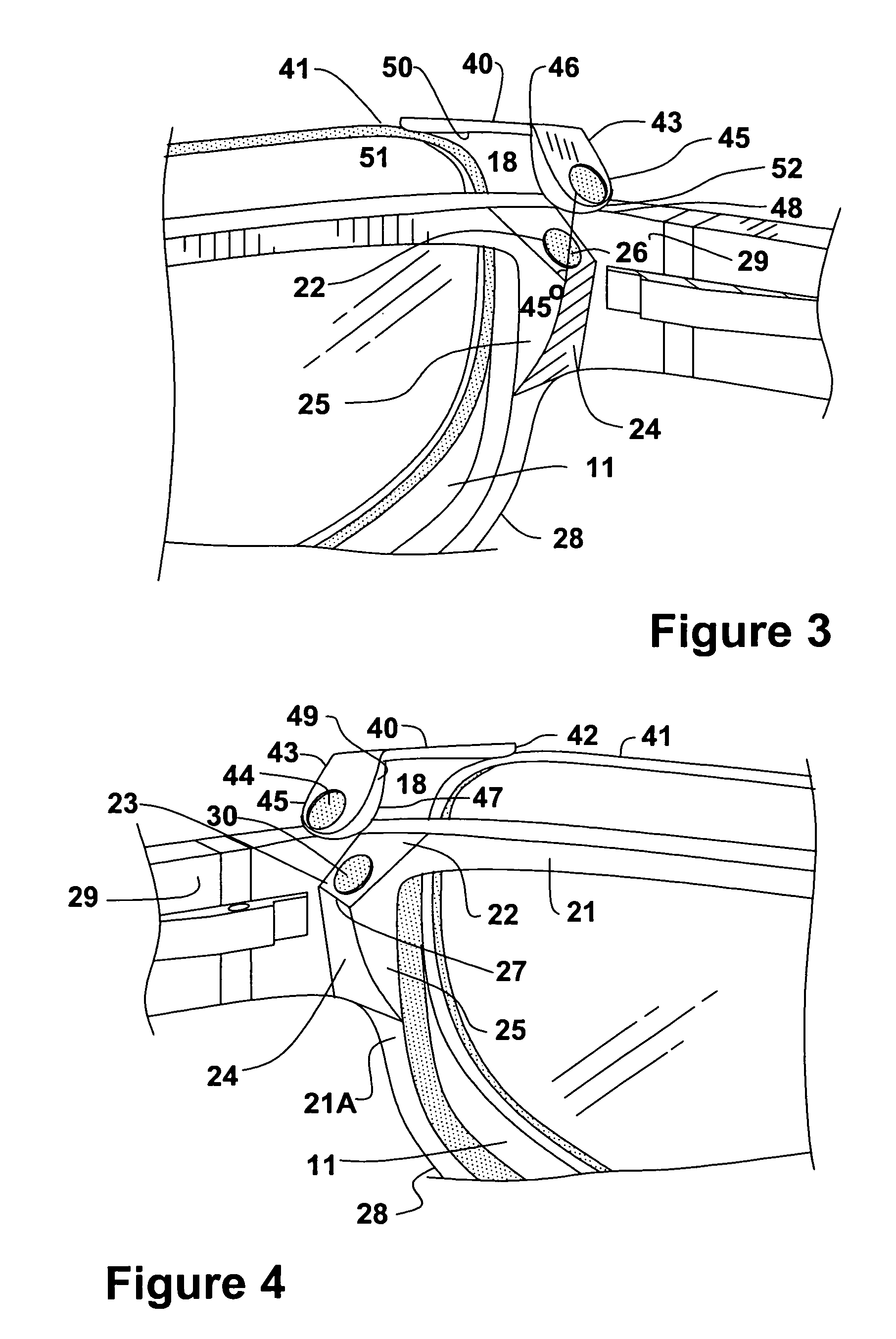

Frame construction for eyewear

ActiveUS8480226B2Less expensiveImprove quality and stabilitySpectales/gogglesAuxillary optical partsVehicle frameEyewear

Owner:IFERGAN NONU

Frame construction for eyewear

ActiveUS20110075094A1Less expensiveImprove quality and stabilitySpectales/gogglesAuxillary optical partsVehicle frameMagnet

An eyeglass assembly is provided and includes a frame assembly and at least one subframe assembly. The frame assembly has at least one lens and a pair of temples. The frame assembly also has a bridge. A rear side of the frame assembly has at least one member extending outwardly therefrom and wherein the extending member has at least one securing surface. The securing surface has a magnetic member thereon. The subframe assembly has a front side and a rear side. The subframe assembly has at least one arm extending rearwardly therefrom. The arm has a first end secured to the subframe assembly and a second end opposite said first end. The second end has a magnetic member thereon. The subframe assembly is magnetically secured to the frame assembly at least in part by the magnetic members, one of the magnetic members being a magnet and a second of the magnetic members being a material that is attracted to a magnet.

Owner:IFERGAN NONU

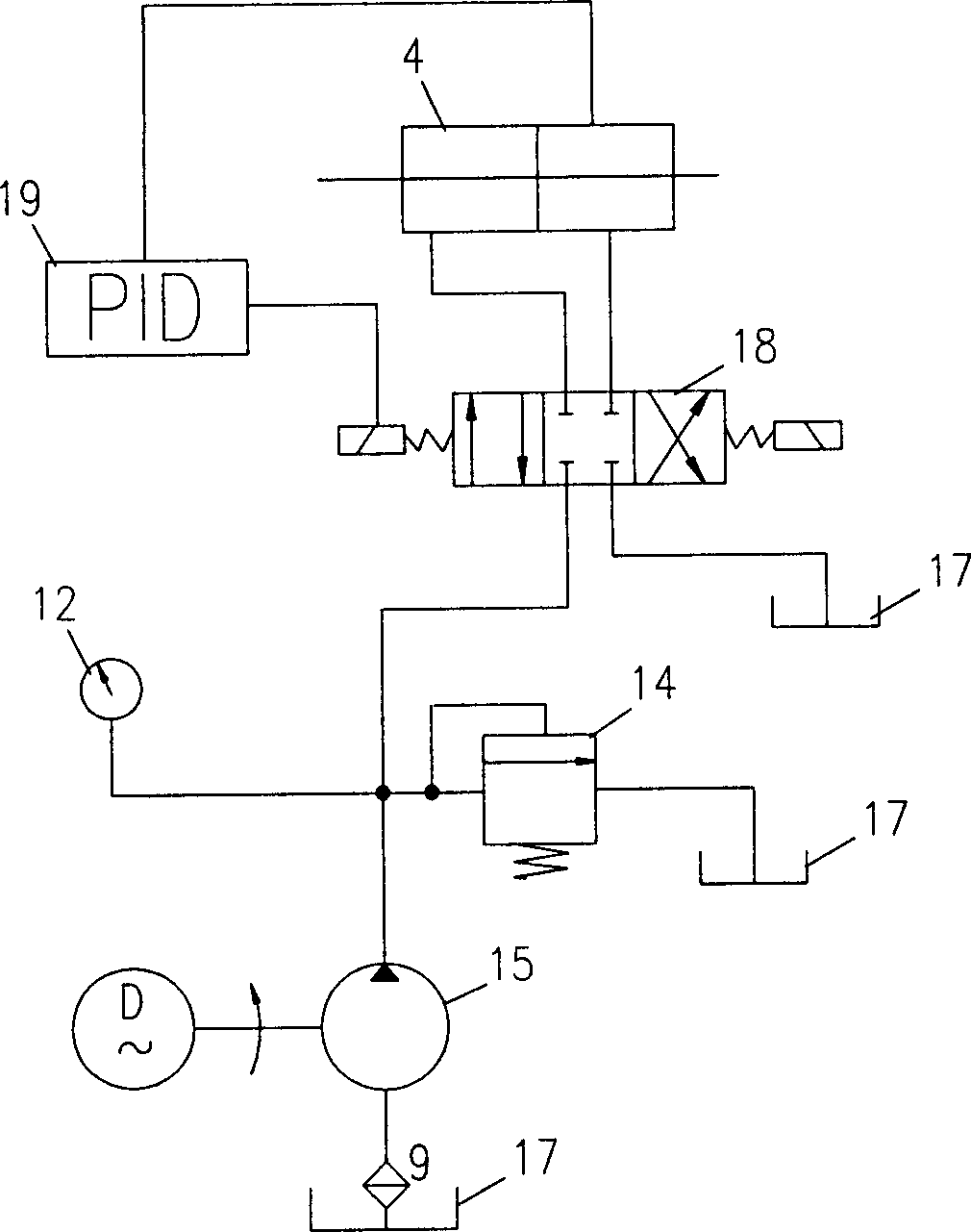

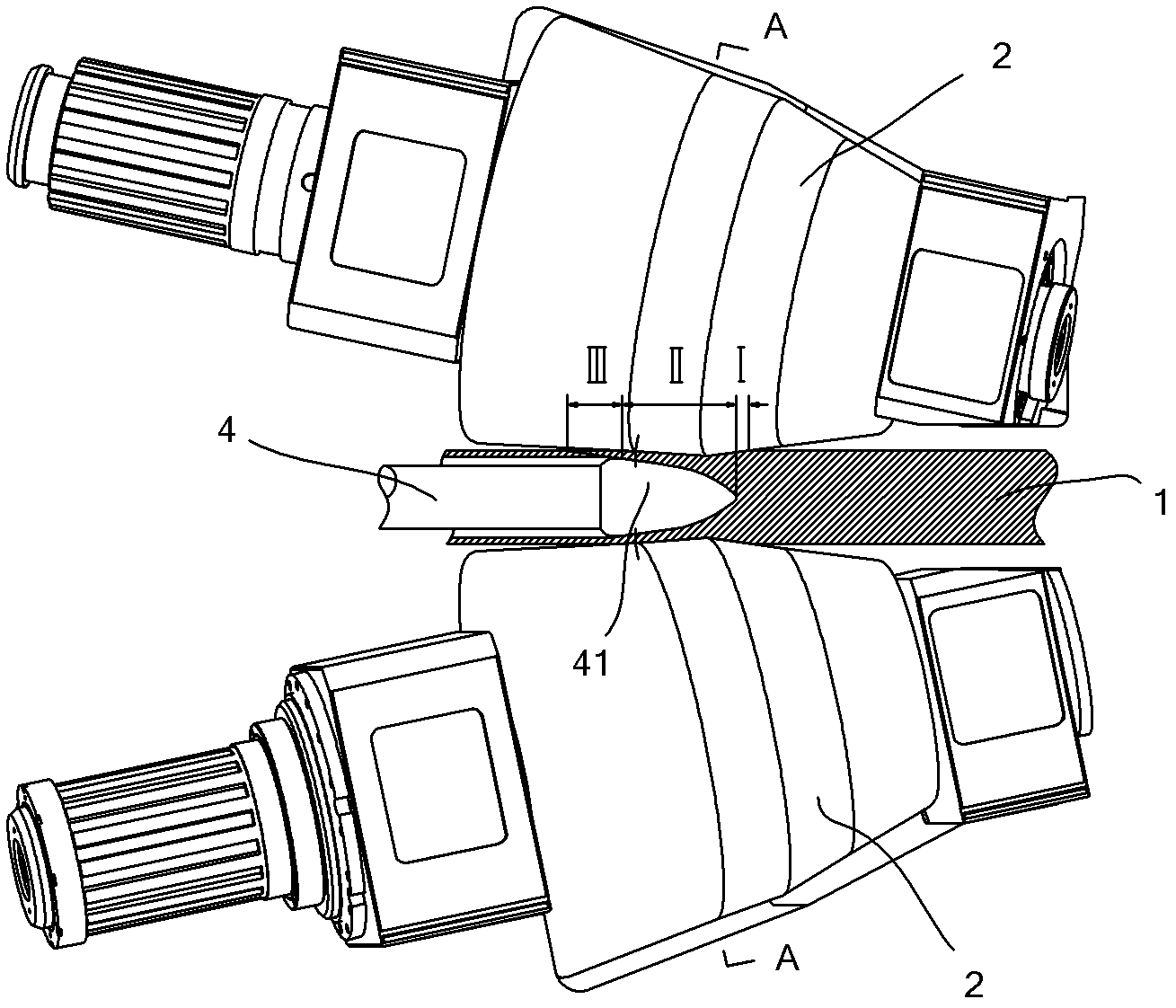

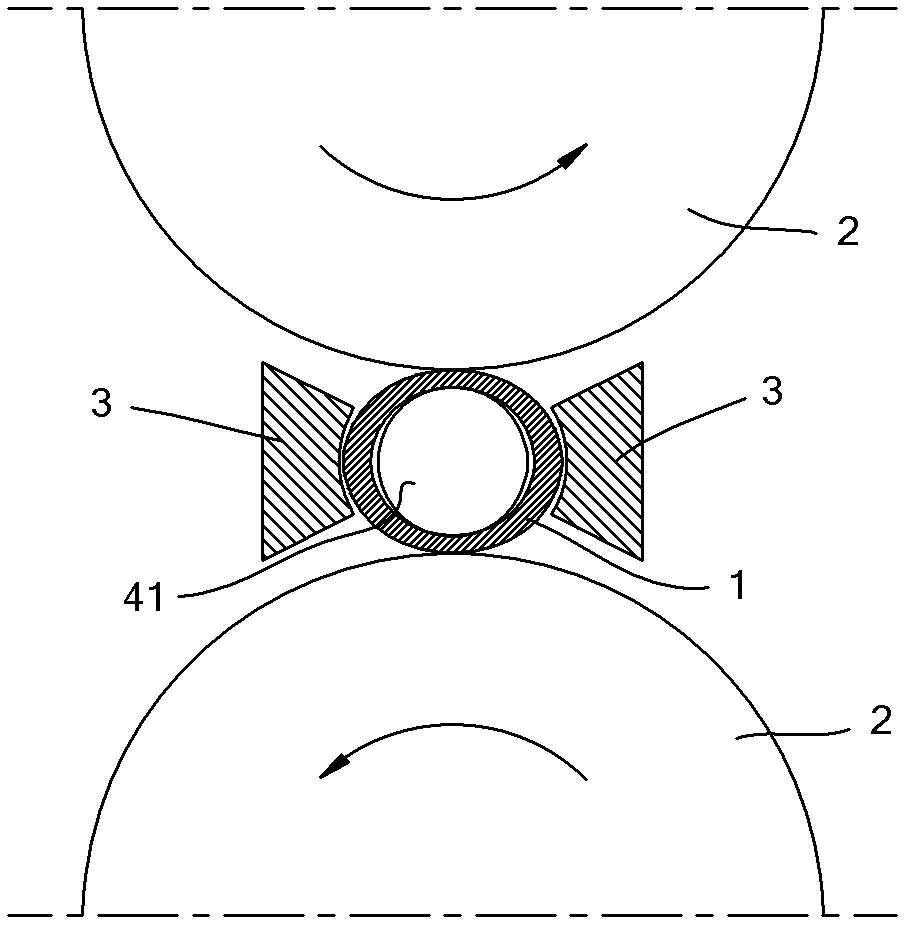

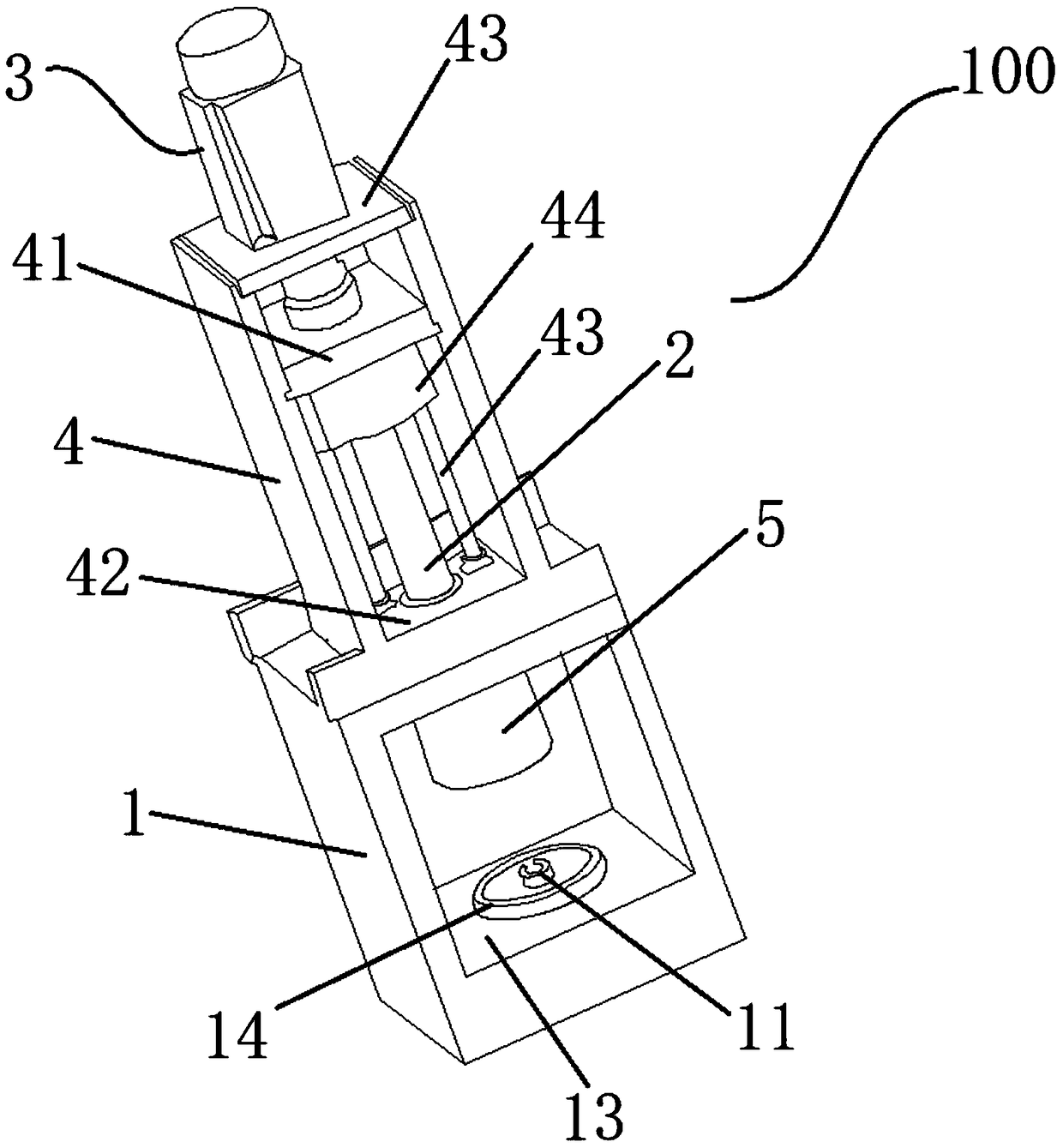

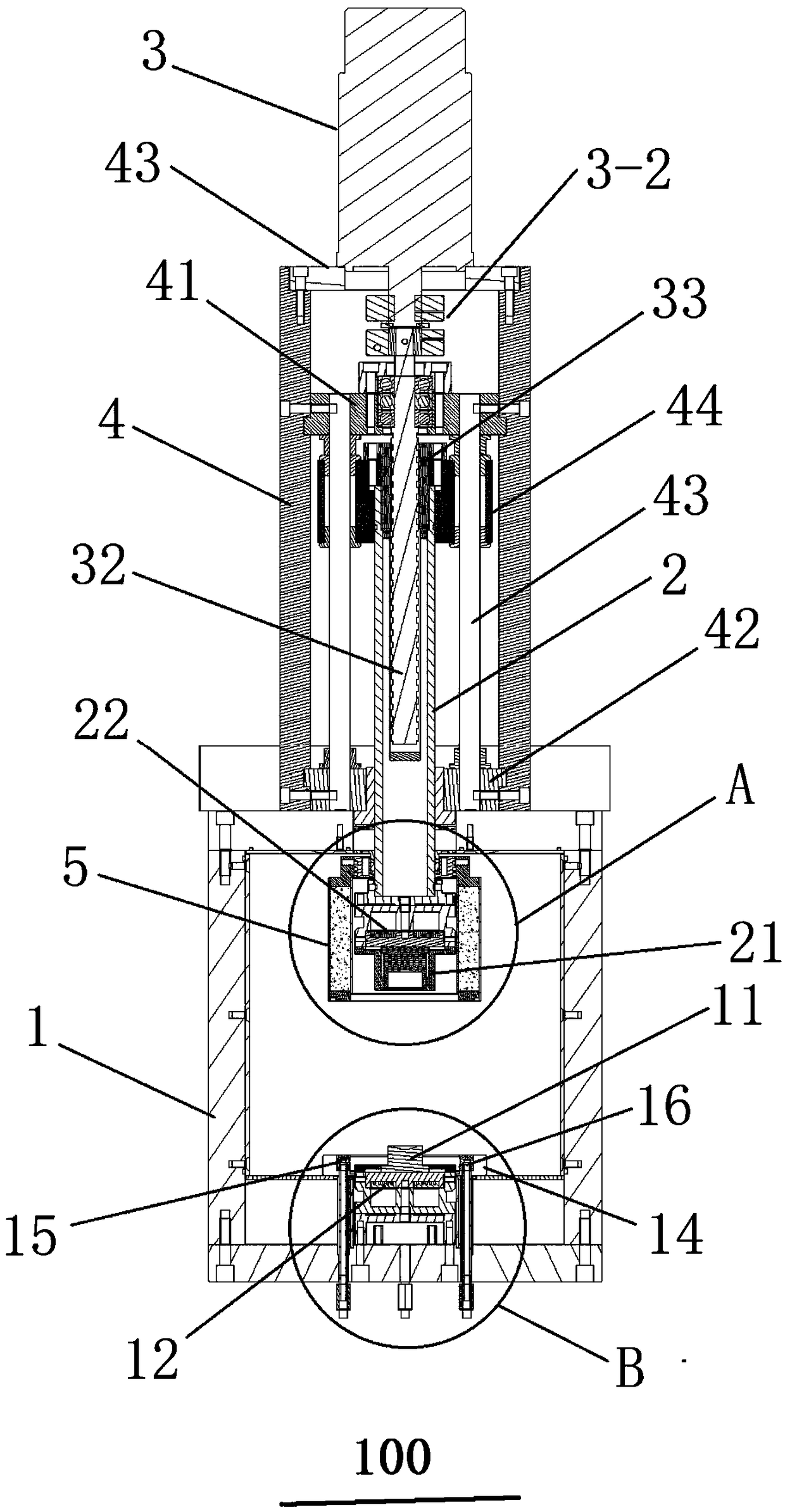

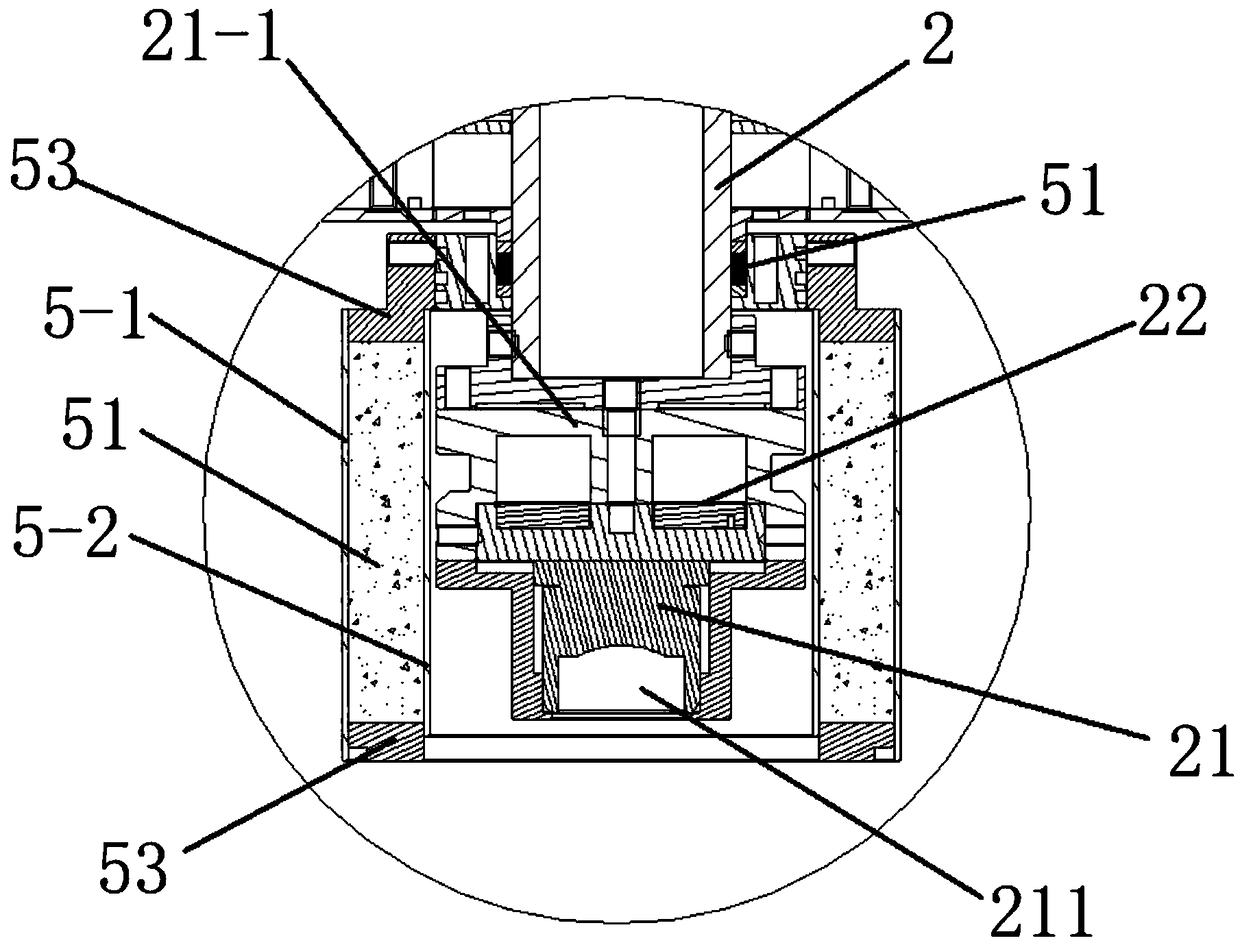

Seamless steel tube perforator piercing point on-line regulating device

ActiveCN102513359AImprove quality and stabilityImprove pass rateMetal rolling arrangementsSteel tubeEngineering

The invention discloses a seamless steel tube perforator piercing point on-line regulating device, which comprises a piercing rod and a piercing rod trolley, wherein the piercing point is at one end of the piercing rod and is a cone; the terminal line of the cone is a straight line with transitional curves at two ends; and the other end of the piercing rod is arranged on the piercing rod trolley. The seamless steel tube perforator piercing point on-line regulating device is characterized by also comprising a locking device, wherein the position of the piercing rod trolley is locked by the locking device; when the piercing point presses a tube blank of a seamless steel tube, the locking device can move the locked position of the piercing rod trolley along the moving direction of the tube blank, so that the piercing rod can move together with the piercing rod trolley by means of a rolling force. According to the device, the piercing point can move along the moving direction of the tube blank in a tube blank perforation process, so that the outside diameter of the piercing point in a tube blank perforating forming region can be reduced to compensate for the increase of the outside diameter of the piercing point with heat expansion in the tube blank perforation process; and thus, the outside diameter of the piercing point in the tube blank perforating forming region can keep stable and constant, and the inside diameter of a tubular billet formed by tube blank perforation is not changed.

Owner:TAIYUAN HEAVY IND

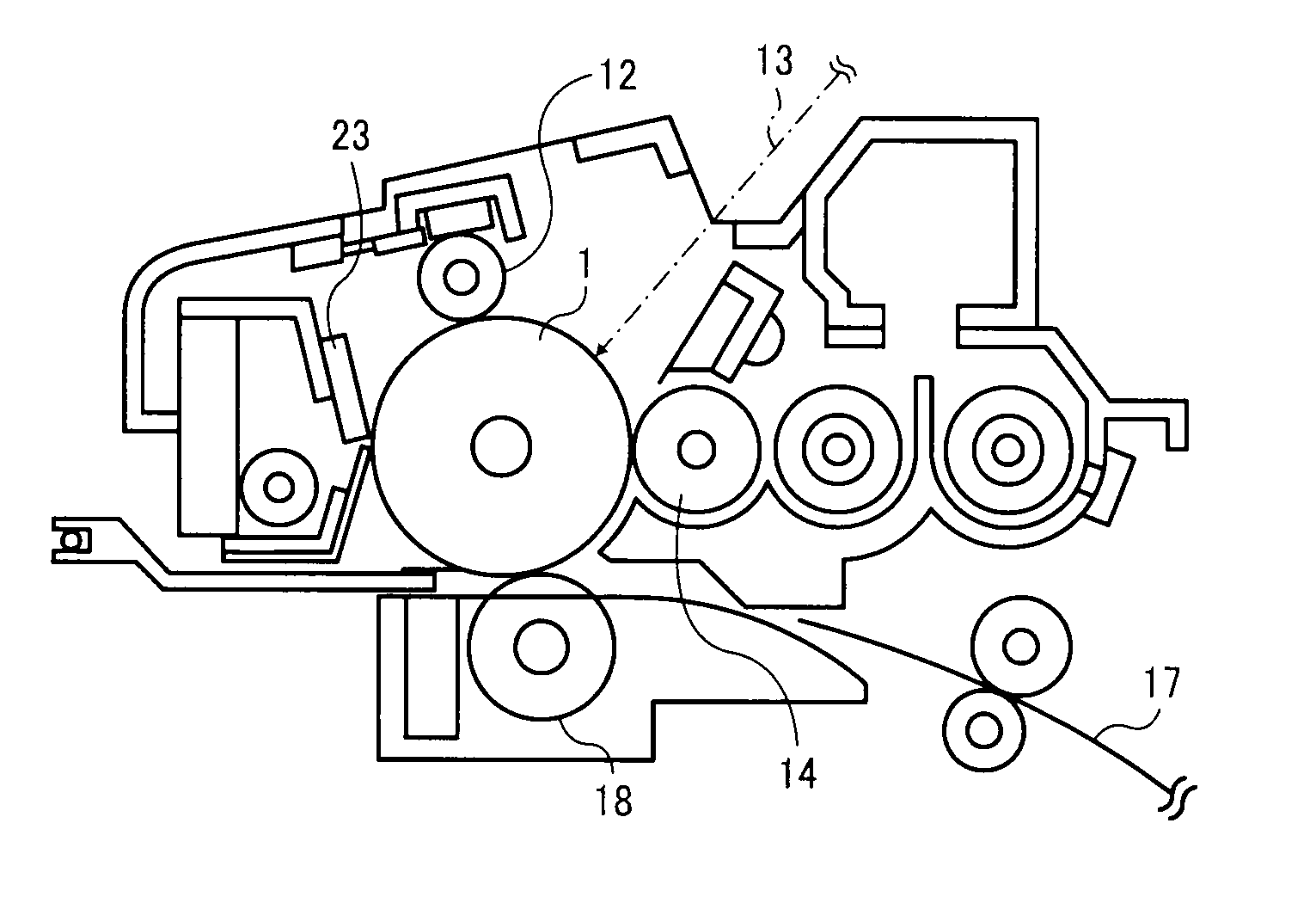

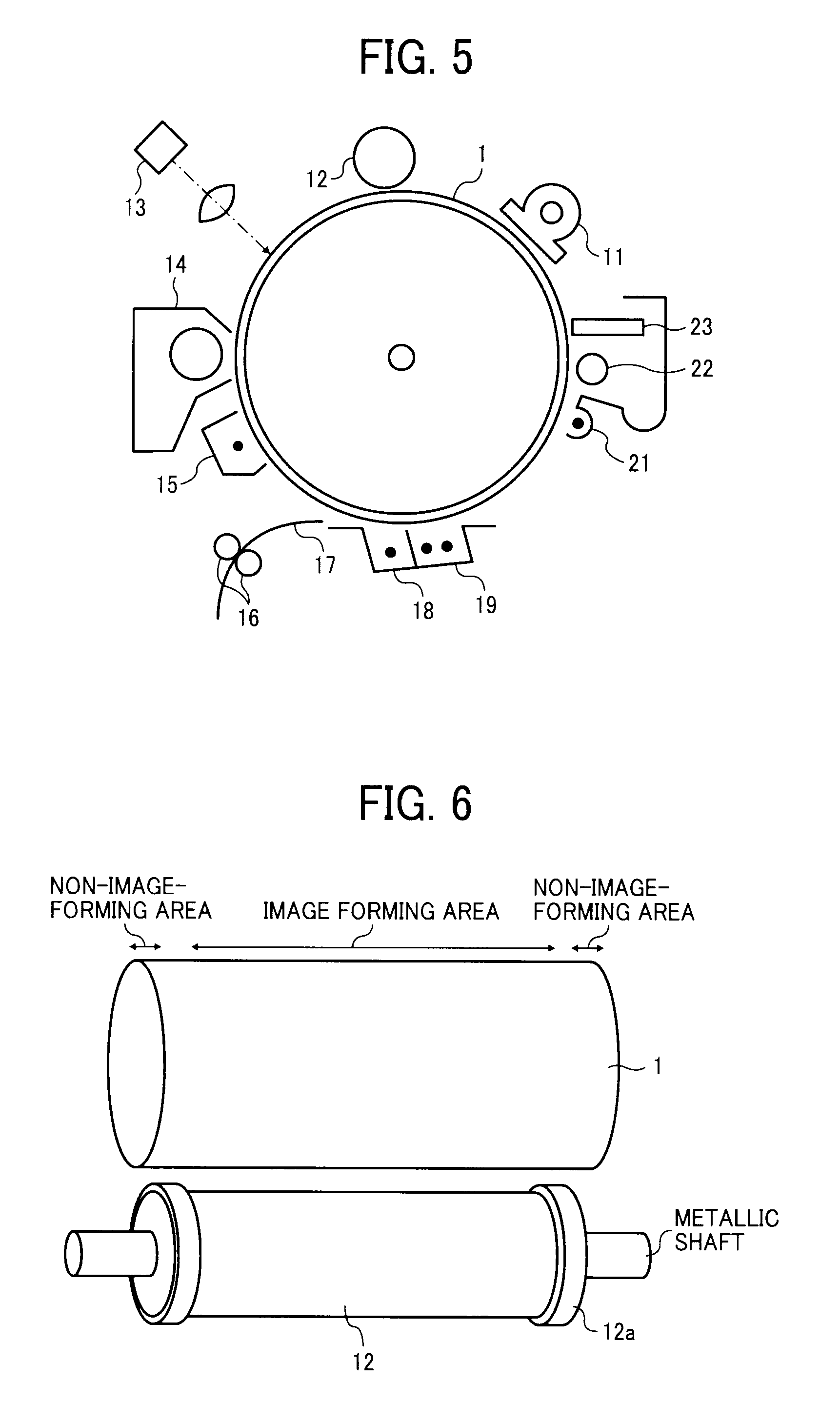

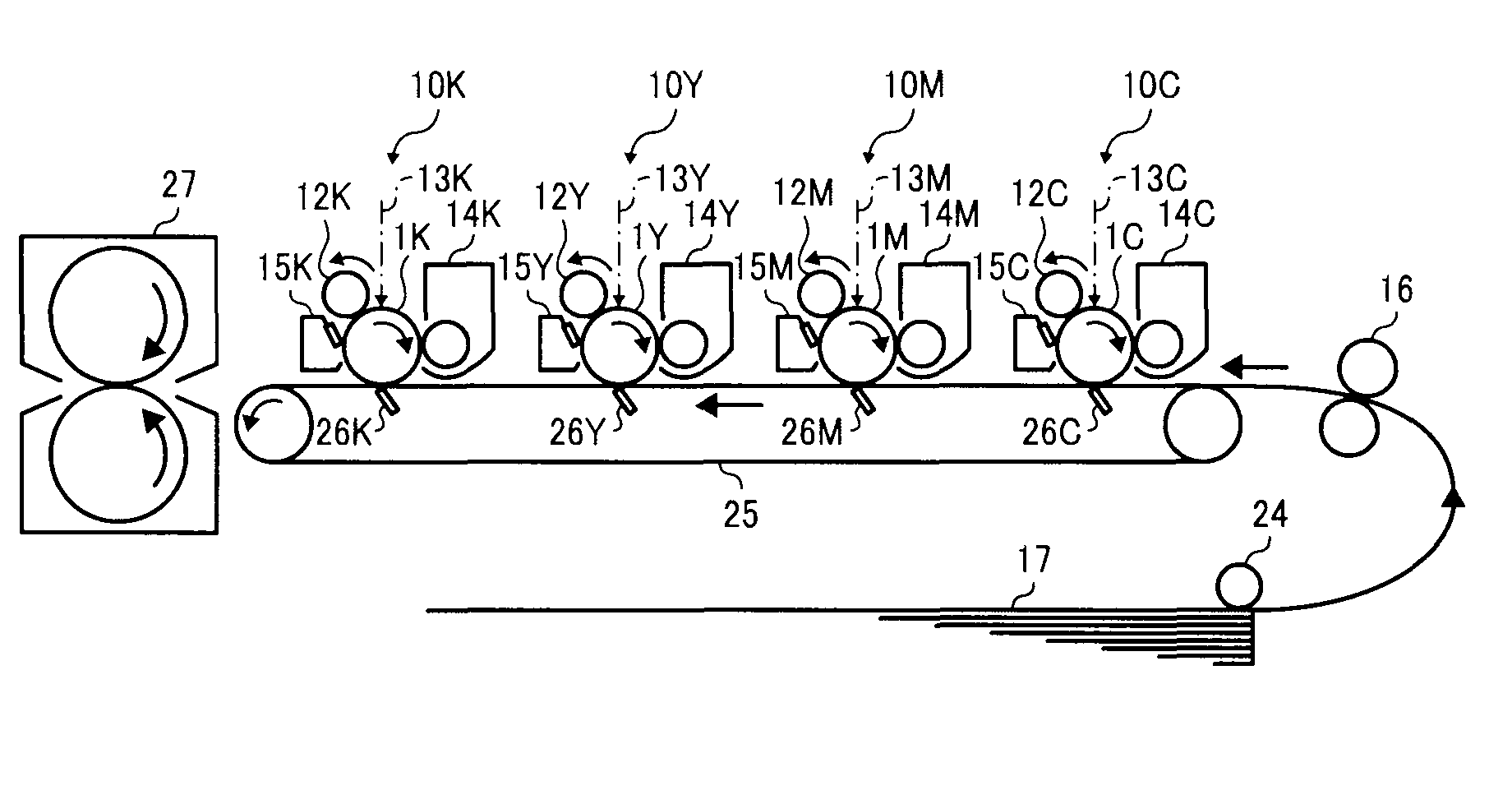

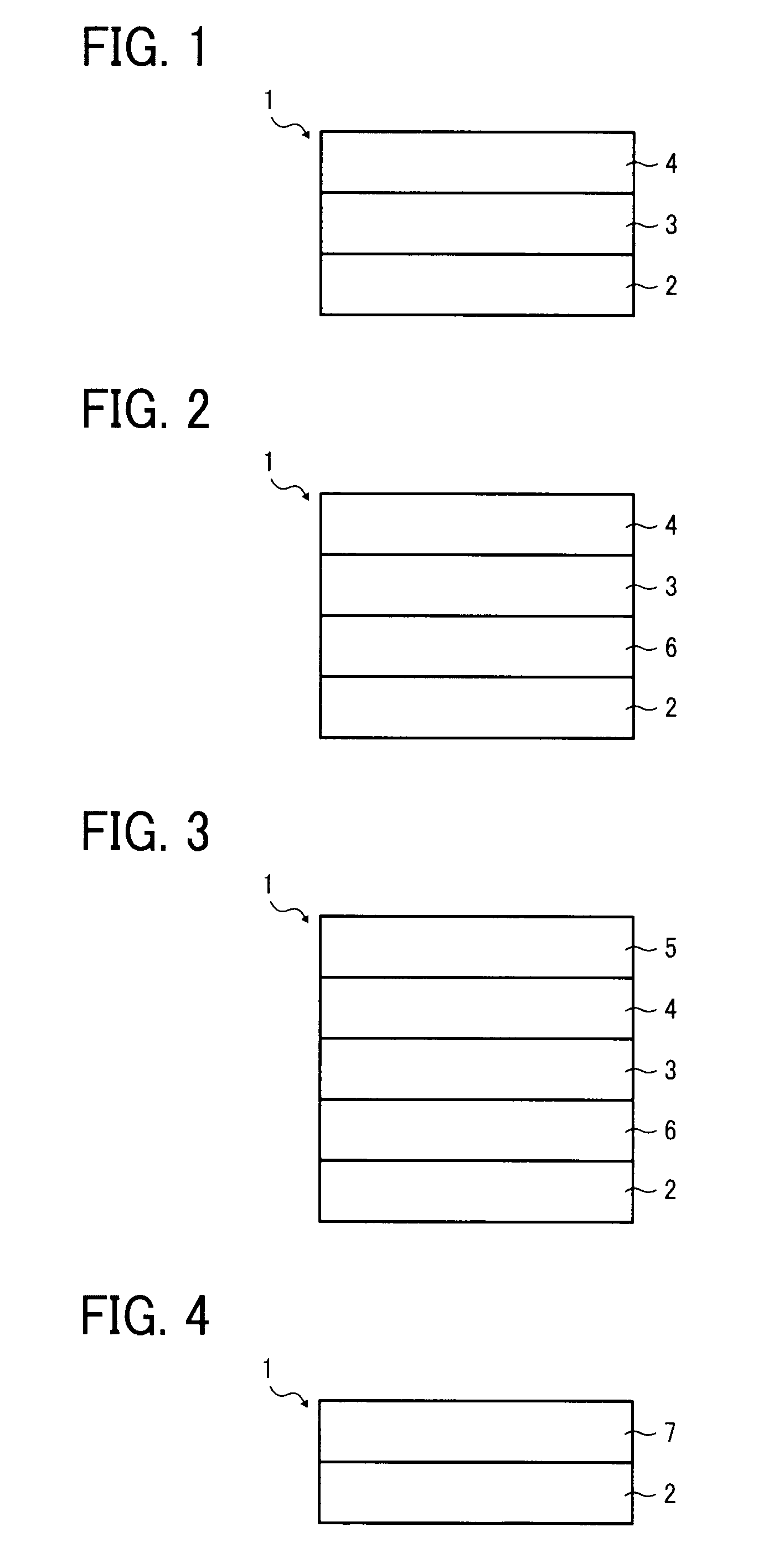

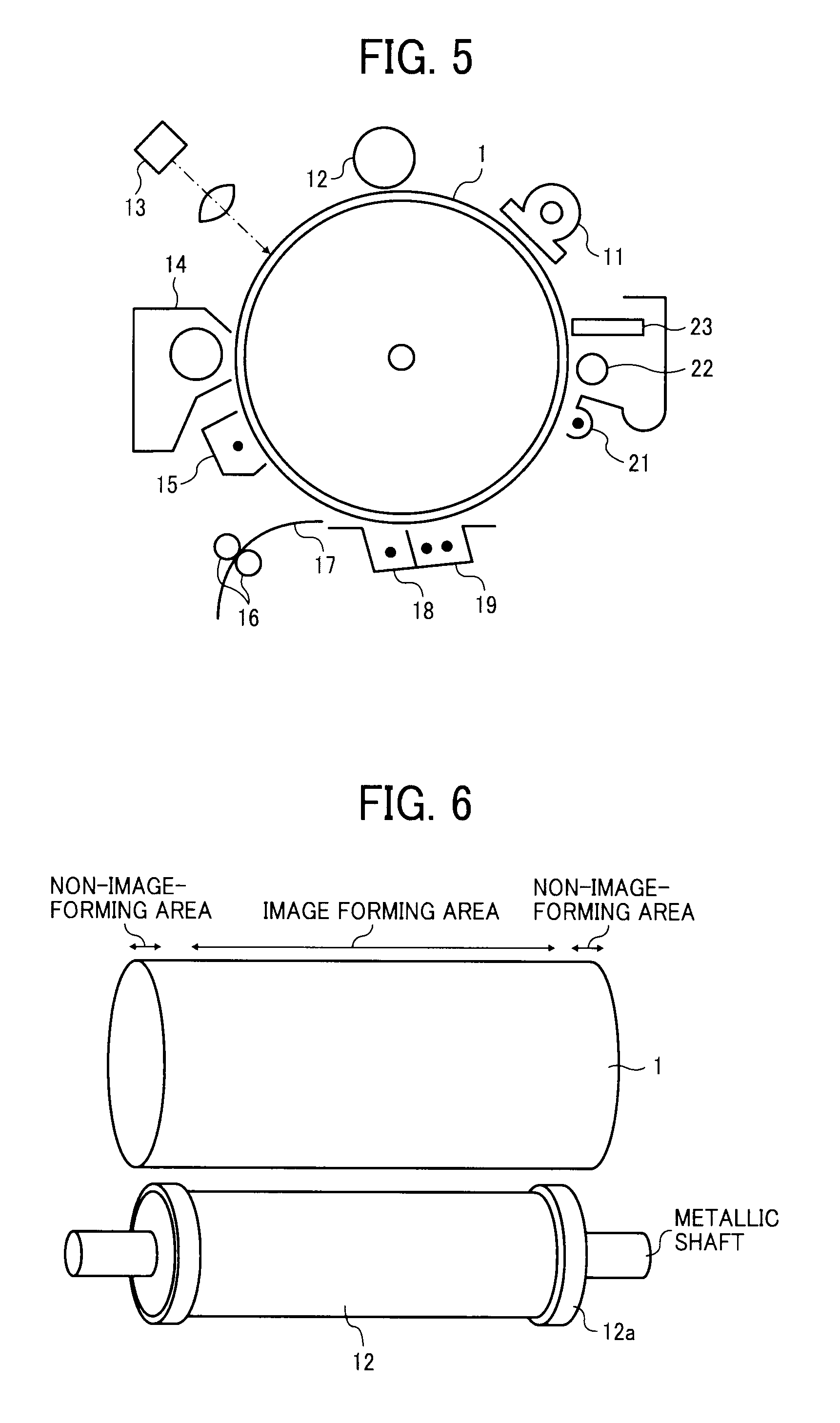

Gallium phthalocyanine compound, and image bearing member, image forming method, image forming apparatus, and process cartridge using the gallium phthalocyanine compound

InactiveUS20110207043A1Quality improvementImprove stabilityReactive dyesPorphines/azaporphinesChemical structureAryl

A gallium phthalocyanine compound represented by the following chemical structure I,where X represents a substituted or non-substituted alkyl group, a substituted or non-substituted alkenyl group, a substituted or non-substituted alkynyl group, a substituted or non-substituted aralkyl group, a substituted or non-substituted cycloalkyl group, a substituted or non-substituted aryl group, or a hydrogen atom, where substitution groups thereof are an alkoxy group, an alkylthio group, an alkyl group, a halogen atom, nitro group, amino group, an aryl group, carboxylic group, and cyano group, R1 to R16 independently represent a hydrogen atom, an alkoxy group, an alkylthio group, an alkyl group, a halogen atom, nitro group, or aryl group, n represents an integer of from 1 to 3 but excluding a combination in which n is 1 and X is methyl group.

Owner:RICOH KK

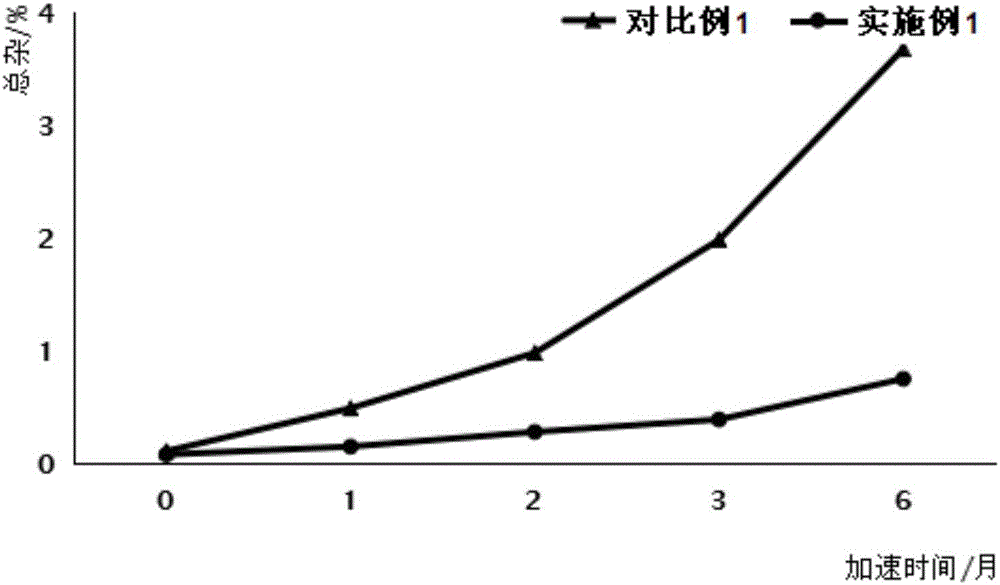

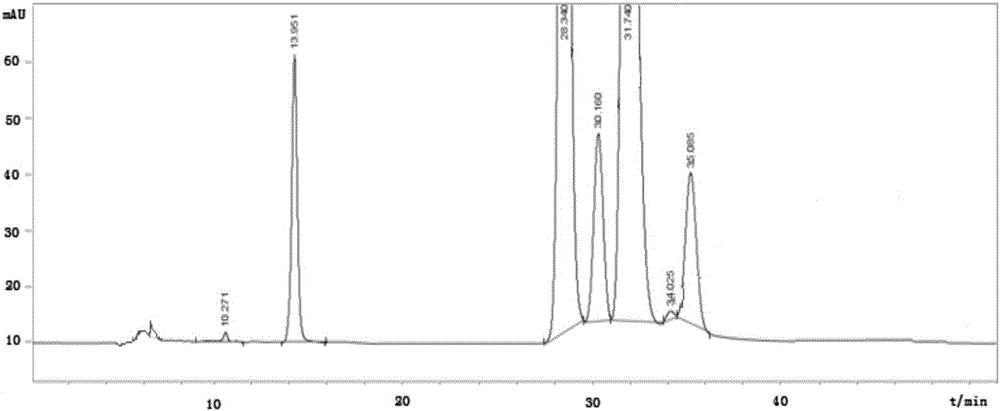

Paroxetine mesylate tablet core, and preparation method of coated tablet of paroxetine mesylate

InactiveCN104523645AImprove stabilityImprove quality and stabilityOrganic active ingredientsNervous disorderWater solublePlasticizer

The invention provides a paroxetine mesylate tablet core, and a preparation method of a coated tablet of paroxetine mesylate. Each paroxetine mesylate tablet core comprises 10 to 40mg of active pharmaceutical ingredient paroxetine mesylate, 20 to 90% of a water insoluble filler, 10 to 60% of a water soluble filler, 3 to 30% of a disintegrating agent, 0 to 10% of an adhesive, and 0.1 to 10% of a flow aid and a lubricant. The paroxetine mesylate tablet core is prepared via wet-method granulation or spray granulation of the ingredients above, and tabletting. The invention also provides the preparation method of the paroxetine mesylate coated tablet. A coating material is opacifying agent-containing opadry or a coating powder composed of 0.5 to 4% of a film forming agent, 0.1 to 2% of a plasticizer, 0.1 to 1% of a colouring agent, 0.1 to 2% of an opacifier, and 0.1 to 1% of a lubricant. The paroxetine mesylate tablet core is subjected to coating using a coating liquid prepared from the coating material. The ingredients of the coating material are commonly used; the preparation method is stable; film coating is capable of covering bitter taste and hemp taste of the main drug, increasing light stability, and improving compliance of patients and stability of preparations. The coated tablet prepared via the preparation method is qualified and stable.

Owner:万全万特制药(厦门)有限公司

Modified asphalt stabilizer and preparation method thereof

InactiveCN105647201AImprove mixing uniformityImprove stabilityBuilding insulationsPolymer scienceSulfur

The invention discloses a modified asphalt stabilizer and a preparation method thereof. The stabilizer is prepared from, by weight, 20-40% of elemental sulfur, 10-20% of organic sulfur, 20-40% of rubber oil, 20-35% of 200# asphalt and 1-5% of dispersing agent. The prepared stabilizer is in a liquid state. Compared with a traditional solid modified asphalt stabilizer, the modified asphalt stabilizer can be combined with all kinds of different modified asphalt products more easily, the stability of modified asphalt can be improved, and storage and long-distance transportation of the modified asphalt can be benefited better.

Owner:ZHONGHAI ASPHALT SICHUAN CO LTD

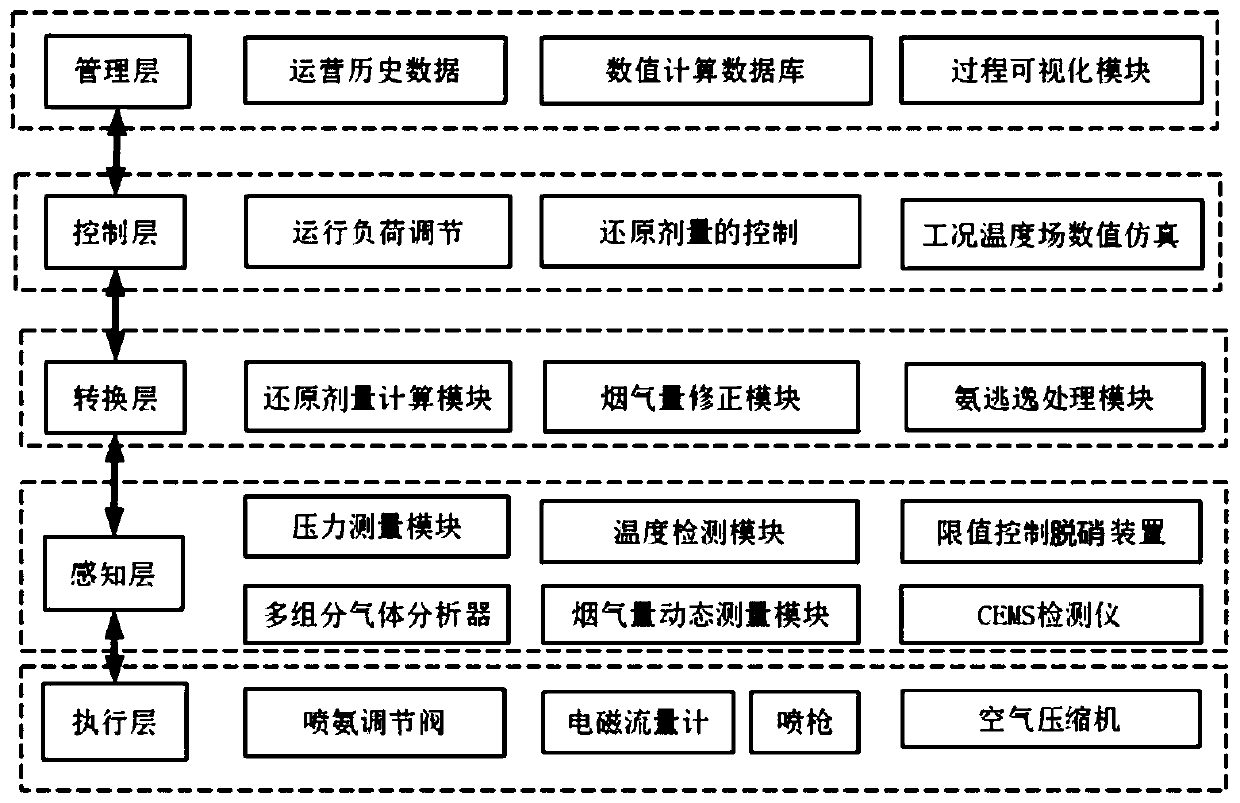

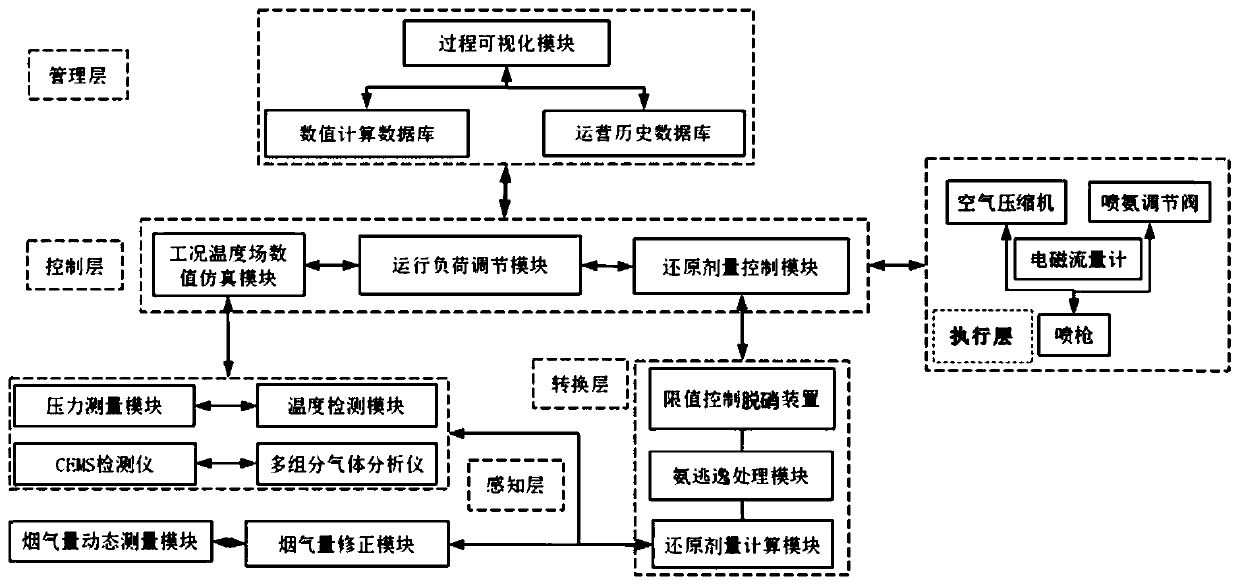

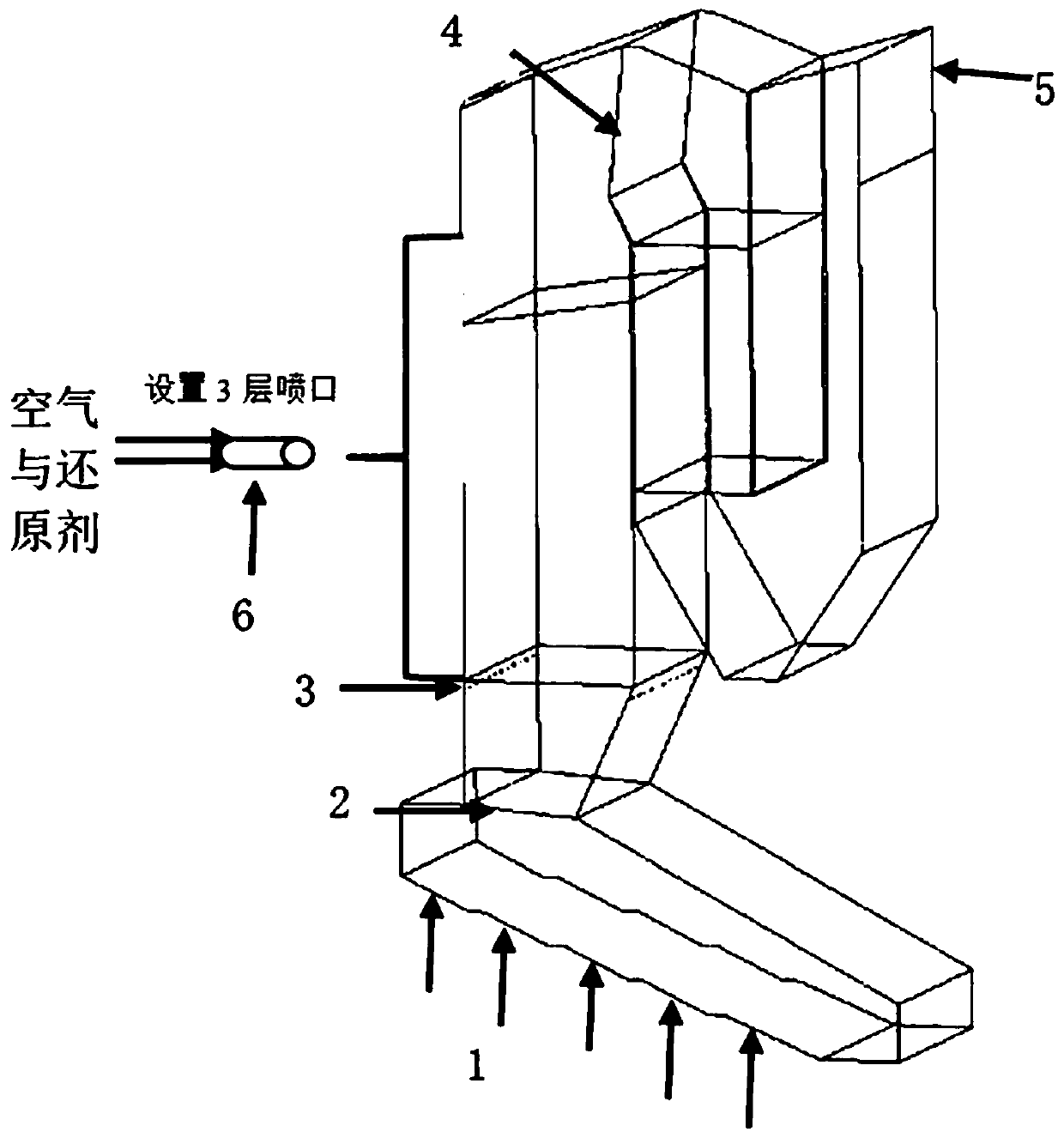

Industrial boiler SNCR denitration control system and control method

PendingCN111459109AAvoid insufficient or wasted reducing agentImprove quality and stabilityGas treatmentDispersed particle separationChemistryNitric oxide

The invention discloses an industrial boiler SNCR denitration control system and control method. The system comprises an execution layer, a sensing layer, a conversion layer, a control layer and a management layer; the sensing layer comprises a flue gas quantity dynamic measurement module; the flue gas quantity dynamic measurement module is used for collecting the first content information of NO and O2 in a hearth; the conversion layer is used for obtaining the concentration of NOx according to the first content information and calculating second content information of NH3 according to the concentration of NOx; the control layer is used for generating a control instruction according to the second content information and controlling the working states of a spray gun, an air compressor and an ammonia spray regulating valve according to the control instruction, so that the spray gun sprays a reducing agent into the hearth. The content of nitric oxide in the hearth is monitored in real time, the amount of the reducing agent is controlled according to the content of nitric oxide, so that the situation that the reducing agent is insufficient or wasted is avoided, control stability and quality are improved, and intelligent control is achieved. The system and method can be widely applied to the technical field of flue gas denitrification.

Owner:SOUTH CHINA UNIV OF TECH

Integrated station mold pressing ing method

InactiveCN109160717AGuaranteed machining accuracyReduce in quantityGlass reforming apparatusPunchingNitrogen

The invention provides an integrated molding method. The method comprises the following steps: S1), placing a to-be-processed workpiece on a lower mold on a station substrate; S2), controlling a punching rod to move downwards to enable a sealing cover sleeve to abut against the station substrate to form a molding chamber; S3), removing air in the molding chamber and feeding nitrogen in the molding chamber to enable the molding chamber to be under protection of nitrogen; S4), heating an upper mold and the lower mold to the molding temperature; S5), controlling the punching rod to continue to move downwards to enable the upper mold and the lower mold to be closed and keep closed for a certain time to finish punching and pressure maintaining; S6), removing high-temperature nitrogen in the molding chamber and feeding low-temperature nitrogen to reduce the temperature in the molding chamber; S7), controlling the punching rod to move up to separate the upper mold from the lower mold; S8), taking out the formed workpiece. According to the integrated molding method, processes such as heating, punching and cooling of an optical glass lens are achieved in one station, the mold is greatly saved, the use cost is reduced, and stability of the workpiece is ensured.

Owner:SHENZHEN SENDIYUAN PNEUMATIC EQUIP MFG CO LTD

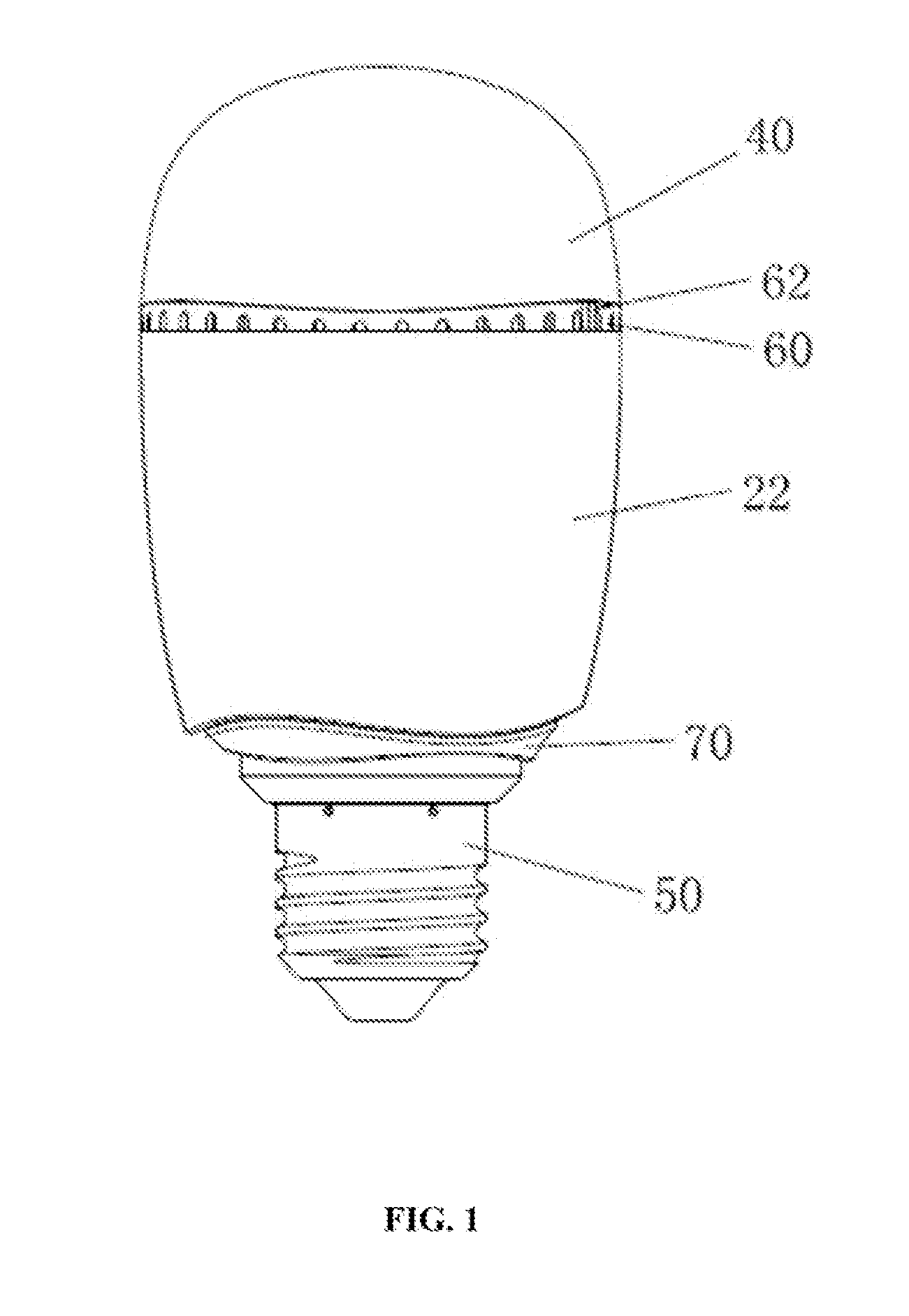

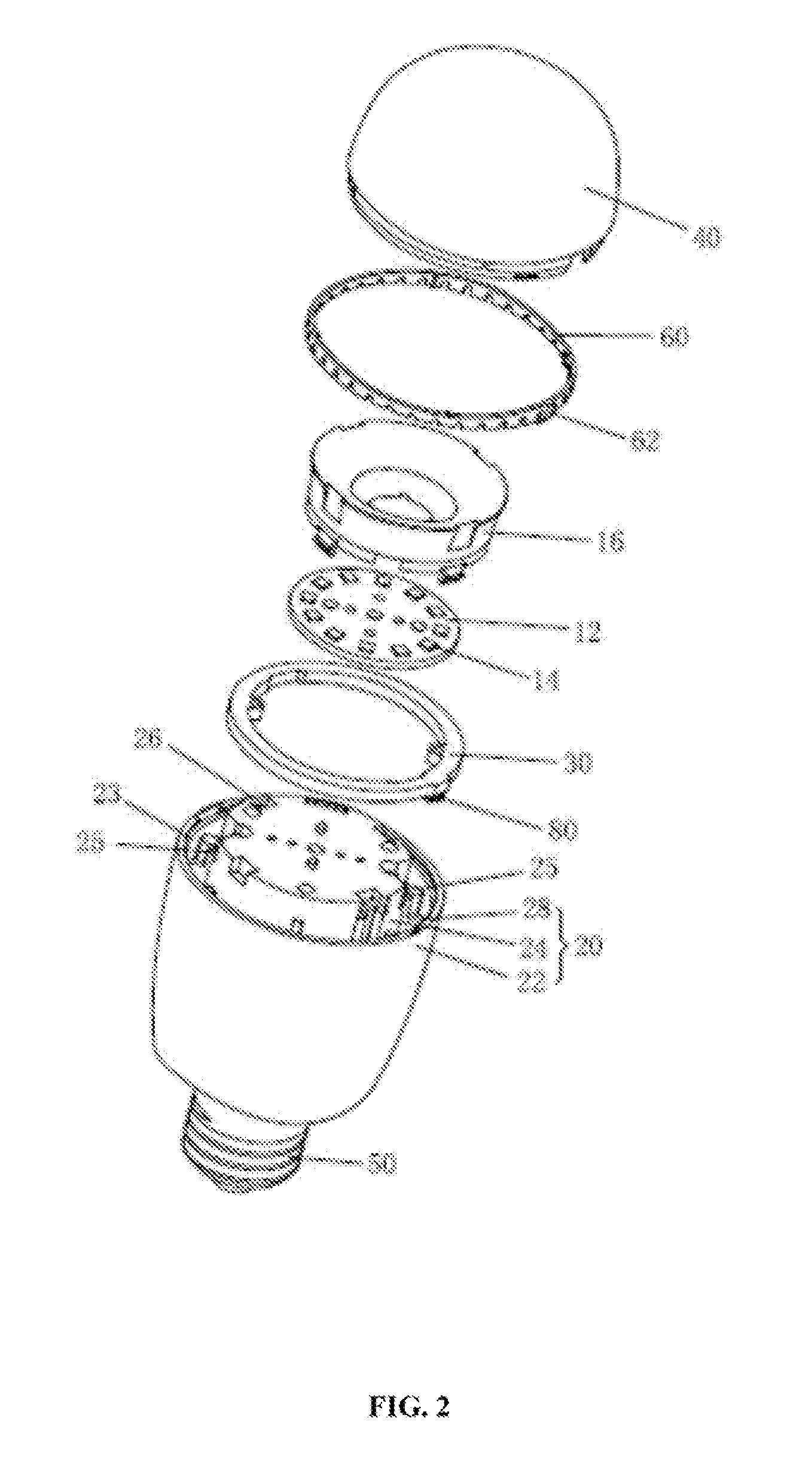

LED lighting device and system, and antenna arrangement method

ActiveUS20160329624A1Improve quality and stabilityHeat dissipationNon-electric lightingPoint-like light sourceRadio frequencyElectric power

A light emitting diode (LED) lighting device is provided. The device includes an LED light source assembly installed on the top of a heat sink body, and an LED driving and power supply unit configured to drive the LED light source assembly and provide electrical power for the LED lighting device. The device also includes a heat sink including the heat sink body and a heat sink covering, where the heat sink covering has an opening; and a plane including the highest point of the top of the heat sink body is higher than a plane including the opening of the heat sink covering. Further, the device includes a radio frequency (RF) antenna installed on periphery of the heat sink body. A plane that includes the highest point of the RF antenna is at the same level or lower than the plane that includes the highest point of the top of the heat sink body.

Owner:SENGLED OPTOELECTRONICS

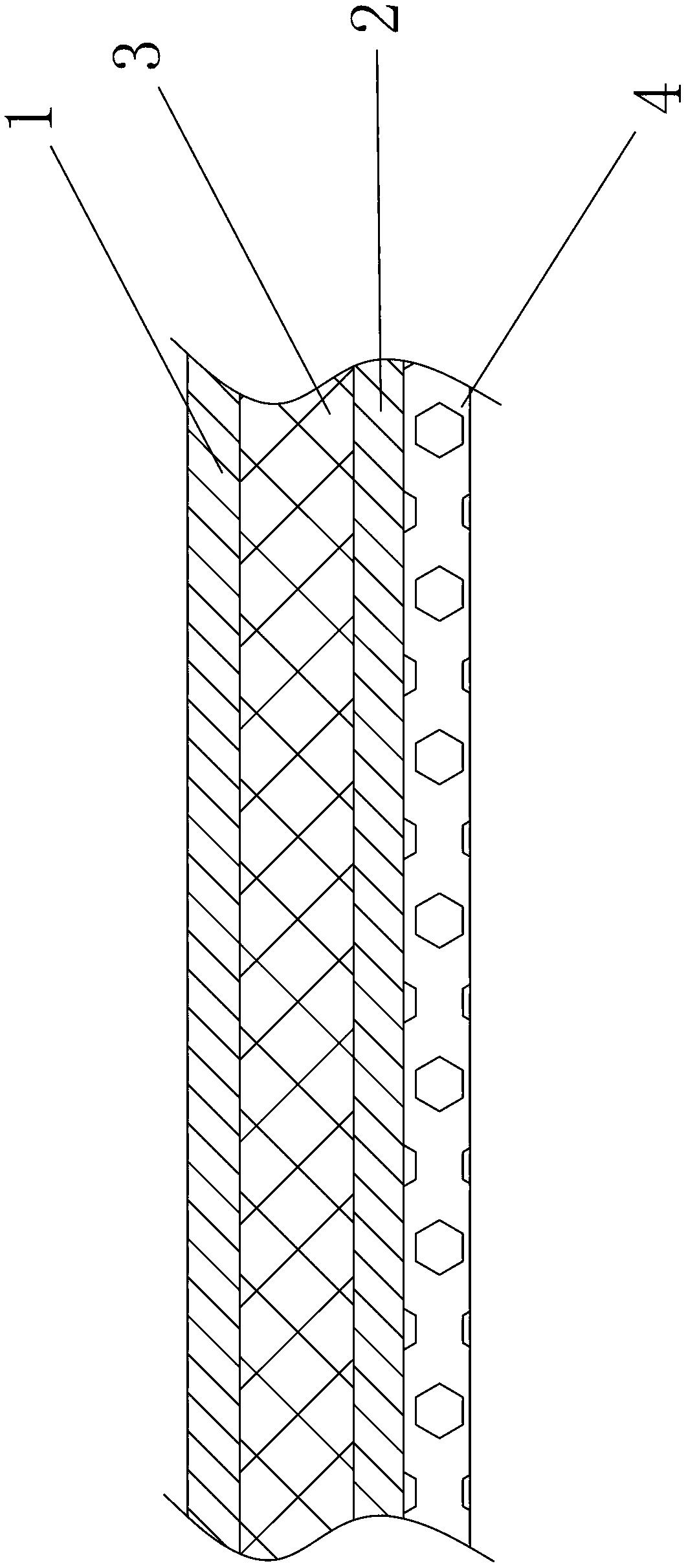

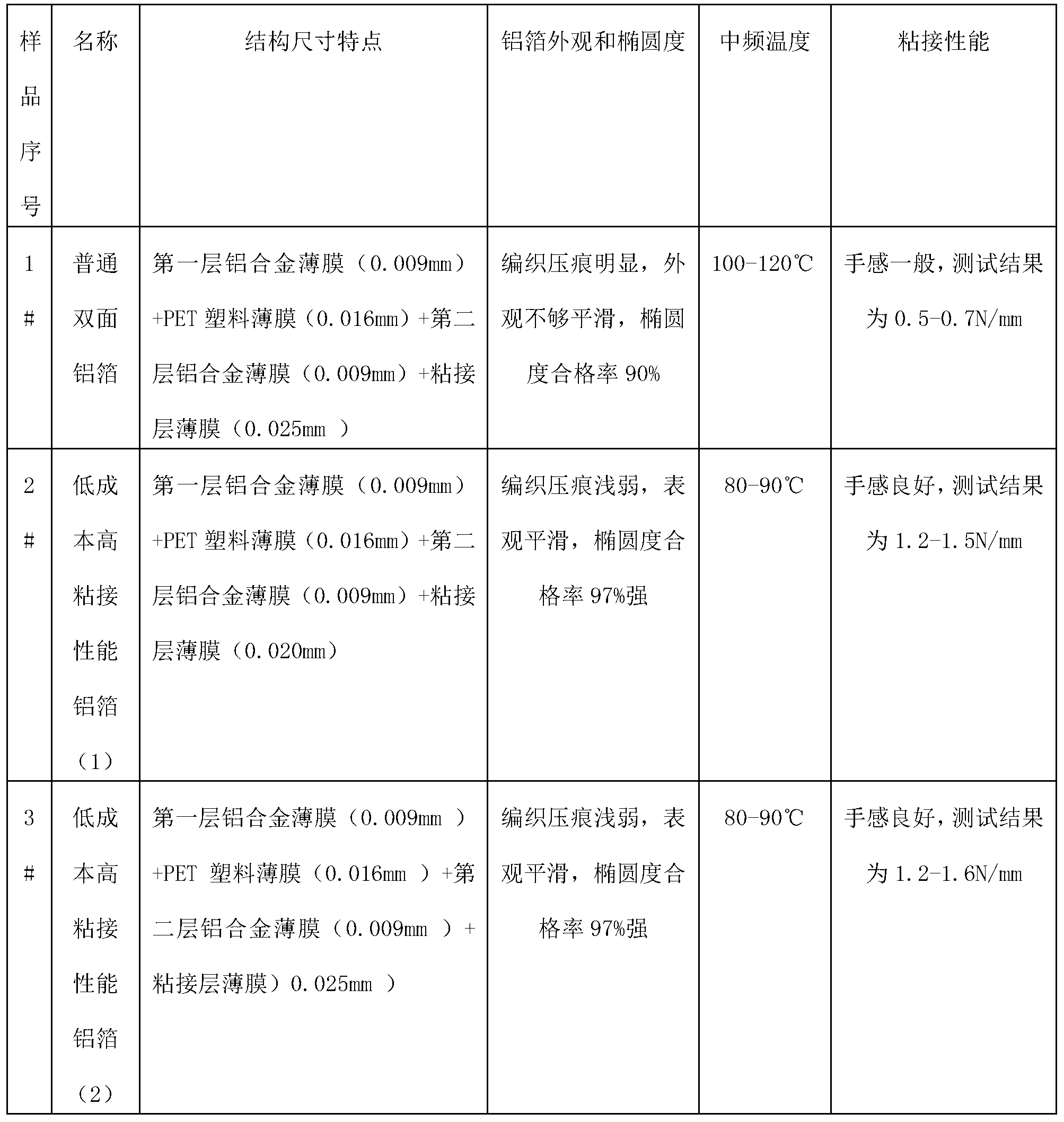

Composite aluminum foil

InactiveCN103236296AGood adhesionSmooth appearanceConductive layers on insulating-supportsMetal layered productsPolyesterSocial benefits

The invention relates to a composite aluminum foil, which comprises a first aluminum foil layer, a second aluminum foil layer and a plastic reinforcing layer, wherein the first aluminum foil layer, the plastic reinforcing layer and the second aluminum foil layer are sequentially arranged, the adjacent layers are respectively compounded together by glue, the surface of the second aluminum foil layer is compounded with an adhering layer, the adhering layer is a polyester adhering thin film, the polyester is grafted and modified with maleic anhydride, and the adhering layer is compounded with the second aluminum foil layer together by glue. The composite aluminum foil has the advantages that the common problem of design and manufacturing technique of a coaxial cable is solved, the quality stability and the suitability of the cable are improved, and the social benefits are obvious; the adhering performance of the cable product is improved, the cost is low, and the process property is favorably prompted to be further improved; and the technique of the composite aluminum foil plays a leading role in the industry and has a great promoting function for market broadening and brand promotion.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

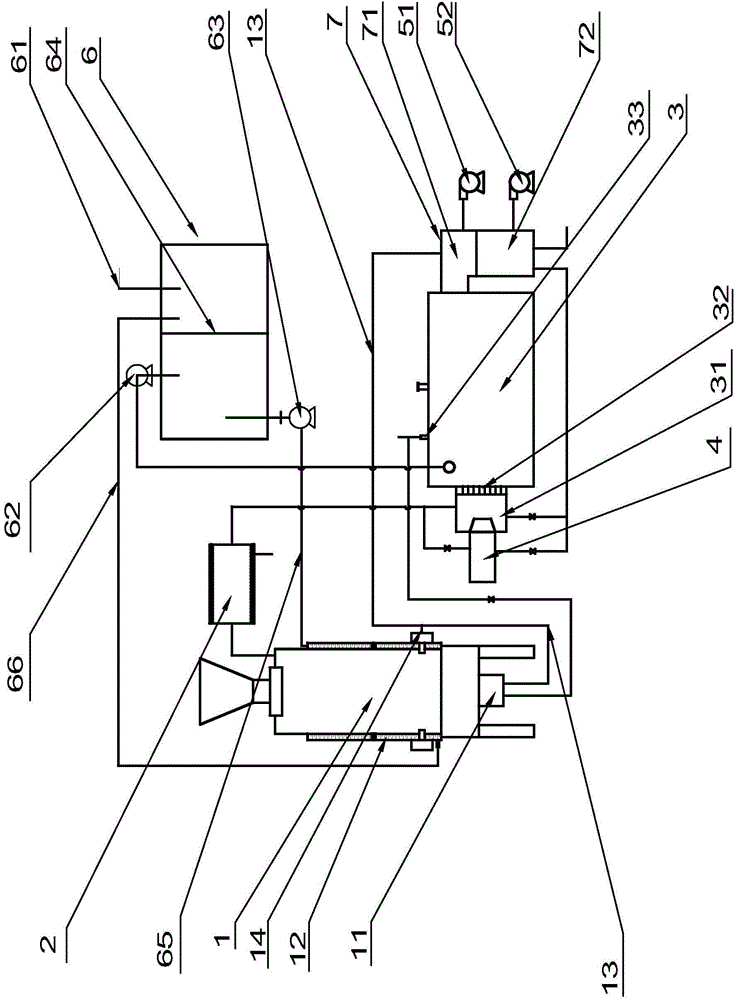

Biomass gasifier/industrial gas boiler combined high-efficiency heating system

ActiveCN104560218AImprove quality and stabilityImprove efficiencyEnergy inputGasification processes detailsTarBiomass

The invention discloses a biomass gasifier / industrial gas boiler combined high-efficiency heating system. The system utilizes steam generated by the industrial gas boiler, part of the steam is supplied to the gasifier for gasification as a gasification medium, and the steam and air are combined for gasification, thereby being beneficial to enhancing the stability and quality of the biomass gas. The preheated air is supplied to the industrial gas boiler as combustion-supporting gas, thereby enhancing the overall heat efficiency. The electrolyic decoking cracking device can crack tar in the biomass gas, thereby enhancing the stability of the biomass gas and being beneficial to combustion of the biomass gas. Meanwhile, the system is subjected to water cooling through a full water cooling jacket, thereby effectively avoiding coking in the biomass gasifier. The system is applicable to the field of boiler heating systems.

Owner:GUANGDONG ZHENGPENG BIOMASS ENERGY TECH

Chinese medicine injection for clearing away heat and toxic matter and its prepn process

InactiveCN1739686AHigh purityImprove quality and stabilityAntibacterial agentsPharmaceutical delivery mechanismToxic materialHouttuynia

The Chinese medicine injection for clearing away heat and toxic material is prepared with honeysuckle, isatis leaf, dandelion and cordate houttuynia in the same proportion as material and through extractive, purification and other steps. The injection has high quality, high stability and high pharmaceutical effect.

Owner:张正生

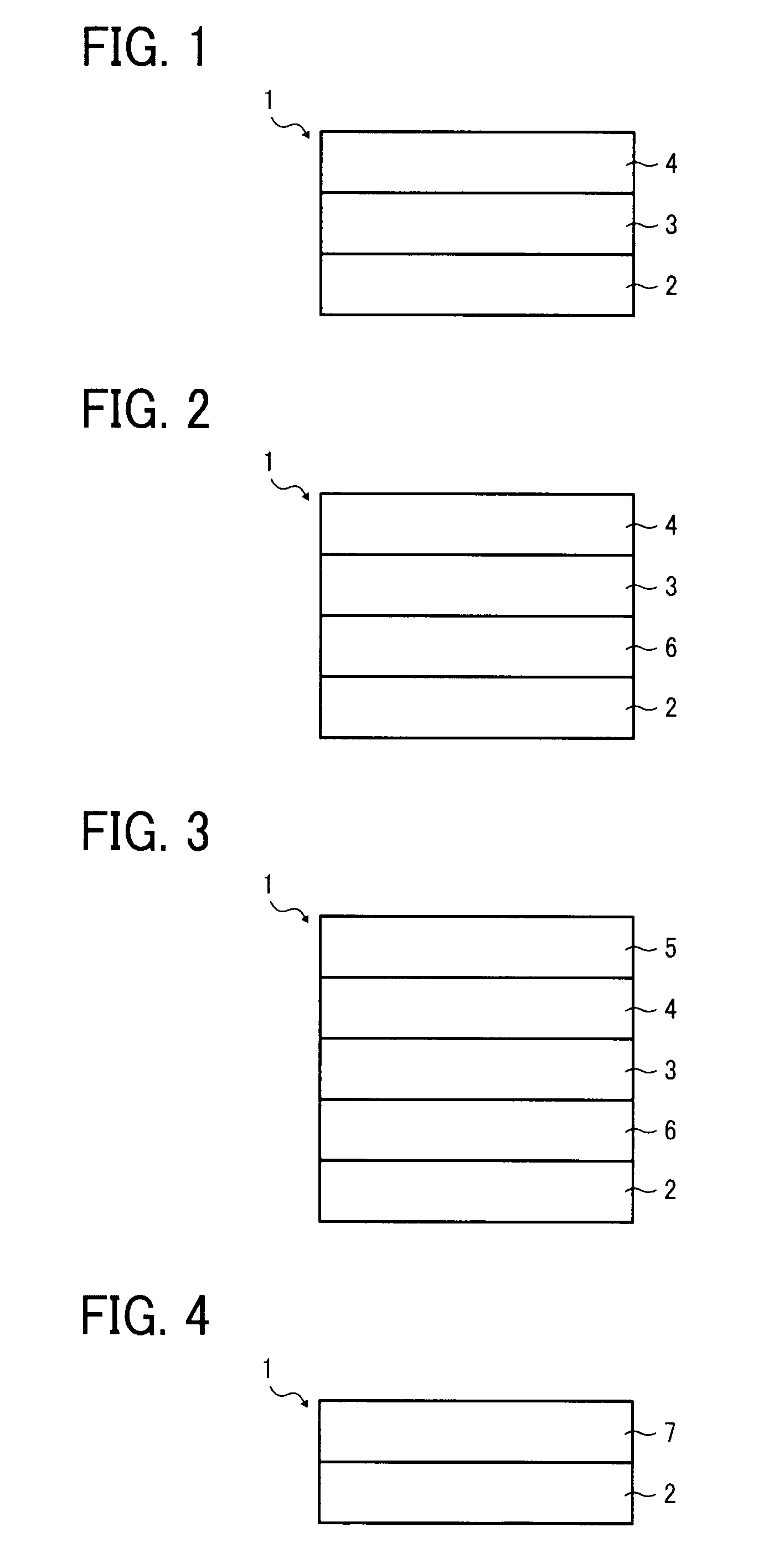

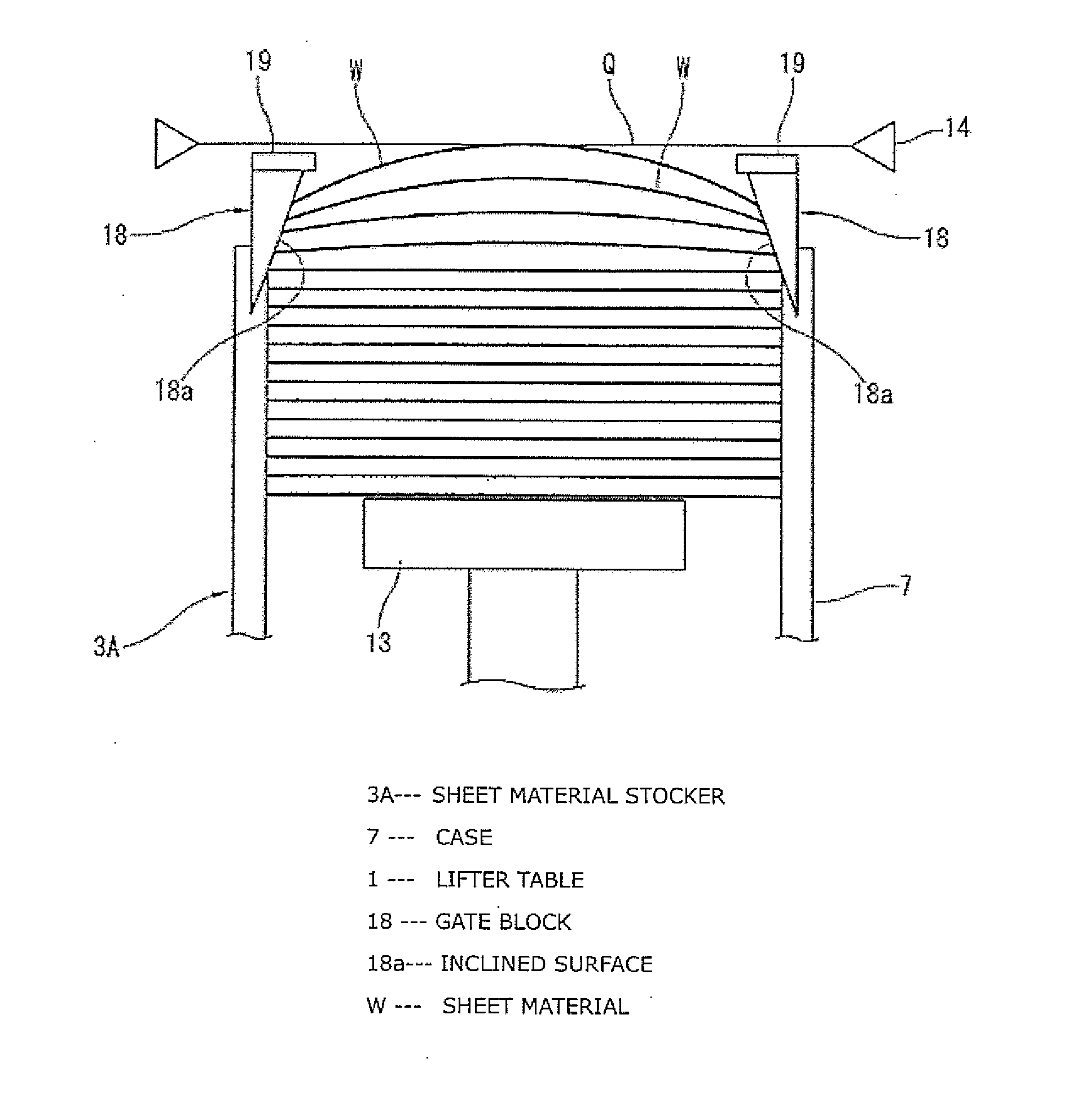

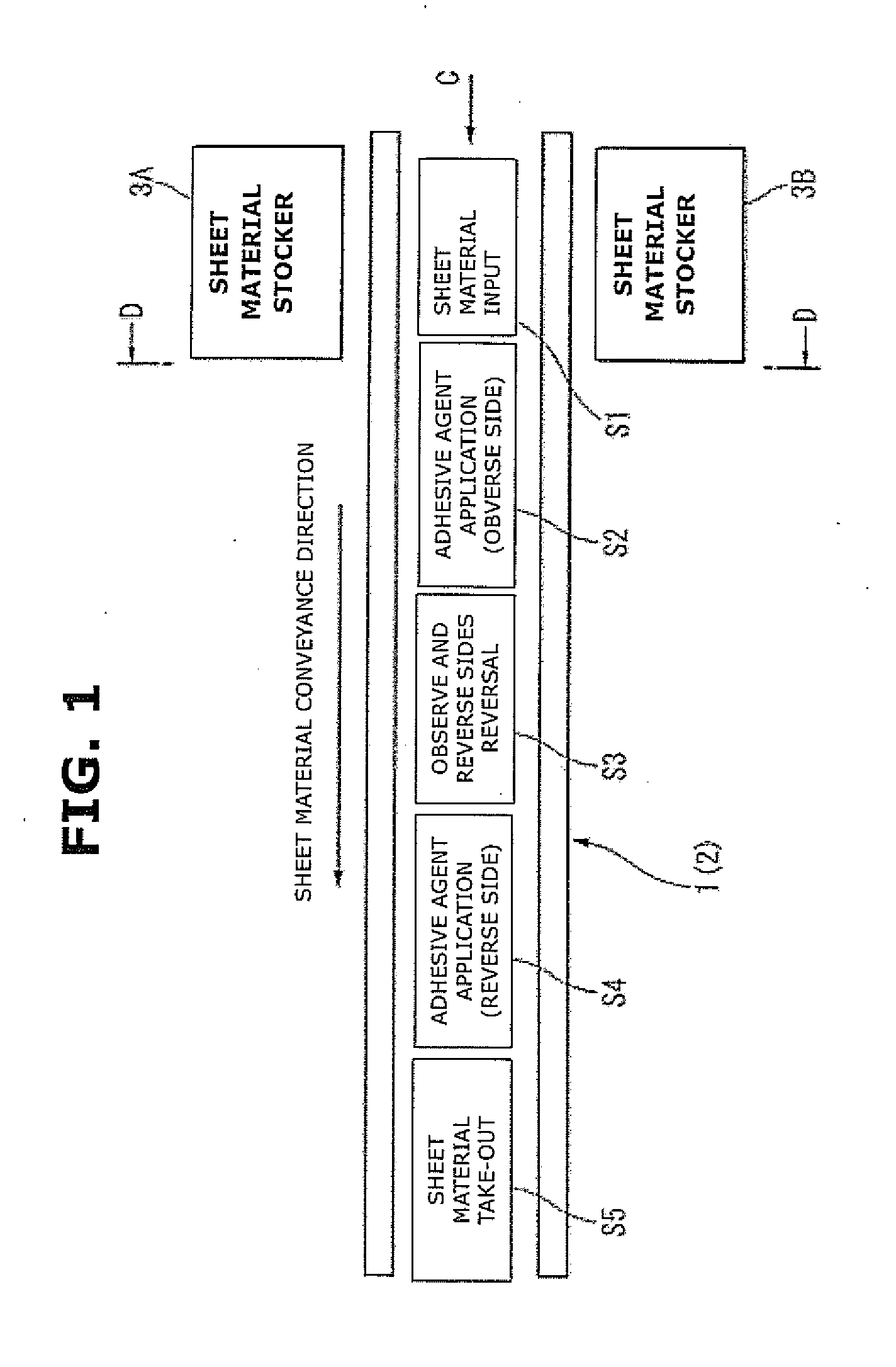

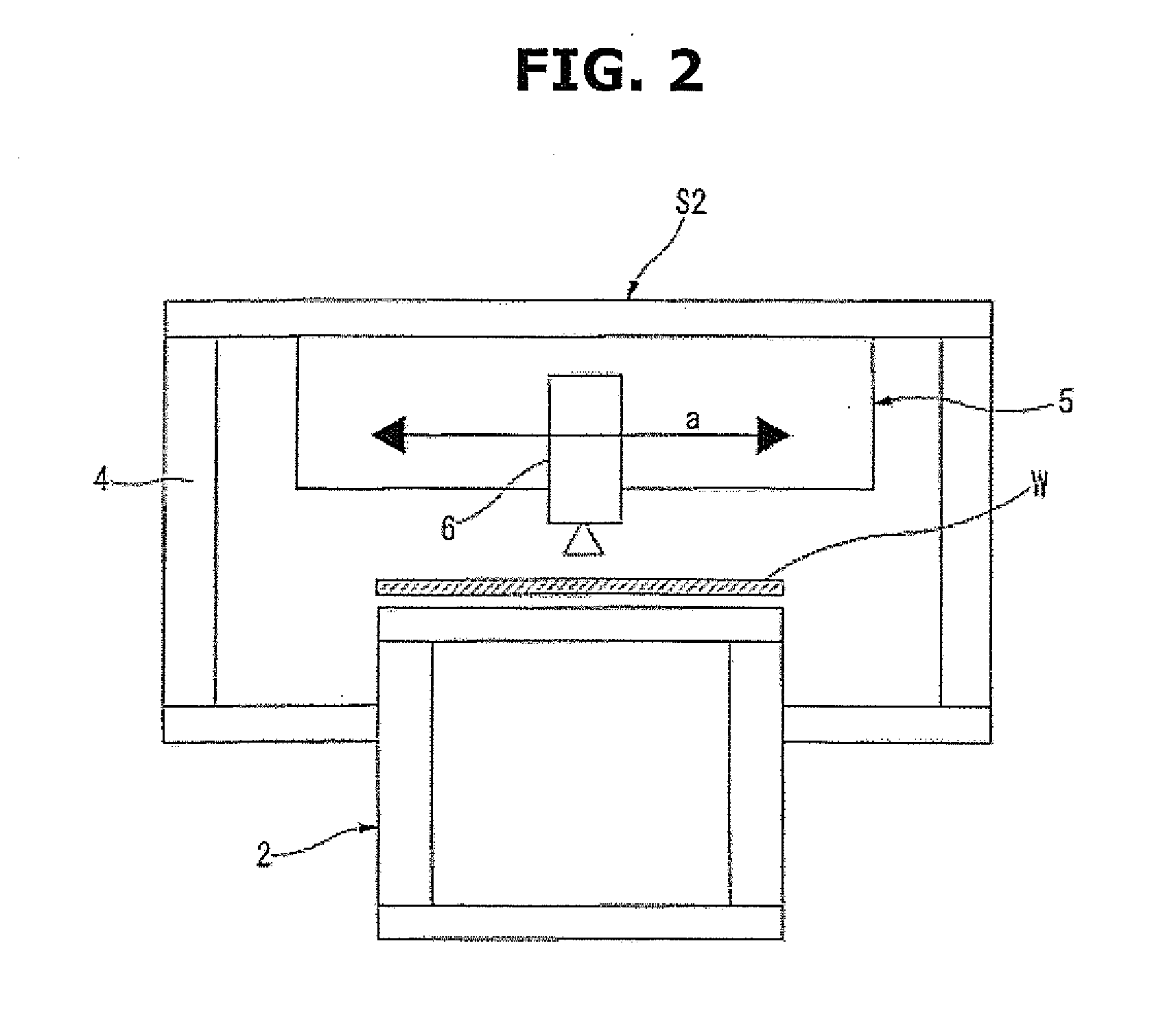

Sheet material adhesive agent application method

ActiveUS20150202654A1Improve quality and stabilityLamination ancillary operationsLarge-sized flat cells/batteriesEngineeringBiomedical engineering

A sheet material adhesive agent application method includes first and second actions. The first action is performed sequentially for stacked multiple sheet materials. The first action is implemented by: taking out an uppermost one of the multiple sheet materials; transferring the taken-out sheet material to an adhesive agent application stage; and applying the adhesive agent to the transferred sheet material at the adhesive agent application stage. The second action is performed in advance to the first action, wherein the second action is implemented by setting an uppermost group of sheet materials so that each sheet material of the uppermost group has a predetermined curvature projecting upward. The first action is completed before the sheet material is restored to a state before the second action.

Owner:ENVISION AESC JAPAN LTD

Orally quick-acting tablet of ginseng stem leaf saponin including orally disintegrating tablet and dispersible tablet and method for preparing the same

ActiveCN1806813AImprove quality and stabilityPromote absorptionOrganic active ingredientsPill deliveryAdditive ingredientFiller Excipient

Disclosed is a quick-effective oral tablet in the form of oral disintegrating tablet and dispersible tablet, and its preparing process, wherein the raw materials comprise the following ingredients (by weight ratio): ginseng stems and leaves saponin 5-100, bulking agent 15-350, disintegrating agent 15-150, lubricant 1-10, and right amount of wetting agent or binding agent such as 10-95% of ethanol. Each tablet contains ginsenoside of stems and leaves 25mg or 50mg.

Owner:ANHUI PROV INST OF BIOLOGICAL MEDICINE

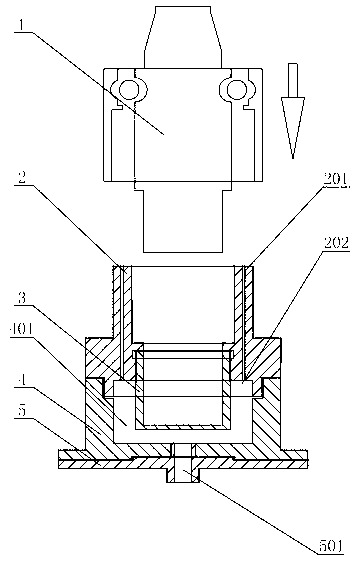

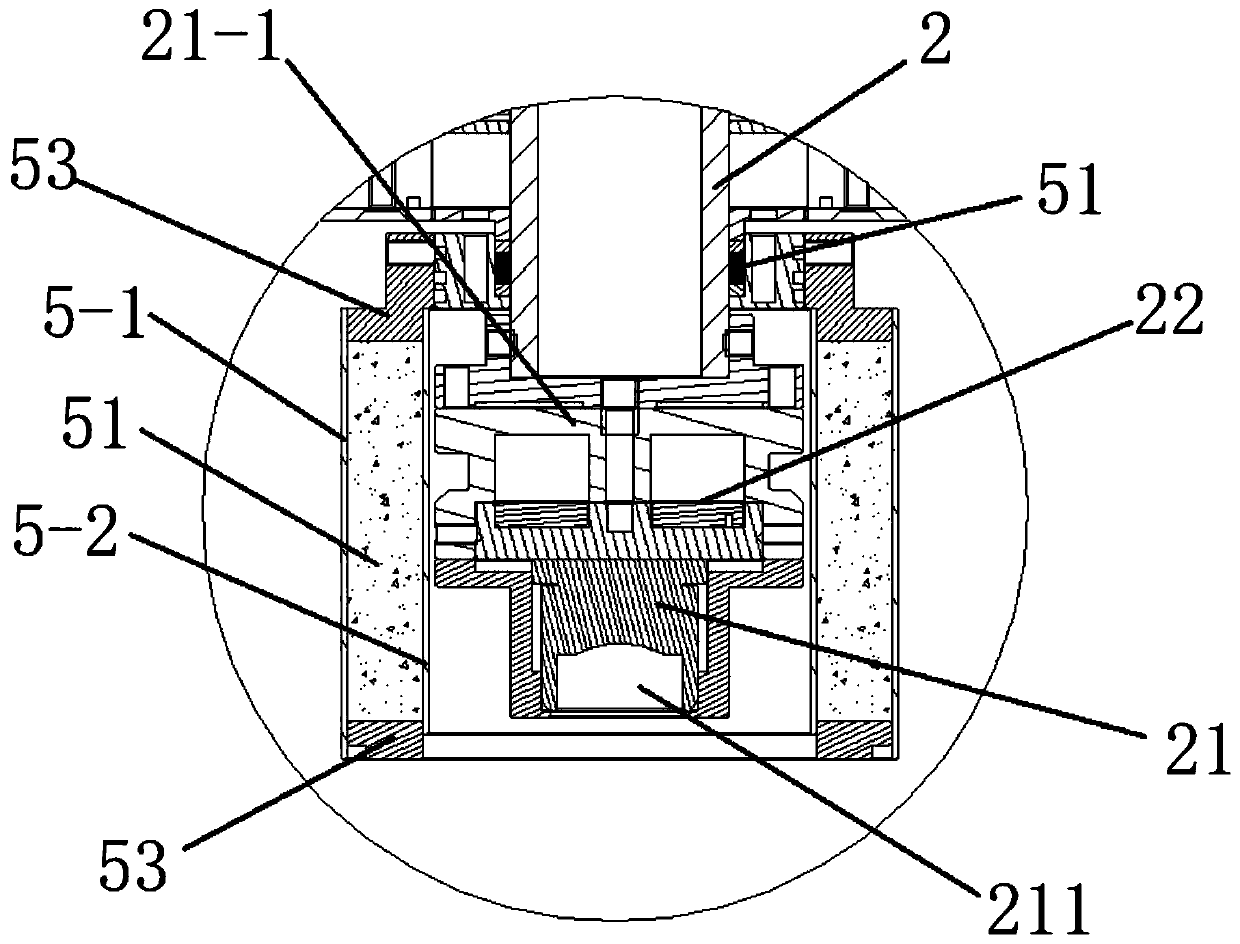

Bearing grease injecting tool

InactiveCN102797961AImprove quality and stabilityExtended service lifeProportioning devicesEngineeringSteel ball

The invention relates to a bearing grease injecting tool, which comprises a bottom plate, wherein the bottom plate is fixedly connected with one end of a lower template; the other end of the lower template is in threaded connection with an upper template; and a middle template is in threaded connection inside the upper template. The bearing grease injection tool is simple in structure, and is convenient to install; the upper template is used for compressing a bearing, two grease storing cavities are formed, and grease which is originally preserved in the tool is uniformly extruded onto a steel ball position in the middle of the inside of the bearing under the action of compression force, so that the quality and the stability of the bearing are improved greatly, and the service life of the bearing is prolonged.

Owner:WUXI SANLI BEARINGS

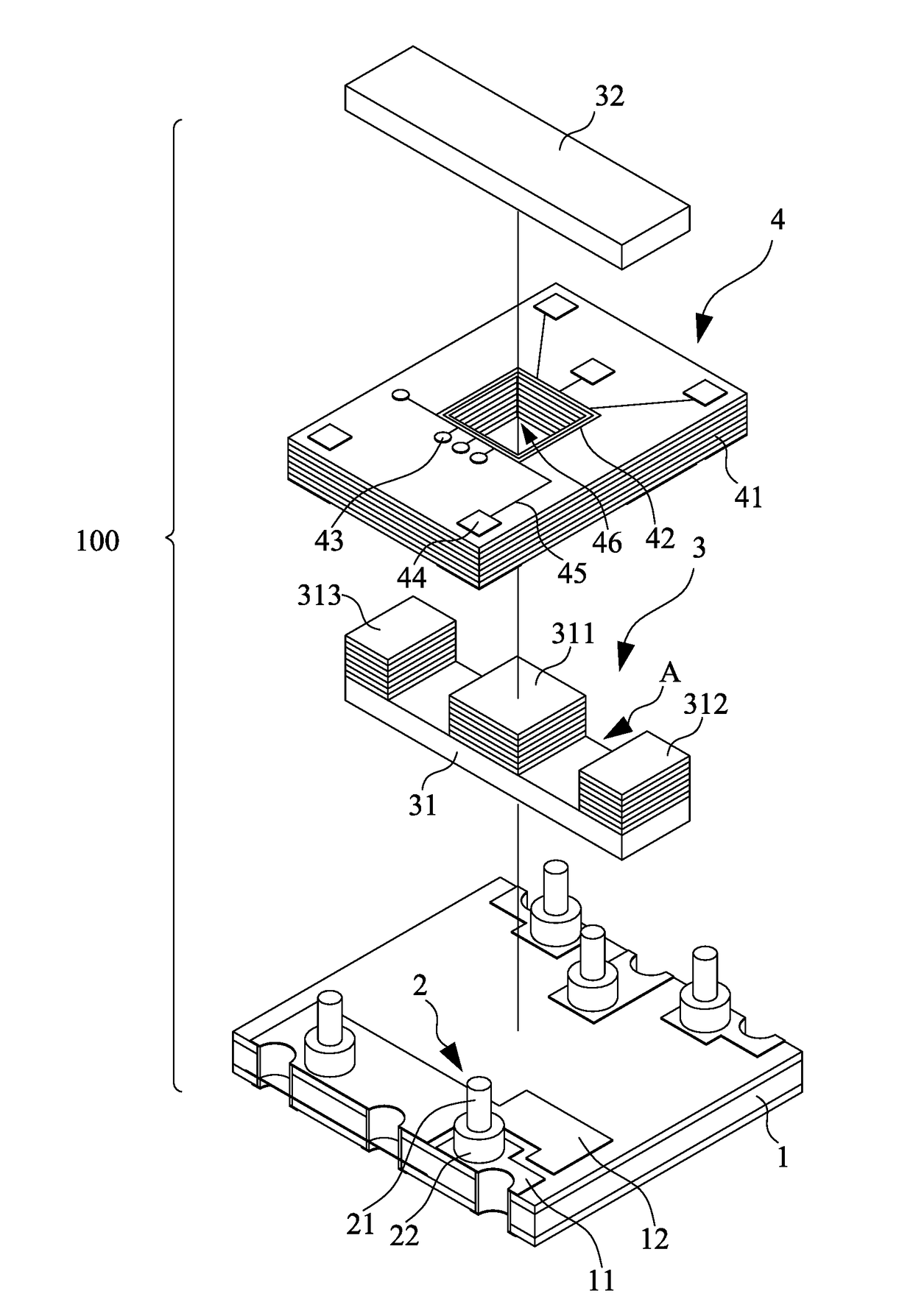

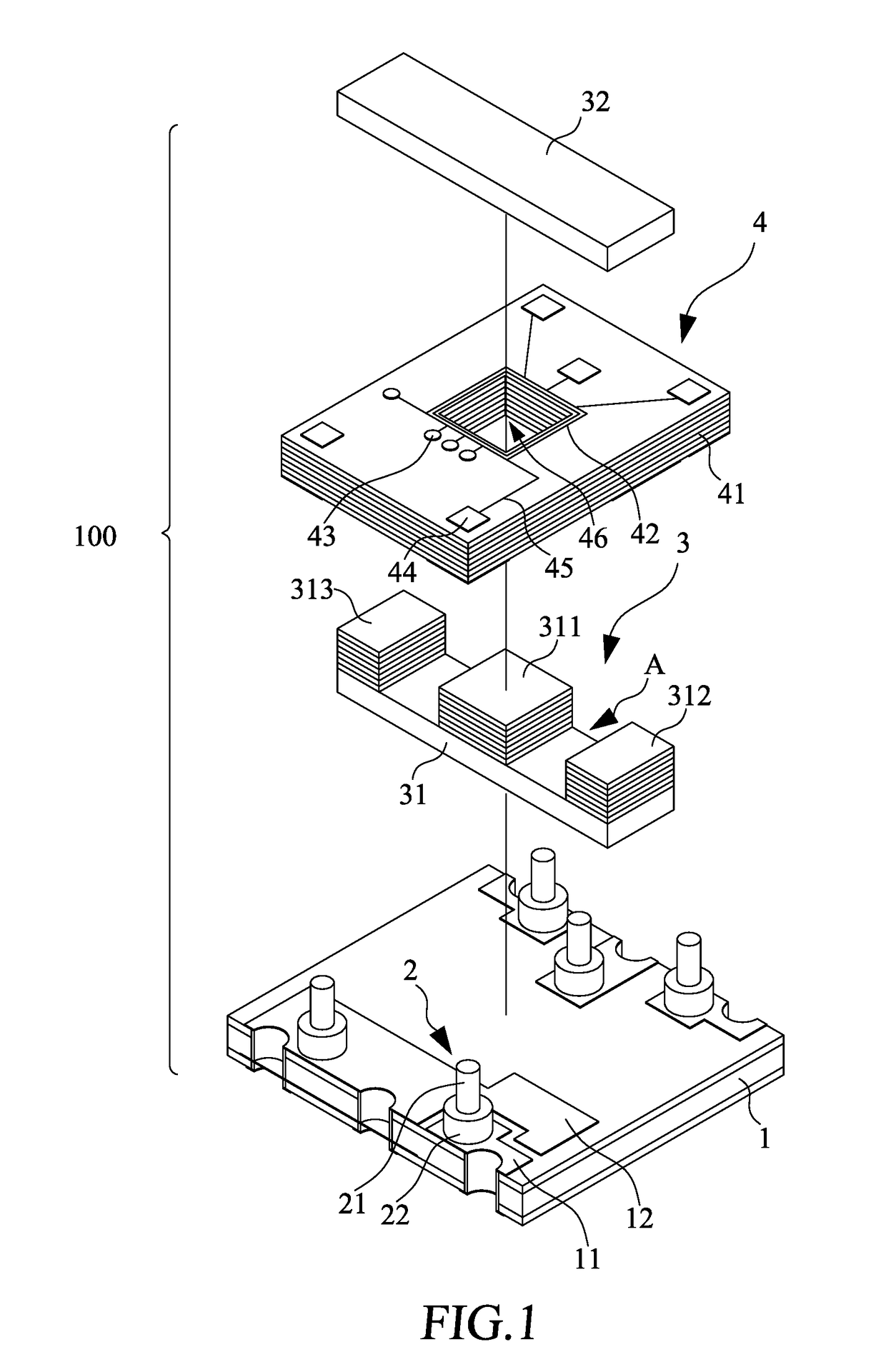

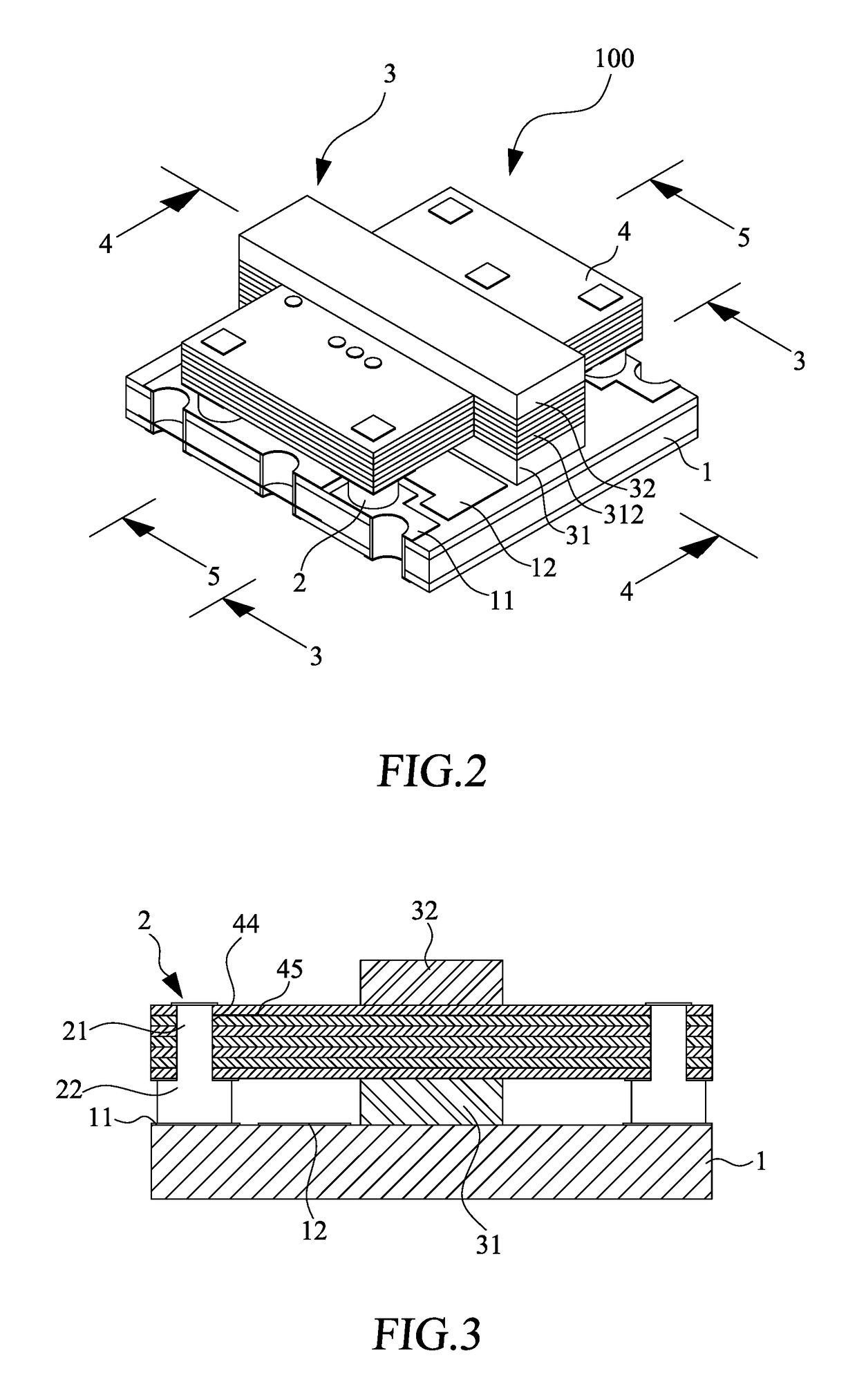

Impedance matching transformer for high-frequency transmission line

InactiveUS20170149407A1Stable production and operationImprove product quality stabilityMultiple-port networksFixed transformers or mutual inductancesElectricityTransformer

An impedance matching transformer for high-frequency transmission line includes a carrier plate, a plurality of conductive posts, a magnetic core and a microstrip inductor. During high frequency transmission, the impedance matching transformer is used as a balanced-to-unbalanced transformation between high-frequency transmission lines. The microstrip inductor includes a plurality of laminated non-conductive substrates, a plurality of conductive tracks laid on the laminated non-conductive substrates respectively. Each of the conductive tracks is electrically connected through vias. Finally, several outlet paths are led out, and then connected to conductively accessing holes.

Owner:PROSPERITY DIELECTRICS

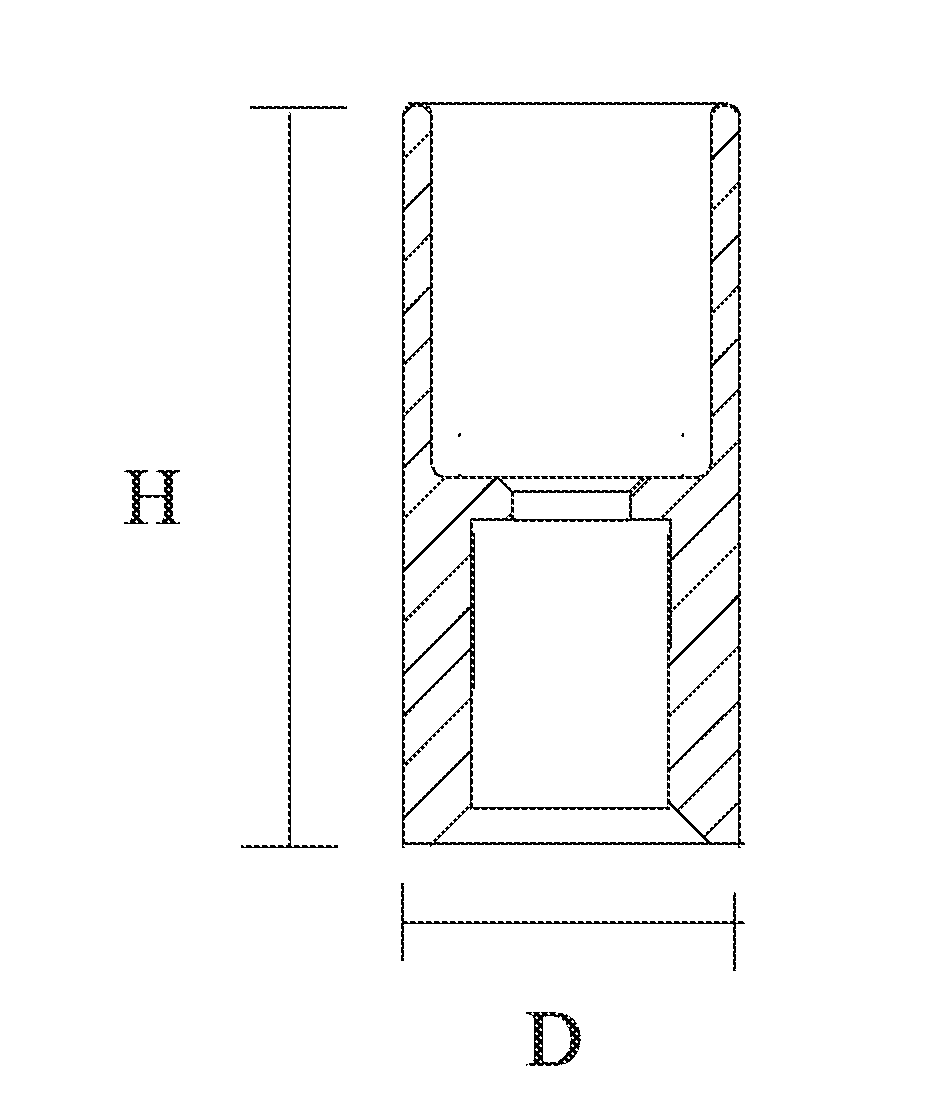

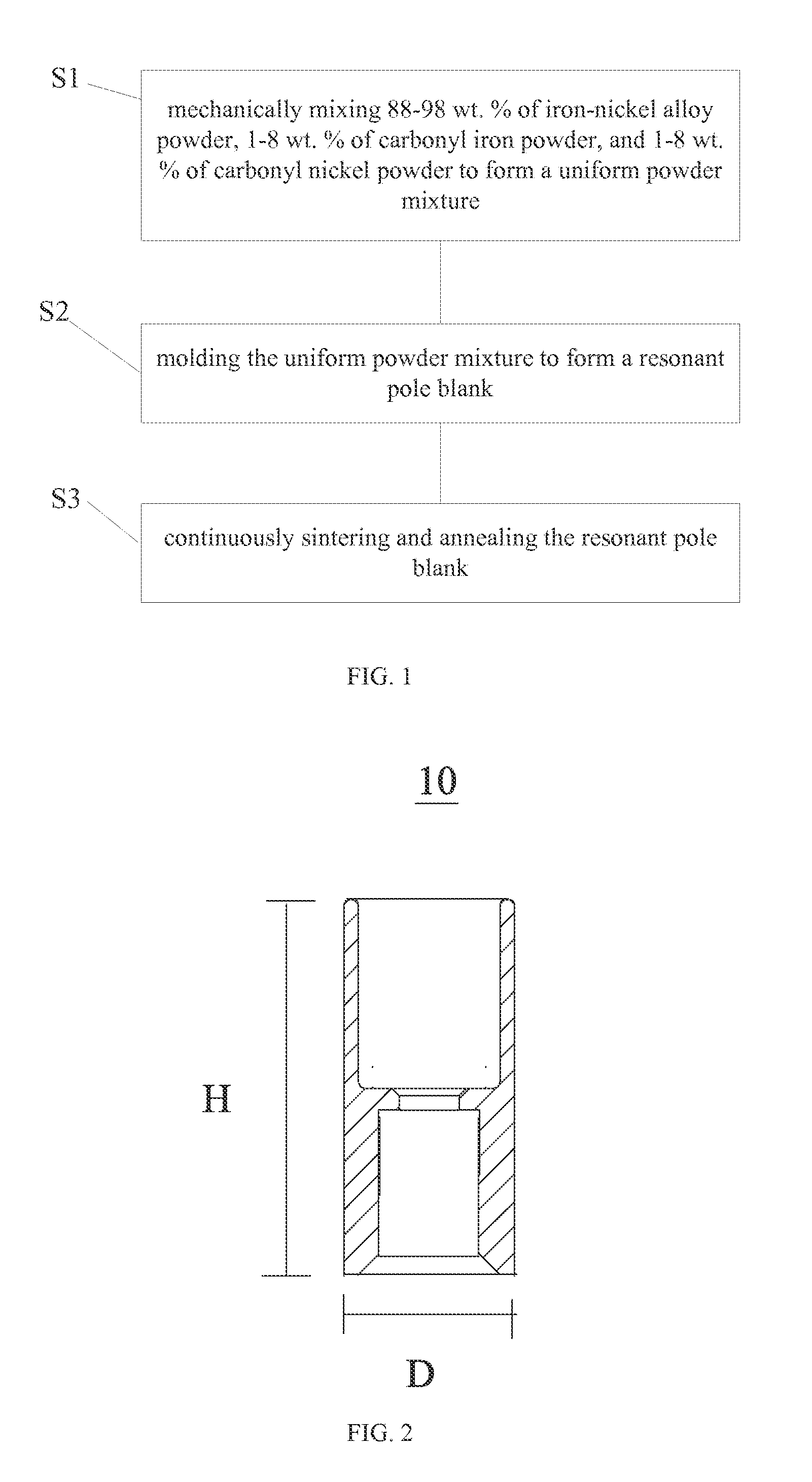

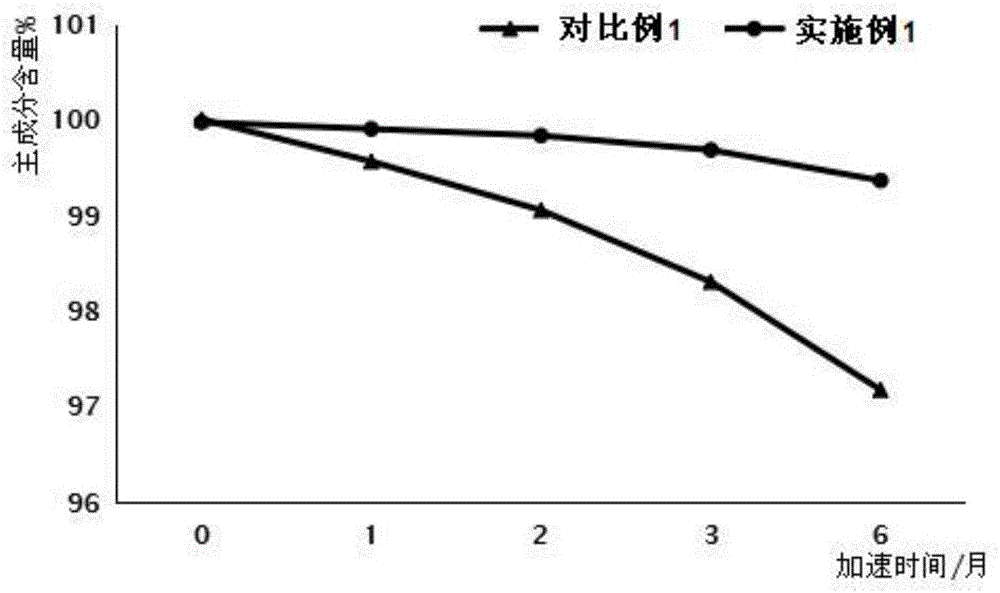

Method for Manufacturing Resonant Tube, Resonant Tube and Cavity Filter

ActiveUS20130127569A1Reduce consumptionImprove processing efficiencyResonatorsCarbonyl groupPowder mixture

A method for manufacturing a resonant tube is provided in the present invention, which comprises: mechanically mixing 88-98 wt. % of iron-nickel alloy powder, 1-8 wt. % of carbonyl iron powder, and 1-8 wt. % of carbonyl nickel powder to form a uniform powder mixture; molding the uniform powder mixture to form a resonant tube blank; and continuously sintering and annealing the resonant tube blank. Also provided in the present invention are a resonant tube and a cavity filter. The method for manufacturing a resonant tube provided in the present invention significantly enhances production efficiency while greatly reducing consumption of raw materials. Moreover, the resonant tube provided in the present invention reduces, to the greatest extent, segregation of alloy components and coarse and uneven microstructures, thereby increasing the performance and stability of the corresponding products.

Owner:SHENZHEN TATFOOK NETWORK TECH

Silybin meglumine preparation

ActiveCN106214646AImprove stabilityLong shelf lifeOrganic active ingredientsDigestive systemDiluentIothalamate Meglumine

The invention provides a silybin meglumine preparation composed of a silybin meglumine drug and an excipient. The excipients contain a diluting agent and a dispersing agent. The silybin drug and diluent, and dispersing agent are subjected to micronization; and the mixture is evenly mixed with the remaining excipients. In the invention, the silybin meglumine drug, diluent and dispersing agent are subjected to micronization, which improves the yield, accelerates the disintegration of preparation, and improves drug dissolution degree, so as to enhance the absorption of drug in body and enhance the stability of the preparation.

Owner:HUNAN QIANJIN XIELI PHARMA CO LTD

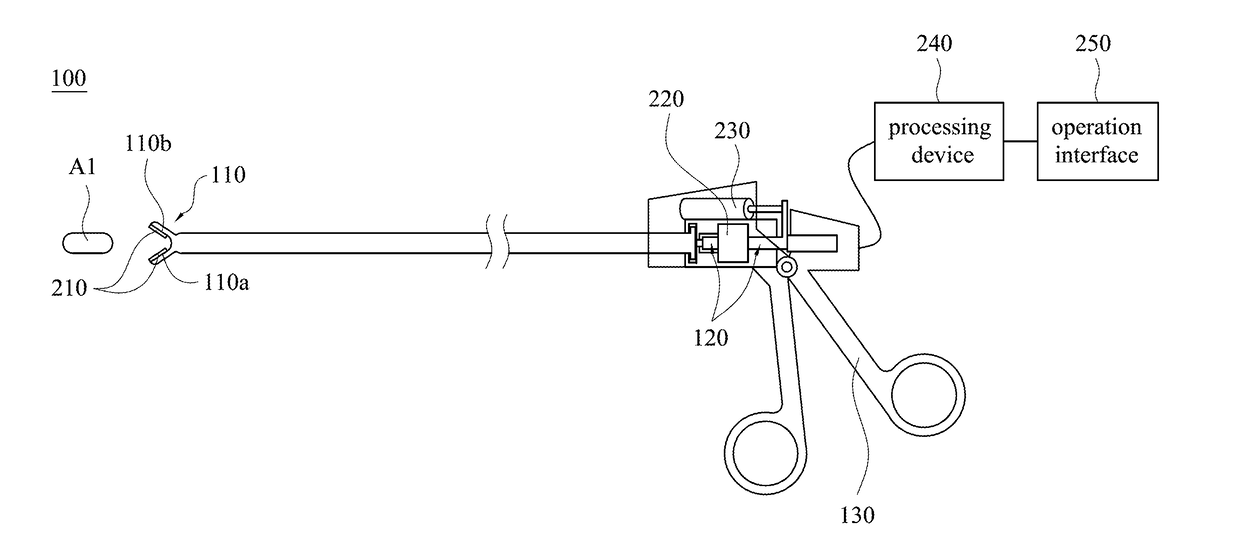

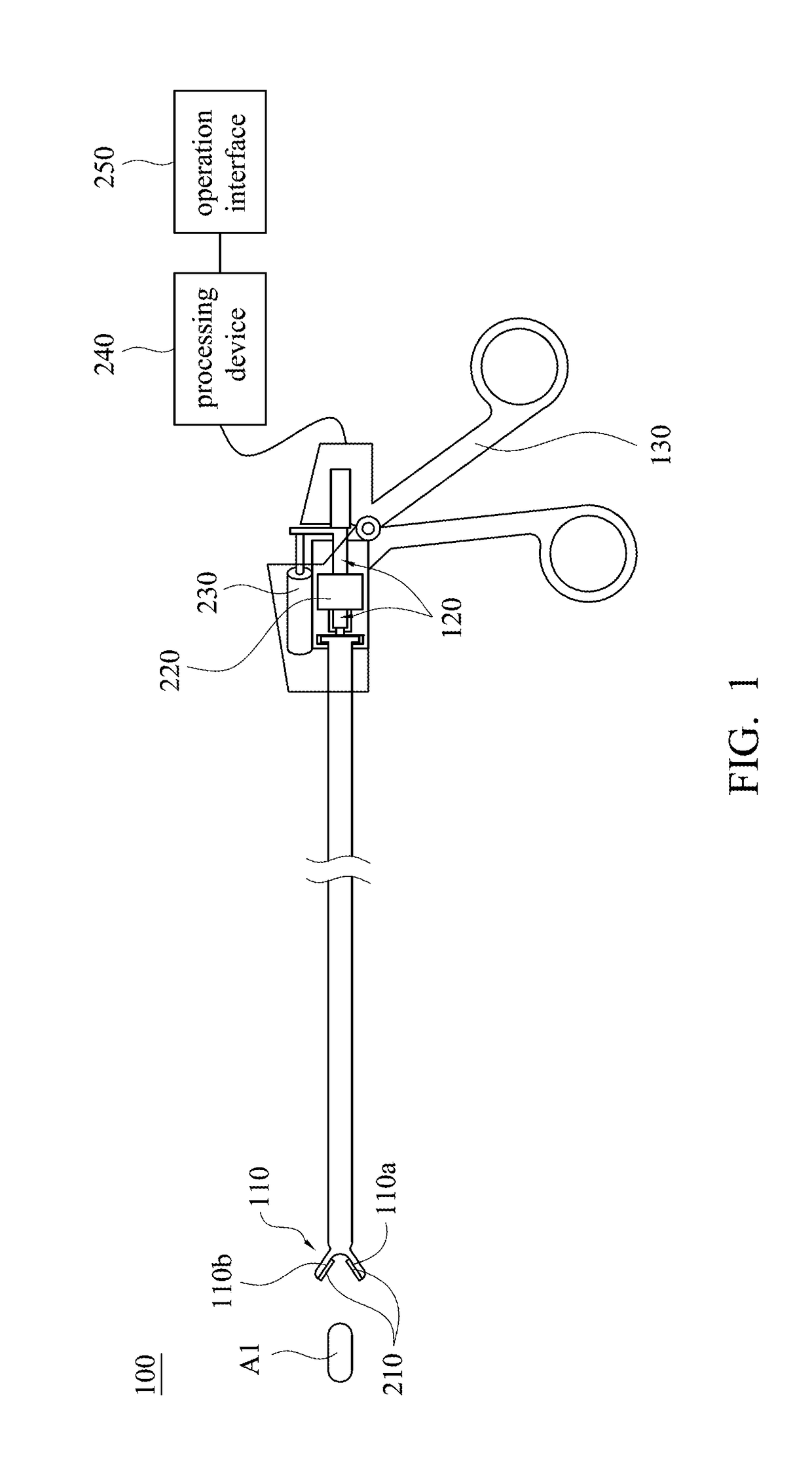

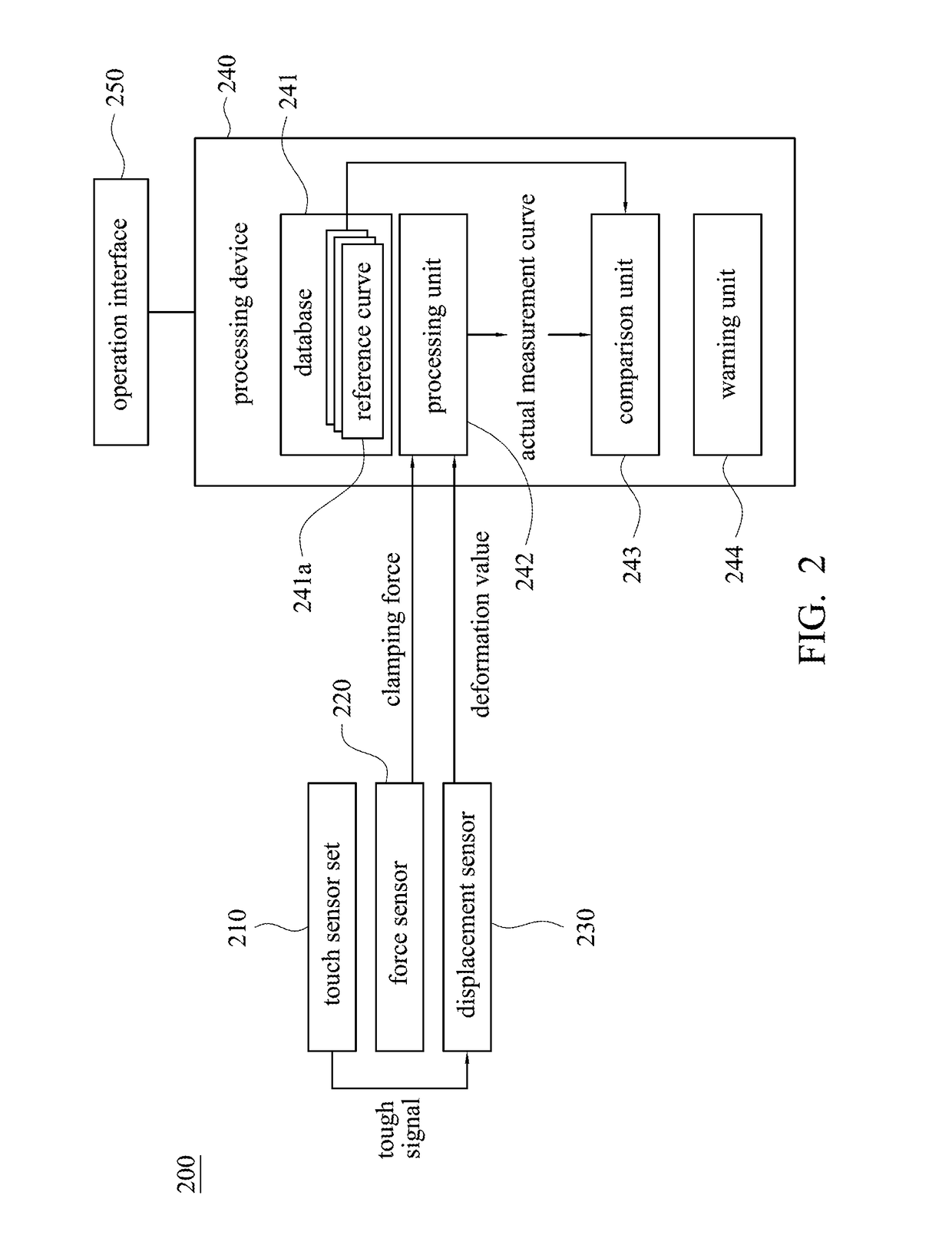

Sensing apparatus and surgical instrument having the same

ActiveUS20170156715A1Improve stability and securityImprove quality and stabilityDiagnosticsComputer-aided planning/modellingEngineeringForce sensor

A sensing apparatus is applicable to a surgical instrument having a clamping portion, a linkage rod member and an operating portion. The damping portion is used to damp a target. The sensing apparatus includes a touch sensor set, a force sensor, a displacement sensor and a processing device. The touch sensor set can sense a touch signal between the target and the clamping portion. The force sensor can sense a clamping force applied on the target. The displacement sensor can measure a displacement of the linkage rod member. The processing device includes a database, a processing unit and a comparison unit. The database stores reference curves of different reference objects. The processing unit can build an actual measurement curve of the target. The comparison unit can compare the actual measurement curve with each of the reference curves to obtain one of the reference curves corresponding to the actual measurement curve.

Owner:METAL INDS RES & DEV CENT

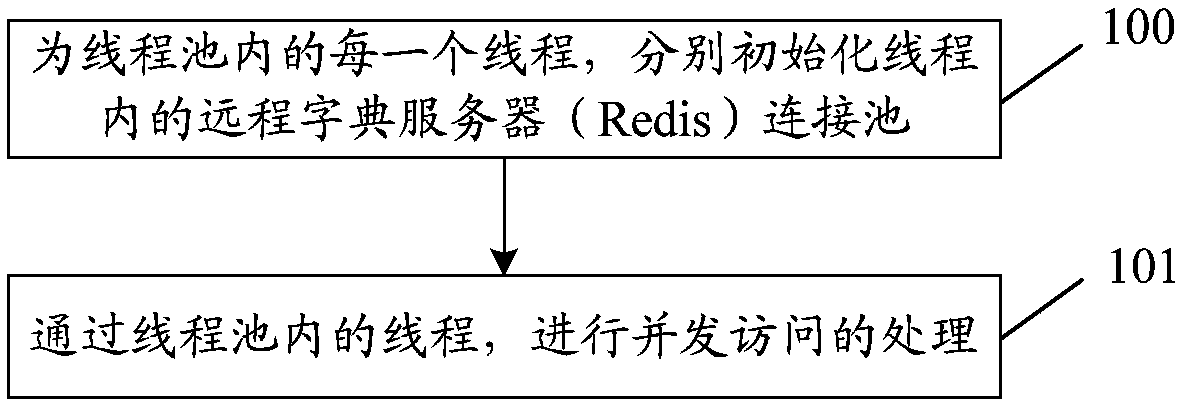

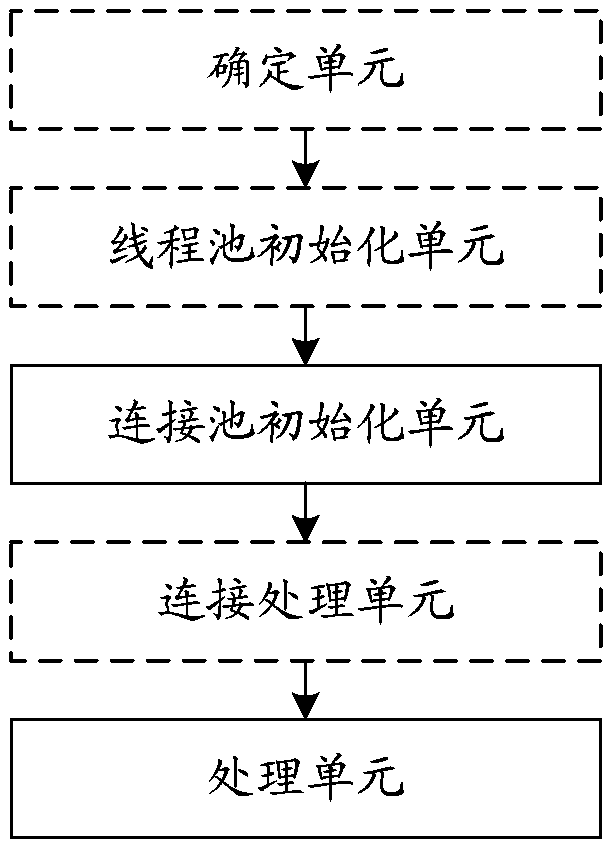

Concurrent access processing method and device and computer storage medium

InactiveCN108829522AImprove quality and stabilityImprove stabilityResource allocationThread poolOperating system

Disclosed are a concurrent access processing method and device and a computer storage medium. The method comprises the steps that a remote dictionary server (Redis) connection pool in each thread in athread pool is initialized; the threads in the thread pool are used for concurrent access processing, wherein the thread pool includes a preset number of threads. By means of the embodiment, the stability and quality of concurrent access processing are improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

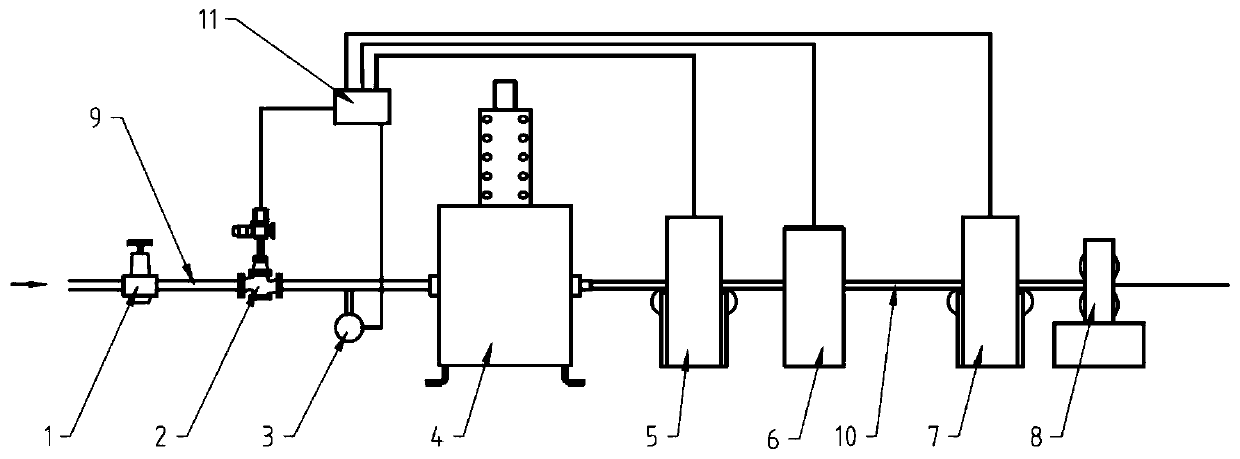

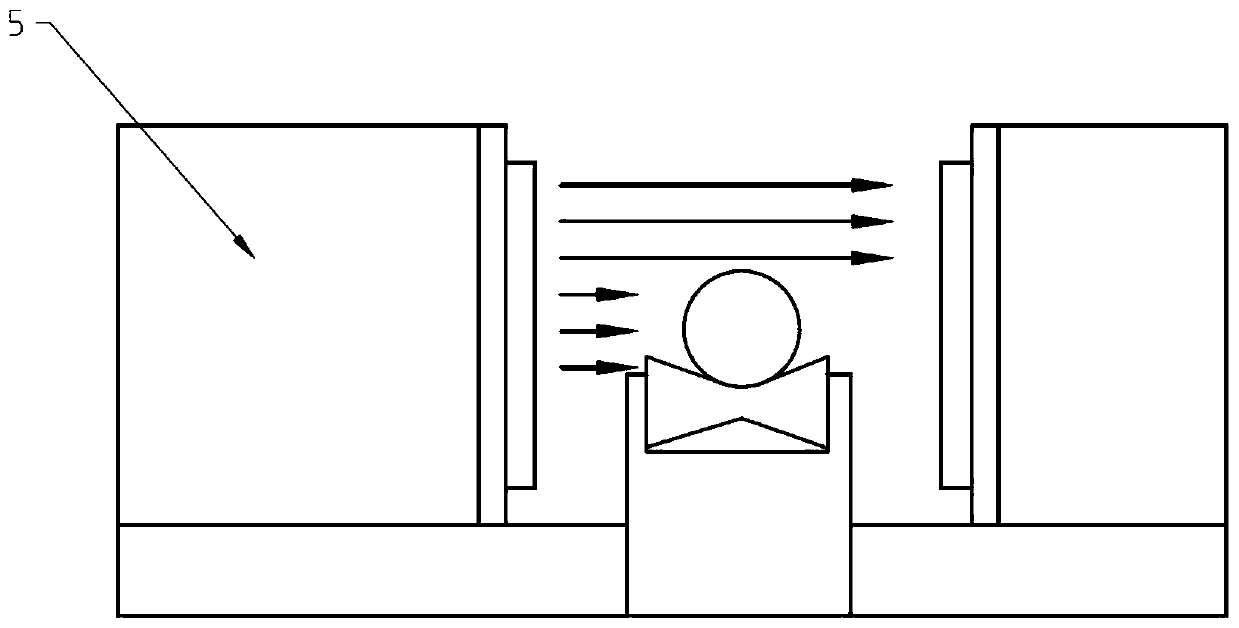

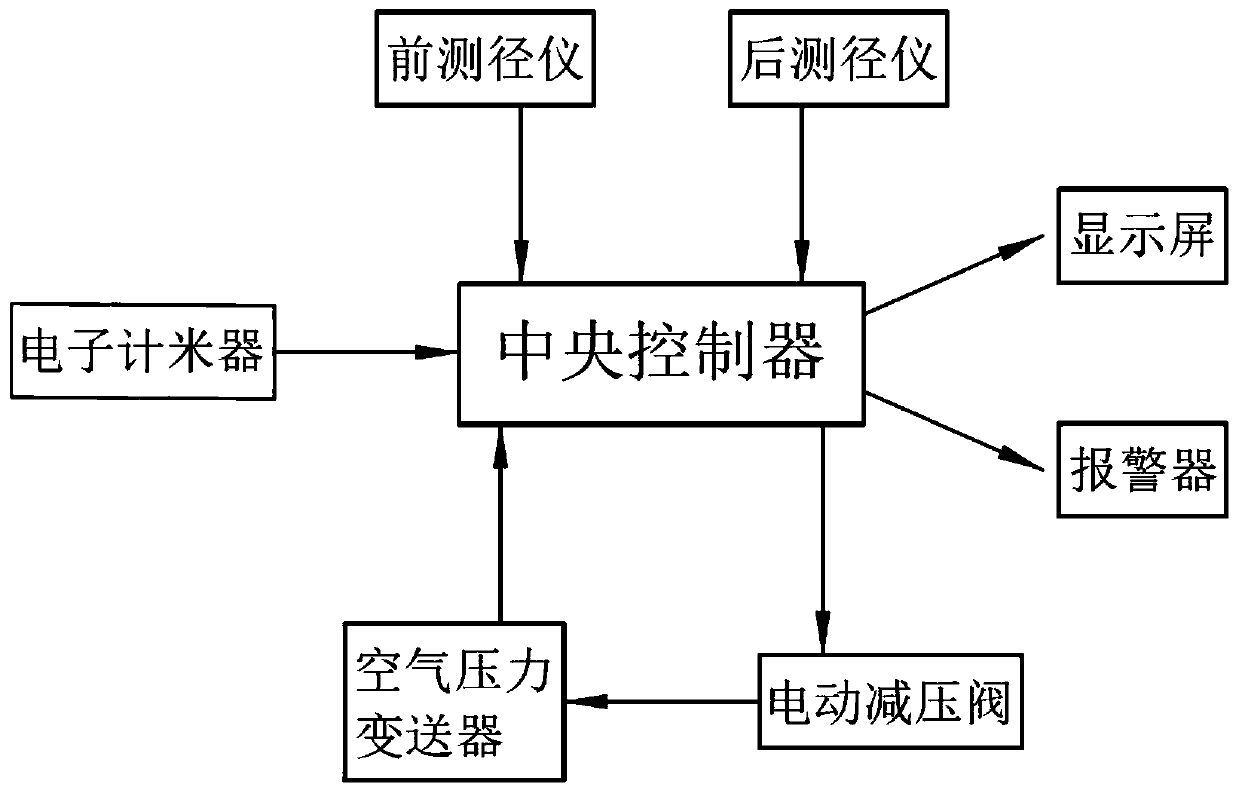

Intelligent sausage casing monitoring system

ActiveCN110926353AEasy to find in timeImprove quality and stabilityFluid pressure measurementUsing optical meansPhysicsEngineering

The invention discloses an intelligent sausage casing monitoring system. The system comprises an air source filtering pressure reducer (1), a sausage casing extruder (4) and a sausage casing drying line, the air source filtering pressure reducer (1) is connected with the casing extruder (4) through an air pipeline (9); a sausage casing flattening device and a collecting device are arranged at therear end of the sausage casing drying line, a secondary air source pressure reducing device and an air pressure sensor (3) are arranged between the air source filtering pressure reducer (1) and the sausage casing extruder (4), and the secondary air source pressure reducing device is located at the front end of the pressure sensor (3). One or more sausage casing diameter measuring devices are arranged between the sausage casing extruder (4) and the sausage casing flattening device, and the positions of the sausage casing diameter measuring devices at least comprise the positions of the rear endof the sausage casing extruder (4) and the front end of the sausage casing drying line. According to the intelligent sausage casing monitoring system, the sausage casing diameter can be convenientlymeasured, so that the diameter of the produced sausage casing is uniform, and the production efficiency can be effectively improved.

Owner:郭显光

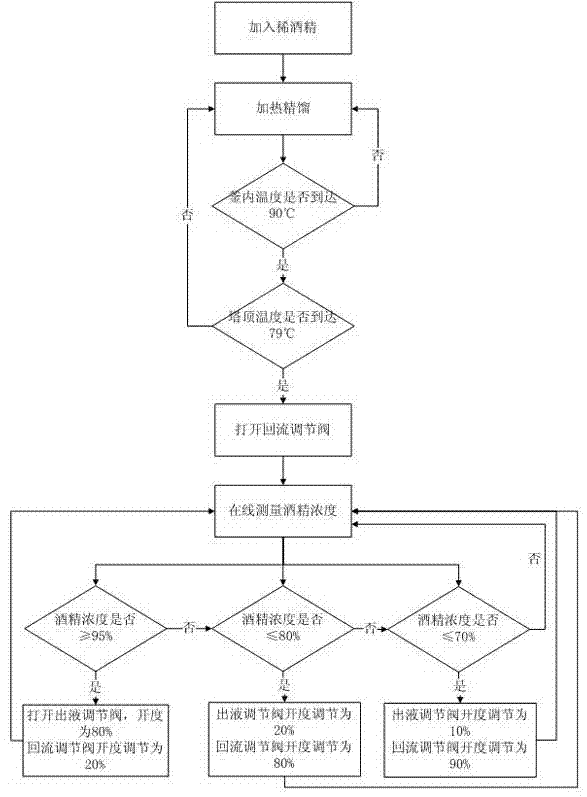

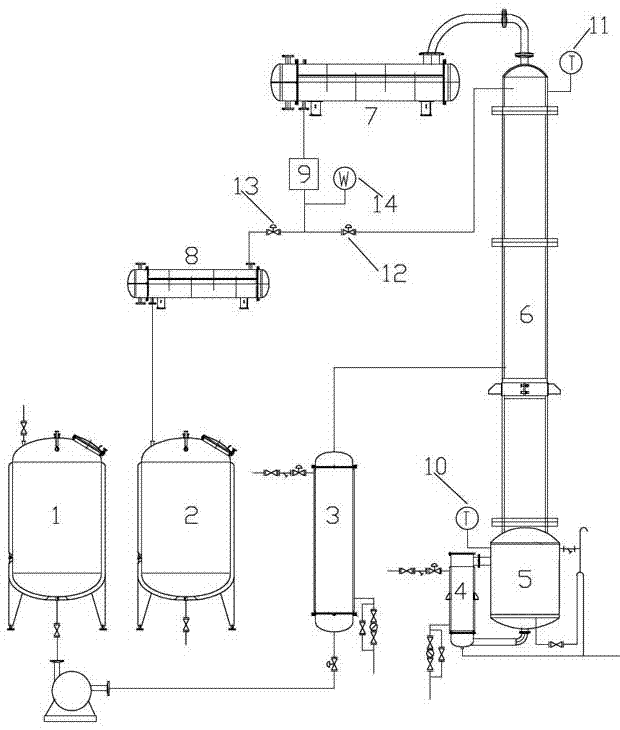

Alcohol recovery concentration on-line detection device during the production process of traditional Chinese medicines, and control method of alcohol recovery concentration during the production process of traditional Chinese medicines

InactiveCN105446376ARealize real-time controlQuality improvementControlling ratio of multiple fluid flowsDistillation regulation/controlRefluxAutomatic control

The invention discloses an alcohol recovery concentration on-line detection device during the production process of traditional Chinese medicines, and a control method of alcohol recovery concentration during the production process of traditional Chinese medicines. The alcohol recovery concentration on-line detection device is characterized in that thermometers are each arranged in a rectifying still and on the top of a rectifying tower; a liquid outlet for a cooler is provided with a hydrops device; an on-line alcoholic strength meter is arranged at a pipeline below the hydrops device; a reflux regulating valve is arranged in a reflux pipeline; and an outlet regulating valve is arranged in an outlet pipeline. The control method comprises: utilizing the on-line alcoholic strength meter to monitor the concentration of the recovered alcohol in real time, and regulating the opening degree of the outlet regulating valve and the opening degree of the reflux regulating valve. Through the above mode, the alcohol recovery concentration on-line detection device and the control method are used in the alcohol recovery process, can realize real time control of the alcohol concentration during the alcohol recovery process and realize stable control of the concentration of the recovered alcohol, improve the automatic control level during the alcohol recovery process for production of traditional Chinese medicines and the homogeneity of the concentration among batches for the recovered alcohol, and provide a new technology for improvement of quality stabilization of traditional Chinese medicine products and modernization of traditional Chinese medicines.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH

Gallium phthalocyanine compound, and image bearing member, image forming method, image forming apparatus, and process cartridge using the gallium phthalocyanine compound

InactiveUS8383304B2Improve quality and stabilityLarge solubilityReactive dyesPorphines/azaporphinesChemical structureAryl

A gallium phthalocyanine compound represented by the following chemical structure I,where X represents a substituted or non-substituted alkyl group, a substituted or non-substituted alkenyl group, a substituted or non-substituted alkynyl group, a substituted or non-substituted aralkyl group, a substituted or non-substituted cycloalkyl group, a substituted or non-substituted aryl group, or a hydrogen atom, where substitution groups thereof are an alkoxy group, an alkylthio group, an alkyl group, a halogen atom, nitro group, amino group, an aryl group, carboxylic group, and cyano group, R1 to R16 independently represent a hydrogen atom, an alkoxy group, an alkylthio group, an alkyl group, a halogen atom, nitro group, or aryl group, n represents an integer of from 1 to 3 but excluding a combination in which n is 1 and X is methyl group.

Owner:RICOH KK

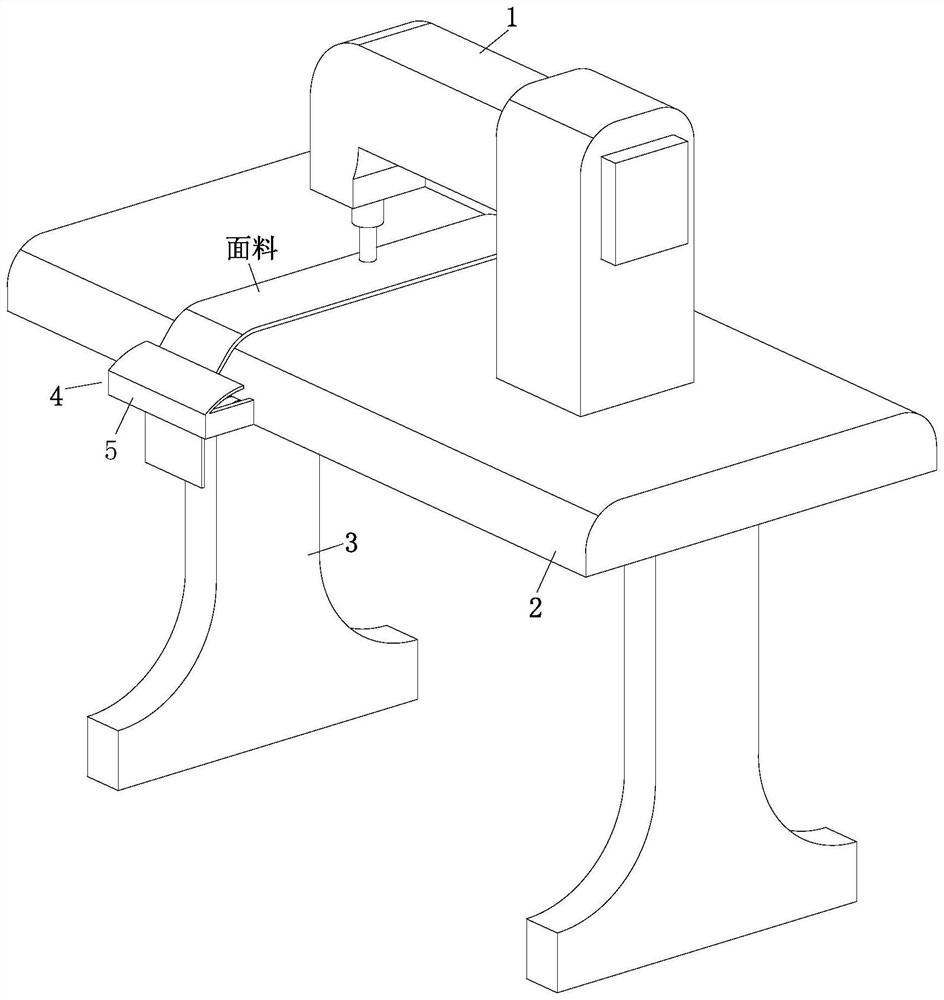

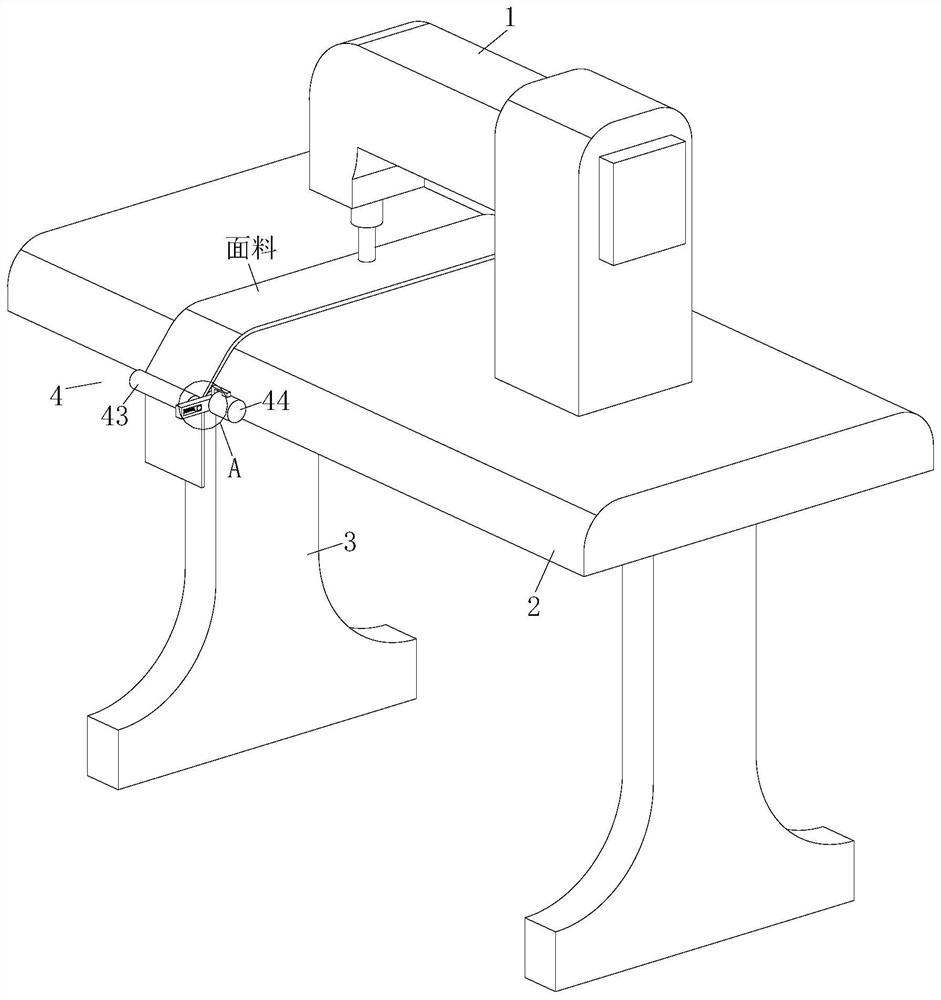

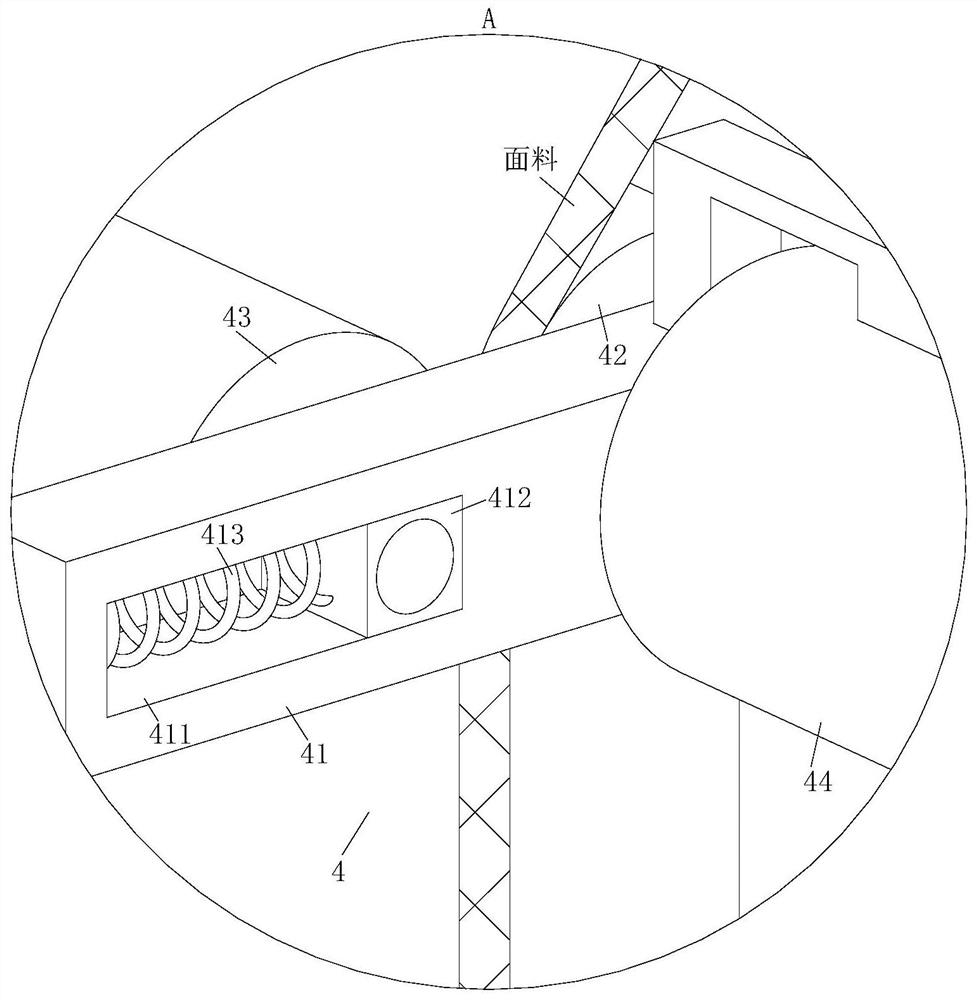

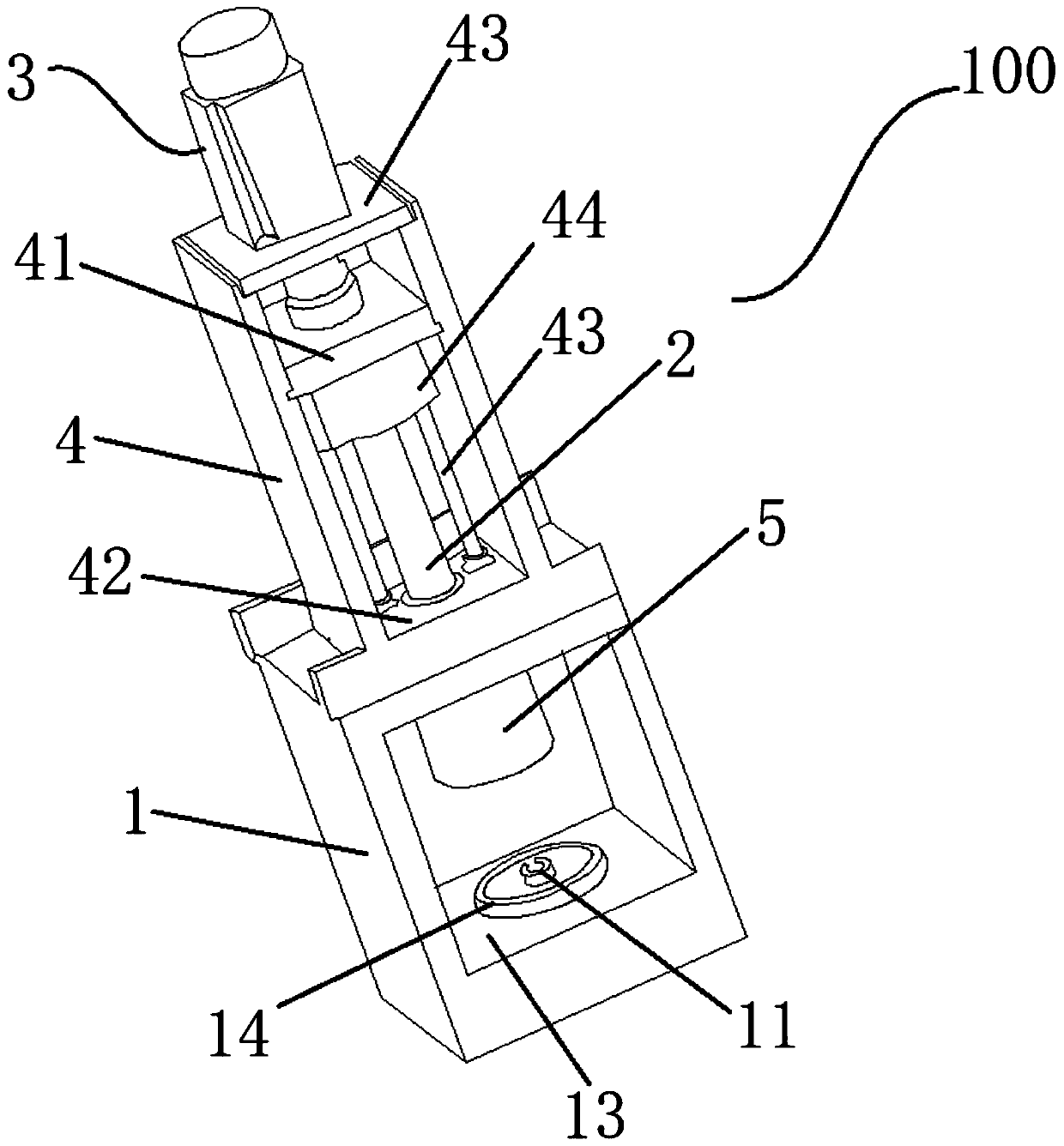

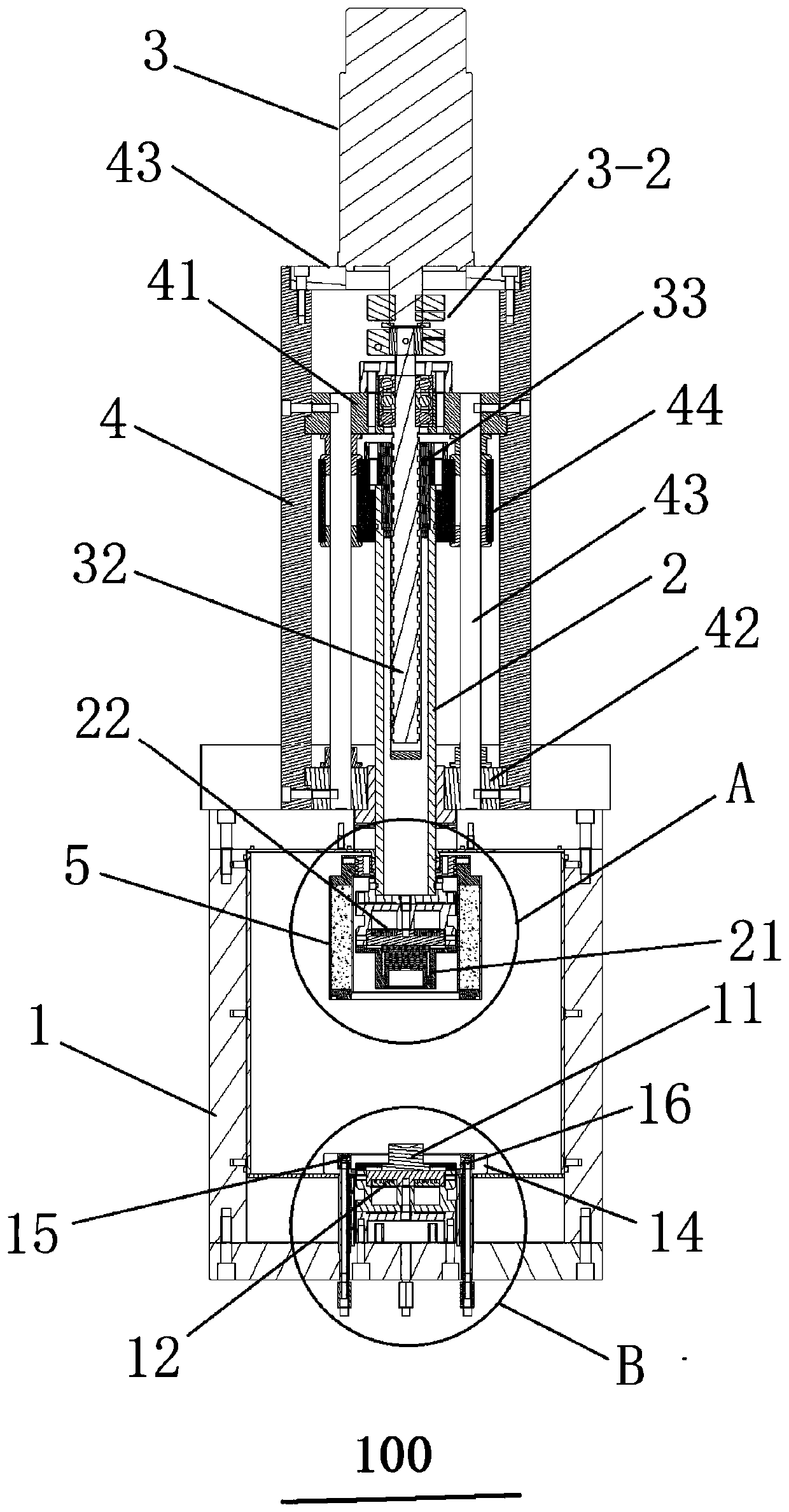

Multi-stitch flat type interlocking seam sewing machine

ActiveCN112877919AGuaranteed flatnessImprove quality and stabilityMechanical cleaningPressure cleaningEngineeringWorkbench

The invention relates to the technical field of interlocking seam sewing machines, in particular to a multi-stitch flat type interlocking seam sewing machine which comprises a sewing machine body, a workbench, supporting legs, guiding mechanisms, a protective shell and a controller, wherein the workbench is located on the supporting legs and fixedly connected with the supporting legs, the sewing machine body is fixedly connected to the upper end of the workbench, and arc chamfers are arranged on two opposite edges of the workbench; the guiding mechanisms are located on two sides of the workbench, and each guiding mechanism comprises a fixing plate, a driving roller, a driven roller and a motor; and each fixing plate is fixedly connected to the corresponding side of the workbench. The guide mechanisms drive fabric to move on the workbench and is matched with the sewing machine body to sew the fabric, so that the guide mechanism can move away the sewed fabric, the smoothness of the fabric on the workbench is guaranteed, the situation of sewing interruption caused by fabric wrinkles is prevented, and therefore, the stability and the quality of the multi-stitch flat type interlocking seam sewing machine for sewing and weaving the fabric are improved.

Owner:东莞市志捷实业有限公司

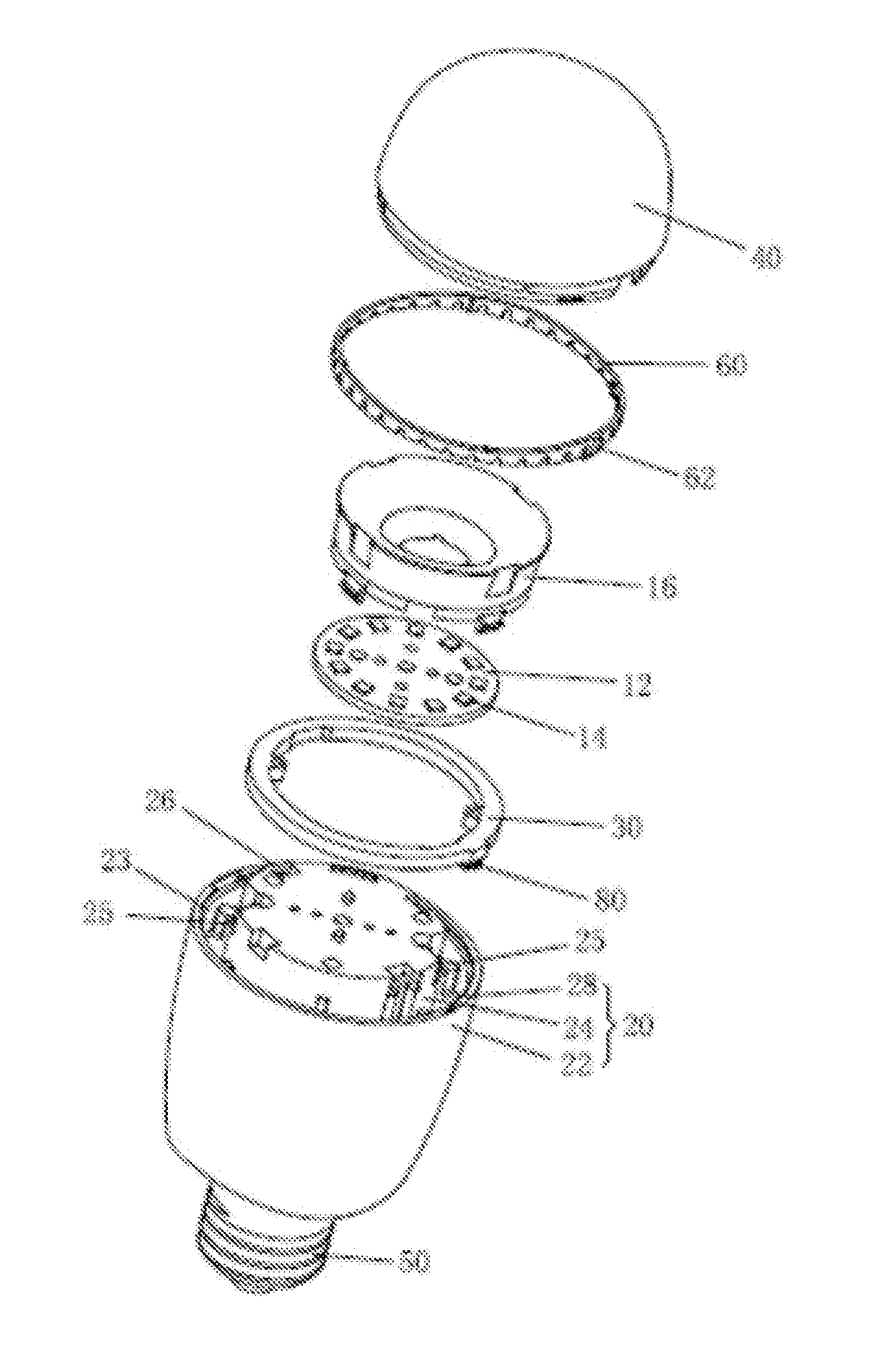

Integrated station mold pressing method

InactiveCN110015837AGuaranteed machining accuracyReduce in quantityGlass reforming apparatusNitrogenEngineering

The invention provides an integrated mold pressing method. The method comprises the steps: (1) putting a to-be-processed workpiece on a lower mold of a station substrate plate; (2) controlling a stamping rod to move downwards so as to abut a sealing cover sleeve against the station substrate plate and form a mold pressing chamber; (3) removing air in the mold pressing chamber, and filling nitrogeninto the mold pressing chamber so as to make the mold pressing chamber under the protection of nitrogen; (4) heating the upper mold and the lower mold to a mold pressing temperature; (5) controllingthe stamping rod to continue to move downwards so as to make the upper mold and the lower mold complete mold clamping, and performing maintaining for a certain period of time so as to complete stamping and pressure maintaining; (6) removing the high temperature nitrogen in the mold pressing chamber, and filling low temperature nitrogen into the mold pressing chamber so as to reduce the temperaturein the mold pressing chamber; (7) controlling the stamping rod to move upwards so as to separate the upper mold and the lower mold; and (8) taking out the formed workpiece. Through the integrated mold pressing method, heating, stamping, cooling and other processes of optical glass lenses can be achieved at one station, the molds are saved greatly, the use cost is reduced, and meanwhile the stability of the workpiece is ensured.

Owner:SHENZHEN SENDIYUAN PNEUMATIC EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com