Composite aluminum foil

A technology of composite aluminum foil and aluminum foil layer, which is applied to conductive layers, layered products, and metal layered products on insulating carriers, can solve problems such as signal leakage, inconvenient connection and installation, and affect transmission performance, so as to solve common problems, The effect of cost reduction and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

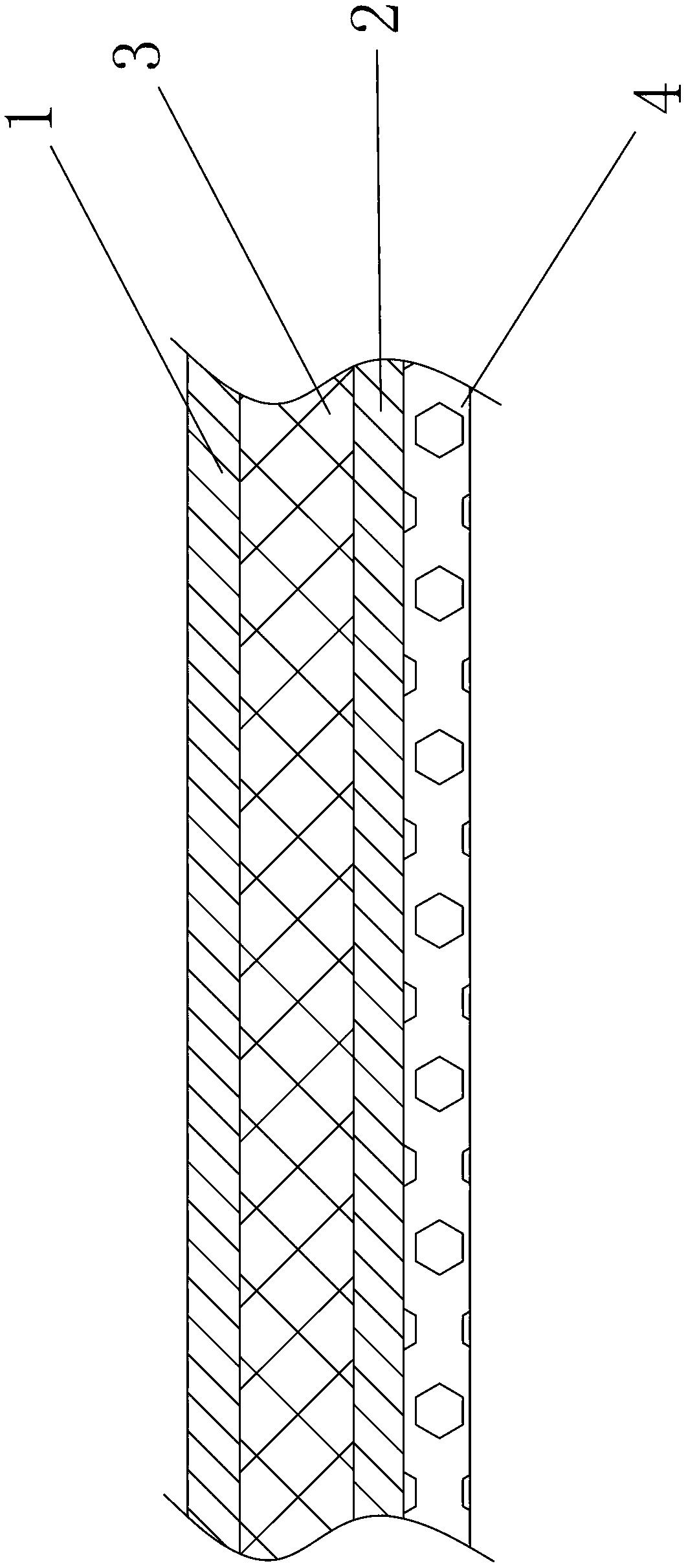

[0026] refer to figure 1 , a composite aluminum foil, including a first aluminum foil layer 1, a second aluminum foil layer 2 and a plastic reinforcement layer 3, the first aluminum foil layer, the plastic reinforcement layer and the second aluminum foil layer are arranged in sequence, and the adjacent layers are all composited by glue One, the surface of the second aluminum foil layer is also compounded with an adhesive layer 4, the adhesive layer is a maleic anhydride graft modified polyethylene adhesive film, and the adhesive layer and the second aluminum foil layer are combined by glue . The thickness of the adhesive layer is 0.020mm.

[0027] The plastic reinforcement layer is a PET polyester film with a thickness of 0.015mm.

[0028] The first aluminum foil layer and the second aluminum foil layer are alloy aluminum foils with a thickness of 0.009 mm.

Embodiment 2

[0030] The plastic reinforcement layer is a PET polyester film layer with a thickness of 0.020 mm. The first aluminum foil layer and the second aluminum foil layer are alloy aluminum foils with a thickness of 0.012 mm. The adhesive layer is a polyethylene adhesive film grafted and modified with maleic anhydride, with a thickness of 0.025 mm.

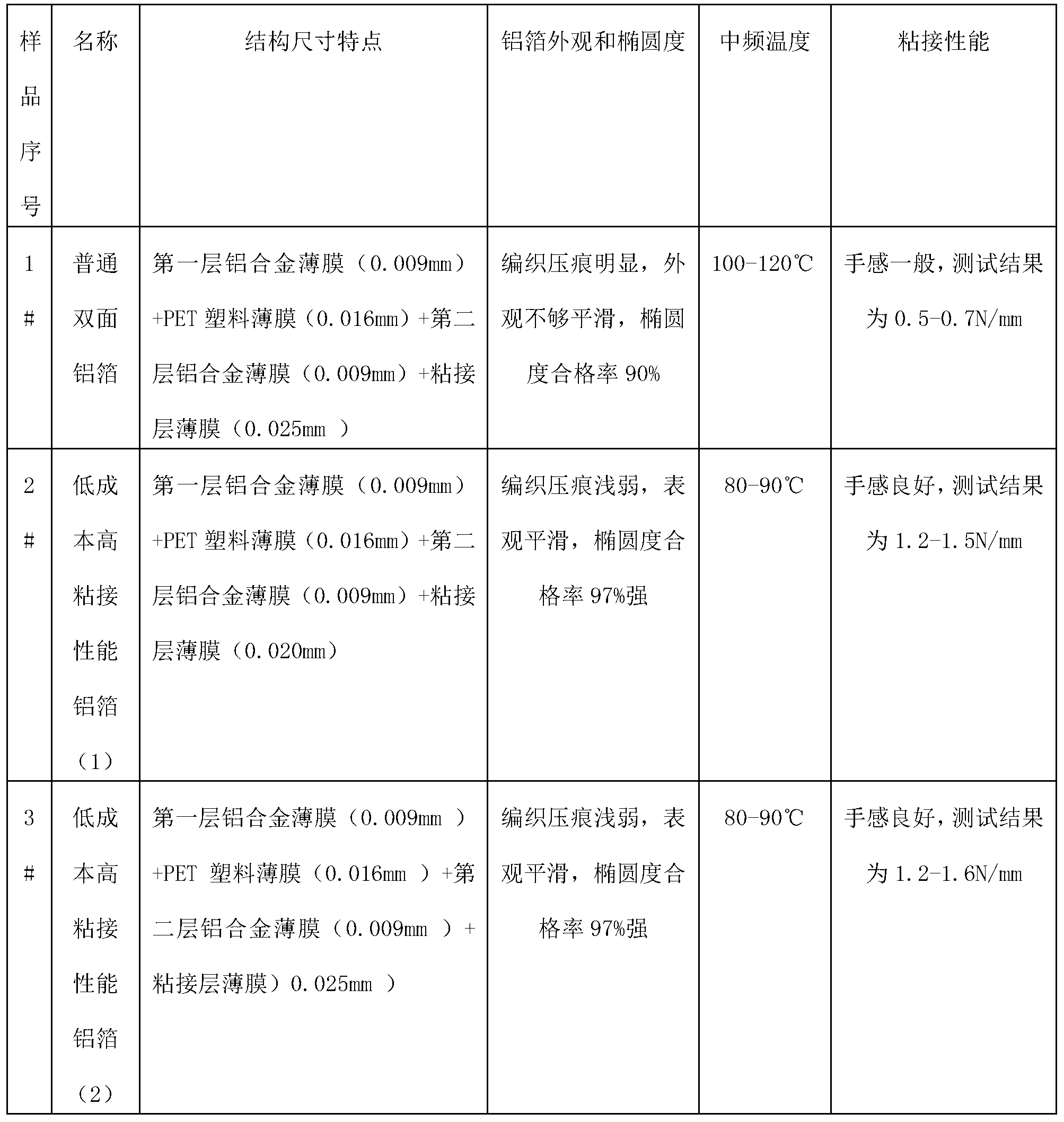

[0031] The following is a comparison table of low-cost high-adhesive performance aluminum foil and ordinary double-sided self-adhesive aluminum foil.

[0032]

[0033] From the above actual test results, it can be seen that the application of low-cost and high-adhesive aluminum foil significantly reduces the intermediate frequency temperature during sheath production, and thus improves the appearance and ovality of the aluminum foil, and the adhesive performance is also significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com