Biomass gasifier/industrial gas boiler combined high-efficiency heating system

An industrial gas and heating system technology, which is applied in gasification technology, chemical industry, petroleum industry, etc., can solve problems such as large heat loss, expensive refractory materials, and blockage of gas pipelines, so as to improve stability and quality, and avoid Effect of coking in the furnace and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

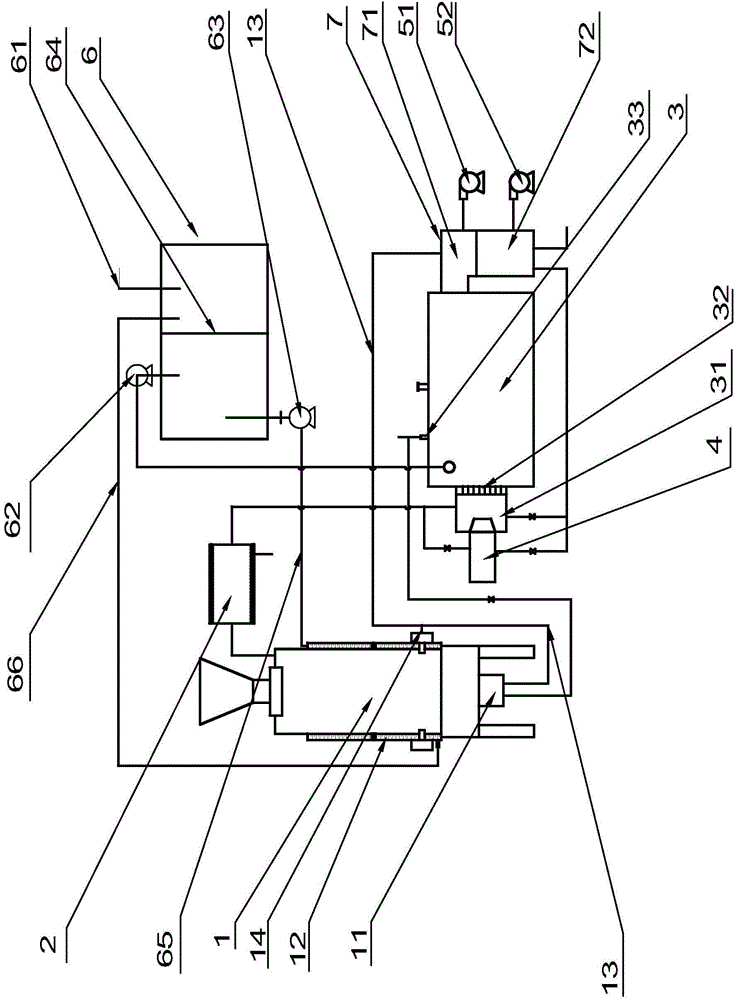

[0019] Reference figure 1 , The present invention is a combined high-efficiency heating system of a biomass gasifier and an industrial gas boiler, including a biomass gasifier 1, an industrial gas boiler 3, divided into a water tank high temperature zone and a water tank low temperature zone by a cold and hot water partition 64 The water circulation device 6 and the electric decoking cracker 2 connected between the biomass gasifier 1 and the industrial gas boiler 3, the biomass gasifier 1 is equipped with a water-cooled jacket 12, and the top of the water-cooled jacket 12 passes gas The chemical furnace circulating water pump 63 is connected to the bottom of the high temperature zone of the water tank, the bottom of the full water cooling jacket 12 is connected to the low temperature zone of the water tank, the industrial gas boiler 3 is connected to the top of the high temperature zone of the water tank through the boiler feed water pump 62, and the bottom of the biomass gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com