Intelligent sausage casing monitoring system

An intelligent monitoring and casing technology, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as too high requirements for operator proficiency, unreasonable casing production process, and inaccurate casing diameter measurement, so as to ensure accuracy , flexible and diverse control methods, easy to find the effect in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

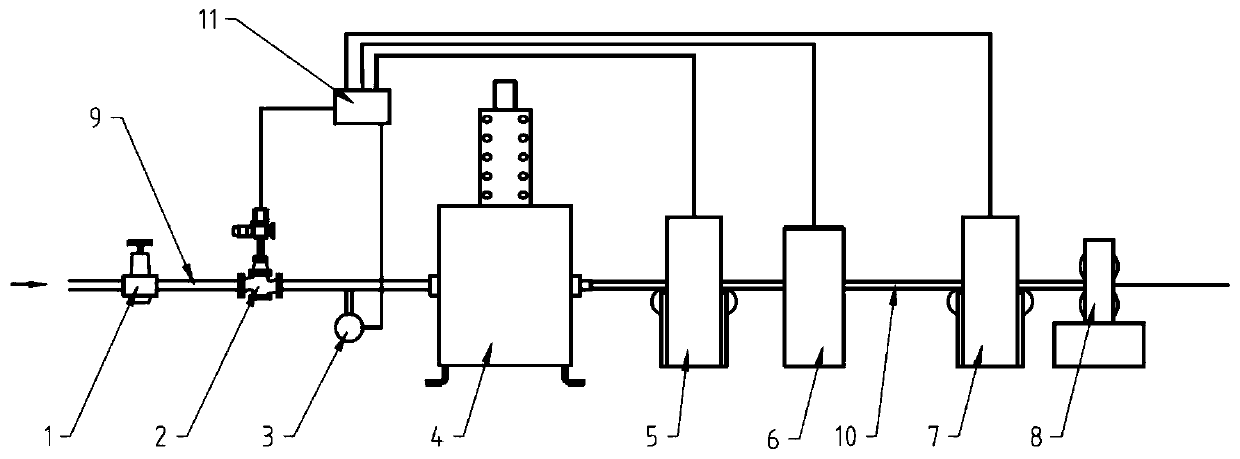

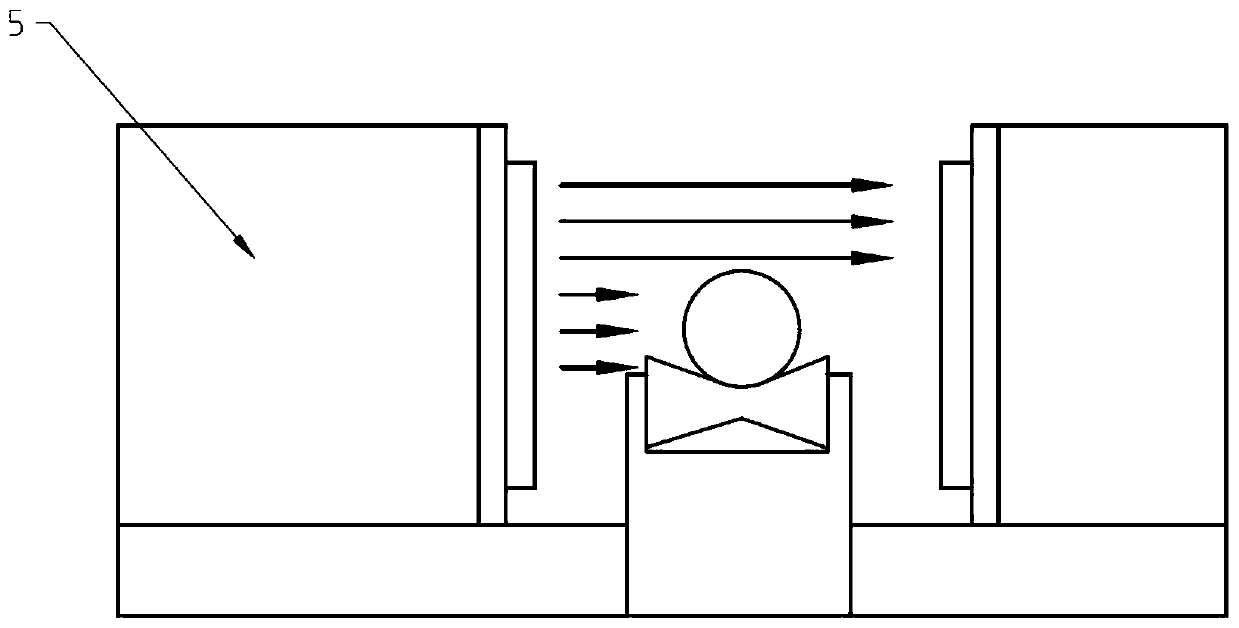

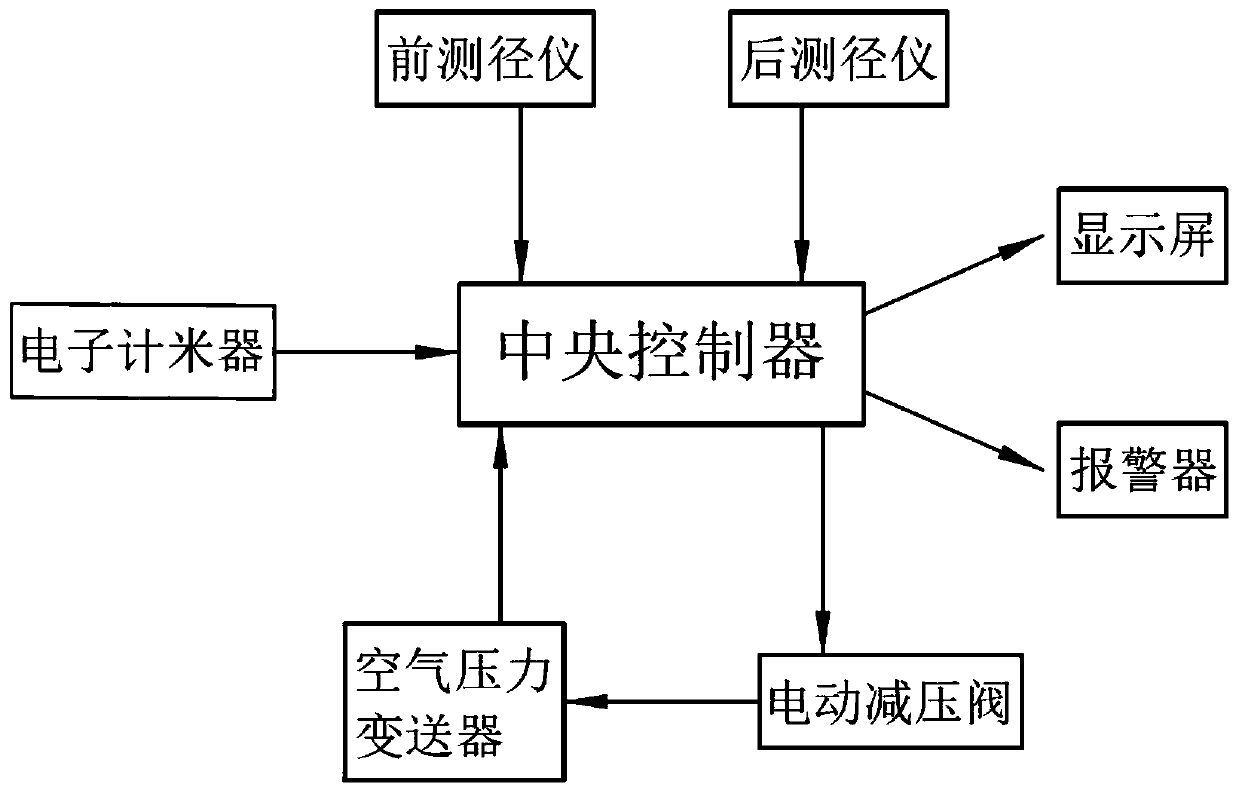

[0037] see figure 1 , figure 1It is an intelligent casing monitoring system of this embodiment, which includes an air source filter decompressor 1, a secondary air source decompression device, an air pressure sensor 3, a casing extruder 4, a casing diameter measuring device, Casing length measuring device, casing drying line, rear casing diameter measuring device and casing flattening device. The air source filter decompressor 1 is connected to the casing extruder 4 through an air pipeline 9, and the secondary air source decompression device is located at the front end of the air pressure sensor 3, and can transmit the pressure from the air source filter decompressor 1 Further down to the specified pressure required for making the casing, the specific pressure value can be checked by the air pressure sensor 3. The rear end of the casing extruder 4 is the output semi-finished casing 10, and the semi-finished casing 10 is finally pressed into a film by a casing flattening devi...

Embodiment 2

[0047] In this embodiment, a gas flow meter 12 is added between the air source filter decompressor 1 and the casing extruder 4, and the gas flow meter 12 is electrically connected to the central controller 11 to further monitor the leakage point problem in casing production , Improve the quality of casing production.

[0048] Combine below Figure 4 with Figure 5 , the gas flow meter 12 of this embodiment is located on the air pipeline 9 between the air source filter pressure reducer 1 and the electric pressure reducing valve 2, and is used to detect the air flow in the air pipeline 9 at the current position in real time, when the casing extruder 4. When there is a leakage point in the casing produced later, the air flow in the air pipe 9 in front of the casing extruder 4 will inevitably increase. After the central controller 11 detects a sudden increase in the value in the gas flow meter 12, it will trigger the alarm device , to remind the operator to pay attention and rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com